Connecting rod JEEP GRAND CHEROKEE 2002 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1260 of 2199

DESCRIPTION SPECIFICATION

Ring Side Clearance

Compression Rings 0.042 to 0.084 mm

(0.0017 to 0.0033 in.)

Oil Control Rings 0.06 to 0.21 mm

(0.0024 to 0.0083 in.)

Piston Ring Groove

Height

Compression Rings 1.530 to 1.555 mm

(0.0602 to 0.0612 in.)

Oil Control Ring 4.035 to 4.060 mm

(0.1589 to 0.1598 in.)

Piston Ring Groove

Diameter

No.1 Compression Ring 88.39 to 88.65 mm

(3.48 to 3.49 in.)

No.2 Compression Ring 87.63 to 87.88 mm

(3.45 to 3.46 in.)

Oil Control Ring 89.66 to 89.92 mm

(3.53 to 3.54 in.)

Piston Pin Bore Diameter 23.650 to 23.658 mm

(0.9312 to 0.9315 in.)

Piston Pin Diameter 23.637 to 23.640 mm

(0.9306 to 0.9307 in.)

Piston-to-Pin Clearance 0.0102 to 0.0208 mm

(0.0005 to 0.0009 in.)

Piston-to-Pin Connecting

Rod (Press Fit) 8.9 kN (2000 lbf.)

OIL PUMP

Gear-to-Body Clearance 0.051 to 0.102 mm

(Radial) (0.002 to 0.004 in.)

Gear-to-Body Clearance

(Radial) Preferred 0.051 mm (0.002 in.)

Gear End Clearance 0.051 to 0.152 mm

Plastigage (0.002 to 0.006 in.)

Gear End Clearance

Plastigage (Preferred) 0.051 mm (0.002 in.)

Gear End Clearance 0.1016 to 0.2032 mm

Feeler Gauge (0.004 to 0.008 in.)DESCRIPTION SPECIFICATION

Gear End Clearance

Feeler Gauge (Preferred) 0.1778 mm (0.007 in.)

Oil Pressure

At Idle Speed 89.6 kPa (13 psi)

At 1600 rpm & Higher 255 to 517 kPa

(37 to 75 psi)

Oil Pressure Relief 517 kPa (75 psi)

TORQUE - 4.0L ENGINE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

A/C CompressorÐBolts 28 Ð 250

Block HeaterÐNut 2 Ð 16

Camshaft SprocketÐBolt 68 50 Ð

Camshaft Thrust Plate to

Cylinder BlockÐScrews 24 18 Ð

Clutch Cover to FlywheelÐBolts 54 40 Ð

Coil Bracket to BlockÐBolts 22 Ð 192

Connecting RodÐNuts 45 33 Ð

Cylinder BlockÐDrain Plugs 34 25 Ð

Cylinder HeadÐBolts 135 100 Ð

Cylinder Head CoverÐBolts 10 Ð 85

Distributor ClampÐBolts 23 Ð 204

Engine MountsÐFront

Support Bracket Bolts 61 45 Ð

Support Cushion Bolts/Nuts 41 30 Ð

Support Cushion Bracket Bolts 54 40 Ð

Support Cushion Bracket Stud

Nuts41 30 Ð

Support Cushion Thru-Bolt 65 48 Ð

Engine MountsÐRear

Crossmember to Sill BoltsÐ

(Automatic) 41 30 Ð

Insulator Stud AssemblyÐNut 41 30 Ð

Support Cushion/

CrossmemberÐ

Nuts 22 Ð 192

Support Cushion/BracketÐNuts

(Manual) 75 55 Ð

WJENGINE - 4.0L 9 - 17

ENGINE - 4.0L (Continued)

Page 1276 of 2199

(16) Install the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

NOTE: During installation, lubricate the hydraulic

valve tappets and all valve components with

MoparTEngine Oil Supplement, or equivalent. TheMoparTEngine Oil Supplement, or equivalent must

remain with the engine oil for at least 1609 km

(1,000 miles). The oil supplement need not be

drained until the next scheduled oil change.

(17) Install the radiator (Refer to 7 - COOLING/

ENGINE/RADIATOR - INSTALLATION).

(18) Check the ignition timing and adjust as nec-

essary.

(19) Install the grille and bumper, if removed.

(20) Connect negative cable to battery.

CONNECTING ROD BEARINGS

STANDARD PROCEDURE - FITTING

CONNECTING ROD BEARINGS

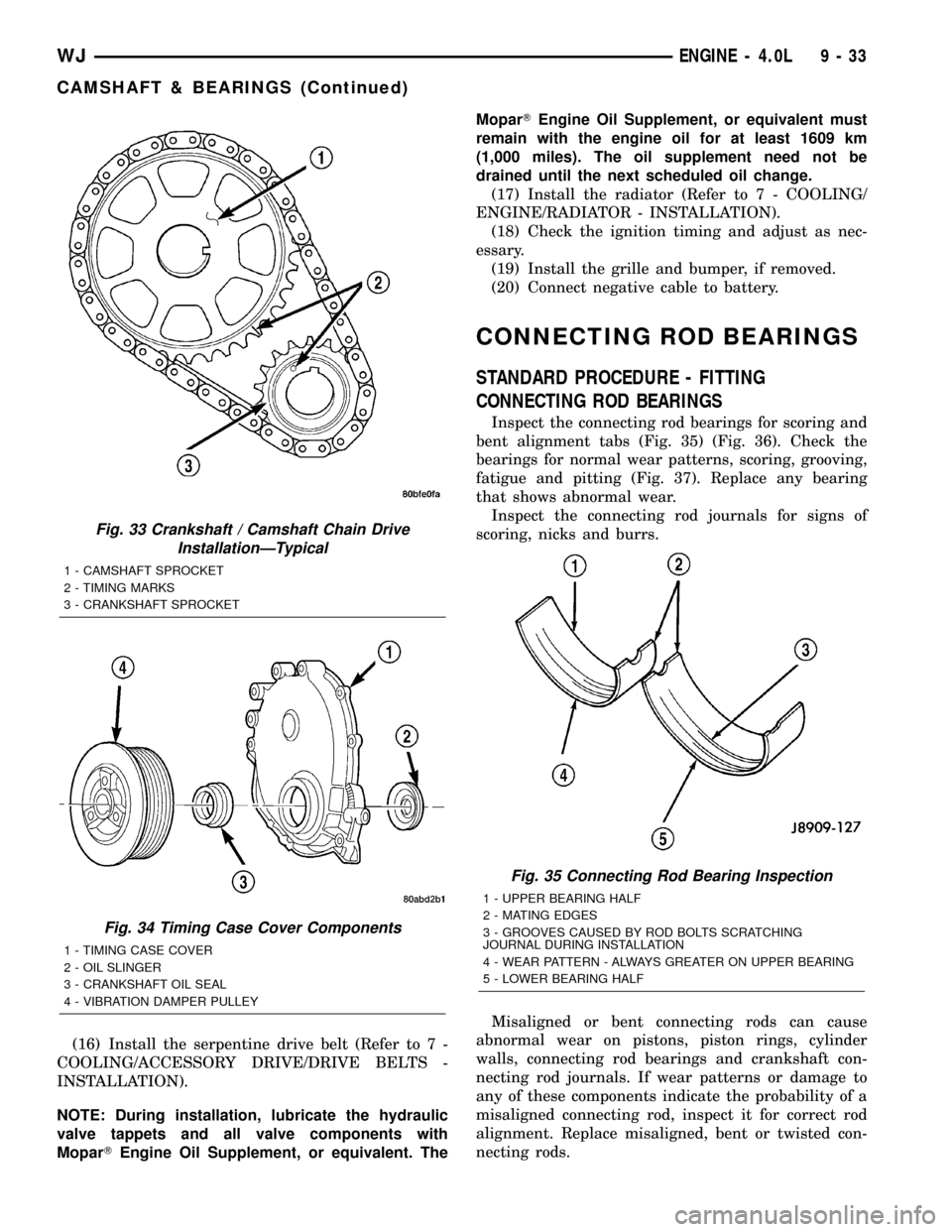

Inspect the connecting rod bearings for scoring and

bent alignment tabs (Fig. 35) (Fig. 36). Check the

bearings for normal wear patterns, scoring, grooving,

fatigue and pitting (Fig. 37). Replace any bearing

that shows abnormal wear.

Inspect the connecting rod journals for signs of

scoring, nicks and burrs.

Misaligned or bent connecting rods can cause

abnormal wear on pistons, piston rings, cylinder

walls, connecting rod bearings and crankshaft con-

necting rod journals. If wear patterns or damage to

any of these components indicate the probability of a

misaligned connecting rod, inspect it for correct rod

alignment. Replace misaligned, bent or twisted con-

necting rods.

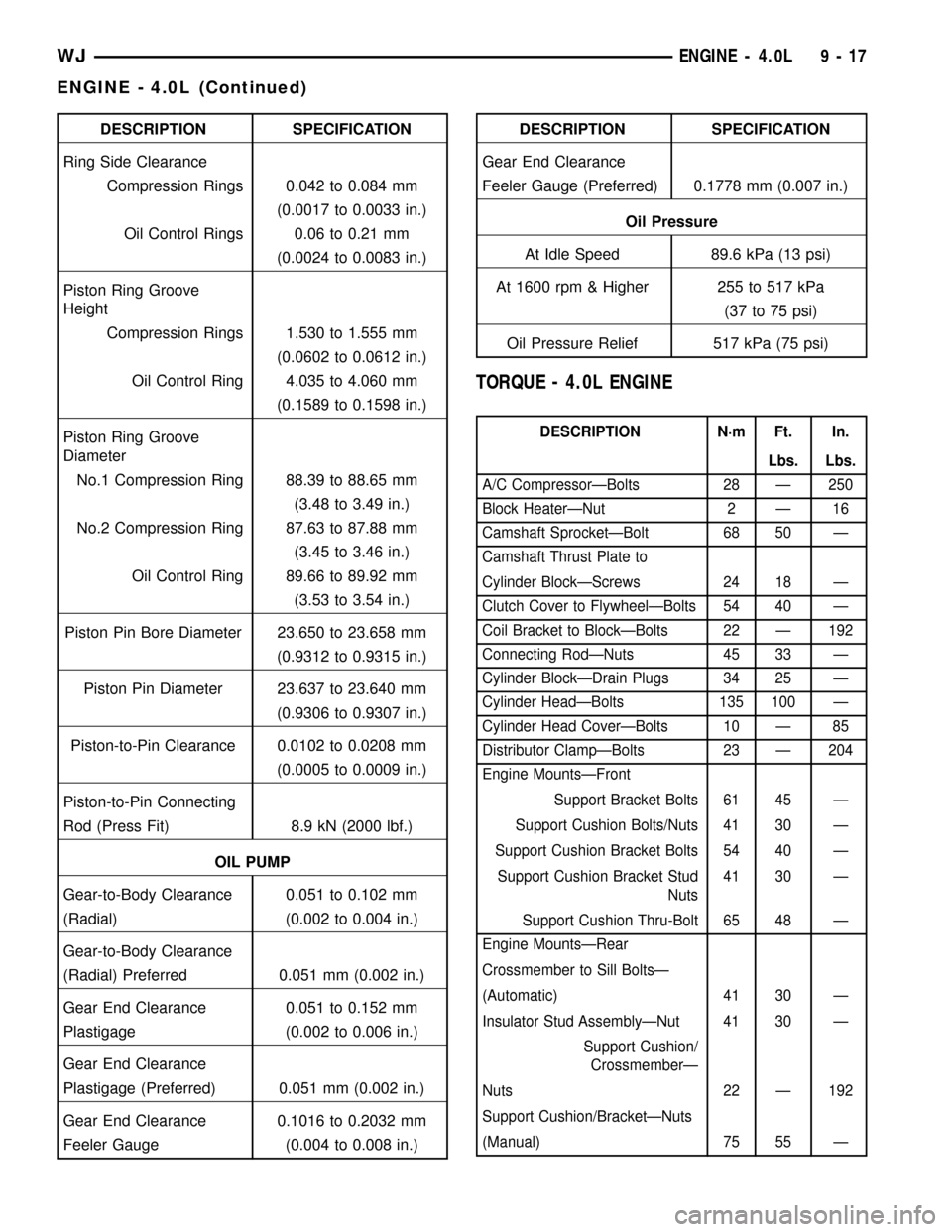

Fig. 33 Crankshaft / Camshaft Chain Drive

InstallationÐTypical

1 - CAMSHAFT SPROCKET

2 - TIMING MARKS

3 - CRANKSHAFT SPROCKET

Fig. 34 Timing Case Cover Components

1 - TIMING CASE COVER

2 - OIL SLINGER

3 - CRANKSHAFT OIL SEAL

4 - VIBRATION DAMPER PULLEY

Fig. 35 Connecting Rod Bearing Inspection

1 - UPPER BEARING HALF

2 - MATING EDGES

3 - GROOVES CAUSED BY ROD BOLTS SCRATCHING

JOURNAL DURING INSTALLATION

4 - WEAR PATTERN - ALWAYS GREATER ON UPPER BEARING

5 - LOWER BEARING HALF

WJENGINE - 4.0L 9 - 33

CAMSHAFT & BEARINGS (Continued)

Page 1277 of 2199

BEARING-TO-JOURNAL CLEARANCE

(1) Wipe the oil from the connecting rod journal.

(2) Use short rubber hose sections over rod bolts

during installation.

(3) Lubricate the upper bearing insert and install

in connecting rod.

(4) Use piston ring compressor to install the rod

and piston assemblies. The oil squirt holes in the

rods must face the camshaft. The arrow on the piston

crown should point to the front of the engine (Fig.

38). Verify that the oil squirt holes in the rods face

the camshaft and that the arrows on the pistons face

the front of the engine.

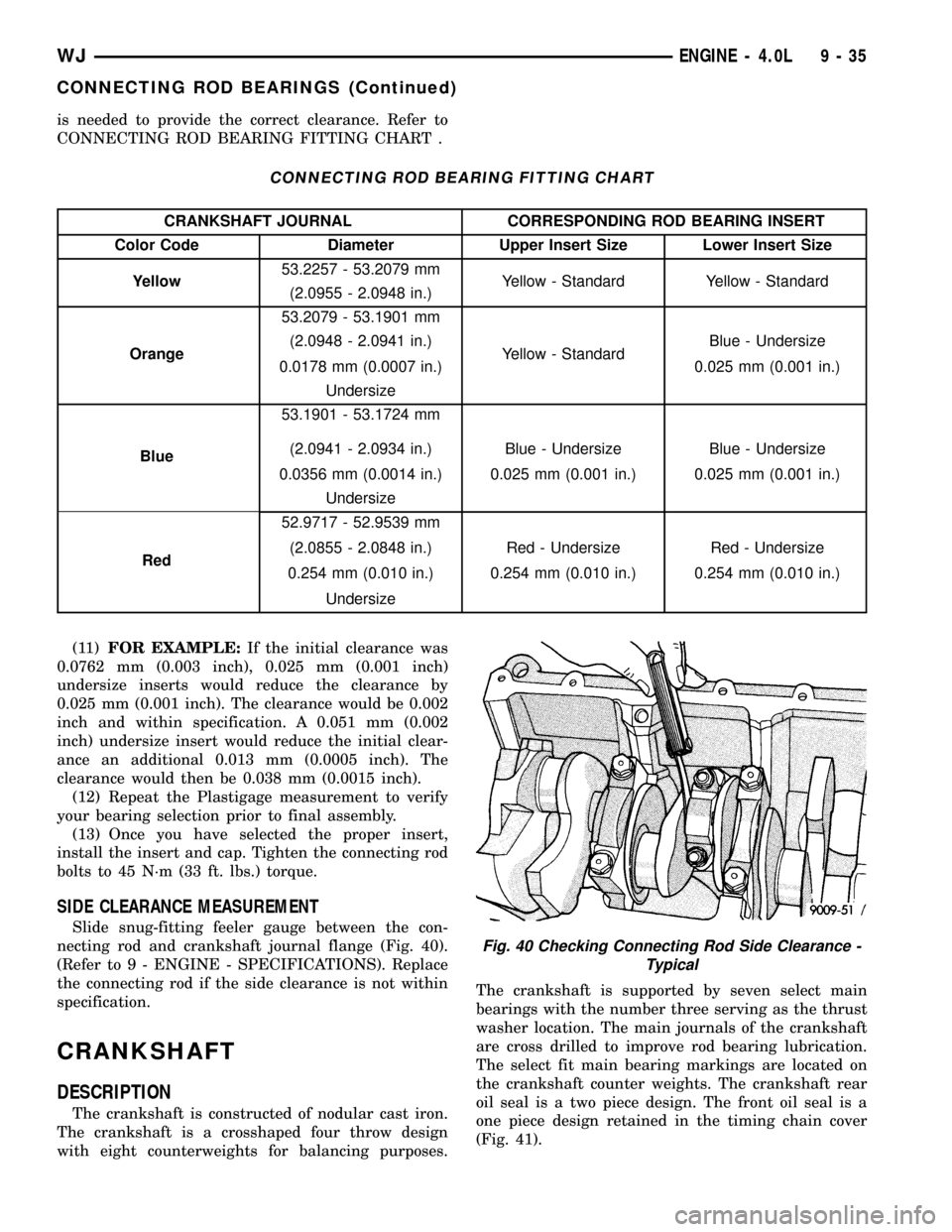

(5) Install the lower bearing insert in the bearing

cap. The lower insert must be dry. Place strip of Plas-

tigage across full width of the lower insert at the cen-

ter of bearing cap. Plastigage must not crumble in

use. If brittle, obtain fresh stock.

(6) Install bearing cap and connecting rod on the

journal and tighten nuts to 45 N´m (33 ft. lbs.)

torque. DO NOT rotate crankshaft. Plastigage will

smear, resulting in inaccurate indication.

(7) Remove the bearing cap and determine amount

of bearing-to- journal clearance by measuring the

width of compressed Plastigage (Fig. 39).Plastigageshould indicate the same clearance across the

entire width of the insert. If the clearance var-

ies, it may be caused by either a tapered jour-

nal, bent connecting rod or foreign material

trapped between the insert and cap or rod.

(8) If the correct clearance is indicated, replace-

ment of the bearing inserts is not necessary. Remove

the Plastigage from crankshaft journal and bearing

insert. Proceed with installation.

(9) If bearing-to-journal clearance exceeds the

specification, install a pair of 0.0254 mm (0.001 inch)

undersize bearing inserts. All the odd size inserts

must be on the bottom. The sizes of the service

replacement bearing inserts are stamped on the

backs of the inserts. Measure the clearance as

described in the previous steps.

(10) The clearance is measured with a pair of

0.0254 mm (0.001 inch) undersize bearing inserts

installed. This will determine if two 0.0254 mm

(0.001 inch) undersize inserts or another combination

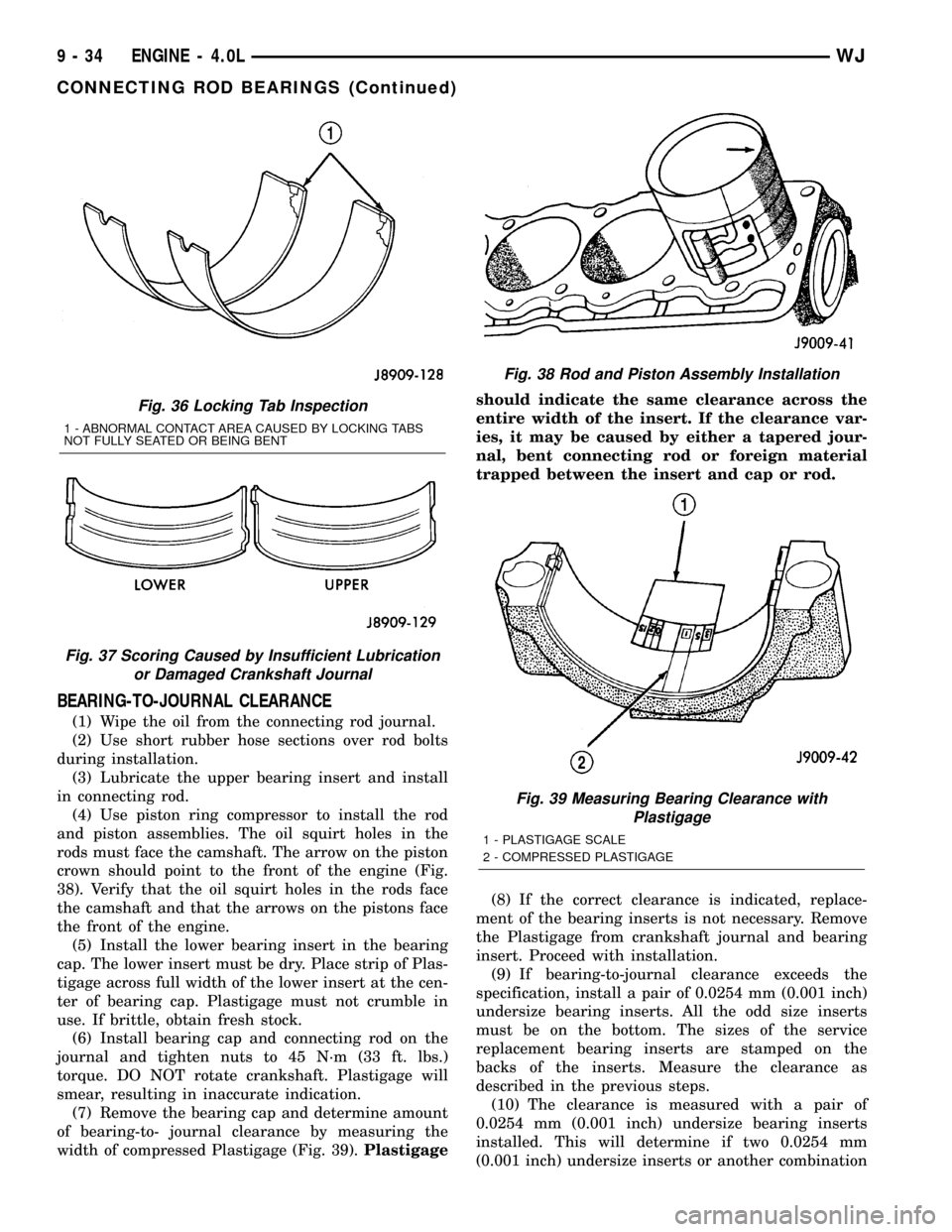

Fig. 36 Locking Tab Inspection

1 - ABNORMAL CONTACT AREA CAUSED BY LOCKING TABS

NOT FULLY SEATED OR BEING BENT

Fig. 37 Scoring Caused by Insufficient Lubrication

or Damaged Crankshaft Journal

Fig. 38 Rod and Piston Assembly Installation

Fig. 39 Measuring Bearing Clearance with

Plastigage

1 - PLASTIGAGE SCALE

2 - COMPRESSED PLASTIGAGE

9 - 34 ENGINE - 4.0LWJ

CONNECTING ROD BEARINGS (Continued)

Page 1278 of 2199

is needed to provide the correct clearance. Refer to

CONNECTING ROD BEARING FITTING CHART .

CONNECTING ROD BEARING FITTING CHART

CRANKSHAFT JOURNAL CORRESPONDING ROD BEARING INSERT

Color Code Diameter Upper Insert Size Lower Insert Size

Yellow53.2257 - 53.2079 mm

Yellow - Standard Yellow - Standard

(2.0955 - 2.0948 in.)

Orange53.2079 - 53.1901 mm

Yellow - StandardBlue - Undersize (2.0948 - 2.0941 in.)

0.0178 mm (0.0007 in.) 0.025 mm (0.001 in.)

Undersize

Blue53.1901 - 53.1724 mm

Blue - Undersize Blue - Undersize (2.0941 - 2.0934 in.)

0.0356 mm (0.0014 in.) 0.025 mm (0.001 in.) 0.025 mm (0.001 in.)

Undersize

Red52.9717 - 52.9539 mm

Red - Undersize Red - Undersize (2.0855 - 2.0848 in.)

0.254 mm (0.010 in.) 0.254 mm (0.010 in.) 0.254 mm (0.010 in.)

Undersize

(11)FOR EXAMPLE:If the initial clearance was

0.0762 mm (0.003 inch), 0.025 mm (0.001 inch)

undersize inserts would reduce the clearance by

0.025 mm (0.001 inch). The clearance would be 0.002

inch and within specification. A 0.051 mm (0.002

inch) undersize insert would reduce the initial clear-

ance an additional 0.013 mm (0.0005 inch). The

clearance would then be 0.038 mm (0.0015 inch).

(12) Repeat the Plastigage measurement to verify

your bearing selection prior to final assembly.

(13) Once you have selected the proper insert,

install the insert and cap. Tighten the connecting rod

bolts to 45 N´m (33 ft. lbs.) torque.

SIDE CLEARANCE MEASUREMENT

Slide snug-fitting feeler gauge between the con-

necting rod and crankshaft journal flange (Fig. 40).

(Refer to 9 - ENGINE - SPECIFICATIONS). Replace

the connecting rod if the side clearance is not within

specification.

CRANKSHAFT

DESCRIPTION

The crankshaft is constructed of nodular cast iron.

The crankshaft is a crosshaped four throw design

with eight counterweights for balancing purposes.The crankshaft is supported by seven select main

bearings with the number three serving as the thrust

washer location. The main journals of the crankshaft

are cross drilled to improve rod bearing lubrication.

The select fit main bearing markings are located on

the crankshaft counter weights. The crankshaft rear

oil seal is a two piece design. The front oil seal is a

one piece design retained in the timing chain cover

(Fig. 41).

Fig. 40 Checking Connecting Rod Side Clearance -

Typical

WJENGINE - 4.0L 9 - 35

CONNECTING ROD BEARINGS (Continued)

Page 1280 of 2199

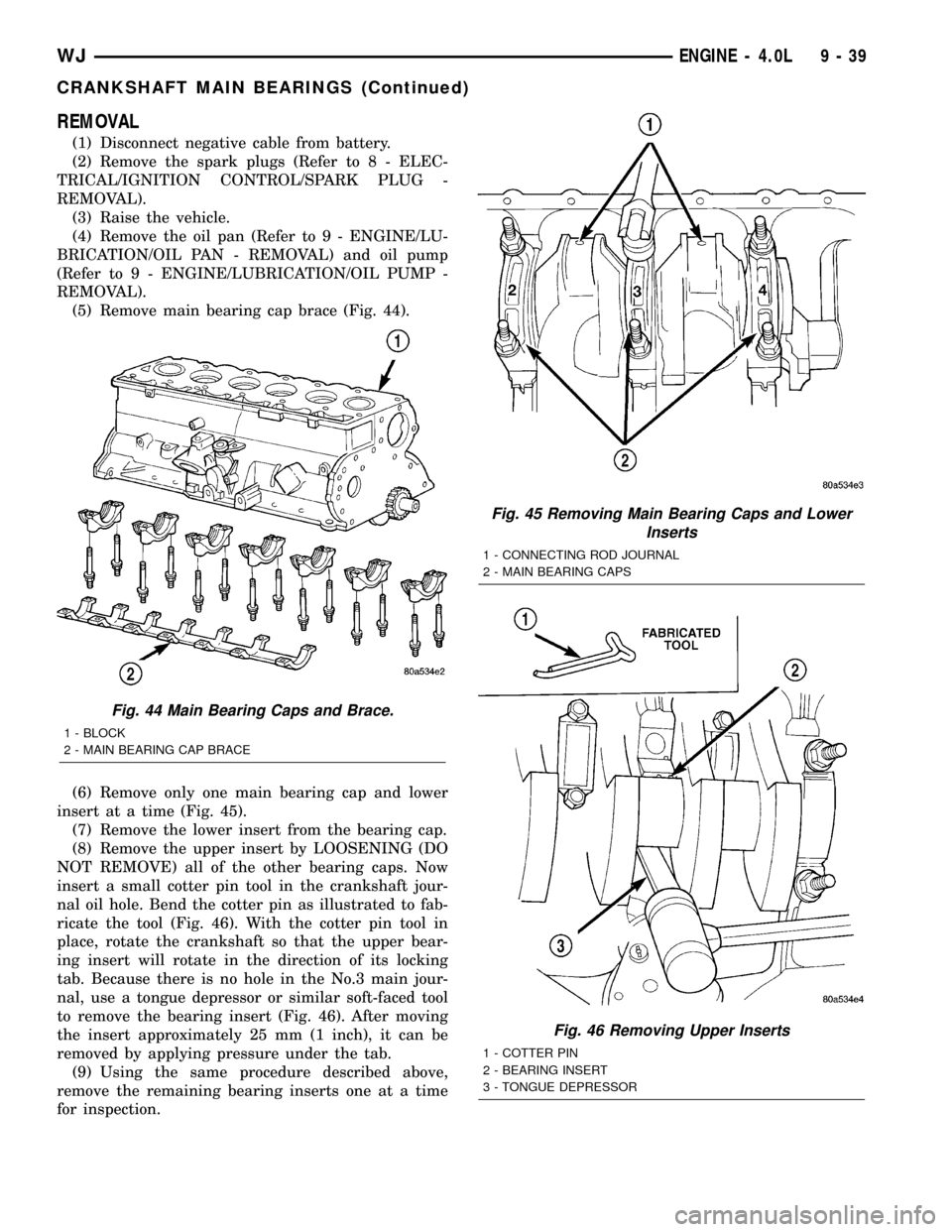

nal clearance an additional 0.0127 mm (0.0005 inch).

The clearance would then be 0.0381 mm (0.0015

inch).

CAUTION: Never use a pair of inserts that differ

more than one bearing size as a pair.

FOR EXAMPLE:DO NOT use a standard size

upper insert and a 0.051 mm (0.002 inch) undersize

lower insert.If the clearance exceeds specification using a pair

of 0.051 mm (0.002 inch) undersize bearing inserts,

measure crankshaft journal diameter with a

micrometer. If the journal diameter is correct, the

crankshaft bore in the cylinder block may be mis-

aligned, which requires cylinder block replacement or

machining to true bore.

Replace the crankshaft or grind to accept the

appropriate undersize bearing inserts if:

²Journal diameters 1 through 6 are less than

63.4517 mm (2.4981 inches)

²Journal 7 diameter is less than 63.4365 mm

(2.4975 inches).

Once the proper clearances have been obtained,

proceed to (Refer to 9 - ENGINE/ENGINE BLOCK/

CRANKSHAFT MAIN BEARINGS - INSTALLA-

TION).

JOURNAL DIAMETER (CRANKSHAFT REMOVED)

Remove the crankshaft from the cylinder block.

Clean the oil off the main bearing journal.

Determine the maximum diameter of the journal

with a micrometer. Measure at two locations 90É

apart at each end of the journal.

The maximum allowable taper and out of round is

0.013 mm (0.0005 inch). Compare the measured

diameter with the journal diameter specification

MAIN BEARING FITTING CHART . Select inserts

required to obtain the specified bearing-to-journal

clearance.

Install the crankshaft into the cylinder block.

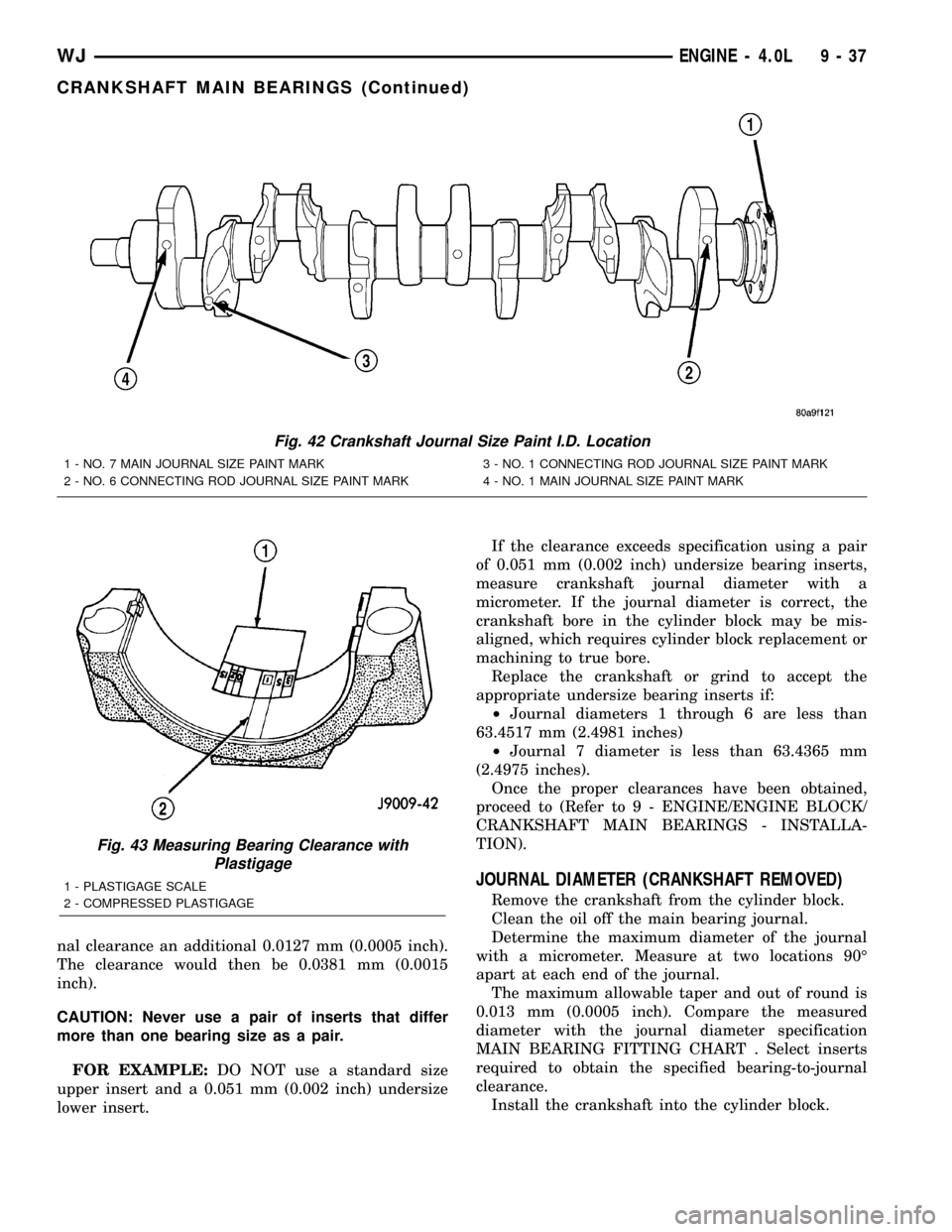

Fig. 42 Crankshaft Journal Size Paint I.D. Location

1 - NO. 7 MAIN JOURNAL SIZE PAINT MARK

2 - NO. 6 CONNECTING ROD JOURNAL SIZE PAINT MARK3 - NO. 1 CONNECTING ROD JOURNAL SIZE PAINT MARK

4 - NO. 1 MAIN JOURNAL SIZE PAINT MARK

Fig. 43 Measuring Bearing Clearance with

Plastigage

1 - PLASTIGAGE SCALE

2 - COMPRESSED PLASTIGAGE

WJENGINE - 4.0L 9 - 37

CRANKSHAFT MAIN BEARINGS (Continued)

Page 1282 of 2199

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the spark plugs (Refer to 8 - ELEC-

TRICAL/IGNITION CONTROL/SPARK PLUG -

REMOVAL).

(3) Raise the vehicle.

(4) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL) and oil pump

(Refer to 9 - ENGINE/LUBRICATION/OIL PUMP -

REMOVAL).

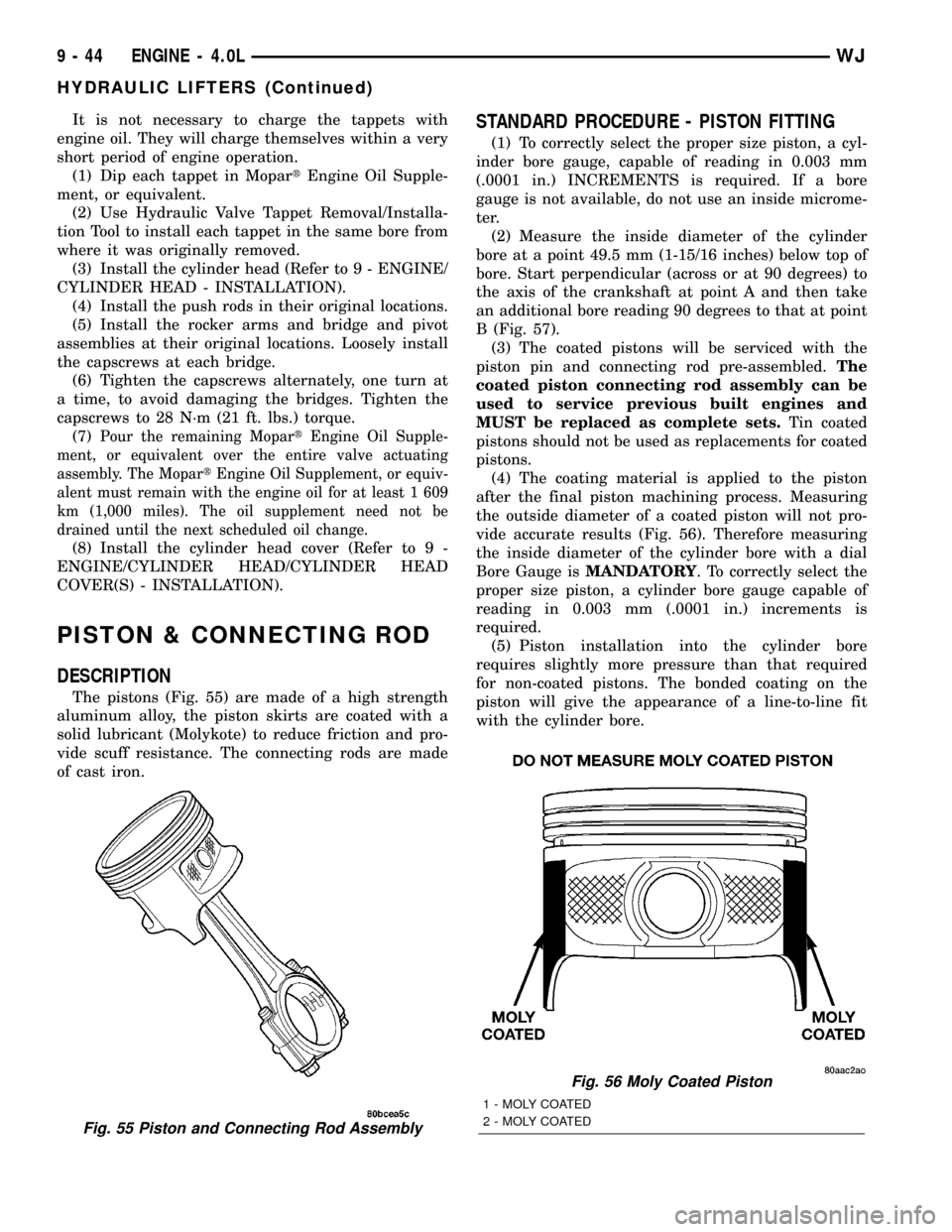

(5) Remove main bearing cap brace (Fig. 44).

(6) Remove only one main bearing cap and lower

insert at a time (Fig. 45).

(7) Remove the lower insert from the bearing cap.

(8) Remove the upper insert by LOOSENING (DO

NOT REMOVE) all of the other bearing caps. Now

insert a small cotter pin tool in the crankshaft jour-

nal oil hole. Bend the cotter pin as illustrated to fab-

ricate the tool (Fig. 46). With the cotter pin tool in

place, rotate the crankshaft so that the upper bear-

ing insert will rotate in the direction of its locking

tab. Because there is no hole in the No.3 main jour-

nal, use a tongue depressor or similar soft-faced tool

to remove the bearing insert (Fig. 46). After moving

the insert approximately 25 mm (1 inch), it can be

removed by applying pressure under the tab.

(9) Using the same procedure described above,

remove the remaining bearing inserts one at a time

for inspection.

Fig. 44 Main Bearing Caps and Brace.

1 - BLOCK

2 - MAIN BEARING CAP BRACE

Fig. 45 Removing Main Bearing Caps and Lower

Inserts

1 - CONNECTING ROD JOURNAL

2 - MAIN BEARING CAPS

Fig. 46 Removing Upper Inserts

1 - COTTER PIN

2 - BEARING INSERT

3 - TONGUE DEPRESSOR

WJENGINE - 4.0L 9 - 39

CRANKSHAFT MAIN BEARINGS (Continued)

Page 1287 of 2199

It is not necessary to charge the tappets with

engine oil. They will charge themselves within a very

short period of engine operation.

(1) Dip each tappet in MopartEngine Oil Supple-

ment, or equivalent.

(2) Use Hydraulic Valve Tappet Removal/Installa-

tion Tool to install each tappet in the same bore from

where it was originally removed.

(3) Install the cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - INSTALLATION).

(4) Install the push rods in their original locations.

(5) Install the rocker arms and bridge and pivot

assemblies at their original locations. Loosely install

the capscrews at each bridge.

(6) Tighten the capscrews alternately, one turn at

a time, to avoid damaging the bridges. Tighten the

capscrews to 28 N´m (21 ft. lbs.) torque.

(7)

Pour the remaining MopartEngine Oil Supple-

ment, or equivalent over the entire valve actuating

assembly. The MopartEngine Oil Supplement, or equiv-

alent must remain with the engine oil for at least 1 609

km (1,000 miles). The oil supplement need not be

drained until the next scheduled oil change.

(8) Install the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

PISTON & CONNECTING ROD

DESCRIPTION

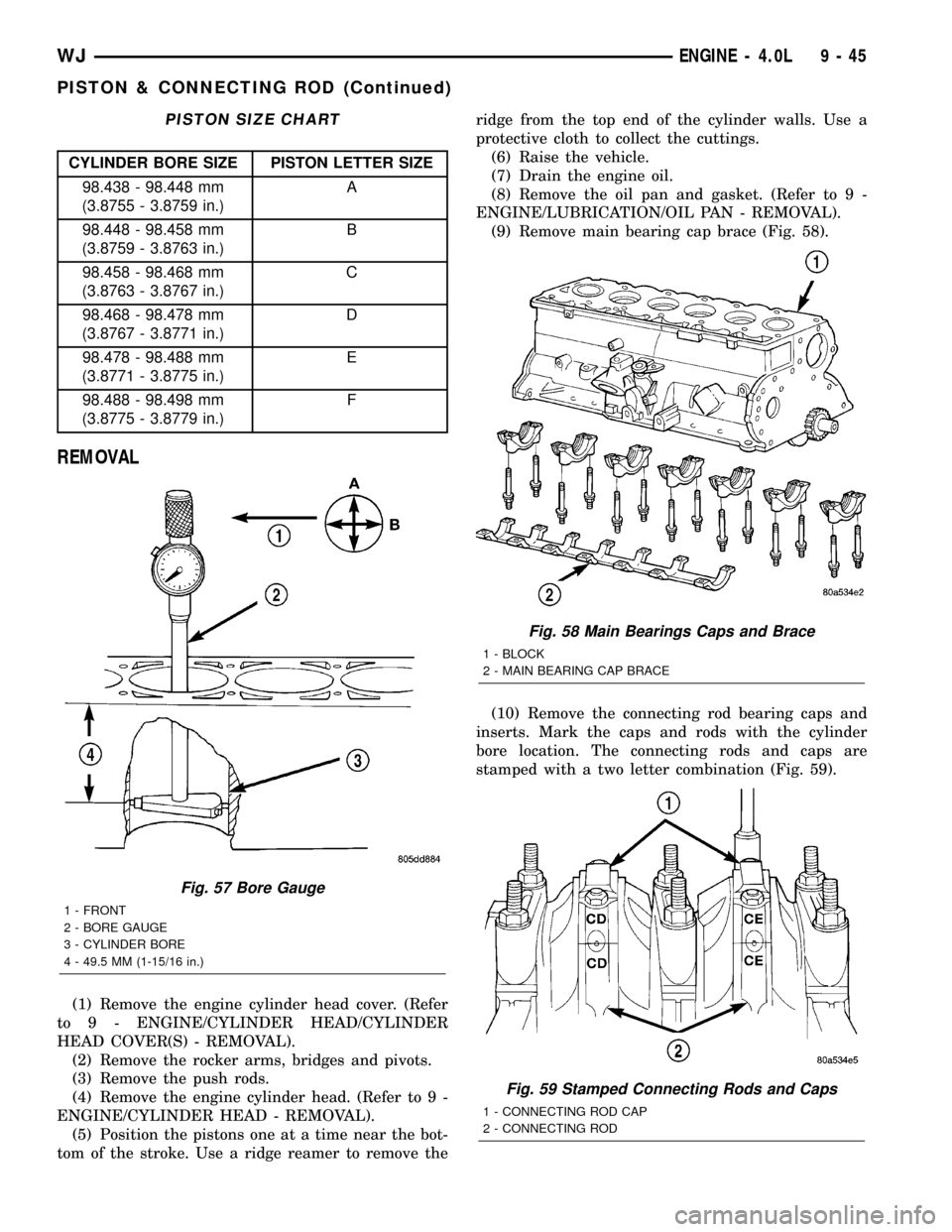

The pistons (Fig. 55) are made of a high strength

aluminum alloy, the piston skirts are coated with a

solid lubricant (Molykote) to reduce friction and pro-

vide scuff resistance. The connecting rods are made

of cast iron.

STANDARD PROCEDURE - PISTON FITTING

(1) To correctly select the proper size piston, a cyl-

inder bore gauge, capable of reading in 0.003 mm

(.0001 in.) INCREMENTS is required. If a bore

gauge is not available, do not use an inside microme-

ter.

(2) Measure the inside diameter of the cylinder

bore at a point 49.5 mm (1-15/16 inches) below top of

bore. Start perpendicular (across or at 90 degrees) to

the axis of the crankshaft at point A and then take

an additional bore reading 90 degrees to that at point

B (Fig. 57).

(3) The coated pistons will be serviced with the

piston pin and connecting rod pre-assembled.The

coated piston connecting rod assembly can be

used to service previous built engines and

MUST be replaced as complete sets.Tin coated

pistons should not be used as replacements for coated

pistons.

(4) The coating material is applied to the piston

after the final piston machining process. Measuring

the outside diameter of a coated piston will not pro-

vide accurate results (Fig. 56). Therefore measuring

the inside diameter of the cylinder bore with a dial

Bore Gauge isMANDATORY. To correctly select the

proper size piston, a cylinder bore gauge capable of

reading in 0.003 mm (.0001 in.) increments is

required.

(5) Piston installation into the cylinder bore

requires slightly more pressure than that required

for non-coated pistons. The bonded coating on the

piston will give the appearance of a line-to-line fit

with the cylinder bore.

Fig. 55 Piston and Connecting Rod Assembly

Fig. 56 Moly Coated Piston

1 - MOLY COATED

2 - MOLY COATED

9 - 44 ENGINE - 4.0LWJ

HYDRAULIC LIFTERS (Continued)

Page 1288 of 2199

PISTON SIZE CHART

CYLINDER BORE SIZE PISTON LETTER SIZE

98.438 - 98.448 mm

(3.8755 - 3.8759 in.)A

98.448 - 98.458 mm

(3.8759 - 3.8763 in.)B

98.458 - 98.468 mm

(3.8763 - 3.8767 in.)C

98.468 - 98.478 mm

(3.8767 - 3.8771 in.)D

98.478 - 98.488 mm

(3.8771 - 3.8775 in.)E

98.488 - 98.498 mm

(3.8775 - 3.8779 in.)F

REMOVAL

(1) Remove the engine cylinder head cover. (Refer

to 9 - ENGINE/CYLINDER HEAD/CYLINDER

HEAD COVER(S) - REMOVAL).

(2) Remove the rocker arms, bridges and pivots.

(3) Remove the push rods.

(4) Remove the engine cylinder head. (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

(5) Position the pistons one at a time near the bot-

tom of the stroke. Use a ridge reamer to remove theridge from the top end of the cylinder walls. Use a

protective cloth to collect the cuttings.

(6) Raise the vehicle.

(7) Drain the engine oil.

(8) Remove the oil pan and gasket. (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - REMOVAL).

(9) Remove main bearing cap brace (Fig. 58).

(10) Remove the connecting rod bearing caps and

inserts. Mark the caps and rods with the cylinder

bore location. The connecting rods and caps are

stamped with a two letter combination (Fig. 59).

Fig. 57 Bore Gauge

1 - FRONT

2 - BORE GAUGE

3 - CYLINDER BORE

4 - 49.5 MM (1-15/16 in.)

Fig. 58 Main Bearings Caps and Brace

1 - BLOCK

2 - MAIN BEARING CAP BRACE

Fig. 59 Stamped Connecting Rods and Caps

1 - CONNECTING ROD CAP

2 - CONNECTING ROD

WJENGINE - 4.0L 9 - 45

PISTON & CONNECTING ROD (Continued)

Page 1289 of 2199

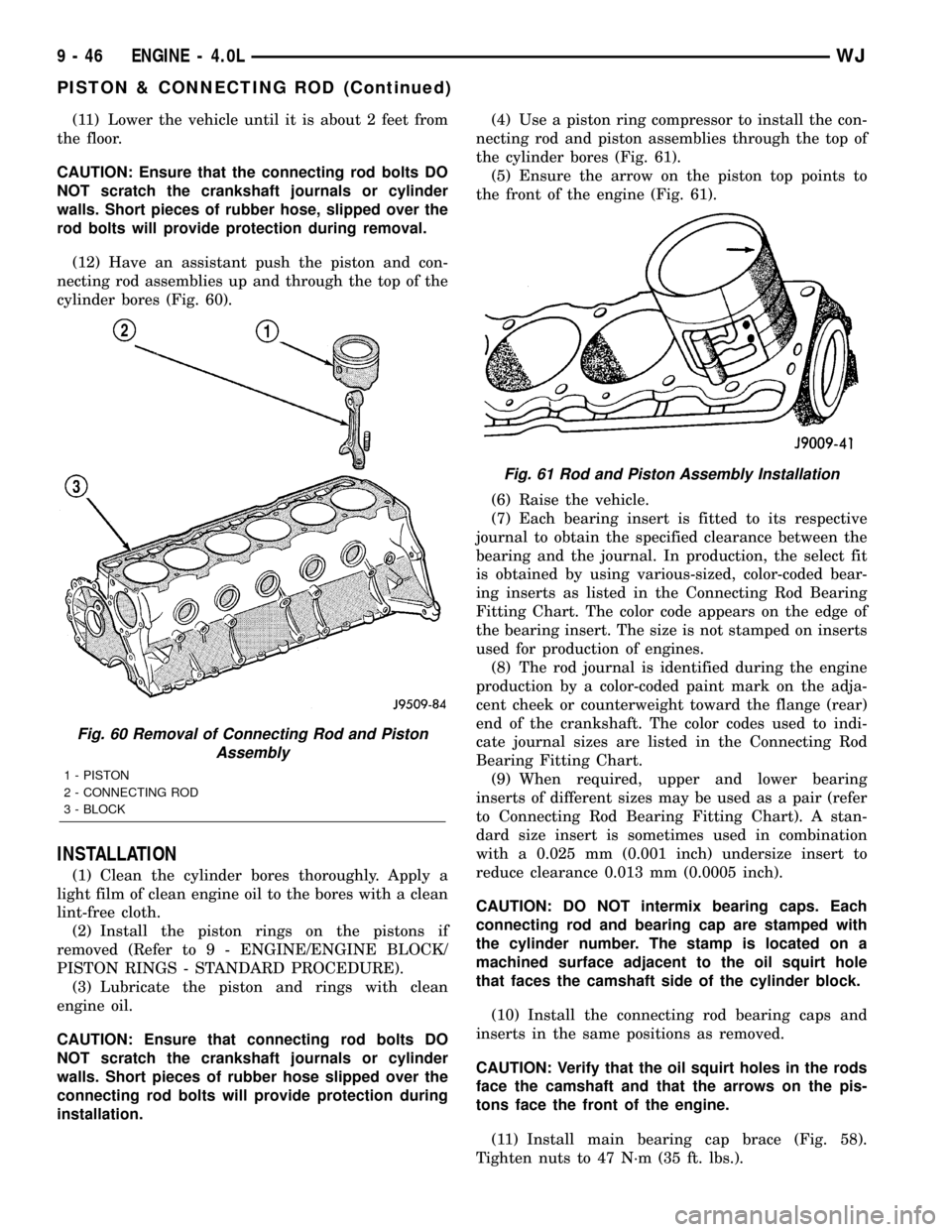

(11) Lower the vehicle until it is about 2 feet from

the floor.

CAUTION: Ensure that the connecting rod bolts DO

NOT scratch the crankshaft journals or cylinder

walls. Short pieces of rubber hose, slipped over the

rod bolts will provide protection during removal.

(12) Have an assistant push the piston and con-

necting rod assemblies up and through the top of the

cylinder bores (Fig. 60).

INSTALLATION

(1) Clean the cylinder bores thoroughly. Apply a

light film of clean engine oil to the bores with a clean

lint-free cloth.

(2) Install the piston rings on the pistons if

removed (Refer to 9 - ENGINE/ENGINE BLOCK/

PISTON RINGS - STANDARD PROCEDURE).

(3) Lubricate the piston and rings with clean

engine oil.

CAUTION: Ensure that connecting rod bolts DO

NOT scratch the crankshaft journals or cylinder

walls. Short pieces of rubber hose slipped over the

connecting rod bolts will provide protection during

installation.(4) Use a piston ring compressor to install the con-

necting rod and piston assemblies through the top of

the cylinder bores (Fig. 61).

(5) Ensure the arrow on the piston top points to

the front of the engine (Fig. 61).

(6) Raise the vehicle.

(7) Each bearing insert is fitted to its respective

journal to obtain the specified clearance between the

bearing and the journal. In production, the select fit

is obtained by using various-sized, color-coded bear-

ing inserts as listed in the Connecting Rod Bearing

Fitting Chart. The color code appears on the edge of

the bearing insert. The size is not stamped on inserts

used for production of engines.

(8) The rod journal is identified during the engine

production by a color-coded paint mark on the adja-

cent cheek or counterweight toward the flange (rear)

end of the crankshaft. The color codes used to indi-

cate journal sizes are listed in the Connecting Rod

Bearing Fitting Chart.

(9) When required, upper and lower bearing

inserts of different sizes may be used as a pair (refer

to Connecting Rod Bearing Fitting Chart). A stan-

dard size insert is sometimes used in combination

with a 0.025 mm (0.001 inch) undersize insert to

reduce clearance 0.013 mm (0.0005 inch).

CAUTION: DO NOT intermix bearing caps. Each

connecting rod and bearing cap are stamped with

the cylinder number. The stamp is located on a

machined surface adjacent to the oil squirt hole

that faces the camshaft side of the cylinder block.

(10) Install the connecting rod bearing caps and

inserts in the same positions as removed.

CAUTION: Verify that the oil squirt holes in the rods

face the camshaft and that the arrows on the pis-

tons face the front of the engine.

(11) Install main bearing cap brace (Fig. 58).

Tighten nuts to 47 N´m (35 ft. lbs.).

Fig. 60 Removal of Connecting Rod and Piston

Assembly

1 - PISTON

2 - CONNECTING ROD

3 - BLOCK

Fig. 61 Rod and Piston Assembly Installation

9 - 46 ENGINE - 4.0LWJ

PISTON & CONNECTING ROD (Continued)

Page 1290 of 2199

(12) Install the oil pan and gasket (Refer to 9 -

ENGINE/LUBRICATION/OIL PAN - INSTALLA-

TION).

(13) Lower the vehicle.

(14) Install the engine cylinder head (Refer to 9 -

ENGINE/CYLINDER HEAD - INSTALLATION),

push rods, rocker arms, bridges, pivots and engine

cylinder head cover(Refer to 9 - ENGINE/CYLINDER

HEAD/CYLINDER HEAD COVER(S) - INSTALLA-

TION).

(15) Fill the crankcase with engine oil.

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING

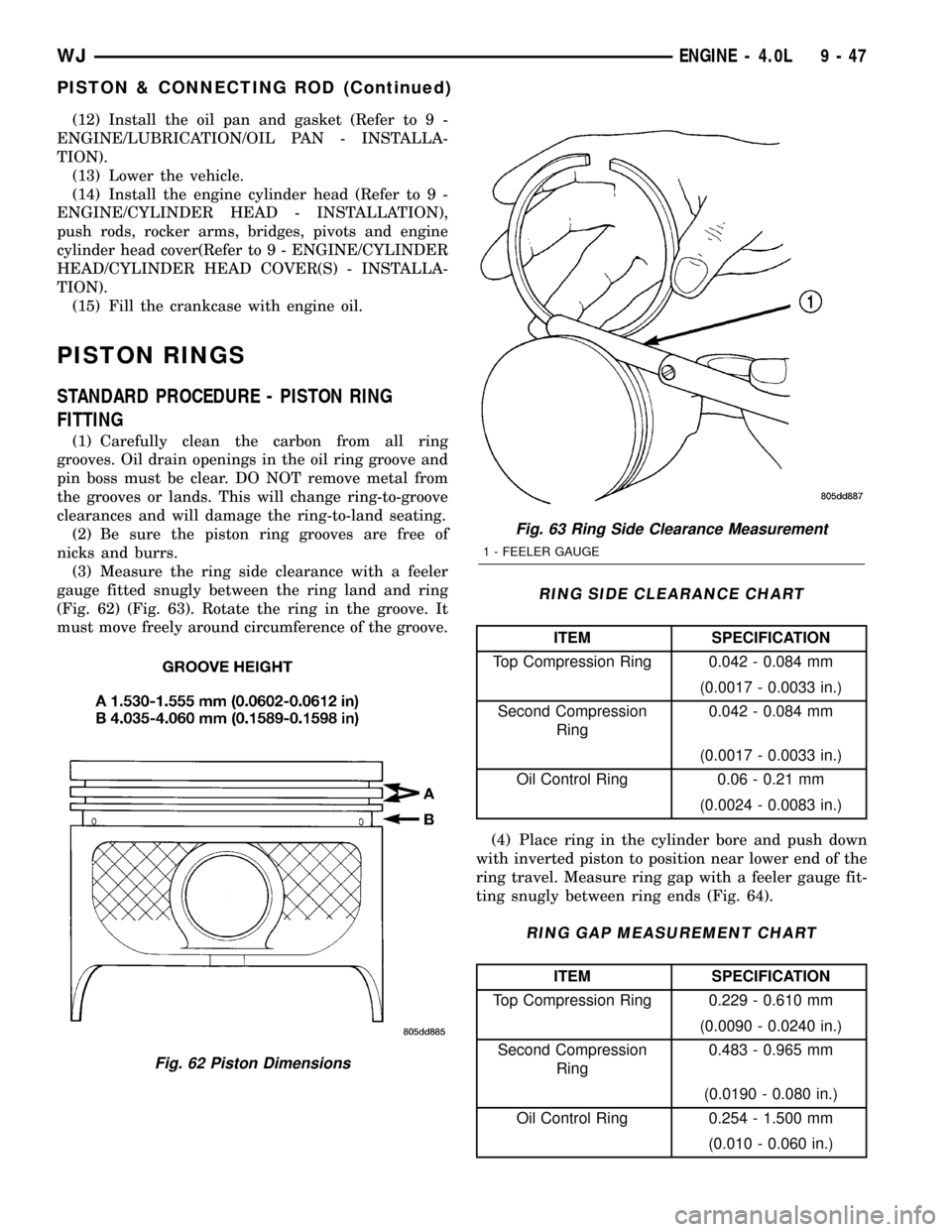

(1) Carefully clean the carbon from all ring

grooves. Oil drain openings in the oil ring groove and

pin boss must be clear. DO NOT remove metal from

the grooves or lands. This will change ring-to-groove

clearances and will damage the ring-to-land seating.

(2) Be sure the piston ring grooves are free of

nicks and burrs.

(3) Measure the ring side clearance with a feeler

gauge fitted snugly between the ring land and ring

(Fig. 62) (Fig. 63). Rotate the ring in the groove. It

must move freely around circumference of the groove.

RING SIDE CLEARANCE CHART

ITEM SPECIFICATION

Top Compression Ring 0.042 - 0.084 mm

(0.0017 - 0.0033 in.)

Second Compression

Ring0.042 - 0.084 mm

(0.0017 - 0.0033 in.)

Oil Control Ring 0.06 - 0.21 mm

(0.0024 - 0.0083 in.)

(4) Place ring in the cylinder bore and push down

with inverted piston to position near lower end of the

ring travel. Measure ring gap with a feeler gauge fit-

ting snugly between ring ends (Fig. 64).

RING GAP MEASUREMENT CHART

ITEM SPECIFICATION

Top Compression Ring 0.229 - 0.610 mm

(0.0090 - 0.0240 in.)

Second Compression

Ring0.483 - 0.965 mm

(0.0190 - 0.080 in.)

Oil Control Ring 0.254 - 1.500 mm

(0.010 - 0.060 in.)

Fig. 62 Piston Dimensions

Fig. 63 Ring Side Clearance Measurement

1 - FEELER GAUGE

WJENGINE - 4.0L 9 - 47

PISTON & CONNECTING ROD (Continued)