head JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 626 of 2199

the more frequently the RSM will send wipe com-

mands to the BCM to operate the front wiper system.

The RSM operates on battery current received

through a fuse in the Junction Block (JB) on a fused

B(+) circuit. This circuit is switched by the power

accessory (sunroof) delay relay in the JB so that the

RSM will operate whenever the relay is energized by

the BCM. The RSM receives ground at all times

through a take out of the left body wire harness with

an eyelet terminal that is secured by a ground screw

to the front seat crossmember on the floor panel

under the left front seat. It is important to note that

the default condition for the wiper system is auto-

matic wipers Off; therefore, if no message is received

from the RSM by the BCM for more than about five

seconds, the automatic wipers will be disabled and

the BCM will default the front wiper system opera-

tion to the low speed continuous wipe mode.

The RSM ground and battery current inputs can be

diagnosed using conventional diagnostic tools and

methods. However, conventional diagnostic methods

may not prove conclusive in the diagnosis of the RSM

internal circuitry, the BCM, the PCI data bus net-

work, or the electronic messages received and trans-

mitted by the RSM over the PCI data bus. The most

reliable, efficient, and accurate means to diagnose

the RSM requires the use of a DRBIIItscan tool.

Refer to the appropriate diagnostic information.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SIDE CURTAIN AIRBAG,

FRONT IMPACT SENSOR, SIDE IMPACT SENSOR,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

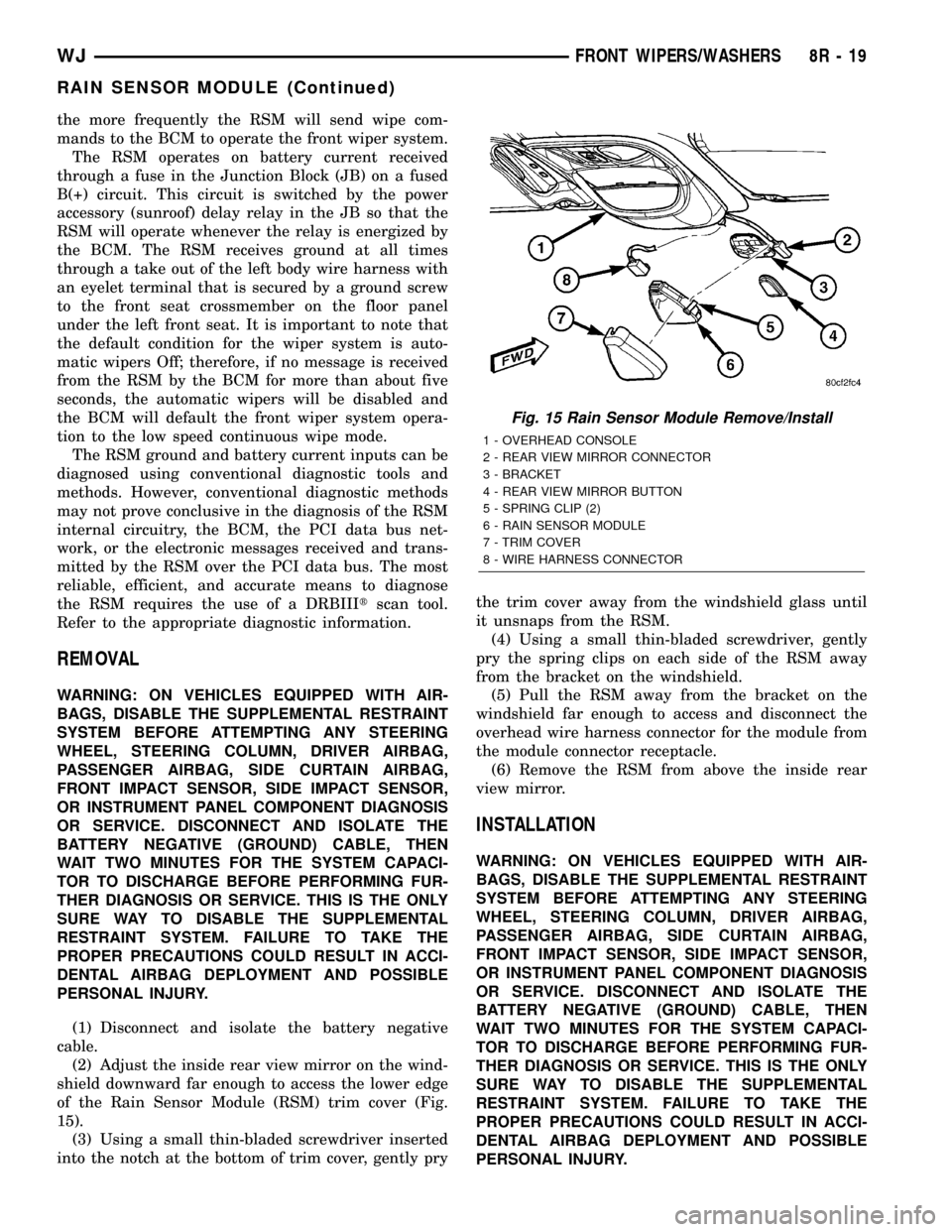

(2) Adjust the inside rear view mirror on the wind-

shield downward far enough to access the lower edge

of the Rain Sensor Module (RSM) trim cover (Fig.

15).

(3) Using a small thin-bladed screwdriver inserted

into the notch at the bottom of trim cover, gently prythe trim cover away from the windshield glass until

it unsnaps from the RSM.

(4) Using a small thin-bladed screwdriver, gently

pry the spring clips on each side of the RSM away

from the bracket on the windshield.

(5) Pull the RSM away from the bracket on the

windshield far enough to access and disconnect the

overhead wire harness connector for the module from

the module connector receptacle.

(6) Remove the RSM from above the inside rear

view mirror.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, SIDE CURTAIN AIRBAG,

FRONT IMPACT SENSOR, SIDE IMPACT SENSOR,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

Fig. 15 Rain Sensor Module Remove/Install

1 - OVERHEAD CONSOLE

2 - REAR VIEW MIRROR CONNECTOR

3 - BRACKET

4 - REAR VIEW MIRROR BUTTON

5 - SPRING CLIP (2)

6 - RAIN SENSOR MODULE

7 - TRIM COVER

8 - WIRE HARNESS CONNECTOR

WJFRONT WIPERS/WASHERS 8R - 19

RAIN SENSOR MODULE (Continued)

Page 627 of 2199

(1) Position the Rain Sensor Module (RSM) above

the inside rear view mirror (Fig. 15).

(2) Reconnect the overhead wire harness connector

for the RSM to the module connector receptacle.

(3) Position the RSM to the bracket on the wind-

shield above the inside rear view mirror.

(4) Using hand pressure, press the spring clips on

each side of the RSM until they snap over the

bracket on the windshield.

NOTE: The spring clips on the RSM will become

deformed after numerous (about ten) removal and

installation cycles. If the spring clips become

deformed, the RSM must be replaced with a new

unit.

(5) Align and engage the top of the trim cover over

the top of the RSM.

(6) Using hand pressure, press the bottom of the

trim cover toward the windshield glass until it snaps

over the bottom of the RSM.

(7) Reconnect the battery negative cable.

RIGHT MULTI-FUNCTION

SWITCH

DESCRIPTION

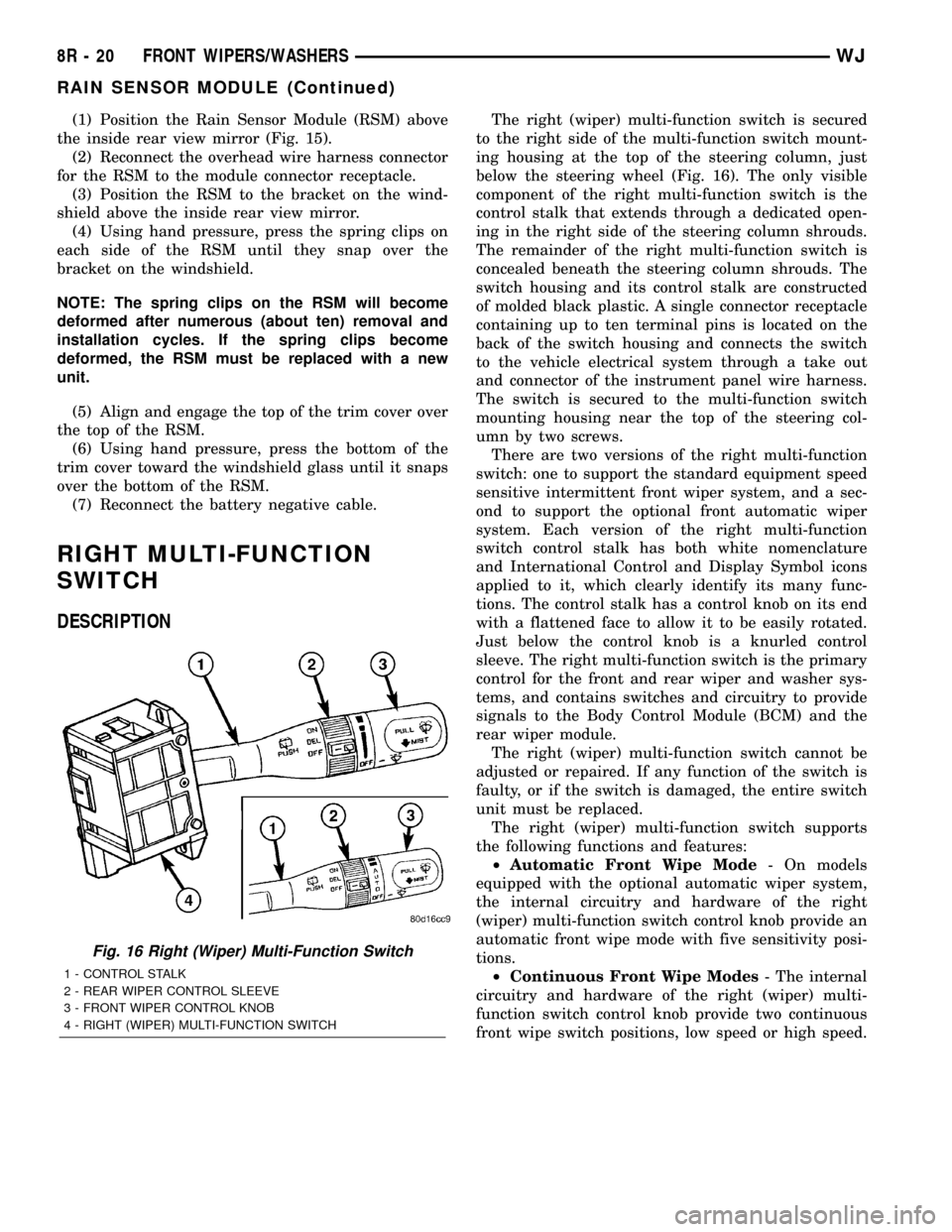

The right (wiper) multi-function switch is secured

to the right side of the multi-function switch mount-

ing housing at the top of the steering column, just

below the steering wheel (Fig. 16). The only visible

component of the right multi-function switch is the

control stalk that extends through a dedicated open-

ing in the right side of the steering column shrouds.

The remainder of the right multi-function switch is

concealed beneath the steering column shrouds. The

switch housing and its control stalk are constructed

of molded black plastic. A single connector receptacle

containing up to ten terminal pins is located on the

back of the switch housing and connects the switch

to the vehicle electrical system through a take out

and connector of the instrument panel wire harness.

The switch is secured to the multi-function switch

mounting housing near the top of the steering col-

umn by two screws.

There are two versions of the right multi-function

switch: one to support the standard equipment speed

sensitive intermittent front wiper system, and a sec-

ond to support the optional front automatic wiper

system. Each version of the right multi-function

switch control stalk has both white nomenclature

and International Control and Display Symbol icons

applied to it, which clearly identify its many func-

tions. The control stalk has a control knob on its end

with a flattened face to allow it to be easily rotated.

Just below the control knob is a knurled control

sleeve. The right multi-function switch is the primary

control for the front and rear wiper and washer sys-

tems, and contains switches and circuitry to provide

signals to the Body Control Module (BCM) and the

rear wiper module.

The right (wiper) multi-function switch cannot be

adjusted or repaired. If any function of the switch is

faulty, or if the switch is damaged, the entire switch

unit must be replaced.

The right (wiper) multi-function switch supports

the following functions and features:

²Automatic Front Wipe Mode- On models

equipped with the optional automatic wiper system,

the internal circuitry and hardware of the right

(wiper) multi-function switch control knob provide an

automatic front wipe mode with five sensitivity posi-

tions.

²Continuous Front Wipe Modes- The internal

circuitry and hardware of the right (wiper) multi-

function switch control knob provide two continuous

front wipe switch positions, low speed or high speed.

Fig. 16 Right (Wiper) Multi-Function Switch

1 - CONTROL STALK

2 - REAR WIPER CONTROL SLEEVE

3 - FRONT WIPER CONTROL KNOB

4 - RIGHT (WIPER) MULTI-FUNCTION SWITCH

8R - 20 FRONT WIPERS/WASHERSWJ

RAIN SENSOR MODULE (Continued)

Page 632 of 2199

switch mounting housing. Tighten the screws to 2.5

N´m (22 in. lbs.).

(3) Reconnect the instrument panel wire harness

connector for the right multi-function switch to the

switch connector receptacle.

(4) Position the lower tilting steering column

shroud to the underside of the steering column (Fig.

18).

(5) Install and tighten the screw that secures the

lower tilting steering column shroud to the multi-

function switch mounting housing. Tighten the screw

to 1.9 N´m (17 in. lbs.).

(6) Position the upper tilting column shroud over

the steering column with the hazard warning switch

button inserted through the hole in the upper surface

of the shroud. Align the upper tilting steering column

shroud to the lower shroud and snap the two shroud

halves together.

(7) Reconnect the battery negative cable.

WASHER FLUID LEVEL

SWITCH

DESCRIPTION

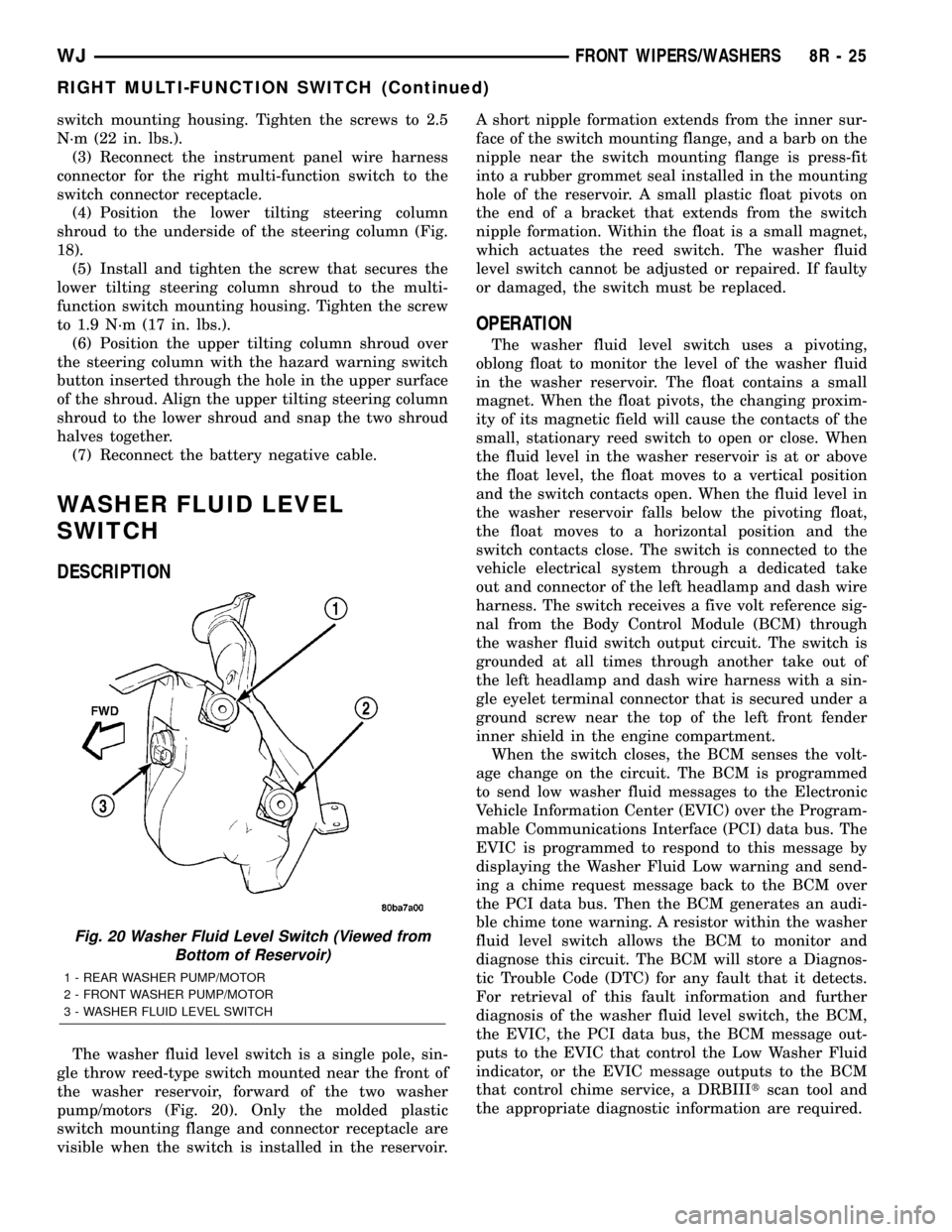

The washer fluid level switch is a single pole, sin-

gle throw reed-type switch mounted near the front of

the washer reservoir, forward of the two washer

pump/motors (Fig. 20). Only the molded plastic

switch mounting flange and connector receptacle are

visible when the switch is installed in the reservoir.A short nipple formation extends from the inner sur-

face of the switch mounting flange, and a barb on the

nipple near the switch mounting flange is press-fit

into a rubber grommet seal installed in the mounting

hole of the reservoir. A small plastic float pivots on

the end of a bracket that extends from the switch

nipple formation. Within the float is a small magnet,

which actuates the reed switch. The washer fluid

level switch cannot be adjusted or repaired. If faulty

or damaged, the switch must be replaced.

OPERATION

The washer fluid level switch uses a pivoting,

oblong float to monitor the level of the washer fluid

in the washer reservoir. The float contains a small

magnet. When the float pivots, the changing proxim-

ity of its magnetic field will cause the contacts of the

small, stationary reed switch to open or close. When

the fluid level in the washer reservoir is at or above

the float level, the float moves to a vertical position

and the switch contacts open. When the fluid level in

the washer reservoir falls below the pivoting float,

the float moves to a horizontal position and the

switch contacts close. The switch is connected to the

vehicle electrical system through a dedicated take

out and connector of the left headlamp and dash wire

harness. The switch receives a five volt reference sig-

nal from the Body Control Module (BCM) through

the washer fluid switch output circuit. The switch is

grounded at all times through another take out of

the left headlamp and dash wire harness with a sin-

gle eyelet terminal connector that is secured under a

ground screw near the top of the left front fender

inner shield in the engine compartment.

When the switch closes, the BCM senses the volt-

age change on the circuit. The BCM is programmed

to send low washer fluid messages to the Electronic

Vehicle Information Center (EVIC) over the Program-

mable Communications Interface (PCI) data bus. The

EVIC is programmed to respond to this message by

displaying the Washer Fluid Low warning and send-

ing a chime request message back to the BCM over

the PCI data bus. Then the BCM generates an audi-

ble chime tone warning. A resistor within the washer

fluid level switch allows the BCM to monitor and

diagnose this circuit. The BCM will store a Diagnos-

tic Trouble Code (DTC) for any fault that it detects.

For retrieval of this fault information and further

diagnosis of the washer fluid level switch, the BCM,

the EVIC, the PCI data bus, the BCM message out-

puts to the EVIC that control the Low Washer Fluid

indicator, or the EVIC message outputs to the BCM

that control chime service, a DRBIIItscan tool and

the appropriate diagnostic information are required.

Fig. 20 Washer Fluid Level Switch (Viewed from

Bottom of Reservoir)

1 - REAR WASHER PUMP/MOTOR

2 - FRONT WASHER PUMP/MOTOR

3 - WASHER FLUID LEVEL SWITCH

WJFRONT WIPERS/WASHERS 8R - 25

RIGHT MULTI-FUNCTION SWITCH (Continued)

Page 633 of 2199

REMOVAL

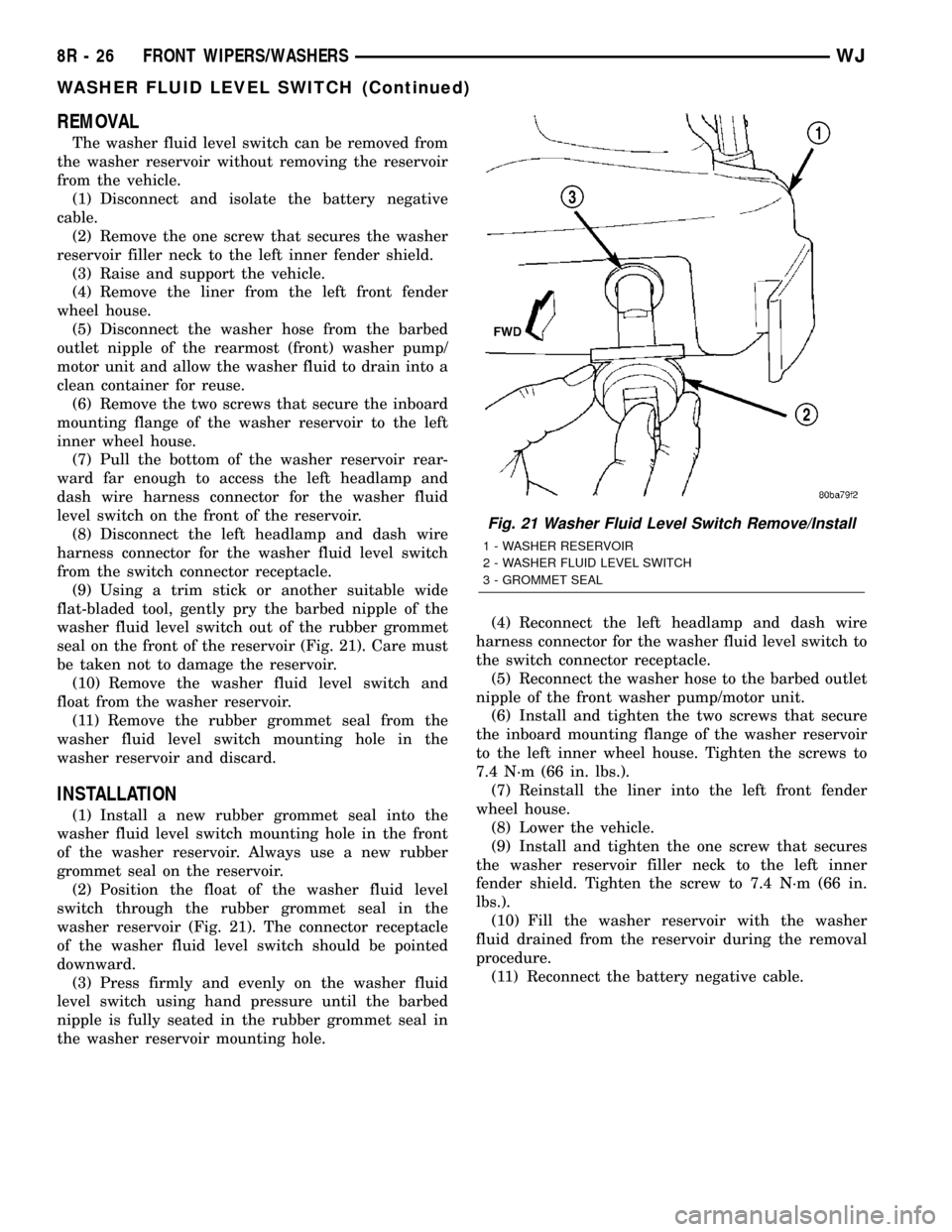

The washer fluid level switch can be removed from

the washer reservoir without removing the reservoir

from the vehicle.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the one screw that secures the washer

reservoir filler neck to the left inner fender shield.

(3) Raise and support the vehicle.

(4) Remove the liner from the left front fender

wheel house.

(5) Disconnect the washer hose from the barbed

outlet nipple of the rearmost (front) washer pump/

motor unit and allow the washer fluid to drain into a

clean container for reuse.

(6) Remove the two screws that secure the inboard

mounting flange of the washer reservoir to the left

inner wheel house.

(7) Pull the bottom of the washer reservoir rear-

ward far enough to access the left headlamp and

dash wire harness connector for the washer fluid

level switch on the front of the reservoir.

(8) Disconnect the left headlamp and dash wire

harness connector for the washer fluid level switch

from the switch connector receptacle.

(9) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the barbed nipple of the

washer fluid level switch out of the rubber grommet

seal on the front of the reservoir (Fig. 21). Care must

be taken not to damage the reservoir.

(10) Remove the washer fluid level switch and

float from the washer reservoir.

(11) Remove the rubber grommet seal from the

washer fluid level switch mounting hole in the

washer reservoir and discard.

INSTALLATION

(1) Install a new rubber grommet seal into the

washer fluid level switch mounting hole in the front

of the washer reservoir. Always use a new rubber

grommet seal on the reservoir.

(2) Position the float of the washer fluid level

switch through the rubber grommet seal in the

washer reservoir (Fig. 21). The connector receptacle

of the washer fluid level switch should be pointed

downward.

(3) Press firmly and evenly on the washer fluid

level switch using hand pressure until the barbed

nipple is fully seated in the rubber grommet seal in

the washer reservoir mounting hole.(4) Reconnect the left headlamp and dash wire

harness connector for the washer fluid level switch to

the switch connector receptacle.

(5) Reconnect the washer hose to the barbed outlet

nipple of the front washer pump/motor unit.

(6) Install and tighten the two screws that secure

the inboard mounting flange of the washer reservoir

to the left inner wheel house. Tighten the screws to

7.4 N´m (66 in. lbs.).

(7) Reinstall the liner into the left front fender

wheel house.

(8) Lower the vehicle.

(9) Install and tighten the one screw that secures

the washer reservoir filler neck to the left inner

fender shield. Tighten the screw to 7.4 N´m (66 in.

lbs.).

(10) Fill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(11) Reconnect the battery negative cable.

Fig. 21 Washer Fluid Level Switch Remove/Install

1 - WASHER RESERVOIR

2 - WASHER FLUID LEVEL SWITCH

3 - GROMMET SEAL

8R - 26 FRONT WIPERS/WASHERSWJ

WASHER FLUID LEVEL SWITCH (Continued)

Page 635 of 2199

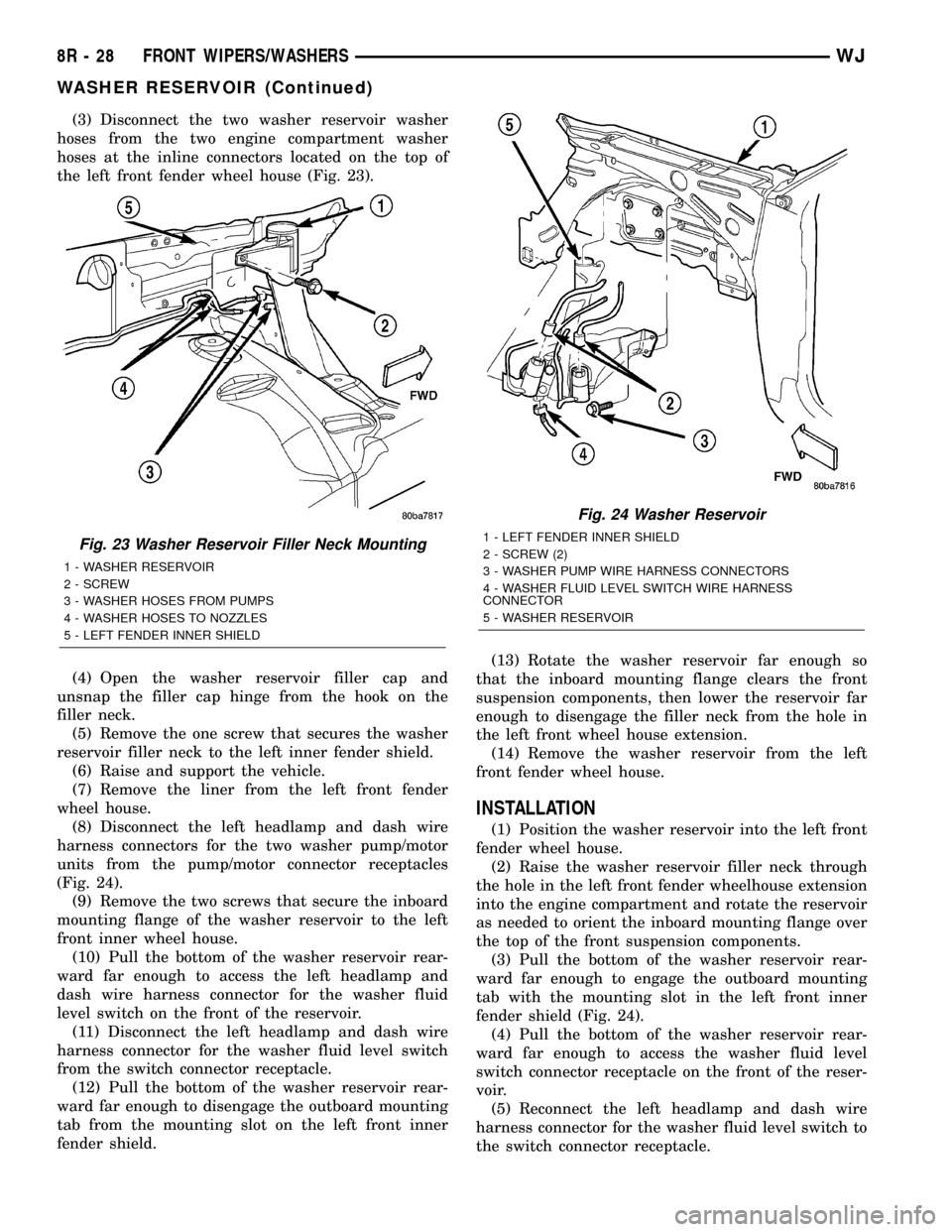

(3) Disconnect the two washer reservoir washer

hoses from the two engine compartment washer

hoses at the inline connectors located on the top of

the left front fender wheel house (Fig. 23).

(4) Open the washer reservoir filler cap and

unsnap the filler cap hinge from the hook on the

filler neck.

(5) Remove the one screw that secures the washer

reservoir filler neck to the left inner fender shield.

(6) Raise and support the vehicle.

(7) Remove the liner from the left front fender

wheel house.

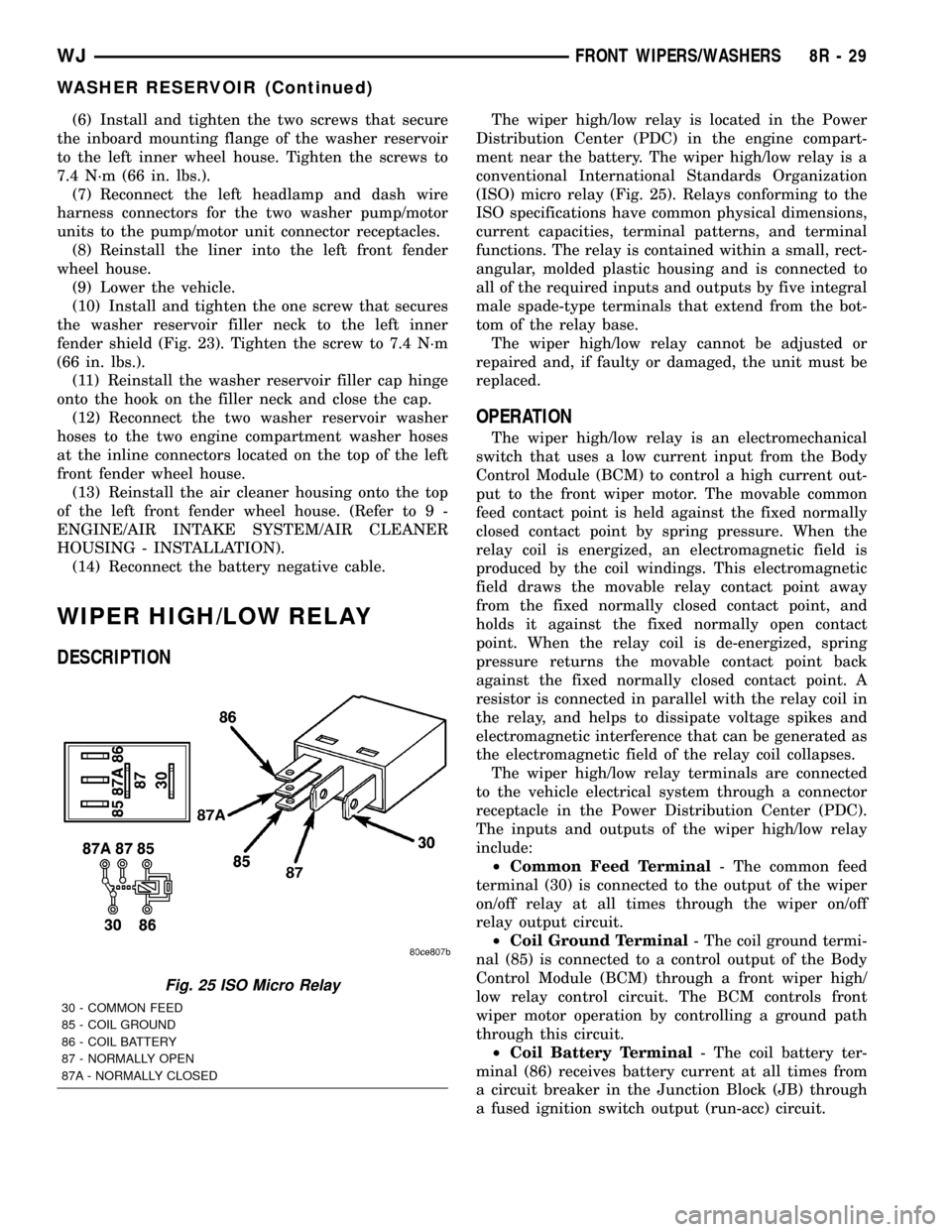

(8) Disconnect the left headlamp and dash wire

harness connectors for the two washer pump/motor

units from the pump/motor connector receptacles

(Fig. 24).

(9) Remove the two screws that secure the inboard

mounting flange of the washer reservoir to the left

front inner wheel house.

(10) Pull the bottom of the washer reservoir rear-

ward far enough to access the left headlamp and

dash wire harness connector for the washer fluid

level switch on the front of the reservoir.

(11) Disconnect the left headlamp and dash wire

harness connector for the washer fluid level switch

from the switch connector receptacle.

(12) Pull the bottom of the washer reservoir rear-

ward far enough to disengage the outboard mounting

tab from the mounting slot on the left front inner

fender shield.(13) Rotate the washer reservoir far enough so

that the inboard mounting flange clears the front

suspension components, then lower the reservoir far

enough to disengage the filler neck from the hole in

the left front wheel house extension.

(14) Remove the washer reservoir from the left

front fender wheel house.

INSTALLATION

(1) Position the washer reservoir into the left front

fender wheel house.

(2) Raise the washer reservoir filler neck through

the hole in the left front fender wheelhouse extension

into the engine compartment and rotate the reservoir

as needed to orient the inboard mounting flange over

the top of the front suspension components.

(3) Pull the bottom of the washer reservoir rear-

ward far enough to engage the outboard mounting

tab with the mounting slot in the left front inner

fender shield (Fig. 24).

(4) Pull the bottom of the washer reservoir rear-

ward far enough to access the washer fluid level

switch connector receptacle on the front of the reser-

voir.

(5) Reconnect the left headlamp and dash wire

harness connector for the washer fluid level switch to

the switch connector receptacle.

Fig. 23 Washer Reservoir Filler Neck Mounting

1 - WASHER RESERVOIR

2 - SCREW

3 - WASHER HOSES FROM PUMPS

4 - WASHER HOSES TO NOZZLES

5 - LEFT FENDER INNER SHIELD

Fig. 24 Washer Reservoir

1 - LEFT FENDER INNER SHIELD

2 - SCREW (2)

3 - WASHER PUMP WIRE HARNESS CONNECTORS

4 - WASHER FLUID LEVEL SWITCH WIRE HARNESS

CONNECTOR

5 - WASHER RESERVOIR

8R - 28 FRONT WIPERS/WASHERSWJ

WASHER RESERVOIR (Continued)

Page 636 of 2199

(6) Install and tighten the two screws that secure

the inboard mounting flange of the washer reservoir

to the left inner wheel house. Tighten the screws to

7.4 N´m (66 in. lbs.).

(7) Reconnect the left headlamp and dash wire

harness connectors for the two washer pump/motor

units to the pump/motor unit connector receptacles.

(8) Reinstall the liner into the left front fender

wheel house.

(9) Lower the vehicle.

(10) Install and tighten the one screw that secures

the washer reservoir filler neck to the left inner

fender shield (Fig. 23). Tighten the screw to 7.4 N´m

(66 in. lbs.).

(11) Reinstall the washer reservoir filler cap hinge

onto the hook on the filler neck and close the cap.

(12) Reconnect the two washer reservoir washer

hoses to the two engine compartment washer hoses

at the inline connectors located on the top of the left

front fender wheel house.

(13) Reinstall the air cleaner housing onto the top

of the left front fender wheel house. (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - INSTALLATION).

(14) Reconnect the battery negative cable.

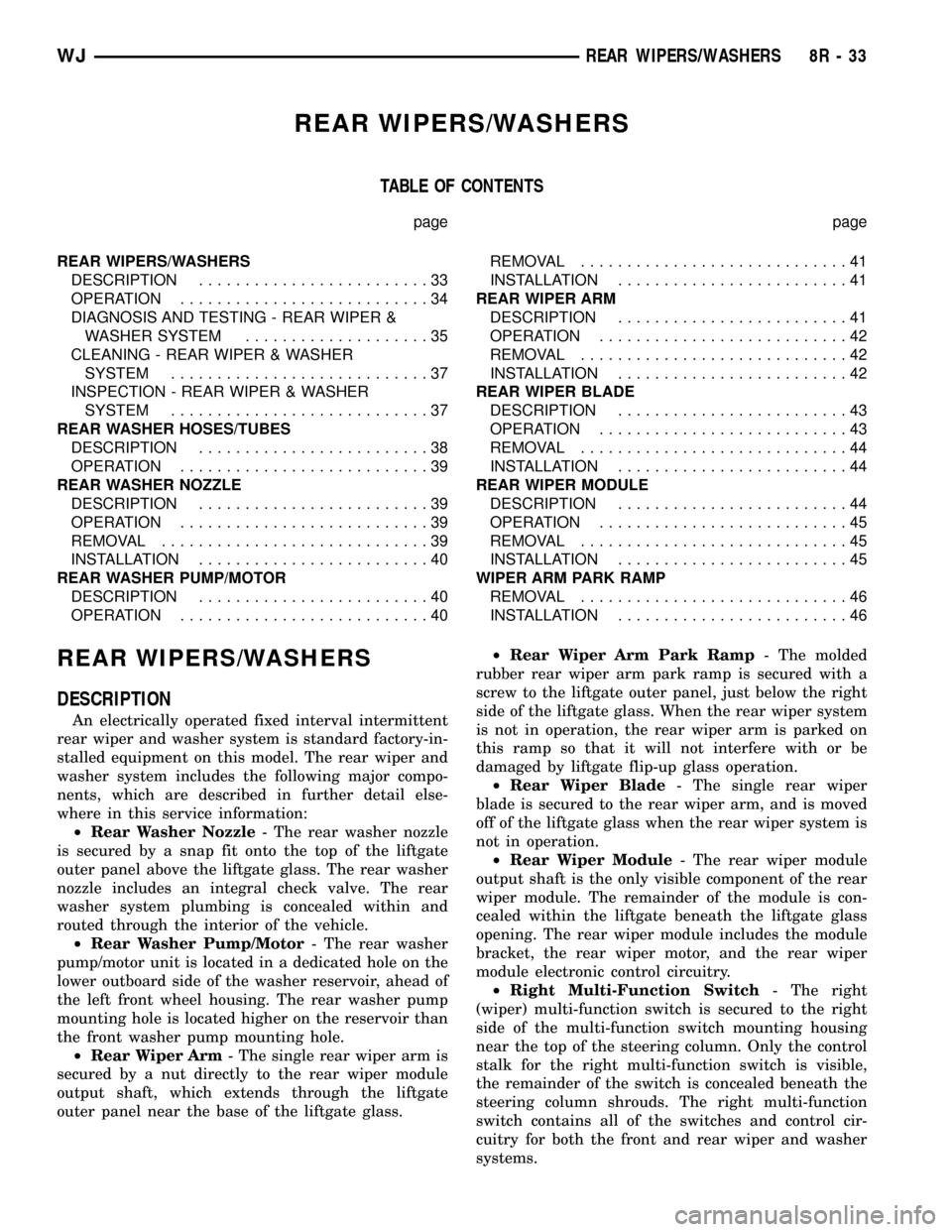

WIPER HIGH/LOW RELAY

DESCRIPTION

The wiper high/low relay is located in the Power

Distribution Center (PDC) in the engine compart-

ment near the battery. The wiper high/low relay is a

conventional International Standards Organization

(ISO) micro relay (Fig. 25). Relays conforming to the

ISO specifications have common physical dimensions,

current capacities, terminal patterns, and terminal

functions. The relay is contained within a small, rect-

angular, molded plastic housing and is connected to

all of the required inputs and outputs by five integral

male spade-type terminals that extend from the bot-

tom of the relay base.

The wiper high/low relay cannot be adjusted or

repaired and, if faulty or damaged, the unit must be

replaced.

OPERATION

The wiper high/low relay is an electromechanical

switch that uses a low current input from the Body

Control Module (BCM) to control a high current out-

put to the front wiper motor. The movable common

feed contact point is held against the fixed normally

closed contact point by spring pressure. When the

relay coil is energized, an electromagnetic field is

produced by the coil windings. This electromagnetic

field draws the movable relay contact point away

from the fixed normally closed contact point, and

holds it against the fixed normally open contact

point. When the relay coil is de-energized, spring

pressure returns the movable contact point back

against the fixed normally closed contact point. A

resistor is connected in parallel with the relay coil in

the relay, and helps to dissipate voltage spikes and

electromagnetic interference that can be generated as

the electromagnetic field of the relay coil collapses.

The wiper high/low relay terminals are connected

to the vehicle electrical system through a connector

receptacle in the Power Distribution Center (PDC).

The inputs and outputs of the wiper high/low relay

include:

²Common Feed Terminal- The common feed

terminal (30) is connected to the output of the wiper

on/off relay at all times through the wiper on/off

relay output circuit.

²Coil Ground Terminal- The coil ground termi-

nal (85) is connected to a control output of the Body

Control Module (BCM) through a front wiper high/

low relay control circuit. The BCM controls front

wiper motor operation by controlling a ground path

through this circuit.

²Coil Battery Terminal- The coil battery ter-

minal (86) receives battery current at all times from

a circuit breaker in the Junction Block (JB) through

a fused ignition switch output (run-acc) circuit.

Fig. 25 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

WJFRONT WIPERS/WASHERS 8R - 29

WASHER RESERVOIR (Continued)

Page 640 of 2199

REAR WIPERS/WASHERS

TABLE OF CONTENTS

page page

REAR WIPERS/WASHERS

DESCRIPTION.........................33

OPERATION...........................34

DIAGNOSIS AND TESTING - REAR WIPER &

WASHER SYSTEM....................35

CLEANING - REAR WIPER & WASHER

SYSTEM............................37

INSPECTION - REAR WIPER & WASHER

SYSTEM............................37

REAR WASHER HOSES/TUBES

DESCRIPTION.........................38

OPERATION...........................39

REAR WASHER NOZZLE

DESCRIPTION.........................39

OPERATION...........................39

REMOVAL.............................39

INSTALLATION.........................40

REAR WASHER PUMP/MOTOR

DESCRIPTION.........................40

OPERATION...........................40REMOVAL.............................41

INSTALLATION.........................41

REAR WIPER ARM

DESCRIPTION.........................41

OPERATION...........................42

REMOVAL.............................42

INSTALLATION.........................42

REAR WIPER BLADE

DESCRIPTION.........................43

OPERATION...........................43

REMOVAL.............................44

INSTALLATION.........................44

REAR WIPER MODULE

DESCRIPTION.........................44

OPERATION...........................45

REMOVAL.............................45

INSTALLATION.........................45

WIPER ARM PARK RAMP

REMOVAL.............................46

INSTALLATION.........................46

REAR WIPERS/WASHERS

DESCRIPTION

An electrically operated fixed interval intermittent

rear wiper and washer system is standard factory-in-

stalled equipment on this model. The rear wiper and

washer system includes the following major compo-

nents, which are described in further detail else-

where in this service information:

²Rear Washer Nozzle- The rear washer nozzle

is secured by a snap fit onto the top of the liftgate

outer panel above the liftgate glass. The rear washer

nozzle includes an integral check valve. The rear

washer system plumbing is concealed within and

routed through the interior of the vehicle.

²Rear Washer Pump/Motor- The rear washer

pump/motor unit is located in a dedicated hole on the

lower outboard side of the washer reservoir, ahead of

the left front wheel housing. The rear washer pump

mounting hole is located higher on the reservoir than

the front washer pump mounting hole.

²Rear Wiper Arm- The single rear wiper arm is

secured by a nut directly to the rear wiper module

output shaft, which extends through the liftgate

outer panel near the base of the liftgate glass.²Rear Wiper Arm Park Ramp- The molded

rubber rear wiper arm park ramp is secured with a

screw to the liftgate outer panel, just below the right

side of the liftgate glass. When the rear wiper system

is not in operation, the rear wiper arm is parked on

this ramp so that it will not interfere with or be

damaged by liftgate flip-up glass operation.

²Rear Wiper Blade- The single rear wiper

blade is secured to the rear wiper arm, and is moved

off of the liftgate glass when the rear wiper system is

not in operation.

²Rear Wiper Module- The rear wiper module

output shaft is the only visible component of the rear

wiper module. The remainder of the module is con-

cealed within the liftgate beneath the liftgate glass

opening. The rear wiper module includes the module

bracket, the rear wiper motor, and the rear wiper

module electronic control circuitry.

²Right Multi-Function Switch- The right

(wiper) multi-function switch is secured to the right

side of the multi-function switch mounting housing

near the top of the steering column. Only the control

stalk for the right multi-function switch is visible,

the remainder of the switch is concealed beneath the

steering column shrouds. The right multi-function

switch contains all of the switches and control cir-

cuitry for both the front and rear wiper and washer

systems.

WJREAR WIPERS/WASHERS 8R - 33

Page 641 of 2199

²Washer Reservoir- The rear washer system

shares a single reservoir with the front washer sys-

tem, but has its own dedicated washer pump/motor

and plumbing. The washer reservoir is concealed

between the left inner fender shield and the left

outer fender panel, behind the inner fender liner and

ahead of the left front wheel. The washer reservoir

filler neck is the only visible portion of the reservoir,

and it is accessed from the left front corner of the

engine compartment.

Features of the rear wiper and washer system

include the following:

²Continuous Wipe Mode- When the right

multi-function switch control sleeve is moved to the

On position, the rear wiper will be operated at a

fixed speed, continual wipe cycle until the switch

sleeve is moved to the Delay or Off positions, until

the ignition switch is turned to the Off position, or

until the liftgate flip-up glass is ajar.

²Intermittent Wipe Mode- When the right

multi-function switch control sleeve is moved to the

Delay position, the rear wiper will be operated in a

fixed interval, intermittent wipe cycle until the

switch sleeve is moved to the On or Off positions,

until the ignition switch is turned to the Off position,

until the liftgate flip-up glass is ajar, or until the

right multi-function switch control stalk is pushed

forward to activate the rear washer system. The

intermittent wipe mode delay time has a fixed delay

interval of about five to eight seconds between

sweeps.

²Washer Mode- When the right multi-function

switch control stalk is pushed forward to activate the

rear washer system, washer fluid will be dispensed

from the washer reservoir onto the liftgate glass

through the rear washer nozzle and the rear wiper

will operate in a fixed cycle (not intermittent) for as

long as the rear washer pump/motor unit remains

energized. When the control stalk is released from

the momentary Wash position, the wipe-after-wash

feature will continue to operate the rear wiper at a

fixed cycle for about three additional wiper sweeps

before returning to the previously selected mode.

Hard wired circuitry connects the rear wiper and

washer system components to the electrical system of

the vehicle. These hard wired circuits are integral to

several wire harnesses, which are routed throughout

the vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the rear wiper and

washer system components through the use of a com-

bination of soldered splices, splice block connectors,

and many different types of wire harness terminal

connectors and insulators. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repairprocedures, further details on wire harness routing

and retention, as well as pin-out and location views

for the various wire harness connectors, splices and

grounds.

OPERATION

The rear wiper and washer system is intended to

provide the vehicle operator with a convenient, safe,

and reliable means of maintaining visibility through

the liftgate glass. The various components of this sys-

tem are designed to convert electrical energy pro-

duced by the vehicle electrical system into the

mechanical action of the wiper blade to wipe the out-

side surface of the glass, as well as into the hydraulic

action of the washer system to apply washer fluid

stored in an on-board reservoir to the area of the

glass to be wiped. When combined, these components

provide the means to effectively maintain clear visi-

bility for the vehicle operator by removing excess

accumulations of rain, snow, bugs, mud, or other

minor debris from the outside liftgate glass surface

that might be encountered while driving the vehicle

under numerous types of inclement operating condi-

tions. The vehicle operator initiates all rear wiper

and washer system functions with the right multi-

function switch located on the right side of the steer-

ing column, just below the steering wheel. Moving

the switch control sleeve to a detent position selects

the rear wiper system operating mode. Moving the

switch control stalk forward to a momentary position

activates the rear washer pump/motor, which dis-

penses washer fluid onto the liftgate glass through

the rear washer nozzle and operates the rear wiper

system in the fixed cycle mode for as long as the

washer switch is closed plus about three wiper

sweeps.

When the ignition switch is in the Accessory or On

positions, battery current from a fuse in the Junction

Block (JB) is provided to the right multi-function

switch through a fused ignition switch output (run-

acc) circuit. A separate fuse in the JB provides bat-

tery current to the electronic control circuitry of the

rear wiper module through a fused B(+) circuit.

When the right multi-function switch control sleeve

On position is selected, the On position circuitry

within the switch directs a battery current rear

wiper motor control signal input to the rear wiper

module electronic circuitry, which causes the rear

wiper motor to run at a fixed continuous wipe cycle.

When the right multi-function switch control sleeve

Delay position is selected, the Delay position cir-

cuitry within the switch directs a battery current

rear washer switch output signal input to the rear

wiper module electronic circuitry, which causes the

rear wiper motor to run at a fixed intermittent wipe

cycle. When the right multi-function switch control

8R - 34 REAR WIPERS/WASHERSWJ

REAR WIPERS/WASHERS (Continued)

Page 644 of 2199

(2) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the left headlamp and dash wire harness

connector for the rear washer pump/motor unit from

the pump/motor unit connector receptacle. Check for

continuity between the ground circuit cavity of the

left headlamp and dash wire harness connector for

the rear washer pump/motor unit and a good ground.

There should be continuity. If OK, go to Step 3. If not

OK, repair the open ground circuit to ground (G106)

as required.

(3) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Push the right

multi-function switch control stalk toward the instru-

ment panel to actuate the rear washer switch. With

the rear washer switch actuated, check for battery

voltage at the rear washer switch output circuit cav-

ity of the left headlamp and dash wire harness con-

nector for the rear washer pump/motor unit. If OK,

replace the faulty rear washer pump/motor unit. If

not OK, repair the open rear washer switch output

circuit between the rear washer pump/motor unit

and the right multi-function switch as required.

CLEANING - REAR WIPER & WASHER SYSTEM

WIPER SYSTEM

The squeegee of a wiper blade exposed to the ele-

ments for a long time tends to lose its wiping effec-

tiveness. Periodic cleaning of the squeegee is

suggested to remove any deposits of salt or road film.

The wiper blade, arm, and liftgate glass should only

be cleaned using a sponge or soft cloth and wind-

shield washer fluid, a mild detergent, or a non-abra-

sive cleaner. If the wiper blade continues to leave

streaks, smears, hazing, or beading on the glass after

thorough cleaning of the squeegees and the glass, the

entire wiper blade assembly must be replaced.

CAUTION: Protect the rubber squeegee of the wiper

blade from any petroleum-based cleaners, solvents,

or contaminants. These products can rapidly deteri-

orate the rubber squeegee.

WASHER SYSTEM

If the washer system is contaminated with foreign

material, drain the washer reservoir by removing the

front washer pump/motor from the reservoir. Clean

foreign material from the inside of the washer reser-

voir using clean washer fluid, a mild detergent, or a

non-abrasive cleaner. Flush foreign material from the

washer system plumbing by first disconnecting the

washer hose from the washer nozzle, then running

the washer pump/motor to run clean washer fluid or

water through the system. A plugged or restricted

washer nozzle should be carefully back-flushed usingcompressed air. If the washer nozzle obstruction can-

not be cleared, replace the washer nozzle.

CAUTION: Never introduce petroleum-based clean-

ers, solvents, or contaminants into the washer sys-

tem. These products can rapidly deteriorate the

rubber seals and hoses of the washer system, as

well as the rubber squeegee of the wiper blade.

CAUTION: Never use compressed air to flush the

washer system plumbing. Compressed air pres-

sures are too great for the washer system plumbing

components and will result in further system dam-

age. Never use sharp instruments to clear a

plugged washer nozzle or damage to the nozzle ori-

fice and improper nozzle spray patterns will result.

INSPECTION - REAR WIPER & WASHER

SYSTEM

WIPER SYSTEM

The rear wiper blade and wiper arm should be

inspected periodically, not just when wiper perfor-

mance problems are experienced. This inspection

should include the following points:

(1) Inspect the wiper arm for any indications of

damage, or contamination. If the wiper arm is con-

taminated with any foreign material, clean as

required. (Refer to 8 - ELECTRICAL/REAR WIPERS/

WASHERS - CLEANING). If a wiper arm is damaged

or corrosion is evident, replace the wiper arm with a

new unit. Do not attempt to repair a wiper arm that

is damaged or corroded.

(2) Carefully lift the wiper arm off of the ramp.

Note the action of the wiper arm hinge. The wiper

arm should pivot freely at the hinge, but with no lat-

eral looseness evident. If there is any binding evident

in the wiper arm hinge, or there is evident lateral

play in the wiper arm hinge, replace the wiper arm.

CAUTION: Do not allow the wiper arm to spring

back against the glass without the wiper blade in

place or the glass may be damaged.

(3) Once proper hinge action of the wiper arm is

confirmed, check the hinge for proper spring tension.

The spring tension of the wiper arm should be suffi-

cient to cause the rubber squeegee to conform to the

curvature of the glass. Replace a wiper arm if it has

low or no spring tension.

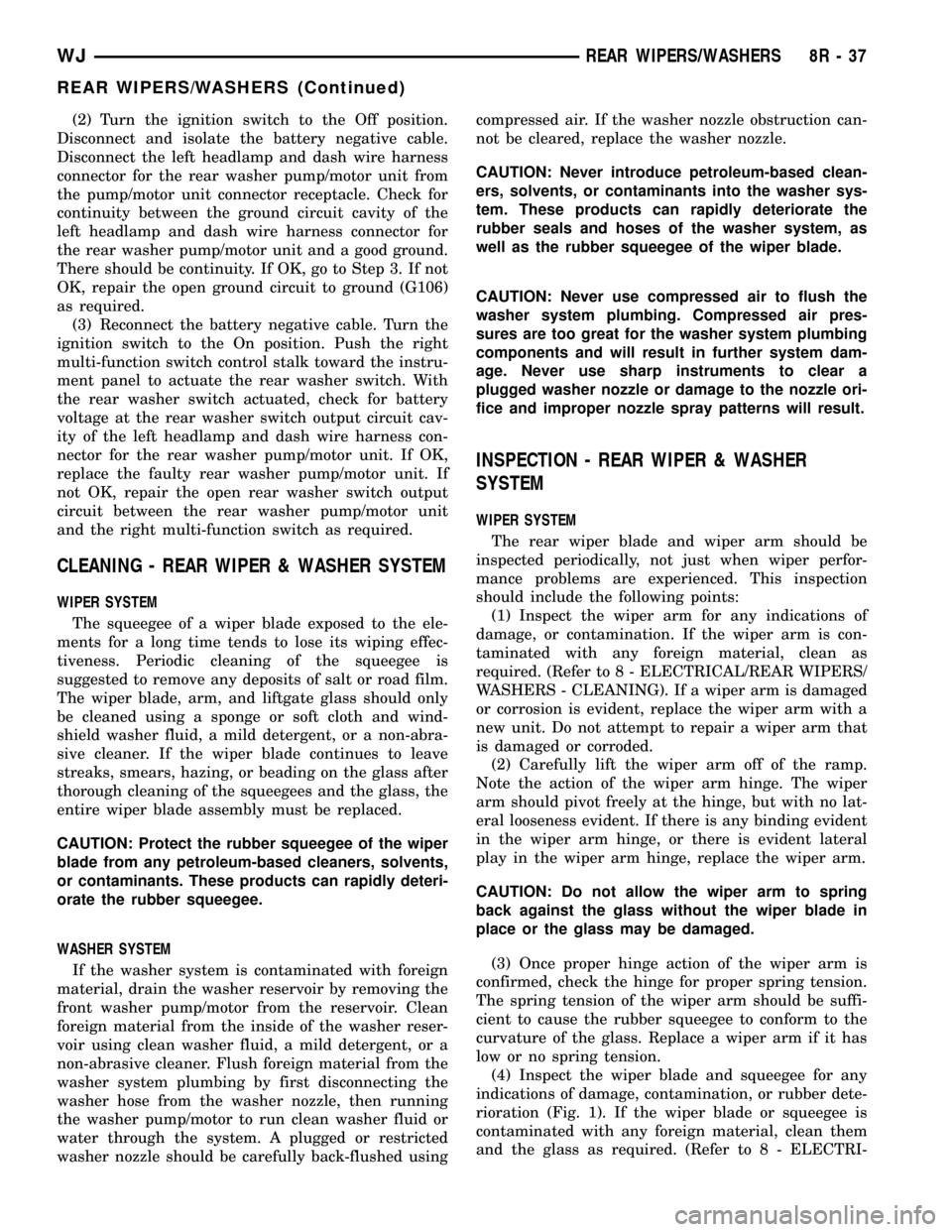

(4) Inspect the wiper blade and squeegee for any

indications of damage, contamination, or rubber dete-

rioration (Fig. 1). If the wiper blade or squeegee is

contaminated with any foreign material, clean them

and the glass as required. (Refer to 8 - ELECTRI-

WJREAR WIPERS/WASHERS 8R - 37

REAR WIPERS/WASHERS (Continued)

Page 645 of 2199

CAL/REAR WIPERS/WASHERS - CLEANING). If

after cleaning the wiper blade and the glass, the

wiper blade fails to clear the glass without smearing,

streaking, chattering, hazing, or beading, replace the

wiper blade. Also, if a wiper blade is damaged or if

the squeegee rubber is damaged or deteriorated,

replace the wiper blade with a new unit. Do not

attempt to repair a wiper blade that is damaged.

WASHER SYSTEM

The washer system components should be

inspected periodically, not just when washer perfor-

mance problems are experienced. This inspection

should include the following points:

(1) Check for ice or other foreign material in the

washer reservoir. If contaminated, clean and flush

the washer system. (Refer to 8 - ELECTRICAL/

REAR WIPERS/WASHERS - CLEANING).

(2) Inspect the washer plumbing for pinched, leak-

ing, deteriorated, or incorrectly routed hoses and

damaged or disconnected hose fittings. Replace dam-

aged or deteriorated hoses and hose fittings. Leaking

washer hoses can sometimes be repaired by cutting

the hose at the leak and splicing it back togetherusing an in-line connector fitting. Similarly, sections

of deteriorated hose can be cut out and replaced by

splicing in new sections of hose using in-line connec-

tor fittings. Whenever routing a washer hose or a

wire harness containing a washer hose, it must be

routed away from hot, sharp, or moving parts. Also,

sharp bends that might pinch the washer hose must

be avoided.

REAR WASHER HOSES/TUBES

DESCRIPTION

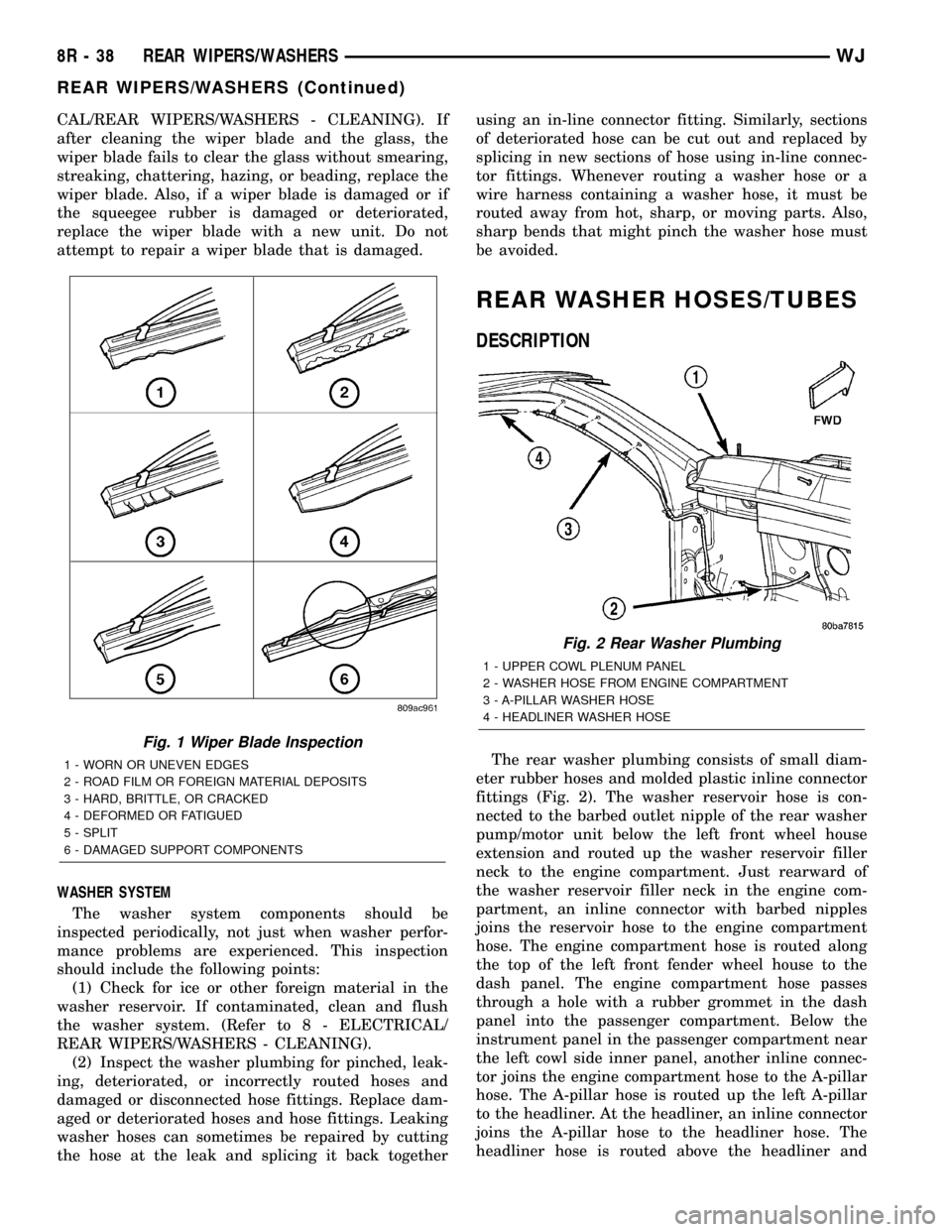

The rear washer plumbing consists of small diam-

eter rubber hoses and molded plastic inline connector

fittings (Fig. 2). The washer reservoir hose is con-

nected to the barbed outlet nipple of the rear washer

pump/motor unit below the left front wheel house

extension and routed up the washer reservoir filler

neck to the engine compartment. Just rearward of

the washer reservoir filler neck in the engine com-

partment, an inline connector with barbed nipples

joins the reservoir hose to the engine compartment

hose. The engine compartment hose is routed along

the top of the left front fender wheel house to the

dash panel. The engine compartment hose passes

through a hole with a rubber grommet in the dash

panel into the passenger compartment. Below the

instrument panel in the passenger compartment near

the left cowl side inner panel, another inline connec-

tor joins the engine compartment hose to the A-pillar

hose. The A-pillar hose is routed up the left A-pillar

to the headliner. At the headliner, an inline connector

joins the A-pillar hose to the headliner hose. The

headliner hose is routed above the headliner and

Fig. 1 Wiper Blade Inspection

1 - WORN OR UNEVEN EDGES

2 - ROAD FILM OR FOREIGN MATERIAL DEPOSITS

3 - HARD, BRITTLE, OR CRACKED

4 - DEFORMED OR FATIGUED

5 - SPLIT

6 - DAMAGED SUPPORT COMPONENTS

Fig. 2 Rear Washer Plumbing

1 - UPPER COWL PLENUM PANEL

2 - WASHER HOSE FROM ENGINE COMPARTMENT

3 - A-PILLAR WASHER HOSE

4 - HEADLINER WASHER HOSE

8R - 38 REAR WIPERS/WASHERSWJ

REAR WIPERS/WASHERS (Continued)