EGR JEEP GRAND CHEROKEE 2002 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 258 of 2199

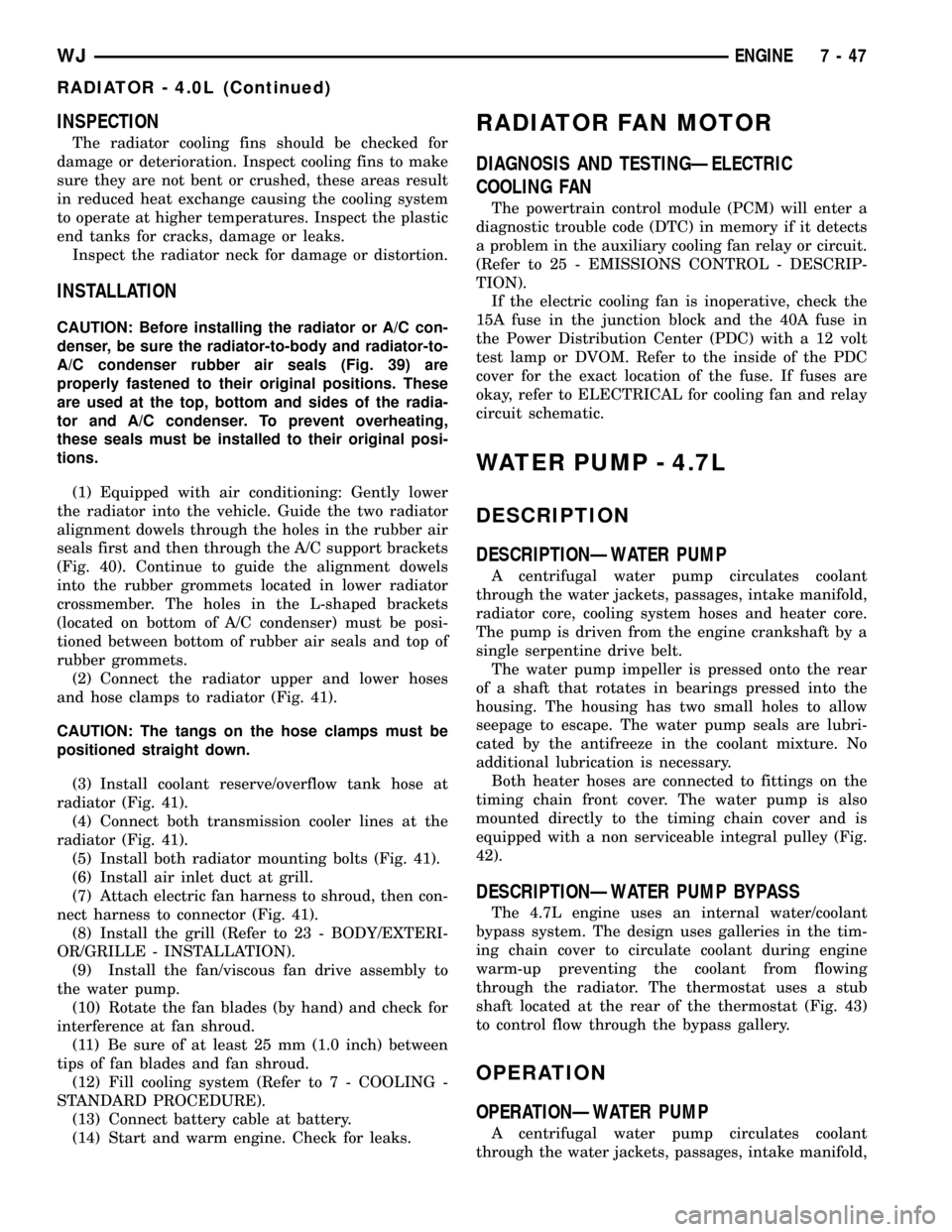

(2) Insert block heater assembly with element loop

pointing at twelve o'clock (Fig. 19).

(3) With block heater fully seated, tighten center

screw to 2 N´m (17 in. lbs.) torque.

(4) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(5) Start and warm the engine. Check for leaks.

ENGINE COOLANT TEMP

SENSOR

DESCRIPTION

The Engine Coolant Temperature (ECT) sensor is

used to sense engine coolant temperature. The sensor

protrudes into an engine water jacket.

The ECT sensor is a two-wire Negative Thermal

Coefficient (NTC) sensor. Meaning, as engine coolant

temperature increases, resistance (voltage) in the

sensor decreases. As temperature decreases, resis-

tance (voltage) in the sensor increases.

OPERATION

At key-on, the Powertrain Control Module (PCM)

sends out a regulated 5 volt signal to the ECT sensor.

The PCM then monitors the signal as it passes

through the ECT sensor to the sensor ground (sensor

return).

When the engine is cold, the PCM will operate in

Open Loop cycle. It will demand slightly richer air-

fuel mixtures and higher idle speeds. This is done

until normal operating temperatures are reached.

The PCM uses inputs from the ECT sensor for the

following calculations:

²for engine coolant temperature gauge operation

through CCD or PCI (J1850) communications

²Injector pulse-width

²Spark-advance curves

²ASD relay shut-down times

²Idle Air Control (IAC) motor key-on steps

²Pulse-width prime-shot during cranking

²O2 sensor closed loop times

²Purge solenoid on/off times

²EGR solenoid on/off times (if equipped)

²Leak Detection Pump operation (if equipped)

²Radiator fan relay on/off times (if equipped)

²Target idle speed

REMOVAL

REMOVALÐ4.0L ENGINE

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING. COOLING SYSTEM

MUST BE PARTIALLY DRAINED BEFORE REMOV-

ING THE ENGINE COOLANT TEMPERATURE (ECT)

SENSOR. REFER TO GROUP 7, COOLING.

(1) Partially drain cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE).

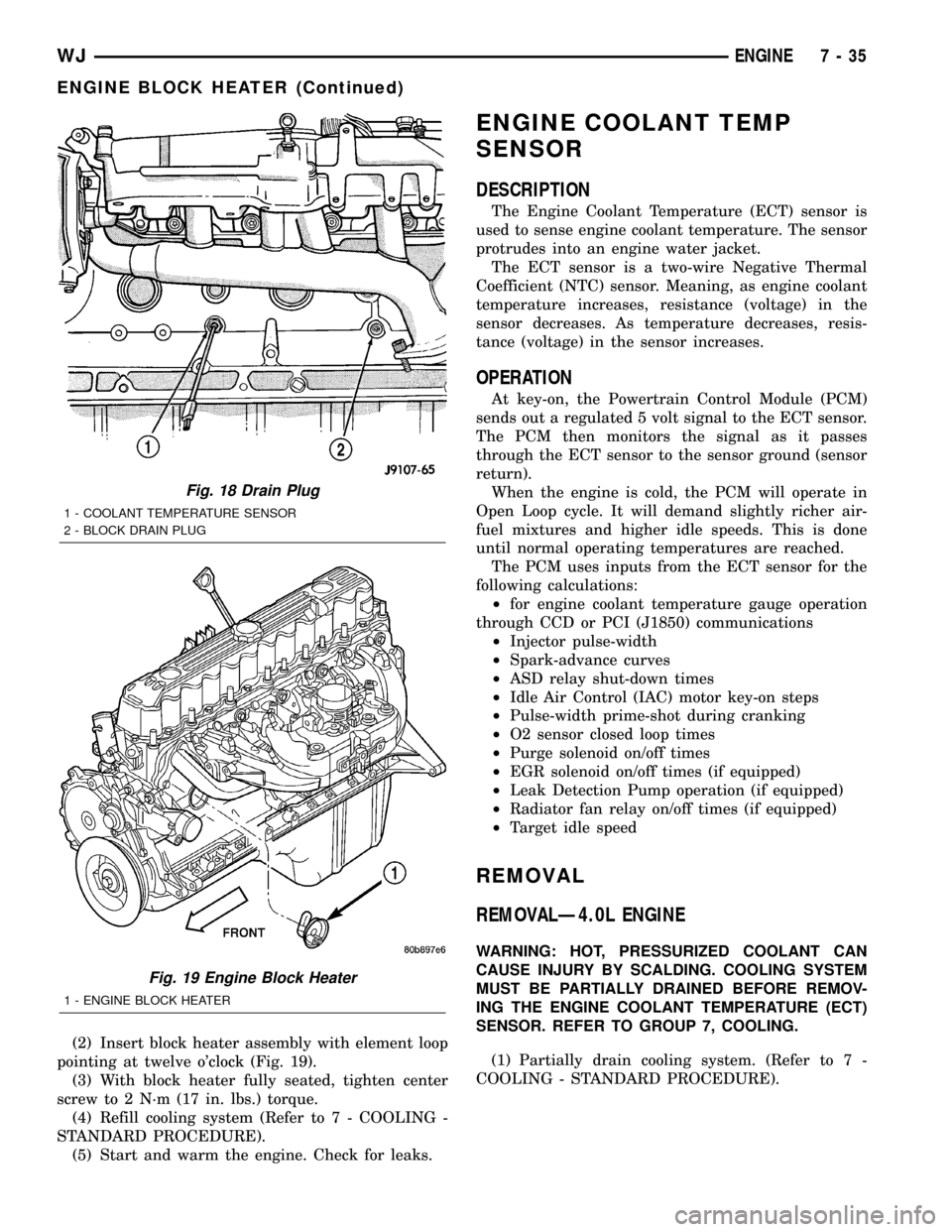

Fig. 18 Drain Plug

1 - COOLANT TEMPERATURE SENSOR

2 - BLOCK DRAIN PLUG

Fig. 19 Engine Block Heater

1 - ENGINE BLOCK HEATER

WJENGINE 7 - 35

ENGINE BLOCK HEATER (Continued)

Page 270 of 2199

INSPECTION

The radiator cooling fins should be checked for

damage or deterioration. Inspect cooling fins to make

sure they are not bent or crushed, these areas result

in reduced heat exchange causing the cooling system

to operate at higher temperatures. Inspect the plastic

end tanks for cracks, damage or leaks.

Inspect the radiator neck for damage or distortion.

INSTALLATION

CAUTION: Before installing the radiator or A/C con-

denser, be sure the radiator-to-body and radiator-to-

A/C condenser rubber air seals (Fig. 39) are

properly fastened to their original positions. These

are used at the top, bottom and sides of the radia-

tor and A/C condenser. To prevent overheating,

these seals must be installed to their original posi-

tions.

(1) Equipped with air conditioning: Gently lower

the radiator into the vehicle. Guide the two radiator

alignment dowels through the holes in the rubber air

seals first and then through the A/C support brackets

(Fig. 40). Continue to guide the alignment dowels

into the rubber grommets located in lower radiator

crossmember. The holes in the L-shaped brackets

(located on bottom of A/C condenser) must be posi-

tioned between bottom of rubber air seals and top of

rubber grommets.

(2) Connect the radiator upper and lower hoses

and hose clamps to radiator (Fig. 41).

CAUTION: The tangs on the hose clamps must be

positioned straight down.

(3) Install coolant reserve/overflow tank hose at

radiator (Fig. 41).

(4) Connect both transmission cooler lines at the

radiator (Fig. 41).

(5) Install both radiator mounting bolts (Fig. 41).

(6) Install air inlet duct at grill.

(7) Attach electric fan harness to shroud, then con-

nect harness to connector (Fig. 41).

(8) Install the grill (Refer to 23 - BODY/EXTERI-

OR/GRILLE - INSTALLATION).

(9) Install the fan/viscous fan drive assembly to

the water pump.

(10) Rotate the fan blades (by hand) and check for

interference at fan shroud.

(11) Be sure of at least 25 mm (1.0 inch) between

tips of fan blades and fan shroud.

(12) Fill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(13) Connect battery cable at battery.

(14) Start and warm engine. Check for leaks.

RADIATOR FAN MOTOR

DIAGNOSIS AND TESTINGÐELECTRIC

COOLING FAN

The powertrain control module (PCM) will enter a

diagnostic trouble code (DTC) in memory if it detects

a problem in the auxiliary cooling fan relay or circuit.

(Refer to 25 - EMISSIONS CONTROL - DESCRIP-

TION).

If the electric cooling fan is inoperative, check the

15A fuse in the junction block and the 40A fuse in

the Power Distribution Center (PDC) with a 12 volt

test lamp or DVOM. Refer to the inside of the PDC

cover for the exact location of the fuse. If fuses are

okay, refer to ELECTRICAL for cooling fan and relay

circuit schematic.

WATER PUMP - 4.7L

DESCRIPTION

DESCRIPTIONÐWATER PUMP

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

radiator core, cooling system hoses and heater core.

The pump is driven from the engine crankshaft by a

single serpentine drive belt.

The water pump impeller is pressed onto the rear

of a shaft that rotates in bearings pressed into the

housing. The housing has two small holes to allow

seepage to escape. The water pump seals are lubri-

cated by the antifreeze in the coolant mixture. No

additional lubrication is necessary.

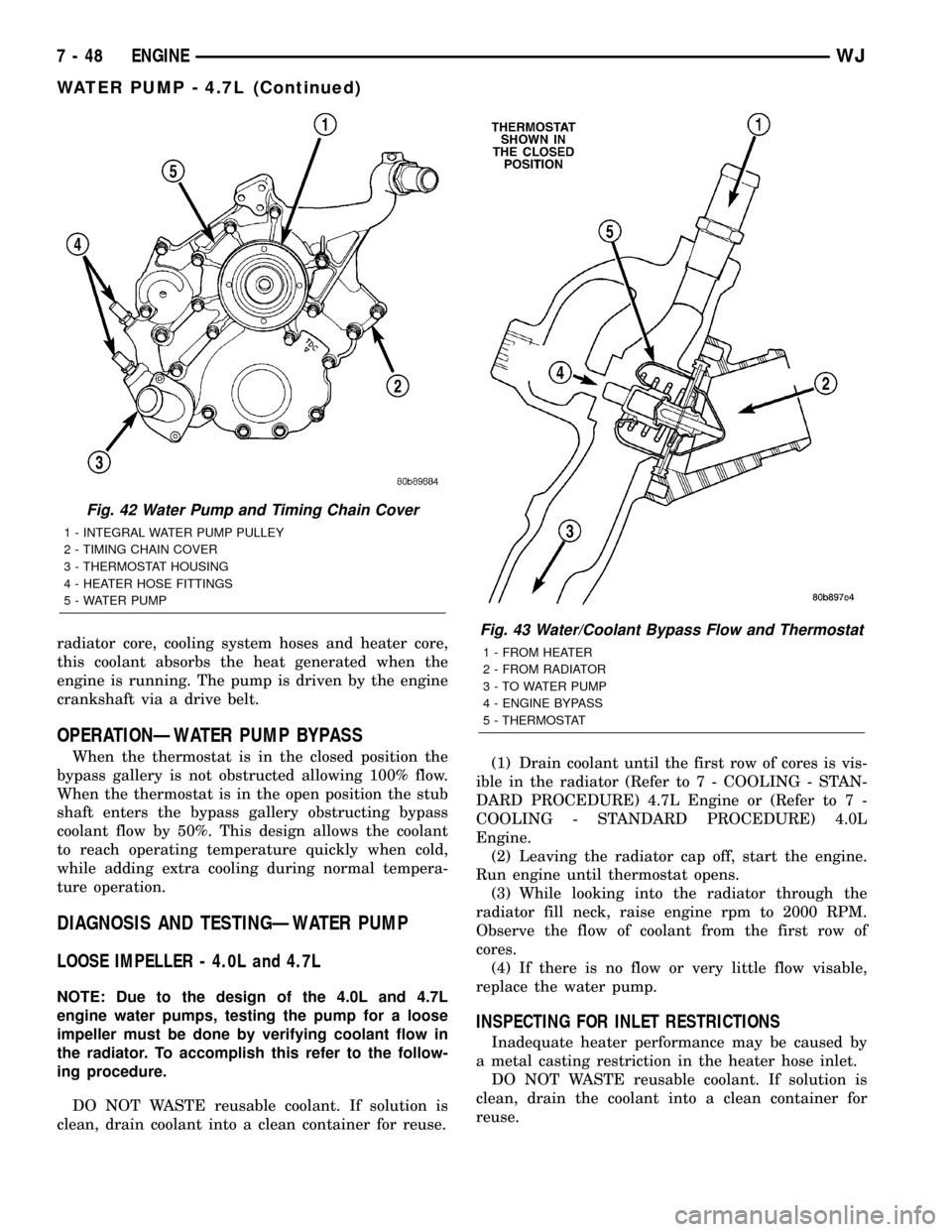

Both heater hoses are connected to fittings on the

timing chain front cover. The water pump is also

mounted directly to the timing chain cover and is

equipped with a non serviceable integral pulley (Fig.

42).

DESCRIPTIONÐWATER PUMP BYPASS

The 4.7L engine uses an internal water/coolant

bypass system. The design uses galleries in the tim-

ing chain cover to circulate coolant during engine

warm-up preventing the coolant from flowing

through the radiator. The thermostat uses a stub

shaft located at the rear of the thermostat (Fig. 43)

to control flow through the bypass gallery.

OPERATION

OPERATIONÐWATER PUMP

A centrifugal water pump circulates coolant

through the water jackets, passages, intake manifold,

WJENGINE 7 - 47

RADIATOR - 4.0L (Continued)

Page 271 of 2199

radiator core, cooling system hoses and heater core,

this coolant absorbs the heat generated when the

engine is running. The pump is driven by the engine

crankshaft via a drive belt.

OPERATIONÐWATER PUMP BYPASS

When the thermostat is in the closed position the

bypass gallery is not obstructed allowing 100% flow.

When the thermostat is in the open position the stub

shaft enters the bypass gallery obstructing bypass

coolant flow by 50%. This design allows the coolant

to reach operating temperature quickly when cold,

while adding extra cooling during normal tempera-

ture operation.

DIAGNOSIS AND TESTINGÐWATER PUMP

LOOSE IMPELLER - 4.0L and 4.7L

NOTE: Due to the design of the 4.0L and 4.7L

engine water pumps, testing the pump for a loose

impeller must be done by verifying coolant flow in

the radiator. To accomplish this refer to the follow-

ing procedure.

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.(1) Drain coolant until the first row of cores is vis-

ible in the radiator (Refer to 7 - COOLING - STAN-

DARD PROCEDURE) 4.7L Engine or (Refer to 7 -

COOLING - STANDARD PROCEDURE) 4.0L

Engine.

(2) Leaving the radiator cap off, start the engine.

Run engine until thermostat opens.

(3) While looking into the radiator through the

radiator fill neck, raise engine rpm to 2000 RPM.

Observe the flow of coolant from the first row of

cores.

(4) If there is no flow or very little flow visable,

replace the water pump.

INSPECTING FOR INLET RESTRICTIONS

Inadequate heater performance may be caused by

a metal casting restriction in the heater hose inlet.

DO NOT WASTE reusable coolant. If solution is

clean, drain the coolant into a clean container for

reuse.

Fig. 42 Water Pump and Timing Chain Cover

1 - INTEGRAL WATER PUMP PULLEY

2 - TIMING CHAIN COVER

3 - THERMOSTAT HOUSING

4 - HEATER HOSE FITTINGS

5 - WATER PUMP

Fig. 43 Water/Coolant Bypass Flow and Thermostat

1 - FROM HEATER

2 - FROM RADIATOR

3 - TO WATER PUMP

4 - ENGINE BYPASS

5 - THERMOSTAT

7 - 48 ENGINEWJ

WATER PUMP - 4.7L (Continued)

Page 280 of 2199

AUDIO

TABLE OF CONTENTS

page page

AUDIO

DESCRIPTION..........................2

OPERATION............................3

DIAGNOSIS AND TESTING - AUDIO..........3

SPECIAL TOOLS

AUDIO SYSTEMS......................6

AMPLIFIER

DESCRIPTION..........................6

OPERATION............................6

DIAGNOSIS AND TESTING - AMPLIFIER......6

REMOVAL.............................6

INSTALLATION..........................6

ANTENNA BODY & CABLE

DESCRIPTION..........................7

OPERATION............................7

DIAGNOSIS AND TESTING - ANTENNA BODY

AND CABLE..........................7

REMOVAL.............................9

INSTALLATION.........................10

ANTENNA MODULE - EXPORT

DESCRIPTION.........................10

OPERATION...........................11

DIAGNOSIS AND TESTING - ANTENNA

MODULE - EXPORT....................11

REMOVAL.............................12

INSTALLATION.........................12

CD CHANGER

DESCRIPTION.........................12

OPERATION...........................13

DIAGNOSIS AND TESTING - CD CHANGER . . . 13

REMOVAL.............................14

INSTALLATION.........................14

INSTRUMENT PANEL ANTENNA CABLE

REMOVAL.............................15

INSTALLATION.........................15

QUARTER GLASS INTEGRAL ANTENNA -

EXPORT

DESCRIPTION.........................16

OPERATION...........................16

DIAGNOSIS AND TESTING - QUARTER

GLASS INTEGRAL ANTENNA - EXPORT....16RADIO

DESCRIPTION.........................16

OPERATION...........................16

DIAGNOSIS AND TESTING - RADIO.........16

REMOVAL.............................17

INSTALLATION.........................18

RADIO NOISE SUPPRESSION GROUND STRAP

DESCRIPTION.........................18

REMOVAL

REMOVAL - ENGINE-TO-BODY GROUND

STRAP.............................18

REMOVAL - EXHAUST-TO-BODY GROUND

STRAP.............................19

INSTALLATION

INSTALLATION - ENGINE TO BODY

GROUND STRAP......................19

INSTALLATION - EXHAUST-TO-BODY

GROUND STRAP......................19

REMOTE SWITCHES

DESCRIPTION.........................19

OPERATION...........................20

DIAGNOSIS AND TESTING - REMOTE

SWITCHES..........................20

REMOVAL.............................21

INSTALLATION.........................21

SPEAKER

DESCRIPTION.........................22

OPERATION...........................22

DIAGNOSIS AND TESTING - SPEAKER......23

REMOVAL

REAR DOOR SPEAKER................24

INSTRUMENT PANEL SPEAKER..........24

FRONT DOOR SPEAKER...............24

INSTALLATION

INSTALLATION - REAR DOOR SPEAKER . . . 25

INSTALLATION - INSTRUMENT PANEL

SPEAKER...........................25

INSTALLATION - FRONT DOOR SPEAKER . . 25

WJAUDIO 8A - 1

Page 281 of 2199

AUDIO

DESCRIPTION

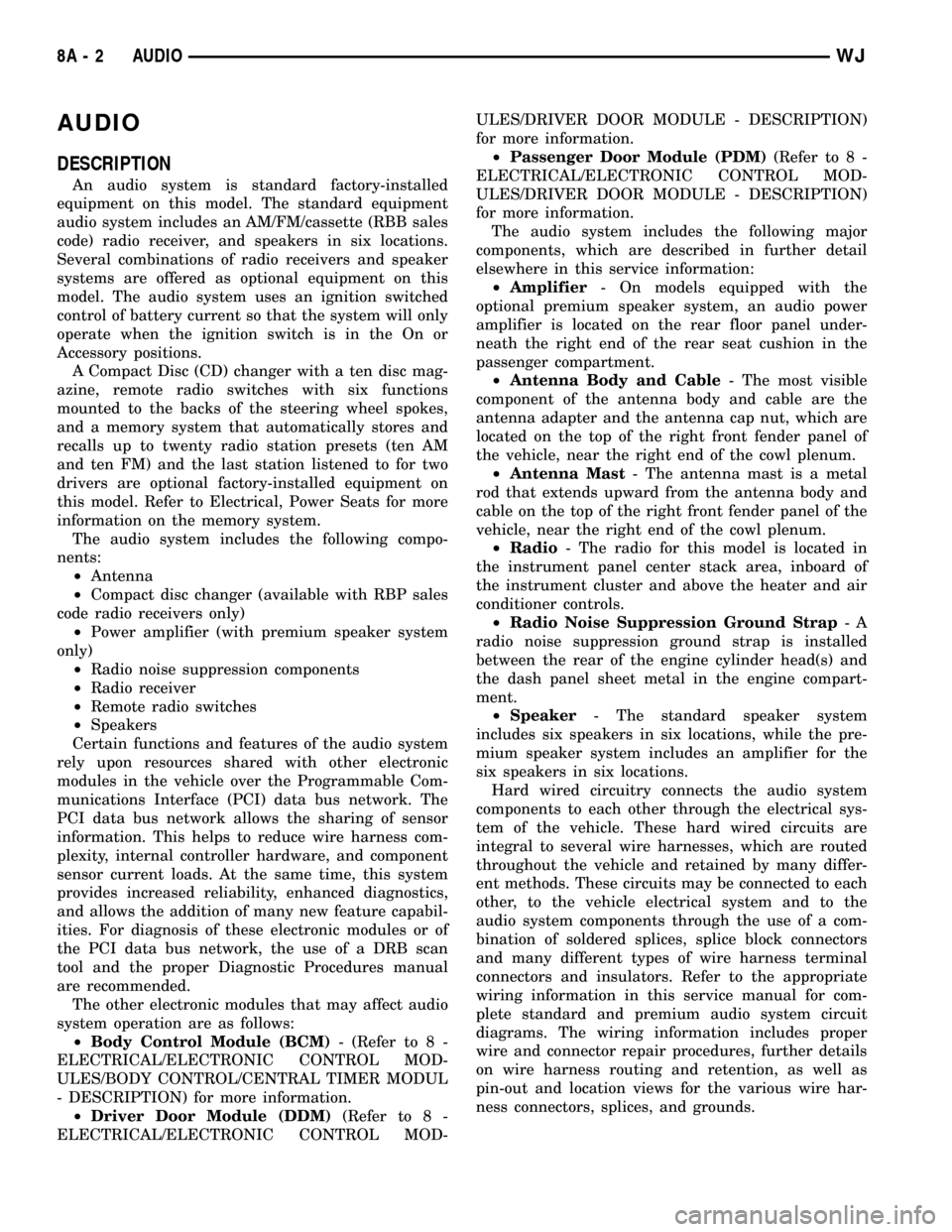

An audio system is standard factory-installed

equipment on this model. The standard equipment

audio system includes an AM/FM/cassette (RBB sales

code) radio receiver, and speakers in six locations.

Several combinations of radio receivers and speaker

systems are offered as optional equipment on this

model. The audio system uses an ignition switched

control of battery current so that the system will only

operate when the ignition switch is in the On or

Accessory positions.

A Compact Disc (CD) changer with a ten disc mag-

azine, remote radio switches with six functions

mounted to the backs of the steering wheel spokes,

and a memory system that automatically stores and

recalls up to twenty radio station presets (ten AM

and ten FM) and the last station listened to for two

drivers are optional factory-installed equipment on

this model. Refer to Electrical, Power Seats for more

information on the memory system.

The audio system includes the following compo-

nents:

²Antenna

²Compact disc changer (available with RBP sales

code radio receivers only)

²Power amplifier (with premium speaker system

only)

²Radio noise suppression components

²Radio receiver

²Remote radio switches

²Speakers

Certain functions and features of the audio system

rely upon resources shared with other electronic

modules in the vehicle over the Programmable Com-

munications Interface (PCI) data bus network. The

PCI data bus network allows the sharing of sensor

information. This helps to reduce wire harness com-

plexity, internal controller hardware, and component

sensor current loads. At the same time, this system

provides increased reliability, enhanced diagnostics,

and allows the addition of many new feature capabil-

ities. For diagnosis of these electronic modules or of

the PCI data bus network, the use of a DRB scan

tool and the proper Diagnostic Procedures manual

are recommended.

The other electronic modules that may affect audio

system operation are as follows:

²Body Control Module (BCM)- (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/BODY CONTROL/CENTRAL TIMER MODUL

- DESCRIPTION) for more information.

²Driver Door Module (DDM)(Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-ULES/DRIVER DOOR MODULE - DESCRIPTION)

for more information.

²Passenger Door Module (PDM)(Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/DRIVER DOOR MODULE - DESCRIPTION)

for more information.

The audio system includes the following major

components, which are described in further detail

elsewhere in this service information:

²Amplifier- On models equipped with the

optional premium speaker system, an audio power

amplifier is located on the rear floor panel under-

neath the right end of the rear seat cushion in the

passenger compartment.

²Antenna Body and Cable- The most visible

component of the antenna body and cable are the

antenna adapter and the antenna cap nut, which are

located on the top of the right front fender panel of

the vehicle, near the right end of the cowl plenum.

²Antenna Mast- The antenna mast is a metal

rod that extends upward from the antenna body and

cable on the top of the right front fender panel of the

vehicle, near the right end of the cowl plenum.

²Radio- The radio for this model is located in

the instrument panel center stack area, inboard of

the instrument cluster and above the heater and air

conditioner controls.

²Radio Noise Suppression Ground Strap-A

radio noise suppression ground strap is installed

between the rear of the engine cylinder head(s) and

the dash panel sheet metal in the engine compart-

ment.

²Speaker- The standard speaker system

includes six speakers in six locations, while the pre-

mium speaker system includes an amplifier for the

six speakers in six locations.

Hard wired circuitry connects the audio system

components to each other through the electrical sys-

tem of the vehicle. These hard wired circuits are

integral to several wire harnesses, which are routed

throughout the vehicle and retained by many differ-

ent methods. These circuits may be connected to each

other, to the vehicle electrical system and to the

audio system components through the use of a com-

bination of soldered splices, splice block connectors

and many different types of wire harness terminal

connectors and insulators. Refer to the appropriate

wiring information in this service manual for com-

plete standard and premium audio system circuit

diagrams. The wiring information includes proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices, and grounds.

8A - 2 AUDIOWJ

Page 287 of 2199

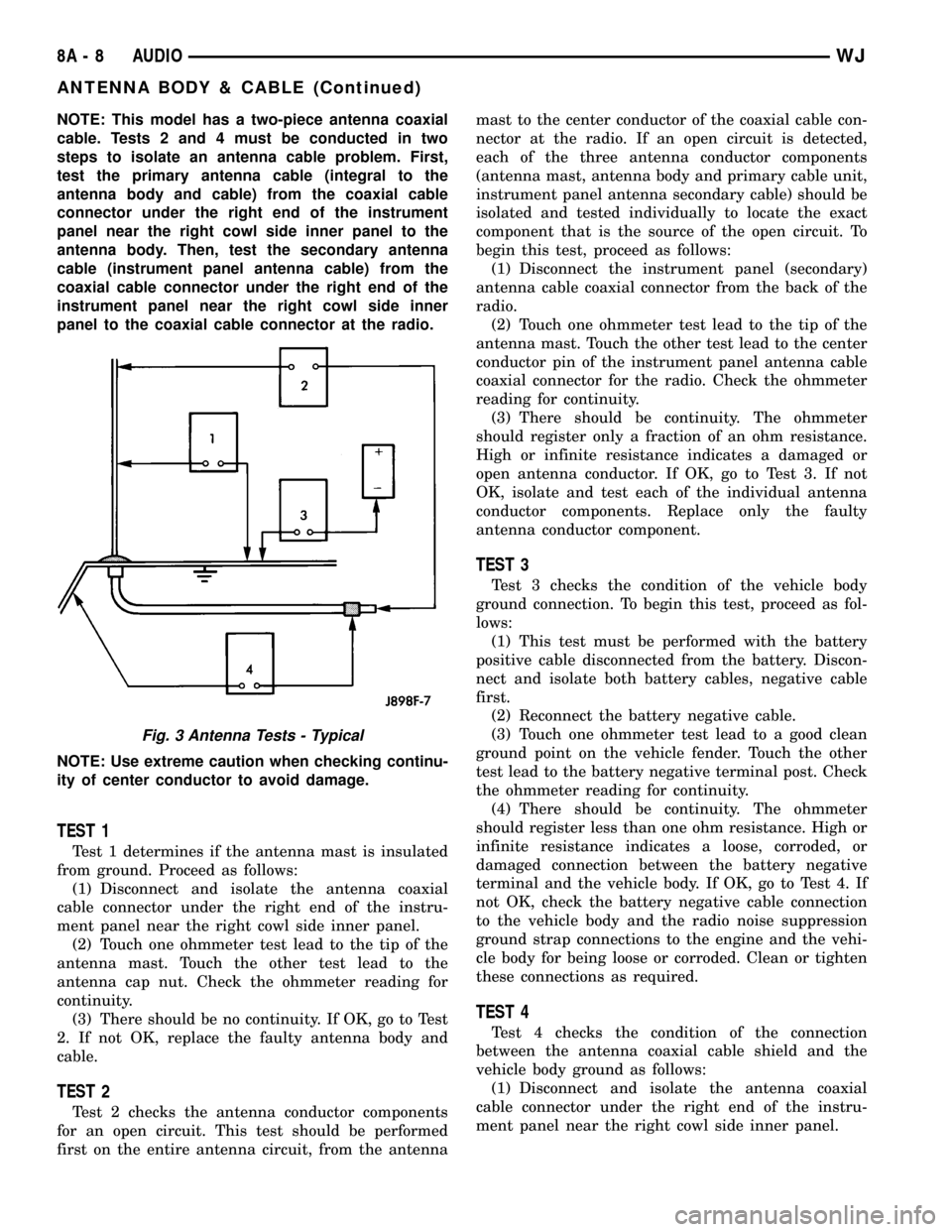

NOTE: This model has a two-piece antenna coaxial

cable. Tests 2 and 4 must be conducted in two

steps to isolate an antenna cable problem. First,

test the primary antenna cable (integral to the

antenna body and cable) from the coaxial cable

connector under the right end of the instrument

panel near the right cowl side inner panel to the

antenna body. Then, test the secondary antenna

cable (instrument panel antenna cable) from the

coaxial cable connector under the right end of the

instrument panel near the right cowl side inner

panel to the coaxial cable connector at the radio.

NOTE: Use extreme caution when checking continu-

ity of center conductor to avoid damage.

TEST 1

Test 1 determines if the antenna mast is insulated

from ground. Proceed as follows:

(1) Disconnect and isolate the antenna coaxial

cable connector under the right end of the instru-

ment panel near the right cowl side inner panel.

(2) Touch one ohmmeter test lead to the tip of the

antenna mast. Touch the other test lead to the

antenna cap nut. Check the ohmmeter reading for

continuity.

(3) There should be no continuity. If OK, go to Test

2. If not OK, replace the faulty antenna body and

cable.

TEST 2

Test 2 checks the antenna conductor components

for an open circuit. This test should be performed

first on the entire antenna circuit, from the antennamast to the center conductor of the coaxial cable con-

nector at the radio. If an open circuit is detected,

each of the three antenna conductor components

(antenna mast, antenna body and primary cable unit,

instrument panel antenna secondary cable) should be

isolated and tested individually to locate the exact

component that is the source of the open circuit. To

begin this test, proceed as follows:

(1) Disconnect the instrument panel (secondary)

antenna cable coaxial connector from the back of the

radio.

(2) Touch one ohmmeter test lead to the tip of the

antenna mast. Touch the other test lead to the center

conductor pin of the instrument panel antenna cable

coaxial connector for the radio. Check the ohmmeter

reading for continuity.

(3) There should be continuity. The ohmmeter

should register only a fraction of an ohm resistance.

High or infinite resistance indicates a damaged or

open antenna conductor. If OK, go to Test 3. If not

OK, isolate and test each of the individual antenna

conductor components. Replace only the faulty

antenna conductor component.

TEST 3

Test 3 checks the condition of the vehicle body

ground connection. To begin this test, proceed as fol-

lows:

(1) This test must be performed with the battery

positive cable disconnected from the battery. Discon-

nect and isolate both battery cables, negative cable

first.

(2) Reconnect the battery negative cable.

(3) Touch one ohmmeter test lead to a good clean

ground point on the vehicle fender. Touch the other

test lead to the battery negative terminal post. Check

the ohmmeter reading for continuity.

(4) There should be continuity. The ohmmeter

should register less than one ohm resistance. High or

infinite resistance indicates a loose, corroded, or

damaged connection between the battery negative

terminal and the vehicle body. If OK, go to Test 4. If

not OK, check the battery negative cable connection

to the vehicle body and the radio noise suppression

ground strap connections to the engine and the vehi-

cle body for being loose or corroded. Clean or tighten

these connections as required.

TEST 4

Test 4 checks the condition of the connection

between the antenna coaxial cable shield and the

vehicle body ground as follows:

(1) Disconnect and isolate the antenna coaxial

cable connector under the right end of the instru-

ment panel near the right cowl side inner panel.

Fig. 3 Antenna Tests - Typical

8A - 8 AUDIOWJ

ANTENNA BODY & CABLE (Continued)

Page 289 of 2199

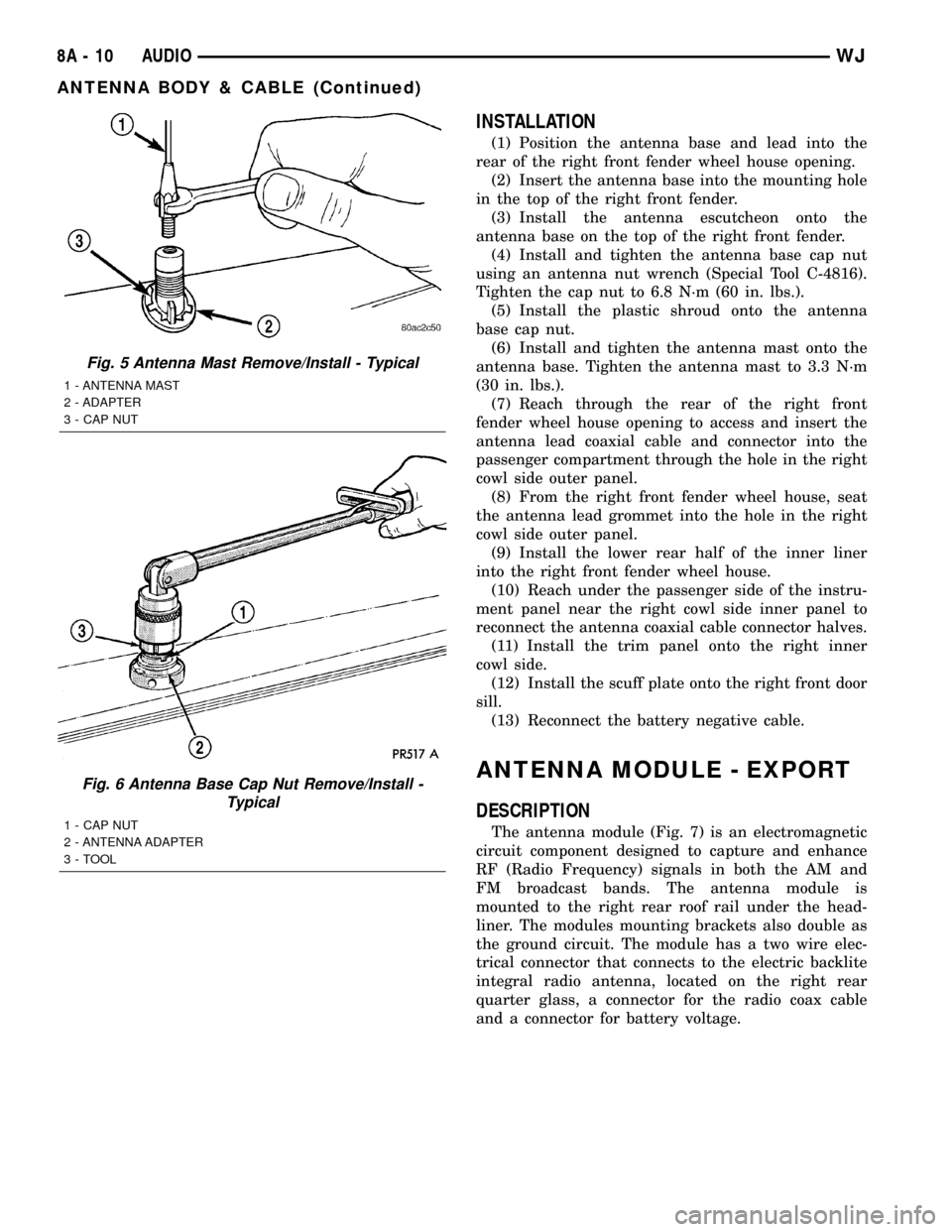

INSTALLATION

(1) Position the antenna base and lead into the

rear of the right front fender wheel house opening.

(2) Insert the antenna base into the mounting hole

in the top of the right front fender.

(3) Install the antenna escutcheon onto the

antenna base on the top of the right front fender.

(4) Install and tighten the antenna base cap nut

using an antenna nut wrench (Special Tool C-4816).

Tighten the cap nut to 6.8 N´m (60 in. lbs.).

(5) Install the plastic shroud onto the antenna

base cap nut.

(6) Install and tighten the antenna mast onto the

antenna base. Tighten the antenna mast to 3.3 N´m

(30 in. lbs.).

(7) Reach through the rear of the right front

fender wheel house opening to access and insert the

antenna lead coaxial cable and connector into the

passenger compartment through the hole in the right

cowl side outer panel.

(8) From the right front fender wheel house, seat

the antenna lead grommet into the hole in the right

cowl side outer panel.

(9) Install the lower rear half of the inner liner

into the right front fender wheel house.

(10) Reach under the passenger side of the instru-

ment panel near the right cowl side inner panel to

reconnect the antenna coaxial cable connector halves.

(11) Install the trim panel onto the right inner

cowl side.

(12) Install the scuff plate onto the right front door

sill.

(13) Reconnect the battery negative cable.

ANTENNA MODULE - EXPORT

DESCRIPTION

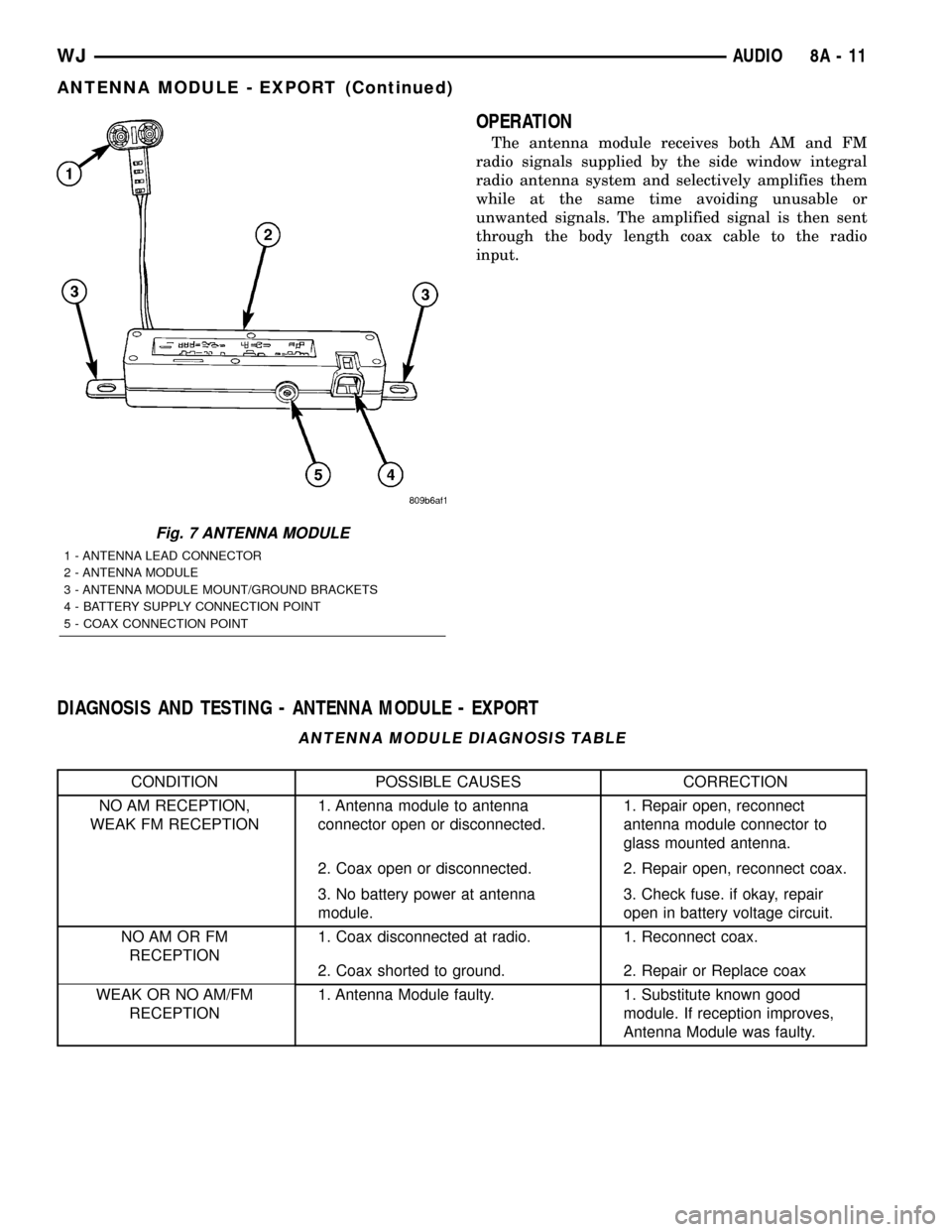

The antenna module (Fig. 7) is an electromagnetic

circuit component designed to capture and enhance

RF (Radio Frequency) signals in both the AM and

FM broadcast bands. The antenna module is

mounted to the right rear roof rail under the head-

liner. The modules mounting brackets also double as

the ground circuit. The module has a two wire elec-

trical connector that connects to the electric backlite

integral radio antenna, located on the right rear

quarter glass, a connector for the radio coax cable

and a connector for battery voltage.

Fig. 5 Antenna Mast Remove/Install - Typical

1 - ANTENNA MAST

2 - ADAPTER

3 - CAP NUT

Fig. 6 Antenna Base Cap Nut Remove/Install -

Typical

1 - CAP NUT

2 - ANTENNA ADAPTER

3 - TOOL

8A - 10 AUDIOWJ

ANTENNA BODY & CABLE (Continued)

Page 290 of 2199

OPERATION

The antenna module receives both AM and FM

radio signals supplied by the side window integral

radio antenna system and selectively amplifies them

while at the same time avoiding unusable or

unwanted signals. The amplified signal is then sent

through the body length coax cable to the radio

input.

DIAGNOSIS AND TESTING - ANTENNA MODULE - EXPORT

ANTENNA MODULE DIAGNOSIS TABLE

CONDITION POSSIBLE CAUSES CORRECTION

NO AM RECEPTION,

WEAK FM RECEPTION1. Antenna module to antenna

connector open or disconnected.1. Repair open, reconnect

antenna module connector to

glass mounted antenna.

2. Coax open or disconnected. 2. Repair open, reconnect coax.

3. No battery power at antenna

module.3. Check fuse. if okay, repair

open in battery voltage circuit.

NO AM OR FM

RECEPTION1. Coax disconnected at radio. 1. Reconnect coax.

2. Coax shorted to ground. 2. Repair or Replace coax

WEAK OR NO AM/FM

RECEPTION1. Antenna Module faulty. 1. Substitute known good

module. If reception improves,

Antenna Module was faulty.

Fig. 7 ANTENNA MODULE

1 - ANTENNA LEAD CONNECTOR

2 - ANTENNA MODULE

3 - ANTENNA MODULE MOUNT/GROUND BRACKETS

4 - BATTERY SUPPLY CONNECTION POINT

5 - COAX CONNECTION POINT

WJAUDIO 8A - 11

ANTENNA MODULE - EXPORT (Continued)

Page 291 of 2199

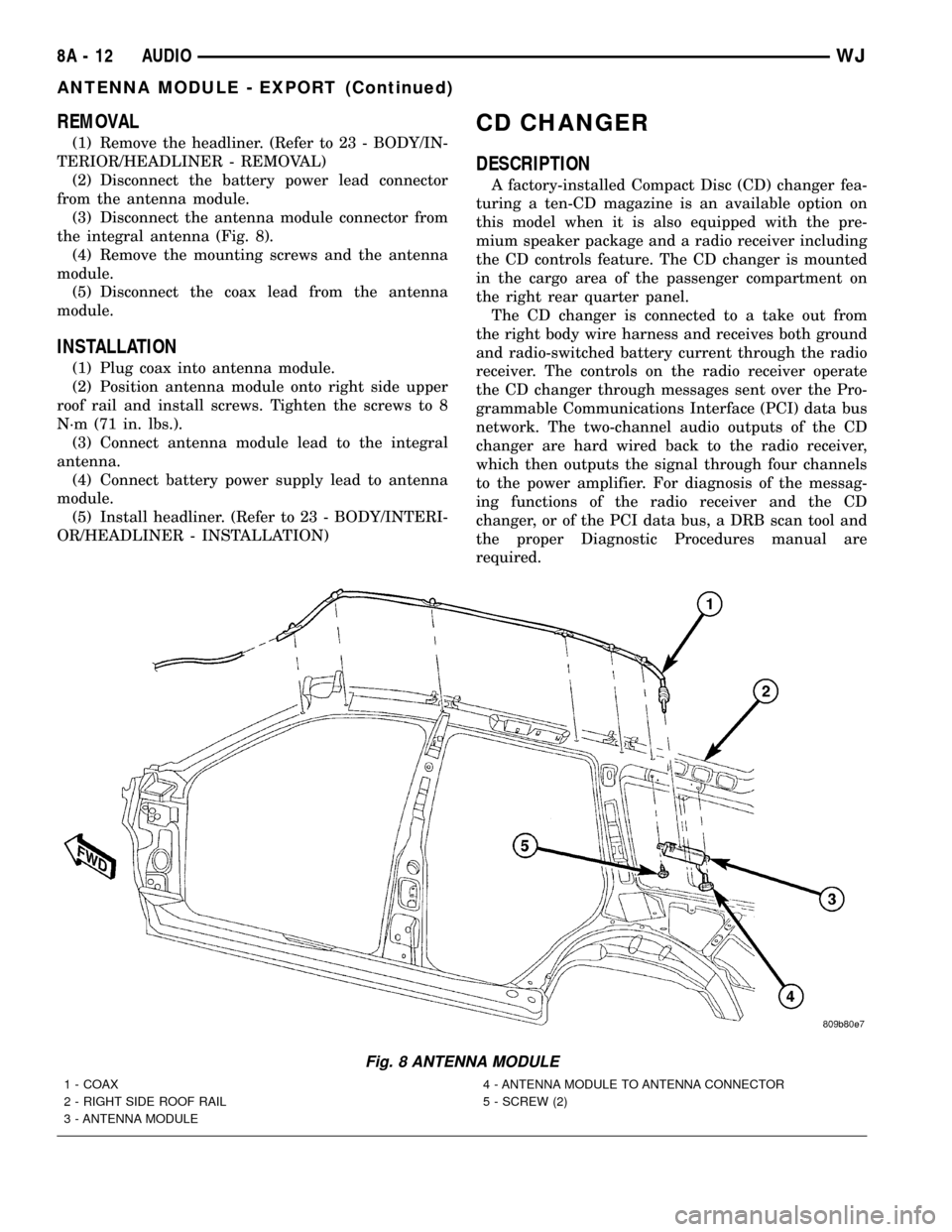

REMOVAL

(1) Remove the headliner. (Refer to 23 - BODY/IN-

TERIOR/HEADLINER - REMOVAL)

(2) Disconnect the battery power lead connector

from the antenna module.

(3) Disconnect the antenna module connector from

the integral antenna (Fig. 8).

(4) Remove the mounting screws and the antenna

module.

(5) Disconnect the coax lead from the antenna

module.

INSTALLATION

(1) Plug coax into antenna module.

(2) Position antenna module onto right side upper

roof rail and install screws. Tighten the screws to 8

N´m (71 in. lbs.).

(3) Connect antenna module lead to the integral

antenna.

(4) Connect battery power supply lead to antenna

module.

(5) Install headliner. (Refer to 23 - BODY/INTERI-

OR/HEADLINER - INSTALLATION)

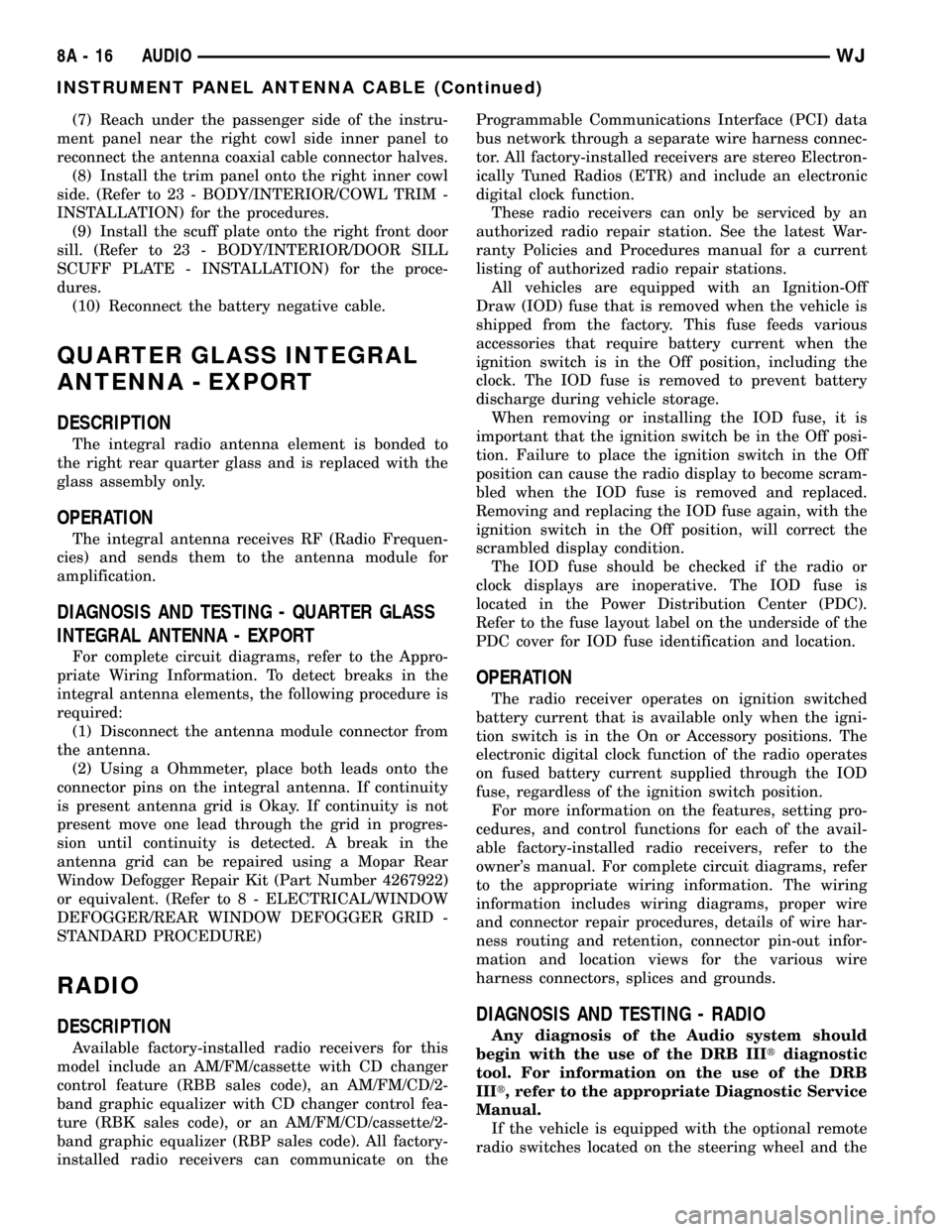

CD CHANGER

DESCRIPTION

A factory-installed Compact Disc (CD) changer fea-

turing a ten-CD magazine is an available option on

this model when it is also equipped with the pre-

mium speaker package and a radio receiver including

the CD controls feature. The CD changer is mounted

in the cargo area of the passenger compartment on

the right rear quarter panel.

The CD changer is connected to a take out from

the right body wire harness and receives both ground

and radio-switched battery current through the radio

receiver. The controls on the radio receiver operate

the CD changer through messages sent over the Pro-

grammable Communications Interface (PCI) data bus

network. The two-channel audio outputs of the CD

changer are hard wired back to the radio receiver,

which then outputs the signal through four channels

to the power amplifier. For diagnosis of the messag-

ing functions of the radio receiver and the CD

changer, or of the PCI data bus, a DRB scan tool and

the proper Diagnostic Procedures manual are

required.

Fig. 8 ANTENNA MODULE

1 - COAX

2 - RIGHT SIDE ROOF RAIL

3 - ANTENNA MODULE4 - ANTENNA MODULE TO ANTENNA CONNECTOR

5 - SCREW (2)

8A - 12 AUDIOWJ

ANTENNA MODULE - EXPORT (Continued)

Page 295 of 2199

(7) Reach under the passenger side of the instru-

ment panel near the right cowl side inner panel to

reconnect the antenna coaxial cable connector halves.

(8) Install the trim panel onto the right inner cowl

side. (Refer to 23 - BODY/INTERIOR/COWL TRIM -

INSTALLATION) for the procedures.

(9) Install the scuff plate onto the right front door

sill. (Refer to 23 - BODY/INTERIOR/DOOR SILL

SCUFF PLATE - INSTALLATION) for the proce-

dures.

(10) Reconnect the battery negative cable.

QUARTER GLASS INTEGRAL

ANTENNA - EXPORT

DESCRIPTION

The integral radio antenna element is bonded to

the right rear quarter glass and is replaced with the

glass assembly only.

OPERATION

The integral antenna receives RF (Radio Frequen-

cies) and sends them to the antenna module for

amplification.

DIAGNOSIS AND TESTING - QUARTER GLASS

INTEGRAL ANTENNA - EXPORT

For complete circuit diagrams, refer to the Appro-

priate Wiring Information. To detect breaks in the

integral antenna elements, the following procedure is

required:

(1) Disconnect the antenna module connector from

the antenna.

(2) Using a Ohmmeter, place both leads onto the

connector pins on the integral antenna. If continuity

is present antenna grid is Okay. If continuity is not

present move one lead through the grid in progres-

sion until continuity is detected. A break in the

antenna grid can be repaired using a Mopar Rear

Window Defogger Repair Kit (Part Number 4267922)

or equivalent. (Refer to 8 - ELECTRICAL/WINDOW

DEFOGGER/REAR WINDOW DEFOGGER GRID -

STANDARD PROCEDURE)

RADIO

DESCRIPTION

Available factory-installed radio receivers for this

model include an AM/FM/cassette with CD changer

control feature (RBB sales code), an AM/FM/CD/2-

band graphic equalizer with CD changer control fea-

ture (RBK sales code), or an AM/FM/CD/cassette/2-

band graphic equalizer (RBP sales code). All factory-

installed radio receivers can communicate on theProgrammable Communications Interface (PCI) data

bus network through a separate wire harness connec-

tor. All factory-installed receivers are stereo Electron-

ically Tuned Radios (ETR) and include an electronic

digital clock function.

These radio receivers can only be serviced by an

authorized radio repair station. See the latest War-

ranty Policies and Procedures manual for a current

listing of authorized radio repair stations.

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is removed when the vehicle is

shipped from the factory. This fuse feeds various

accessories that require battery current when the

ignition switch is in the Off position, including the

clock. The IOD fuse is removed to prevent battery

discharge during vehicle storage.

When removing or installing the IOD fuse, it is

important that the ignition switch be in the Off posi-

tion. Failure to place the ignition switch in the Off

position can cause the radio display to become scram-

bled when the IOD fuse is removed and replaced.

Removing and replacing the IOD fuse again, with the

ignition switch in the Off position, will correct the

scrambled display condition.

The IOD fuse should be checked if the radio or

clock displays are inoperative. The IOD fuse is

located in the Power Distribution Center (PDC).

Refer to the fuse layout label on the underside of the

PDC cover for IOD fuse identification and location.

OPERATION

The radio receiver operates on ignition switched

battery current that is available only when the igni-

tion switch is in the On or Accessory positions. The

electronic digital clock function of the radio operates

on fused battery current supplied through the IOD

fuse, regardless of the ignition switch position.

For more information on the features, setting pro-

cedures, and control functions for each of the avail-

able factory-installed radio receivers, refer to the

owner's manual. For complete circuit diagrams, refer

to the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, details of wire har-

ness routing and retention, connector pin-out infor-

mation and location views for the various wire

harness connectors, splices and grounds.

DIAGNOSIS AND TESTING - RADIO

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

If the vehicle is equipped with the optional remote

radio switches located on the steering wheel and the

8A - 16 AUDIOWJ

INSTRUMENT PANEL ANTENNA CABLE (Continued)