Engine wiring JEEP GRAND CHEROKEE 2002 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 463 of 2199

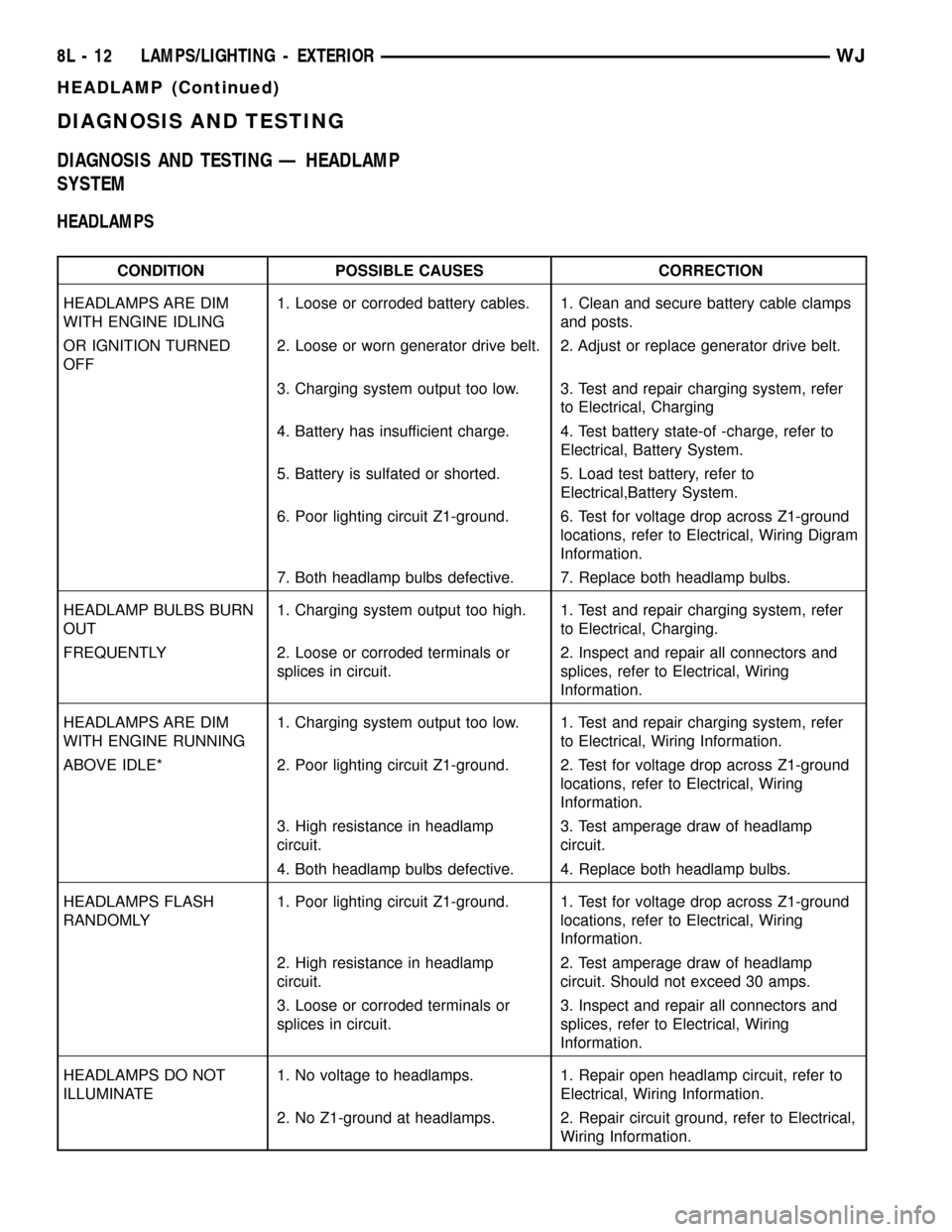

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING Ð HEADLAMP

SYSTEM

HEADLAMPS

CONDITION POSSIBLE CAUSES CORRECTION

HEADLAMPS ARE DIM

WITH ENGINE IDLING1. Loose or corroded battery cables. 1. Clean and secure battery cable clamps

and posts.

OR IGNITION TURNED

OFF2. Loose or worn generator drive belt. 2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system, refer

to Electrical, Charging

4. Battery has insufficient charge. 4. Test battery state-of -charge, refer to

Electrical, Battery System.

5. Battery is sulfated or shorted. 5. Load test battery, refer to

Electrical,Battery System.

6. Poor lighting circuit Z1-ground. 6. Test for voltage drop across Z1-ground

locations, refer to Electrical, Wiring Digram

Information.

7. Both headlamp bulbs defective. 7. Replace both headlamp bulbs.

HEADLAMP BULBS BURN

OUT1. Charging system output too high. 1. Test and repair charging system, refer

to Electrical, Charging.

FREQUENTLY 2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and

splices, refer to Electrical, Wiring

Information.

HEADLAMPS ARE DIM

WITH ENGINE RUNNING1. Charging system output too low. 1. Test and repair charging system, refer

to Electrical, Wiring Information.

ABOVE IDLE* 2. Poor lighting circuit Z1-ground. 2. Test for voltage drop across Z1-ground

locations, refer to Electrical, Wiring

Information.

3. High resistance in headlamp

circuit.3. Test amperage draw of headlamp

circuit.

4. Both headlamp bulbs defective. 4. Replace both headlamp bulbs.

HEADLAMPS FLASH

RANDOMLY1. Poor lighting circuit Z1-ground. 1. Test for voltage drop across Z1-ground

locations, refer to Electrical, Wiring

Information.

2. High resistance in headlamp

circuit.2. Test amperage draw of headlamp

circuit. Should not exceed 30 amps.

3. Loose or corroded terminals or

splices in circuit.3. Inspect and repair all connectors and

splices, refer to Electrical, Wiring

Information.

HEADLAMPS DO NOT

ILLUMINATE1. No voltage to headlamps. 1. Repair open headlamp circuit, refer to

Electrical, Wiring Information.

2. No Z1-ground at headlamps. 2. Repair circuit ground, refer to Electrical,

Wiring Information.

8L - 12 LAMPS/LIGHTING - EXTERIORWJ

HEADLAMP (Continued)

Page 464 of 2199

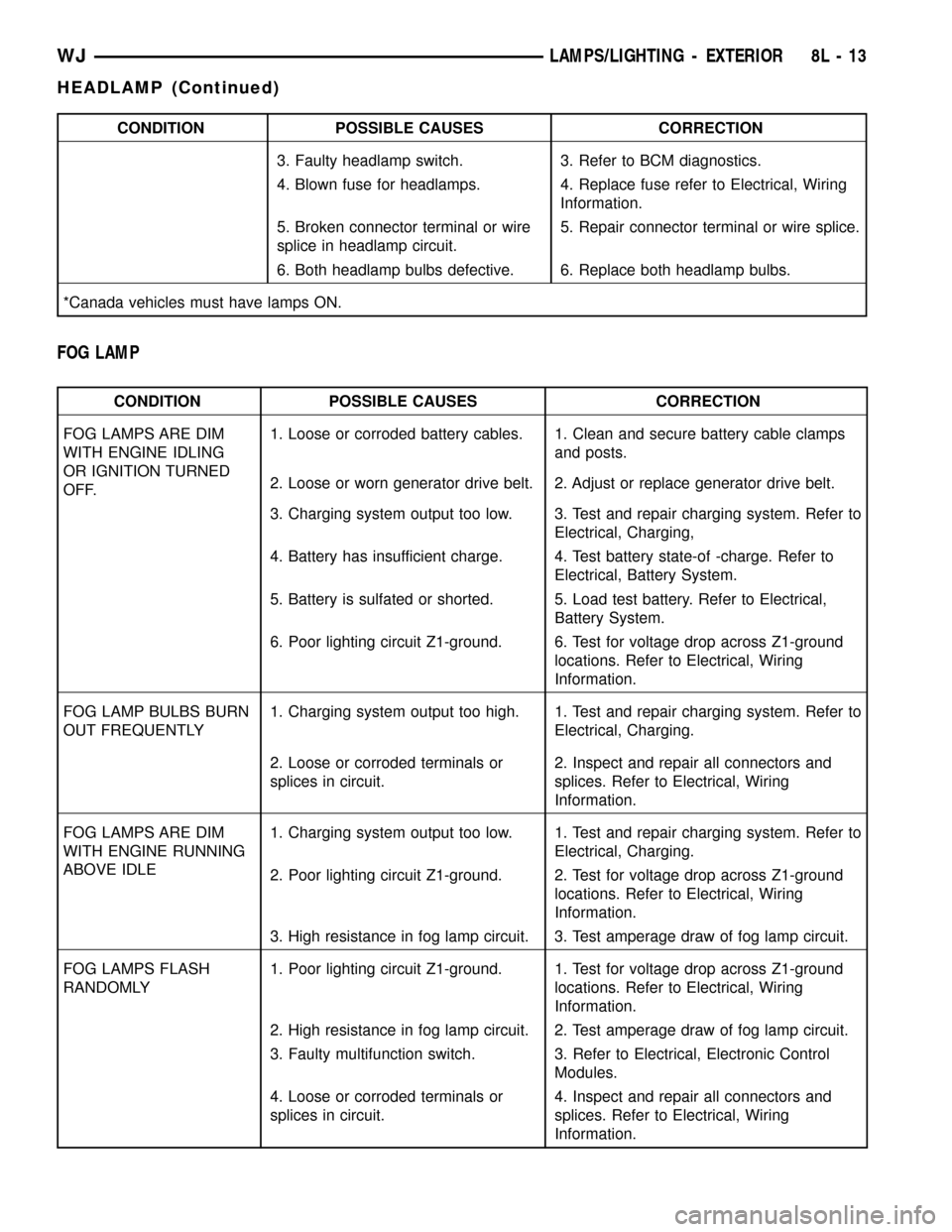

CONDITION POSSIBLE CAUSES CORRECTION

3. Faulty headlamp switch. 3. Refer to BCM diagnostics.

4. Blown fuse for headlamps. 4. Replace fuse refer to Electrical, Wiring

Information.

5. Broken connector terminal or wire

splice in headlamp circuit.5. Repair connector terminal or wire splice.

6. Both headlamp bulbs defective. 6. Replace both headlamp bulbs.

*Canada vehicles must have lamps ON.

FOG LAMP

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS ARE DIM

WITH ENGINE IDLING

OR IGNITION TURNED

OFF.1. Loose or corroded battery cables. 1. Clean and secure battery cable clamps

and posts.

2. Loose or worn generator drive belt. 2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system. Refer to

Electrical, Charging,

4. Battery has insufficient charge. 4. Test battery state-of -charge. Refer to

Electrical, Battery System.

5. Battery is sulfated or shorted. 5. Load test battery. Refer to Electrical,

Battery System.

6. Poor lighting circuit Z1-ground. 6. Test for voltage drop across Z1-ground

locations. Refer to Electrical, Wiring

Information.

FOG LAMP BULBS BURN

OUT FREQUENTLY1. Charging system output too high. 1. Test and repair charging system. Refer to

Electrical, Charging.

2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and

splices. Refer to Electrical, Wiring

Information.

FOG LAMPS ARE DIM

WITH ENGINE RUNNING

ABOVE IDLE1. Charging system output too low. 1. Test and repair charging system. Refer to

Electrical, Charging.

2. Poor lighting circuit Z1-ground. 2. Test for voltage drop across Z1-ground

locations. Refer to Electrical, Wiring

Information.

3. High resistance in fog lamp circuit. 3. Test amperage draw of fog lamp circuit.

FOG LAMPS FLASH

RANDOMLY1. Poor lighting circuit Z1-ground. 1. Test for voltage drop across Z1-ground

locations. Refer to Electrical, Wiring

Information.

2. High resistance in fog lamp circuit. 2. Test amperage draw of fog lamp circuit.

3. Faulty multifunction switch. 3. Refer to Electrical, Electronic Control

Modules.

4. Loose or corroded terminals or

splices in circuit.4. Inspect and repair all connectors and

splices. Refer to Electrical, Wiring

Information.

WJLAMPS/LIGHTING - EXTERIOR 8L - 13

HEADLAMP (Continued)

Page 495 of 2199

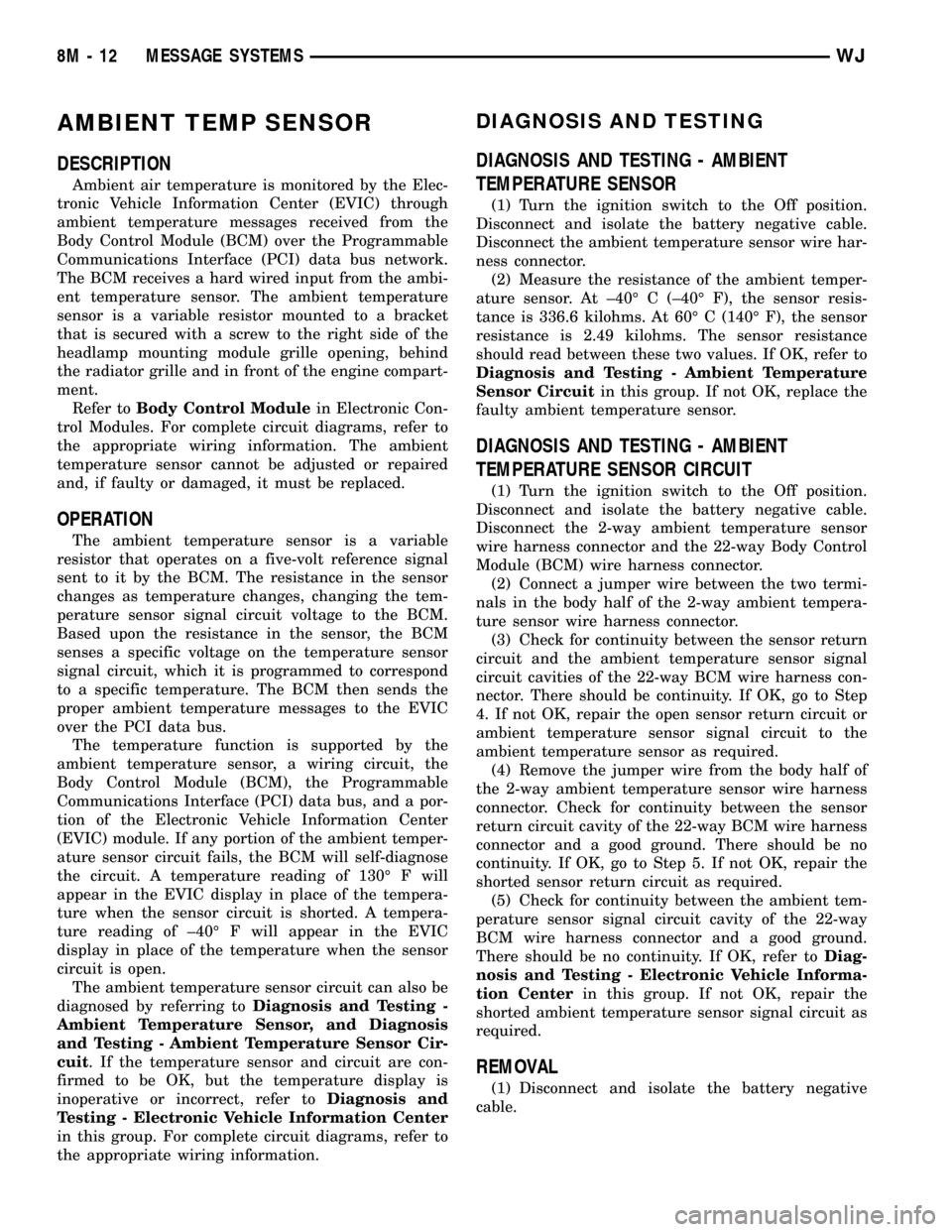

AMBIENT TEMP SENSOR

DESCRIPTION

Ambient air temperature is monitored by the Elec-

tronic Vehicle Information Center (EVIC) through

ambient temperature messages received from the

Body Control Module (BCM) over the Programmable

Communications Interface (PCI) data bus network.

The BCM receives a hard wired input from the ambi-

ent temperature sensor. The ambient temperature

sensor is a variable resistor mounted to a bracket

that is secured with a screw to the right side of the

headlamp mounting module grille opening, behind

the radiator grille and in front of the engine compart-

ment.

Refer toBody Control Modulein Electronic Con-

trol Modules. For complete circuit diagrams, refer to

the appropriate wiring information. The ambient

temperature sensor cannot be adjusted or repaired

and, if faulty or damaged, it must be replaced.

OPERATION

The ambient temperature sensor is a variable

resistor that operates on a five-volt reference signal

sent to it by the BCM. The resistance in the sensor

changes as temperature changes, changing the tem-

perature sensor signal circuit voltage to the BCM.

Based upon the resistance in the sensor, the BCM

senses a specific voltage on the temperature sensor

signal circuit, which it is programmed to correspond

to a specific temperature. The BCM then sends the

proper ambient temperature messages to the EVIC

over the PCI data bus.

The temperature function is supported by the

ambient temperature sensor, a wiring circuit, the

Body Control Module (BCM), the Programmable

Communications Interface (PCI) data bus, and a por-

tion of the Electronic Vehicle Information Center

(EVIC) module. If any portion of the ambient temper-

ature sensor circuit fails, the BCM will self-diagnose

the circuit. A temperature reading of 130É F will

appear in the EVIC display in place of the tempera-

ture when the sensor circuit is shorted. A tempera-

ture reading of ±40É F will appear in the EVIC

display in place of the temperature when the sensor

circuit is open.

The ambient temperature sensor circuit can also be

diagnosed by referring toDiagnosis and Testing -

Ambient Temperature Sensor, and Diagnosis

and Testing - Ambient Temperature Sensor Cir-

cuit. If the temperature sensor and circuit are con-

firmed to be OK, but the temperature display is

inoperative or incorrect, refer toDiagnosis and

Testing - Electronic Vehicle Information Center

in this group. For complete circuit diagrams, refer to

the appropriate wiring information.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector.

(2) Measure the resistance of the ambient temper-

ature sensor. At ±40É C (±40É F), the sensor resis-

tance is 336.6 kilohms. At 60É C (140É F), the sensor

resistance is 2.49 kilohms. The sensor resistance

should read between these two values. If OK, refer to

Diagnosis and Testing - Ambient Temperature

Sensor Circuitin this group. If not OK, replace the

faulty ambient temperature sensor.

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR CIRCUIT

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the 2-way ambient temperature sensor

wire harness connector and the 22-way Body Control

Module (BCM) wire harness connector.

(2) Connect a jumper wire between the two termi-

nals in the body half of the 2-way ambient tempera-

ture sensor wire harness connector.

(3) Check for continuity between the sensor return

circuit and the ambient temperature sensor signal

circuit cavities of the 22-way BCM wire harness con-

nector. There should be continuity. If OK, go to Step

4. If not OK, repair the open sensor return circuit or

ambient temperature sensor signal circuit to the

ambient temperature sensor as required.

(4) Remove the jumper wire from the body half of

the 2-way ambient temperature sensor wire harness

connector. Check for continuity between the sensor

return circuit cavity of the 22-way BCM wire harness

connector and a good ground. There should be no

continuity. If OK, go to Step 5. If not OK, repair the

shorted sensor return circuit as required.

(5) Check for continuity between the ambient tem-

perature sensor signal circuit cavity of the 22-way

BCM wire harness connector and a good ground.

There should be no continuity. If OK, refer toDiag-

nosis and Testing - Electronic Vehicle Informa-

tion Centerin this group. If not OK, repair the

shorted ambient temperature sensor signal circuit as

required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

8M - 12 MESSAGE SYSTEMSWJ

Page 501 of 2199

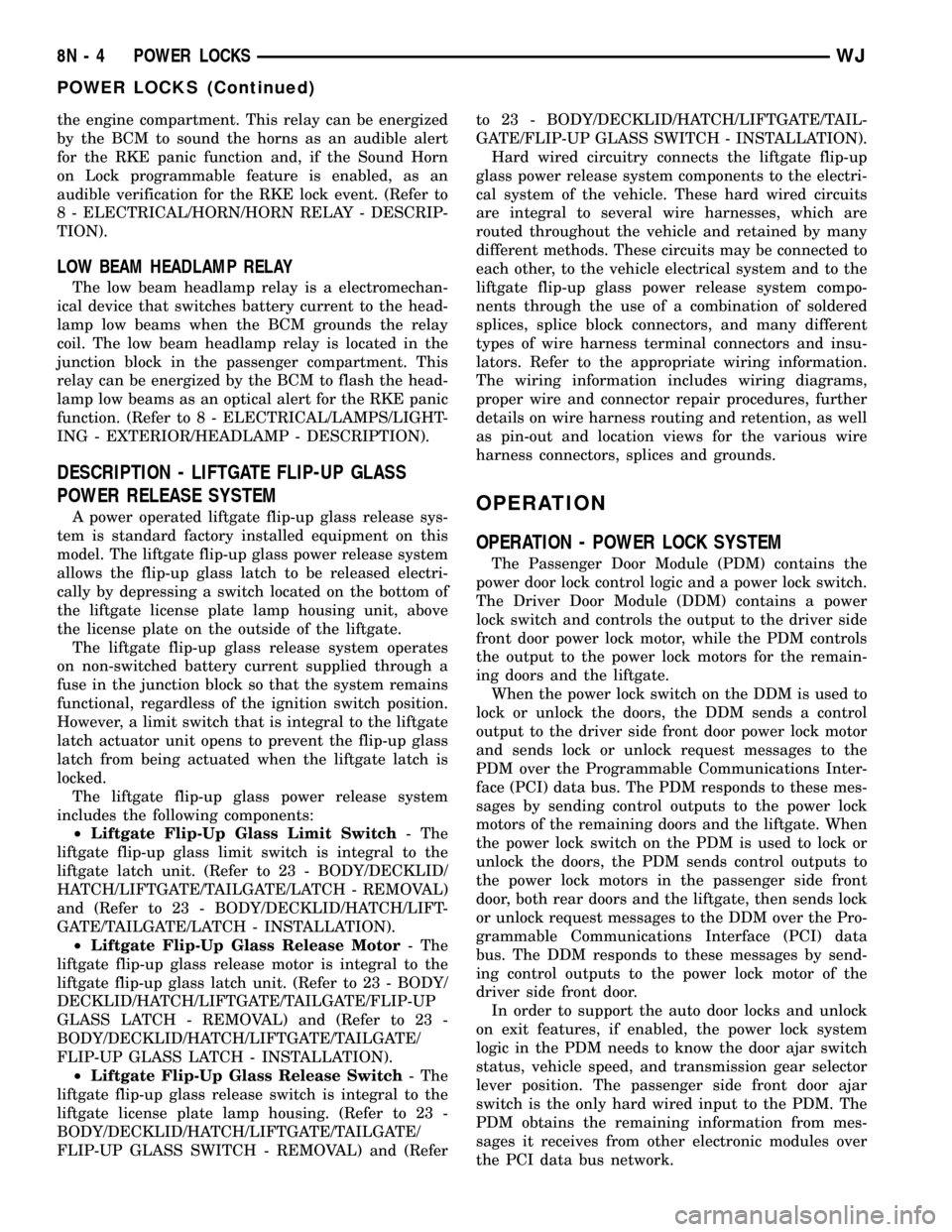

the engine compartment. This relay can be energized

by the BCM to sound the horns as an audible alert

for the RKE panic function and, if the Sound Horn

on Lock programmable feature is enabled, as an

audible verification for the RKE lock event. (Refer to

8 - ELECTRICAL/HORN/HORN RELAY - DESCRIP-

TION).

LOW BEAM HEADLAMP RELAY

The low beam headlamp relay is a electromechan-

ical device that switches battery current to the head-

lamp low beams when the BCM grounds the relay

coil. The low beam headlamp relay is located in the

junction block in the passenger compartment. This

relay can be energized by the BCM to flash the head-

lamp low beams as an optical alert for the RKE panic

function. (Refer to 8 - ELECTRICAL/LAMPS/LIGHT-

ING - EXTERIOR/HEADLAMP - DESCRIPTION).

DESCRIPTION - LIFTGATE FLIP-UP GLASS

POWER RELEASE SYSTEM

A power operated liftgate flip-up glass release sys-

tem is standard factory installed equipment on this

model. The liftgate flip-up glass power release system

allows the flip-up glass latch to be released electri-

cally by depressing a switch located on the bottom of

the liftgate license plate lamp housing unit, above

the license plate on the outside of the liftgate.

The liftgate flip-up glass release system operates

on non-switched battery current supplied through a

fuse in the junction block so that the system remains

functional, regardless of the ignition switch position.

However, a limit switch that is integral to the liftgate

latch actuator unit opens to prevent the flip-up glass

latch from being actuated when the liftgate latch is

locked.

The liftgate flip-up glass power release system

includes the following components:

²Liftgate Flip-Up Glass Limit Switch- The

liftgate flip-up glass limit switch is integral to the

liftgate latch unit. (Refer to 23 - BODY/DECKLID/

HATCH/LIFTGATE/TAILGATE/LATCH - REMOVAL)

and (Refer to 23 - BODY/DECKLID/HATCH/LIFT-

GATE/TAILGATE/LATCH - INSTALLATION).

²Liftgate Flip-Up Glass Release Motor- The

liftgate flip-up glass release motor is integral to the

liftgate flip-up glass latch unit. (Refer to 23 - BODY/

DECKLID/HATCH/LIFTGATE/TAILGATE/FLIP-UP

GLASS LATCH - REMOVAL) and (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

FLIP-UP GLASS LATCH - INSTALLATION).

²Liftgate Flip-Up Glass Release Switch- The

liftgate flip-up glass release switch is integral to the

liftgate license plate lamp housing. (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

FLIP-UP GLASS SWITCH - REMOVAL) and (Referto 23 - BODY/DECKLID/HATCH/LIFTGATE/TAIL-

GATE/FLIP-UP GLASS SWITCH - INSTALLATION).

Hard wired circuitry connects the liftgate flip-up

glass power release system components to the electri-

cal system of the vehicle. These hard wired circuits

are integral to several wire harnesses, which are

routed throughout the vehicle and retained by many

different methods. These circuits may be connected to

each other, to the vehicle electrical system and to the

liftgate flip-up glass power release system compo-

nents through the use of a combination of soldered

splices, splice block connectors, and many different

types of wire harness terminal connectors and insu-

lators. Refer to the appropriate wiring information.

The wiring information includes wiring diagrams,

proper wire and connector repair procedures, further

details on wire harness routing and retention, as well

as pin-out and location views for the various wire

harness connectors, splices and grounds.OPERATION

OPERATION - POWER LOCK SYSTEM

The Passenger Door Module (PDM) contains the

power door lock control logic and a power lock switch.

The Driver Door Module (DDM) contains a power

lock switch and controls the output to the driver side

front door power lock motor, while the PDM controls

the output to the power lock motors for the remain-

ing doors and the liftgate.

When the power lock switch on the DDM is used to

lock or unlock the doors, the DDM sends a control

output to the driver side front door power lock motor

and sends lock or unlock request messages to the

PDM over the Programmable Communications Inter-

face (PCI) data bus. The PDM responds to these mes-

sages by sending control outputs to the power lock

motors of the remaining doors and the liftgate. When

the power lock switch on the PDM is used to lock or

unlock the doors, the PDM sends control outputs to

the power lock motors in the passenger side front

door, both rear doors and the liftgate, then sends lock

or unlock request messages to the DDM over the Pro-

grammable Communications Interface (PCI) data

bus. The DDM responds to these messages by send-

ing control outputs to the power lock motor of the

driver side front door.

In order to support the auto door locks and unlock

on exit features, if enabled, the power lock system

logic in the PDM needs to know the door ajar switch

status, vehicle speed, and transmission gear selector

lever position. The passenger side front door ajar

switch is the only hard wired input to the PDM. The

PDM obtains the remaining information from mes-

sages it receives from other electronic modules over

the PCI data bus network.

8N - 4 POWER LOCKSWJ

POWER LOCKS (Continued)

Page 586 of 2199

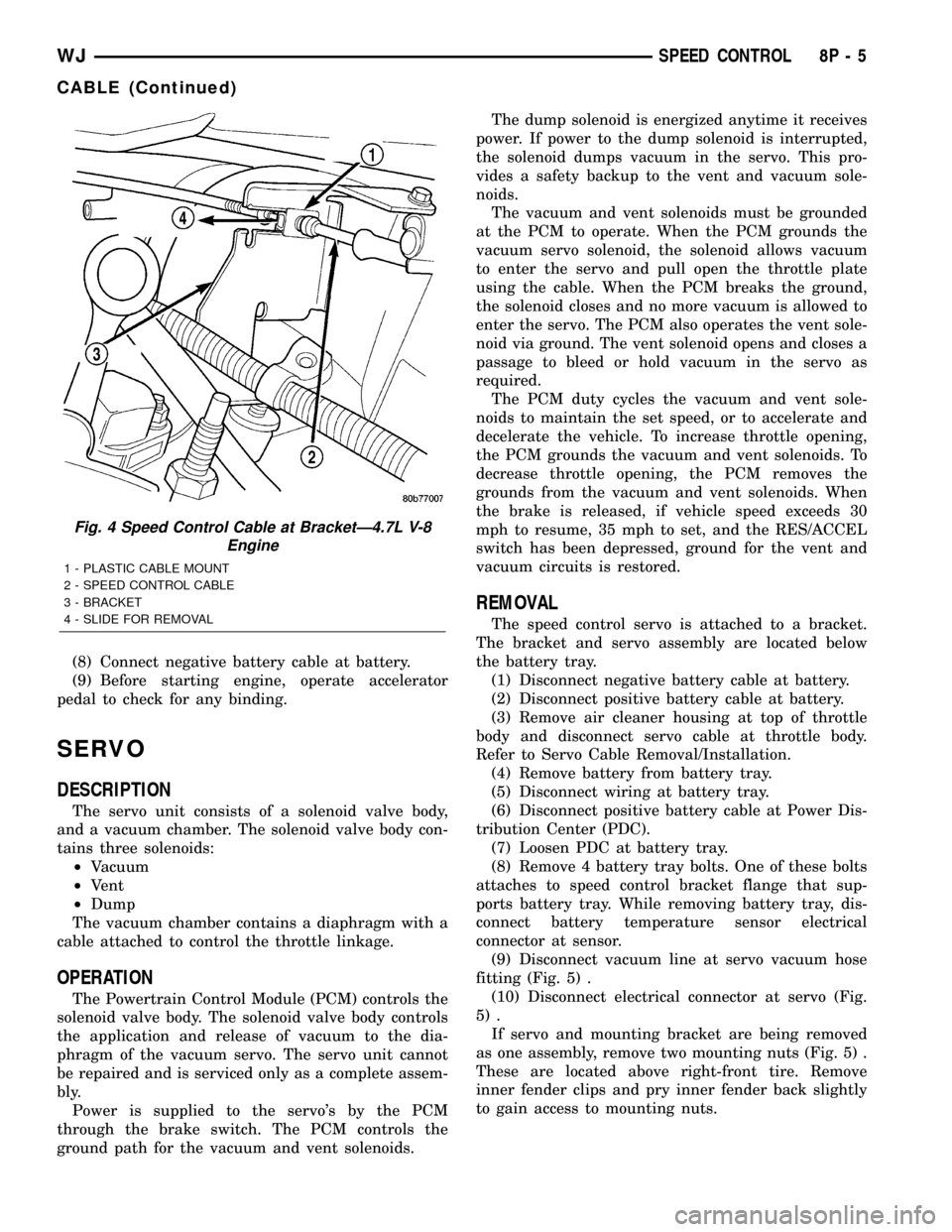

(8) Connect negative battery cable at battery.

(9) Before starting engine, operate accelerator

pedal to check for any binding.

SERVO

DESCRIPTION

The servo unit consists of a solenoid valve body,

and a vacuum chamber. The solenoid valve body con-

tains three solenoids:

²Vacuum

²Vent

²Dump

The vacuum chamber contains a diaphragm with a

cable attached to control the throttle linkage.

OPERATION

The Powertrain Control Module (PCM) controls the

solenoid valve body. The solenoid valve body controls

the application and release of vacuum to the dia-

phragm of the vacuum servo. The servo unit cannot

be repaired and is serviced only as a complete assem-

bly.

Power is supplied to the servo's by the PCM

through the brake switch. The PCM controls the

ground path for the vacuum and vent solenoids.The dump solenoid is energized anytime it receives

power. If power to the dump solenoid is interrupted,

the solenoid dumps vacuum in the servo. This pro-

vides a safety backup to the vent and vacuum sole-

noids.

The vacuum and vent solenoids must be grounded

at the PCM to operate. When the PCM grounds the

vacuum servo solenoid, the solenoid allows vacuum

to enter the servo and pull open the throttle plate

using the cable. When the PCM breaks the ground,

the solenoid closes and no more vacuum is allowed to

enter the servo. The PCM also operates the vent sole-

noid via ground. The vent solenoid opens and closes a

passage to bleed or hold vacuum in the servo as

required.

The PCM duty cycles the vacuum and vent sole-

noids to maintain the set speed, or to accelerate and

decelerate the vehicle. To increase throttle opening,

the PCM grounds the vacuum and vent solenoids. To

decrease throttle opening, the PCM removes the

grounds from the vacuum and vent solenoids. When

the brake is released, if vehicle speed exceeds 30

mph to resume, 35 mph to set, and the RES/ACCEL

switch has been depressed, ground for the vent and

vacuum circuits is restored.

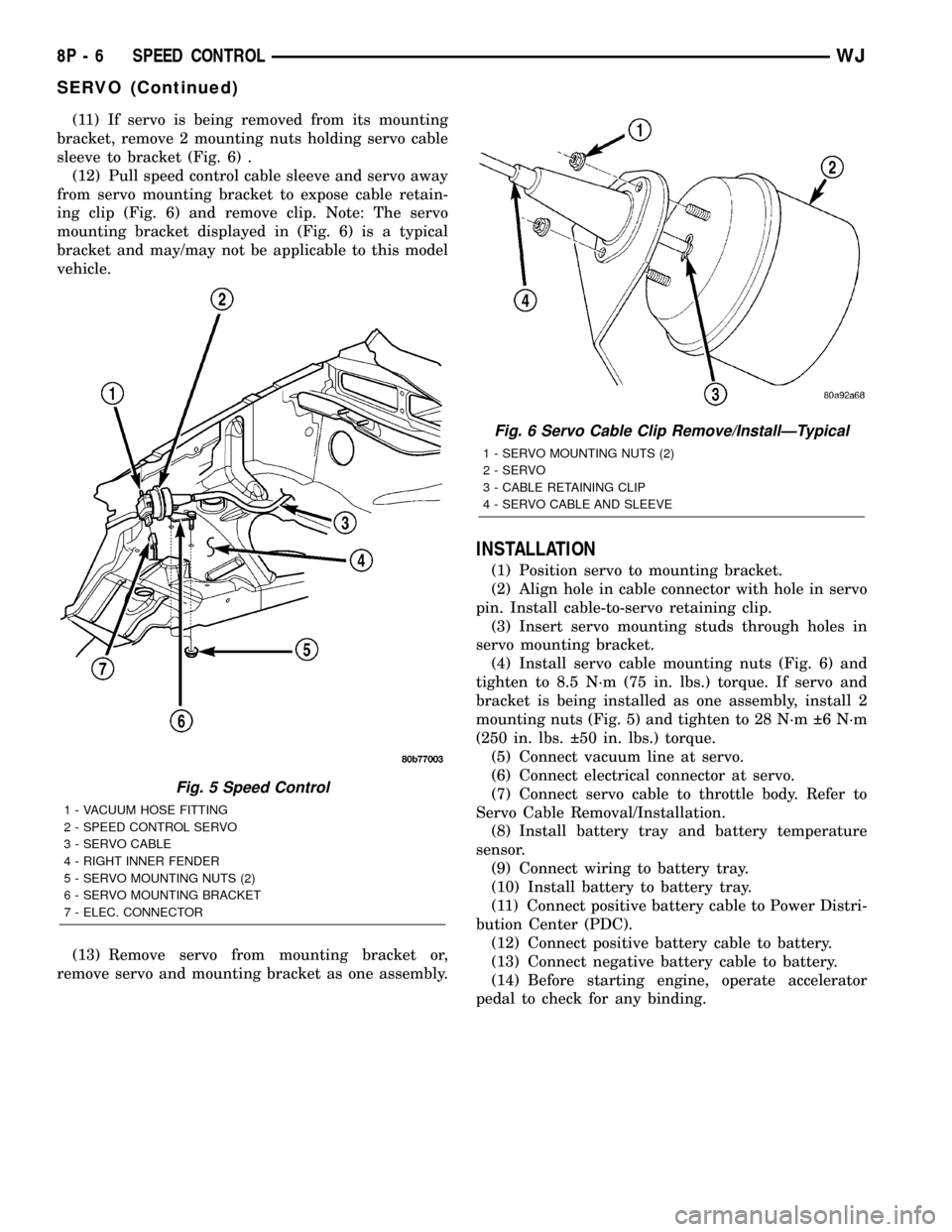

REMOVAL

The speed control servo is attached to a bracket.

The bracket and servo assembly are located below

the battery tray.

(1) Disconnect negative battery cable at battery.

(2) Disconnect positive battery cable at battery.

(3) Remove air cleaner housing at top of throttle

body and disconnect servo cable at throttle body.

Refer to Servo Cable Removal/Installation.

(4) Remove battery from battery tray.

(5) Disconnect wiring at battery tray.

(6) Disconnect positive battery cable at Power Dis-

tribution Center (PDC).

(7) Loosen PDC at battery tray.

(8) Remove 4 battery tray bolts. One of these bolts

attaches to speed control bracket flange that sup-

ports battery tray. While removing battery tray, dis-

connect battery temperature sensor electrical

connector at sensor.

(9) Disconnect vacuum line at servo vacuum hose

fitting (Fig. 5) .

(10) Disconnect electrical connector at servo (Fig.

5) .

If servo and mounting bracket are being removed

as one assembly, remove two mounting nuts (Fig. 5) .

These are located above right-front tire. Remove

inner fender clips and pry inner fender back slightly

to gain access to mounting nuts.

Fig. 4 Speed Control Cable at BracketÐ4.7L V-8

Engine

1 - PLASTIC CABLE MOUNT

2 - SPEED CONTROL CABLE

3 - BRACKET

4 - SLIDE FOR REMOVAL

WJSPEED CONTROL 8P - 5

CABLE (Continued)

Page 587 of 2199

(11) If servo is being removed from its mounting

bracket, remove 2 mounting nuts holding servo cable

sleeve to bracket (Fig. 6) .

(12) Pull speed control cable sleeve and servo away

from servo mounting bracket to expose cable retain-

ing clip (Fig. 6) and remove clip. Note: The servo

mounting bracket displayed in (Fig. 6) is a typical

bracket and may/may not be applicable to this model

vehicle.

(13) Remove servo from mounting bracket or,

remove servo and mounting bracket as one assembly.

INSTALLATION

(1) Position servo to mounting bracket.

(2) Align hole in cable connector with hole in servo

pin. Install cable-to-servo retaining clip.

(3) Insert servo mounting studs through holes in

servo mounting bracket.

(4) Install servo cable mounting nuts (Fig. 6) and

tighten to 8.5 N´m (75 in. lbs.) torque. If servo and

bracket is being installed as one assembly, install 2

mounting nuts (Fig. 5) and tighten to 28 N´m 6 N´m

(250 in. lbs. 50 in. lbs.) torque.

(5) Connect vacuum line at servo.

(6) Connect electrical connector at servo.

(7) Connect servo cable to throttle body. Refer to

Servo Cable Removal/Installation.

(8) Install battery tray and battery temperature

sensor.

(9) Connect wiring to battery tray.

(10) Install battery to battery tray.

(11) Connect positive battery cable to Power Distri-

bution Center (PDC).

(12) Connect positive battery cable to battery.

(13) Connect negative battery cable to battery.

(14) Before starting engine, operate accelerator

pedal to check for any binding.

Fig. 5 Speed Control

1 - VACUUM HOSE FITTING

2 - SPEED CONTROL SERVO

3 - SERVO CABLE

4 - RIGHT INNER FENDER

5 - SERVO MOUNTING NUTS (2)

6 - SERVO MOUNTING BRACKET

7 - ELEC. CONNECTOR

Fig. 6 Servo Cable Clip Remove/InstallÐTypical

1 - SERVO MOUNTING NUTS (2)

2 - SERVO

3 - CABLE RETAINING CLIP

4 - SERVO CABLE AND SLEEVE

8P - 6 SPEED CONTROLWJ

SERVO (Continued)

Page 595 of 2199

tion feature of the ITM can be disabled by depressing

the ªLockº button on the RKE transmitter three

times or cycling the key in the driver door cylinder

from the center to lock position within fifteen seconds

during VTA arming, while the security indicator is

still flashing rapidly. The VTA provides a single short

siren ªchirpº as an audible conformation that the

motion detect disable request has been received. The

ITM must be electronically enabled in order for the

intrusion alarm to perform as designed. The intru-

sion alarm function of the ITM is enabled on vehicles

equipped with this option at the factory, but a service

replacement ITM must be configured and enabled by

the dealer using the DRBIIItscan tool. Refer to the

appropriate diagnostic information.

OPERATION - SENTRY KEY IMMOBILIZER

SYSTEM

The Sentry Key Immobilizer System (SKIS) is

designed to provide passive protection against unau-

thorized vehicle use by disabling the engine after

about two seconds of running, whenever any method

other than a valid Sentry Key is used to start the

vehicle. The SKIS is considered a passive protection

system because it is always active when the ignition

system is energized and does not require any cus-

tomer intervention. The SKIS uses Radio Frequency

(RF) communication to obtain confirmation that the

key in the ignition switch is a valid key for operating

the vehicle. The microprocessor-based SKIS hard-

ware and software also uses messages to communi-

cate with other modules in the vehicle over the

Programmable Communications Interface (PCI) data

bus. (Refer to 8 - ELECTRICAL/ELECTRONIC CON-

TROL MODULES/COMMUNICATION - OPERA-

TION).

Pre-programmed Sentry Key transponders are pro-

vided with the vehicle from the factory. Each Sentry

Key Immobilizer Module (SKIM) will recognize a

maximum of eight Sentry Keys. If the customer

would like additional keys other than those provided

with the vehicle, they may be purchased from any

authorized dealer. These additional keys must be pro-

grammed to the SKIM in the vehicle in order for the

system to recognize them as valid keys. This can be

done by the dealer using a DRBIIItscan tool or, if

Customer Learn programming is an available SKIS

feature in the market where the vehicle was pur-

chased, the customer can program the additional

keys, as long as at least two valid Sentry Keys are

already available. (Refer to 8 - ELECTRICAL/VEHI-

CLE THEFT SECURITY - STANDARD PROCE-

DURE - TRANSPONDER PROGRAMMING).

The SKIS performs a self-test each time the igni-

tion switch is turned to the On position, and will

store fault information in the form of DiagnosticTrouble Codes (DTC's) if a system malfunction is

detected. Refer to the appropriate diagnostic informa-

tion.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - VEHICLE THEFT

SECURITY SYSTEM

The VTSS-related hard wired inputs to and out-

puts from the Body Control Module (BCM), the

Driver Door Module (DDM), or the Passenger Door

Module (PDM) may be diagnosed and tested using

conventional diagnostic tools and procedures. Refer

to the appropriate wiring information.

However, conventional diagnostic methods may not

prove conclusive in the diagnosis of the BCM, the

DDM, the PDM, or the Programmable Communica-

tions Interface (PCI) data bus network. In order to

obtain conclusive testing of the VTSS, the BCM, the

DDM, the PDM, and the PCI data bus network must

also be checked. The most reliable, efficient, and

accurate means to diagnose the VTSS requires the

use of a DRBIIItscan tool and the appropriate diag-

nostic information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

8Q - 4 VEHICLE THEFT SECURITYWJ

VEHICLE THEFT SECURITY (Continued)

Page 600 of 2199

(5) Remove the door cylinder lock switch from the

back of the lock cylinder.

INSTALLATION

(1) Position the door cylinder lock switch onto the

back of the lock cylinder with its pigtail wire harness

oriented toward the bottom (Fig. 2).

(2) Position the lock lever onto the pin on the back

of the door lock cylinder with the lever oriented

toward the rear.

(3) Install the retainer clip onto the pin on the

back of the door lock cylinder. Be certain that the

center tab of the retainer is engaged in the retention

hole on the lock lever.

(4) Reinstall the outside door handle unit onto the

outer door panel. (Refer to 23 - BODY/DOOR -

FRONT/EXTERIOR HANDLE - INSTALLATION).

(5) Reconnect the battery negative cable.

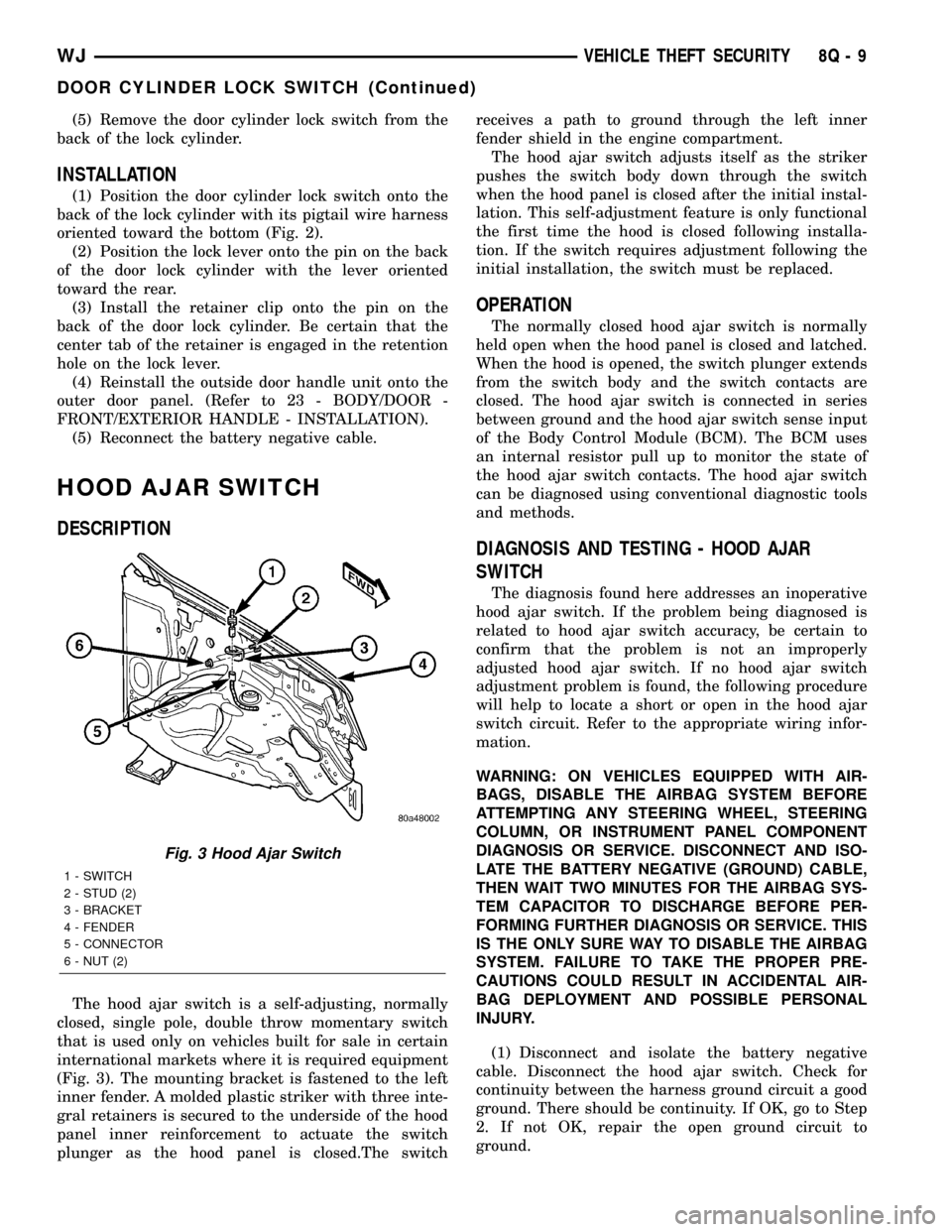

HOOD AJAR SWITCH

DESCRIPTION

The hood ajar switch is a self-adjusting, normally

closed, single pole, double throw momentary switch

that is used only on vehicles built for sale in certain

international markets where it is required equipment

(Fig. 3). The mounting bracket is fastened to the left

inner fender. A molded plastic striker with three inte-

gral retainers is secured to the underside of the hood

panel inner reinforcement to actuate the switch

plunger as the hood panel is closed.The switchreceives a path to ground through the left inner

fender shield in the engine compartment.

The hood ajar switch adjusts itself as the striker

pushes the switch body down through the switch

when the hood panel is closed after the initial instal-

lation. This self-adjustment feature is only functional

the first time the hood is closed following installa-

tion. If the switch requires adjustment following the

initial installation, the switch must be replaced.

OPERATION

The normally closed hood ajar switch is normally

held open when the hood panel is closed and latched.

When the hood is opened, the switch plunger extends

from the switch body and the switch contacts are

closed. The hood ajar switch is connected in series

between ground and the hood ajar switch sense input

of the Body Control Module (BCM). The BCM uses

an internal resistor pull up to monitor the state of

the hood ajar switch contacts. The hood ajar switch

can be diagnosed using conventional diagnostic tools

and methods.

DIAGNOSIS AND TESTING - HOOD AJAR

SWITCH

The diagnosis found here addresses an inoperative

hood ajar switch. If the problem being diagnosed is

related to hood ajar switch accuracy, be certain to

confirm that the problem is not an improperly

adjusted hood ajar switch. If no hood ajar switch

adjustment problem is found, the following procedure

will help to locate a short or open in the hood ajar

switch circuit. Refer to the appropriate wiring infor-

mation.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable. Disconnect the hood ajar switch. Check for

continuity between the harness ground circuit a good

ground. There should be continuity. If OK, go to Step

2. If not OK, repair the open ground circuit to

ground.

Fig. 3 Hood Ajar Switch

1 - SWITCH

2 - STUD (2)

3 - BRACKET

4 - FENDER

5 - CONNECTOR

6 - NUT (2)

WJVEHICLE THEFT SECURITY 8Q - 9

DOOR CYLINDER LOCK SWITCH (Continued)

Page 610 of 2199

²Front Check Valve- The front washer system

check valve is integral to the wye fitting located in

the washer plumbing between the cowl plenum

washer hose and the front washer nozzles, and is

concealed beneath the cowl plenum cover/grille panel

at the base of the windshield.

²Front Washer Nozzle- Two fluidic front

washer nozzles are secured with integral snap fea-

tures to dedicated openings in the cowl plenum cover/

grille panel located near the base of the windshield.

²Front Washer Plumbing- The plumbing for

the front washer system consists of rubber hoses and

molded plastic fittings. The plumbing is routed along

the left side of the engine compartment from the

washer reservoir, and through the dash panel into

the cowl plenum to the front washer nozzle fittings

beneath the cowl plenum cover/grille panel.

²Front Washer Pump/Motor- The front washer

pump/motor unit is located in a dedicated hole on the

lower outboard side of the washer reservoir, behind

the inner fender liner ahead of the left front wheel.

The front washer pump is located ahead of and below

the rear washer pump.

²Front Wiper Arm- The two front wiper arms

are secured with nuts to the threaded studs on the

ends of the two wiper pivot shafts, which extend

through the cowl plenum cover/grille panel located

near the base of the windshield.

²Front Wiper Blade- The two front wiper

blades are secured to the two front wiper arms with

an integral latch, and are parked on the glass near

the bottom of the windshield when the front wiper

system is not in operation.

²Front Wiper Module- The front wiper pivot

shafts are the only visible components of the front

wiper module. The remainder of the module is con-

cealed within the cowl plenum beneath the cowl ple-

num cover/grille panel. The front wiper module

includes the module bracket, four rubber-isolated

wiper module mounts, the front wiper motor, the

wiper motor crank arm, the two wiper drive links,

and the two front wiper pivots.

²Rain Sensor Module- Models equipped with

the optional automatic wiper feature have a Rain

Sensor Module (RSM) located behind a trim cover on

a bracket bonded to the inside surface of the wind-

shield glass, just above the inside rear view mirror

mounting button.

²Right Multi-Function Switch- The right

(wiper) multi-function switch is secured to the right

side of the multi-function switch mounting housing

near the top of the steering column, just below the

steering wheel. Only the control stalk for the right

multi-function switch is visible, while the remainder

of the switch is concealed beneath the steering col-

umn shrouds. The right multi-function switch con-tains all of the switches and control circuitry for both

the front and rear wiper and washer systems.

²Washer Fluid Level Switch- The washer fluid

level switch is located in a dedicated hole near the

center of the forward surface of the washer reservoir,

behind the left front wheel house splash shield.

²Washer Reservoir- The washer reservoir is

concealed between the left inner fender shield and

the left outer fender panel, behind the inner fender

liner and ahead of the left front wheel. The washer

reservoir filler neck is the only visible portion of the

reservoir, and it is accessed from the left front corner

of the engine compartment.

²Wiper High-Low Relay- The wiper high-low

relay is an International Standards Organization

(ISO) micro relay located in the Power Distribution

Center (PDC) in the engine compartment near the

battery.

²Wiper On-Off Relay- The wiper on-off relay is

an International Standards Organization (ISO) micro

relay located in the Power Distribution Center (PDC)

in the engine compartment near the battery.

Hard wired circuitry connects the front wiper and

washer system components to the electrical system of

the vehicle. These hard wired circuits are integral to

several wire harnesses, which are routed throughout

the vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the front wiper and

washer system components through the use of a com-

bination of soldered splices, splice block connectors,

and many different types of wire harness terminal

connectors and insulators. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, further details on wire harness routing

and retention, as well as pin-out and location views

for the various wire harness connectors, splices and

grounds.

OPERATING MODES

The components of the front wiper and washer sys-

tem are designed to work in concert to provide the

following operating modes:

²Automatic Wiper- In models equipped with

the optional automatic wiper feature, the internal

circuitry of both the right (wiper) multi-function

switch, the rain sensor module, and the BCM work

in concert to provide an automatic wiper mode with

five sensitivity selections. The BCM tells the Rain

Sensor Module (RSM) when the automatic wiper

mode is selected and the manually selected sensitiv-

ity level, then the rain sensor module tells the BCM

each time enough water droplets have accumulated

within the wipe pattern on the windshield to require

front wiper operation. The BCM then automatically

WJFRONT WIPERS/WASHERS 8R - 3

FRONT WIPERS/WASHERS (Continued)

Page 637 of 2199

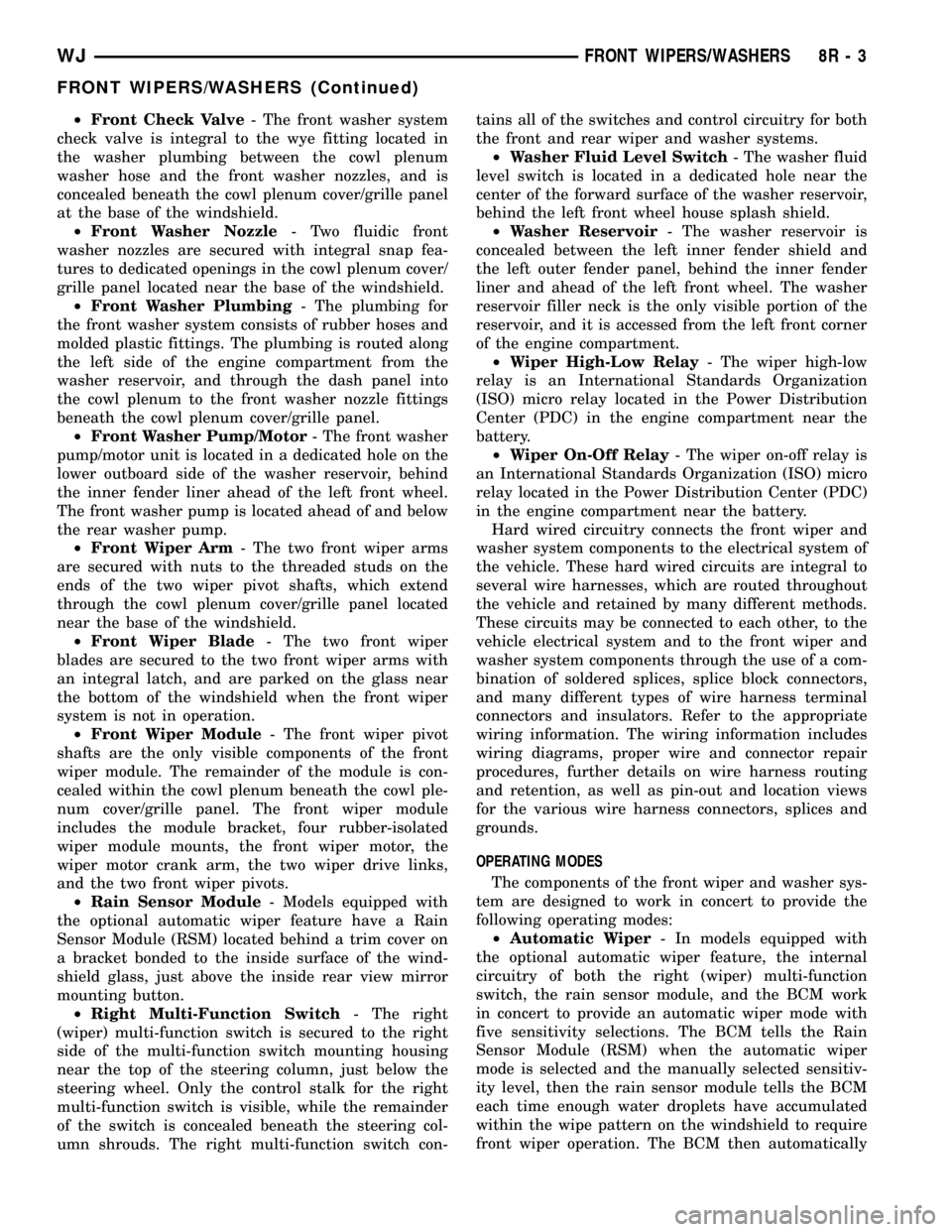

²Normally Open Terminal- The normally open

terminal (87) is connected to the high speed brush of

the front wiper motor through a front wiper high/low

relay high speed output circuit, and is connected to

the high speed brush whenever the relay is ener-

gized.

²Normally Closed Terminal- The normally

closed terminal (87A) is connected to the low speed

brush of the front wiper motor through a front wiper

high/low relay low speed output circuit, and is con-

nected to the low speed brush whenever the relay is

de-energized.

The wiper high/low relay can be diagnosed using

conventional diagnostic tools and methods.

DIAGNOSIS AND TESTING - WIPER HIGH/LOW

RELAY

The wiper high/low relay (Fig. 26) is located in the

Power Distribution Center (PDC) in the engine com-

partment near the battery. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.

(1) Remove the wiper high/low relay from the

PDC. (Refer to 8 - ELECTRICAL/WIPERS/WASH-

ERS/WIPER HIGH/LOW RELAY - REMOVAL).

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, andno continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 8 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, reinstall the relay and use a DRBIIIt

scan tool to perform further testing. Refer to the

appropriate diagnostic information.

REMOVAL

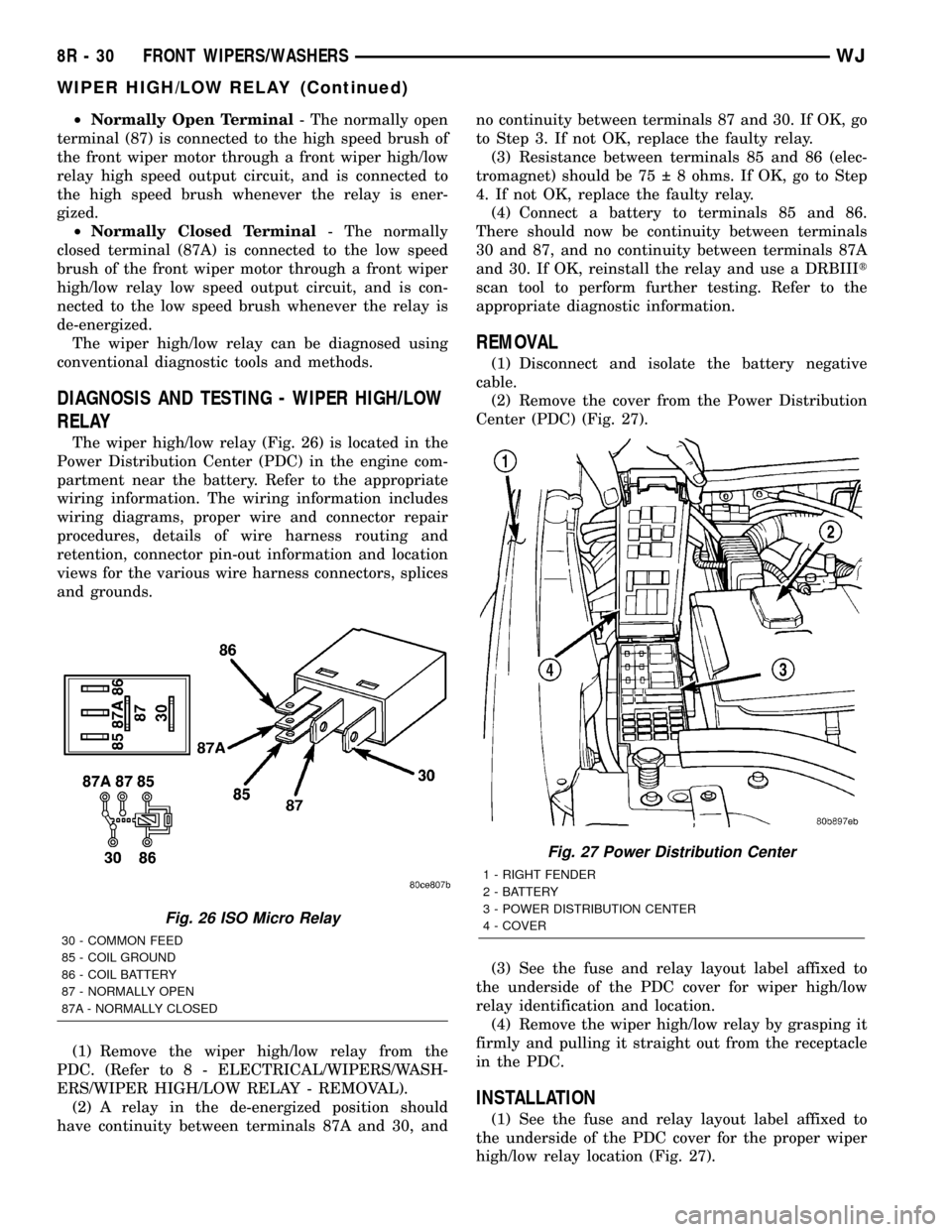

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 27).

(3) See the fuse and relay layout label affixed to

the underside of the PDC cover for wiper high/low

relay identification and location.

(4) Remove the wiper high/low relay by grasping it

firmly and pulling it straight out from the receptacle

in the PDC.

INSTALLATION

(1) See the fuse and relay layout label affixed to

the underside of the PDC cover for the proper wiper

high/low relay location (Fig. 27).

Fig. 26 ISO Micro Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

Fig. 27 Power Distribution Center

1 - RIGHT FENDER

2 - BATTERY

3 - POWER DISTRIBUTION CENTER

4 - COVER

8R - 30 FRONT WIPERS/WASHERSWJ

WIPER HIGH/LOW RELAY (Continued)