Dif JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1273 of 2199

ENGINE BLOCK

CLEANING

Thoroughly clean the oil pan and engine block gas-

ket surfaces.

Use compressed air to clean out:

²The galley at the oil filter adaptor hole.

²The front and rear oil galley holes.

²The feed holes for the crankshaft main bearings.

Once the block has been completely cleaned, apply

Loctite PST pipe sealant with Teflon 592 to the

threads of the front and rear oil galley plugs. Tighten

the plugs to 34 N´m (25 ft. lbs.) torque.

INSPECTION

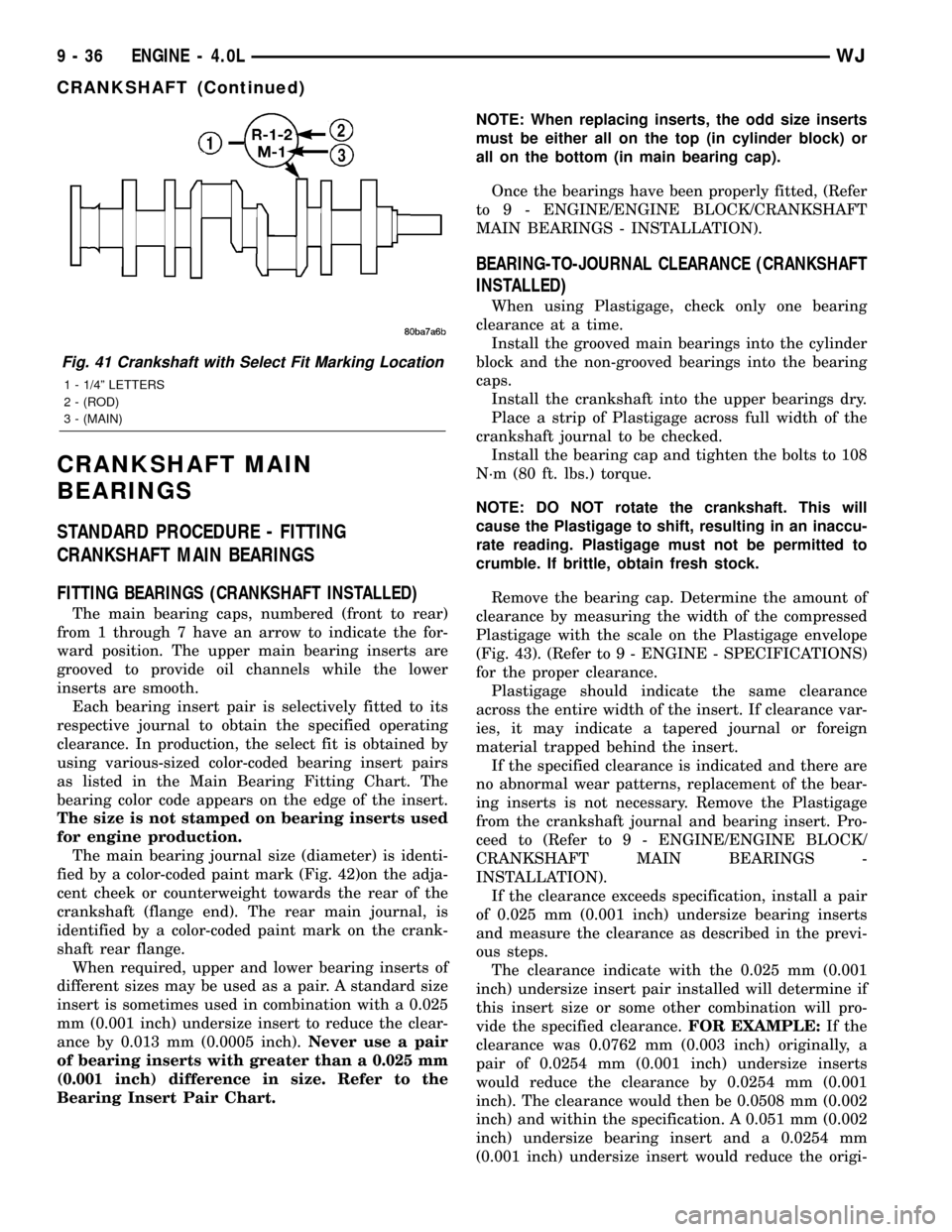

(1) It is mandatory to use a dial bore gauge to

measure each cylinder bore diameter (Fig. 29). To

correctly select the proper size piston, a cylinder bore

gauge, capable of reading in 0.003 mm (.0001 in.)

INCREMENTS is required. If a bore gauge is not

available, do not use an inside micrometer.

(2) Measure the inside diameter of the cylinder

bore at three levels below top of bore. Start perpen-

dicular (across or at 90 degrees) to the axis of the

crankshaft and then take two additional reading.(3) Measure the cylinder bore diameter crosswise

to the cylinder block near the top of the bore. Repeat

the measurement near the middle of the bore, then

repeat the measurement near the bottom of the bore.

(4) Determine taper by subtracting the smaller

diameter from the larger diameter.

(5) Rotate measuring device 90É and repeat steps

above.

(6) Determine out-of-roundness by comparing the

difference between each measurement.

(7) If cylinder bore taper does not exceed 0.025

mm (0.001 inch) and out-of-roundness does not

exceed 0.025 mm (0.001 inch), the cylinder bore can

be honed. If the cylinder bore taper or out- of-round

condition exceeds these maximum limits, the cylinder

must be bored and then honed to accept an oversize

piston. A slight amount of taper always exists in the

cylinder bore after the engine has been in use for a

period of time.

CAMSHAFT & BEARINGS

DESCRIPTION

The camshaft is made of gray cast iron with twelve

machined lobes and four bearing journals (Fig. 30).

When the camshaft rotates the lobes actuate the tap-

pets and push rods, forcing upward on the rocker

arms which applies downward force on the valves.

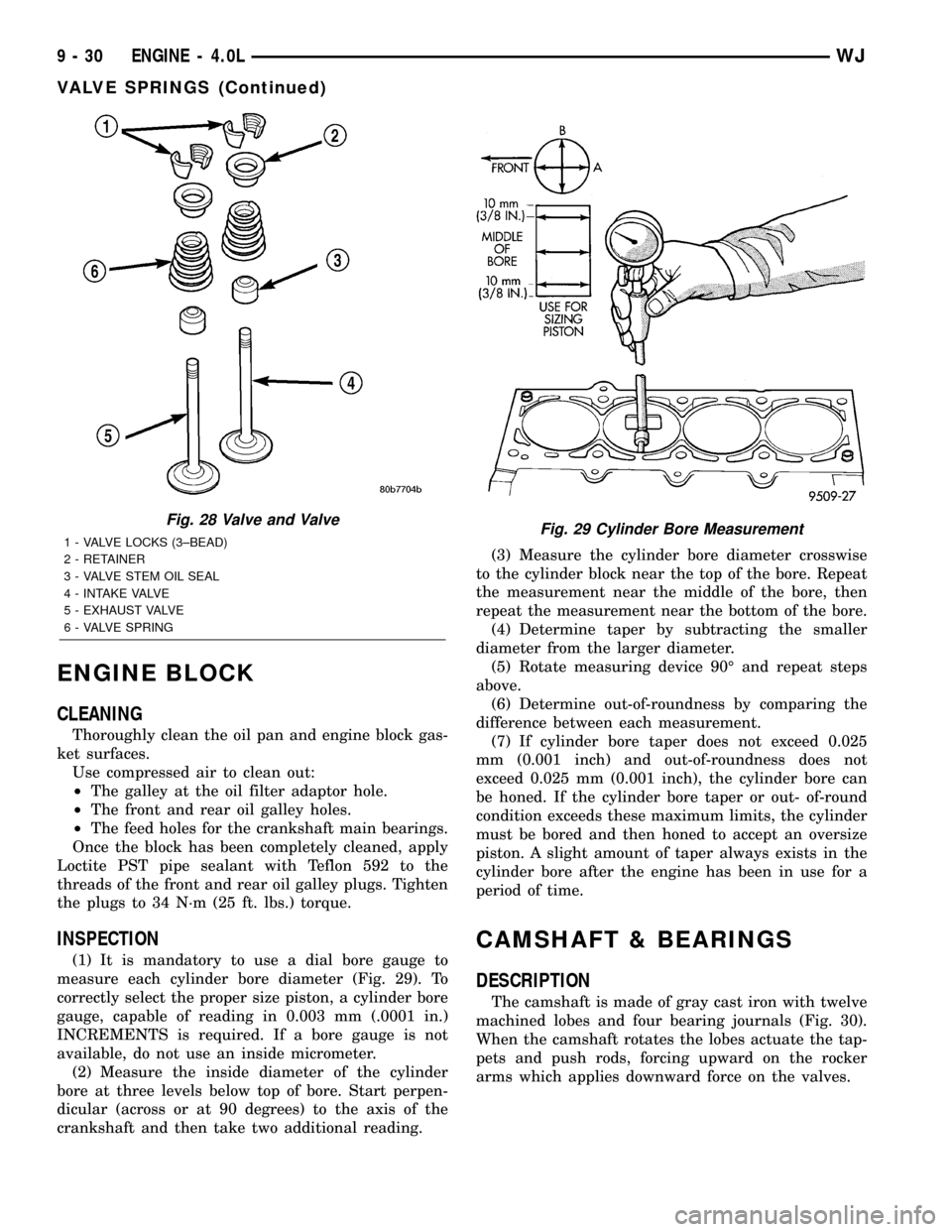

Fig. 28 Valve and Valve

1 - VALVE LOCKS (3±BEAD)

2 - RETAINER

3 - VALVE STEM OIL SEAL

4 - INTAKE VALVE

5 - EXHAUST VALVE

6 - VALVE SPRINGFig. 29 Cylinder Bore Measurement

9 - 30 ENGINE - 4.0LWJ

VALVE SPRINGS (Continued)

Page 1279 of 2199

CRANKSHAFT MAIN

BEARINGS

STANDARD PROCEDURE - FITTING

CRANKSHAFT MAIN BEARINGS

FITTING BEARINGS (CRANKSHAFT INSTALLED)

The main bearing caps, numbered (front to rear)

from 1 through 7 have an arrow to indicate the for-

ward position. The upper main bearing inserts are

grooved to provide oil channels while the lower

inserts are smooth.

Each bearing insert pair is selectively fitted to its

respective journal to obtain the specified operating

clearance. In production, the select fit is obtained by

using various-sized color-coded bearing insert pairs

as listed in the Main Bearing Fitting Chart. The

bearing color code appears on the edge of the insert.

The size is not stamped on bearing inserts used

for engine production.

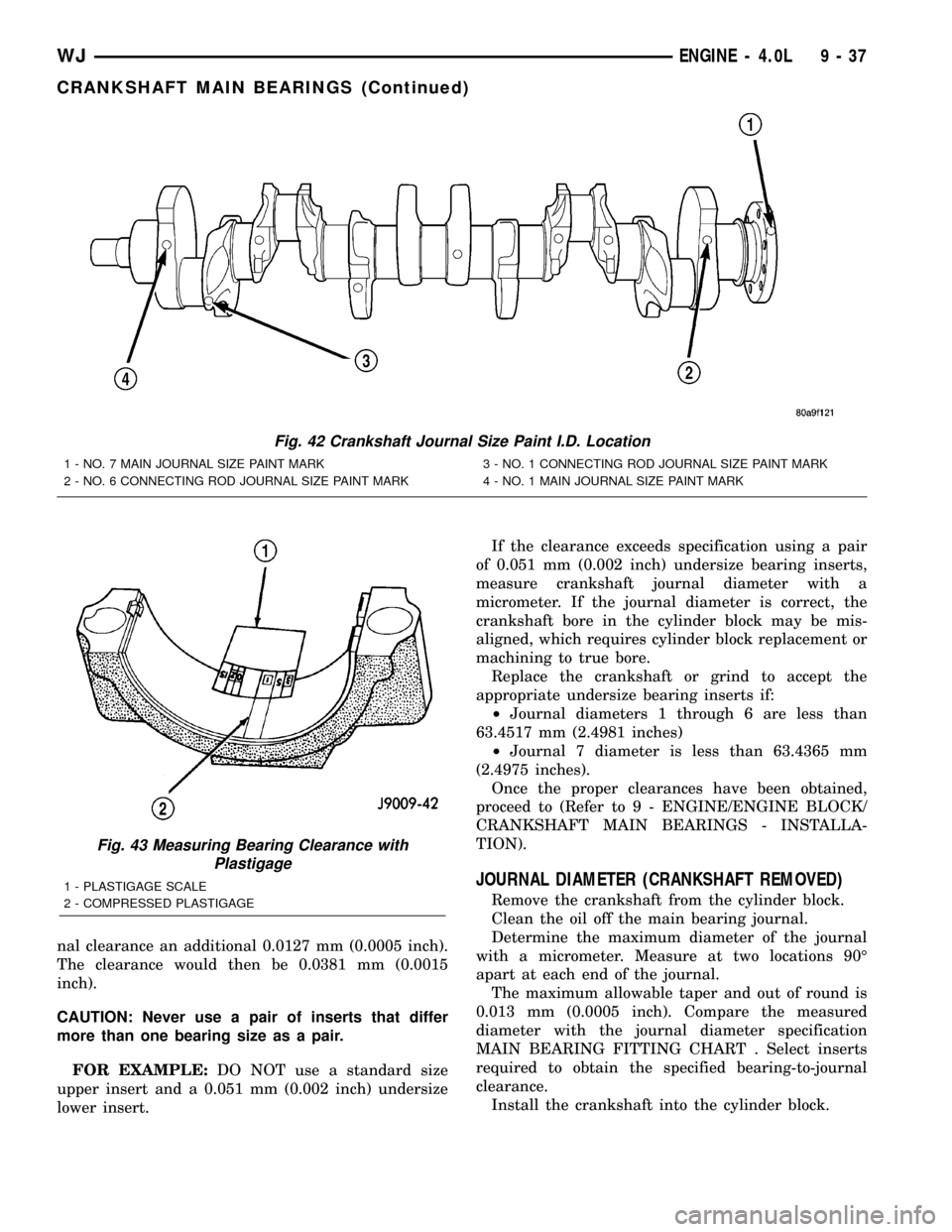

The main bearing journal size (diameter) is identi-

fied by a color-coded paint mark (Fig. 42)on the adja-

cent cheek or counterweight towards the rear of the

crankshaft (flange end). The rear main journal, is

identified by a color-coded paint mark on the crank-

shaft rear flange.

When required, upper and lower bearing inserts of

different sizes may be used as a pair. A standard size

insert is sometimes used in combination with a 0.025

mm (0.001 inch) undersize insert to reduce the clear-

ance by 0.013 mm (0.0005 inch).Never use a pair

of bearing inserts with greater than a 0.025 mm

(0.001 inch) difference in size. Refer to the

Bearing Insert Pair Chart.NOTE: When replacing inserts, the odd size inserts

must be either all on the top (in cylinder block) or

all on the bottom (in main bearing cap).

Once the bearings have been properly fitted, (Refer

to 9 - ENGINE/ENGINE BLOCK/CRANKSHAFT

MAIN BEARINGS - INSTALLATION).

BEARING-TO-JOURNAL CLEARANCE (CRANKSHAFT

INSTALLED)

When using Plastigage, check only one bearing

clearance at a time.

Install the grooved main bearings into the cylinder

block and the non-grooved bearings into the bearing

caps.

Install the crankshaft into the upper bearings dry.

Place a strip of Plastigage across full width of the

crankshaft journal to be checked.

Install the bearing cap and tighten the bolts to 108

N´m (80 ft. lbs.) torque.

NOTE: DO NOT rotate the crankshaft. This will

cause the Plastigage to shift, resulting in an inaccu-

rate reading. Plastigage must not be permitted to

crumble. If brittle, obtain fresh stock.

Remove the bearing cap. Determine the amount of

clearance by measuring the width of the compressed

Plastigage with the scale on the Plastigage envelope

(Fig. 43). (Refer to 9 - ENGINE - SPECIFICATIONS)

for the proper clearance.

Plastigage should indicate the same clearance

across the entire width of the insert. If clearance var-

ies, it may indicate a tapered journal or foreign

material trapped behind the insert.

If the specified clearance is indicated and there are

no abnormal wear patterns, replacement of the bear-

ing inserts is not necessary. Remove the Plastigage

from the crankshaft journal and bearing insert. Pro-

ceed to (Refer to 9 - ENGINE/ENGINE BLOCK/

CRANKSHAFT MAIN BEARINGS -

INSTALLATION).

If the clearance exceeds specification, install a pair

of 0.025 mm (0.001 inch) undersize bearing inserts

and measure the clearance as described in the previ-

ous steps.

The clearance indicate with the 0.025 mm (0.001

inch) undersize insert pair installed will determine if

this insert size or some other combination will pro-

vide the specified clearance.FOR EXAMPLE:If the

clearance was 0.0762 mm (0.003 inch) originally, a

pair of 0.0254 mm (0.001 inch) undersize inserts

would reduce the clearance by 0.0254 mm (0.001

inch). The clearance would then be 0.0508 mm (0.002

inch) and within the specification. A 0.051 mm (0.002

inch) undersize bearing insert and a 0.0254 mm

(0.001 inch) undersize insert would reduce the origi-

Fig. 41 Crankshaft with Select Fit Marking Location

1 - 1/4º LETTERS

2 - (ROD)

3 - (MAIN)

9 - 36 ENGINE - 4.0LWJ

CRANKSHAFT (Continued)

Page 1280 of 2199

nal clearance an additional 0.0127 mm (0.0005 inch).

The clearance would then be 0.0381 mm (0.0015

inch).

CAUTION: Never use a pair of inserts that differ

more than one bearing size as a pair.

FOR EXAMPLE:DO NOT use a standard size

upper insert and a 0.051 mm (0.002 inch) undersize

lower insert.If the clearance exceeds specification using a pair

of 0.051 mm (0.002 inch) undersize bearing inserts,

measure crankshaft journal diameter with a

micrometer. If the journal diameter is correct, the

crankshaft bore in the cylinder block may be mis-

aligned, which requires cylinder block replacement or

machining to true bore.

Replace the crankshaft or grind to accept the

appropriate undersize bearing inserts if:

²Journal diameters 1 through 6 are less than

63.4517 mm (2.4981 inches)

²Journal 7 diameter is less than 63.4365 mm

(2.4975 inches).

Once the proper clearances have been obtained,

proceed to (Refer to 9 - ENGINE/ENGINE BLOCK/

CRANKSHAFT MAIN BEARINGS - INSTALLA-

TION).

JOURNAL DIAMETER (CRANKSHAFT REMOVED)

Remove the crankshaft from the cylinder block.

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper and out of round is

0.013 mm (0.0005 inch). Compare the measured

diameter with the journal diameter specification

MAIN BEARING FITTING CHART . Select inserts

required to obtain the specified bearing-to-journal

clearance.

Install the crankshaft into the cylinder block.

Fig. 42 Crankshaft Journal Size Paint I.D. Location

1 - NO. 7 MAIN JOURNAL SIZE PAINT MARK

2 - NO. 6 CONNECTING ROD JOURNAL SIZE PAINT MARK3 - NO. 1 CONNECTING ROD JOURNAL SIZE PAINT MARK

4 - NO. 1 MAIN JOURNAL SIZE PAINT MARK

Fig. 43 Measuring Bearing Clearance with

Plastigage

1 - PLASTIGAGE SCALE

2 - COMPRESSED PLASTIGAGE

WJENGINE - 4.0L 9 - 37

CRANKSHAFT MAIN BEARINGS (Continued)

Page 1283 of 2199

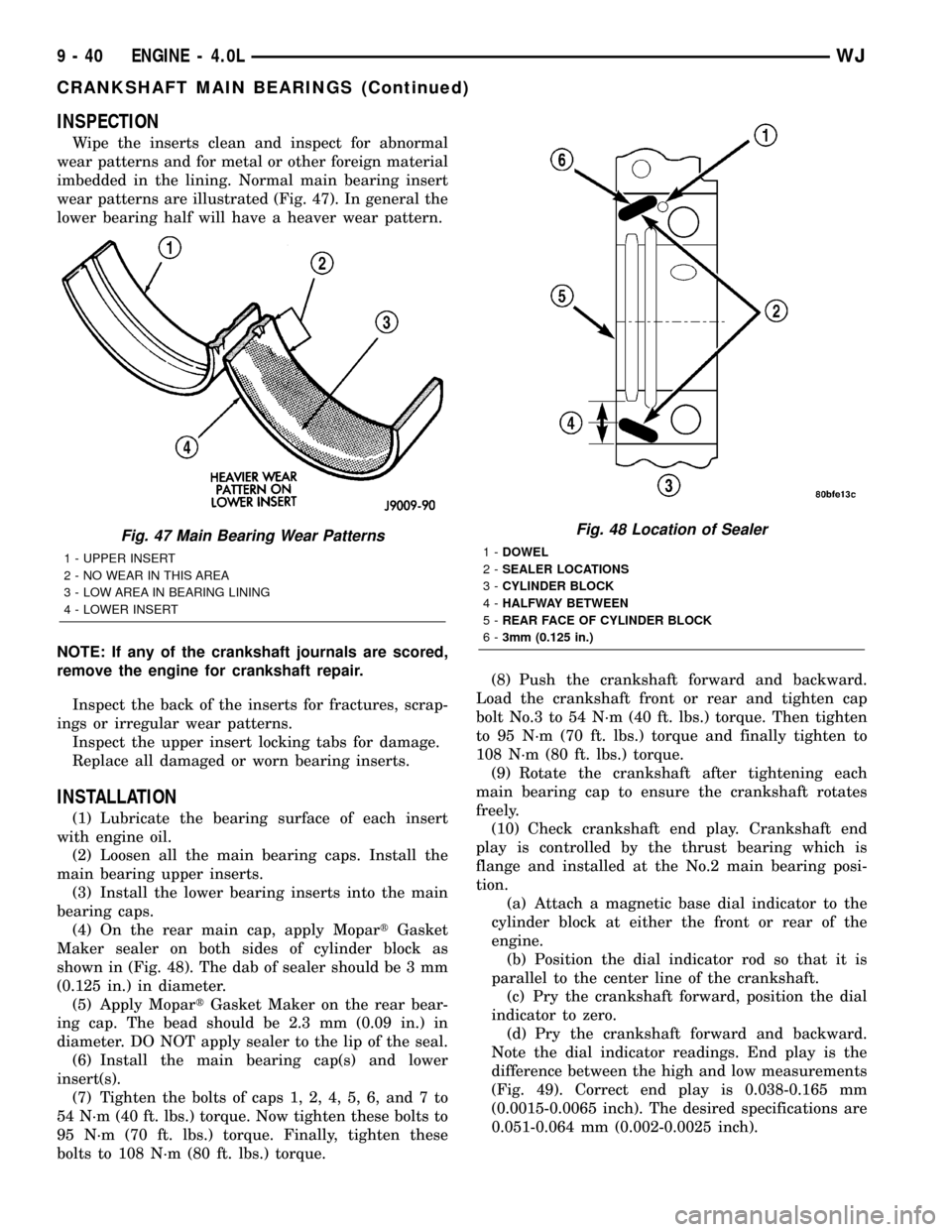

INSPECTION

Wipe the inserts clean and inspect for abnormal

wear patterns and for metal or other foreign material

imbedded in the lining. Normal main bearing insert

wear patterns are illustrated (Fig. 47). In general the

lower bearing half will have a heaver wear pattern.

NOTE: If any of the crankshaft journals are scored,

remove the engine for crankshaft repair.

Inspect the back of the inserts for fractures, scrap-

ings or irregular wear patterns.

Inspect the upper insert locking tabs for damage.

Replace all damaged or worn bearing inserts.

INSTALLATION

(1) Lubricate the bearing surface of each insert

with engine oil.

(2) Loosen all the main bearing caps. Install the

main bearing upper inserts.

(3) Install the lower bearing inserts into the main

bearing caps.

(4) On the rear main cap, apply MopartGasket

Maker sealer on both sides of cylinder block as

shown in (Fig. 48). The dab of sealer should be 3 mm

(0.125 in.) in diameter.

(5) Apply MopartGasket Maker on the rear bear-

ing cap. The bead should be 2.3 mm (0.09 in.) in

diameter. DO NOT apply sealer to the lip of the seal.

(6) Install the main bearing cap(s) and lower

insert(s).

(7) Tighten the bolts of caps 1, 2, 4, 5, 6, and 7 to

54 N´m (40 ft. lbs.) torque. Now tighten these bolts to

95 N´m (70 ft. lbs.) torque. Finally, tighten these

bolts to 108 N´m (80 ft. lbs.) torque.(8) Push the crankshaft forward and backward.

Load the crankshaft front or rear and tighten cap

bolt No.3 to 54 N´m (40 ft. lbs.) torque. Then tighten

to 95 N´m (70 ft. lbs.) torque and finally tighten to

108 N´m (80 ft. lbs.) torque.

(9) Rotate the crankshaft after tightening each

main bearing cap to ensure the crankshaft rotates

freely.

(10) Check crankshaft end play. Crankshaft end

play is controlled by the thrust bearing which is

flange and installed at the No.2 main bearing posi-

tion.

(a) Attach a magnetic base dial indicator to the

cylinder block at either the front or rear of the

engine.

(b) Position the dial indicator rod so that it is

parallel to the center line of the crankshaft.

(c) Pry the crankshaft forward, position the dial

indicator to zero.

(d) Pry the crankshaft forward and backward.

Note the dial indicator readings. End play is the

difference between the high and low measurements

(Fig. 49). Correct end play is 0.038-0.165 mm

(0.0015-0.0065 inch). The desired specifications are

0.051-0.064 mm (0.002-0.0025 inch).

Fig. 47 Main Bearing Wear Patterns

1 - UPPER INSERT

2 - NO WEAR IN THIS AREA

3 - LOW AREA IN BEARING LINING

4 - LOWER INSERT

Fig. 48 Location of Sealer

1-DOWEL

2-SEALER LOCATIONS

3-CYLINDER BLOCK

4-HALFWAY BETWEEN

5-REAR FACE OF CYLINDER BLOCK

6-3mm (0.125 in.)

9 - 40 ENGINE - 4.0LWJ

CRANKSHAFT MAIN BEARINGS (Continued)

Page 1289 of 2199

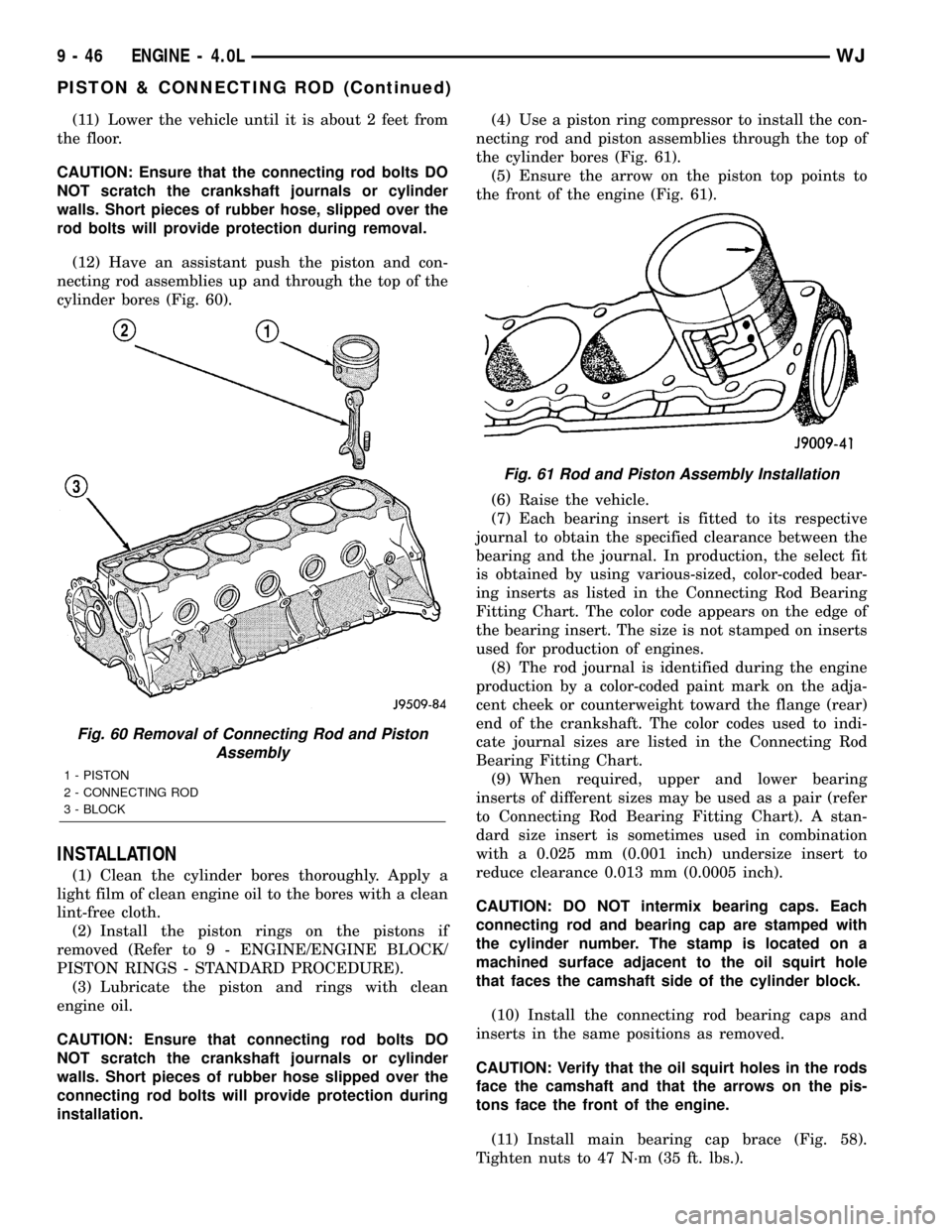

(11) Lower the vehicle until it is about 2 feet from

the floor.

CAUTION: Ensure that the connecting rod bolts DO

NOT scratch the crankshaft journals or cylinder

walls. Short pieces of rubber hose, slipped over the

rod bolts will provide protection during removal.

(12) Have an assistant push the piston and con-

necting rod assemblies up and through the top of the

cylinder bores (Fig. 60).

INSTALLATION

(1) Clean the cylinder bores thoroughly. Apply a

light film of clean engine oil to the bores with a clean

lint-free cloth.

(2) Install the piston rings on the pistons if

removed (Refer to 9 - ENGINE/ENGINE BLOCK/

PISTON RINGS - STANDARD PROCEDURE).

(3) Lubricate the piston and rings with clean

engine oil.

CAUTION: Ensure that connecting rod bolts DO

NOT scratch the crankshaft journals or cylinder

walls. Short pieces of rubber hose slipped over the

connecting rod bolts will provide protection during

installation.(4) Use a piston ring compressor to install the con-

necting rod and piston assemblies through the top of

the cylinder bores (Fig. 61).

(5) Ensure the arrow on the piston top points to

the front of the engine (Fig. 61).

(6) Raise the vehicle.

(7) Each bearing insert is fitted to its respective

journal to obtain the specified clearance between the

bearing and the journal. In production, the select fit

is obtained by using various-sized, color-coded bear-

ing inserts as listed in the Connecting Rod Bearing

Fitting Chart. The color code appears on the edge of

the bearing insert. The size is not stamped on inserts

used for production of engines.

(8) The rod journal is identified during the engine

production by a color-coded paint mark on the adja-

cent cheek or counterweight toward the flange (rear)

end of the crankshaft. The color codes used to indi-

cate journal sizes are listed in the Connecting Rod

Bearing Fitting Chart.

(9) When required, upper and lower bearing

inserts of different sizes may be used as a pair (refer

to Connecting Rod Bearing Fitting Chart). A stan-

dard size insert is sometimes used in combination

with a 0.025 mm (0.001 inch) undersize insert to

reduce clearance 0.013 mm (0.0005 inch).

CAUTION: DO NOT intermix bearing caps. Each

connecting rod and bearing cap are stamped with

the cylinder number. The stamp is located on a

machined surface adjacent to the oil squirt hole

that faces the camshaft side of the cylinder block.

(10) Install the connecting rod bearing caps and

inserts in the same positions as removed.

CAUTION: Verify that the oil squirt holes in the rods

face the camshaft and that the arrows on the pis-

tons face the front of the engine.

(11) Install main bearing cap brace (Fig. 58).

Tighten nuts to 47 N´m (35 ft. lbs.).

Fig. 60 Removal of Connecting Rod and Piston

Assembly

1 - PISTON

2 - CONNECTING ROD

3 - BLOCK

Fig. 61 Rod and Piston Assembly Installation

9 - 46 ENGINE - 4.0LWJ

PISTON & CONNECTING ROD (Continued)

Page 1291 of 2199

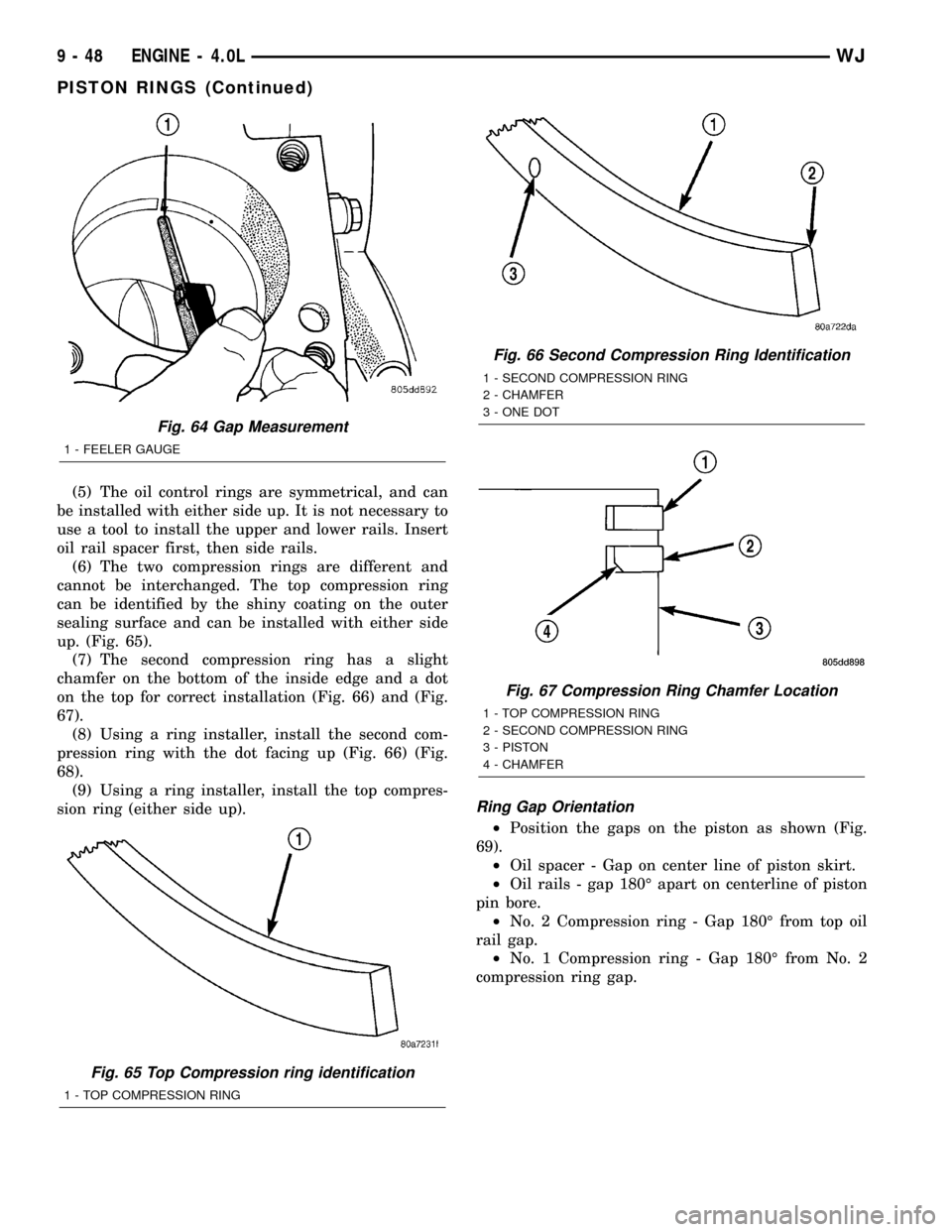

(5) The oil control rings are symmetrical, and can

be installed with either side up. It is not necessary to

use a tool to install the upper and lower rails. Insert

oil rail spacer first, then side rails.

(6) The two compression rings are different and

cannot be interchanged. The top compression ring

can be identified by the shiny coating on the outer

sealing surface and can be installed with either side

up. (Fig. 65).

(7) The second compression ring has a slight

chamfer on the bottom of the inside edge and a dot

on the top for correct installation (Fig. 66) and (Fig.

67).

(8) Using a ring installer, install the second com-

pression ring with the dot facing up (Fig. 66) (Fig.

68).

(9) Using a ring installer, install the top compres-

sion ring (either side up).

Ring Gap Orientation

²Position the gaps on the piston as shown (Fig.

69).

²Oil spacer - Gap on center line of piston skirt.

²Oil rails - gap 180É apart on centerline of piston

pin bore.

²No. 2 Compression ring - Gap 180É from top oil

rail gap.

²No. 1 Compression ring - Gap 180É from No. 2

compression ring gap.

Fig. 64 Gap Measurement

1 - FEELER GAUGE

Fig. 65 Top Compression ring identification

1 - TOP COMPRESSION RING

Fig. 66 Second Compression Ring Identification

1 - SECOND COMPRESSION RING

2 - CHAMFER

3 - ONE DOT

Fig. 67 Compression Ring Chamfer Location

1 - TOP COMPRESSION RING

2 - SECOND COMPRESSION RING

3 - PISTON

4 - CHAMFER

9 - 48 ENGINE - 4.0LWJ

PISTON RINGS (Continued)

Page 1294 of 2199

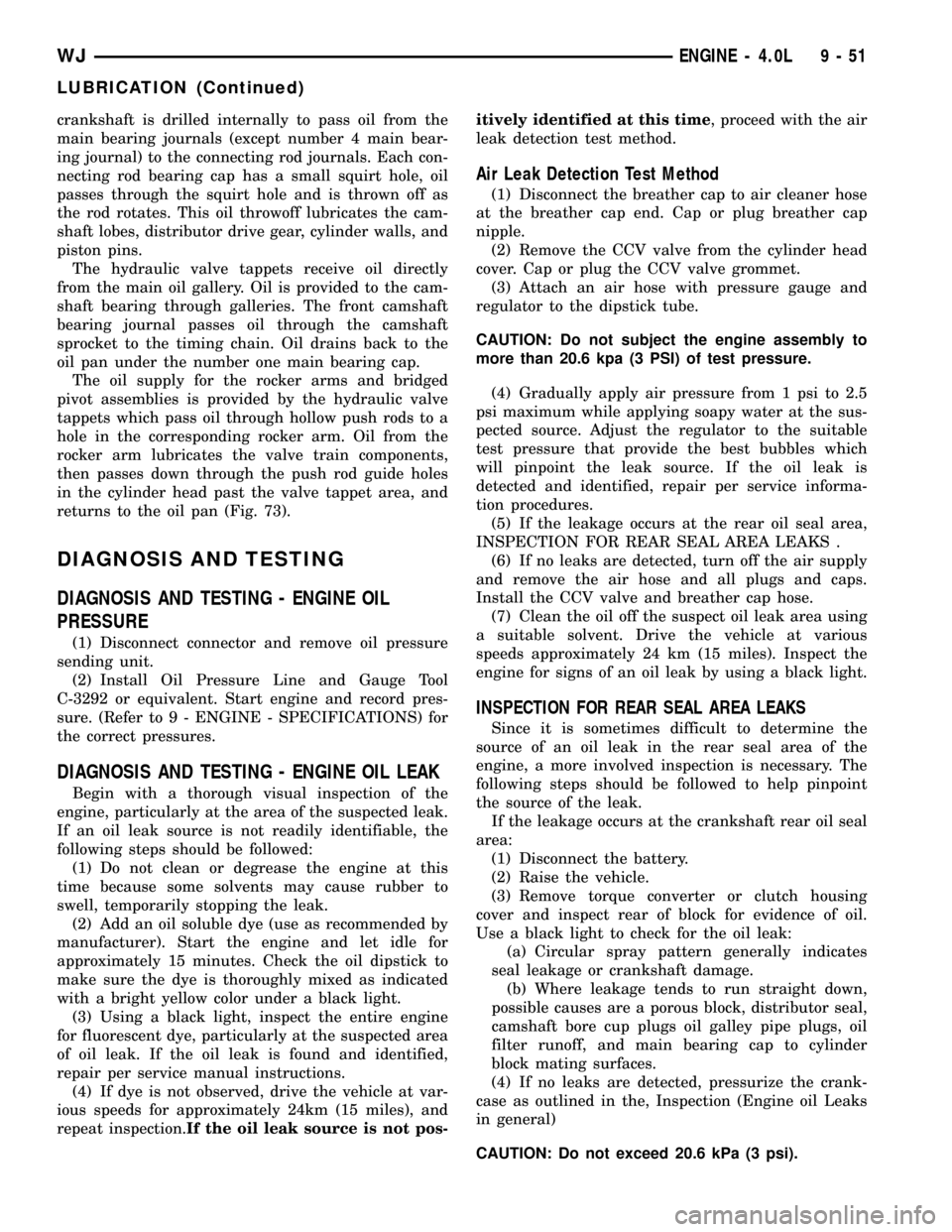

crankshaft is drilled internally to pass oil from the

main bearing journals (except number 4 main bear-

ing journal) to the connecting rod journals. Each con-

necting rod bearing cap has a small squirt hole, oil

passes through the squirt hole and is thrown off as

the rod rotates. This oil throwoff lubricates the cam-

shaft lobes, distributor drive gear, cylinder walls, and

piston pins.

The hydraulic valve tappets receive oil directly

from the main oil gallery. Oil is provided to the cam-

shaft bearing through galleries. The front camshaft

bearing journal passes oil through the camshaft

sprocket to the timing chain. Oil drains back to the

oil pan under the number one main bearing cap.

The oil supply for the rocker arms and bridged

pivot assemblies is provided by the hydraulic valve

tappets which pass oil through hollow push rods to a

hole in the corresponding rocker arm. Oil from the

rocker arm lubricates the valve train components,

then passes down through the push rod guide holes

in the cylinder head past the valve tappet area, and

returns to the oil pan (Fig. 73).

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE OIL

PRESSURE

(1) Disconnect connector and remove oil pressure

sending unit.

(2) Install Oil Pressure Line and Gauge Tool

C-3292 or equivalent. Start engine and record pres-

sure. (Refer to 9 - ENGINE - SPECIFICATIONS) for

the correct pressures.

DIAGNOSIS AND TESTING - ENGINE OIL LEAK

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat inspection.If the oil leak source is not pos-itively identified at this time, proceed with the air

leak detection test method.

Air Leak Detection Test Method

(1) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(2) Remove the CCV valve from the cylinder head

cover. Cap or plug the CCV valve grommet.

(3) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(4) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service informa-

tion procedures.

(5) If the leakage occurs at the rear oil seal area,

INSPECTION FOR REAR SEAL AREA LEAKS .

(6) If no leaks are detected, turn off the air supply

and remove the air hose and all plugs and caps.

Install the CCV valve and breather cap hose.

(7) Clean the oil off the suspect oil leak area using

a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

INSPECTION FOR REAR SEAL AREA LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs oil galley pipe plugs, oil

filter runoff, and main bearing cap to cylinder

block mating surfaces.

(4) If no leaks are detected, pressurize the crank-

case as outlined in the, Inspection (Engine oil Leaks

in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

WJENGINE - 4.0L 9 - 51

LUBRICATION (Continued)

Page 1299 of 2199

(9) Lower the engine until it is properly located on

the engine mounts.

(10) Install the through bolts and tighten the nuts.

(11) Lower the jack stand and remove the piece of

wood.

(12) Install the engine flywheel and transmission

torque converter housing access cover.

(13) Install the engine starter motor. (Refer to 8 -

ELECTRICAL/STARTING/STARTER MOTOR -

INSTALLATION).

(14) Connect the exhaust pipe to the hanger and to

the engine exhaust manifold.

(15) Install transmission oil cooling lines (if

equipped) and oxygen sensor wiring supports that

attach to the oil pan studs.

(16) Install the oil pan drain plug (Fig. 81).

Tighten the plug to 34 N´m (25 ft. lbs.) torque.

(17) Lower the vehicle.

(18) Connect negative cable to battery.

(19) Fill the oil pan with engine oil to the specified

level.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(20) Start the engine and inspect for leaks.

ENGINE OIL PRESSURE

SENSOR

DESCRIPTION

The 3±wire, solid-state engine oil pressure sensor

(sending unit) is located in an engine oil pressure

gallery.

OPERATION

The oil pressure sensor uses three circuits. They

are:

²A 5±volt power supply from the Powertrain Con-

trol Module (PCM)

²A sensor ground through the PCM's sensor

return

²A signal to the PCM relating to engine oil pres-

sure

The oil pressure sensor has a 3±wire electrical

function very much like the Manifold Absolute Pres-

sure (MAP) sensor. Meaning different pressures

relate to different output voltages.

A 5±volt supply is sent to the sensor from the PCM

to power up the sensor. The sensor returns a voltage

signal back to the PCM relating to engine oil pres-

sure. This signal is then transferred (bussed) to theinstrument panel on either a CCD or PCI bus circuit

(depending on vehicle line) to operate the oil pressure

gauge and the check gauges lamp. Ground for the

sensor is provided by the PCM through a low-noise

sensor return.

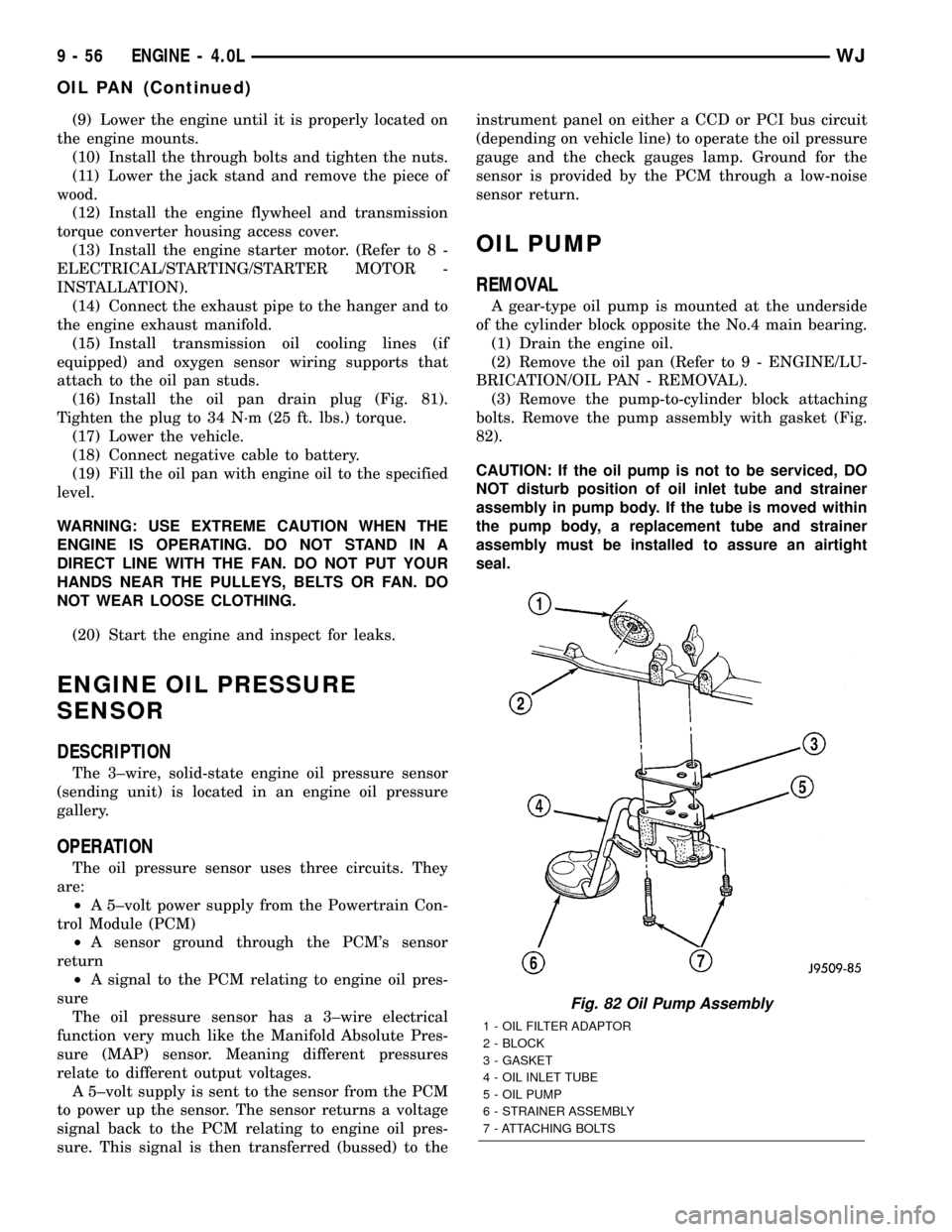

OIL PUMP

REMOVAL

A gear-type oil pump is mounted at the underside

of the cylinder block opposite the No.4 main bearing.

(1) Drain the engine oil.

(2) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(3) Remove the pump-to-cylinder block attaching

bolts. Remove the pump assembly with gasket (Fig.

82).

CAUTION: If the oil pump is not to be serviced, DO

NOT disturb position of oil inlet tube and strainer

assembly in pump body. If the tube is moved within

the pump body, a replacement tube and strainer

assembly must be installed to assure an airtight

seal.

Fig. 82 Oil Pump Assembly

1 - OIL FILTER ADAPTOR

2 - BLOCK

3 - GASKET

4 - OIL INLET TUBE

5 - OIL PUMP

6 - STRAINER ASSEMBLY

7 - ATTACHING BOLTS

9 - 56 ENGINE - 4.0LWJ

OIL PAN (Continued)

Page 1306 of 2199

VALVE TIMING

DESCRIPTION - TIMING DRIVE SYSTEM....141

OPERATION - TIMING DRIVE SYSTEM.....141

STANDARD PROCEDURE

STANDARD PROCEDURE - ENGINE TIMING

- VERIFICATION.....................141

STANDARD PROCEDUREÐMEASURING

TIMING CHAIN WEAR.................145TIMING BELT / CHAIN COVER(S)

REMOVAL............................146

INSTALLATION........................146

TIMING BELT/CHAIN AND SPROCKETS

REMOVAL............................147

INSPECTION.........................149

INSTALLATION........................149

ENGINE - 4.7L

DESCRIPTIONÐ4.7L ENGINE

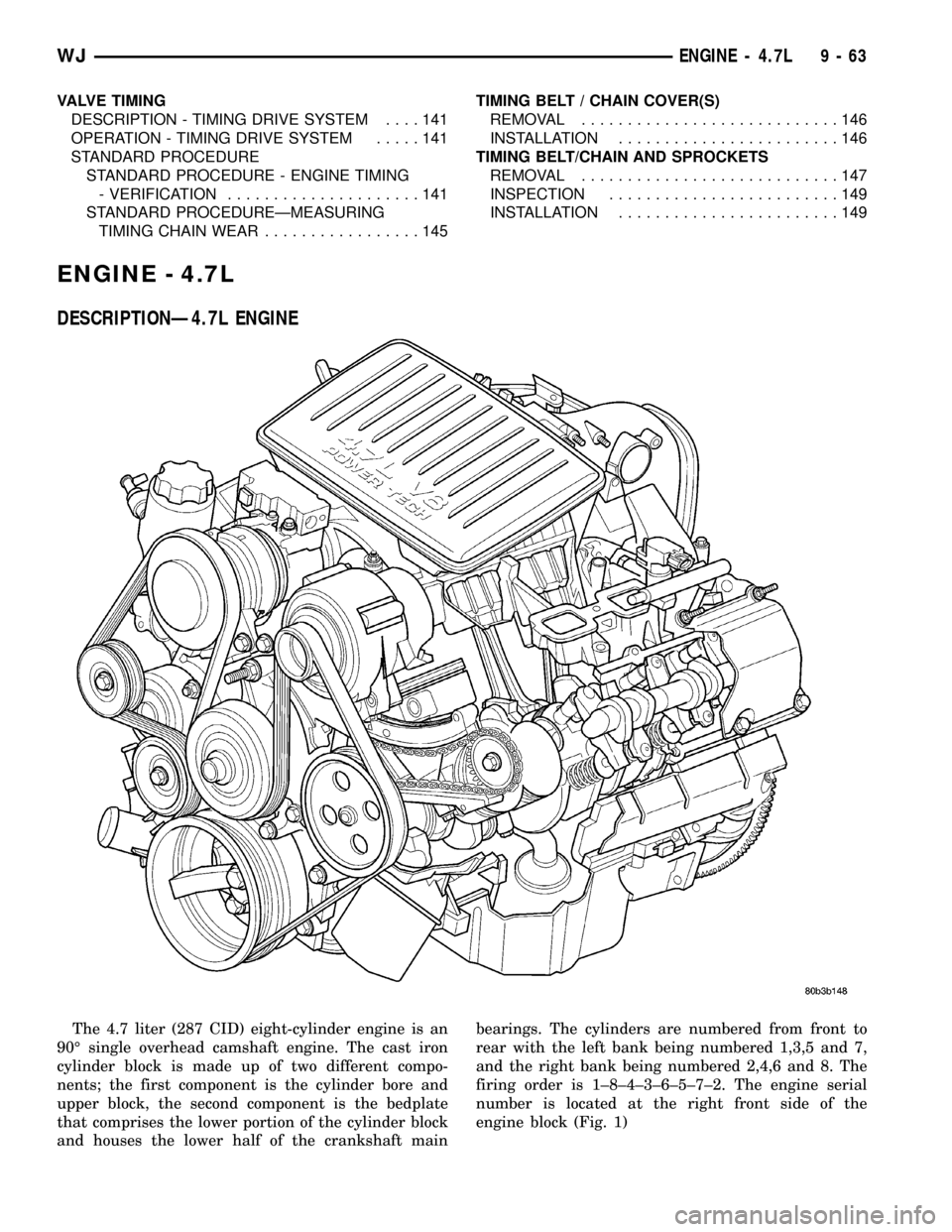

The 4.7 liter (287 CID) eight-cylinder engine is an

90É single overhead camshaft engine. The cast iron

cylinder block is made up of two different compo-

nents; the first component is the cylinder bore and

upper block, the second component is the bedplate

that comprises the lower portion of the cylinder block

and houses the lower half of the crankshaft mainbearings. The cylinders are numbered from front to

rear with the left bank being numbered 1,3,5 and 7,

and the right bank being numbered 2,4,6 and 8. The

firing order is 1±8±4±3±6±5±7±2. The engine serial

number is located at the right front side of the

engine block (Fig. 1)

WJENGINE - 4.7L 9 - 63

Page 1313 of 2199

STANDARD PROCEDURE

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of airwhen squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - ENGINE GASKET

SURFACE PREPARATION

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

Neveruse the following to clean gasket surfaces:

²Metal scraper

9 - 70 ENGINE - 4.7LWJ

ENGINE - 4.7L (Continued)