intake manifold JEEP GRAND CHEROKEE 2002 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 351 of 2199

(4) Loosen the battery positive cable terminal

clamp pinch-bolt hex nut.

(5) Disconnect the battery positive cable terminal

clamp from the battery positive terminal post. If nec-

essary, use a battery terminal puller to remove the

terminal clamp from the battery post.

(6) Unlatch and open the cover on the Power Dis-

tribution Center (PDC).

(7) Remove the two nuts that secure the battery

positive cable and generator output cable eyelet ter-

minal to the B(+) terminal studs in the PDC.

(8) Remove the battery positive cable and genera-

tor output cable eyelet terminal from the B(+) termi-

nal studs in the PDC.

(9) Disconnect the battery wire harness connector

from the right headlamp and dash wire harness con-

nector located near the front of the battery.

(10) Remove the screw that secures the battery

negative cable eyelet terminal to the inner fender

shield near the front of the battery.

(11) On models with the 4.7L engine, remove the

nut that secures the battery harness clip to the stud

on the right side of the intake manifold and remove

the clip from the stud.

(12) Unlatch and remove the cover from the gener-

ator output terminal stud housing on the back of the

generator.

(13) Remove the nut that secures the generator

output cable eyelet terminal to the generator output

terminal stud.

(14) Remove the generator output cable eyelet ter-

minal from the generator output terminal stud.

(15) Disconnect the battery wire harness connector

from the generator field terminal connector recepta-

cle on the back of the generator.(16) Remove the screw that secures the battery

negative cable ground eyelet terminal to the right

side of the engine block.

(17) Remove the nut that secures the battery pos-

itive cable eyelet terminal to the B(+) terminal stud

on the starter solenoid.

(18) Remove the battery positive cable eyelet ter-

minal from the B(+) terminal stud on the starter

solenoid.

(19) Disconnect the battery wire harness connector

from the connector receptacle on the starter solenoid.

(20) Remove the battery wire harness from the

engine compartment.

INSTALLATION

Both the battery negative cable and the battery

positive cable are serviced in the battery wire har-

ness. If either battery cable is damaged or faulty, the

battery wire harness unit must be replaced.

(1) Clean and inspect the battery cable terminal

clamps and the battery terminal posts.

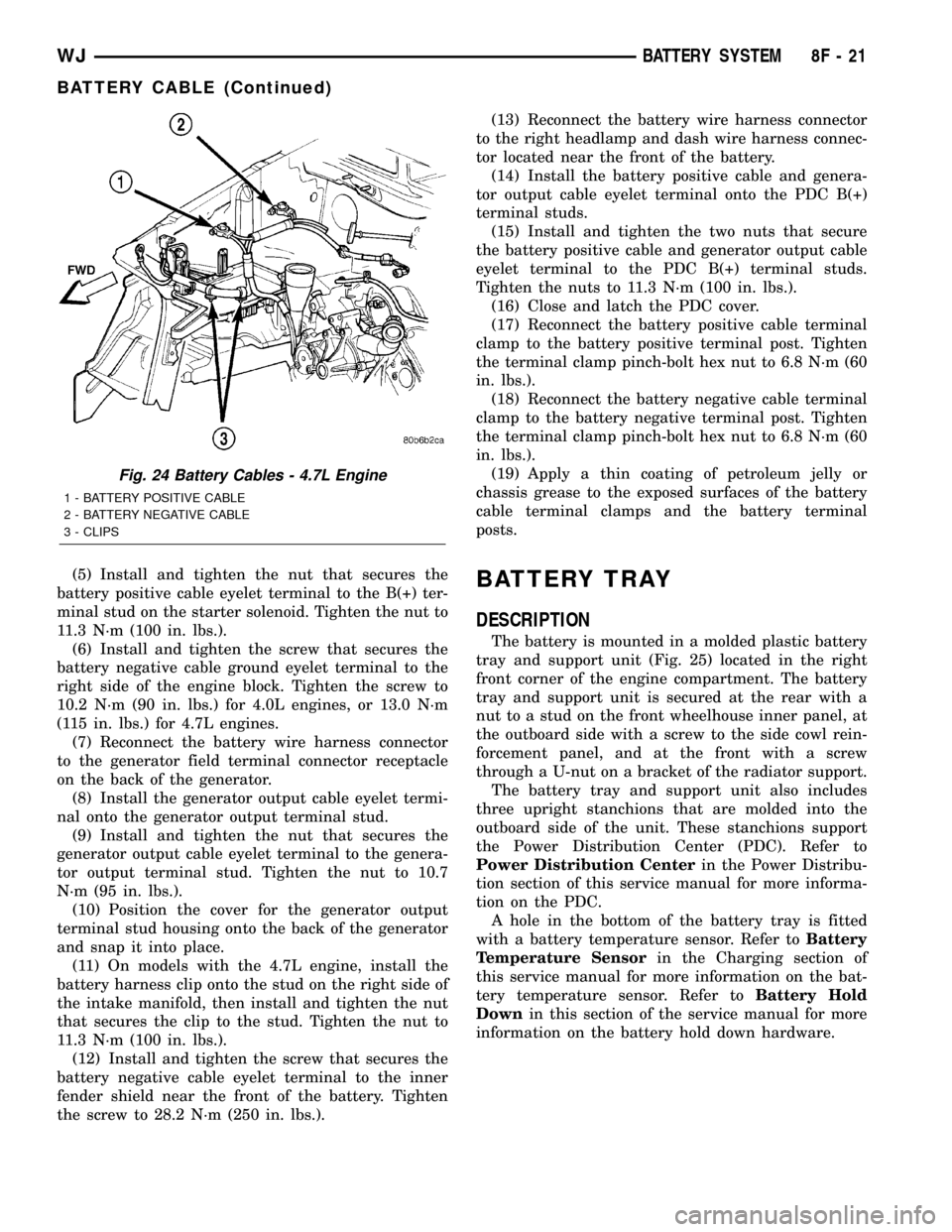

(2) Position the battery wire harness into the

engine compartment (Fig. 23) or (Fig. 24).

(3) Reconnect the battery wire harness connector

to the connector receptacle on the starter solenoid.

(4) Install the battery positive cable eyelet termi-

nal onto the B(+) terminal stud on the starter sole-

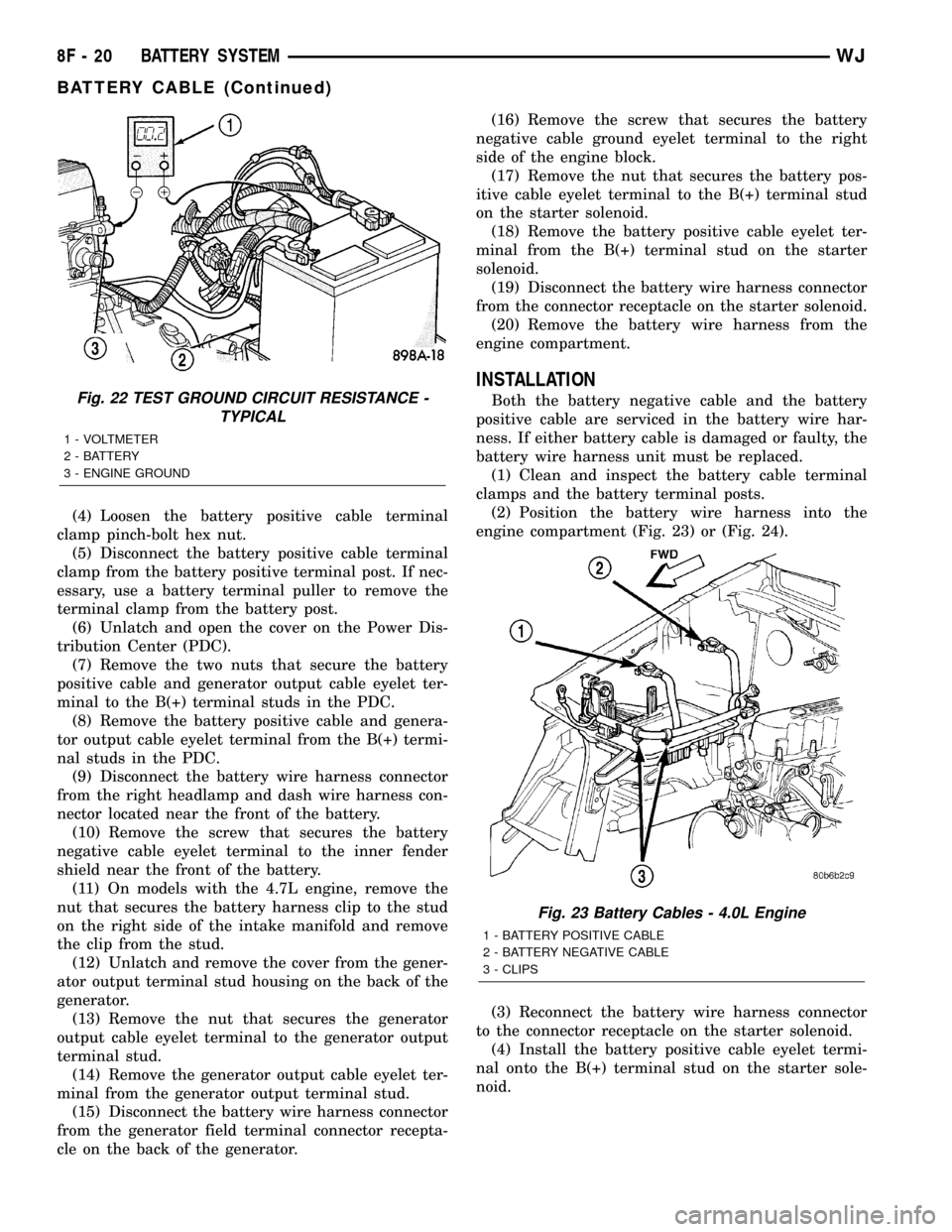

noid.Fig. 22 TEST GROUND CIRCUIT RESISTANCE -

TYPICAL

1 - VOLTMETER

2 - BATTERY

3 - ENGINE GROUND

Fig. 23 Battery Cables - 4.0L Engine

1 - BATTERY POSITIVE CABLE

2 - BATTERY NEGATIVE CABLE

3 - CLIPS

8F - 20 BATTERY SYSTEMWJ

BATTERY CABLE (Continued)

Page 352 of 2199

(5) Install and tighten the nut that secures the

battery positive cable eyelet terminal to the B(+) ter-

minal stud on the starter solenoid. Tighten the nut to

11.3 N´m (100 in. lbs.).

(6) Install and tighten the screw that secures the

battery negative cable ground eyelet terminal to the

right side of the engine block. Tighten the screw to

10.2 N´m (90 in. lbs.) for 4.0L engines, or 13.0 N´m

(115 in. lbs.) for 4.7L engines.

(7) Reconnect the battery wire harness connector

to the generator field terminal connector receptacle

on the back of the generator.

(8) Install the generator output cable eyelet termi-

nal onto the generator output terminal stud.

(9) Install and tighten the nut that secures the

generator output cable eyelet terminal to the genera-

tor output terminal stud. Tighten the nut to 10.7

N´m (95 in. lbs.).

(10) Position the cover for the generator output

terminal stud housing onto the back of the generator

and snap it into place.

(11) On models with the 4.7L engine, install the

battery harness clip onto the stud on the right side of

the intake manifold, then install and tighten the nut

that secures the clip to the stud. Tighten the nut to

11.3 N´m (100 in. lbs.).

(12) Install and tighten the screw that secures the

battery negative cable eyelet terminal to the inner

fender shield near the front of the battery. Tighten

the screw to 28.2 N´m (250 in. lbs.).(13) Reconnect the battery wire harness connector

to the right headlamp and dash wire harness connec-

tor located near the front of the battery.

(14) Install the battery positive cable and genera-

tor output cable eyelet terminal onto the PDC B(+)

terminal studs.

(15) Install and tighten the two nuts that secure

the battery positive cable and generator output cable

eyelet terminal to the PDC B(+) terminal studs.

Tighten the nuts to 11.3 N´m (100 in. lbs.).

(16) Close and latch the PDC cover.

(17) Reconnect the battery positive cable terminal

clamp to the battery positive terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 6.8 N´m (60

in. lbs.).

(18) Reconnect the battery negative cable terminal

clamp to the battery negative terminal post. Tighten

the terminal clamp pinch-bolt hex nut to 6.8 N´m (60

in. lbs.).

(19) Apply a thin coating of petroleum jelly or

chassis grease to the exposed surfaces of the battery

cable terminal clamps and the battery terminal

posts.BATTERY TRAY

DESCRIPTION

The battery is mounted in a molded plastic battery

tray and support unit (Fig. 25) located in the right

front corner of the engine compartment. The battery

tray and support unit is secured at the rear with a

nut to a stud on the front wheelhouse inner panel, at

the outboard side with a screw to the side cowl rein-

forcement panel, and at the front with a screw

through a U-nut on a bracket of the radiator support.

The battery tray and support unit also includes

three upright stanchions that are molded into the

outboard side of the unit. These stanchions support

the Power Distribution Center (PDC). Refer to

Power Distribution Centerin the Power Distribu-

tion section of this service manual for more informa-

tion on the PDC.

A hole in the bottom of the battery tray is fitted

with a battery temperature sensor. Refer toBattery

Temperature Sensorin the Charging section of

this service manual for more information on the bat-

tery temperature sensor. Refer toBattery Hold

Downin this section of the service manual for more

information on the battery hold down hardware.

Fig. 24 Battery Cables - 4.7L Engine

1 - BATTERY POSITIVE CABLE

2 - BATTERY NEGATIVE CABLE

3 - CLIPS

WJBATTERY SYSTEM 8F - 21

BATTERY CABLE (Continued)

Page 409 of 2199

OPERATION

Battery voltage is supplied to the 8 ignition coils

from the ASD relay. The Powertrain Control Module

(PCM) opens and closes each ignition coil ground cir-

cuit at a determined time for ignition coil operation.

Base ignition timing is not adjustable.By con-

trolling the coil ground circuit, the PCM is able to set

the base timing and adjust the ignition timing

advance. This is done to meet changing engine oper-

ating conditions.

The ignition coil is not oil filled. The windings are

embedded in an epoxy compound. This provides heat

and vibration resistance that allows the ignition coil

to be mounted on the engine.

Because of coil design, spark plug cables (second-

ary cables) are not used.

REMOVAL

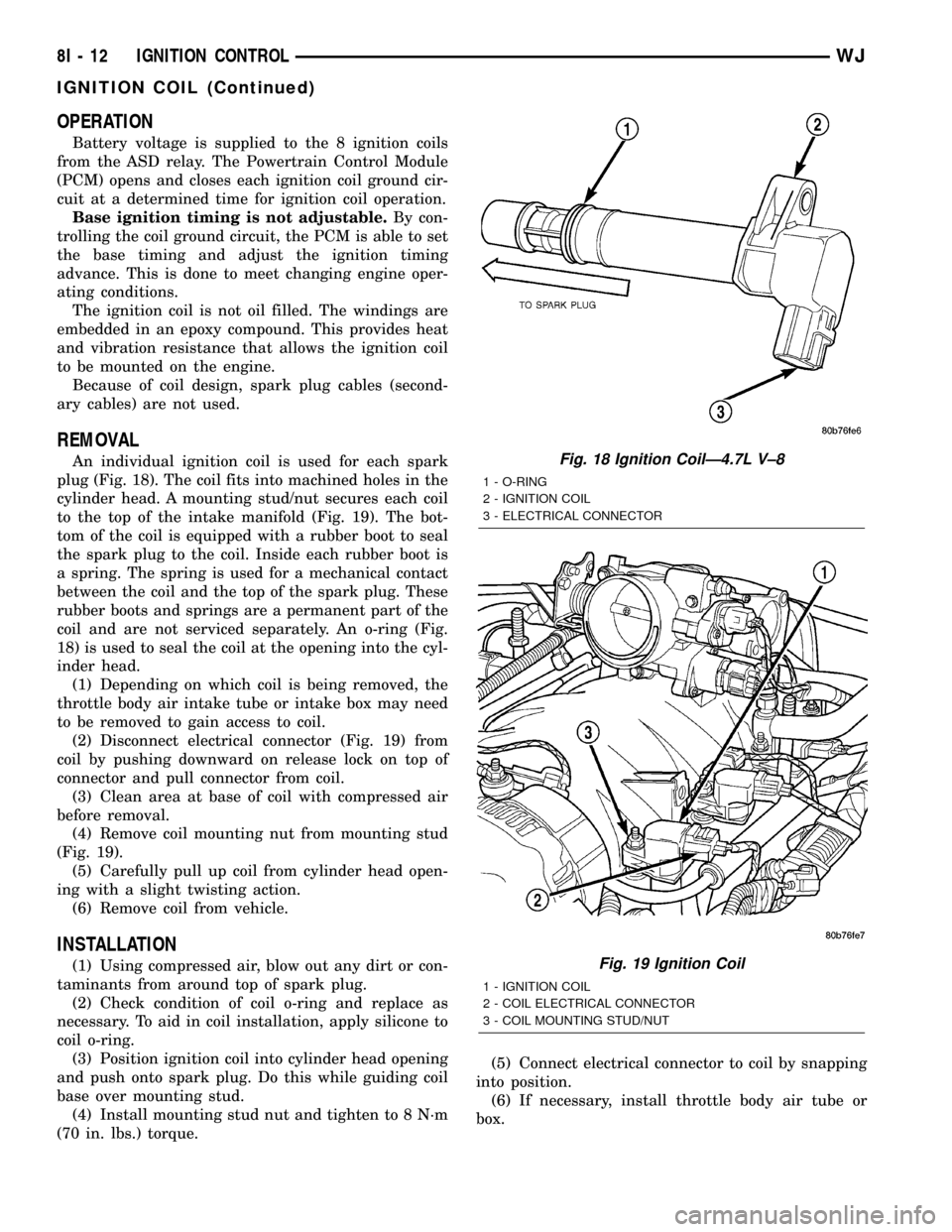

An individual ignition coil is used for each spark

plug (Fig. 18). The coil fits into machined holes in the

cylinder head. A mounting stud/nut secures each coil

to the top of the intake manifold (Fig. 19). The bot-

tom of the coil is equipped with a rubber boot to seal

the spark plug to the coil. Inside each rubber boot is

a spring. The spring is used for a mechanical contact

between the coil and the top of the spark plug. These

rubber boots and springs are a permanent part of the

coil and are not serviced separately. An o-ring (Fig.

18) is used to seal the coil at the opening into the cyl-

inder head.

(1) Depending on which coil is being removed, the

throttle body air intake tube or intake box may need

to be removed to gain access to coil.

(2) Disconnect electrical connector (Fig. 19) from

coil by pushing downward on release lock on top of

connector and pull connector from coil.

(3) Clean area at base of coil with compressed air

before removal.

(4) Remove coil mounting nut from mounting stud

(Fig. 19).

(5) Carefully pull up coil from cylinder head open-

ing with a slight twisting action.

(6) Remove coil from vehicle.

INSTALLATION

(1) Using compressed air, blow out any dirt or con-

taminants from around top of spark plug.

(2) Check condition of coil o-ring and replace as

necessary. To aid in coil installation, apply silicone to

coil o-ring.

(3) Position ignition coil into cylinder head opening

and push onto spark plug. Do this while guiding coil

base over mounting stud.

(4) Install mounting stud nut and tighten to 8 N´m

(70 in. lbs.) torque.(5) Connect electrical connector to coil by snapping

into position.

(6) If necessary, install throttle body air tube or

box.

Fig. 18 Ignition CoilÐ4.7L V±8

1 - O-RING

2 - IGNITION COIL

3 - ELECTRICAL CONNECTOR

Fig. 19 Ignition Coil

1 - IGNITION COIL

2 - COIL ELECTRICAL CONNECTOR

3 - COIL MOUNTING STUD/NUT

8I - 12 IGNITION CONTROLWJ

IGNITION COIL (Continued)

Page 410 of 2199

IGNITION COIL CAPACITOR

DESCRIPTION

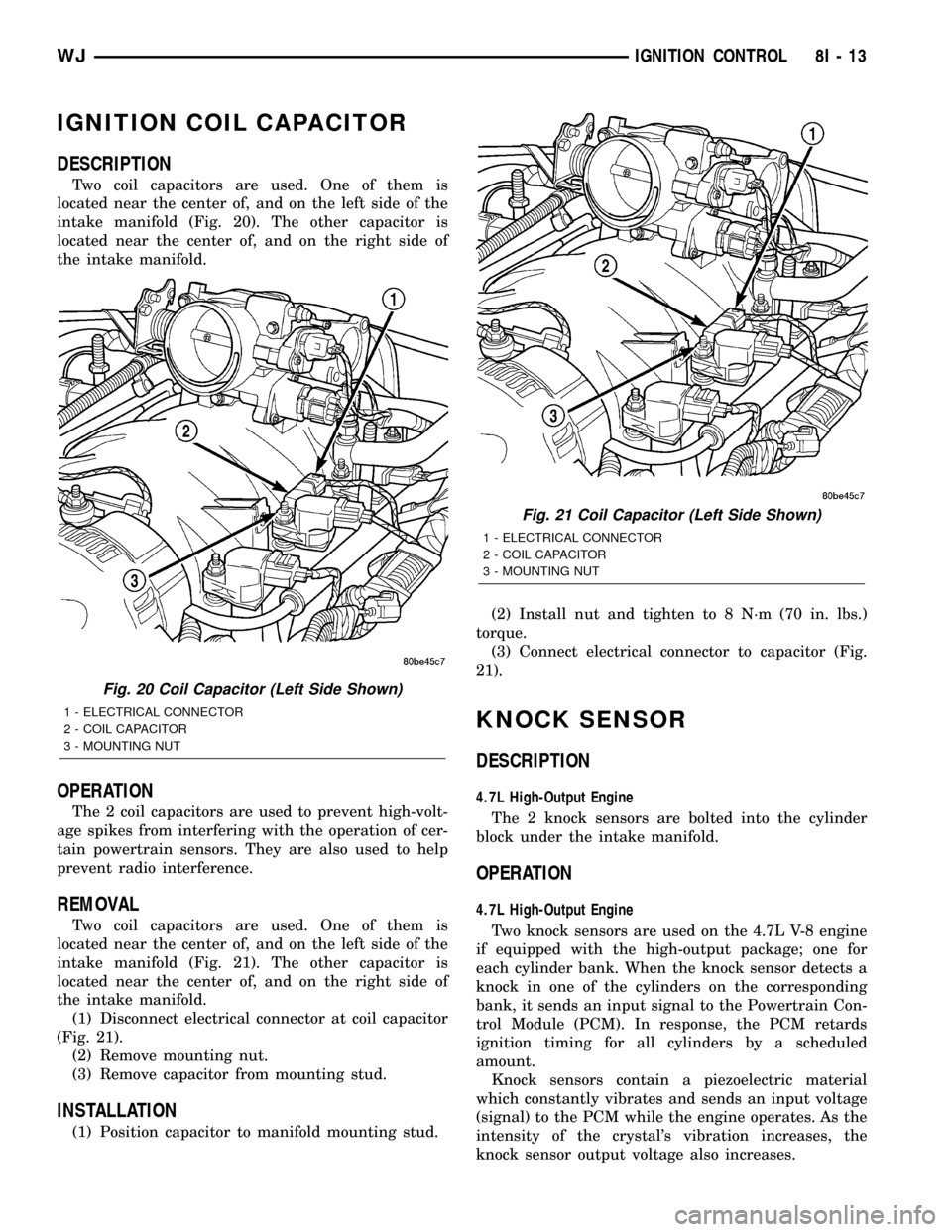

Two coil capacitors are used. One of them is

located near the center of, and on the left side of the

intake manifold (Fig. 20). The other capacitor is

located near the center of, and on the right side of

the intake manifold.

OPERATION

The 2 coil capacitors are used to prevent high-volt-

age spikes from interfering with the operation of cer-

tain powertrain sensors. They are also used to help

prevent radio interference.

REMOVAL

Two coil capacitors are used. One of them is

located near the center of, and on the left side of the

intake manifold (Fig. 21). The other capacitor is

located near the center of, and on the right side of

the intake manifold.

(1) Disconnect electrical connector at coil capacitor

(Fig. 21).

(2) Remove mounting nut.

(3) Remove capacitor from mounting stud.

INSTALLATION

(1) Position capacitor to manifold mounting stud.(2) Install nut and tighten to 8 N´m (70 in. lbs.)

torque.

(3) Connect electrical connector to capacitor (Fig.

21).

KNOCK SENSOR

DESCRIPTION

4.7L High-Output Engine

The 2 knock sensors are bolted into the cylinder

block under the intake manifold.

OPERATION

4.7L High-Output Engine

Two knock sensors are used on the 4.7L V-8 engine

if equipped with the high-output package; one for

each cylinder bank. When the knock sensor detects a

knock in one of the cylinders on the corresponding

bank, it sends an input signal to the Powertrain Con-

trol Module (PCM). In response, the PCM retards

ignition timing for all cylinders by a scheduled

amount.

Knock sensors contain a piezoelectric material

which constantly vibrates and sends an input voltage

(signal) to the PCM while the engine operates. As the

intensity of the crystal's vibration increases, the

knock sensor output voltage also increases.

Fig. 20 Coil Capacitor (Left Side Shown)

1 - ELECTRICAL CONNECTOR

2 - COIL CAPACITOR

3 - MOUNTING NUT

Fig. 21 Coil Capacitor (Left Side Shown)

1 - ELECTRICAL CONNECTOR

2 - COIL CAPACITOR

3 - MOUNTING NUT

WJIGNITION CONTROL 8I - 13

Page 411 of 2199

The voltage signal produced by the knock sensor

increases with the amplitude of vibration. The PCM

receives the knock sensor voltage signal as an input.

If the signal rises above a predetermined level, the

PCM will store that value in memory and retard

ignition timing to reduce engine knock. If the knock

sensor voltage exceeds a preset value, the PCM

retards ignition timing for all cylinders. It is not a

selective cylinder retard.

The PCM ignores knock sensor input during engine

idle conditions. Once the engine speed exceeds a

specified value, knock retard is allowed.

Knock retard uses its own short term and long

term memory program.

Long term memory stores previous detonation

information in its battery-backed RAM. The maxi-

mum authority that long term memory has over tim-

ing retard can be calibrated.

Short term memory is allowed to retard timing up

to a preset amount under all operating conditions (as

long as rpm is above the minimum rpm) except at

Wide Open Throttle (WOT). The PCM, using short

term memory, can respond quickly to retard timing

when engine knock is detected. Short term memory

is lost any time the ignition key is turned off.

NOTE: Over or under tightening the sensor mount-

ing bolts will affect knock sensor performance, pos-

sibly causing improper spark control. Always use

the specified torque when installing the knock sen-

sors.

REMOVAL

4.7L High-Output Engine Only

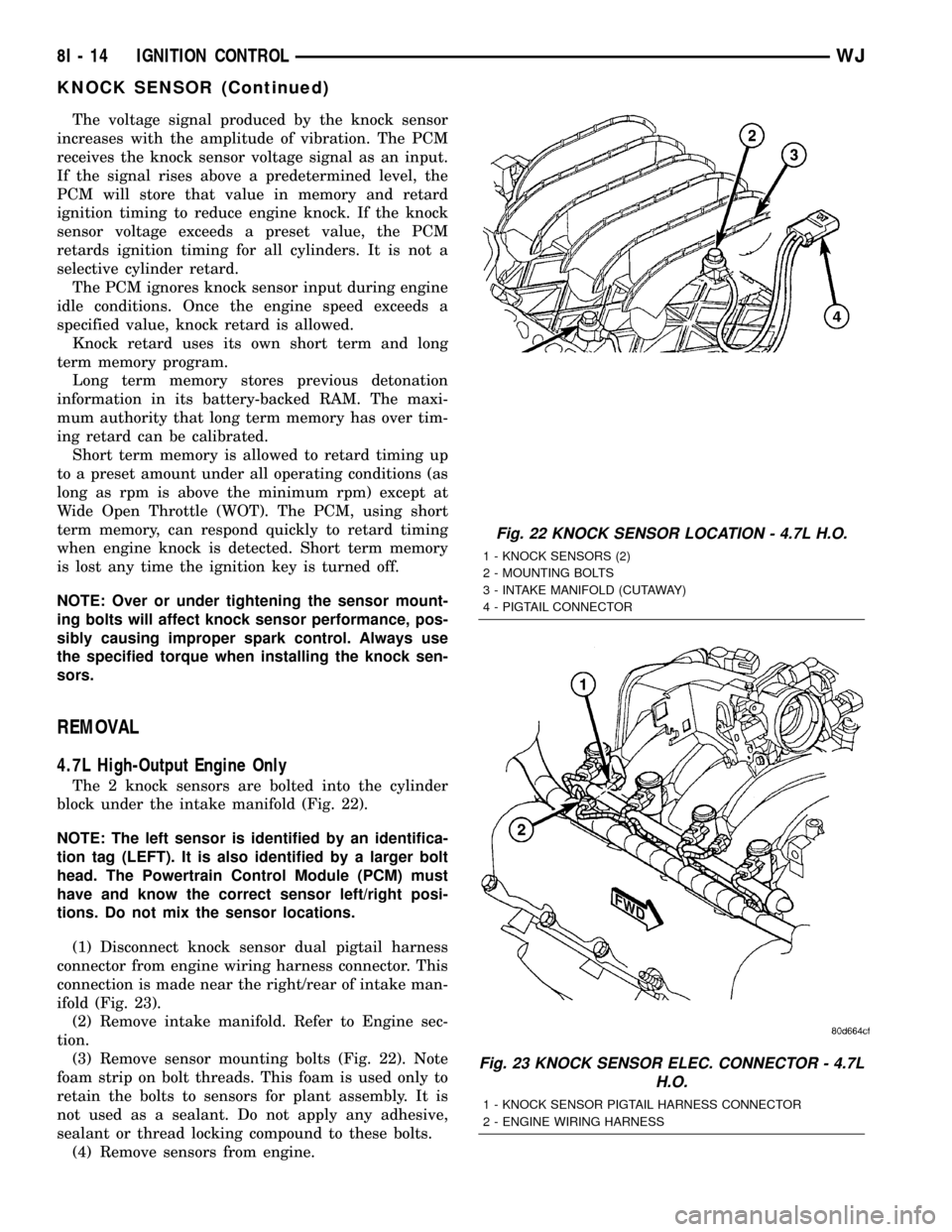

The 2 knock sensors are bolted into the cylinder

block under the intake manifold (Fig. 22).

NOTE: The left sensor is identified by an identifica-

tion tag (LEFT). It is also identified by a larger bolt

head. The Powertrain Control Module (PCM) must

have and know the correct sensor left/right posi-

tions. Do not mix the sensor locations.

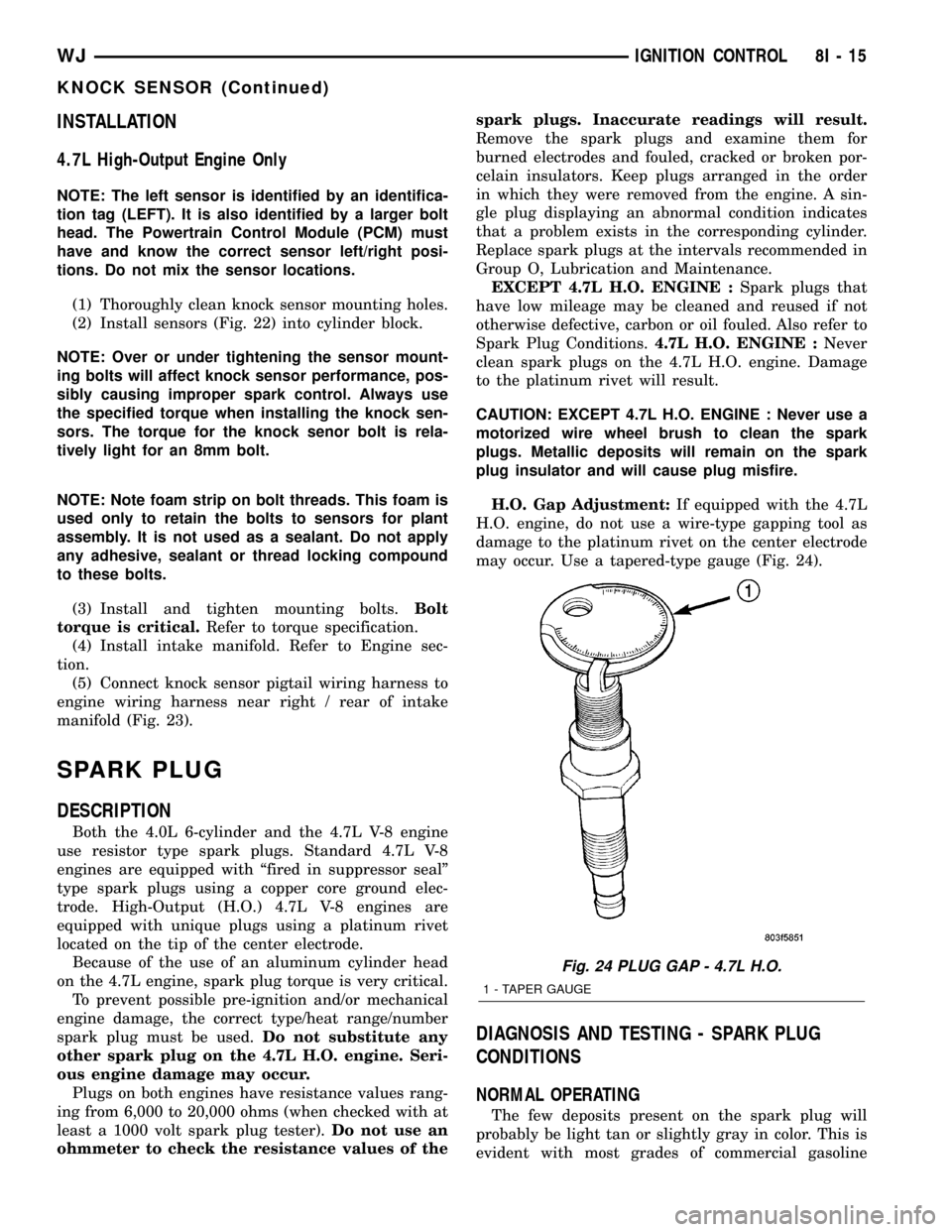

(1) Disconnect knock sensor dual pigtail harness

connector from engine wiring harness connector. This

connection is made near the right/rear of intake man-

ifold (Fig. 23).

(2) Remove intake manifold. Refer to Engine sec-

tion.

(3) Remove sensor mounting bolts (Fig. 22). Note

foam strip on bolt threads. This foam is used only to

retain the bolts to sensors for plant assembly. It is

not used as a sealant. Do not apply any adhesive,

sealant or thread locking compound to these bolts.

(4) Remove sensors from engine.

Fig. 22 KNOCK SENSOR LOCATION - 4.7L H.O.

1 - KNOCK SENSORS (2)

2 - MOUNTING BOLTS

3 - INTAKE MANIFOLD (CUTAWAY)

4 - PIGTAIL CONNECTOR

Fig. 23 KNOCK SENSOR ELEC. CONNECTOR - 4.7L

H.O.

1 - KNOCK SENSOR PIGTAIL HARNESS CONNECTOR

2 - ENGINE WIRING HARNESS

8I - 14 IGNITION CONTROLWJ

KNOCK SENSOR (Continued)

Page 412 of 2199

INSTALLATION

4.7L High-Output Engine Only

NOTE: The left sensor is identified by an identifica-

tion tag (LEFT). It is also identified by a larger bolt

head. The Powertrain Control Module (PCM) must

have and know the correct sensor left/right posi-

tions. Do not mix the sensor locations.

(1) Thoroughly clean knock sensor mounting holes.

(2) Install sensors (Fig. 22) into cylinder block.

NOTE: Over or under tightening the sensor mount-

ing bolts will affect knock sensor performance, pos-

sibly causing improper spark control. Always use

the specified torque when installing the knock sen-

sors. The torque for the knock senor bolt is rela-

tively light for an 8mm bolt.

NOTE: Note foam strip on bolt threads. This foam is

used only to retain the bolts to sensors for plant

assembly. It is not used as a sealant. Do not apply

any adhesive, sealant or thread locking compound

to these bolts.

(3) Install and tighten mounting bolts.Bolt

torque is critical.Refer to torque specification.

(4) Install intake manifold. Refer to Engine sec-

tion.

(5) Connect knock sensor pigtail wiring harness to

engine wiring harness near right / rear of intake

manifold (Fig. 23).

SPARK PLUG

DESCRIPTION

Both the 4.0L 6-cylinder and the 4.7L V-8 engine

use resistor type spark plugs. Standard 4.7L V-8

engines are equipped with ªfired in suppressor sealº

type spark plugs using a copper core ground elec-

trode. High-Output (H.O.) 4.7L V-8 engines are

equipped with unique plugs using a platinum rivet

located on the tip of the center electrode.

Because of the use of an aluminum cylinder head

on the 4.7L engine, spark plug torque is very critical.

To prevent possible pre-ignition and/or mechanical

engine damage, the correct type/heat range/number

spark plug must be used.Do not substitute any

other spark plug on the 4.7L H.O. engine. Seri-

ous engine damage may occur.

Plugs on both engines have resistance values rang-

ing from 6,000 to 20,000 ohms (when checked with at

least a 1000 volt spark plug tester).Do not use an

ohmmeter to check the resistance values of thespark plugs. Inaccurate readings will result.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. A sin-

gle plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Replace spark plugs at the intervals recommended in

Group O, Lubrication and Maintenance.

EXCEPT 4.7L H.O. ENGINE :Spark plugs that

have low mileage may be cleaned and reused if not

otherwise defective, carbon or oil fouled. Also refer to

Spark Plug Conditions.4.7L H.O. ENGINE :Never

clean spark plugs on the 4.7L H.O. engine. Damage

to the platinum rivet will result.

CAUTION: EXCEPT 4.7L H.O. ENGINE : Never use a

motorized wire wheel brush to clean the spark

plugs. Metallic deposits will remain on the spark

plug insulator and will cause plug misfire.

H.O. Gap Adjustment:If equipped with the 4.7L

H.O. engine, do not use a wire-type gapping tool as

damage to the platinum rivet on the center electrode

may occur. Use a tapered-type gauge (Fig. 24).

DIAGNOSIS AND TESTING - SPARK PLUG

CONDITIONS

NORMAL OPERATING

The few deposits present on the spark plug will

probably be light tan or slightly gray in color. This is

evident with most grades of commercial gasoline

Fig. 24 PLUG GAP - 4.7L H.O.

1 - TAPER GAUGE

WJIGNITION CONTROL 8I - 15

KNOCK SENSOR (Continued)

Page 589 of 2199

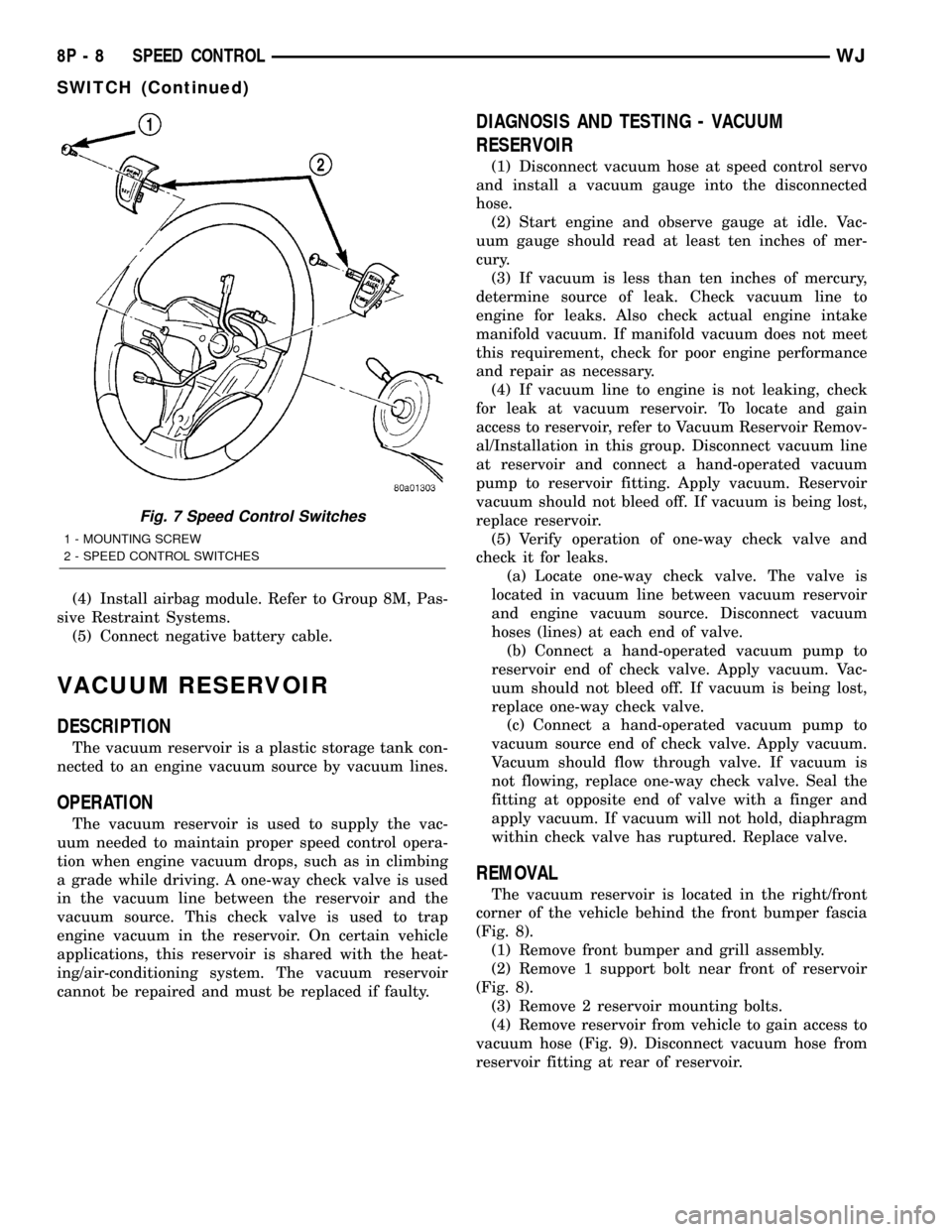

(4) Install airbag module. Refer to Group 8M, Pas-

sive Restraint Systems.

(5) Connect negative battery cable.

VACUUM RESERVOIR

DESCRIPTION

The vacuum reservoir is a plastic storage tank con-

nected to an engine vacuum source by vacuum lines.

OPERATION

The vacuum reservoir is used to supply the vac-

uum needed to maintain proper speed control opera-

tion when engine vacuum drops, such as in climbing

a grade while driving. A one-way check valve is used

in the vacuum line between the reservoir and the

vacuum source. This check valve is used to trap

engine vacuum in the reservoir. On certain vehicle

applications, this reservoir is shared with the heat-

ing/air-conditioning system. The vacuum reservoir

cannot be repaired and must be replaced if faulty.

DIAGNOSIS AND TESTING - VACUUM

RESERVOIR

(1) Disconnect vacuum hose at speed control servo

and install a vacuum gauge into the disconnected

hose.

(2) Start engine and observe gauge at idle. Vac-

uum gauge should read at least ten inches of mer-

cury.

(3) If vacuum is less than ten inches of mercury,

determine source of leak. Check vacuum line to

engine for leaks. Also check actual engine intake

manifold vacuum. If manifold vacuum does not meet

this requirement, check for poor engine performance

and repair as necessary.

(4) If vacuum line to engine is not leaking, check

for leak at vacuum reservoir. To locate and gain

access to reservoir, refer to Vacuum Reservoir Remov-

al/Installation in this group. Disconnect vacuum line

at reservoir and connect a hand-operated vacuum

pump to reservoir fitting. Apply vacuum. Reservoir

vacuum should not bleed off. If vacuum is being lost,

replace reservoir.

(5) Verify operation of one-way check valve and

check it for leaks.

(a) Locate one-way check valve. The valve is

located in vacuum line between vacuum reservoir

and engine vacuum source. Disconnect vacuum

hoses (lines) at each end of valve.

(b) Connect a hand-operated vacuum pump to

reservoir end of check valve. Apply vacuum. Vac-

uum should not bleed off. If vacuum is being lost,

replace one-way check valve.

(c) Connect a hand-operated vacuum pump to

vacuum source end of check valve. Apply vacuum.

Vacuum should flow through valve. If vacuum is

not flowing, replace one-way check valve. Seal the

fitting at opposite end of valve with a finger and

apply vacuum. If vacuum will not hold, diaphragm

within check valve has ruptured. Replace valve.

REMOVAL

The vacuum reservoir is located in the right/front

corner of the vehicle behind the front bumper fascia

(Fig. 8).

(1) Remove front bumper and grill assembly.

(2) Remove 1 support bolt near front of reservoir

(Fig. 8).

(3) Remove 2 reservoir mounting bolts.

(4) Remove reservoir from vehicle to gain access to

vacuum hose (Fig. 9). Disconnect vacuum hose from

reservoir fitting at rear of reservoir.

Fig. 7 Speed Control Switches

1 - MOUNTING SCREW

2 - SPEED CONTROL SWITCHES

8P - 8 SPEED CONTROLWJ

SWITCH (Continued)

Page 672 of 2199

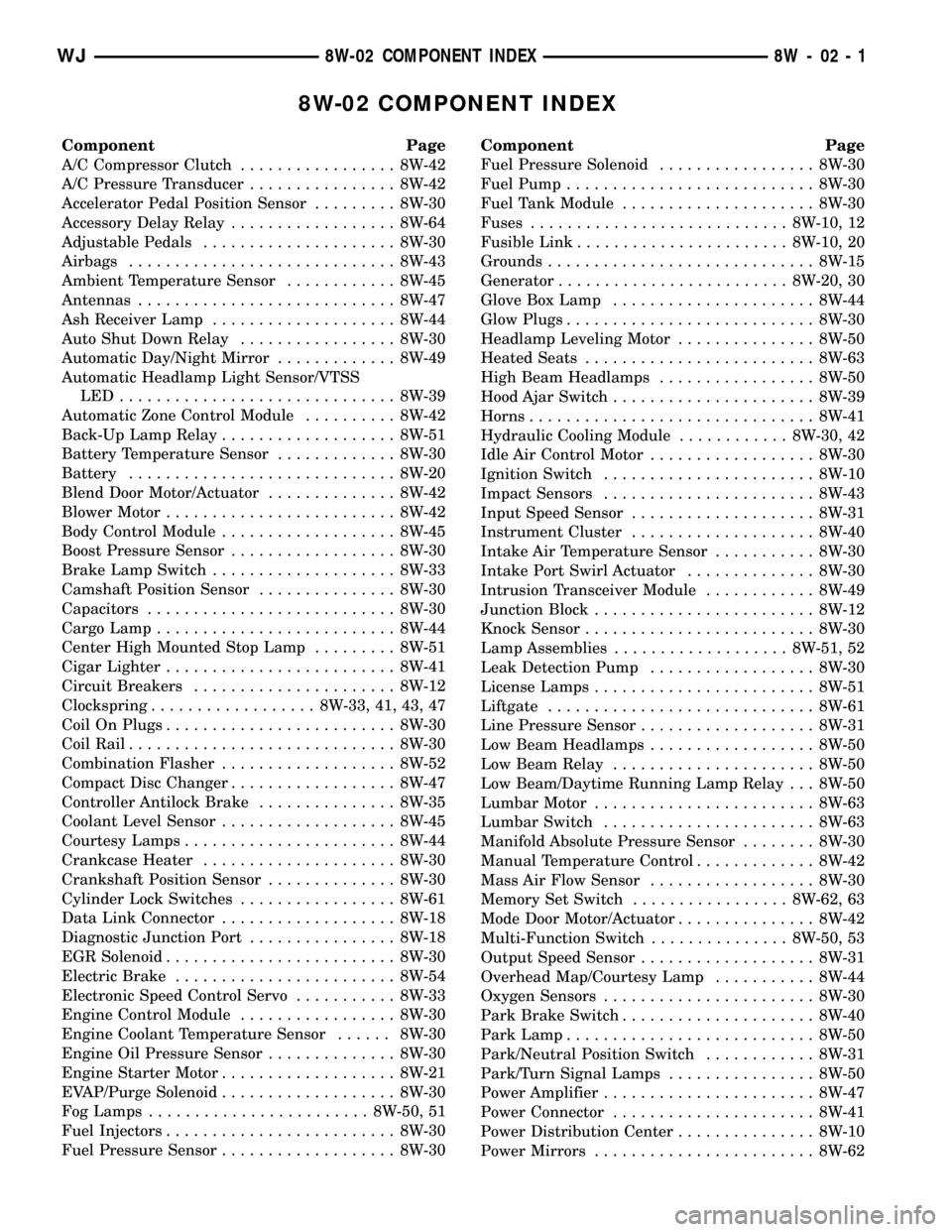

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch................. 8W-42

A/C Pressure Transducer................ 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Accessory Delay Relay.................. 8W-64

Adjustable Pedals..................... 8W-30

Airbags............................. 8W-43

Ambient Temperature Sensor............ 8W-45

Antennas............................ 8W-47

Ash Receiver Lamp.................... 8W-44

Auto Shut Down Relay................. 8W-30

Automatic Day/Night Mirror............. 8W-49

Automatic Headlamp Light Sensor/VTSS

LED.............................. 8W-39

Automatic Zone Control Module.......... 8W-42

Back-Up Lamp Relay................... 8W-51

Battery Temperature Sensor............. 8W-30

Battery............................. 8W-20

Blend Door Motor/Actuator.............. 8W-42

Blower Motor......................... 8W-42

Body Control Module................... 8W-45

Boost Pressure Sensor.................. 8W-30

Brake Lamp Switch.................... 8W-33

Camshaft Position Sensor............... 8W-30

Capacitors........................... 8W-30

Cargo Lamp.......................... 8W-44

Center High Mounted Stop Lamp......... 8W-51

Cigar Lighter......................... 8W-41

Circuit Breakers...................... 8W-12

Clockspring.................. 8W-33, 41, 43, 47

Coil On Plugs......................... 8W-30

Coil Rail............................. 8W-30

Combination Flasher................... 8W-52

Compact Disc Changer.................. 8W-47

Controller Antilock Brake............... 8W-35

Coolant Level Sensor................... 8W-45

Courtesy Lamps....................... 8W-44

Crankcase Heater..................... 8W-30

Crankshaft Position Sensor.............. 8W-30

Cylinder Lock Switches................. 8W-61

Data Link Connector................... 8W-18

Diagnostic Junction Port................ 8W-18

EGR Solenoid......................... 8W-30

Electric Brake........................ 8W-54

Electronic Speed Control Servo........... 8W-33

Engine Control Module................. 8W-30

Engine Coolant Temperature Sensor...... 8W-30

Engine Oil Pressure Sensor.............. 8W-30

Engine Starter Motor................... 8W-21

EVAP/Purge Solenoid................... 8W-30

Fog Lamps........................ 8W-50, 51

Fuel Injectors......................... 8W-30

Fuel Pressure Sensor................... 8W-30Component Page

Fuel Pressure Solenoid................. 8W-30

Fuel Pump........................... 8W-30

Fuel Tank Module..................... 8W-30

Fuses............................ 8W-10, 12

Fusible Link....................... 8W-10, 20

Grounds............................. 8W-15

Generator......................... 8W-20, 30

Glove Box Lamp...................... 8W-44

Glow Plugs........................... 8W-30

Headlamp Leveling Motor............... 8W-50

Heated Seats......................... 8W-63

High Beam Headlamps................. 8W-50

Hood Ajar Switch...................... 8W-39

Horns............................... 8W-41

Hydraulic Cooling Module............ 8W-30, 42

Idle Air Control Motor.................. 8W-30

Ignition Switch....................... 8W-10

Impact Sensors....................... 8W-43

Input Speed Sensor.................... 8W-31

Instrument Cluster.................... 8W-40

Intake Air Temperature Sensor........... 8W-30

Intake Port Swirl Actuator.............. 8W-30

Intrusion Transceiver Module............ 8W-49

Junction Block........................ 8W-12

Knock Sensor......................... 8W-30

Lamp Assemblies................... 8W-51, 52

Leak Detection Pump.................. 8W-30

License Lamps........................ 8W-51

Liftgate............................. 8W-61

Line Pressure Sensor................... 8W-31

Low Beam Headlamps.................. 8W-50

Low Beam Relay...................... 8W-50

Low Beam/Daytime Running Lamp Relay . . . 8W-50

Lumbar Motor........................ 8W-63

Lumbar Switch....................... 8W-63

Manifold Absolute Pressure Sensor........ 8W-30

Manual Temperature Control............. 8W-42

Mass Air Flow Sensor.................. 8W-30

Memory Set Switch................. 8W-62, 63

Mode Door Motor/Actuator............... 8W-42

Multi-Function Switch............... 8W-50, 53

Output Speed Sensor................... 8W-31

Overhead Map/Courtesy Lamp........... 8W-44

Oxygen Sensors....................... 8W-30

Park Brake Switch..................... 8W-40

Park Lamp........................... 8W-50

Park/Neutral Position Switch............ 8W-31

Park/Turn Signal Lamps................ 8W-50

Power Amplifier....................... 8W-47

Power Connector...................... 8W-41

Power Distribution Center............... 8W-10

Power Mirrors........................ 8W-62

WJ8W-02 COMPONENT INDEX 8W - 02 - 1

Page 782 of 2199

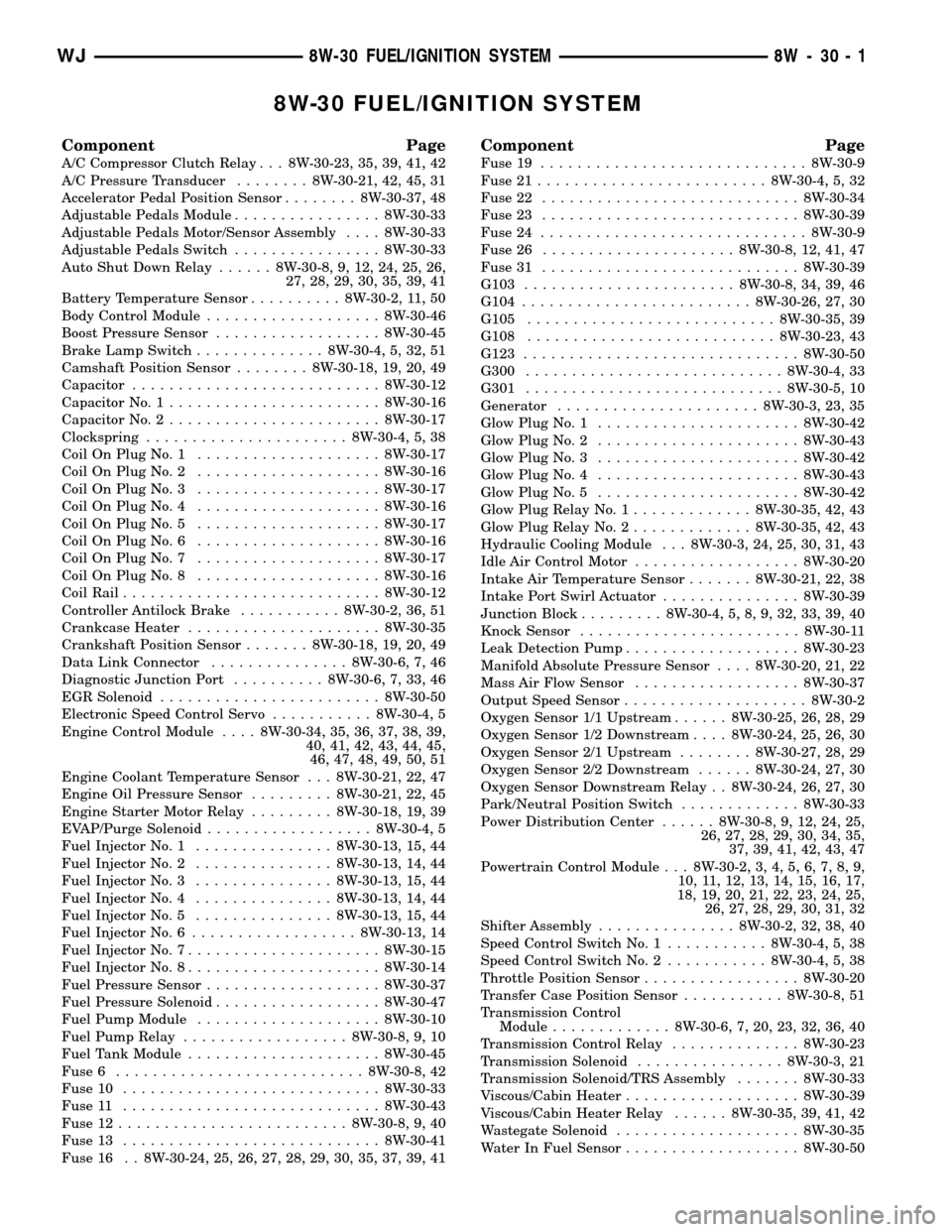

8W-30 FUEL/IGNITION SYSTEM

Component Page

A/C Compressor Clutch Relay . . . 8W-30-23, 35, 39, 41, 42

A/C Pressure Transducer........ 8W-30-21, 42, 45, 31

Accelerator Pedal Position Sensor........ 8W-30-37, 48

Adjustable Pedals Module................ 8W-30-33

Adjustable Pedals Motor/Sensor Assembly.... 8W-30-33

Adjustable Pedals Switch................ 8W-30-33

Auto Shut Down Relay...... 8W-30-8, 9, 12, 24, 25, 26,

27, 28, 29, 30, 35, 39, 41

Battery Temperature Sensor.......... 8W-30-2, 11, 50

Body Control Module................... 8W-30-46

Boost Pressure Sensor.................. 8W-30-45

Brake Lamp Switch.............. 8W-30-4, 5, 32, 51

Camshaft Position Sensor........ 8W-30-18, 19, 20, 49

Capacitor........................... 8W-30-12

Capacitor No. 1....................... 8W-30-16

Capacitor No. 2....................... 8W-30-17

Clockspring...................... 8W-30-4, 5, 38

Coil On Plug No. 1.................... 8W-30-17

Coil On Plug No. 2.................... 8W-30-16

Coil On Plug No. 3.................... 8W-30-17

Coil On Plug No. 4.................... 8W-30-16

Coil On Plug No. 5.................... 8W-30-17

Coil On Plug No. 6.................... 8W-30-16

Coil On Plug No. 7.................... 8W-30-17

Coil On Plug No. 8.................... 8W-30-16

Coil Rail............................ 8W-30-12

Controller Antilock Brake........... 8W-30-2, 36, 51

Crankcase Heater..................... 8W-30-35

Crankshaft Position Sensor....... 8W-30-18, 19, 20, 49

Data Link Connector............... 8W-30-6, 7, 46

Diagnostic Junction Port.......... 8W-30-6, 7, 33, 46

EGR Solenoid........................ 8W-30-50

Electronic Speed Control Servo........... 8W-30-4, 5

Engine Control Module.... 8W-30-34, 35, 36, 37, 38, 39,

40, 41, 42, 43, 44, 45,

46, 47, 48, 49, 50, 51

Engine Coolant Temperature Sensor . . . 8W-30-21, 22, 47

Engine Oil Pressure Sensor......... 8W-30-21, 22, 45

Engine Starter Motor Relay......... 8W-30-18, 19, 39

EVAP/Purge Solenoid.................. 8W-30-4, 5

Fuel Injector No. 1............... 8W-30-13, 15, 44

Fuel Injector No. 2............... 8W-30-13, 14, 44

Fuel Injector No. 3............... 8W-30-13, 15, 44

Fuel Injector No. 4............... 8W-30-13, 14, 44

Fuel Injector No. 5............... 8W-30-13, 15, 44

Fuel Injector No. 6.................. 8W-30-13, 14

Fuel Injector No. 7..................... 8W-30-15

Fuel Injector No. 8..................... 8W-30-14

Fuel Pressure Sensor................... 8W-30-37

Fuel Pressure Solenoid.................. 8W-30-47

Fuel Pump Module.................... 8W-30-10

Fuel Pump Relay.................. 8W-30-8, 9, 10

Fuel Tank Module..................... 8W-30-45

Fuse 6........................... 8W-30-8, 42

Fuse 10............................ 8W-30-33

Fuse 11............................ 8W-30-43

Fuse 12......................... 8W-30-8, 9, 40

Fuse 13............................ 8W-30-41

Fuse 16 . . 8W-30-24, 25, 26, 27, 28, 29, 30, 35, 37, 39, 41

Component Page

Fuse 19............................. 8W-30-9

Fuse 21......................... 8W-30-4, 5, 32

Fuse 22............................ 8W-30-34

Fuse 23............................ 8W-30-39

Fuse 24............................. 8W-30-9

Fuse 26..................... 8W-30-8, 12, 41, 47

Fuse 31............................ 8W-30-39

G103....................... 8W-30-8, 34, 39, 46

G104......................... 8W-30-26, 27, 30

G105........................... 8W-30-35, 39

G108........................... 8W-30-23, 43

G123.............................. 8W-30-50

G300............................ 8W-30-4, 33

G301............................ 8W-30-5, 10

Generator...................... 8W-30-3, 23, 35

Glow Plug No. 1...................... 8W-30-42

Glow Plug No. 2...................... 8W-30-43

Glow Plug No. 3...................... 8W-30-42

Glow Plug No. 4...................... 8W-30-43

Glow Plug No. 5...................... 8W-30-42

Glow Plug Relay No. 1............. 8W-30-35, 42, 43

Glow Plug Relay No. 2............. 8W-30-35, 42, 43

Hydraulic Cooling Module . . . 8W-30-3, 24, 25, 30, 31, 43

Idle Air Control Motor.................. 8W-30-20

Intake Air Temperature Sensor....... 8W-30-21, 22, 38

Intake Port Swirl Actuator............... 8W-30-39

Junction Block......... 8W-30-4, 5, 8, 9, 32, 33, 39, 40

Knock Sensor........................ 8W-30-11

Leak Detection Pump................... 8W-30-23

Manifold Absolute Pressure Sensor.... 8W-30-20, 21, 22

Mass Air Flow Sensor.................. 8W-30-37

Output Speed Sensor.................... 8W-30-2

Oxygen Sensor 1/1 Upstream...... 8W-30-25, 26, 28, 29

Oxygen Sensor 1/2 Downstream.... 8W-30-24, 25, 26, 30

Oxygen Sensor 2/1 Upstream........ 8W-30-27, 28, 29

Oxygen Sensor 2/2 Downstream...... 8W-30-24, 27, 30

Oxygen Sensor Downstream Relay . . 8W-30-24, 26, 27, 30

Park/Neutral Position Switch............. 8W-30-33

Power Distribution Center...... 8W-30-8, 9, 12, 24, 25,

26, 27, 28, 29, 30, 34, 35,

37, 39, 41, 42, 43, 47

Powertrain Control Module . . . 8W-30-2, 3, 4, 5, 6, 7, 8, 9,

10, 11, 12, 13, 14, 15, 16, 17,

18, 19, 20, 21, 22, 23, 24, 25,

26, 27, 28, 29, 30, 31, 32

Shifter Assembly............... 8W-30-2, 32, 38, 40

Speed Control Switch No. 1........... 8W-30-4, 5, 38

Speed Control Switch No. 2........... 8W-30-4, 5, 38

Throttle Position Sensor................. 8W-30-20

Transfer Case Position Sensor........... 8W-30-8, 51

Transmission Control

Module............. 8W-30-6, 7, 20, 23, 32, 36, 40

Transmission Control Relay.............. 8W-30-23

Transmission Solenoid................ 8W-30-3, 21

Transmission Solenoid/TRS Assembly....... 8W-30-33

Viscous/Cabin Heater................... 8W-30-39

Viscous/Cabin Heater Relay...... 8W-30-35, 39, 41, 42

Wastegate Solenoid.................... 8W-30-35

Water In Fuel Sensor................... 8W-30-50

WJ8W-30 FUEL/IGNITION SYSTEM 8W - 30 - 1

Page 1245 of 2199

REMOVAL

REMOVAL - CAMSHAFT BEARINGS.......31

REMOVAL - CAMSHAFT................31

INSPECTION

INSPECTION - CAMSHAFT BEARINGS.....31

INSPECTION - CAMSHAFT..............31

INSTALLATION

INSTALLATION - CAMSHAFT BEARINGS . . . 32

INSTALLATION - CAMSHAFT............32

CONNECTING ROD BEARINGS

STANDARD PROCEDURE - FITTING

CONNECTING ROD BEARINGS..........33

CRANKSHAFT

DESCRIPTION.........................35

CRANKSHAFT MAIN BEARINGS

STANDARD PROCEDURE - FITTING

CRANKSHAFT MAIN BEARINGS..........36

REMOVAL.............................39

INSPECTION..........................40

INSTALLATION.........................40

CRANKSHAFT OIL SEAL - FRONT

REMOVAL.............................41

INSTALLATION.........................41

CRANKSHAFT OIL SEAL - REAR

REMOVAL.............................42

INSTALLATION.........................42

HYDRAULIC LIFTERS

DESCRIPTION.........................43

REMOVAL.............................43

CLEANING............................43

INSPECTION..........................43

INSTALLATION.........................43

PISTON & CONNECTING ROD

DESCRIPTION.........................44

STANDARD PROCEDURE - PISTON FITTING . 44

REMOVAL.............................45

INSTALLATION.........................46

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING.............................47

VIBRATION DAMPER

REMOVAL.............................49

INSTALLATION.........................49STRUCTURAL SUPPORT

REMOVAL.............................49

INSTALLATION.........................50

LUBRICATION

DESCRIPTION.........................50

OPERATION...........................50

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE OIL

PRESSURE..........................51

DIAGNOSIS AND TESTING - ENGINE OIL

LEAK...............................51

OIL

STANDARD PROCEDURE - ENGINE OIL

SERVICE............................53

OIL FILTER

REMOVAL.............................53

INSTALLATION.........................54

OIL PAN

DESCRIPTION.........................54

REMOVAL.............................54

INSTALLATION.........................55

ENGINE OIL PRESSURE SENSOR

DESCRIPTION.........................56

OPERATION...........................56

OIL PUMP

REMOVAL.............................56

INSTALLATION.........................57

INTAKE MANIFOLD

DESCRIPTION.........................57

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKAGE..................57

REMOVAL.............................57

INSTALLATION.........................57

EXHAUST MANIFOLD

DESCRIPTION.........................58

REMOVAL.............................58

INSTALLATION.........................58

TIMING BELT / CHAIN COVER(S)

REMOVAL.............................58

INSTALLATION.........................58

TIMING BELT/CHAIN AND SPROCKETS

REMOVAL.............................60

INSTALLATION.........................60

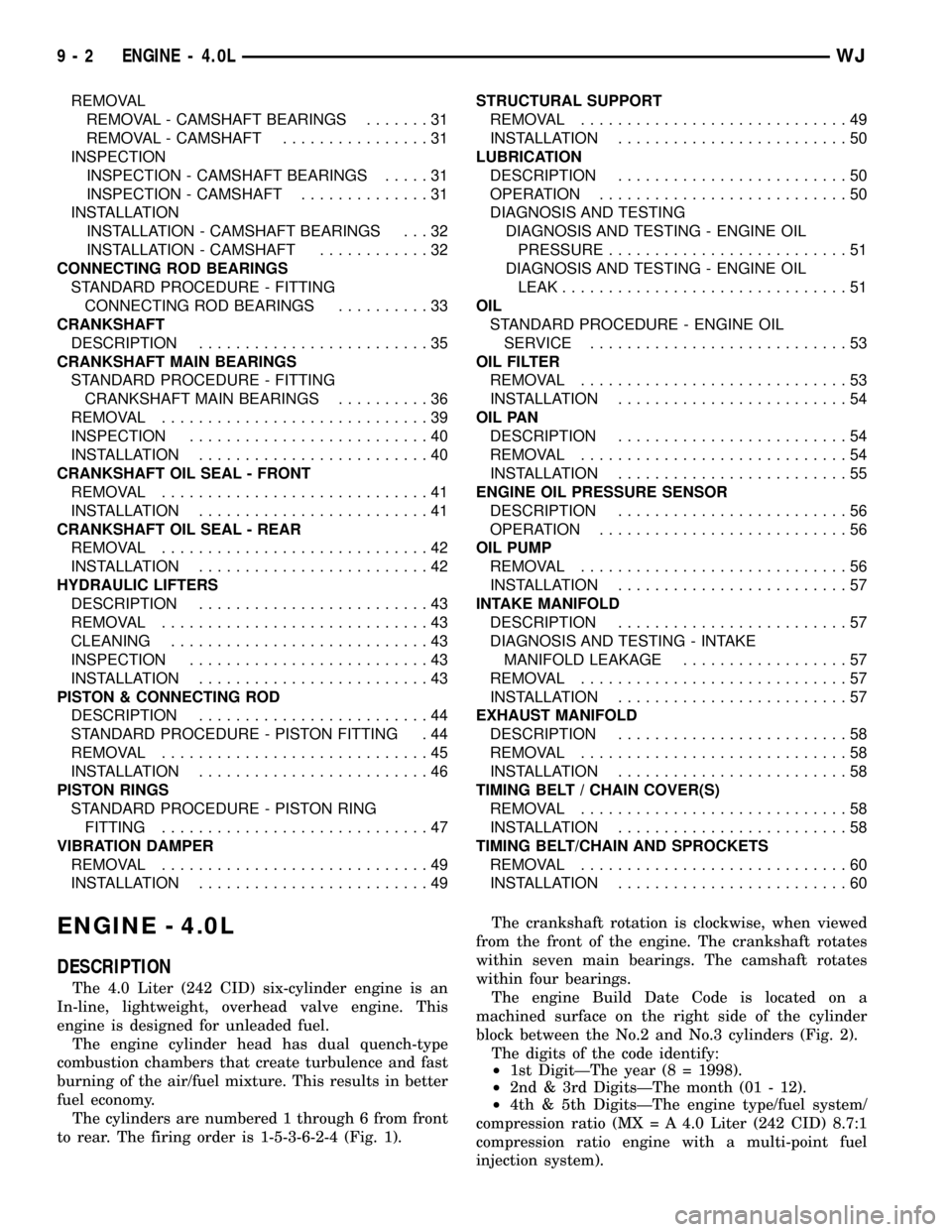

ENGINE - 4.0L

DESCRIPTION

The 4.0 Liter (242 CID) six-cylinder engine is an

In-line, lightweight, overhead valve engine. This

engine is designed for unleaded fuel.

The engine cylinder head has dual quench-type

combustion chambers that create turbulence and fast

burning of the air/fuel mixture. This results in better

fuel economy.

The cylinders are numbered 1 through 6 from front

to rear. The firing order is 1-5-3-6-2-4 (Fig. 1).The crankshaft rotation is clockwise, when viewed

from the front of the engine. The crankshaft rotates

within seven main bearings. The camshaft rotates

within four bearings.

The engine Build Date Code is located on a

machined surface on the right side of the cylinder

block between the No.2 and No.3 cylinders (Fig. 2).

The digits of the code identify:

²1st DigitÐThe year (8 = 1998).

²2nd & 3rd DigitsÐThe month (01 - 12).

²4th & 5th DigitsÐThe engine type/fuel system/

compression ratio (MX = A 4.0 Liter (242 CID) 8.7:1

compression ratio engine with a multi-point fuel

injection system).

9 - 2 ENGINE - 4.0LWJ