Engine wiring JEEP GRAND CHEROKEE 2002 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 360 of 2199

STARTING

TABLE OF CONTENTS

page page

STARTING

DESCRIPTION.........................29

OPERATION...........................30

DIAGNOSIS AND TESTING - STARTING

SYSTEM............................30

SPECIFICATIONS

TORQUE - STARTER...................35

STARTER MOTOR - GAS POWERED......35

STARTER MOTOR

DESCRIPTION.........................35

OPERATION...........................36DIAGNOSIS AND TESTING - STARTER

MOTOR .............................36

REMOVAL.............................37

INSTALLATION.........................38

STARTER MOTOR RELAY

DESCRIPTION.........................38

OPERATION...........................38

DIAGNOSIS AND TESTING - STARTER RELAY . 38

REMOVAL.............................39

INSTALLATION.........................40

STARTING

DESCRIPTION

An electrically operated engine starting system is

standard factory-installed equipment on this model.

The starting system is designed to provide the vehi-

cle operator with a convenient, efficient and reliable

means of cranking and starting the internal combus-

tion engine used to power the vehicle and all of its

accessory systems from within the safe and secure

confines of the passenger compartment. See the own-

er's manual in the vehicle glove box for more infor-

mation and instructions on the recommended use

and operation of the factory-installed starting sys-

tem.

The starting system consists of the following com-

ponents:

²Battery

²Starter relay

²Starter motor (including an integral starter sole-

noid)

²Ignition switch

²Park/neutral position switch

²Wire harnesses and connections (including the

battery cables).

This group provides complete service information

for the starter motor and the starter relay. Complete

service information for the other starting system

components can be located as follows:

²Refer toBatteryin the proper section of Group

8A - Battery for complete service information for the

battery.

²Refer toIgnition Switch and Key Lock Cyl-

inderin the proper section of Group 8D - Ignition

System for complete service information for the igni-

tion switch.²Refer toPark/Neutral Position Switchin the

proper section of Group 21 - Transmission for com-

plete service information for the park/neutral posi-

tion switch.

²Refer to the proper section ofGroup 8W - Wir-

ing Diagramsfor complete service information and

circuit diagrams for the starting system wiring com-

ponents.

Group 8A covers the Battery, Group 8B covers the

Starting Systems, and Group 8C covers the Charging

System. We have separated these systems to make it

easier to locate the information you are seeking

within this Service Manual. However, when attempt-

ing to diagnose any of these systems, it is important

that you keep their interdependency in mind.

The battery, starting, and charging systems in the

vehicle operate with one another, and must be tested

as a complete system. In order for the vehicle to start

and charge properly, all of the components that are

used in these systems must perform within specifica-

tions.

The diagnostic procedures used in each of these

groups include the most basic conventional diagnostic

methods, to the more sophisticated On-Board Diag-

nostics (OBD) built into the Powertrain Control Mod-

ule (PCM). Use of an induction-type milliampere

ammeter, volt/ohmmeter, battery charger, carbon pile

rheostat (load tester), and 12-volt test lamp may be

required.

All OBD-sensed systems are monitored by the

PCM. Each monitored circuit is assigned a Diagnos-

tic Trouble Code (DTC). The PCM will store a DTC in

electronic memory for any failure it detects. Refer to

On-Board Diagnostic Test For Charging System

in the Diagnosis and Testing section of Group 8C -

Charging System for more information.

WJSTARTING 8F - 29

Page 362 of 2199

Starting System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS TO

OPERATE.1. Battery discharged or

faulty.1. Refer to Battery in the Diagnosis and Testing section of

Group 8A - Battery. Charge or replace the battery, if

required.

2. Starting circuit wiring

faulty.2. Refer to Starting System in Group 8W - Wiring

Diagrams. Test and repair the starter feed and/or control

circuits, if required.

3. Starter relay faulty. 3. Refer to Starter Relay in the Diagnosis and Testing

section of this group. Replace the starter relay, if

required.

4. Ignition switch faulty. 4. Refer to Ignition Switch and Key Lock Cylinder in the

Diagnosis and Testing section of Group 8D - Ignition

System. Replace the ignition switch, if required.

5. Park/Neutral position

switch faulty or

misadjusted.5. Refer to Park/Neutral Position Switch in the Diagnosis

and Testing section of Group 21 - Transmission. Replace

the park/neutral position switch, if required.

6. Starter solenoid faulty. 6. Refer to Starter Motor in the Diagnosis and Testing

section of this group. Replace the starter motor assembly,

if required.

7. Starter motor faulty. 7. If all other starting system components and circuits test

OK, replace the starter motor assembly.

STARTER ENGAGES,

FAILS TO TURN

ENGINE.1. Battery discharged or

faulty.1. Refer to Battery in the Diagnosis and Testing section of

Group 8A - Battery. Charge or replace the battery, if

required.

2. Starting circuit wiring

faulty.2. Refer to Starting System in Group 8W - Wiring

Diagrams. Test and repair the starter feed and/or control

circuits, if required.

3. Starter motor faulty. 3. If all other starting system components and circuits test

OK, replace the starter motor assembly.

4. Engine seized. 4. Refer to Engine Diagnosis in the Diagnosis and Testing

section of Group 9 - Engine.

STARTER ENGAGES,

SPINS OUT BEFORE

ENGINE STARTS.1. Starter ring gear faulty. 1. Refer to Starter Motor in the Removal and Installation

section of this group. Remove the starter motor to inspect

the starter ring gear. Replace the starter ring gear, if

required.

2. Starter motor faulty. 2. If all other starting system components and circuits test

OK, replace the starter motor assembly.

STARTER DOES NOT

DISENGAGE.1. Starter motor

improperly installed.1. Refer to Starter Motor in the Removal and Installation

section of this group. Tighten the starter mounting

hardware to the correct tightness specifications.

2. Starter relay faulty. 2. Refer to Starter Relay in the Diagnosis and Testing

section of this group. Replace the starter relay, if

required.

3. Ignition switch faulty. 3. Refer to Ignition Switch and Key Lock Cylinder in the

Diagnosis and Testing section of Group 8D - Ignition

System. Replace the ignition switch, if required.

4. Starter motor faulty. 4. If all other starting system components and circuits test

OK, replace the starter motor assembly.

WJSTARTING 8F - 31

STARTING (Continued)

Page 363 of 2199

INSPECTION

For complete circuit diagrams, refer toStarting

Systemin the Contents of Group 8W - Wiring Dia-

grams. Before removing any unit from the starting

system for repair or diagnosis, perform the following

inspections:

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

²Battery- Visually inspect the battery for indi-

cations of physical damage and loose or corroded

cable connections. Determine the state-of-charge and

cranking capacity of the battery. Charge or replace

the battery, if required. Refer toBatteryin the

proper section of Group 8A - Battery for complete ser-

vice information for the battery.

²Ignition Switch- Visually inspect the ignition

switch for indications of physical damage and loose

or corroded wire harness connections. Refer toIgni-

tion Switch and Key Lock Cylinderin the proper

section of Group 8D - Ignition System for complete

service information for the ignition switch.

²Park/Neutral Position Switch- Visually

inspect the park/neutral position switch for indica-

tions of physical damage and loose or corroded wire

harness connections. Refer toPark/Neutral Posi-

tion Switchin the proper section of Group 21 -

Transmission for complete service information for the

park/neutral position switch.

²Starter Relay- Visually inspect the starter

relay for indications of physical damage and loose or

corroded wire harness connections.

²Starter Motor- Visually inspect the starter

motor for indications of physical damage and loose or

corroded wire harness connections.

²Starter Solenoid- Visually inspect the starter

solenoid for indications of physical damage and loose

or corroded wire harness connections.

²Wiring- Visually inspect the wire harnesses for

damage. Repair or replace any faulty wiring, as

required. Refer to the proper section ofGroup 8W -

Wiring Diagramsfor complete service information

and circuit diagrams for the starting system wiring

components.TESTING

COLD CRANKING TEST

For complete circuit diagrams, refer toStarting

Systemin the Contents of Group 8W - Wiring Dia-

grams. The battery must be fully-charged and load-

tested before proceeding. Refer toBatteryin the

Diagnosis and Testing section of Group 8A - Battery

for the procedures.

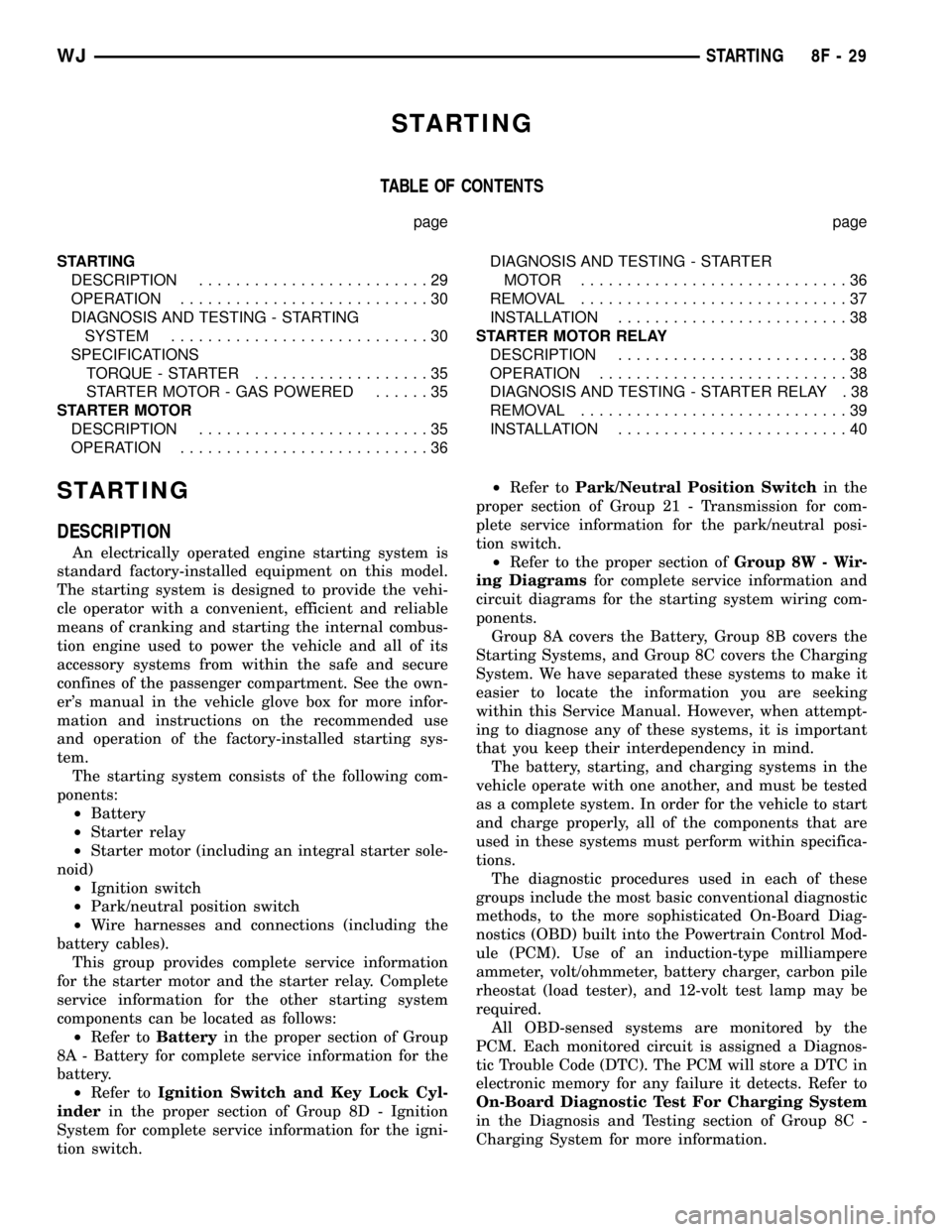

(1) Connect a suitable volt-ampere tester to the

battery terminals (Fig. 1). See the instructions pro-

vided by the manufacturer of the volt-ampere tester

being used.

(2) Fully engage the parking brake.

(3) Place the automatic transmission gearshift

selector lever in the Park position.

(4) Verify that all lamps and accessories are

turned off.

(5) To prevent the engine from starting, remove

the Automatic ShutDown (ASD) relay. The ASD relay

is located in the Power Distribution Center (PDC), in

the engine compartment. Refer to the fuse and relay

layout label affixed to the underside of the PDC cover

for ASD relay identification and location.

(6) Rotate and hold the ignition switch in the Start

position. Note the cranking voltage and current

(amperage) draw readings shown on the volt-ampere

tester.

(a) If the voltage reads below 9.6 volts, refer to

Starter Motorin the Diagnosis and Testing sec-

tion of this group. If the starter motor is OK, refer

toEngine Diagnosisin the Diagnosis and Testing

section of Group 9 - Engine for further testing of

the engine. If the starter motor is not OK, replace

the faulty starter motor.

Fig. 1 Volts-Amps Tester Connections - Typical

1 - POSITIVE CLAMP

2 - NEGATIVE CLAMP

3 - INDUCTION AMMETER CLAMP

8F - 32 STARTINGWJ

STARTING (Continued)

Page 364 of 2199

(b) If the voltage reads above 9.6 volts and the

current (amperage) draw reads below specifica-

tions, refer toFeed Circuit Testin this section.

(c) If the voltage reads 12.5 volts or greater and

the starter motor does not turn, refer toControl

Circuit Testingin this section.

(d) If the voltage reads 12.5 volts or greater and

the starter motor turns very slowly, refer toFeed

Circuit Testin this section.

NOTE: A cold engine will increase the starter cur-

rent (amperage) draw reading, and reduce the bat-

tery voltage reading.

FEED CIRCUIT TEST

The starter feed circuit test (voltage drop method)

will determine if there is excessive resistance in the

high-amperage feed circuit. For complete circuit dia-

grams, refer toStarting Systemin the Contents of

Group 8W - Wiring Diagrams.

When performing these tests, it is important to

remember that the voltage drop is giving an indica-

tion of the resistance between the two points at

which the voltmeter probes are attached.

Example:When testing the resistance of the bat-

tery positive cable, touch the voltmeter leads to the

battery positive cable clamp and the cable connector

at the starter solenoid. If you probe the battery pos-

itive terminal post and the cable connector at the

starter solenoid, you are reading the combined volt-

age drop in the battery positive cable clamp-to-termi-

nal post connection and the battery positive cable.

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing the

tests, be certain that the following procedures are

accomplished:

²Battery is fully-charged and load-tested. Refer to

Batteryin the Diagnosis and Testing section of

Group 8A - Battery for the procedures.

²Fully engage the parking brake.

²Place the automatic transmission gearshift selec-

tor lever in the Park position.

²

Verify that all lamps and accessories are turned off.

²To prevent the engine from starting, remove the

Automatic ShutDown (ASD) relay. The ASD relay is

located in the Power Distribution Center (PDC), in

the engine compartment. Refer to the fuse and relay

layout label affixed to the underside of the PDC cover

for ASD relay identification and location.

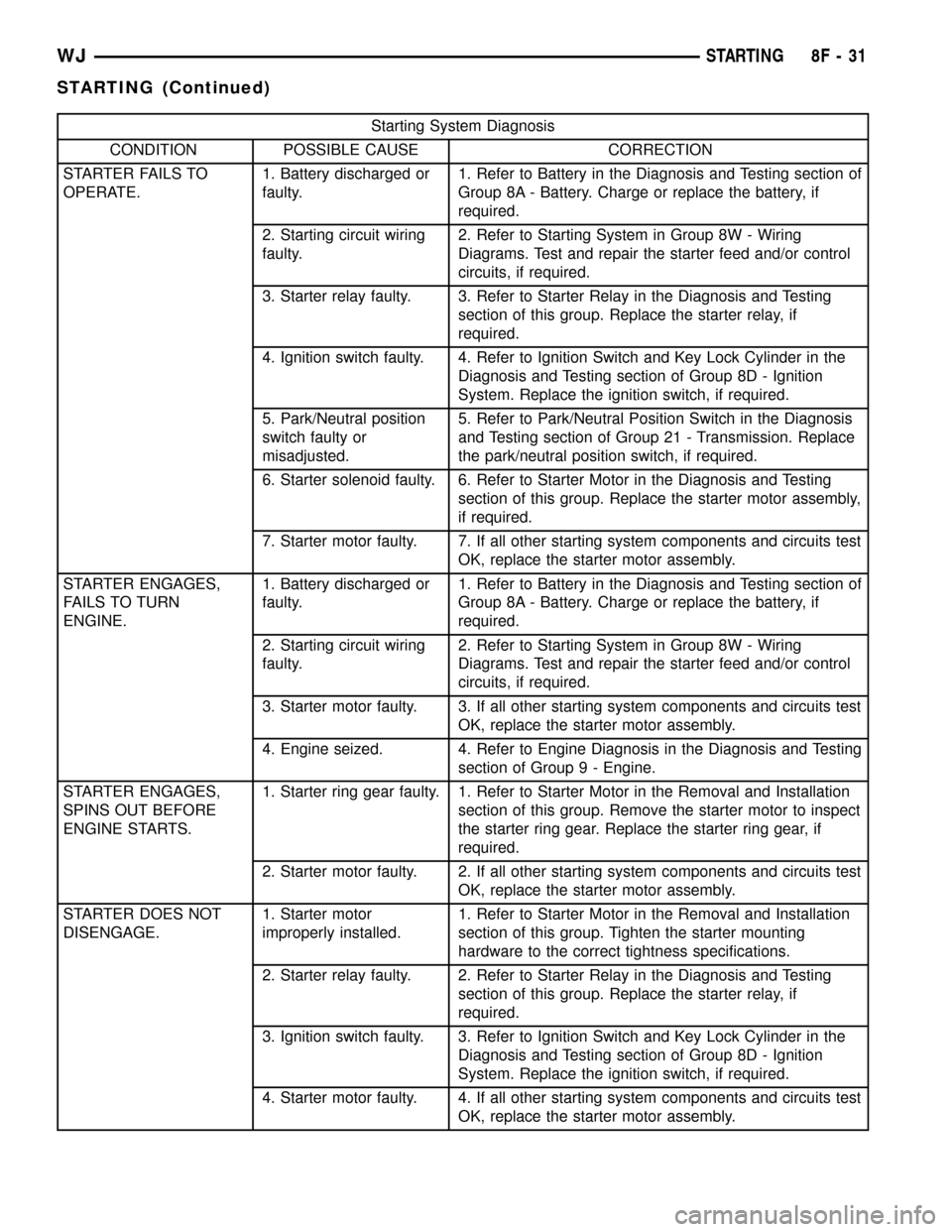

(1) Connect the positive lead of the voltmeter to

the battery negative terminal post. Connect the neg-

ative lead of the voltmeter to the battery negative

cable clamp (Fig. 2). Rotate and hold the ignition

switch in the Start position. Observe the voltmeter. If

voltage is detected, correct the poor contact between

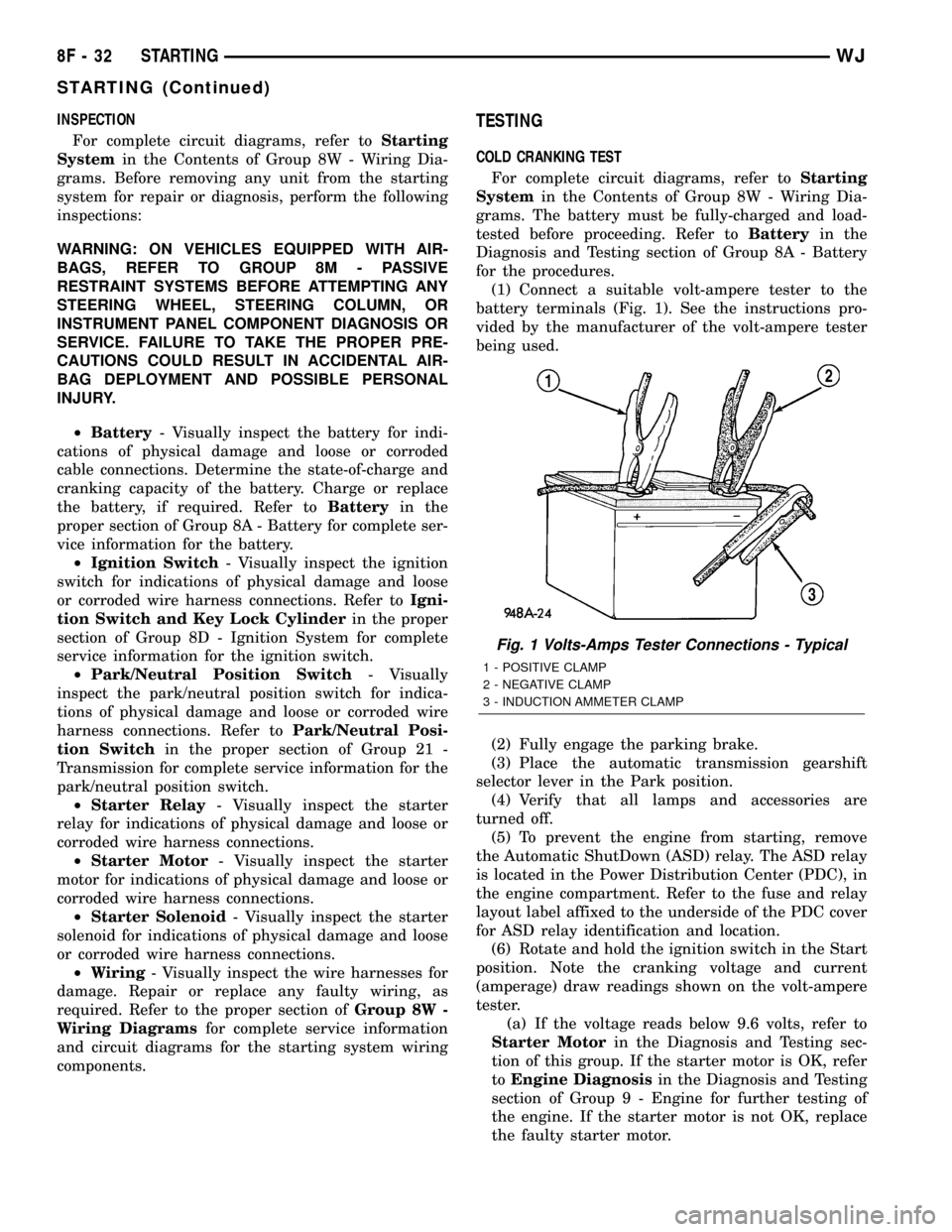

the cable clamp and the terminal post.(2) Connect the positive lead of the voltmeter to

the battery positive terminal post. Connect the nega-

tive lead of the voltmeter to the battery positive cable

clamp (Fig. 3). Rotate and hold the ignition switch in

the Start position. Observe the voltmeter. If voltage

is detected, correct the poor contact between the

cable clamp and the terminal post.

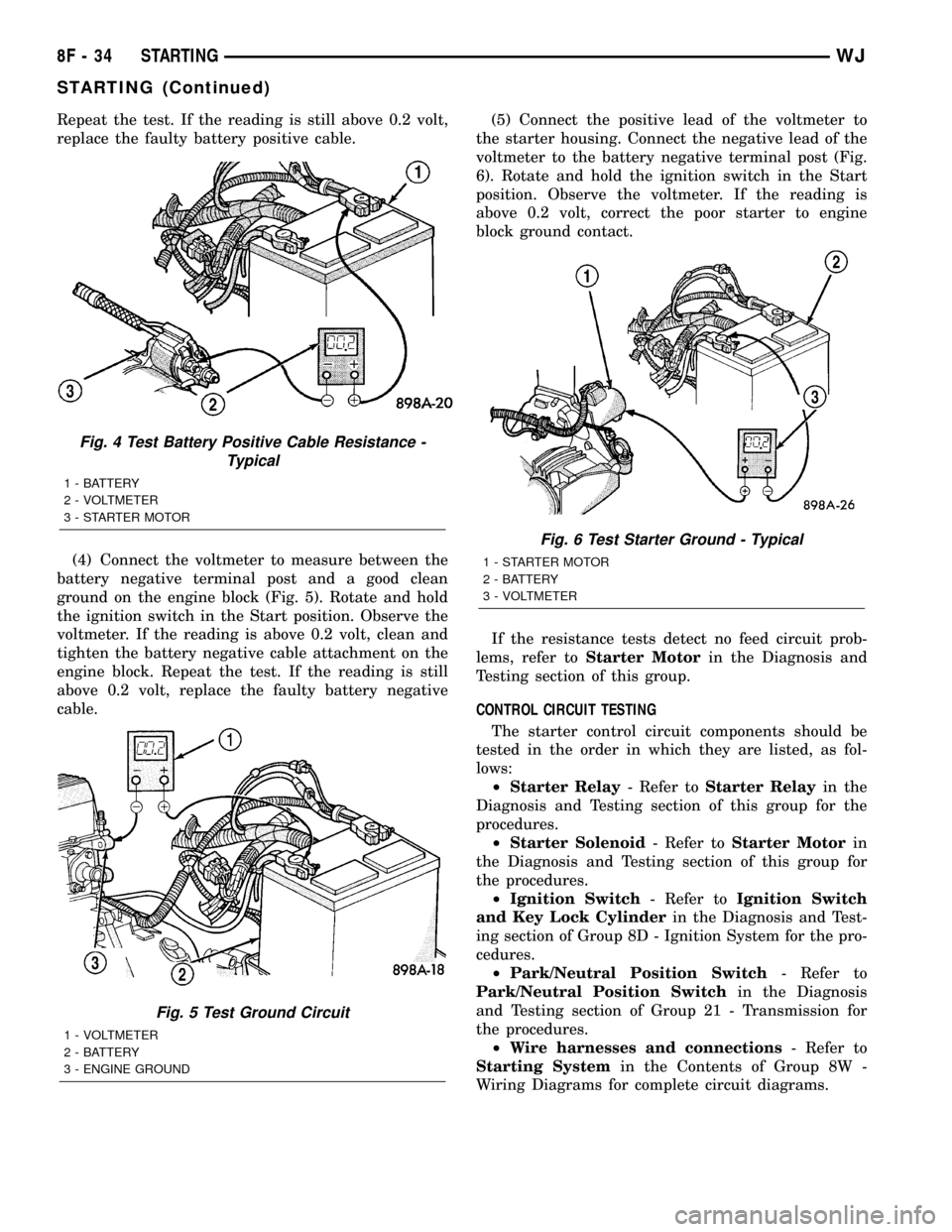

(3) Connect the voltmeter to measure between the

battery positive terminal post and the starter sole-

noid battery terminal stud (Fig. 4). Rotate and hold

the ignition switch in the Start position. Observe the

voltmeter. If the reading is above 0.2 volt, clean and

tighten the battery cable connection at the solenoid.

Fig. 2 Test Battery Negative Connection Resistance

- Typical

1 - VOLTMETER

2 - BATTERY

Fig. 3 Test Battery Positive Connection Resistance -

Typical

1 - VOLTMETER

2 - BATTERY

WJSTARTING 8F - 33

STARTING (Continued)

Page 365 of 2199

Repeat the test. If the reading is still above 0.2 volt,

replace the faulty battery positive cable.

(4) Connect the voltmeter to measure between the

battery negative terminal post and a good clean

ground on the engine block (Fig. 5). Rotate and hold

the ignition switch in the Start position. Observe the

voltmeter. If the reading is above 0.2 volt, clean and

tighten the battery negative cable attachment on the

engine block. Repeat the test. If the reading is still

above 0.2 volt, replace the faulty battery negative

cable.(5) Connect the positive lead of the voltmeter to

the starter housing. Connect the negative lead of the

voltmeter to the battery negative terminal post (Fig.

6). Rotate and hold the ignition switch in the Start

position. Observe the voltmeter. If the reading is

above 0.2 volt, correct the poor starter to engine

block ground contact.

If the resistance tests detect no feed circuit prob-

lems, refer toStarter Motorin the Diagnosis and

Testing section of this group.

CONTROL CIRCUIT TESTING

The starter control circuit components should be

tested in the order in which they are listed, as fol-

lows:

²Starter Relay- Refer toStarter Relayin the

Diagnosis and Testing section of this group for the

procedures.

²Starter Solenoid- Refer toStarter Motorin

the Diagnosis and Testing section of this group for

the procedures.

²Ignition Switch- Refer toIgnition Switch

and Key Lock Cylinderin the Diagnosis and Test-

ing section of Group 8D - Ignition System for the pro-

cedures.

²Park/Neutral Position Switch- Refer to

Park/Neutral Position Switchin the Diagnosis

and Testing section of Group 21 - Transmission for

the procedures.

²Wire harnesses and connections- Refer to

Starting Systemin the Contents of Group 8W -

Wiring Diagrams for complete circuit diagrams.

Fig. 4 Test Battery Positive Cable Resistance -

Typical

1 - BATTERY

2 - VOLTMETER

3 - STARTER MOTOR

Fig. 5 Test Ground Circuit

1 - VOLTMETER

2 - BATTERY

3 - ENGINE GROUND

Fig. 6 Test Starter Ground - Typical

1 - STARTER MOTOR

2 - BATTERY

3 - VOLTMETER

8F - 34 STARTINGWJ

STARTING (Continued)

Page 369 of 2199

(8) Remove the starter motor from the engine com-

partment.

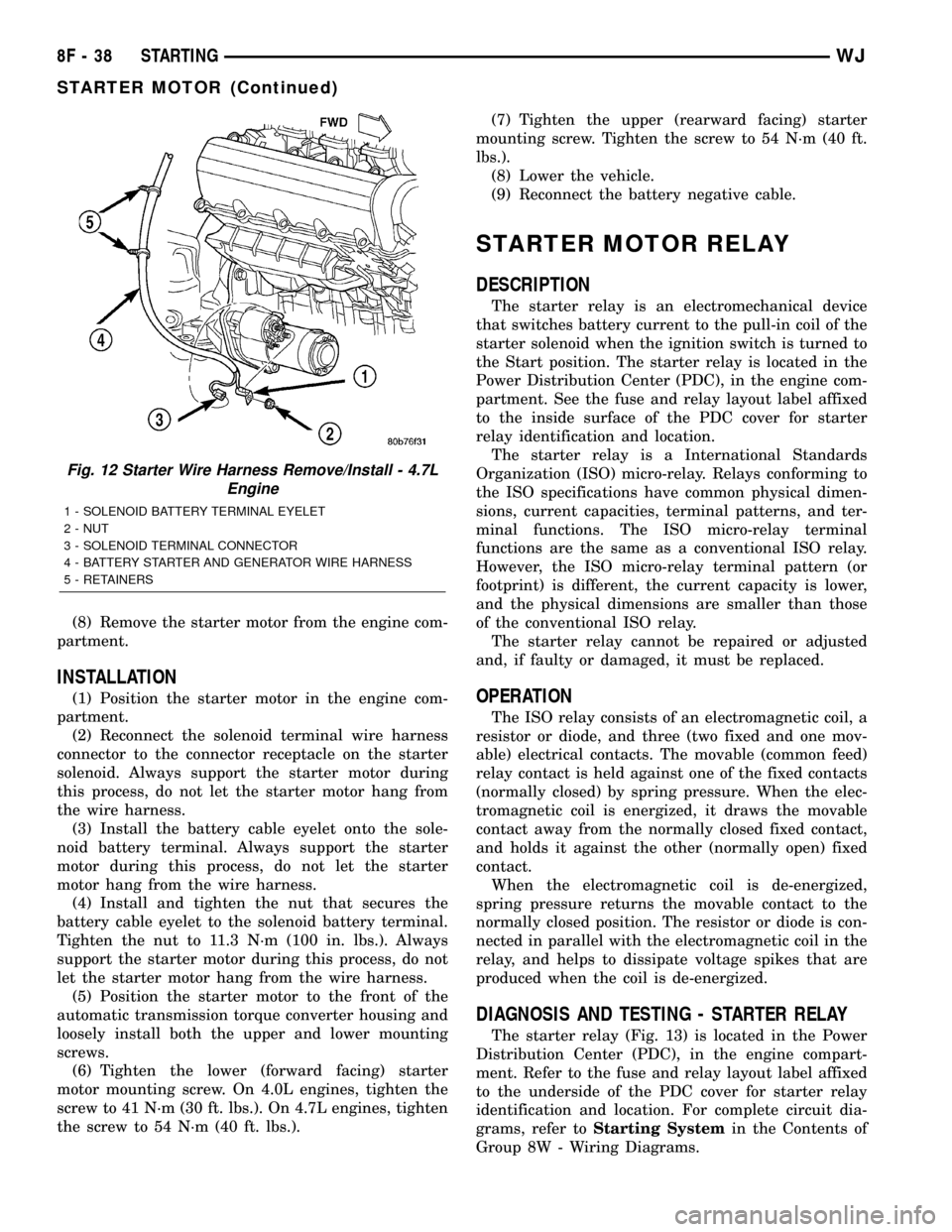

INSTALLATION

(1) Position the starter motor in the engine com-

partment.

(2) Reconnect the solenoid terminal wire harness

connector to the connector receptacle on the starter

solenoid. Always support the starter motor during

this process, do not let the starter motor hang from

the wire harness.

(3) Install the battery cable eyelet onto the sole-

noid battery terminal. Always support the starter

motor during this process, do not let the starter

motor hang from the wire harness.

(4) Install and tighten the nut that secures the

battery cable eyelet to the solenoid battery terminal.

Tighten the nut to 11.3 N´m (100 in. lbs.). Always

support the starter motor during this process, do not

let the starter motor hang from the wire harness.

(5) Position the starter motor to the front of the

automatic transmission torque converter housing and

loosely install both the upper and lower mounting

screws.

(6) Tighten the lower (forward facing) starter

motor mounting screw. On 4.0L engines, tighten the

screw to 41 N´m (30 ft. lbs.). On 4.7L engines, tighten

the screw to 54 N´m (40 ft. lbs.).(7) Tighten the upper (rearward facing) starter

mounting screw. Tighten the screw to 54 N´m (40 ft.

lbs.).

(8) Lower the vehicle.

(9) Reconnect the battery negative cable.

STARTER MOTOR RELAY

DESCRIPTION

The starter relay is an electromechanical device

that switches battery current to the pull-in coil of the

starter solenoid when the ignition switch is turned to

the Start position. The starter relay is located in the

Power Distribution Center (PDC), in the engine com-

partment. See the fuse and relay layout label affixed

to the inside surface of the PDC cover for starter

relay identification and location.

The starter relay is a International Standards

Organization (ISO) micro-relay. Relays conforming to

the ISO specifications have common physical dimen-

sions, current capacities, terminal patterns, and ter-

minal functions. The ISO micro-relay terminal

functions are the same as a conventional ISO relay.

However, the ISO micro-relay terminal pattern (or

footprint) is different, the current capacity is lower,

and the physical dimensions are smaller than those

of the conventional ISO relay.

The starter relay cannot be repaired or adjusted

and, if faulty or damaged, it must be replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact.

When the electromagnetic coil is de-energized,

spring pressure returns the movable contact to the

normally closed position. The resistor or diode is con-

nected in parallel with the electromagnetic coil in the

relay, and helps to dissipate voltage spikes that are

produced when the coil is de-energized.

DIAGNOSIS AND TESTING - STARTER RELAY

The starter relay (Fig. 13) is located in the Power

Distribution Center (PDC), in the engine compart-

ment. Refer to the fuse and relay layout label affixed

to the underside of the PDC cover for starter relay

identification and location. For complete circuit dia-

grams, refer toStarting Systemin the Contents of

Group 8W - Wiring Diagrams.

Fig. 12 Starter Wire Harness Remove/Install - 4.7L

Engine

1 - SOLENOID BATTERY TERMINAL EYELET

2 - NUT

3 - SOLENOID TERMINAL CONNECTOR

4 - BATTERY STARTER AND GENERATOR WIRE HARNESS

5 - RETAINERS

8F - 38 STARTINGWJ

STARTER MOTOR (Continued)

Page 393 of 2199

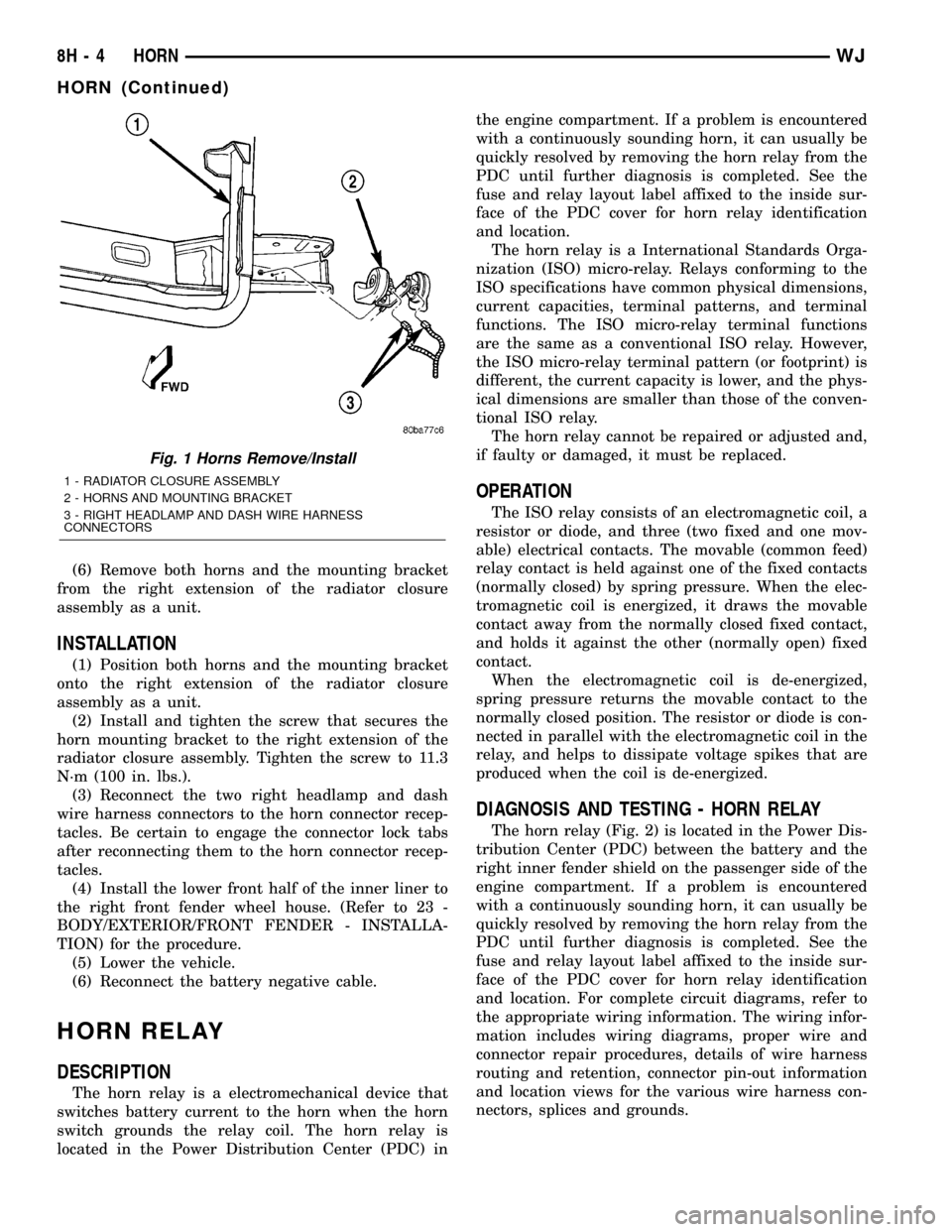

(6) Remove both horns and the mounting bracket

from the right extension of the radiator closure

assembly as a unit.

INSTALLATION

(1) Position both horns and the mounting bracket

onto the right extension of the radiator closure

assembly as a unit.

(2) Install and tighten the screw that secures the

horn mounting bracket to the right extension of the

radiator closure assembly. Tighten the screw to 11.3

N´m (100 in. lbs.).

(3) Reconnect the two right headlamp and dash

wire harness connectors to the horn connector recep-

tacles. Be certain to engage the connector lock tabs

after reconnecting them to the horn connector recep-

tacles.

(4) Install the lower front half of the inner liner to

the right front fender wheel house. (Refer to 23 -

BODY/EXTERIOR/FRONT FENDER - INSTALLA-

TION) for the procedure.

(5) Lower the vehicle.

(6) Reconnect the battery negative cable.

HORN RELAY

DESCRIPTION

The horn relay is a electromechanical device that

switches battery current to the horn when the horn

switch grounds the relay coil. The horn relay is

located in the Power Distribution Center (PDC) inthe engine compartment. If a problem is encountered

with a continuously sounding horn, it can usually be

quickly resolved by removing the horn relay from the

PDC until further diagnosis is completed. See the

fuse and relay layout label affixed to the inside sur-

face of the PDC cover for horn relay identification

and location.

The horn relay is a International Standards Orga-

nization (ISO) micro-relay. Relays conforming to the

ISO specifications have common physical dimensions,

current capacities, terminal patterns, and terminal

functions. The ISO micro-relay terminal functions

are the same as a conventional ISO relay. However,

the ISO micro-relay terminal pattern (or footprint) is

different, the current capacity is lower, and the phys-

ical dimensions are smaller than those of the conven-

tional ISO relay.

The horn relay cannot be repaired or adjusted and,

if faulty or damaged, it must be replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact.

When the electromagnetic coil is de-energized,

spring pressure returns the movable contact to the

normally closed position. The resistor or diode is con-

nected in parallel with the electromagnetic coil in the

relay, and helps to dissipate voltage spikes that are

produced when the coil is de-energized.

DIAGNOSIS AND TESTING - HORN RELAY

The horn relay (Fig. 2) is located in the Power Dis-

tribution Center (PDC) between the battery and the

right inner fender shield on the passenger side of the

engine compartment. If a problem is encountered

with a continuously sounding horn, it can usually be

quickly resolved by removing the horn relay from the

PDC until further diagnosis is completed. See the

fuse and relay layout label affixed to the inside sur-

face of the PDC cover for horn relay identification

and location. For complete circuit diagrams, refer to

the appropriate wiring information. The wiring infor-

mation includes wiring diagrams, proper wire and

connector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

Fig. 1 Horns Remove/Install

1 - RADIATOR CLOSURE ASSEMBLY

2 - HORNS AND MOUNTING BRACKET

3 - RIGHT HEADLAMP AND DASH WIRE HARNESS

CONNECTORS

8H - 4 HORNWJ

HORN (Continued)

Page 411 of 2199

The voltage signal produced by the knock sensor

increases with the amplitude of vibration. The PCM

receives the knock sensor voltage signal as an input.

If the signal rises above a predetermined level, the

PCM will store that value in memory and retard

ignition timing to reduce engine knock. If the knock

sensor voltage exceeds a preset value, the PCM

retards ignition timing for all cylinders. It is not a

selective cylinder retard.

The PCM ignores knock sensor input during engine

idle conditions. Once the engine speed exceeds a

specified value, knock retard is allowed.

Knock retard uses its own short term and long

term memory program.

Long term memory stores previous detonation

information in its battery-backed RAM. The maxi-

mum authority that long term memory has over tim-

ing retard can be calibrated.

Short term memory is allowed to retard timing up

to a preset amount under all operating conditions (as

long as rpm is above the minimum rpm) except at

Wide Open Throttle (WOT). The PCM, using short

term memory, can respond quickly to retard timing

when engine knock is detected. Short term memory

is lost any time the ignition key is turned off.

NOTE: Over or under tightening the sensor mount-

ing bolts will affect knock sensor performance, pos-

sibly causing improper spark control. Always use

the specified torque when installing the knock sen-

sors.

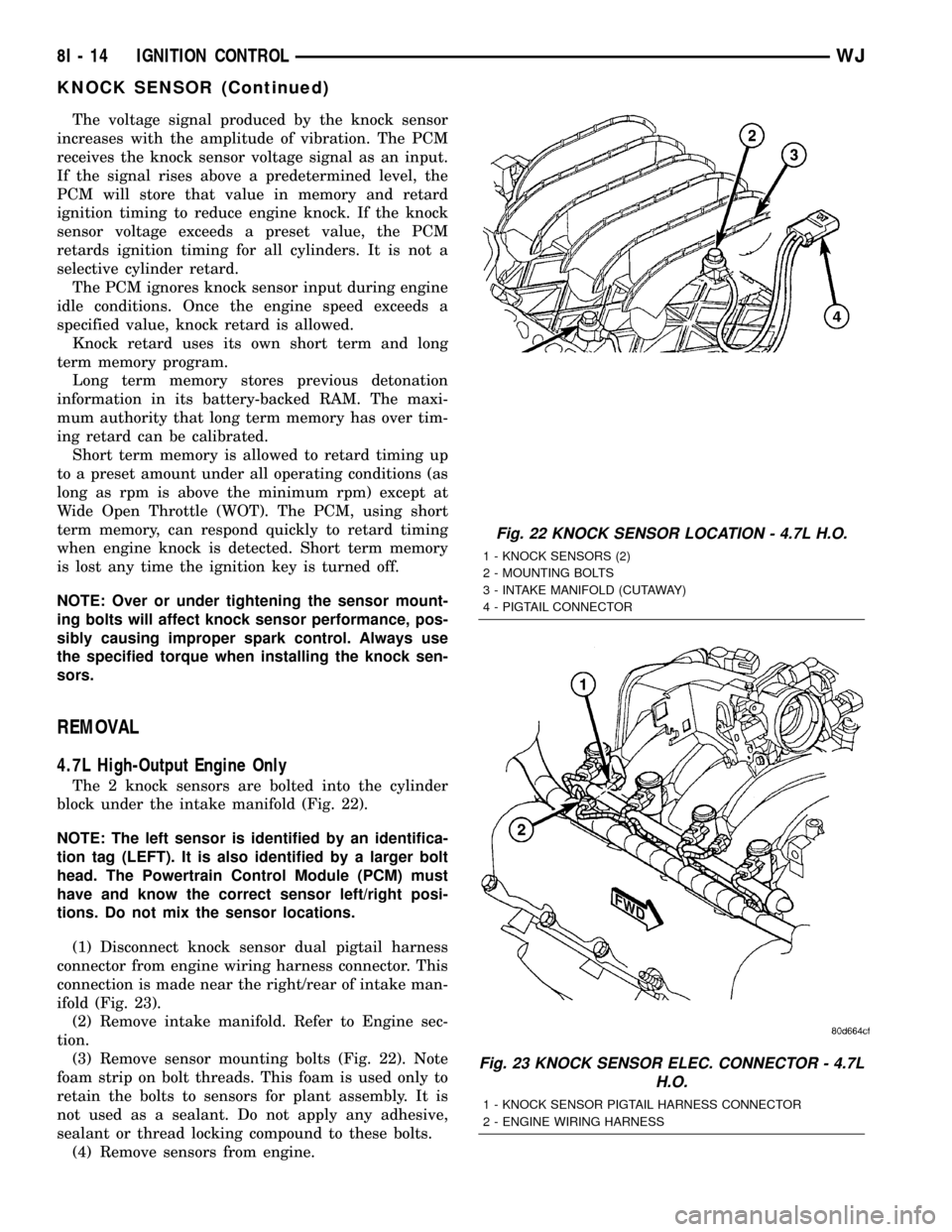

REMOVAL

4.7L High-Output Engine Only

The 2 knock sensors are bolted into the cylinder

block under the intake manifold (Fig. 22).

NOTE: The left sensor is identified by an identifica-

tion tag (LEFT). It is also identified by a larger bolt

head. The Powertrain Control Module (PCM) must

have and know the correct sensor left/right posi-

tions. Do not mix the sensor locations.

(1) Disconnect knock sensor dual pigtail harness

connector from engine wiring harness connector. This

connection is made near the right/rear of intake man-

ifold (Fig. 23).

(2) Remove intake manifold. Refer to Engine sec-

tion.

(3) Remove sensor mounting bolts (Fig. 22). Note

foam strip on bolt threads. This foam is used only to

retain the bolts to sensors for plant assembly. It is

not used as a sealant. Do not apply any adhesive,

sealant or thread locking compound to these bolts.

(4) Remove sensors from engine.

Fig. 22 KNOCK SENSOR LOCATION - 4.7L H.O.

1 - KNOCK SENSORS (2)

2 - MOUNTING BOLTS

3 - INTAKE MANIFOLD (CUTAWAY)

4 - PIGTAIL CONNECTOR

Fig. 23 KNOCK SENSOR ELEC. CONNECTOR - 4.7L

H.O.

1 - KNOCK SENSOR PIGTAIL HARNESS CONNECTOR

2 - ENGINE WIRING HARNESS

8I - 14 IGNITION CONTROLWJ

KNOCK SENSOR (Continued)

Page 412 of 2199

INSTALLATION

4.7L High-Output Engine Only

NOTE: The left sensor is identified by an identifica-

tion tag (LEFT). It is also identified by a larger bolt

head. The Powertrain Control Module (PCM) must

have and know the correct sensor left/right posi-

tions. Do not mix the sensor locations.

(1) Thoroughly clean knock sensor mounting holes.

(2) Install sensors (Fig. 22) into cylinder block.

NOTE: Over or under tightening the sensor mount-

ing bolts will affect knock sensor performance, pos-

sibly causing improper spark control. Always use

the specified torque when installing the knock sen-

sors. The torque for the knock senor bolt is rela-

tively light for an 8mm bolt.

NOTE: Note foam strip on bolt threads. This foam is

used only to retain the bolts to sensors for plant

assembly. It is not used as a sealant. Do not apply

any adhesive, sealant or thread locking compound

to these bolts.

(3) Install and tighten mounting bolts.Bolt

torque is critical.Refer to torque specification.

(4) Install intake manifold. Refer to Engine sec-

tion.

(5) Connect knock sensor pigtail wiring harness to

engine wiring harness near right / rear of intake

manifold (Fig. 23).

SPARK PLUG

DESCRIPTION

Both the 4.0L 6-cylinder and the 4.7L V-8 engine

use resistor type spark plugs. Standard 4.7L V-8

engines are equipped with ªfired in suppressor sealº

type spark plugs using a copper core ground elec-

trode. High-Output (H.O.) 4.7L V-8 engines are

equipped with unique plugs using a platinum rivet

located on the tip of the center electrode.

Because of the use of an aluminum cylinder head

on the 4.7L engine, spark plug torque is very critical.

To prevent possible pre-ignition and/or mechanical

engine damage, the correct type/heat range/number

spark plug must be used.Do not substitute any

other spark plug on the 4.7L H.O. engine. Seri-

ous engine damage may occur.

Plugs on both engines have resistance values rang-

ing from 6,000 to 20,000 ohms (when checked with at

least a 1000 volt spark plug tester).Do not use an

ohmmeter to check the resistance values of thespark plugs. Inaccurate readings will result.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. A sin-

gle plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Replace spark plugs at the intervals recommended in

Group O, Lubrication and Maintenance.

EXCEPT 4.7L H.O. ENGINE :Spark plugs that

have low mileage may be cleaned and reused if not

otherwise defective, carbon or oil fouled. Also refer to

Spark Plug Conditions.4.7L H.O. ENGINE :Never

clean spark plugs on the 4.7L H.O. engine. Damage

to the platinum rivet will result.

CAUTION: EXCEPT 4.7L H.O. ENGINE : Never use a

motorized wire wheel brush to clean the spark

plugs. Metallic deposits will remain on the spark

plug insulator and will cause plug misfire.

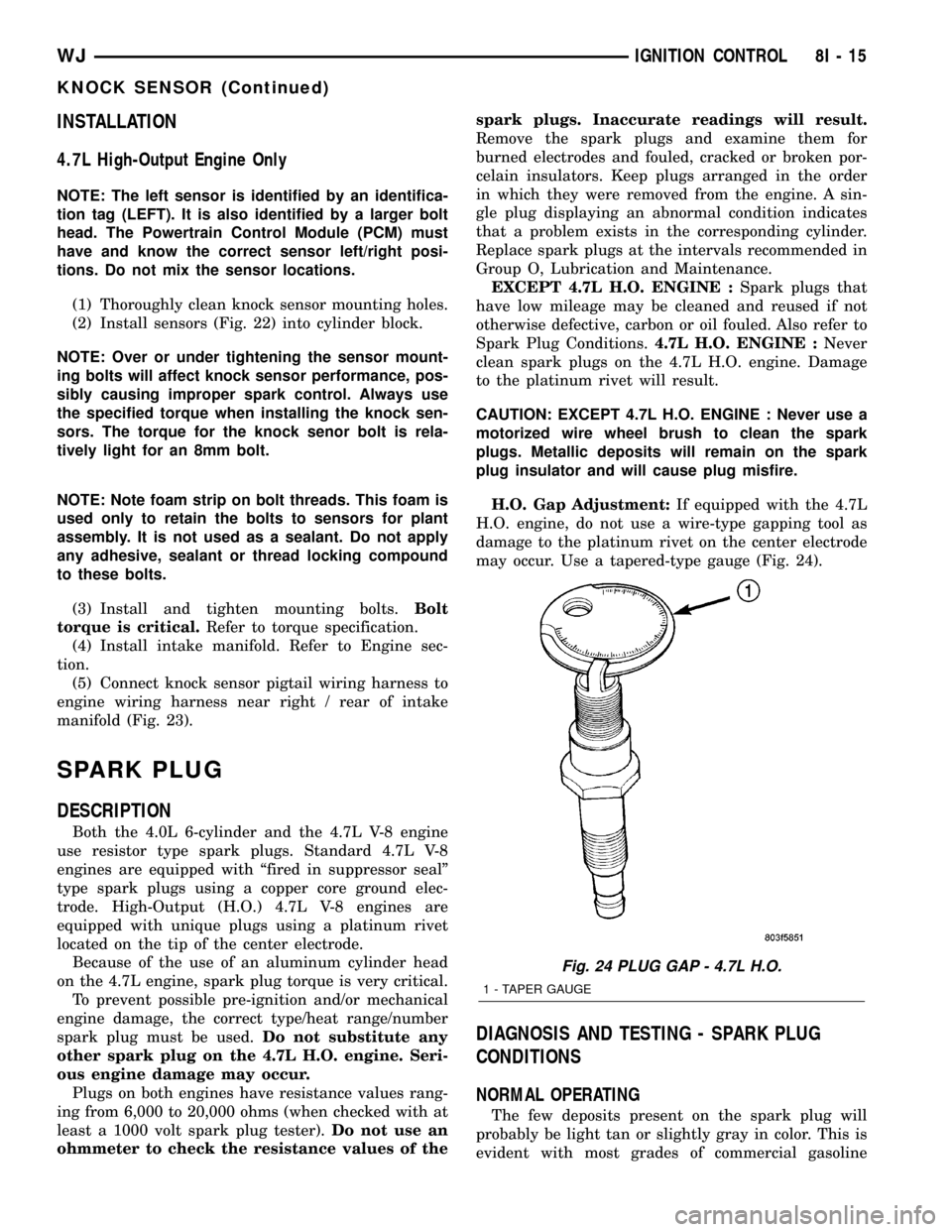

H.O. Gap Adjustment:If equipped with the 4.7L

H.O. engine, do not use a wire-type gapping tool as

damage to the platinum rivet on the center electrode

may occur. Use a tapered-type gauge (Fig. 24).

DIAGNOSIS AND TESTING - SPARK PLUG

CONDITIONS

NORMAL OPERATING

The few deposits present on the spark plug will

probably be light tan or slightly gray in color. This is

evident with most grades of commercial gasoline

Fig. 24 PLUG GAP - 4.7L H.O.

1 - TAPER GAUGE

WJIGNITION CONTROL 8I - 15

KNOCK SENSOR (Continued)

Page 418 of 2199

EMIC also uses several hard wired inputs in order to

perform its many functions. The EMIC module incor-

porates a blue-green digital Vacuum Fluorescent Dis-

play (VFD) for displaying odometer and trip

odometer information.

The EMIC houses six analog gauges and has pro-

visions for up to twenty indicators (Fig. 2). The

EMIC includes the following analog gauges:

²Coolant Temperature Gauge

²Fuel Gauge

²Oil Pressure Gauge

²Speedometer

²Tachometer

²Voltage Gauge

Some of the EMIC indicators are automatically

configured when the EMIC is connected to the vehi-

cle electrical system for compatibility with certain

optional equipment or equipment required for regula-

tory purposes in certain markets. While each EMIC

may have provisions for indicators to support every

available option, the configurable indicators will not

be functional in a vehicle that does not have the

equipment that an indicator supports. The EMIC

includes provisions for the following indicators (Fig.

2):

²Airbag Indicator (with Airbags only)

²Antilock Brake System (ABS) Indicator

²Brake Indicator

²Check Gauges Indicator

²Coolant Low Indicator (with Diesel Engine

only)

²Cruise Indicator

²Four-Wheel Drive Part Time Indicator

(with Selec-Trac NVG-242 Transfer Case only)

²Front Fog Lamp Indicator (with Front Fog

Lamps only)

²High Beam Indicator

²Low Fuel Indicator

²Malfunction Indicator Lamp (MIL)

²Overdrive-Off Indicator (except Diesel

Engine)

²Rear Fog Lamp Indicator (with Rear Fog

Lamps only)

²Seatbelt Indicator

²Sentry Key Immobilizer System (SKIS)

Indicator

²Transmission Overtemp Indicator (except

Diesel Engine)²Turn Signal (Right and Left) Indicators

²Wait-To-Start Indicator (with Diesel Engine

only)

²Water-In-Fuel Indicator (with Diesel Engine

only)

Many indicators in the EMIC are illuminated by a

dedicated Light Emitting Diode (LED) that is sol-

dered onto the EMIC electronic circuit board. The

LEDs are not available for service replacement and,

if damaged or faulty, the entire EMIC must be

replaced. Base cluster illumination is accomplished

by dimmable incandescent back lighting, which illu-

minates the gauges for visibility when the exterior

lighting is turned on. Premium cluster illumination

is accomplished by a dimmable electro-luminescent

lamp that is serviced only as a unit with the EMIC.

Each of the incandescent bulbs is secured by an inte-

gral bulb holder to the electronic circuit board from

the back of the cluster housing. The incandescent

bulb/bulb holder units are available for service

replacement.

Hard wired circuitry connects the EMIC to the

electrical system of the vehicle. These hard wired cir-

cuits are integral to several wire harnesses, which

are routed throughout the vehicle and retained by

many different methods. These circuits may be con-

nected to each other, to the vehicle electrical system

and to the EMIC through the use of a combination of

soldered splices, splice block connectors, and many

different types of wire harness terminal connectors

and insulators. Refer to the appropriate wiring infor-

mation. The wiring information includes wiring dia-

grams, proper wire and connector repair procedures,

further details on wire harness routing and reten-

tion, as well as pin-out and location views for the

various wire harness connectors, splices and grounds.

The EMIC modules for this model are serviced only

as complete units. The EMIC module cannot be

adjusted or repaired. If a gauge, an LED indicator,

the VFD, the electronic circuit board, the circuit

board hardware, the cluster overlay, the electro-lumi-

nescent lamp (premium model only) or the EMIC

housing are damaged or faulty, the entire EMIC mod-

ule must be replaced. The cluster lens, hood and

mask unit and the individual incandescent lamp

bulbs with holders are available for service replace-

ment.

WJINSTRUMENT CLUSTER 8J - 3

INSTRUMENT CLUSTER (Continued)