bleed JEEP GRAND CHEROKEE 2002 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 200 of 2199

STANDARD PROCEDURE - MASTER CYLINDER

BLEEDING PROCEDURE

A new master cylinder should be bled before instal-

lation on the vehicle. Required bleeding tools include

bleed tubes and a wood dowel to stroke the pistons.

Bleed tubes can be fabricated from brake line.

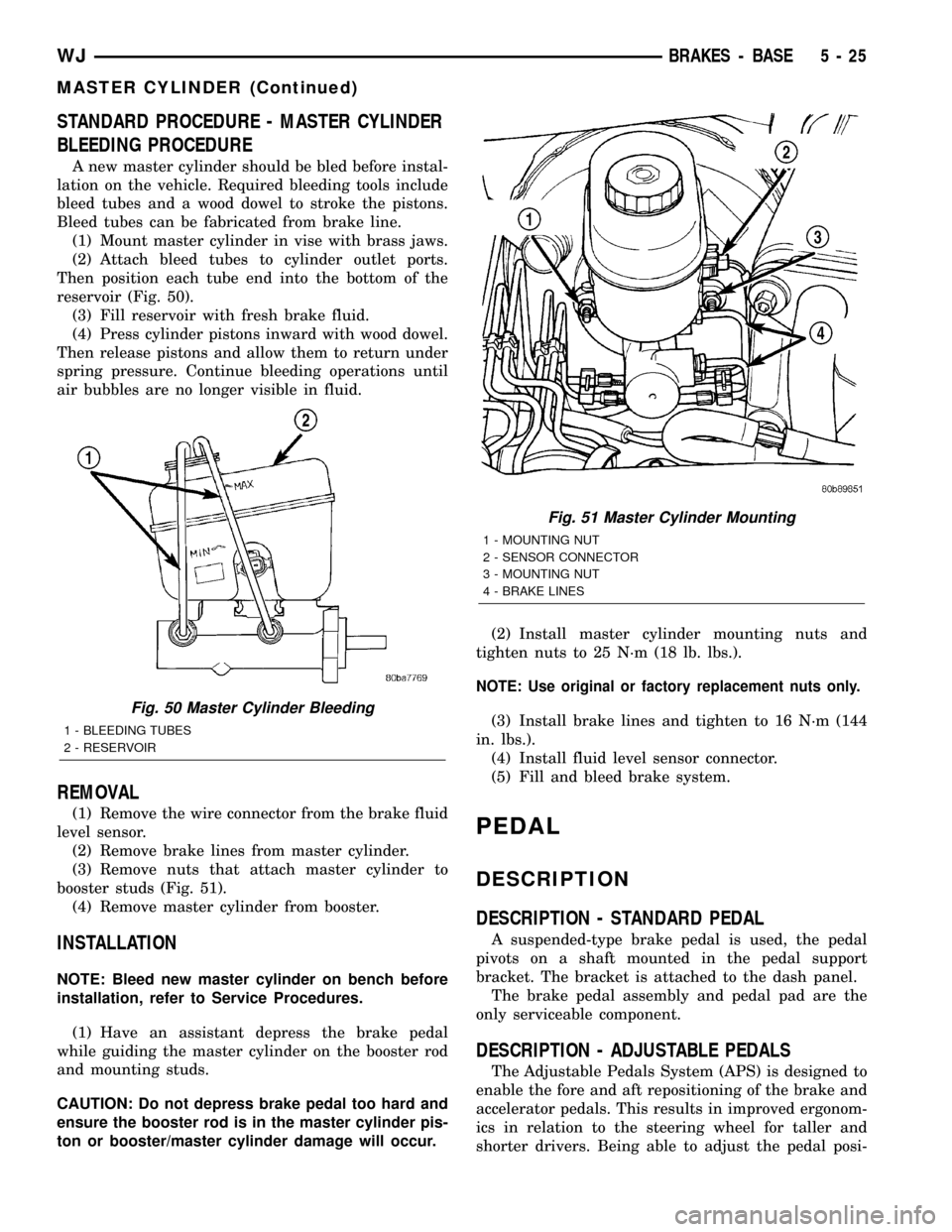

(1) Mount master cylinder in vise with brass jaws.

(2) Attach bleed tubes to cylinder outlet ports.

Then position each tube end into the bottom of the

reservoir (Fig. 50).

(3) Fill reservoir with fresh brake fluid.

(4) Press cylinder pistons inward with wood dowel.

Then release pistons and allow them to return under

spring pressure. Continue bleeding operations until

air bubbles are no longer visible in fluid.

REMOVAL

(1) Remove the wire connector from the brake fluid

level sensor.

(2) Remove brake lines from master cylinder.

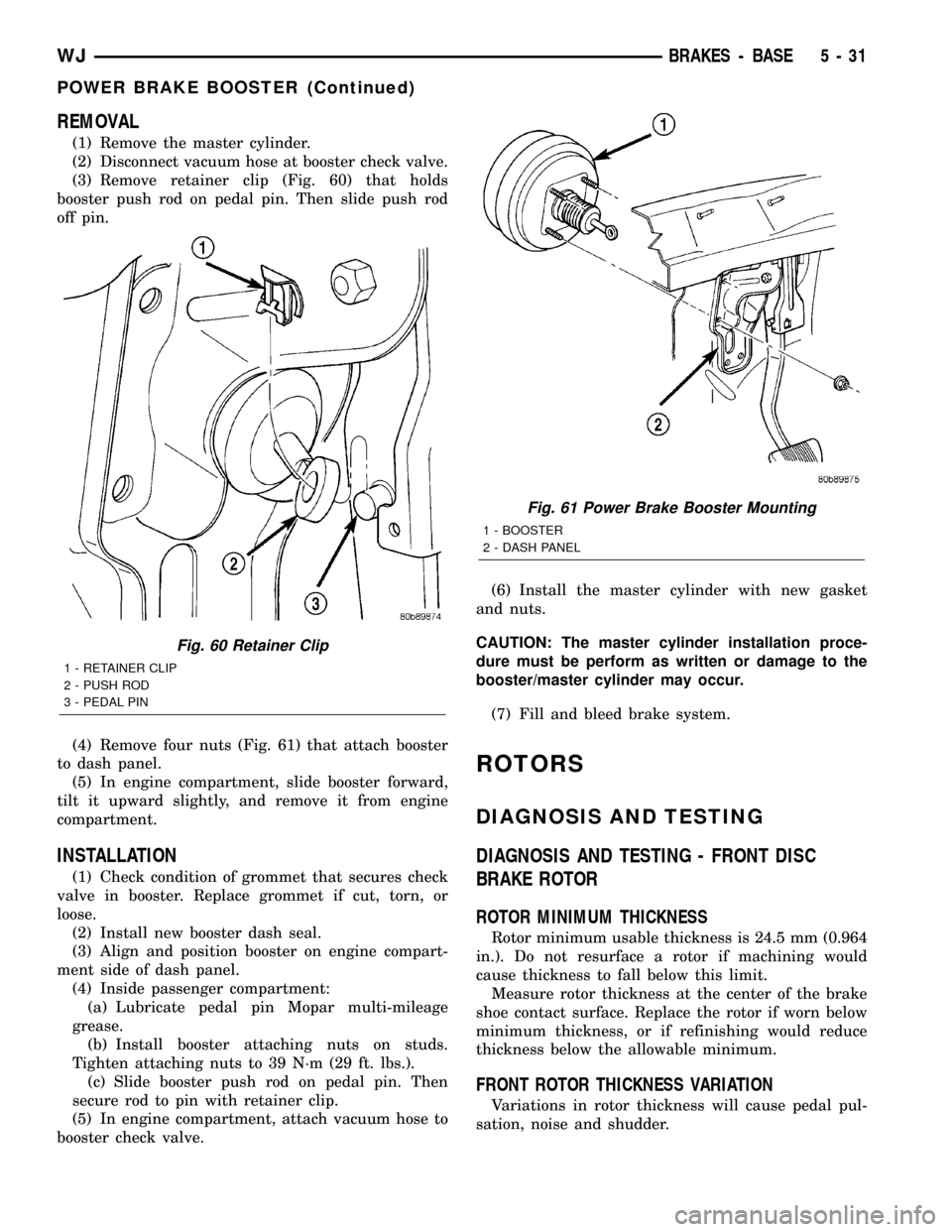

(3) Remove nuts that attach master cylinder to

booster studs (Fig. 51).

(4) Remove master cylinder from booster.

INSTALLATION

NOTE: Bleed new master cylinder on bench before

installation, refer to Service Procedures.

(1) Have an assistant depress the brake pedal

while guiding the master cylinder on the booster rod

and mounting studs.

CAUTION: Do not depress brake pedal too hard and

ensure the booster rod is in the master cylinder pis-

ton or booster/master cylinder damage will occur.(2) Install master cylinder mounting nuts and

tighten nuts to 25 N´m (18 lb. lbs.).

NOTE: Use original or factory replacement nuts only.

(3) Install brake lines and tighten to 16 N´m (144

in. lbs.).

(4) Install fluid level sensor connector.

(5) Fill and bleed brake system.

PEDAL

DESCRIPTION

DESCRIPTION - STANDARD PEDAL

A suspended-type brake pedal is used, the pedal

pivots on a shaft mounted in the pedal support

bracket. The bracket is attached to the dash panel.

The brake pedal assembly and pedal pad are the

only serviceable component.

DESCRIPTION - ADJUSTABLE PEDALS

The Adjustable Pedals System (APS) is designed to

enable the fore and aft repositioning of the brake and

accelerator pedals. This results in improved ergonom-

ics in relation to the steering wheel for taller and

shorter drivers. Being able to adjust the pedal posi-

Fig. 50 Master Cylinder Bleeding

1 - BLEEDING TUBES

2 - RESERVOIR

Fig. 51 Master Cylinder Mounting

1 - MOUNTING NUT

2 - SENSOR CONNECTOR

3 - MOUNTING NUT

4 - BRAKE LINES

WJBRAKES - BASE 5 - 25

MASTER CYLINDER (Continued)

Page 206 of 2199

REMOVAL

(1) Remove the master cylinder.

(2) Disconnect vacuum hose at booster check valve.

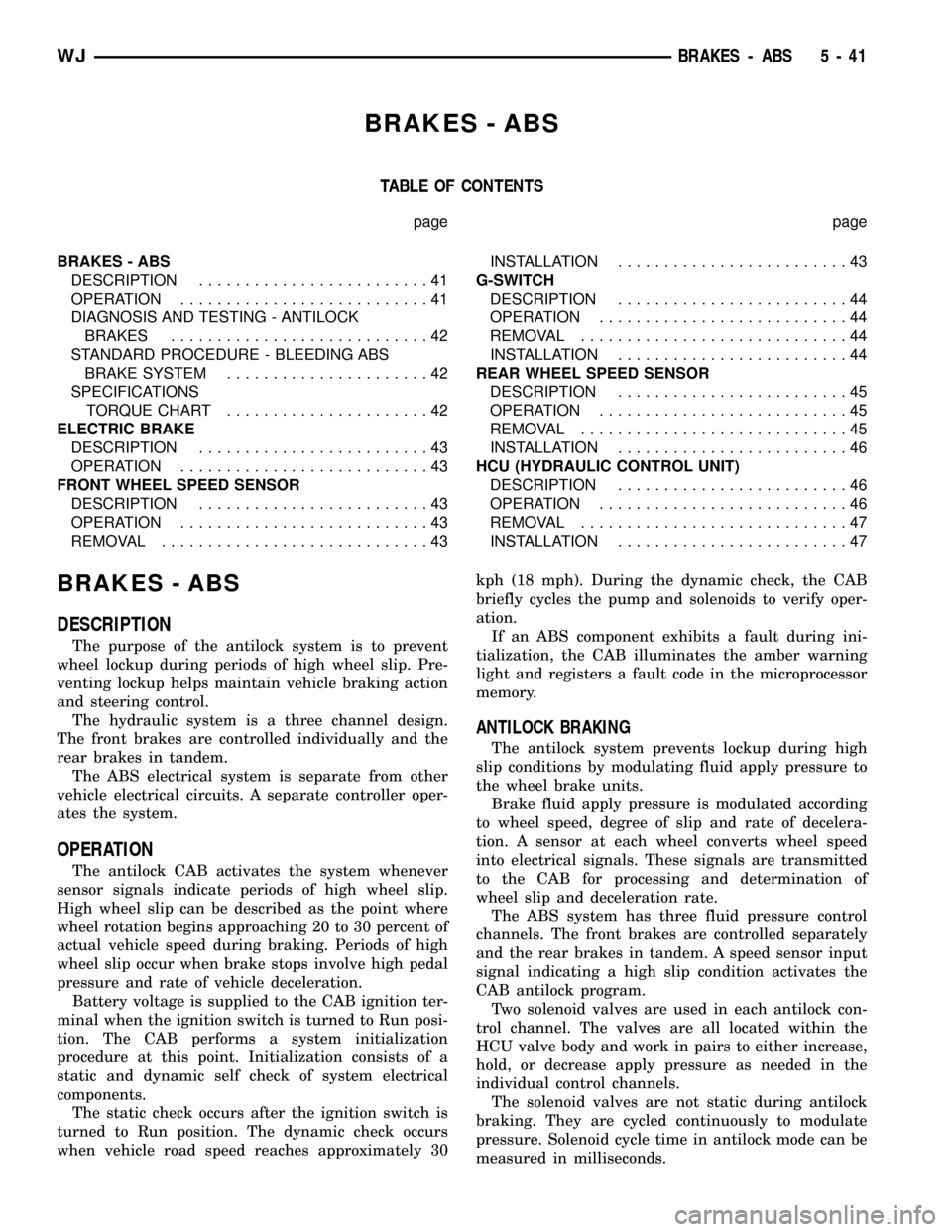

(3) Remove retainer clip (Fig. 60) that holds

booster push rod on pedal pin. Then slide push rod

off pin.

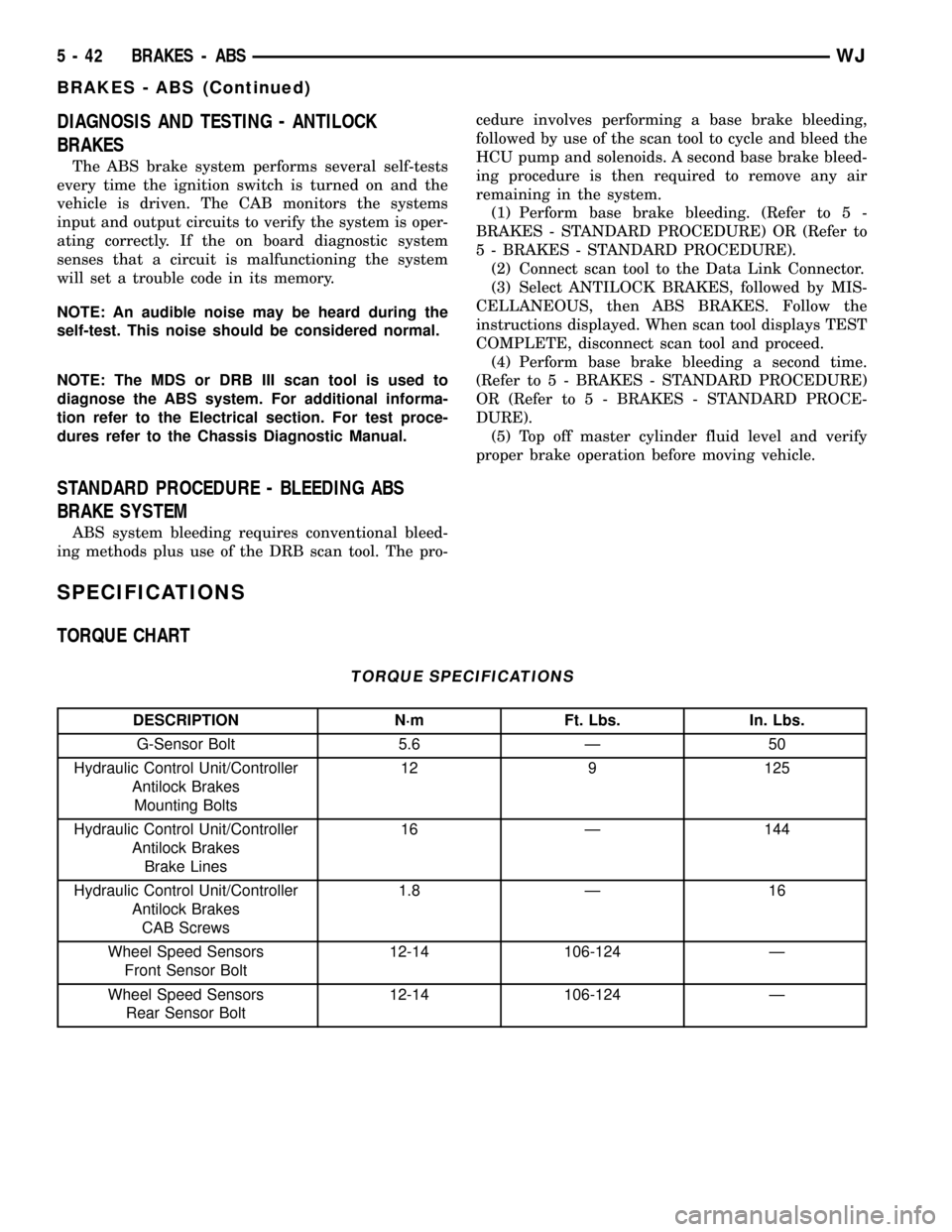

(4) Remove four nuts (Fig. 61) that attach booster

to dash panel.

(5) In engine compartment, slide booster forward,

tilt it upward slightly, and remove it from engine

compartment.

INSTALLATION

(1) Check condition of grommet that secures check

valve in booster. Replace grommet if cut, torn, or

loose.

(2) Install new booster dash seal.

(3) Align and position booster on engine compart-

ment side of dash panel.

(4) Inside passenger compartment:

(a) Lubricate pedal pin Mopar multi-mileage

grease.

(b) Install booster attaching nuts on studs.

Tighten attaching nuts to 39 N´m (29 ft. lbs.).

(c) Slide booster push rod on pedal pin. Then

secure rod to pin with retainer clip.

(5) In engine compartment, attach vacuum hose to

booster check valve.(6) Install the master cylinder with new gasket

and nuts.

CAUTION: The master cylinder installation proce-

dure must be perform as written or damage to the

booster/master cylinder may occur.

(7) Fill and bleed brake system.

ROTORS

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - FRONT DISC

BRAKE ROTOR

ROTOR MINIMUM THICKNESS

Rotor minimum usable thickness is 24.5 mm (0.964

in.). Do not resurface a rotor if machining would

cause thickness to fall below this limit.

Measure rotor thickness at the center of the brake

shoe contact surface. Replace the rotor if worn below

minimum thickness, or if refinishing would reduce

thickness below the allowable minimum.

FRONT ROTOR THICKNESS VARIATION

Variations in rotor thickness will cause pedal pul-

sation, noise and shudder.

Fig. 60 Retainer Clip

1 - RETAINER CLIP

2 - PUSH ROD

3 - PEDAL PIN

Fig. 61 Power Brake Booster Mounting

1 - BOOSTER

2 - DASH PANEL

WJBRAKES - BASE 5 - 31

POWER BRAKE BOOSTER (Continued)

Page 216 of 2199

BRAKES - ABS

TABLE OF CONTENTS

page page

BRAKES - ABS

DESCRIPTION.........................41

OPERATION...........................41

DIAGNOSIS AND TESTING - ANTILOCK

BRAKES............................42

STANDARD PROCEDURE - BLEEDING ABS

BRAKE SYSTEM......................42

SPECIFICATIONS

TORQUE CHART......................42

ELECTRIC BRAKE

DESCRIPTION.........................43

OPERATION...........................43

FRONT WHEEL SPEED SENSOR

DESCRIPTION.........................43

OPERATION...........................43

REMOVAL.............................43INSTALLATION.........................43

G-SWITCH

DESCRIPTION.........................44

OPERATION...........................44

REMOVAL.............................44

INSTALLATION.........................44

REAR WHEEL SPEED SENSOR

DESCRIPTION.........................45

OPERATION...........................45

REMOVAL.............................45

INSTALLATION.........................46

HCU (HYDRAULIC CONTROL UNIT)

DESCRIPTION.........................46

OPERATION...........................46

REMOVAL.............................47

INSTALLATION.........................47

BRAKES - ABS

DESCRIPTION

The purpose of the antilock system is to prevent

wheel lockup during periods of high wheel slip. Pre-

venting lockup helps maintain vehicle braking action

and steering control.

The hydraulic system is a three channel design.

The front brakes are controlled individually and the

rear brakes in tandem.

The ABS electrical system is separate from other

vehicle electrical circuits. A separate controller oper-

ates the system.

OPERATION

The antilock CAB activates the system whenever

sensor signals indicate periods of high wheel slip.

High wheel slip can be described as the point where

wheel rotation begins approaching 20 to 30 percent of

actual vehicle speed during braking. Periods of high

wheel slip occur when brake stops involve high pedal

pressure and rate of vehicle deceleration.

Battery voltage is supplied to the CAB ignition ter-

minal when the ignition switch is turned to Run posi-

tion. The CAB performs a system initialization

procedure at this point. Initialization consists of a

static and dynamic self check of system electrical

components.

The static check occurs after the ignition switch is

turned to Run position. The dynamic check occurs

when vehicle road speed reaches approximately 30kph (18 mph). During the dynamic check, the CAB

briefly cycles the pump and solenoids to verify oper-

ation.

If an ABS component exhibits a fault during ini-

tialization, the CAB illuminates the amber warning

light and registers a fault code in the microprocessor

memory.

ANTILOCK BRAKING

The antilock system prevents lockup during high

slip conditions by modulating fluid apply pressure to

the wheel brake units.

Brake fluid apply pressure is modulated according

to wheel speed, degree of slip and rate of decelera-

tion. A sensor at each wheel converts wheel speed

into electrical signals. These signals are transmitted

to the CAB for processing and determination of

wheel slip and deceleration rate.

The ABS system has three fluid pressure control

channels. The front brakes are controlled separately

and the rear brakes in tandem. A speed sensor input

signal indicating a high slip condition activates the

CAB antilock program.

Two solenoid valves are used in each antilock con-

trol channel. The valves are all located within the

HCU valve body and work in pairs to either increase,

hold, or decrease apply pressure as needed in the

individual control channels.

The solenoid valves are not static during antilock

braking. They are cycled continuously to modulate

pressure. Solenoid cycle time in antilock mode can be

measured in milliseconds.

WJBRAKES - ABS 5 - 41

Page 217 of 2199

DIAGNOSIS AND TESTING - ANTILOCK

BRAKES

The ABS brake system performs several self-tests

every time the ignition switch is turned on and the

vehicle is driven. The CAB monitors the systems

input and output circuits to verify the system is oper-

ating correctly. If the on board diagnostic system

senses that a circuit is malfunctioning the system

will set a trouble code in its memory.

NOTE: An audible noise may be heard during the

self-test. This noise should be considered normal.

NOTE: The MDS or DRB III scan tool is used to

diagnose the ABS system. For additional informa-

tion refer to the Electrical section. For test proce-

dures refer to the Chassis Diagnostic Manual.

STANDARD PROCEDURE - BLEEDING ABS

BRAKE SYSTEM

ABS system bleeding requires conventional bleed-

ing methods plus use of the DRB scan tool. The pro-cedure involves performing a base brake bleeding,

followed by use of the scan tool to cycle and bleed the

HCU pump and solenoids. A second base brake bleed-

ing procedure is then required to remove any air

remaining in the system.

(1) Perform base brake bleeding. (Refer to 5 -

BRAKES - STANDARD PROCEDURE) OR (Refer to

5 - BRAKES - STANDARD PROCEDURE).

(2) Connect scan tool to the Data Link Connector.

(3) Select ANTILOCK BRAKES, followed by MIS-

CELLANEOUS, then ABS BRAKES. Follow the

instructions displayed. When scan tool displays TEST

COMPLETE, disconnect scan tool and proceed.

(4) Perform base brake bleeding a second time.

(Refer to 5 - BRAKES - STANDARD PROCEDURE)

OR (Refer to 5 - BRAKES - STANDARD PROCE-

DURE).

(5) Top off master cylinder fluid level and verify

proper brake operation before moving vehicle.

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

G-Sensor Bolt 5.6 Ð 50

Hydraulic Control Unit/Controller

Antilock Brakes

Mounting Bolts12 9 125

Hydraulic Control Unit/Controller

Antilock Brakes

Brake Lines16 Ð 144

Hydraulic Control Unit/Controller

Antilock Brakes

CAB Screws1.8 Ð 16

Wheel Speed Sensors

Front Sensor Bolt12-14 106-124 Ð

Wheel Speed Sensors

Rear Sensor Bolt12-14 106-124 Ð

5 - 42 BRAKES - ABSWJ

BRAKES - ABS (Continued)

Page 221 of 2199

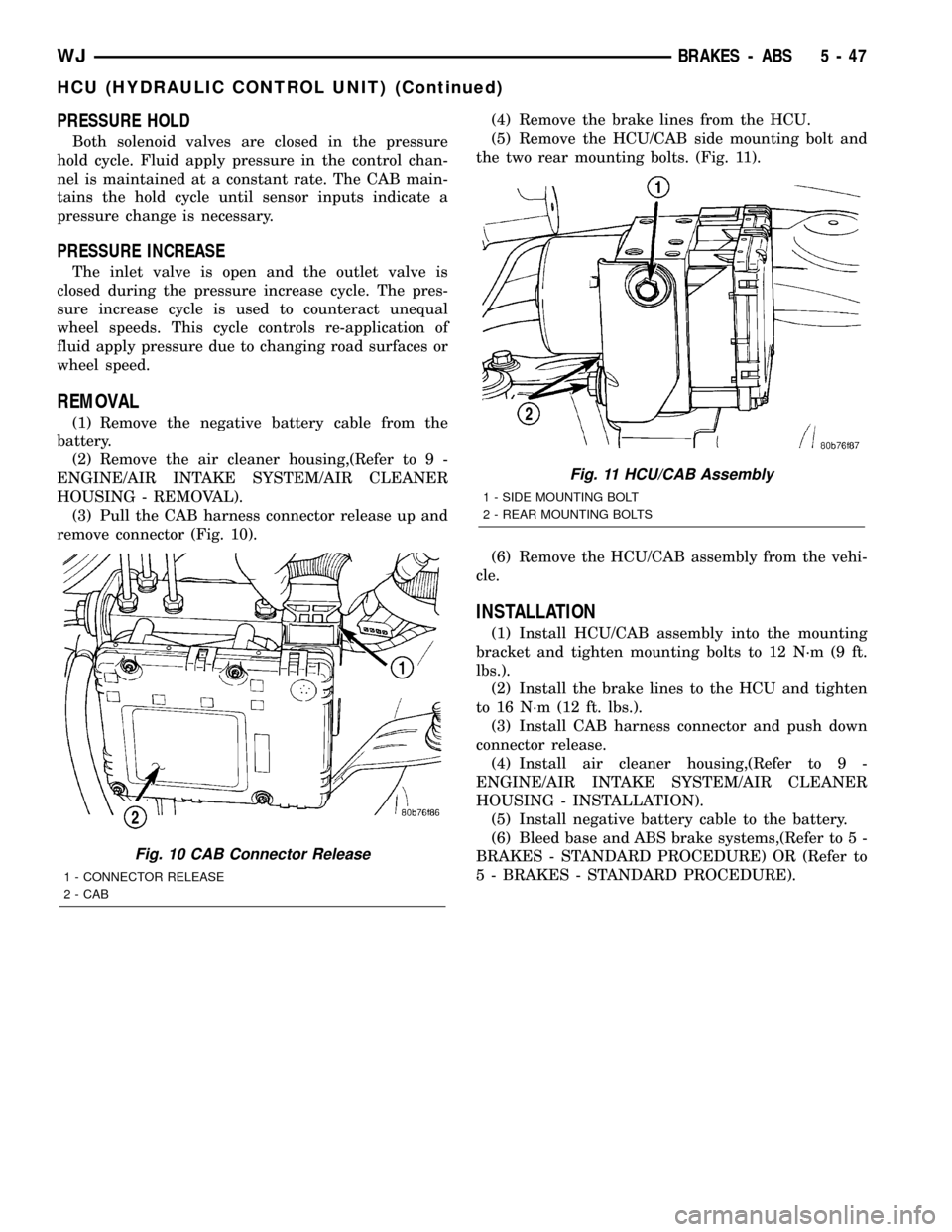

INSTALLATION

(1) Insert the sensor through the backing plate

(Fig. 9).

(2) Apply Mopar Lock N' Seal or Loctite 242tto

the original sensor bolt. Use a new bolt if the original

is worn or damaged.

(3) Tighten the sensor bolt to 12-14 N´m (106-124

in. lbs.).

(4) Secure the sensor wire in the brackets and the

retainers on the rear brake lines. Verify that the sen-

sor wire is secure and clear of the rotating compo-

nents.

(5) Route the sensor wires to the rear seat area.

(6) Feed the sensor wires the through floorpan

access hole and seat the sensor grommets into the

floorpan.

(7) Remove the support and lower the vehicle.(8) Fold the rear seat and carpet forward for

access to the sensor wires and connectors.

(9) Connect the sensor wires to the harness con-

nectors.

(10) Reposition the carpet and fold the rear seat

down.

HCU (HYDRAULIC CONTROL

UNIT)

DESCRIPTION

The HCU consists of a valve body, pump motor,

and wire harness.

OPERATION

Accumulators in the valve body store extra fluid

released to the system for ABS mode operation. The

pump is used to clear the accumulator of brake fluid

and is operated by a DC type motor. The motor is

controlled by the CAB.

The valves modulate brake pressure during

antilock braking and are controlled by the CAB.

The HCU provides three channel pressure control

to the front and rear brakes. One channel controls

the rear wheel brakes in tandem. The two remaining

channels control the front wheel brakes individually.

During antilock braking, the solenoid valves are

opened and closed as needed. The valves are not

static. They are cycled rapidly and continuously to

modulate pressure and control wheel slip and decel-

eration.

During normal braking, the HCU solenoid valves

and pump are not activated. The master cylinder and

power booster operate the same as a vehicle without

an ABS brake system.

During antilock braking, solenoid valve pressure

modulation occurs in three stages, pressure increase,

pressure hold, and pressure decrease. The valves are

all contained in the valve body portion of the HCU.

PRESSURE DECREASE

The outlet valve is opened and the inlet valve is

closed during the pressure decrease cycle.

A pressure decrease cycle is initiated when speed

sensor signals indicate high wheel slip at one or

more wheels. At this point, the CAB closes the inlet

then opens the outlet valve, which also opens the

return circuit to the accumulators. Fluid pressure is

allowed to bleed off (decrease) as needed to prevent

wheel lock.

Once the period of high wheel slip has ended, the

CAB closes the outlet valve and begins a pressure

increase or hold cycle as needed.

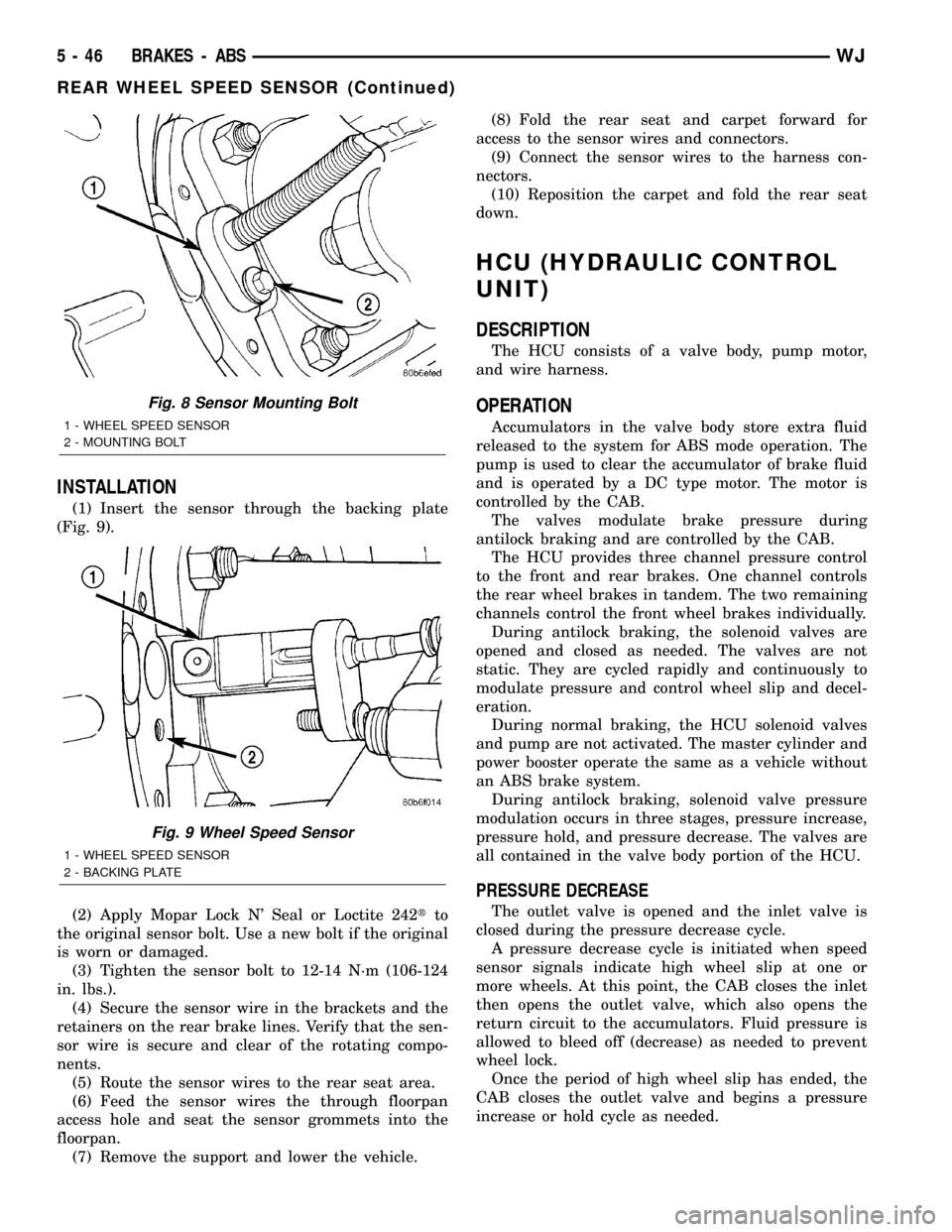

Fig. 8 Sensor Mounting Bolt

1 - WHEEL SPEED SENSOR

2 - MOUNTING BOLT

Fig. 9 Wheel Speed Sensor

1 - WHEEL SPEED SENSOR

2 - BACKING PLATE

5 - 46 BRAKES - ABSWJ

REAR WHEEL SPEED SENSOR (Continued)

Page 222 of 2199

PRESSURE HOLD

Both solenoid valves are closed in the pressure

hold cycle. Fluid apply pressure in the control chan-

nel is maintained at a constant rate. The CAB main-

tains the hold cycle until sensor inputs indicate a

pressure change is necessary.

PRESSURE INCREASE

The inlet valve is open and the outlet valve is

closed during the pressure increase cycle. The pres-

sure increase cycle is used to counteract unequal

wheel speeds. This cycle controls re-application of

fluid apply pressure due to changing road surfaces or

wheel speed.

REMOVAL

(1) Remove the negative battery cable from the

battery.

(2) Remove the air cleaner housing,(Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - REMOVAL).

(3) Pull the CAB harness connector release up and

remove connector (Fig. 10).(4) Remove the brake lines from the HCU.

(5) Remove the HCU/CAB side mounting bolt and

the two rear mounting bolts. (Fig. 11).

(6) Remove the HCU/CAB assembly from the vehi-

cle.

INSTALLATION

(1) Install HCU/CAB assembly into the mounting

bracket and tighten mounting bolts to 12 N´m (9 ft.

lbs.).

(2) Install the brake lines to the HCU and tighten

to 16 N´m (12 ft. lbs.).

(3) Install CAB harness connector and push down

connector release.

(4) Install air cleaner housing,(Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - INSTALLATION).

(5) Install negative battery cable to the battery.

(6) Bleed base and ABS brake systems,(Refer to 5 -

BRAKES - STANDARD PROCEDURE) OR (Refer to

5 - BRAKES - STANDARD PROCEDURE).

Fig. 10 CAB Connector Release

1 - CONNECTOR RELEASE

2 - CAB

Fig. 11 HCU/CAB Assembly

1 - SIDE MOUNTING BOLT

2 - REAR MOUNTING BOLTS

WJBRAKES - ABS 5 - 47

HCU (HYDRAULIC CONTROL UNIT) (Continued)

Page 225 of 2199

replacement is necessary, replace with the original

Mopartequipment spring type clamp.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter (Fig. 4).

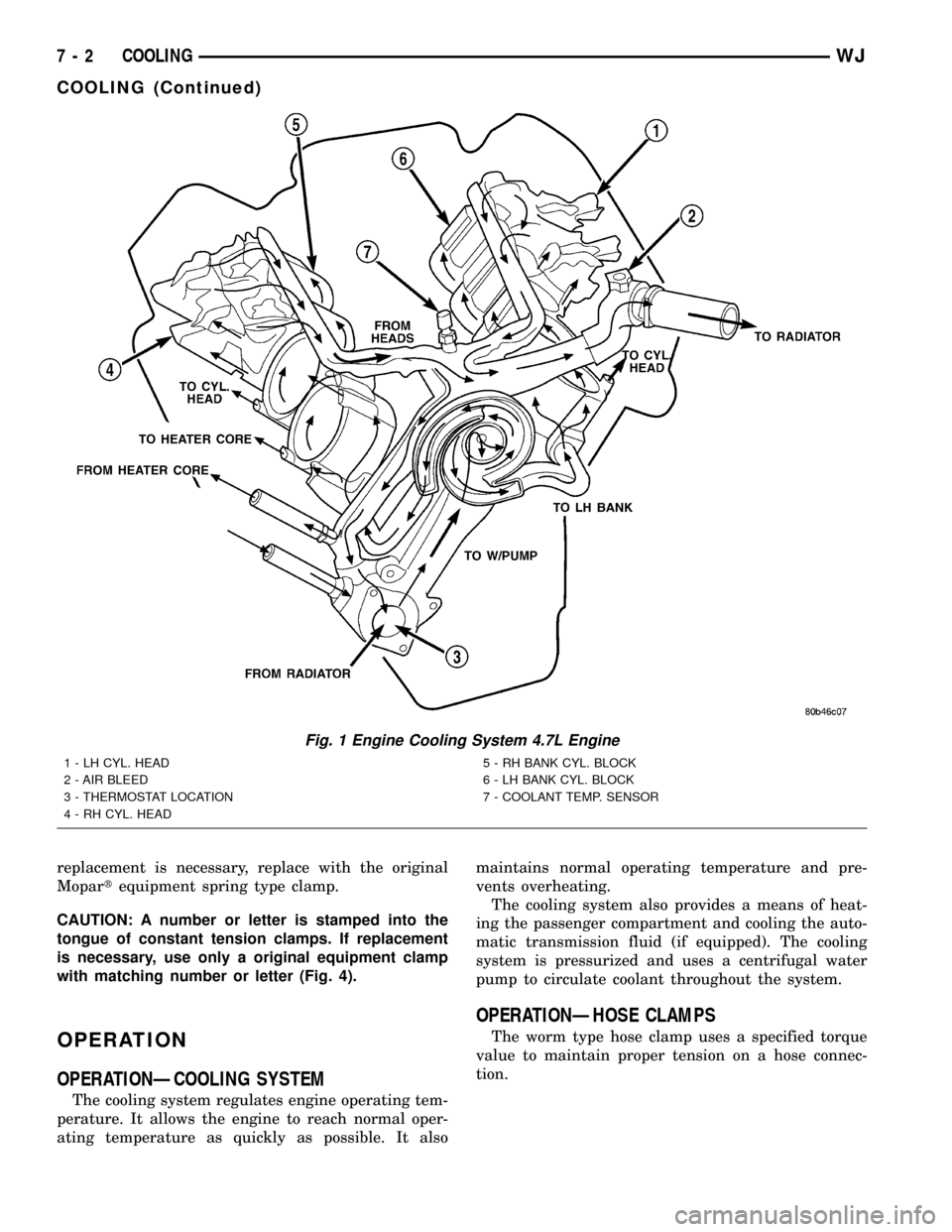

OPERATION

OPERATIONÐCOOLING SYSTEM

The cooling system regulates engine operating tem-

perature. It allows the engine to reach normal oper-

ating temperature as quickly as possible. It alsomaintains normal operating temperature and pre-

vents overheating.

The cooling system also provides a means of heat-

ing the passenger compartment and cooling the auto-

matic transmission fluid (if equipped). The cooling

system is pressurized and uses a centrifugal water

pump to circulate coolant throughout the system.

OPERATIONÐHOSE CLAMPS

The worm type hose clamp uses a specified torque

value to maintain proper tension on a hose connec-

tion.

Fig. 1 Engine Cooling System 4.7L Engine

1 - LH CYL. HEAD

2 - AIR BLEED

3 - THERMOSTAT LOCATION

4 - RH CYL. HEAD5 - RH BANK CYL. BLOCK

6 - LH BANK CYL. BLOCK

7 - COOLANT TEMP. SENSOR

7 - 2 COOLINGWJ

COOLING (Continued)

Page 235 of 2199

accessory drive belt (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - REMOVAL).

Add coolant to radiator to bring level to within 6.3

mm (1/4 in) of top of thermostat housing.

CAUTION: Avoid overheating. Do not operate

engine for an excessive period of time. Open drain-

cock immediately after test to eliminate boil over.

Start engine and accelerate rapidly three times, to

approximately 3000 rpm while observing coolant. If

internal engine combustion gases are leaking into

cooling system, bubbles will appear in coolant. If bub-

bles do not appear, internal combustion gas leakage

is not present.

DIAGNOSIS AND TESTING - COOLING SYSTEM

DEAERATION

As the engine operates, any air trapped in cooling

system gathers under the radiator cap. The next time

the engine is operated, thermal expansion of coolant

will push any trapped air past radiator cap into the

coolant reserve/overflow tank. Here it escapes to the

atmosphere into the tank. When the engine cools

down the coolant, it will be drawn from the reserve/

overflow tank into the radiator to replace any

removed air.

STANDARD PROCEDURE

STANDARD PROCEDUREÐDRAINING COOLING

SYSTEM 4.7L ENGINE

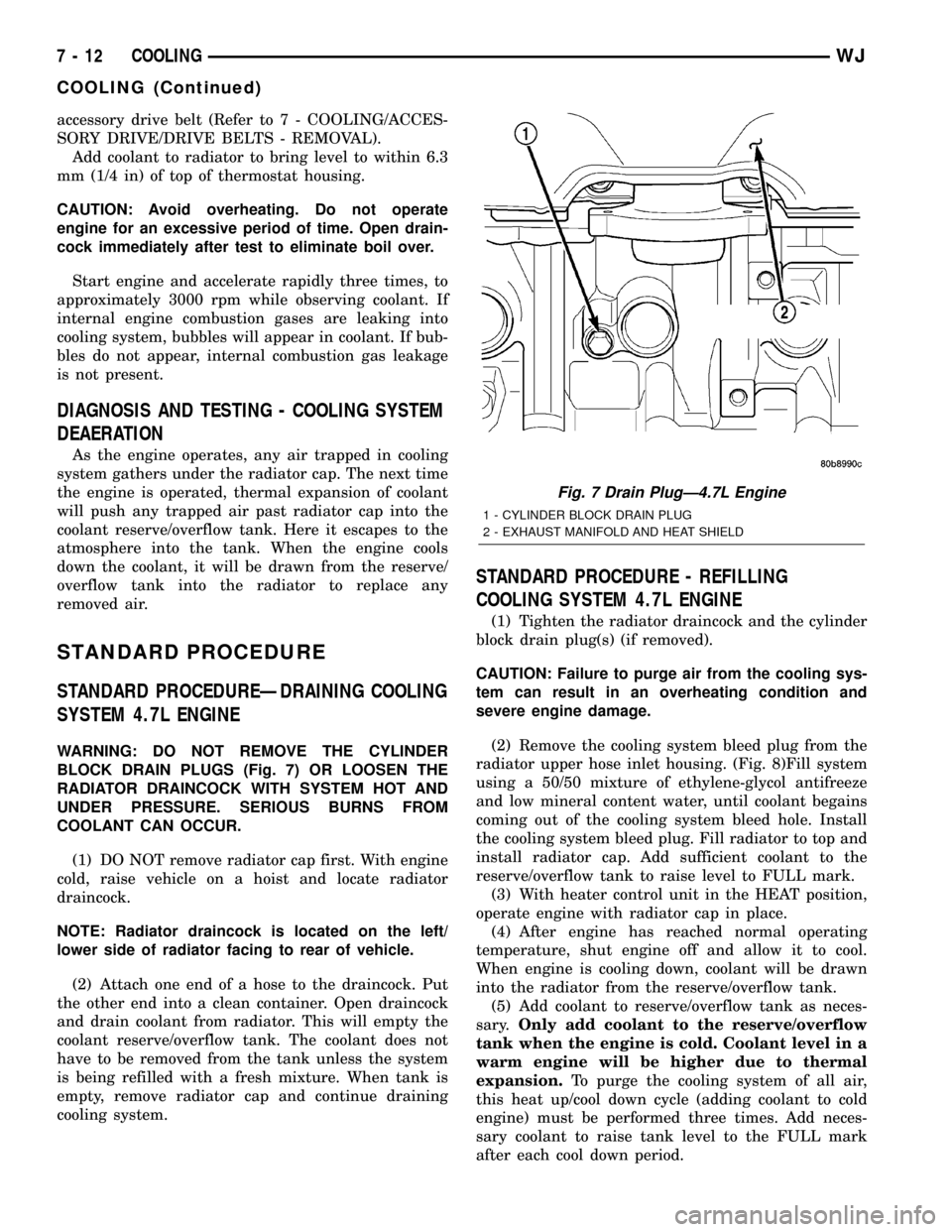

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS (Fig. 7) OR LOOSEN THE

RADIATOR DRAINCOCK WITH SYSTEM HOT AND

UNDER PRESSURE. SERIOUS BURNS FROM

COOLANT CAN OCCUR.

(1) DO NOT remove radiator cap first. With engine

cold, raise vehicle on a hoist and locate radiator

draincock.

NOTE: Radiator draincock is located on the left/

lower side of radiator facing to rear of vehicle.

(2) Attach one end of a hose to the draincock. Put

the other end into a clean container. Open draincock

and drain coolant from radiator. This will empty the

coolant reserve/overflow tank. The coolant does not

have to be removed from the tank unless the system

is being refilled with a fresh mixture. When tank is

empty, remove radiator cap and continue draining

cooling system.

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM 4.7L ENGINE

(1) Tighten the radiator draincock and the cylinder

block drain plug(s) (if removed).

CAUTION: Failure to purge air from the cooling sys-

tem can result in an overheating condition and

severe engine damage.

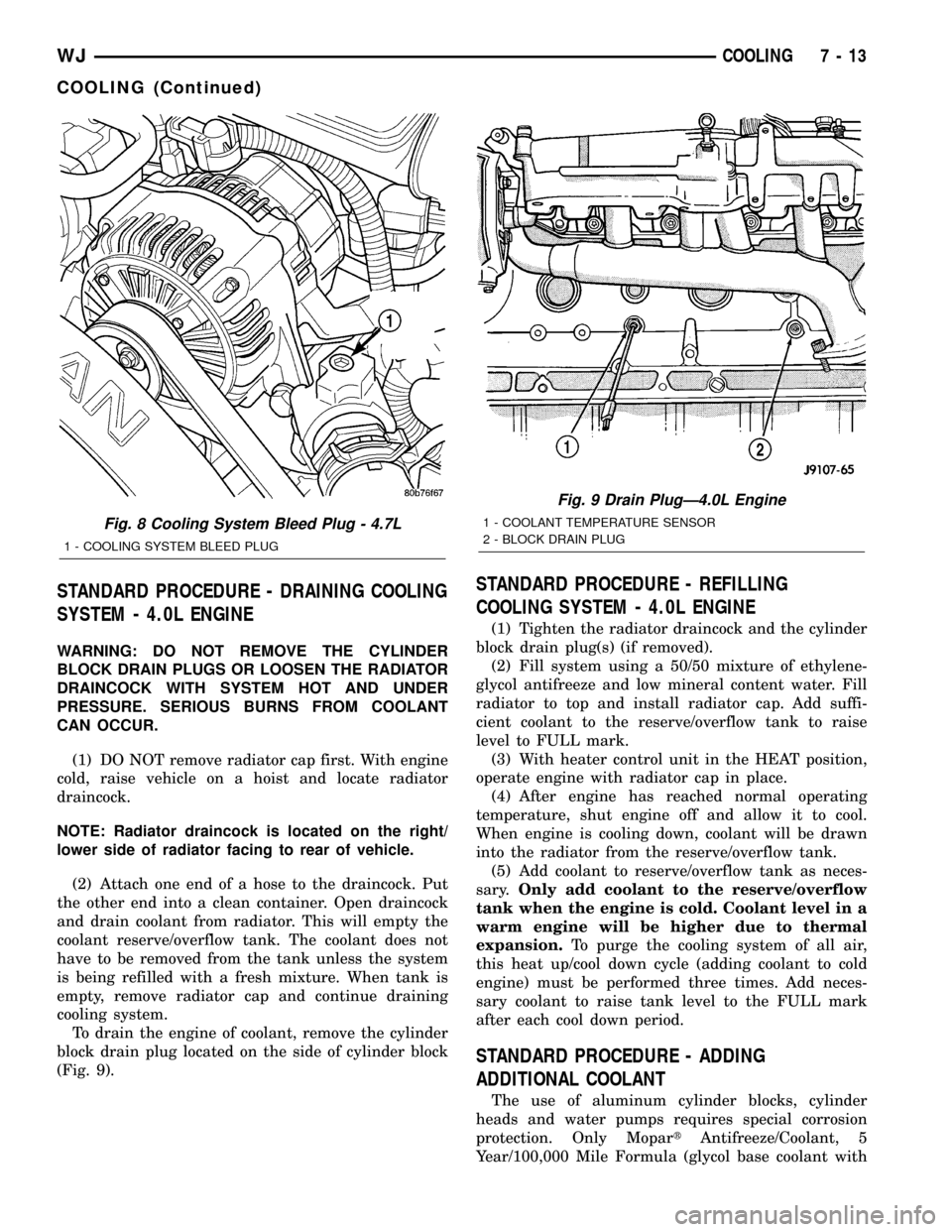

(2) Remove the cooling system bleed plug from the

radiator upper hose inlet housing. (Fig. 8)Fill system

using a 50/50 mixture of ethylene-glycol antifreeze

and low mineral content water, until coolant begains

coming out of the cooling system bleed hole. Install

the cooling system bleed plug. Fill radiator to top and

install radiator cap. Add sufficient coolant to the

reserve/overflow tank to raise level to FULL mark.

(3) With heater control unit in the HEAT position,

operate engine with radiator cap in place.

(4) After engine has reached normal operating

temperature, shut engine off and allow it to cool.

When engine is cooling down, coolant will be drawn

into the radiator from the reserve/overflow tank.

(5) Add coolant to reserve/overflow tank as neces-

sary.Only add coolant to the reserve/overflow

tank when the engine is cold. Coolant level in a

warm engine will be higher due to thermal

expansion.To purge the cooling system of all air,

this heat up/cool down cycle (adding coolant to cold

engine) must be performed three times. Add neces-

sary coolant to raise tank level to the FULL mark

after each cool down period.

Fig. 7 Drain PlugÐ4.7L Engine

1 - CYLINDER BLOCK DRAIN PLUG

2 - EXHAUST MANIFOLD AND HEAT SHIELD

7 - 12 COOLINGWJ

COOLING (Continued)

Page 236 of 2199

STANDARD PROCEDURE - DRAINING COOLING

SYSTEM - 4.0L ENGINE

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAINCOCK WITH SYSTEM HOT AND UNDER

PRESSURE. SERIOUS BURNS FROM COOLANT

CAN OCCUR.

(1) DO NOT remove radiator cap first. With engine

cold, raise vehicle on a hoist and locate radiator

draincock.

NOTE: Radiator draincock is located on the right/

lower side of radiator facing to rear of vehicle.

(2) Attach one end of a hose to the draincock. Put

the other end into a clean container. Open draincock

and drain coolant from radiator. This will empty the

coolant reserve/overflow tank. The coolant does not

have to be removed from the tank unless the system

is being refilled with a fresh mixture. When tank is

empty, remove radiator cap and continue draining

cooling system.

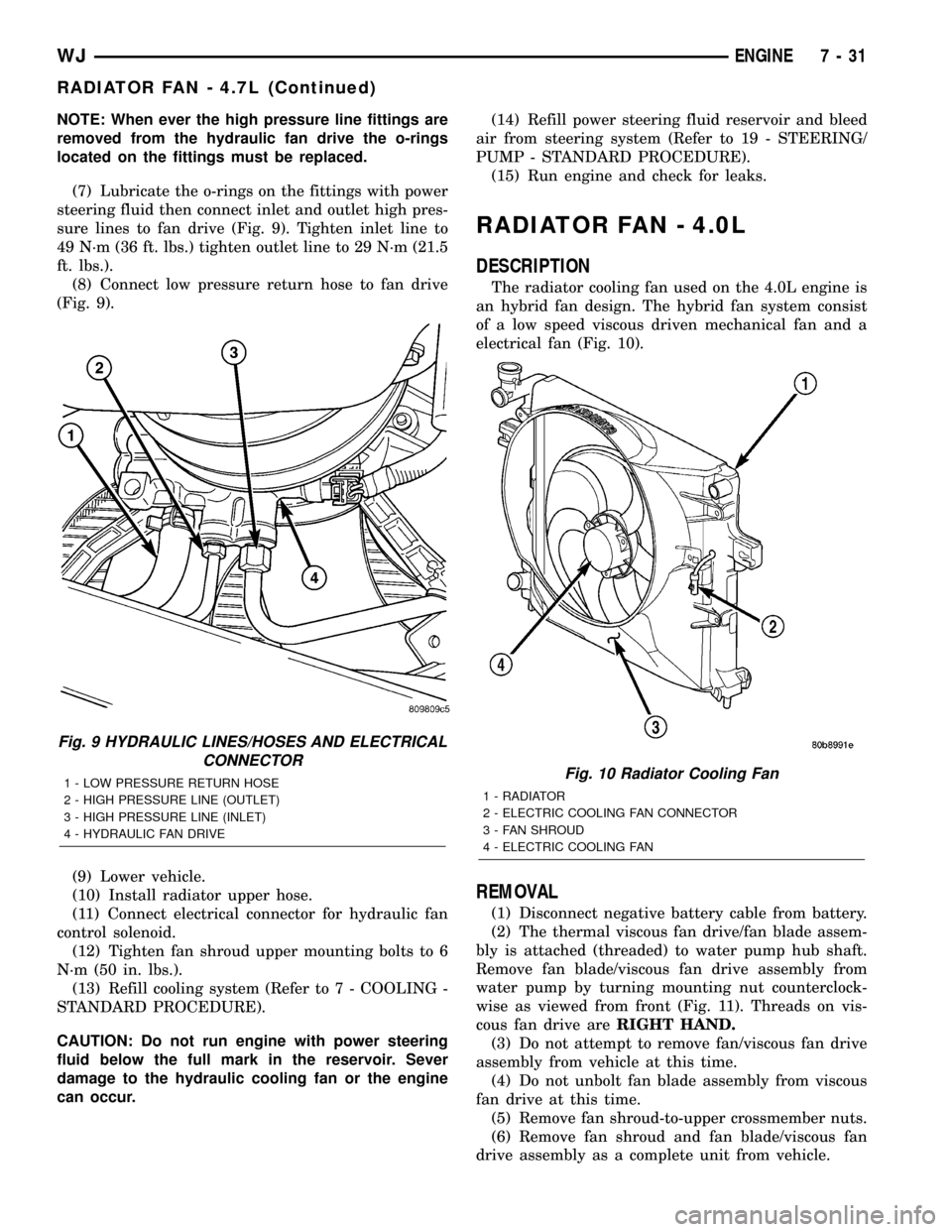

To drain the engine of coolant, remove the cylinder

block drain plug located on the side of cylinder block

(Fig. 9).

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM - 4.0L ENGINE

(1) Tighten the radiator draincock and the cylinder

block drain plug(s) (if removed).

(2) Fill system using a 50/50 mixture of ethylene-

glycol antifreeze and low mineral content water. Fill

radiator to top and install radiator cap. Add suffi-

cient coolant to the reserve/overflow tank to raise

level to FULL mark.

(3) With heater control unit in the HEAT position,

operate engine with radiator cap in place.

(4) After engine has reached normal operating

temperature, shut engine off and allow it to cool.

When engine is cooling down, coolant will be drawn

into the radiator from the reserve/overflow tank.

(5) Add coolant to reserve/overflow tank as neces-

sary.Only add coolant to the reserve/overflow

tank when the engine is cold. Coolant level in a

warm engine will be higher due to thermal

expansion.To purge the cooling system of all air,

this heat up/cool down cycle (adding coolant to cold

engine) must be performed three times. Add neces-

sary coolant to raise tank level to the FULL mark

after each cool down period.

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT

The use of aluminum cylinder blocks, cylinder

heads and water pumps requires special corrosion

protection. Only MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (glycol base coolant with

Fig. 8 Cooling System Bleed Plug - 4.7L

1 - COOLING SYSTEM BLEED PLUG

Fig. 9 Drain PlugÐ4.0L Engine

1 - COOLANT TEMPERATURE SENSOR

2 - BLOCK DRAIN PLUG

WJCOOLING 7 - 13

COOLING (Continued)

Page 254 of 2199

NOTE: When ever the high pressure line fittings are

removed from the hydraulic fan drive the o-rings

located on the fittings must be replaced.

(7) Lubricate the o-rings on the fittings with power

steering fluid then connect inlet and outlet high pres-

sure lines to fan drive (Fig. 9). Tighten inlet line to

49 N´m (36 ft. lbs.) tighten outlet line to 29 N´m (21.5

ft. lbs.).

(8) Connect low pressure return hose to fan drive

(Fig. 9).

(9) Lower vehicle.

(10) Install radiator upper hose.

(11) Connect electrical connector for hydraulic fan

control solenoid.

(12) Tighten fan shroud upper mounting bolts to 6

N´m (50 in. lbs.).

(13) Refill cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

CAUTION: Do not run engine with power steering

fluid below the full mark in the reservoir. Sever

damage to the hydraulic cooling fan or the engine

can occur.(14) Refill power steering fluid reservoir and bleed

air from steering system (Refer to 19 - STEERING/

PUMP - STANDARD PROCEDURE).

(15) Run engine and check for leaks.

RADIATOR FAN - 4.0L

DESCRIPTION

The radiator cooling fan used on the 4.0L engine is

an hybrid fan design. The hybrid fan system consist

of a low speed viscous driven mechanical fan and a

electrical fan (Fig. 10).

REMOVAL

(1) Disconnect negative battery cable from battery.

(2) The thermal viscous fan drive/fan blade assem-

bly is attached (threaded) to water pump hub shaft.

Remove fan blade/viscous fan drive assembly from

water pump by turning mounting nut counterclock-

wise as viewed from front (Fig. 11). Threads on vis-

cous fan drive areRIGHT HAND.

(3) Do not attempt to remove fan/viscous fan drive

assembly from vehicle at this time.

(4) Do not unbolt fan blade assembly from viscous

fan drive at this time.

(5) Remove fan shroud-to-upper crossmember nuts.

(6) Remove fan shroud and fan blade/viscous fan

drive assembly as a complete unit from vehicle.

Fig. 9 HYDRAULIC LINES/HOSES AND ELECTRICAL

CONNECTOR

1 - LOW PRESSURE RETURN HOSE

2 - HIGH PRESSURE LINE (OUTLET)

3 - HIGH PRESSURE LINE (INLET)

4 - HYDRAULIC FAN DRIVEFig. 10 Radiator Cooling Fan

1 - RADIATOR

2 - ELECTRIC COOLING FAN CONNECTOR

3 - FAN SHROUD

4 - ELECTRIC COOLING FAN

WJENGINE 7 - 31

RADIATOR FAN - 4.7L (Continued)