Control JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 479 of 2199

LAMPS/LIGHTING - INTERIOR

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

...................................28

COURTESY LAMP

REMOVAL

REMOVAL - BULB.....................29

REMOVAL - LAMP.....................29

INSTALLATION

INSTALLATION - BULB.................29

INSTALLATION - LAMP.................29

DOME LAMP

REMOVAL

REMOVAL - BULB.....................29

REMOVAL - LAMP.....................29

INSTALLATION

INSTALLATION - BULB.................29

INSTALLATION - LAMP.................29

DOOR AJAR SWITCH

DESCRIPTION

DESCRIPTION - DOOR AJAR SWITCH.....29

DESCRIPTION - FLIP UP GLASS AJAR

SWITCH............................29DESCRIPTION - LIFTGATE AJAR SWITCH . . 30

OPERATION

OPERATION - DOOR AJAR SWITCH.......30

OPERATION - FLIP UP GLASS AJAR

SWITCH............................30

OPERATION - LIFTGATE AJAR SWITCH....30

DIAGNOSIS AND TESTING - DOOR AJAR

SWITCH............................30

GLOVE BOX LAMP/SWITCH

REMOVAL.............................31

INSTALLATION.........................31

READING LAMP

DESCRIPTION.........................32

OPERATION...........................32

REMOVAL.............................32

INSTALLATION.........................32

TRANS RANGE INDICATOR ILLUMINATION

DESCRIPTION.........................32

VANITY LAMP

REMOVAL.............................32

INSTALLATION.........................32

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

CAUTION: Do not use bulbs other than the bulbs

listed in the Bulb Application Table. Damage to

lamp can result.

Service procedures for most of the lamps in the

instrument panel, are located in Electrical, Instru-

ment Panel. Some components have lamps that can

only be serviced by an Authorized Service Center

(ASC) after the component is removed from the vehi-

cle.

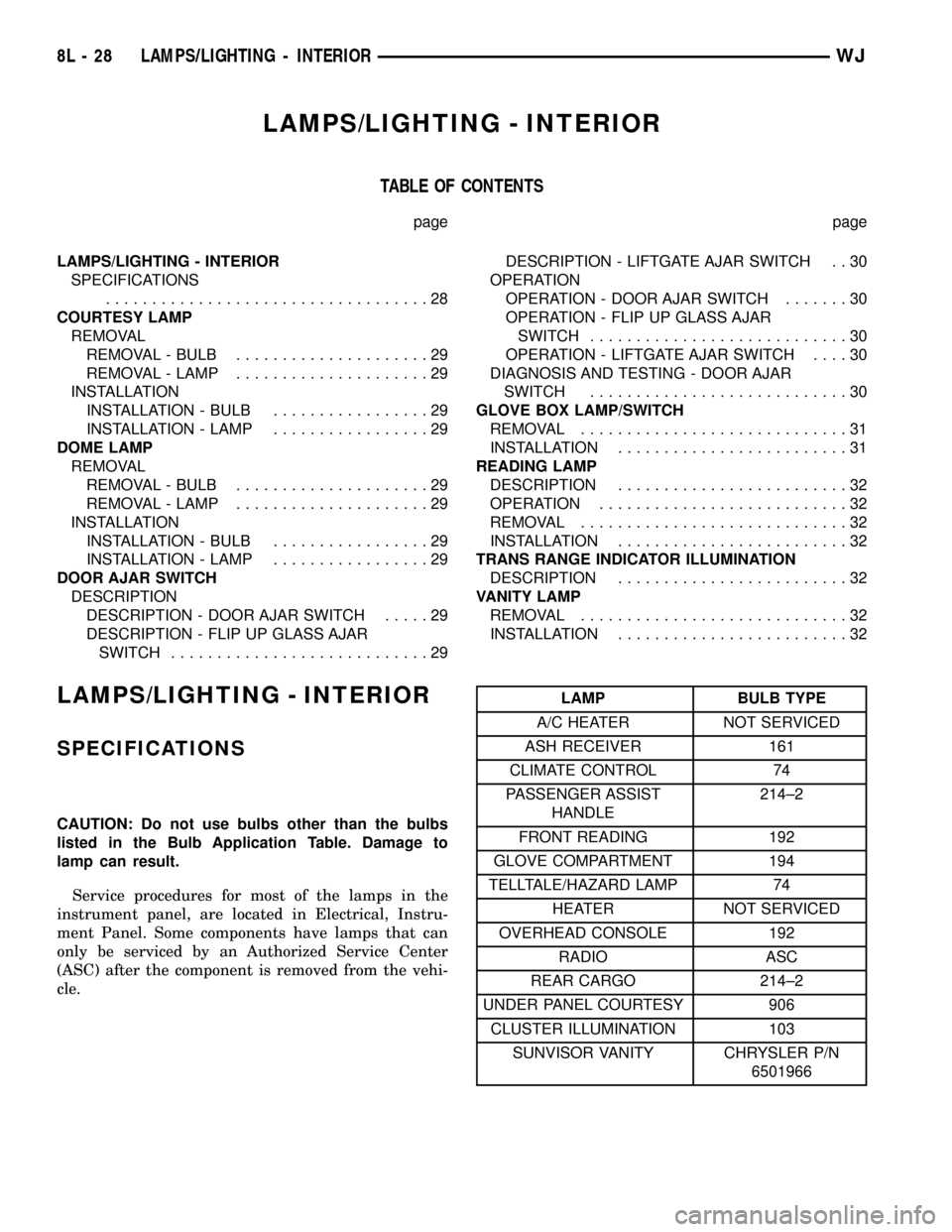

LAMP BULB TYPE

A/C HEATER NOT SERVICED

ASH RECEIVER 161

CLIMATE CONTROL 74

PASSENGER ASSIST

HANDLE214±2

FRONT READING 192

GLOVE COMPARTMENT 194

TELLTALE/HAZARD LAMP 74

HEATER NOT SERVICED

OVERHEAD CONSOLE 192

RADIO ASC

REAR CARGO 214±2

UNDER PANEL COURTESY 906

CLUSTER ILLUMINATION 103

SUNVISOR VANITY CHRYSLER P/N

6501966

8L - 28 LAMPS/LIGHTING - INTERIORWJ

Page 480 of 2199

COURTESY LAMP

REMOVAL

REMOVAL - BULB

(1) Remove the door trim panel. (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL)

for the service procedures.

(2) Remove the bulb socket from the lamp.

(3) Remove the bulb from the socket.

REMOVAL - LAMP

(1) Remove door trim panel. (Refer to 23 - BODY/

DOOR - FRONT/TRIM PANEL - REMOVAL) for the

procedures.

(2) Disengage the electrical connectors.

(3) Depress the locking tabs and remove the lamp

module.

(4) Remove the bulb socket.

INSTALLATION

INSTALLATION - BULB

(1) Install the bulb in the socket.

(2) Install the bulb socket in the lamp.

(3) Install the door trim panel.

INSTALLATION - LAMP

(1) Install the bulb socket into the lamp module.

(2) Align the lamp module with the door trim

panel.

(3) Snap the lamp module into place.

(4) Install the door panel.

DOME LAMP

REMOVAL

REMOVAL - BULB

(1) Rotate the the grab handle down.

(2) Remove the screws retaining the grab handle/

dome lens.

(3) Remove the grab handle/lens from the module.

(4) Remove the bulb from the lamp terminals.

REMOVAL - LAMP

It will be necessary to partially remove the head-

liner to remove the bulb socket.

(1) Remove the screws holding the grab handle/

lens assembly to the headliner and roof panel.(2) Lower the headliner as needed. (Refer to 23 -

BODY/INTERIOR/HEADLINER - REMOVAL) for the

service procedure.

(3) Separate the lamp socket from the headliner

and roof panel.

(4) Disconnect the wire connector.

INSTALLATION

INSTALLATION - BULB

(1) Insert the bulb into the lamp terminals.

(2) Position the grab handle/lens on the lamp mod-

ule.

(3) Install the screws retaining the grab handle/

lens to the lamp module.

INSTALLATION - LAMP

(1) Position the lamp socket on the headliner and

roof panel.

(2) Connect the wire harness.

(3) Install the headliner.

(4) Position the grab handle/lens on the lamp mod-

ule.

(5) Install the screws retaining the grab handle/

lens into the lamp socket.

DOOR AJAR SWITCH

DESCRIPTION

DESCRIPTION - DOOR AJAR SWITCH

The door ajar switches are integral to the door

latch mechnicism. The front door ajar switches are

actuated by the front door latch mechanisms, and are

hard wired between a body ground and the Driver

Door Module (DDM) or the Passenger Door Module

(PDM). The rear door ajar switches are actuated by

the rear door latch mechanisms, and are hard wired

between a body ground and the Body Control Module

(BCM) through the rear door and body wire har-

nesses.

The door ajar switches cannot be adjusted or

repaired and, if faulty or damaged, the door latch

unit must be replaced. (Refer to 23 - BODY/DOOR -

FRONT/LATCH - REMOVAL) or (Refer to 23 -

BODY/DOORS - REAR/LATCH - REMOVAL) for the

service procedures. For complete circuit diagrams,

refer to the appropriate wiring information.

DESCRIPTION - FLIP UP GLASS AJAR SWITCH

The liftgate flip-up glass ajar switch is integral to

the liftgate flip-up glass latch mechnicism. The lift-

gate flip-up glass ajar switch is actuated by the lift-

gate flip-up glass latch mechanism, and is hard

WJLAMPS/LIGHTING - INTERIOR 8L - 29

Page 481 of 2199

wired between a body ground, the Body Control Mod-

ule (BCM) and the rear wiper motor module through

the liftgate and body wire harnesses.

The liftgate flip-up glass ajar switch cannot be

adjusted or repaired and, if faulty or damaged, the

liftgate flip-up glass latch unit must be replaced.

(Refer to 23 - BODY/DECKLID/HATCH/LIFTGATE/

TAILGATE/FLIP-UP GLASS LATCH - REMOVAL)

for the service procedures. For complete circuit dia-

grams, refer to the appropriate wiring information.

DESCRIPTION - LIFTGATE AJAR SWITCH

The two liftgate ajar switches are integral to the

two liftgate latch mechanisms. The two liftgate ajar

switches are actuated by the liftgate latch mecha-

nisms, and are hard wired with each other between a

body ground and the Body Control Module (BCM)

through the liftgate and body wire harnesses.

The liftgate ajar switches cannot be adjusted or

repaired and, if faulty or damaged, the liftgate latch

unit must be replaced. (Refer to 23 - BODY/DECK-

LID/HATCH/LIFTGATE/TAILGATE/LATCH -

REMOVAL) for the service procedures. For complete

circuit diagrams, refer to the appropriate wiring

information.

OPERATION

OPERATION - DOOR AJAR SWITCH

The front door ajar switches close a path to ground

for the DDM or the PDM when a front door is

opened, and opens the ground path when a front door

is closed. The rear door ajar switches close a path to

ground for the BCM when a rear door is opened, and

opens the ground path when a rear door is closed.

The DDM, PDM, or BCM read the switch status then

send the proper switch status messages to other

modules over the Programmable Communications

Interface (PCI) data bus network. The door ajar

switch status message is used by the BCM as an

input for Vehicle Theft Security System (VTSS) oper-

ation.

OPERATION - FLIP UP GLASS AJAR SWITCH

The liftgate flip-up glass ajar switch can close a

path to ground for the BCM and the rear wiper

motor module when the liftgate flip-up glass is

opened, and opens the ground path when the liftgate

flip-up glass is closed. The rear wiper motor module

uses the liftgate flip-up glass ajar switch input to

control the rear wiper operation, and will park the

rear wiper blade if this input indicates that the lift-

gate flip-up glass is ajar. The BCM reads the switch

status then sends the proper switch status message

to other modules over the Programmable Communi-cations Interface (PCI) data bus network. The liftgate

flip-up glass ajar switch status message is used by

the BCM as an input for Vehicle Theft Security Sys-

tem (VTSS) operation.

OPERATION - LIFTGATE AJAR SWITCH

Each of the liftgate ajar switches can close a path

to ground for the BCM when the liftgate is opened,

and opens the ground path when the liftgate is

closed. The BCM reads the switch status then sends

the proper switch status message to other modules

over the Programmable Communications Interface

(PCI) data bus network. The liftgate ajar switch sta-

tus message is used by the BCM as an input for

Vehicle Theft Security System (VTSS) operation.

DIAGNOSIS AND TESTING - DOOR AJAR

SWITCH

The following diagnosis and testing is only

for the chime functions. For interior lamp diag-

nosis, refer to the appropriate wiring informa-

tion.The driver door ajar switch is hard wired to the

Driver Door Module (DDM). The DDM communicates

the switch status to the other modules in the vehicle

on the Programmable Communications Interface

(PCI) data bus network. The following test will diag-

nose a faulty driver door ajar switch and circuits. For

complete circuit diagrams, refer to the appropriate

wiring information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

(1) Check that the interior lighting switch on the

control stalk of the left multi-function switch is not

in the dome lamp disable position. Open the driver

side front door and note whether the interior lamps

light. They should light. If OK, refer to Key-In Igni-

tion Switch in the Diagnosis and Testing section of

this group for further diagnosis of the chime warning

system. If not OK, go to Step 2.

(2) Disconnect and isolate the battery negative

cable. Remove the trim panel from the driver front

door and disconnect the 4-way door wire harness con-

nector from the front door latch connector. Check for

continuity between the ground circuit of the 4-way

door wire harness connector and a good ground.

There should be continuity. If OK, go to Step 3. If not

OK, repair the ground circuit.

8L - 30 LAMPS/LIGHTING - INTERIORWJ

DOOR AJAR SWITCH (Continued)

Page 490 of 2199

for door and liftgate open indications and to show if a

turn signal has been left on. The EVIC messages and

displays are coordinated with warning indicators in

the instrument cluster to avoid duplication.

The EVIC module contains a central processing

unit and interfaces with other electronic modules in

the vehicle over the Programmable Communications

Interface (PCI) data bus network. The PCI data bus

network allows the sharing of sensor information.

This helps to reduce wire harness complexity, reduce

internal controller hardware, and reduce component

sensor current loads. At the same time, this system

provides increased reliability, enhanced diagnostics,

and allows the addition of many new feature capabil-

ities.

The EVIC module includes the following display

options:

²Compass and Temperature- provides the out-

side temperature and one of eight compass readings

to indicate the direction the vehicle is facing.

²Average fuel economy- shows the average

fuel economy since the last trip computer reset.

²Distance to empty- shows the estimated dis-

tance that can be travelled with the fuel remaining

in the fuel tank. This estimated distance is computed

using the average miles-per-gallon from the last 30

gallons of fuel used.

²Instant fuel economy- shows the present fuel

economy based upon the current vehicle distance and

fuel used information.

²Trip distance- shows the distance travelled

since the last trip computer reset.

²Elapsed time- shows the accumulated igni-

tion-on time since the last trip computer reset.

²Distance to service- shows the distance

remaining until the next scheduled service interval.

²Tire Pressure- shows the tire pressure in each

tire.

²Blank screen- the EVIC compass/temperature/

trip computer VFD is turned off.

The EVIC is capable of displaying the following

alert messages, which are accompanied by an audible

announcement consisting of a series of beeps:

²TURN SIGNALS ON (with vehicle graphic)-

Indicates that a turn signal has remained on for

about 1.6 kilometers (one mile).

²PERFORM SERVICE- Indicates that a cus-

tomer programmable service interval distance has

been reached.

²DOOR OPEN (one or more, with vehicle

graphic)- Indicates that a door is open or not fully

closed.

²LIFTGATE OPEN (with vehicle graphic)-

Indicates that the liftgate is open or not fully closed.

²LIFTGLASS OPEN (with vehicle graphic)-

Indicates that the liftglass is open or not fully closed.²COOLANT LEVEL LOW (with vehicle

graphic)- Indicates that the coolant level in the

engine coolant reservoir is low.

²XX LOW PRESSURE (with vehicle graphic)

- Indicates that the air pressure in the selected tire

is low.

²WASHER FLUID LOW (with vehicle

graphic)- Indicates that the fluid level in the

washer fluid reservoir is low.

The EVIC ªMenuº push button provides the vehicle

operator with a user interface, which allows the

selection of several optional customer programmable

electronic features to suit individual preferences.

Refer toELECTRONIC VEHICLE INFORMA-

TION CENTER PROGRAMMINGin the Service

Procedures section of this group for more information

on the customer programmable feature options.

If the vehicle is equipped with the optional mem-

ory system, the EVIC will display the following mem-

ory system messages:

²MEMORY #X POSITION SET (X = Driver 1

or Driver 2)- This message appears in the EVIC

display each time the memory system is successfully

programmed. It is accompanied by an audible

announcement chime tone.

²MEMORY SYSTEM DISABLED- The memory

system is automatically disabled while the driver

side seat belt is fastened and/or while the automatic

transmission gear selector is in any position except

Park or Neutral. This message appears in the EVIC

display as a reminder when a memory switch push

button is depressed while the memory system is dis-

abled. If the REMOTE LINKED TO MEMORY cus-

tomer programmable feature has been selected, this

message will also appear when the Unlock button of

the Remote Keyless Entry (RKE) transmitter is

depressed while the memory system is disabled.

If the vehicle is equipped with the optional Univer-

sal Transmitter transceiver, the EVIC will also dis-

play messages and an icon indicating when the

Universal Transmitter is being trained, which of the

three transmitter buttons is transmitting, and when

the transceiver is cleared.

If the vehicle is equipped with the optionalTire

Pressure Monitoring System, the EVIC will also

display messages and an icon indicating when the

tire air pressure falls below a given set-point, and

which of the five tires is transmitting the low pres-

sure warning, and when the condition is cleared.

Refer to the Tires/Wheels section of this manual for

complete Tire Pressure Monitoring System descrip-

tion. Refer to this section of the service manual for

EVIC modules function description for the Tire Pres-

sure Monitoring.

Data input for all EVIC functions, including VFD

dimming level, is received through PCI data bus

WJMESSAGE SYSTEMS 8M - 7

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 491 of 2199

messages. The EVIC module uses its internal pro-

gramming and all of its data inputs to calculate and

display the requested data. If the data displayed is

incorrect, perform the self-diagnostic tests as

described in this group. If these tests prove inconclu-

sive, the use of a DRBIIItscan tool and the proper

Diagnostic Procedures manual are recommended for

further testing of the EVIC module and the PCI data

bus.

The EVIC module cannot be repaired, and is avail-

able for service only as a unit. This unit includes the

push button switches and the plastic housed module.

If any of these components are faulty or damaged,

the complete EVIC module must be replaced. The

incandescent bulbs used for EVIC push button back-

lighting and the display lens are available for service

replacement.

ELECTRONIC VEHICLE INFORMATION CENTER

CHIME

The Electronic Vehicle Information Center (EVIC)

uses the chime warning system for two different

kinds of support. In addition to requesting chime

tones from the Body Control Module (BCM) as tactile

beep support, the EVIC is programmed to send chime

request messages over the Programmable Communi-

cations Interface (PCI) data bus when it detects the

following conditions:

²Door Open Warning- A door is open above a

critical speed [about 16 kilometers-per-hour (10

miles-per-hour) for the driver side front door, or

about 5 kilometers-per-hour (3 miles-per-hour) for

any other door].

²Liftgate Open Warning- The liftgate is open

above a critical speed [about 5 kilometers-per-hour (3

miles-per-hour)].

²Liftglass Open Warning- The liftgate flip-up

glass is open above a critical speed [about 5 kilome-

ters-per-hour (3 miles-per-hour)].

²Low Coolant Level Warning- The coolant

level in the engine coolant reservoir is low.

²Perform Service Alert- An audible alert that

a ªPerform Serviceº reminder message is being dis-

played by the EVIC.

²Turn Signal On Warning- A turn signal

remains on for about 1.6 kilometers (one mile).

²Washer Fluid Low Warning- The fluid level

in the washer reservoir is low.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the EVIC. (Refer to 8 - ELECTRICAL/OVERHEAD

CONSOLE/ELECTRONIC VEHICLE INFO CENTER

- DESCRIPTION) for more information on the EVIC.

COMPASS

While in the compass/temperature mode, the com-

pass will display the direction in which the vehicle is

pointed using the eight major compass headings

(Examples: north is N, northeast is NE). The self-cal-

ibrating compass unit requires no adjusting in nor-

mal use. The only calibration that may prove

necessary is to drive the vehicle in one circle at 5 to

8 kilometers-per-hour (3 to 5 miles-per-hour), on level

ground, in not less than 20 seconds. This will reori-

ent the compass unit to its vehicle.

The compass unit also will compensate for magne-

tism the body of the vehicle may acquire during nor-

mal use. However, avoid placing anything magnetic

directly on the roof of the vehicle. Magnetic mounts

for an antenna, a repair order hat, or a funeral pro-

cession flag can exceed the compensating ability of

the compass unit if placed on the roof panel. Mag-

netic bit drivers used on the fasteners that hold the

overhead console assembly to the roof header can

also affect compass operation. If the vehicle roof

should become magnetized, the demagnetizing and

calibration procedures found in this group may be

required to restore proper compass operation.

TEMPERATURE

The outside ambient temperature is displayed in

whole degrees. The temperature display can be tog-

gled from Fahrenheit to Celsius by selecting the

desired U.S./Metric option from the customer pro-

grammable features as described inELECTRONIC

VEHICLE INFORMATION CENTER PROGRAM-

MINGin the Standard Procedures section of this

group. The displayed temperature is not an instant

reading of conditions, but an average temperature. It

may take the temperature display several minutes to

respond to a major temperature change, such as driv-

ing out of a heated garage into winter temperatures.

When the ignition switch is turned to the Off posi-

tion, the last displayed temperature reading stays in

the Body Control Module (BCM) unit memory. When

the ignition switch is turned to the On position

again, the EVIC will display the memory tempera-

ture for one minute; then update the display to the

current average temperature reading within five

minutes.

The temperature function is supported by an ambi-

ent temperature sensor. The sensor is mounted out-

side the passenger compartment near the front and

center of the vehicle, and is hard wired to the Body

Control Module (BCM). The BCM sends temperature

status messages to the EVIC module over the PCI

data bus network. The ambient temperature sensor

is available as a separate service item.

8M - 8 MESSAGE SYSTEMSWJ

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 492 of 2199

OPERATION

The EVIC has access to both non-switched and

ignition switched sources of battery current so that

some of its features remain operational at any time,

while others may only operate with the ignition

switch in the On position. When the ignition switch

is turned to the On position, the EVIC module VFD

will return to the last function being displayed before

the ignition was turned to the Off position.

The compass/temperature display is the normal

EVIC display. With the ignition switch in the On

position, momentarily depressing and releasing the

C/T (compass/temperature) push button switch will

cause the EVIC to return to the compass/tempera-

ture/trip computer display mode from any other

mode. While in the compass/temperature/trip com-

puter display mode, momentarily depressing and

releasing the Step push button will step through the

available trip computer display options.

The EVIC trip computer features several functions

that can be reset. The functions that can be reset

are: average fuel economy, trip odometer and elapsed

time. With the ignition switch in the On position and

with one of the functions of the trip computer that

can be reset currently displayed, depressing the

Reset push button twice within three seconds will

perform a global reset, and all of the trip computer

information that can be reset will be reset to zero.

With the ignition switch in the On position and the

function that is to be reset currently displayed,

momentarily depressing and releasing the Reset

push button once will perform a local reset, and only

the value of the displayed function will be reset to

zero. A global or local reset will only occur if the

function currently displayed is a function that can be

reset. The distance to service function can also be

reset using the local reset method, but it will reset

back to the Service Interval distance that is set in

the EVIC programmable features mode. Refer to

ELECTRONIC VEHICLE INFORMATION CEN-

TER PROGRAMMINGin the Service Procedures

section of this group for more information on setting

the Service Interval.

For more information on the features, control func-

tions and setting procedures for the EVIC module,

see the owner's manual in the vehicle glove box.

DIAGNOSIS AND TESTING - ELECTRONIC

VEHICLE INFORMATION CENTER

If the problem with the Electronic Vehicle Informa-

tion Center (EVIC) is a temperature reading of 130É

F or -40ÉF shown in the compass/temperature dis-

play, refer toAmbient Temperature Sensor Diag-

nosis and Testingin this group. If the problem with

the EVIC is an inaccurate or scrambled display, refer

toSelf-Diagnostic Testin this group. If the prob-lem with the EVIC is incorrect Vacuum Fluorescent

Display (VFD) dimming levels, use a DRBtscan tool

and the proper Diagnostic Procedures manual to test

for the correct dimming message inputs being

received from the Body Control Module (BCM) over

the Programmable Communications Interface (PCI)

data bus. If the problem is a no-display condition,

use the following procedures. For complete circuit

diagrams, refer toOverhead Consolein Wiring

Diagrams.

(1) Check the fused B(+) fuse in the junction block.

If OK, go to Step 2. If not OK, repair the shorted cir-

cuit or component as required and replace the faulty

fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the junction block. If OK, go to Step 3. If not OK,

repair the open fused B(+) circuit to the fused B(+)

fuse in the PDC as required.

(3) Check the fused ignition switch output (run/

start) fuse in the junction block. If OK, go to Step 4.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) fuse in the junction block. If OK,

go to Step 5. If not OK, repair the open fused ignition

switch output (run/start) circuit to the ignition switch

as required.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the overhead console. Check for continuity

between the ground circuit cavity of the roof wire

harness connector for the EVIC module and a good

ground. There should be continuity. If OK, go to Step

6. If not OK, repair the open ground circuit to ground

as required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

roof wire harness connector for the EVIC module. If

OK, go to Step 7. If not OK, repair the open fused

B(+) circuit to the fused B(+) fuse in the junction

block as required.

(7) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) circuit cavity of the roof wire har-

ness connector for the EVIC module. If OK, refer to

Self-Diagnostic Testbelow for further diagnosis of

the EVIC module and the PCI data bus. If not OK,

repair the open fused ignition switch output (run/

start) circuit to the fuse in the junction block as

required.

SELF-DIAGNOSTIC TEST

A self-diagnostic test is used to determine that the

EVIC module is operating properly, and that all PCI

WJMESSAGE SYSTEMS 8M - 9

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 494 of 2199

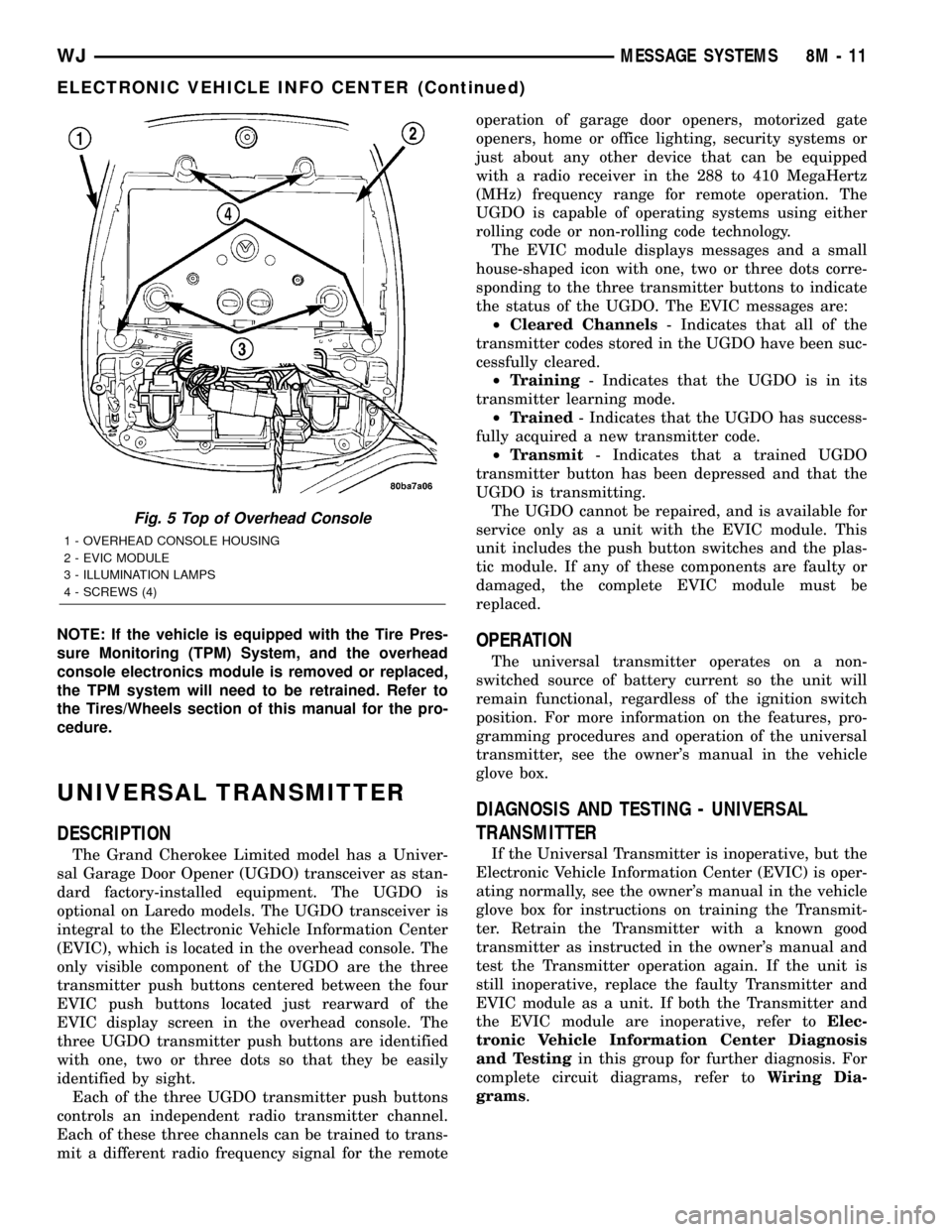

NOTE: If the vehicle is equipped with the Tire Pres-

sure Monitoring (TPM) System, and the overhead

console electronics module is removed or replaced,

the TPM system will need to be retrained. Refer to

the Tires/Wheels section of this manual for the pro-

cedure.

UNIVERSAL TRANSMITTER

DESCRIPTION

The Grand Cherokee Limited model has a Univer-

sal Garage Door Opener (UGDO) transceiver as stan-

dard factory-installed equipment. The UGDO is

optional on Laredo models. The UGDO transceiver is

integral to the Electronic Vehicle Information Center

(EVIC), which is located in the overhead console. The

only visible component of the UGDO are the three

transmitter push buttons centered between the four

EVIC push buttons located just rearward of the

EVIC display screen in the overhead console. The

three UGDO transmitter push buttons are identified

with one, two or three dots so that they be easily

identified by sight.

Each of the three UGDO transmitter push buttons

controls an independent radio transmitter channel.

Each of these three channels can be trained to trans-

mit a different radio frequency signal for the remoteoperation of garage door openers, motorized gate

openers, home or office lighting, security systems or

just about any other device that can be equipped

with a radio receiver in the 288 to 410 MegaHertz

(MHz) frequency range for remote operation. The

UGDO is capable of operating systems using either

rolling code or non-rolling code technology.

The EVIC module displays messages and a small

house-shaped icon with one, two or three dots corre-

sponding to the three transmitter buttons to indicate

the status of the UGDO. The EVIC messages are:

²Cleared Channels- Indicates that all of the

transmitter codes stored in the UGDO have been suc-

cessfully cleared.

²Training- Indicates that the UGDO is in its

transmitter learning mode.

²Trained- Indicates that the UGDO has success-

fully acquired a new transmitter code.

²Transmit- Indicates that a trained UGDO

transmitter button has been depressed and that the

UGDO is transmitting.

The UGDO cannot be repaired, and is available for

service only as a unit with the EVIC module. This

unit includes the push button switches and the plas-

tic module. If any of these components are faulty or

damaged, the complete EVIC module must be

replaced.

OPERATION

The universal transmitter operates on a non-

switched source of battery current so the unit will

remain functional, regardless of the ignition switch

position. For more information on the features, pro-

gramming procedures and operation of the universal

transmitter, see the owner's manual in the vehicle

glove box.

DIAGNOSIS AND TESTING - UNIVERSAL

TRANSMITTER

If the Universal Transmitter is inoperative, but the

Electronic Vehicle Information Center (EVIC) is oper-

ating normally, see the owner's manual in the vehicle

glove box for instructions on training the Transmit-

ter. Retrain the Transmitter with a known good

transmitter as instructed in the owner's manual and

test the Transmitter operation again. If the unit is

still inoperative, replace the faulty Transmitter and

EVIC module as a unit. If both the Transmitter and

the EVIC module are inoperative, refer toElec-

tronic Vehicle Information Center Diagnosis

and Testingin this group for further diagnosis. For

complete circuit diagrams, refer toWiring Dia-

grams.

Fig. 5 Top of Overhead Console

1 - OVERHEAD CONSOLE HOUSING

2 - EVIC MODULE

3 - ILLUMINATION LAMPS

4 - SCREWS (4)

WJMESSAGE SYSTEMS 8M - 11

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 495 of 2199

AMBIENT TEMP SENSOR

DESCRIPTION

Ambient air temperature is monitored by the Elec-

tronic Vehicle Information Center (EVIC) through

ambient temperature messages received from the

Body Control Module (BCM) over the Programmable

Communications Interface (PCI) data bus network.

The BCM receives a hard wired input from the ambi-

ent temperature sensor. The ambient temperature

sensor is a variable resistor mounted to a bracket

that is secured with a screw to the right side of the

headlamp mounting module grille opening, behind

the radiator grille and in front of the engine compart-

ment.

Refer toBody Control Modulein Electronic Con-

trol Modules. For complete circuit diagrams, refer to

the appropriate wiring information. The ambient

temperature sensor cannot be adjusted or repaired

and, if faulty or damaged, it must be replaced.

OPERATION

The ambient temperature sensor is a variable

resistor that operates on a five-volt reference signal

sent to it by the BCM. The resistance in the sensor

changes as temperature changes, changing the tem-

perature sensor signal circuit voltage to the BCM.

Based upon the resistance in the sensor, the BCM

senses a specific voltage on the temperature sensor

signal circuit, which it is programmed to correspond

to a specific temperature. The BCM then sends the

proper ambient temperature messages to the EVIC

over the PCI data bus.

The temperature function is supported by the

ambient temperature sensor, a wiring circuit, the

Body Control Module (BCM), the Programmable

Communications Interface (PCI) data bus, and a por-

tion of the Electronic Vehicle Information Center

(EVIC) module. If any portion of the ambient temper-

ature sensor circuit fails, the BCM will self-diagnose

the circuit. A temperature reading of 130É F will

appear in the EVIC display in place of the tempera-

ture when the sensor circuit is shorted. A tempera-

ture reading of ±40É F will appear in the EVIC

display in place of the temperature when the sensor

circuit is open.

The ambient temperature sensor circuit can also be

diagnosed by referring toDiagnosis and Testing -

Ambient Temperature Sensor, and Diagnosis

and Testing - Ambient Temperature Sensor Cir-

cuit. If the temperature sensor and circuit are con-

firmed to be OK, but the temperature display is

inoperative or incorrect, refer toDiagnosis and

Testing - Electronic Vehicle Information Center

in this group. For complete circuit diagrams, refer to

the appropriate wiring information.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector.

(2) Measure the resistance of the ambient temper-

ature sensor. At ±40É C (±40É F), the sensor resis-

tance is 336.6 kilohms. At 60É C (140É F), the sensor

resistance is 2.49 kilohms. The sensor resistance

should read between these two values. If OK, refer to

Diagnosis and Testing - Ambient Temperature

Sensor Circuitin this group. If not OK, replace the

faulty ambient temperature sensor.

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR CIRCUIT

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the 2-way ambient temperature sensor

wire harness connector and the 22-way Body Control

Module (BCM) wire harness connector.

(2) Connect a jumper wire between the two termi-

nals in the body half of the 2-way ambient tempera-

ture sensor wire harness connector.

(3) Check for continuity between the sensor return

circuit and the ambient temperature sensor signal

circuit cavities of the 22-way BCM wire harness con-

nector. There should be continuity. If OK, go to Step

4. If not OK, repair the open sensor return circuit or

ambient temperature sensor signal circuit to the

ambient temperature sensor as required.

(4) Remove the jumper wire from the body half of

the 2-way ambient temperature sensor wire harness

connector. Check for continuity between the sensor

return circuit cavity of the 22-way BCM wire harness

connector and a good ground. There should be no

continuity. If OK, go to Step 5. If not OK, repair the

shorted sensor return circuit as required.

(5) Check for continuity between the ambient tem-

perature sensor signal circuit cavity of the 22-way

BCM wire harness connector and a good ground.

There should be no continuity. If OK, refer toDiag-

nosis and Testing - Electronic Vehicle Informa-

tion Centerin this group. If not OK, repair the

shorted ambient temperature sensor signal circuit as

required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

8M - 12 MESSAGE SYSTEMSWJ

Page 499 of 2199

This vehicle also offers several customer program-

mable features, which allows the selection of several

optional electronic features to suit individual prefer-

ences. (Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE/ELECTRONIC VEHICLE INFO CENTER -

DESCRIPTION). Customer programmable feature

options affecting the power door lock system include:

²Auto Door Locks- Automatically locks all of

the vehicle doors and the liftgate when the vehicle

reaches a speed of about 24 kilometers-per-hour (15

miles-per-hour) with 10% throttle tip-in.

²Auto Unlock on Exit- Automatically unlocks

all of the vehicle doors and the liftgate when the

driver side front door is opened, if the vehicle is

stopped and the transmission gear selector is in the

Park or Neutral positions. This feature is linked to

the Auto Door Locks feature, and will only occur one

time following each Auto Door Lock event.

The power lock system for this vehicle can also be

operated remotely using the standard equipment

Remote Keyless Entry (RKE) system radio frequency

transmitters. (Refer to 8 - ELECTRICAL/POWER

LOCKS - DESCRIPTION - REMOTE KEYLESS

ENTRY SYSTEM).

The components of the power lock system include:

²Driver Door Module (DDM)

²Passenger Door Module (PDM)

²PCI Bus Messages

²Power Lock Motors

Certain functions and features of the power lock

system rely upon resources shared with other elec-

tronic modules in the vehicle over the Programmable

Communications Interface (PCI) data bus network.

The PCI data bus network allows the sharing of sen-

sor information. This helps to reduce wire harness

complexity, internal controller hardware, and compo-

nent sensor current loads. At the same time, this sys-

tem provides increased reliability, enhanced

diagnostics, and allows the addition of many new fea-

ture capabilities. For proper diagnosis of these elec-

tronic modules or of the PCI data bus network, the

use of a DRBIIItscan tool and the appropriate diag-

nostic information are required.

The other electronic modules that may affect power

lock system operation are as follows:

²Body Control Module (BCM)- (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/BODY CONTROL/CENTRAL TIMER MOD-

ULE - DESCRIPTION).

²Electronic Vehicle Information Center

(EVIC)- (Refer to 8 - ELECTRICAL/OVERHEAD

CONSOLE/ELECTRONIC VEHICLE INFO CENTER

- DESCRIPTION).

²Powertrain Control Module (PCM)- (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROLMODULES/POWERTRAIN CONTROL MODULE -

DESCRIPTION).

Hard wired circuitry connects the power lock sys-

tem components to the electrical system of the vehi-

cle. These hard wired circuits are integral to several

wire harnesses, which are routed throughout the

vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the power lock sys-

tem components through the use of a combination of

soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

DESCRIPTION - REMOTE KEYLESS ENTRY

SYSTEM

A Radio Frequency (RF) type Remote Keyless

Entry (RKE) system is standard factory-installed

equipment on this model. The RKE system allows

the use of a remote battery-powered radio transmit-

ter to control the power lock system. The RKE

receiver operates on non-switched battery current

through a fuse in the Power Distribution Center

(PDC), so that the system remains operational,

regardless of the ignition switch position.

In addition to Lock and Unlock buttons, the RKE

transmitters are also equipped with a Panic button.

If the Panic button on the RKE transmitter is

depressed, the horn will sound and the exterior lights

will flash on the vehicle for about three minutes, or

until the Panic button is depressed a second time, if

ignition is in the Off position. A vehicle speed of

about 24 kilometers-per-hour (15 miles-per-hour) will

also cancel the panic event.

The RKE system can also perform other functions

on this vehicle. If the vehicle is equipped with the

optional Vehicle Theft Security System (VTSS), the

RKE transmitter will arm the VTSS when the Lock

button is depressed, and disarm the VTSS when the

Unlock button is depressed. (Refer to 8 - ELECTRI-

CAL/VEHICLE THEFT SECURITY - DESCRIPTION

- VEHICLE THEFT SECURITY SYSTEM). If the

vehicle is equipped with the optional Memory Sys-

tem, each of the two numbered and color-coded RKE

transmitters can be used to recall the stored driver

side front seat position, both outside power rear view

mirror positions, and the radio station presets for the

two assigned drivers. (Refer to 8 - ELECTRICAL/

POWER SEATS - DESCRIPTION - MEMORY SYS-

TEM).

8N - 2 POWER LOCKSWJ

POWER LOCKS (Continued)

Page 500 of 2199

The RKE system includes two transmitters when

the vehicle is shipped from the factory, but the sys-

tem can retain the vehicle access codes of up to four

transmitters. The transmitter codes are retained in

the RKE receiver memory, even if the battery is dis-

connected. If an RKE transmitter is faulty or lost,

new transmitter vehicle access codes can be pro-

grammed into the system using a DRBIIItscan tool

and the appropriate diagnostic information.

This vehicle also offers several customer program-

mable features, which allows the selection of several

optional electronic features to suit individual prefer-

ences. (Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE/ELECTRONIC VEHICLE INFO CENTER -

DESCRIPTION). Customer programmable feature

options affecting the RKE system include:

²Remote Unlock- Allows the option of having

only the driver side front door unlock when the RKE

transmitter Unlock button is depressed the first time

and the remaining doors and the liftgate unlock

when the button is depressed a second time, or hav-

ing all doors and the liftgate unlock upon the first

depression of the RKE transmitter Unlock button.

²Remote Linked to Memory- If the vehicle is

equipped with the Memory System, this feature

allows the option of having the RKE transmitter

Unlock button activate the recall of the stored set-

tings, or having the recall function assigned solely to

the memory switch on the driver side front door trim

panel.

²Sound Horn on Lock- Allows the option of

having the horn sound a short chirp as an audible

verification that the doors have locked, or having no

audible verification.

²Flash Lights with Lock- Allows the option of

having the lights flash as an optical verification that

the doors have locked, or having no optical verifica-

tion.

This group covers the following components of the

RKE system:

²RKE Receiver

²RKE Transmitter

Certain functions and features of the RKE system

rely upon resources shared with other electronic

modules in the vehicle over the Programmable Com-

munications Interface (PCI) data bus network. The

PCI data bus network allows the sharing of sensor

information. This helps to reduce wire harness com-

plexity, internal controller hardware, and component

sensor current loads. At the same time, this system

provides increased reliability, enhanced diagnostics,

and allows the addition of many new feature capabil-

ities. For diagnosis of these electronic modules or of

the PCI data bus network, the use of a DRBIIItscan

tool and the appropriate diagnostic information are

required.The other electronic modules that may affect RKE

system operation are as follows:

²Body Control Module (BCM)- (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/BODY CONTROL/CENTRAL TIMER MOD-

ULE - DESCRIPTION).

²Driver Door Module (DDM)- (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/DOOR MODULE - DESCRIPTION).

²Electronic Vehicle Information Center

(EVIC)- (Refer to 8 - ELECTRICAL/OVERHEAD

CONSOLE/ELECTRONIC VEHICLE INFO CENTER

- DESCRIPTION).

²Passenger Door Module (PDM)- (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/DOOR MODULE - DESCRIPTION).

²Powertrain Control Module (PCM)- (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/POWERTRAIN CONTROL MODULE -

DESCRIPTION).

Hard wired circuitry connects the RKE system

components via the PDM to the electrical system of

the vehicle. These hard wired circuits are integral to

several wire harnesses, which are routed throughout

the vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the RKE system com-

ponents through the use of a combination of soldered

splices, splice block connectors, and many different

types of wire harness terminal connectors and insu-

lators. Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.

COMBINATION FLASHER

The combination flasher is a smart relay that func-

tions as both the turn signal system and the hazard

warning system flasher. The combination flasher con-

tains active electronic Integrated Circuitry (IC) ele-

ments. This flasher can be energized by the BCM to

flash all of the park/turn signal/front side marker

lamps as an optical alert for the RKE panic function

and, if the Flash Lights with Lock programmable fea-

ture is enabled, as an optical verification for the RKE

lock event. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/COMBINATION FLASHER

- DESCRIPTION).

HORN RELAY

The horn relay is a electromechanical device that

switches battery current to the horn when the horn

switch grounds the relay coil. The horn relay is

located in the Power Distribution Center (PDC) in

WJPOWER LOCKS 8N - 3

POWER LOCKS (Continued)