Heating & Air Conditioning JEEP GRAND CHEROKEE 2002 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1256 of 2199

INSTALLATION

CAUTION: When installing the engine into a vehicle

equipped with an automatic transmission, be care-

ful not to damage the trigger wheel on the engine

flywheel.

(1) Attach a lifting device to the engine and lower

the engine into the engine compartment. For easier

installation, it may be necessary to remove the

engine mount bracket as an aid in alignment of the

engine to the transmission.

(2) Align the transmission torque converter hous-

ing with the engine.

(3) Loosely install the converter housing lower

bolts and install the next higher bolt and nut on each

side.

(4) Tighten all 4 bolts finger tight.

(5) Install the engine mount brackets (if removed).

(6) Lower the engine and engine mount brackets

onto the engine compartment cushions. Install the

bolts and finger tighten the nuts.

(7) Remove the engine lifting device.

(8) Raise and support the vehicle.

(9) Install the remaining engine flywheel/converter

housing bolts. Tighten all bolts to 38 N´m (28 ft. lbs.)

torque.

(10) Install the converter-to-drive plate bolts.

(11) Ensure the installation reference marks are

aligned.

(12) Install the engine flywheel/converter housing

access cover.

(13) Install the exhaust pipe support and tighten

the screw.

(14) Install the engine bending brace (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCT SUPPORT -

INSTALLATION).

(15) Tighten the engine mount-to-bracket bolts.

(16) Connect the vehicle speed sensor wire connec-

tions and tighten the screws.

(17) Connect the exhaust pipe to the manifold.

(18) Install the engine starter motor (Refer to 8 -

ELECTRICAL/STARTING/STARTER MOTOR -

INSTALLATION).

(19) Connect the wires to the engine starter motor

solenoid.

(20) Lower the vehicle.

(21) Connect all the vacuum hoses and wire con-

nectors identified during engine removal.

(22) Remove protective caps from the power steer-

ing hoses.

(23) Connect the hoses to the fittings at the steer-

ing gear. Tighten the nut to 52 N´m (38 ft. lbs.)

torque.

(24) Fill the pump reservoir with fluid.(25) Inspect the fuel supply line o-ring(s) and

replace if necessary. Connect fuel supply line to injec-

tior rail and verify connection by pulling outward on

the line.

(26) Install the fuel line bracket to the intake

manifold.

(27) Connect the coil rail electrical connectors and

oil pressure switch connector.

(28) Connect the following electrical connectors:

²Power steering pressure switch

²Coolant temperature sensor

²Six (6) fuel injector connectors

²Intake air temperature sensor

²Throttle position sensor

²Map sensor

²Crankshaft position sensor

²Oxygen sensor

²Camshaft position sensor

²Generator connector and B+ terminal wire

(29) Connect all previously removed vacuum hoses.

(30) Connect the body ground strap.

(31) Install the throttle, transmission line pres-

sure, and speed control cables to their mounting

bracket and connect them to the throttle body.

(32) Connect the heater hoses at the engine ther-

mostat housing and water pump.

(33) Install the fan assembly (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - INSTALLATION).

(34) Place the fan shroud in position over the fan.

(35) Install the radiator (Refer to 7 - COOLING/

ENGINE/RADIATOR - INSTALLATION).

(36) Connect the service valves to the A/C com-

pressor ports, if equipped with A/C.

(37) Charge the air conditioner system (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

(38) Connect the radiator hoses and automatic

transmission fluid cooler pipes, if equipped.

(39) Install the fan shroud to the radiator or radi-

ator/condenser (if equipped with A/C).

(40) Install upper radiator support.

(41) Connect the upper radiator hose and tighten

the clamp.

(42) Connect the lower radiator hose and tighten

the clamp.

(43) Fill crankcase with engine oil. (Refer to

LUBRICATION & MAINTENANCE/FLUID CAPACI-

TIES - SPECIFICATIONS) for correct capacities.

(44) Fill the cooling system with reusable coolant

or new coolant (Refer to 7 - COOLING - STANDARD

PROCEDURE).

(45) Align the hood to the scribe marks. Install the

hood.

(46) Install the air cleaner assembly.

(47) Install the battery and connect the battery

cable.

WJENGINE - 4.0L 9 - 13

ENGINE - 4.0L (Continued)

Page 1265 of 2199

(12) Install the push rods, rocker arms, pivots and

bridges in the order they were removed (Refer to 9 -

ENGINE/CYLINDER HEAD/ROCKER ARM /

ADJUSTER ASSY - INSTALLATION).

(13) Install the engine cylinder head cover (Refer

to 9 - ENGINE/CYLINDER HEAD/CYLINDER

HEAD COVER(S) - INSTALLATION).

(14) Attach the air conditioner compressor mount-

ing bracket to the engine cylinder head and block.

Tighten the bolts to 40 N´m (30 ft. lbs.) torque.

(15) Attach the air conditioning compressor to the

bracket. Tighten the bolts to 27 N´m (20 ft. lbs.)

torque.

CAUTION: The serpentine drive belt must be routed

correctly. Incorrect routing can cause the water

pump to turn in the opposite direction causing the

engine to overheat.

(16) Install the serpentine drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(17) Install the air cleaner and ducting.

(18) Connect the hoses to the engine thermostat

housing and fill the cooling system to the specified

level (Refer to 7 - COOLING - STANDARD PROCE-

DURE).

(19) The automatic transmission throttle linkage

and cable must be adjusted after completing the

engine cylinder head installation (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - AW4/

THROTTLE VALVE CABLE - ADJUSTMENTS).

(20) Install the temperature sending unit and con-

nect the wire connector.

(21) If equipped with air conditioning, install A/C

compressor (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/A/C COMPRESSOR -

INSTALLATION) and charge A/C system (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

(22) Connect negative cable to battery.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN DIRECT

LINE WITH THE FAN. DO NOT PUT HANDS NEAR

THE PULLEYS, BELTS OR FAN. DO NOT WEAR

LOOSE CLOTHING.

(23) Operate the engine with the radiator cap off.

Inspect for leaks and continue operating the engine

until the engine thermostat opens. Add coolant, if

required.CYLINDER HEAD COVER(S)

DESCRIPTION

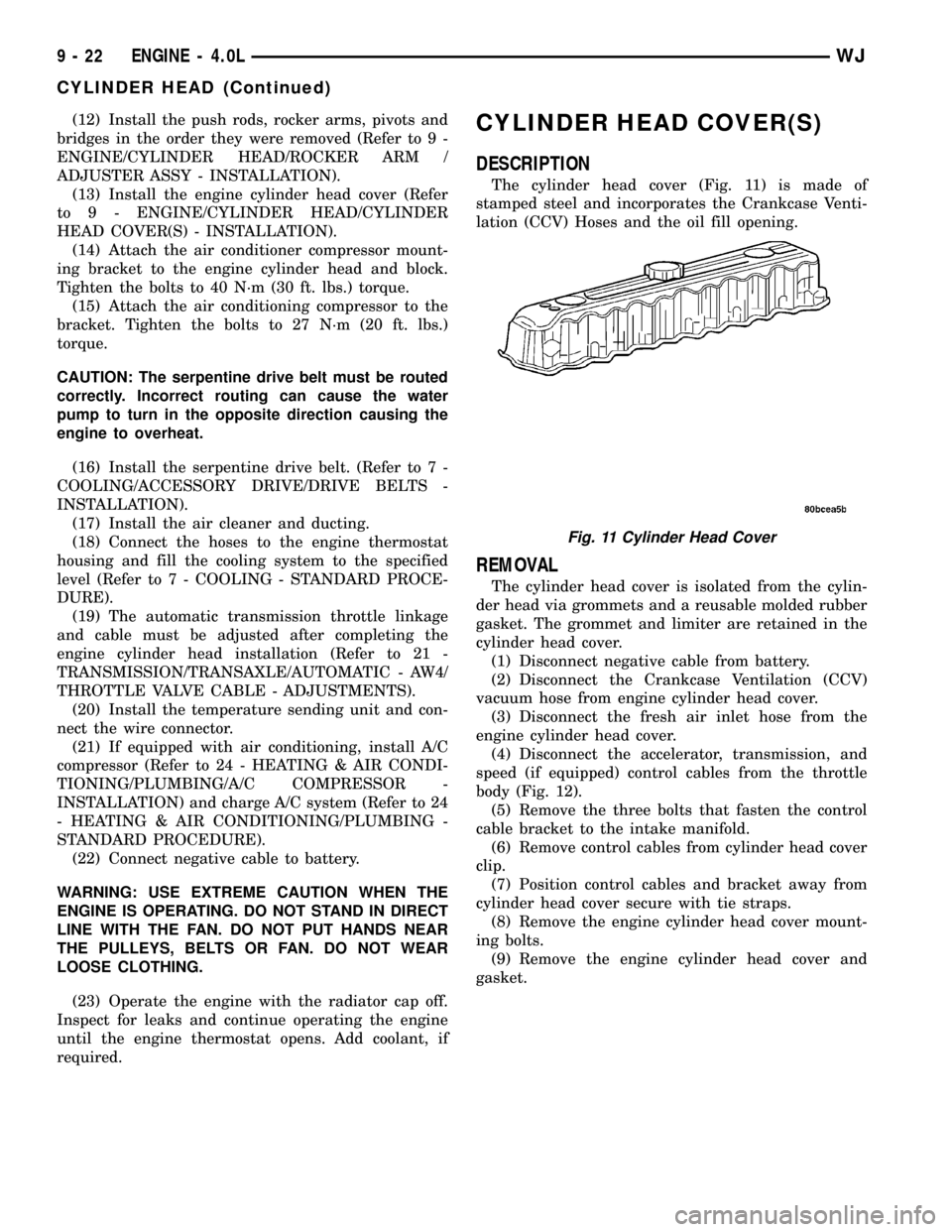

The cylinder head cover (Fig. 11) is made of

stamped steel and incorporates the Crankcase Venti-

lation (CCV) Hoses and the oil fill opening.

REMOVAL

The cylinder head cover is isolated from the cylin-

der head via grommets and a reusable molded rubber

gasket. The grommet and limiter are retained in the

cylinder head cover.

(1) Disconnect negative cable from battery.

(2) Disconnect the Crankcase Ventilation (CCV)

vacuum hose from engine cylinder head cover.

(3) Disconnect the fresh air inlet hose from the

engine cylinder head cover.

(4) Disconnect the accelerator, transmission, and

speed (if equipped) control cables from the throttle

body (Fig. 12).

(5) Remove the three bolts that fasten the control

cable bracket to the intake manifold.

(6) Remove control cables from cylinder head cover

clip.

(7) Position control cables and bracket away from

cylinder head cover secure with tie straps.

(8) Remove the engine cylinder head cover mount-

ing bolts.

(9) Remove the engine cylinder head cover and

gasket.

Fig. 11 Cylinder Head Cover

9 - 22 ENGINE - 4.0LWJ

CYLINDER HEAD (Continued)

Page 1274 of 2199

REMOVAL

REMOVAL - CAMSHAFT BEARINGS

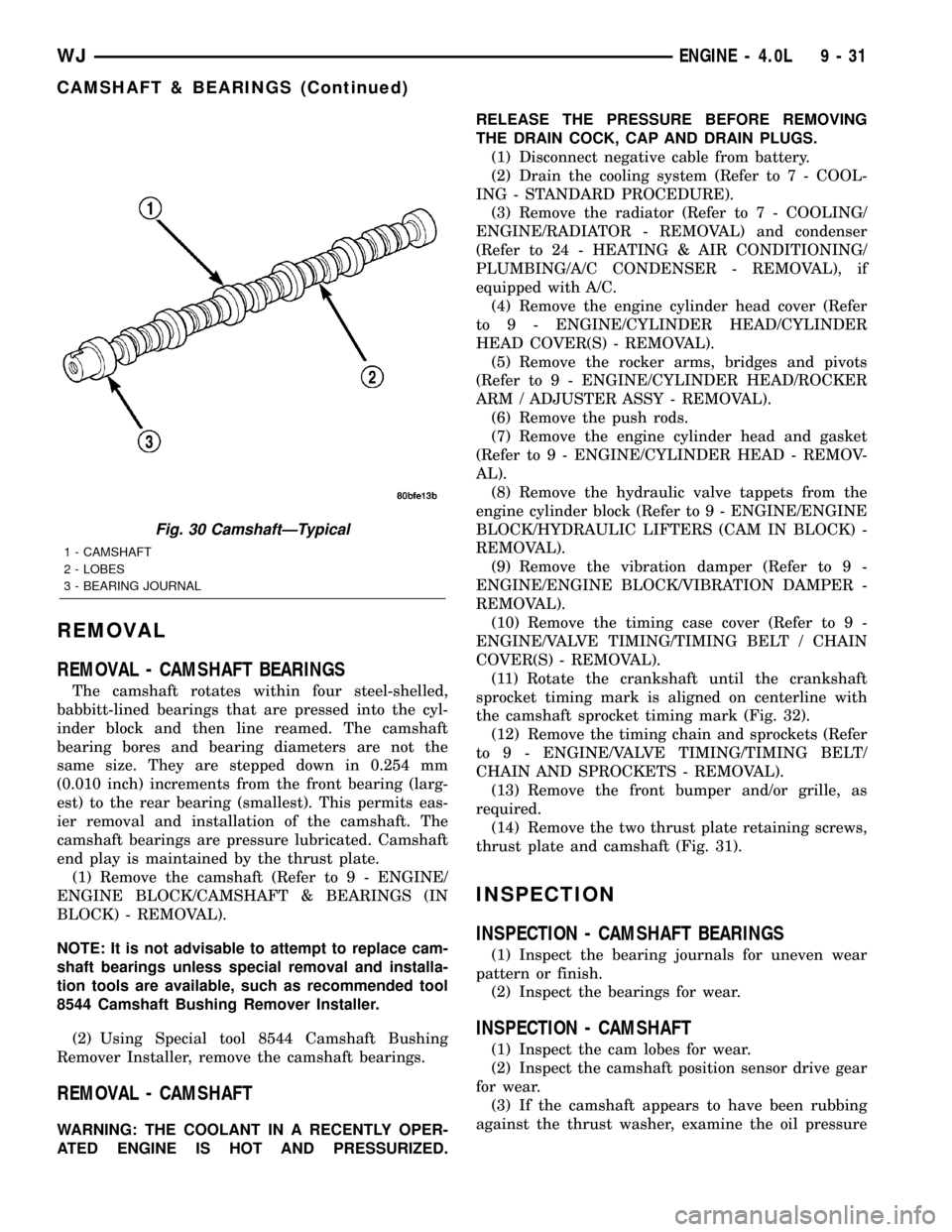

The camshaft rotates within four steel-shelled,

babbitt-lined bearings that are pressed into the cyl-

inder block and then line reamed. The camshaft

bearing bores and bearing diameters are not the

same size. They are stepped down in 0.254 mm

(0.010 inch) increments from the front bearing (larg-

est) to the rear bearing (smallest). This permits eas-

ier removal and installation of the camshaft. The

camshaft bearings are pressure lubricated. Camshaft

end play is maintained by the thrust plate.

(1) Remove the camshaft (Refer to 9 - ENGINE/

ENGINE BLOCK/CAMSHAFT & BEARINGS (IN

BLOCK) - REMOVAL).

NOTE: It is not advisable to attempt to replace cam-

shaft bearings unless special removal and installa-

tion tools are available, such as recommended tool

8544 Camshaft Bushing Remover Installer.

(2) Using Special tool 8544 Camshaft Bushing

Remover Installer, remove the camshaft bearings.

REMOVAL - CAMSHAFT

WARNING: THE COOLANT IN A RECENTLY OPER-

ATED ENGINE IS HOT AND PRESSURIZED.RELEASE THE PRESSURE BEFORE REMOVING

THE DRAIN COCK, CAP AND DRAIN PLUGS.

(1) Disconnect negative cable from battery.

(2) Drain the cooling system (Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(3) Remove the radiator (Refer to 7 - COOLING/

ENGINE/RADIATOR - REMOVAL) and condenser

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING/A/C CONDENSER - REMOVAL), if

equipped with A/C.

(4) Remove the engine cylinder head cover (Refer

to 9 - ENGINE/CYLINDER HEAD/CYLINDER

HEAD COVER(S) - REMOVAL).

(5) Remove the rocker arms, bridges and pivots

(Refer to 9 - ENGINE/CYLINDER HEAD/ROCKER

ARM / ADJUSTER ASSY - REMOVAL).

(6) Remove the push rods.

(7) Remove the engine cylinder head and gasket

(Refer to 9 - ENGINE/CYLINDER HEAD - REMOV-

AL).

(8) Remove the hydraulic valve tappets from the

engine cylinder block (Refer to 9 - ENGINE/ENGINE

BLOCK/HYDRAULIC LIFTERS (CAM IN BLOCK) -

REMOVAL).

(9) Remove the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(10) Remove the timing case cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(11) Rotate the crankshaft until the crankshaft

sprocket timing mark is aligned on centerline with

the camshaft sprocket timing mark (Fig. 32).

(12) Remove the timing chain and sprockets (Refer

to 9 - ENGINE/VALVE TIMING/TIMING BELT/

CHAIN AND SPROCKETS - REMOVAL).

(13) Remove the front bumper and/or grille, as

required.

(14) Remove the two thrust plate retaining screws,

thrust plate and camshaft (Fig. 31).

INSPECTION

INSPECTION - CAMSHAFT BEARINGS

(1) Inspect the bearing journals for uneven wear

pattern or finish.

(2) Inspect the bearings for wear.

INSPECTION - CAMSHAFT

(1) Inspect the cam lobes for wear.

(2) Inspect the camshaft position sensor drive gear

for wear.

(3) If the camshaft appears to have been rubbing

against the thrust washer, examine the oil pressure

Fig. 30 CamshaftÐTypical

1 - CAMSHAFT

2 - LOBES

3 - BEARING JOURNAL

WJENGINE - 4.0L 9 - 31

CAMSHAFT & BEARINGS (Continued)

Page 1301 of 2199

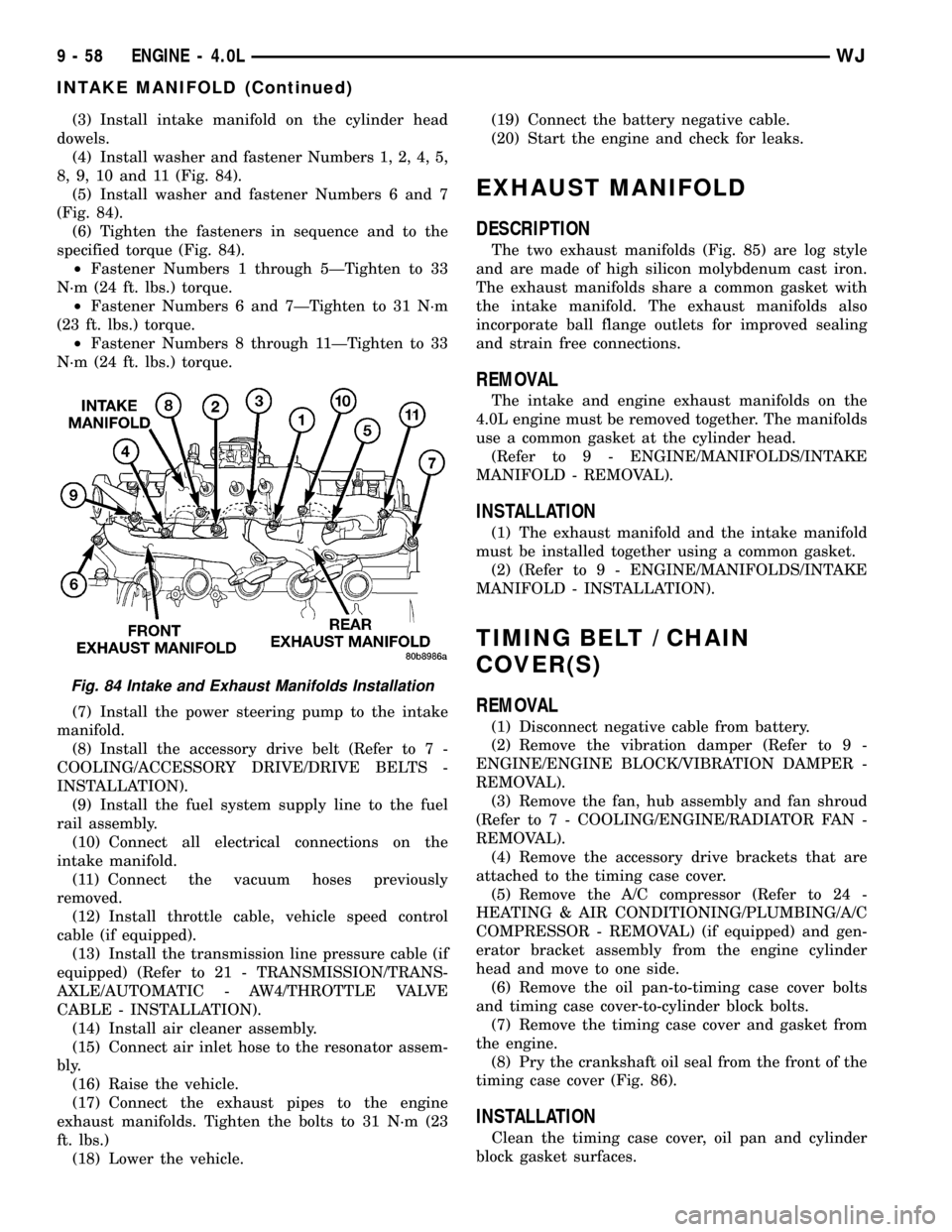

(3) Install intake manifold on the cylinder head

dowels.

(4) Install washer and fastener Numbers 1, 2, 4, 5,

8, 9, 10 and 11 (Fig. 84).

(5) Install washer and fastener Numbers 6 and 7

(Fig. 84).

(6) Tighten the fasteners in sequence and to the

specified torque (Fig. 84).

²Fastener Numbers 1 through 5ÐTighten to 33

N´m (24 ft. lbs.) torque.

²Fastener Numbers 6 and 7ÐTighten to 31 N´m

(23 ft. lbs.) torque.

²Fastener Numbers 8 through 11ÐTighten to 33

N´m (24 ft. lbs.) torque.

(7) Install the power steering pump to the intake

manifold.

(8) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(9) Install the fuel system supply line to the fuel

rail assembly.

(10) Connect all electrical connections on the

intake manifold.

(11) Connect the vacuum hoses previously

removed.

(12) Install throttle cable, vehicle speed control

cable (if equipped).

(13) Install the transmission line pressure cable (if

equipped) (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - AW4/THROTTLE VALVE

CABLE - INSTALLATION).

(14) Install air cleaner assembly.

(15) Connect air inlet hose to the resonator assem-

bly.

(16) Raise the vehicle.

(17) Connect the exhaust pipes to the engine

exhaust manifolds. Tighten the bolts to 31 N´m (23

ft. lbs.)

(18) Lower the vehicle.(19) Connect the battery negative cable.

(20) Start the engine and check for leaks.

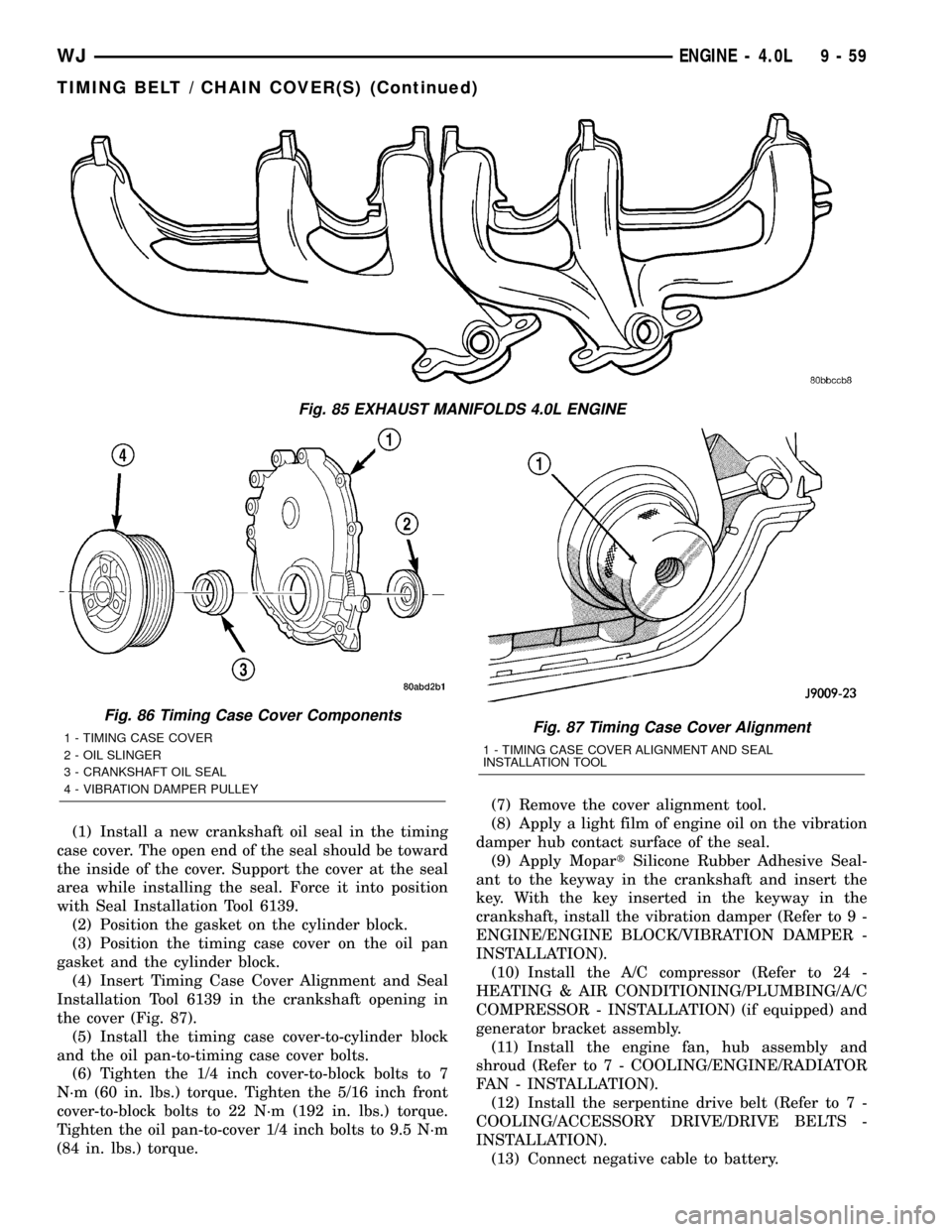

EXHAUST MANIFOLD

DESCRIPTION

The two exhaust manifolds (Fig. 85) are log style

and are made of high silicon molybdenum cast iron.

The exhaust manifolds share a common gasket with

the intake manifold. The exhaust manifolds also

incorporate ball flange outlets for improved sealing

and strain free connections.

REMOVAL

The intake and engine exhaust manifolds on the

4.0L engine must be removed together. The manifolds

use a common gasket at the cylinder head.

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE

MANIFOLD - REMOVAL).

INSTALLATION

(1) The exhaust manifold and the intake manifold

must be installed together using a common gasket.

(2) (Refer to 9 - ENGINE/MANIFOLDS/INTAKE

MANIFOLD - INSTALLATION).

TIMING BELT / CHAIN

COVER(S)

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(3) Remove the fan, hub assembly and fan shroud

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

(4) Remove the accessory drive brackets that are

attached to the timing case cover.

(5) Remove the A/C compressor (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - REMOVAL) (if equipped) and gen-

erator bracket assembly from the engine cylinder

head and move to one side.

(6) Remove the oil pan-to-timing case cover bolts

and timing case cover-to-cylinder block bolts.

(7) Remove the timing case cover and gasket from

the engine.

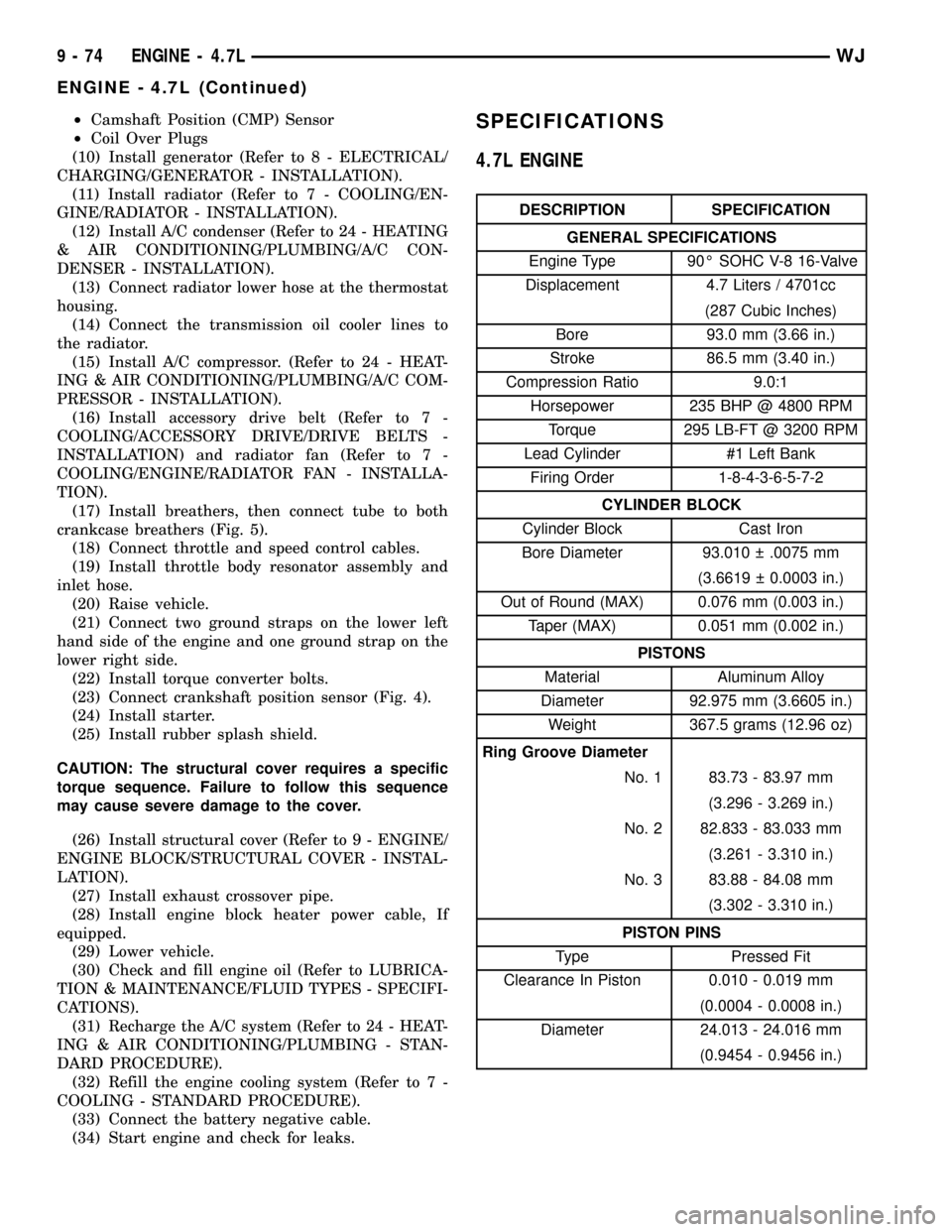

(8) Pry the crankshaft oil seal from the front of the

timing case cover (Fig. 86).

INSTALLATION

Clean the timing case cover, oil pan and cylinder

block gasket surfaces.

Fig. 84 Intake and Exhaust Manifolds Installation

9 - 58 ENGINE - 4.0LWJ

INTAKE MANIFOLD (Continued)

Page 1302 of 2199

(1) Install a new crankshaft oil seal in the timing

case cover. The open end of the seal should be toward

the inside of the cover. Support the cover at the seal

area while installing the seal. Force it into position

with Seal Installation Tool 6139.

(2) Position the gasket on the cylinder block.

(3) Position the timing case cover on the oil pan

gasket and the cylinder block.

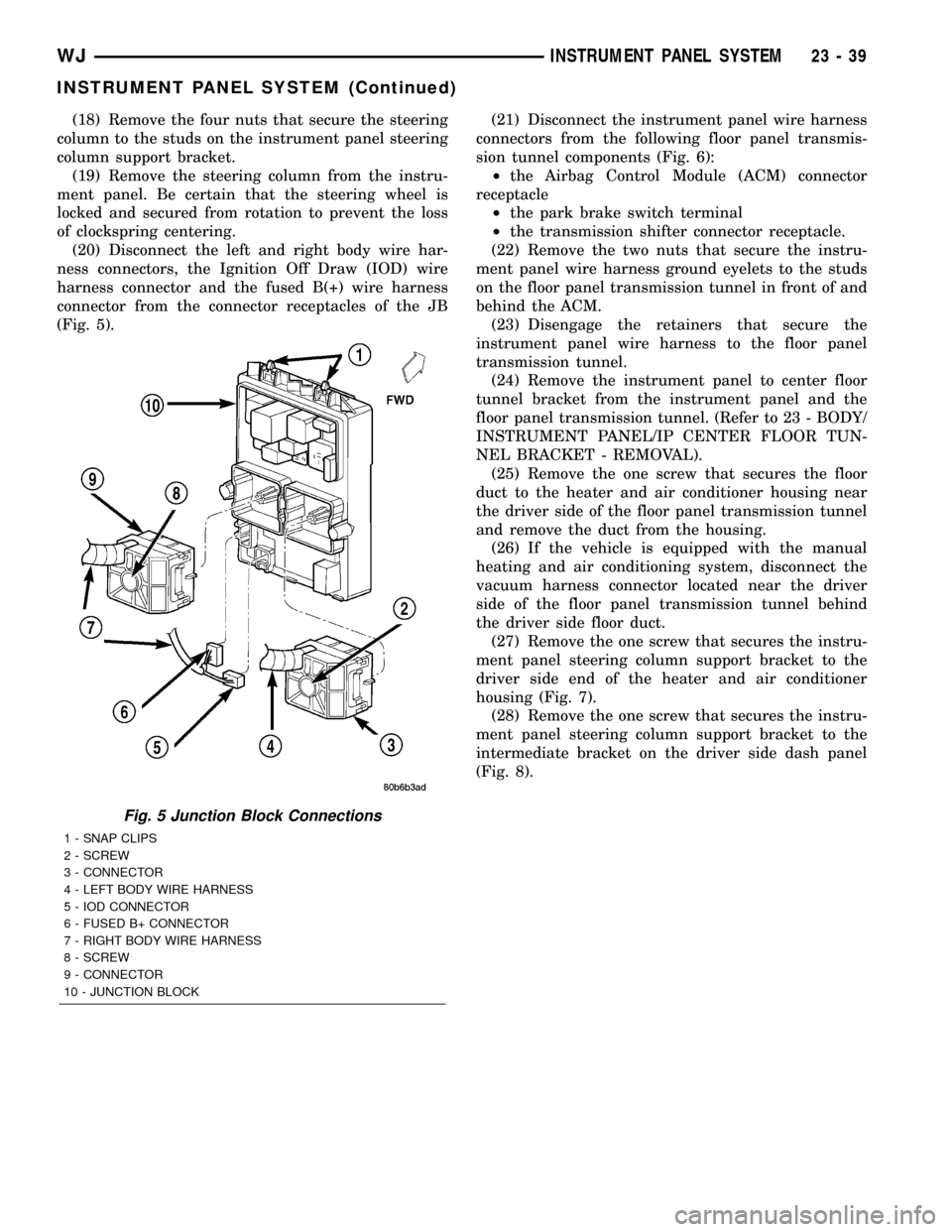

(4) Insert Timing Case Cover Alignment and Seal

Installation Tool 6139 in the crankshaft opening in

the cover (Fig. 87).

(5) Install the timing case cover-to-cylinder block

and the oil pan-to-timing case cover bolts.

(6) Tighten the 1/4 inch cover-to-block bolts to 7

N´m (60 in. lbs.) torque. Tighten the 5/16 inch front

cover-to-block bolts to 22 N´m (192 in. lbs.) torque.

Tighten the oil pan-to-cover 1/4 inch bolts to 9.5 N´m

(84 in. lbs.) torque.(7) Remove the cover alignment tool.

(8) Apply a light film of engine oil on the vibration

damper hub contact surface of the seal.

(9) Apply MopartSilicone Rubber Adhesive Seal-

ant to the keyway in the crankshaft and insert the

key. With the key inserted in the keyway in the

crankshaft, install the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION).

(10) Install the A/C compressor (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - INSTALLATION) (if equipped) and

generator bracket assembly.

(11) Install the engine fan, hub assembly and

shroud (Refer to 7 - COOLING/ENGINE/RADIATOR

FAN - INSTALLATION).

(12) Install the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(13) Connect negative cable to battery.

Fig. 85 EXHAUST MANIFOLDS 4.0L ENGINE

Fig. 86 Timing Case Cover Components

1 - TIMING CASE COVER

2 - OIL SLINGER

3 - CRANKSHAFT OIL SEAL

4 - VIBRATION DAMPER PULLEYFig. 87 Timing Case Cover Alignment

1 - TIMING CASE COVER ALIGNMENT AND SEAL

INSTALLATION TOOL

WJENGINE - 4.0L 9 - 59

TIMING BELT / CHAIN COVER(S) (Continued)

Page 1317 of 2199

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

(10) Install generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - INSTALLATION).

(11) Install radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - INSTALLATION).

(12) Install A/C condenser (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/A/C CON-

DENSER - INSTALLATION).

(13) Connect radiator lower hose at the thermostat

housing.

(14) Connect the transmission oil cooler lines to

the radiator.

(15) Install A/C compressor. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - INSTALLATION).

(16) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION) and radiator fan (Refer to 7 -

COOLING/ENGINE/RADIATOR FAN - INSTALLA-

TION).

(17) Install breathers, then connect tube to both

crankcase breathers (Fig. 5).

(18) Connect throttle and speed control cables.

(19) Install throttle body resonator assembly and

inlet hose.

(20) Raise vehicle.

(21) Connect two ground straps on the lower left

hand side of the engine and one ground strap on the

lower right side.

(22) Install torque converter bolts.

(23) Connect crankshaft position sensor (Fig. 4).

(24) Install starter.

(25) Install rubber splash shield.

CAUTION: The structural cover requires a specific

torque sequence. Failure to follow this sequence

may cause severe damage to the cover.

(26) Install structural cover (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - INSTAL-

LATION).

(27) Install exhaust crossover pipe.

(28) Install engine block heater power cable, If

equipped.

(29) Lower vehicle.

(30) Check and fill engine oil (Refer to LUBRICA-

TION & MAINTENANCE/FLUID TYPES - SPECIFI-

CATIONS).

(31) Recharge the A/C system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE).

(32) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(33) Connect the battery negative cable.

(34) Start engine and check for leaks.SPECIFICATIONS

4.7L ENGINE

DESCRIPTION SPECIFICATION

GENERAL SPECIFICATIONS

Engine Type 90É SOHC V-8 16-Valve

Displacement 4.7 Liters / 4701cc

(287 Cubic Inches)

Bore 93.0 mm (3.66 in.)

Stroke 86.5 mm (3.40 in.)

Compression Ratio 9.0:1

Horsepower 235 BHP @ 4800 RPM

Torque 295 LB-FT @ 3200 RPM

Lead Cylinder #1 Left Bank

Firing Order 1-8-4-3-6-5-7-2

CYLINDER BLOCK

Cylinder Block Cast Iron

Bore Diameter 93.010 .0075 mm

(3.6619 0.0003 in.)

Out of Round (MAX) 0.076 mm (0.003 in.)

Taper (MAX) 0.051 mm (0.002 in.)

PISTONS

Material Aluminum Alloy

Diameter 92.975 mm (3.6605 in.)

Weight 367.5 grams (12.96 oz)

Ring Groove Diameter

No. 1 83.73 - 83.97 mm

(3.296 - 3.269 in.)

No. 2 82.833 - 83.033 mm

(3.261 - 3.310 in.)

No. 3 83.88 - 84.08 mm

(3.302 - 3.310 in.)

PISTON PINS

Type Pressed Fit

Clearance In Piston 0.010 - 0.019 mm

(0.0004 - 0.0008 in.)

Diameter 24.013 - 24.016 mm

(0.9454 - 0.9456 in.)

9 - 74 ENGINE - 4.7LWJ

ENGINE - 4.7L (Continued)

Page 1912 of 2199

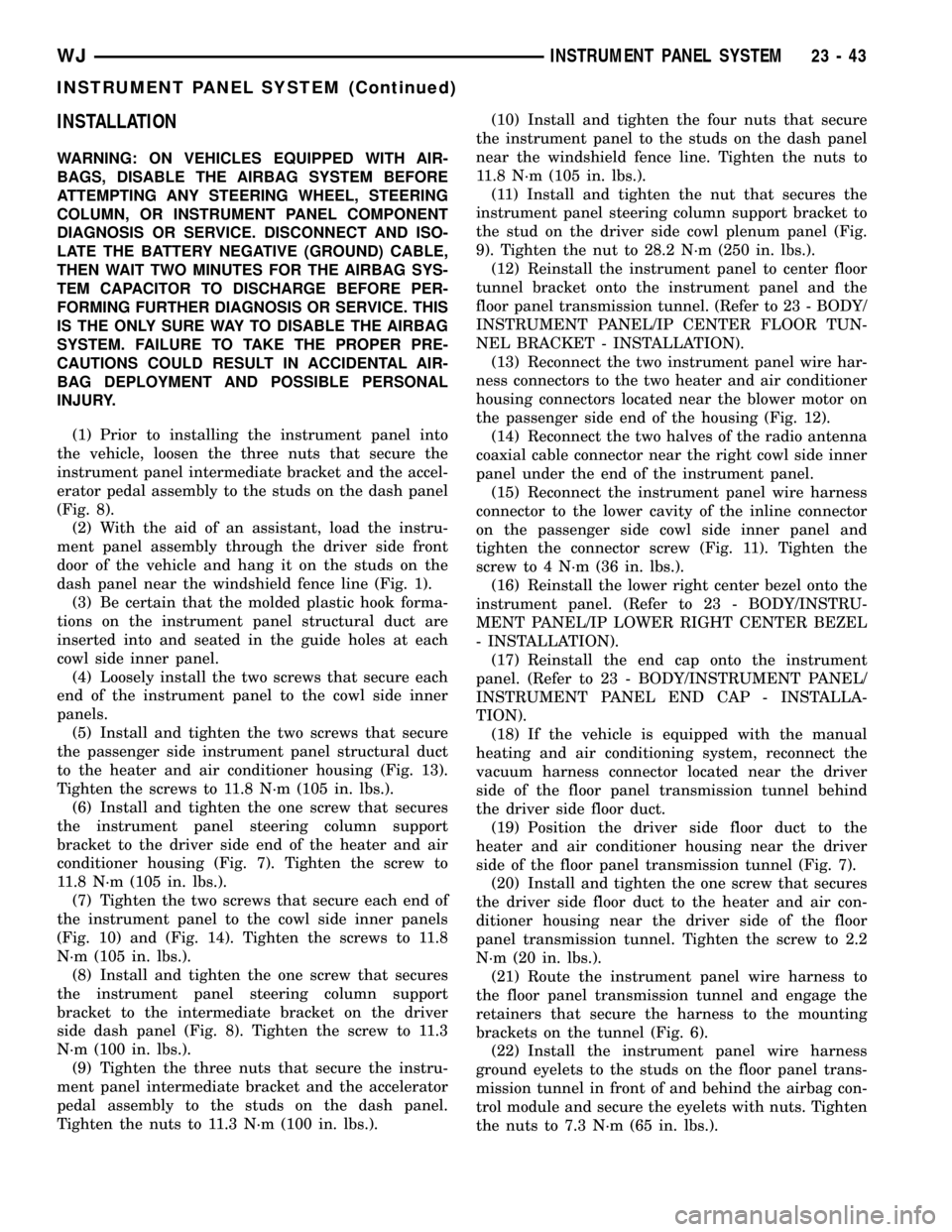

(18) Remove the four nuts that secure the steering

column to the studs on the instrument panel steering

column support bracket.

(19) Remove the steering column from the instru-

ment panel. Be certain that the steering wheel is

locked and secured from rotation to prevent the loss

of clockspring centering.

(20) Disconnect the left and right body wire har-

ness connectors, the Ignition Off Draw (IOD) wire

harness connector and the fused B(+) wire harness

connector from the connector receptacles of the JB

(Fig. 5).(21) Disconnect the instrument panel wire harness

connectors from the following floor panel transmis-

sion tunnel components (Fig. 6):

²the Airbag Control Module (ACM) connector

receptacle

²the park brake switch terminal

²the transmission shifter connector receptacle.

(22) Remove the two nuts that secure the instru-

ment panel wire harness ground eyelets to the studs

on the floor panel transmission tunnel in front of and

behind the ACM.

(23) Disengage the retainers that secure the

instrument panel wire harness to the floor panel

transmission tunnel.

(24) Remove the instrument panel to center floor

tunnel bracket from the instrument panel and the

floor panel transmission tunnel. (Refer to 23 - BODY/

INSTRUMENT PANEL/IP CENTER FLOOR TUN-

NEL BRACKET - REMOVAL).

(25) Remove the one screw that secures the floor

duct to the heater and air conditioner housing near

the driver side of the floor panel transmission tunnel

and remove the duct from the housing.

(26) If the vehicle is equipped with the manual

heating and air conditioning system, disconnect the

vacuum harness connector located near the driver

side of the floor panel transmission tunnel behind

the driver side floor duct.

(27) Remove the one screw that secures the instru-

ment panel steering column support bracket to the

driver side end of the heater and air conditioner

housing (Fig. 7).

(28) Remove the one screw that secures the instru-

ment panel steering column support bracket to the

intermediate bracket on the driver side dash panel

(Fig. 8).

Fig. 5 Junction Block Connections

1 - SNAP CLIPS

2 - SCREW

3 - CONNECTOR

4 - LEFT BODY WIRE HARNESS

5 - IOD CONNECTOR

6 - FUSED B+ CONNECTOR

7 - RIGHT BODY WIRE HARNESS

8 - SCREW

9 - CONNECTOR

10 - JUNCTION BLOCK

WJINSTRUMENT PANEL SYSTEM 23 - 39

INSTRUMENT PANEL SYSTEM (Continued)

Page 1916 of 2199

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Prior to installing the instrument panel into

the vehicle, loosen the three nuts that secure the

instrument panel intermediate bracket and the accel-

erator pedal assembly to the studs on the dash panel

(Fig. 8).

(2) With the aid of an assistant, load the instru-

ment panel assembly through the driver side front

door of the vehicle and hang it on the studs on the

dash panel near the windshield fence line (Fig. 1).

(3) Be certain that the molded plastic hook forma-

tions on the instrument panel structural duct are

inserted into and seated in the guide holes at each

cowl side inner panel.

(4) Loosely install the two screws that secure each

end of the instrument panel to the cowl side inner

panels.

(5) Install and tighten the two screws that secure

the passenger side instrument panel structural duct

to the heater and air conditioner housing (Fig. 13).

Tighten the screws to 11.8 N´m (105 in. lbs.).

(6) Install and tighten the one screw that secures

the instrument panel steering column support

bracket to the driver side end of the heater and air

conditioner housing (Fig. 7). Tighten the screw to

11.8 N´m (105 in. lbs.).

(7) Tighten the two screws that secure each end of

the instrument panel to the cowl side inner panels

(Fig. 10) and (Fig. 14). Tighten the screws to 11.8

N´m (105 in. lbs.).

(8) Install and tighten the one screw that secures

the instrument panel steering column support

bracket to the intermediate bracket on the driver

side dash panel (Fig. 8). Tighten the screw to 11.3

N´m (100 in. lbs.).

(9) Tighten the three nuts that secure the instru-

ment panel intermediate bracket and the accelerator

pedal assembly to the studs on the dash panel.

Tighten the nuts to 11.3 N´m (100 in. lbs.).(10) Install and tighten the four nuts that secure

the instrument panel to the studs on the dash panel

near the windshield fence line. Tighten the nuts to

11.8 N´m (105 in. lbs.).

(11) Install and tighten the nut that secures the

instrument panel steering column support bracket to

the stud on the driver side cowl plenum panel (Fig.

9). Tighten the nut to 28.2 N´m (250 in. lbs.).

(12) Reinstall the instrument panel to center floor

tunnel bracket onto the instrument panel and the

floor panel transmission tunnel. (Refer to 23 - BODY/

INSTRUMENT PANEL/IP CENTER FLOOR TUN-

NEL BRACKET - INSTALLATION).

(13) Reconnect the two instrument panel wire har-

ness connectors to the two heater and air conditioner

housing connectors located near the blower motor on

the passenger side end of the housing (Fig. 12).

(14) Reconnect the two halves of the radio antenna

coaxial cable connector near the right cowl side inner

panel under the end of the instrument panel.

(15) Reconnect the instrument panel wire harness

connector to the lower cavity of the inline connector

on the passenger side cowl side inner panel and

tighten the connector screw (Fig. 11). Tighten the

screw to 4 N´m (36 in. lbs.).

(16) Reinstall the lower right center bezel onto the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/IP LOWER RIGHT CENTER BEZEL

- INSTALLATION).

(17) Reinstall the end cap onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL END CAP - INSTALLA-

TION).

(18) If the vehicle is equipped with the manual

heating and air conditioning system, reconnect the

vacuum harness connector located near the driver

side of the floor panel transmission tunnel behind

the driver side floor duct.

(19) Position the driver side floor duct to the

heater and air conditioner housing near the driver

side of the floor panel transmission tunnel (Fig. 7).

(20) Install and tighten the one screw that secures

the driver side floor duct to the heater and air con-

ditioner housing near the driver side of the floor

panel transmission tunnel. Tighten the screw to 2.2

N´m (20 in. lbs.).

(21) Route the instrument panel wire harness to

the floor panel transmission tunnel and engage the

retainers that secure the harness to the mounting

brackets on the tunnel (Fig. 6).

(22) Install the instrument panel wire harness

ground eyelets to the studs on the floor panel trans-

mission tunnel in front of and behind the airbag con-

trol module and secure the eyelets with nuts. Tighten

the nuts to 7.3 N´m (65 in. lbs.).

WJINSTRUMENT PANEL SYSTEM 23 - 43

INSTRUMENT PANEL SYSTEM (Continued)

Page 2078 of 2199

HEATING & AIR CONDITIONING

TABLE OF CONTENTS

page page

HEATING & AIR CONDITIONING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM

REQUIREMENTS.......................1

DESCRIPTION - HEATER AND AIR

CONDITIONER........................1

DESCRIPTION - REFRIGERANT SYSTEM

SERVICE PORT........................1

OPERATION

OPERATION - HEATER AND AIR

CONDITIONER........................2

OPERATION - REFRIGERANT SYSTEM

SERVICE PORT........................2DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE.......................2

DIAGNOSIS AND TESTING - HEATER

PERFORMANCE.......................6

STANDARD PROCEDURE - DIODE

REPLACEMENT.......................6

SPECIFICATIONS

A/C APPLICATION TABLE................7

TORQUE SPECIFICATIONS..............8

CONTROLS.............................9

DISTRIBUTION..........................36

PLUMBING.............................51

HEATING & AIR

CONDITIONING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM

REQUIREMENTS

To maintain the performance level of the heating-

air conditioning system, the engine cooling system

must be properly maintained. The use of a bug

screen is not recommended. Any obstructions in front

of the radiator or condenser will reduce the perfor-

mance of the air conditioning and engine cooling sys-

tems.

The engine cooling system includes the heater core

and the heater hoses. Refer to Cooling for more infor-

mation before opening, or attempting any service to

the engine cooling system.

DESCRIPTION - HEATER AND AIR

CONDITIONER

A manual temperature control type heating-air

conditioning system is standard factory-installed

equipment on this model. An electronically controlled

Automatic Zone Control (AZC) type heating-air con-

ditioning system is an available factory-installed

option.

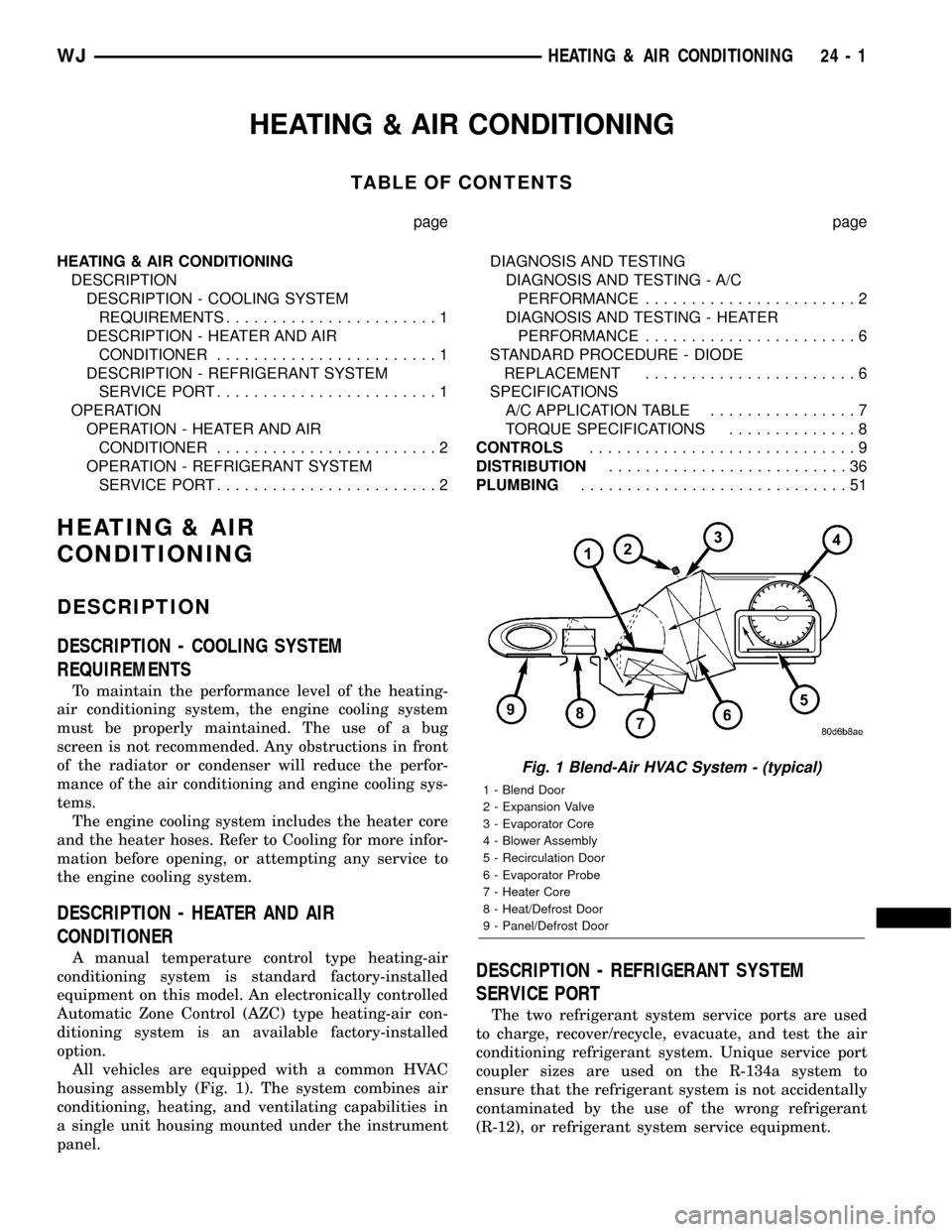

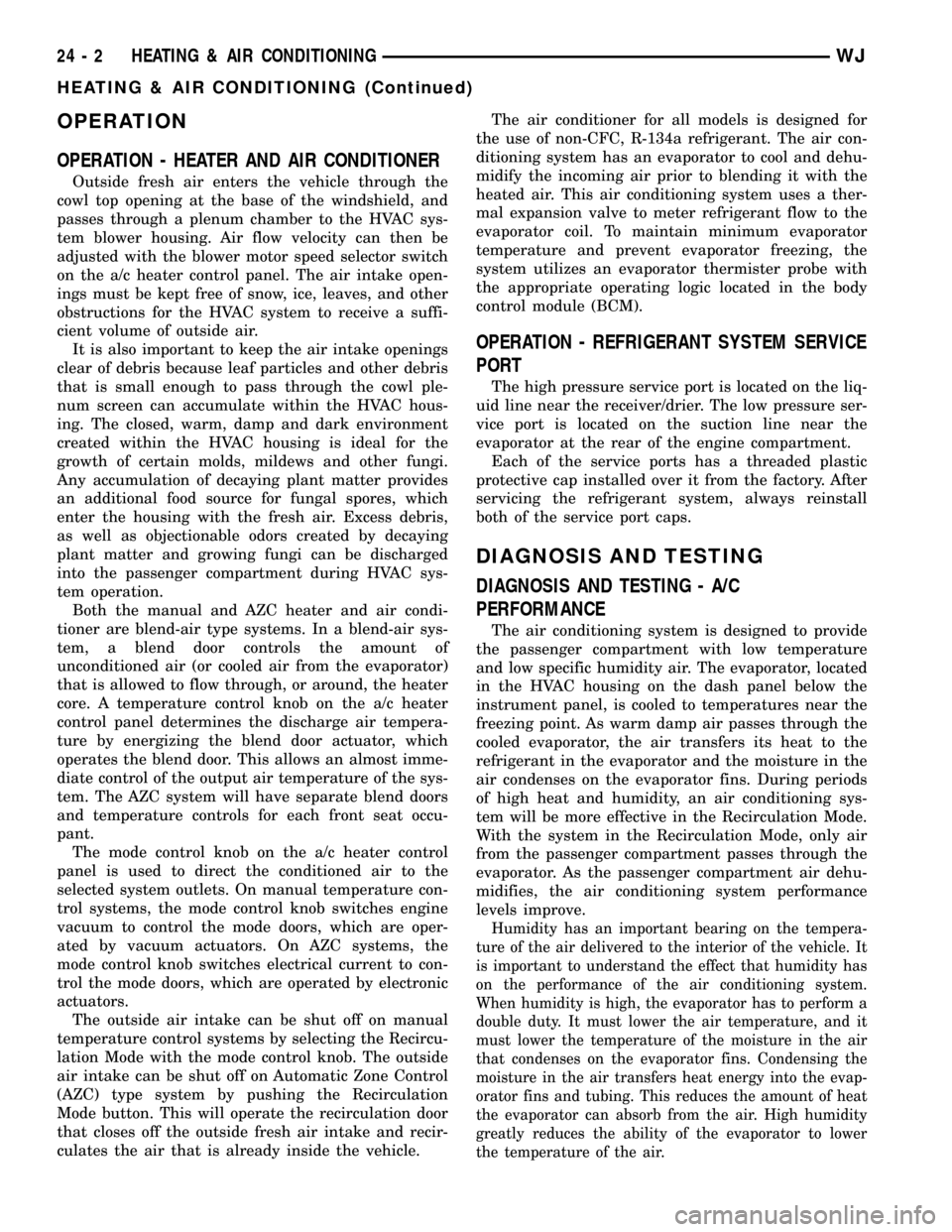

All vehicles are equipped with a common HVAC

housing assembly (Fig. 1). The system combines air

conditioning, heating, and ventilating capabilities in

a single unit housing mounted under the instrument

panel.DESCRIPTION - REFRIGERANT SYSTEM

SERVICE PORT

The two refrigerant system service ports are used

to charge, recover/recycle, evacuate, and test the air

conditioning refrigerant system. Unique service port

coupler sizes are used on the R-134a system to

ensure that the refrigerant system is not accidentally

contaminated by the use of the wrong refrigerant

(R-12), or refrigerant system service equipment.

Fig. 1 Blend-Air HVAC System - (typical)

1 - Blend Door

2 - Expansion Valve

3 - Evaporator Core

4 - Blower Assembly

5 - Recirculation Door

6 - Evaporator Probe

7 - Heater Core

8 - Heat/Defrost Door

9 - Panel/Defrost Door

WJHEATING & AIR CONDITIONING 24 - 1

Page 2079 of 2199

OPERATION

OPERATION - HEATER AND AIR CONDITIONER

Outside fresh air enters the vehicle through the

cowl top opening at the base of the windshield, and

passes through a plenum chamber to the HVAC sys-

tem blower housing. Air flow velocity can then be

adjusted with the blower motor speed selector switch

on the a/c heater control panel. The air intake open-

ings must be kept free of snow, ice, leaves, and other

obstructions for the HVAC system to receive a suffi-

cient volume of outside air.

It is also important to keep the air intake openings

clear of debris because leaf particles and other debris

that is small enough to pass through the cowl ple-

num screen can accumulate within the HVAC hous-

ing. The closed, warm, damp and dark environment

created within the HVAC housing is ideal for the

growth of certain molds, mildews and other fungi.

Any accumulation of decaying plant matter provides

an additional food source for fungal spores, which

enter the housing with the fresh air. Excess debris,

as well as objectionable odors created by decaying

plant matter and growing fungi can be discharged

into the passenger compartment during HVAC sys-

tem operation.

Both the manual and AZC heater and air condi-

tioner are blend-air type systems. In a blend-air sys-

tem, a blend door controls the amount of

unconditioned air (or cooled air from the evaporator)

that is allowed to flow through, or around, the heater

core. A temperature control knob on the a/c heater

control panel determines the discharge air tempera-

ture by energizing the blend door actuator, which

operates the blend door. This allows an almost imme-

diate control of the output air temperature of the sys-

tem. The AZC system will have separate blend doors

and temperature controls for each front seat occu-

pant.

The mode control knob on the a/c heater control

panel is used to direct the conditioned air to the

selected system outlets. On manual temperature con-

trol systems, the mode control knob switches engine

vacuum to control the mode doors, which are oper-

ated by vacuum actuators. On AZC systems, the

mode control knob switches electrical current to con-

trol the mode doors, which are operated by electronic

actuators.

The outside air intake can be shut off on manual

temperature control systems by selecting the Recircu-

lation Mode with the mode control knob. The outside

air intake can be shut off on Automatic Zone Control

(AZC) type system by pushing the Recirculation

Mode button. This will operate the recirculation door

that closes off the outside fresh air intake and recir-

culates the air that is already inside the vehicle.The air conditioner for all models is designed for

the use of non-CFC, R-134a refrigerant. The air con-

ditioning system has an evaporator to cool and dehu-

midify the incoming air prior to blending it with the

heated air. This air conditioning system uses a ther-

mal expansion valve to meter refrigerant flow to the

evaporator coil. To maintain minimum evaporator

temperature and prevent evaporator freezing, the

system utilizes an evaporator thermister probe with

the appropriate operating logic located in the body

control module (BCM).

OPERATION - REFRIGERANT SYSTEM SERVICE

PORT

The high pressure service port is located on the liq-

uid line near the receiver/drier. The low pressure ser-

vice port is located on the suction line near the

evaporator at the rear of the engine compartment.

Each of the service ports has a threaded plastic

protective cap installed over it from the factory. After

servicing the refrigerant system, always reinstall

both of the service port caps.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE

The air conditioning system is designed to provide

the passenger compartment with low temperature

and low specific humidity air. The evaporator, located

in the HVAC housing on the dash panel below the

instrument panel, is cooled to temperatures near the

freezing point. As warm damp air passes through the

cooled evaporator, the air transfers its heat to the

refrigerant in the evaporator and the moisture in the

air condenses on the evaporator fins. During periods

of high heat and humidity, an air conditioning sys-

tem will be more effective in the Recirculation Mode.

With the system in the Recirculation Mode, only air

from the passenger compartment passes through the

evaporator. As the passenger compartment air dehu-

midifies, the air conditioning system performance

levels improve.

Humidity has an important bearing on the tempera-

ture of the air delivered to the interior of the vehicle. It

is important to understand the effect that humidity has

on the performance of the air conditioning system.

When humidity is high, the evaporator has to perform a

double duty. It must lower the air temperature, and it

must lower the temperature of the moisture in the air

that condenses on the evaporator fins. Condensing the

moisture in the air transfers heat energy into the evap-

orator fins and tubing. This reduces the amount of heat

the evaporator can absorb from the air. High humidity

greatly reduces the ability of the evaporator to lower

the temperature of the air.

24 - 2 HEATING & AIR CONDITIONINGWJ

HEATING & AIR CONDITIONING (Continued)