Trans JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1187 of 2199

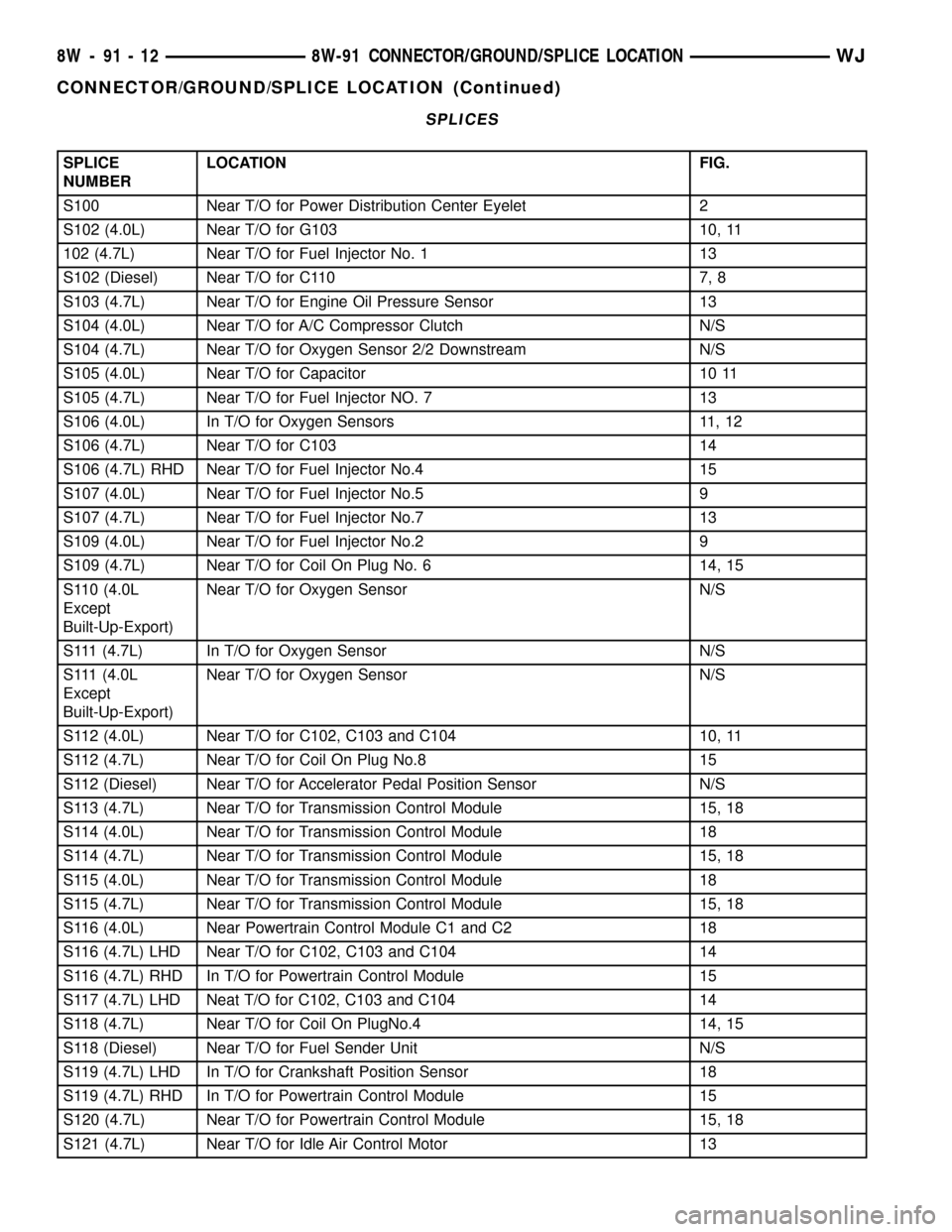

SPLICES

SPLICE

NUMBERLOCATION FIG.

S100 Near T/O for Power Distribution Center Eyelet 2

S102 (4.0L) Near T/O for G103 10, 11

102 (4.7L) Near T/O for Fuel Injector No. 1 13

S102 (Diesel) Near T/O for C110 7, 8

S103 (4.7L) Near T/O for Engine Oil Pressure Sensor 13

S104 (4.0L) Near T/O for A/C Compressor Clutch N/S

S104 (4.7L) Near T/O for Oxygen Sensor 2/2 Downstream N/S

S105 (4.0L) Near T/O for Capacitor 10 11

S105 (4.7L) Near T/O for Fuel Injector NO. 7 13

S106 (4.0L) In T/O for Oxygen Sensors 11, 12

S106 (4.7L) Near T/O for C103 14

S106 (4.7L) RHD Near T/O for Fuel Injector No.4 15

S107 (4.0L) Near T/O for Fuel Injector No.5 9

S107 (4.7L) Near T/O for Fuel Injector No.7 13

S109 (4.0L) Near T/O for Fuel Injector No.2 9

S109 (4.7L) Near T/O for Coil On Plug No. 6 14, 15

S110 (4.0L

Except

Built-Up-Export)Near T/O for Oxygen Sensor N/S

S111 (4.7L) In T/O for Oxygen Sensor N/S

S111 (4.0L

Except

Built-Up-Export)Near T/O for Oxygen Sensor N/S

S112 (4.0L) Near T/O for C102, C103 and C104 10, 11

S112 (4.7L) Near T/O for Coil On Plug No.8 15

S112 (Diesel) Near T/O for Accelerator Pedal Position Sensor N/S

S113 (4.7L) Near T/O for Transmission Control Module 15, 18

S114 (4.0L) Near T/O for Transmission Control Module 18

S114 (4.7L) Near T/O for Transmission Control Module 15, 18

S115 (4.0L) Near T/O for Transmission Control Module 18

S115 (4.7L) Near T/O for Transmission Control Module 15, 18

S116 (4.0L) Near Powertrain Control Module C1 and C2 18

S116 (4.7L) LHD Near T/O for C102, C103 and C104 14

S116 (4.7L) RHD In T/O for Powertrain Control Module 15

S117 (4.7L) LHD Neat T/O for C102, C103 and C104 14

S118 (4.7L) Near T/O for Coil On PlugNo.4 14, 15

S118 (Diesel) Near T/O for Fuel Sender Unit N/S

S119 (4.7L) LHD In T/O for Crankshaft Position Sensor 18

S119 (4.7L) RHD In T/O for Powertrain Control Module 15

S120 (4.7L) Near T/O for Powertrain Control Module 15, 18

S121 (4.7L) Near T/O for Idle Air Control Motor 13

8W - 91 - 12 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1204 of 2199

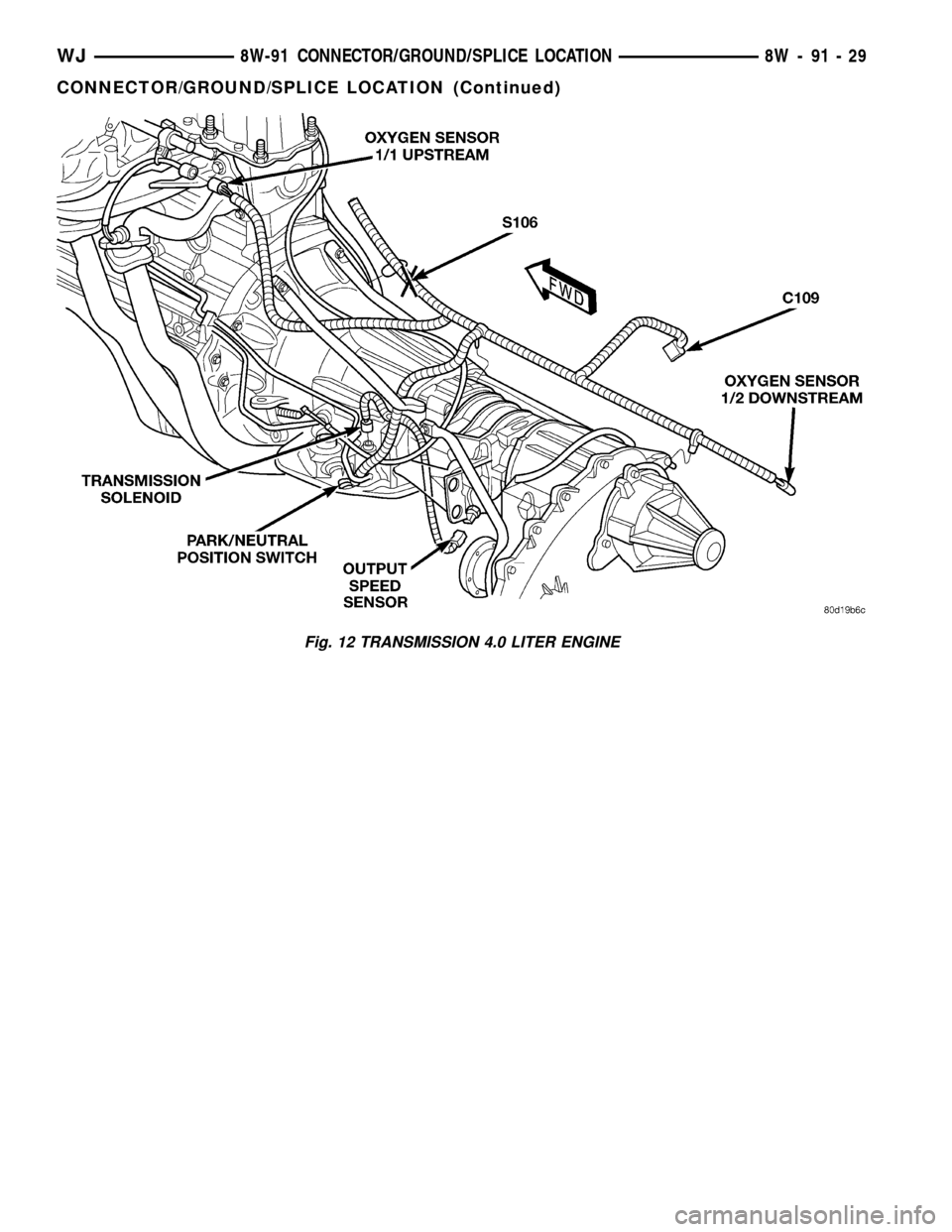

Fig. 12 TRANSMISSION 4.0 LITER ENGINE

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 29

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1208 of 2199

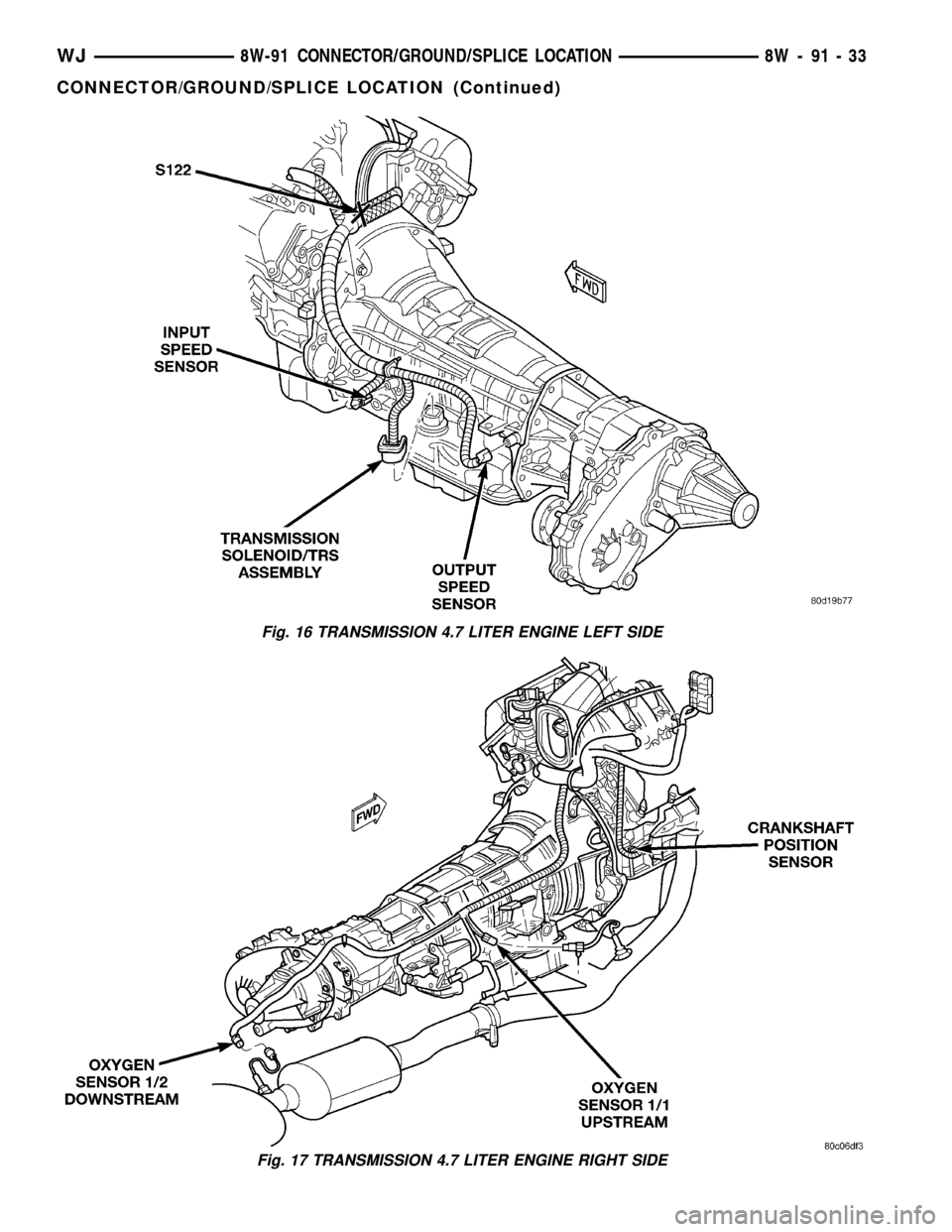

Fig. 16 TRANSMISSION 4.7 LITER ENGINE LEFT SIDE

Fig. 17 TRANSMISSION 4.7 LITER ENGINE RIGHT SIDE

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 33

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1229 of 2199

of the preparation procedures performed just prior to

new vehicle delivery.

The PDC has a molded plastic cover that can be

removed to provide service access to all of the fuses

and relays in the PDC. An integral latch and hinges

are molded into the PDC cover for easy removal. A

fuse layout map is integral to the underside of the

PDC cover to ensure proper fuse and relay identifica-

tion. The IOD fuse is a 50 ampere maxi-type car-

tridge fuse and, when removed, it is stored in a spare

fuse cavity within the PDC.

OPERATION

The term ignition-off draw identifies a normal con-

dition where power is being drained from the battery

with the ignition switch in the Off position. The IOD

fuse feeds the memory and sleep mode functions for

some of the electronic modules in the vehicle as well

as various other accessories that require battery cur-

rent when the ignition switch is in the Off position,

including the clock. The only reason the IOD fuse is

removed is to reduce the normal IOD of the vehicle

electrical system during new vehicle transportation

and pre-delivery storage to reduce battery depletion,

while still allowing vehicle operation so that the

vehicle can be loaded, unloaded and moved as needed

by both vehicle transportation company and dealer

personnel.

The IOD fuse is removed from PDC fuse cavity 15

when the vehicle is shipped from the assembly plant.

Dealer personnel must install the IOD fuse when the

vehicle is being prepared for delivery in order to

restore full electrical system operation. Once the

vehicle is prepared for delivery, the IOD function of

this fuse becomes transparent and the fuse that has

been assigned the IOD designation becomes only

another Fused B(+) circuit fuse. The IOD fuse serves

no useful purpose to the dealer technician in the ser-

vice or diagnosis of any vehicle system or condition,

other than the same purpose as that of any other

standard circuit protection device.

The IOD fuse can be used by the vehicle owner as

a convenient means of reducing battery depletion

when a vehicle is to be stored for periods not toexceed about thirty days. However, it must be

remembered that removing the IOD fuse will not

eliminate IOD, but only reduce this normal condition.

If a vehicle will be stored for more than about thirty

days, the battery negative cable should be discon-

nected to eliminate normal IOD; and, the battery

should be tested and recharged at regular intervals

during the vehicle storage period to prevent the bat-

tery from becoming discharged or damaged. Refer to

Battery Systemfor additional service information.

REMOVAL

The Ignition-Off Draw (IOD) fuses normal installa-

tion location is cavity 15 in the power distribution

center. When the vehicle is shipped from the assem-

bly plant the fuse is removed to maintain proper bat-

tery voltage during vehicle storage (in some cases).

Dealer personnel must install the IOD fuse when the

vehicle is being prepared for customer delivery in

order to restore full electrical system operation.

(1) Turn the ignition switch to the Off position.

(2) Unlatch and open the cover of the power distri-

bution center.

(3) Remove the IOD fuse from fusecavity 15of

the power distribution center (Fig. 2).

(4) Store the removed IOD fuse by installing it in

the unused fuse storagecavity 11of the PDC (Fig.

2).

(5) Close and latch the power distribution center

cover.

INSTALLATION

(1) Be certain the ignition switch is in the Off posi-

tion.

(2) Unlatch and open the cover of the power distri-

bution center.

(3) Remove the stored IOD fuse from fuse storage

cavity 11of the power distribution center.

(4) Use a thumb to press the IOD fuse firmly down

into power distribution center fusecavity 15.

(5) Close and latch the power distribution center

cover.

8W - 97 - 4 8W-97 POWER DISTRIBUTIONWJ

IOD FUSE (Continued)

Page 1231 of 2199

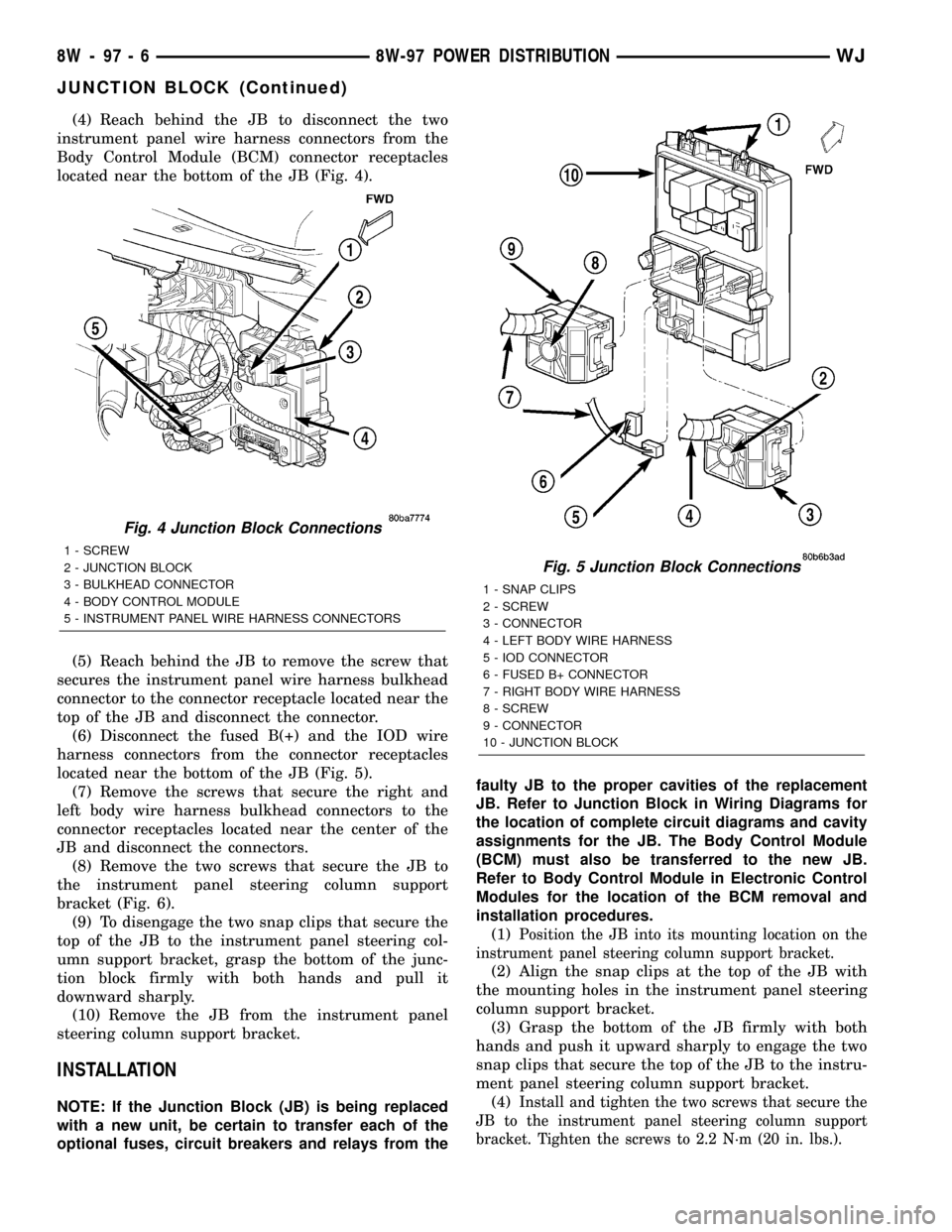

(4) Reach behind the JB to disconnect the two

instrument panel wire harness connectors from the

Body Control Module (BCM) connector receptacles

located near the bottom of the JB (Fig. 4).

(5) Reach behind the JB to remove the screw that

secures the instrument panel wire harness bulkhead

connector to the connector receptacle located near the

top of the JB and disconnect the connector.

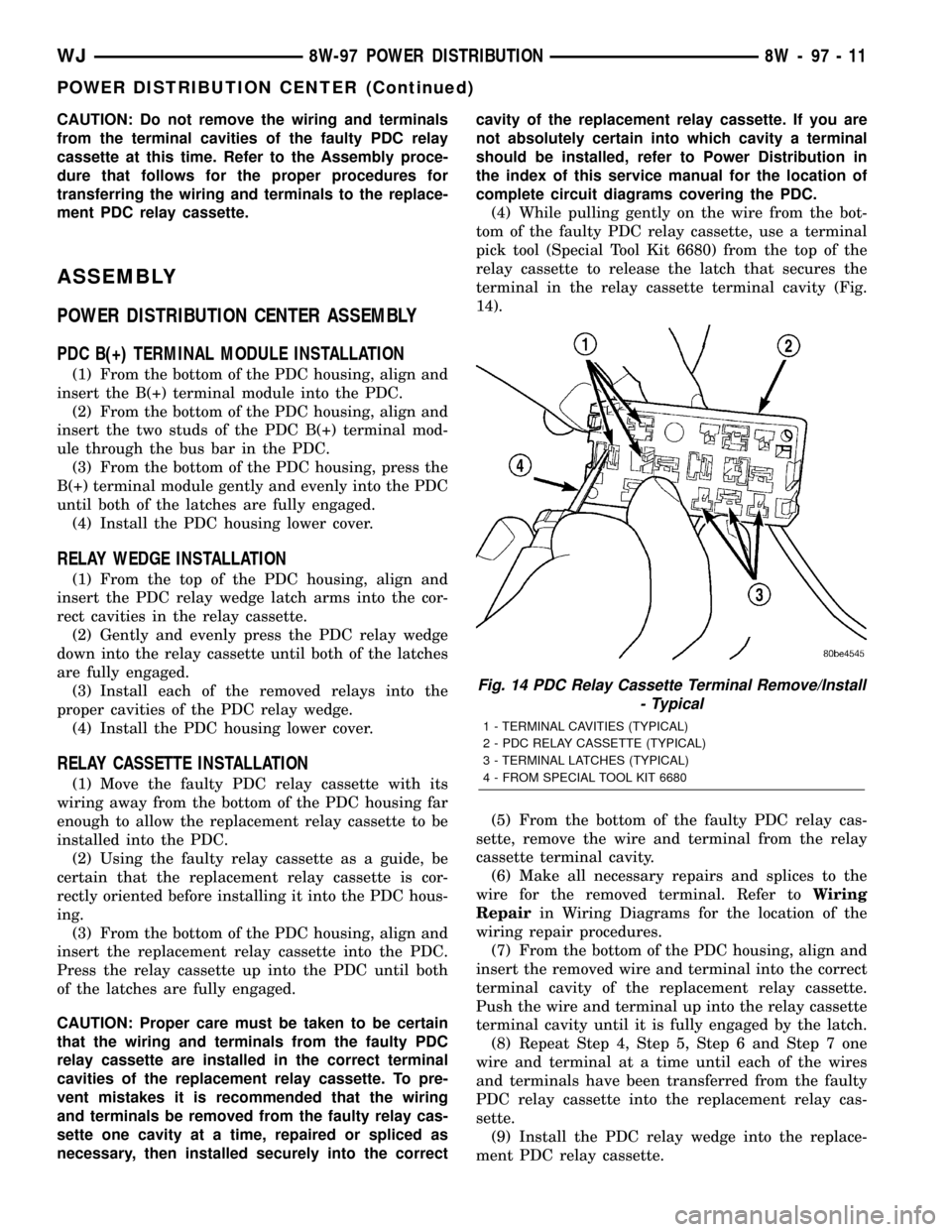

(6) Disconnect the fused B(+) and the IOD wire

harness connectors from the connector receptacles

located near the bottom of the JB (Fig. 5).

(7) Remove the screws that secure the right and

left body wire harness bulkhead connectors to the

connector receptacles located near the center of the

JB and disconnect the connectors.

(8) Remove the two screws that secure the JB to

the instrument panel steering column support

bracket (Fig. 6).

(9) To disengage the two snap clips that secure the

top of the JB to the instrument panel steering col-

umn support bracket, grasp the bottom of the junc-

tion block firmly with both hands and pull it

downward sharply.

(10) Remove the JB from the instrument panel

steering column support bracket.

INSTALLATION

NOTE: If the Junction Block (JB) is being replaced

with a new unit, be certain to transfer each of the

optional fuses, circuit breakers and relays from thefaulty JB to the proper cavities of the replacement

JB. Refer to Junction Block in Wiring Diagrams for

the location of complete circuit diagrams and cavity

assignments for the JB. The Body Control Module

(BCM) must also be transferred to the new JB.

Refer to Body Control Module in Electronic Control

Modules for the location of the BCM removal and

installation procedures.

(1)

Position the JB into its mounting location on the

instrument panel steering column support bracket.

(2) Align the snap clips at the top of the JB with

the mounting holes in the instrument panel steering

column support bracket.

(3) Grasp the bottom of the JB firmly with both

hands and push it upward sharply to engage the two

snap clips that secure the top of the JB to the instru-

ment panel steering column support bracket.

(4)

Install and tighten the two screws that secure the

JB to the instrument panel steering column support

bracket. Tighten the screws to 2.2 N´m (20 in. lbs.).

Fig. 4 Junction Block Connections

1 - SCREW

2 - JUNCTION BLOCK

3 - BULKHEAD CONNECTOR

4 - BODY CONTROL MODULE

5 - INSTRUMENT PANEL WIRE HARNESS CONNECTORS

Fig. 5 Junction Block Connections

1 - SNAP CLIPS

2 - SCREW

3 - CONNECTOR

4 - LEFT BODY WIRE HARNESS

5 - IOD CONNECTOR

6 - FUSED B+ CONNECTOR

7 - RIGHT BODY WIRE HARNESS

8 - SCREW

9 - CONNECTOR

10 - JUNCTION BLOCK

8W - 97 - 6 8W-97 POWER DISTRIBUTIONWJ

JUNCTION BLOCK (Continued)

Page 1236 of 2199

CAUTION: Do not remove the wiring and terminals

from the terminal cavities of the faulty PDC relay

cassette at this time. Refer to the Assembly proce-

dure that follows for the proper procedures for

transferring the wiring and terminals to the replace-

ment PDC relay cassette.

ASSEMBLY

POWER DISTRIBUTION CENTER ASSEMBLY

PDC B(+) TERMINAL MODULE INSTALLATION

(1) From the bottom of the PDC housing, align and

insert the B(+) terminal module into the PDC.

(2) From the bottom of the PDC housing, align and

insert the two studs of the PDC B(+) terminal mod-

ule through the bus bar in the PDC.

(3) From the bottom of the PDC housing, press the

B(+) terminal module gently and evenly into the PDC

until both of the latches are fully engaged.

(4) Install the PDC housing lower cover.

RELAY WEDGE INSTALLATION

(1) From the top of the PDC housing, align and

insert the PDC relay wedge latch arms into the cor-

rect cavities in the relay cassette.

(2) Gently and evenly press the PDC relay wedge

down into the relay cassette until both of the latches

are fully engaged.

(3) Install each of the removed relays into the

proper cavities of the PDC relay wedge.

(4) Install the PDC housing lower cover.

RELAY CASSETTE INSTALLATION

(1) Move the faulty PDC relay cassette with its

wiring away from the bottom of the PDC housing far

enough to allow the replacement relay cassette to be

installed into the PDC.

(2) Using the faulty relay cassette as a guide, be

certain that the replacement relay cassette is cor-

rectly oriented before installing it into the PDC hous-

ing.

(3) From the bottom of the PDC housing, align and

insert the replacement relay cassette into the PDC.

Press the relay cassette up into the PDC until both

of the latches are fully engaged.

CAUTION: Proper care must be taken to be certain

that the wiring and terminals from the faulty PDC

relay cassette are installed in the correct terminal

cavities of the replacement relay cassette. To pre-

vent mistakes it is recommended that the wiring

and terminals be removed from the faulty relay cas-

sette one cavity at a time, repaired or spliced as

necessary, then installed securely into the correctcavity of the replacement relay cassette. If you are

not absolutely certain into which cavity a terminal

should be installed, refer to Power Distribution in

the index of this service manual for the location of

complete circuit diagrams covering the PDC.

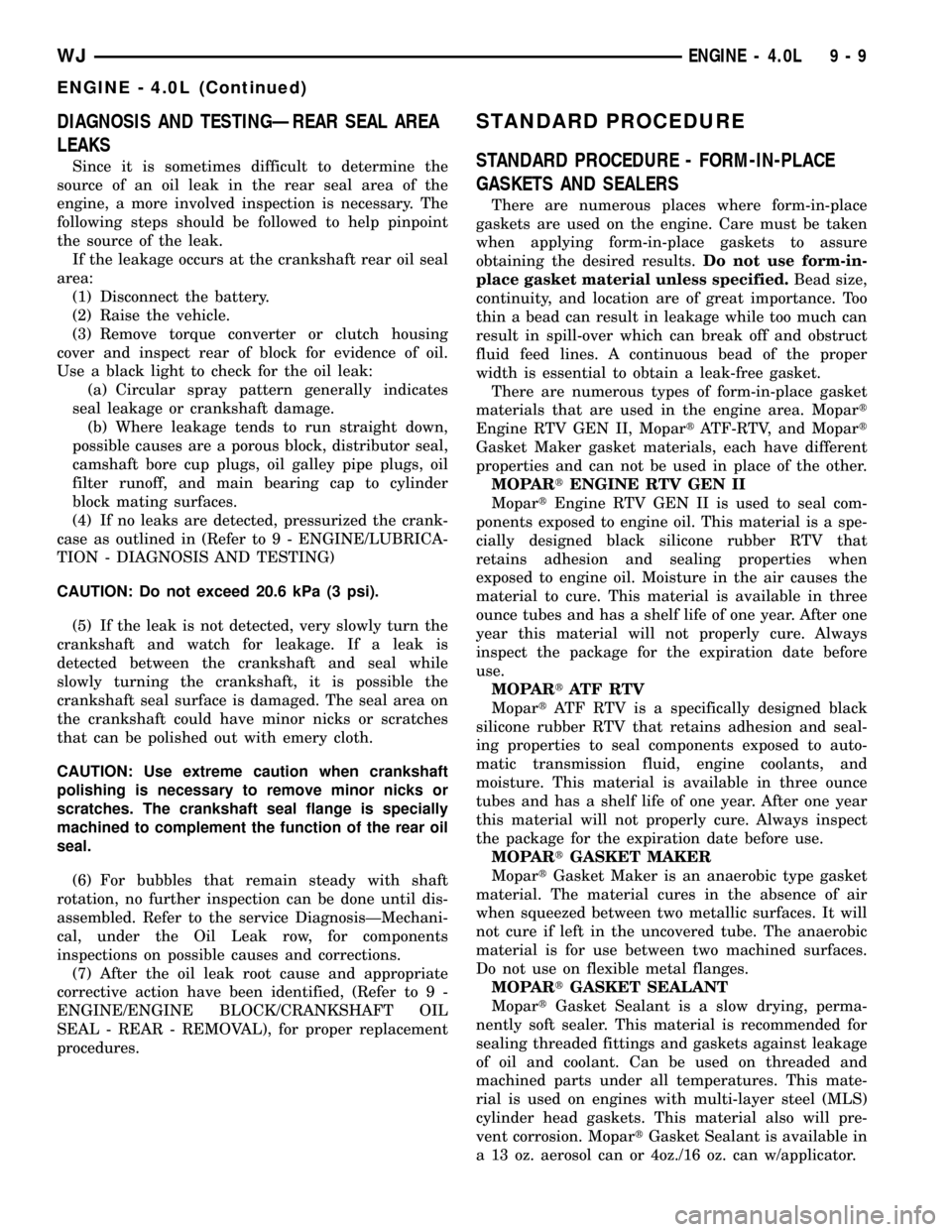

(4) While pulling gently on the wire from the bot-

tom of the faulty PDC relay cassette, use a terminal

pick tool (Special Tool Kit 6680) from the top of the

relay cassette to release the latch that secures the

terminal in the relay cassette terminal cavity (Fig.

14).

(5) From the bottom of the faulty PDC relay cas-

sette, remove the wire and terminal from the relay

cassette terminal cavity.

(6) Make all necessary repairs and splices to the

wire for the removed terminal. Refer toWiring

Repairin Wiring Diagrams for the location of the

wiring repair procedures.

(7) From the bottom of the PDC housing, align and

insert the removed wire and terminal into the correct

terminal cavity of the replacement relay cassette.

Push the wire and terminal up into the relay cassette

terminal cavity until it is fully engaged by the latch.

(8) Repeat Step 4, Step 5, Step 6 and Step 7 one

wire and terminal at a time until each of the wires

and terminals have been transferred from the faulty

PDC relay cassette into the replacement relay cas-

sette.

(9) Install the PDC relay wedge into the replace-

ment PDC relay cassette.

Fig. 14 PDC Relay Cassette Terminal Remove/Install

- Typical

1 - TERMINAL CAVITIES (TYPICAL)

2 - PDC RELAY CASSETTE (TYPICAL)

3 - TERMINAL LATCHES (TYPICAL)

4 - FROM SPECIAL TOOL KIT 6680

WJ8W-97 POWER DISTRIBUTION 8W - 97 - 11

POWER DISTRIBUTION CENTER (Continued)

Page 1252 of 2199

DIAGNOSIS AND TESTINGÐREAR SEAL AREA

LEAKS

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs, oil galley pipe plugs, oil

filter runoff, and main bearing cap to cylinder

block mating surfaces.

(4) If no leaks are detected, pressurized the crank-

case as outlined in (Refer to 9 - ENGINE/LUBRICA-

TION - DIAGNOSIS AND TESTING)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled. Refer to the service DiagnosisÐMechani-

cal, under the Oil Leak row, for components

inspections on possible causes and corrections.

(7) After the oil leak root cause and appropriate

corrective action have been identified, (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - REAR - REMOVAL), for proper replacement

procedures.

STANDARD PROCEDURE

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN II

MopartEngine RTV GEN II is used to seal com-

ponents exposed to engine oil. This material is a spe-

cially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTV

MopartATF RTV is a specifically designed black

silicone rubber RTV that retains adhesion and seal-

ing properties to seal components exposed to auto-

matic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKER

MopartGasket Maker is an anaerobic type gasket

material. The material cures in the absence of air

when squeezed between two metallic surfaces. It will

not cure if left in the uncovered tube. The anaerobic

material is for use between two machined surfaces.

Do not use on flexible metal flanges.

MOPARtGASKET SEALANT

MopartGasket Sealant is a slow drying, perma-

nently soft sealer. This material is recommended for

sealing threaded fittings and gaskets against leakage

of oil and coolant. Can be used on threaded and

machined parts under all temperatures. This mate-

rial is used on engines with multi-layer steel (MLS)

cylinder head gaskets. This material also will pre-

vent corrosion. MopartGasket Sealant is available in

a 13 oz. aerosol can or 4oz./16 oz. can w/applicator.

WJENGINE - 4.0L 9 - 9

ENGINE - 4.0L (Continued)

Page 1254 of 2199

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

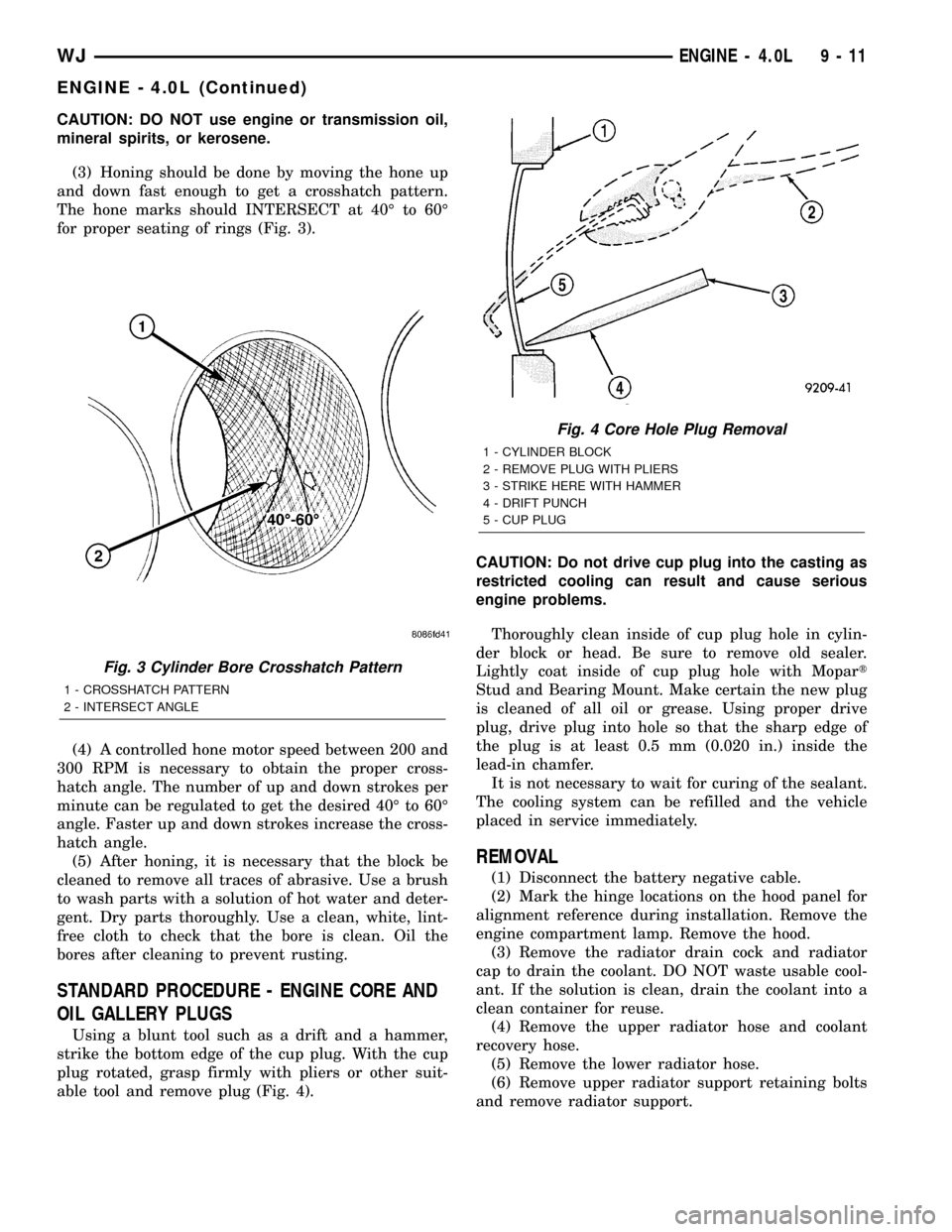

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 40É to 60É

for proper seating of rings (Fig. 3).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 40É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

STANDARD PROCEDURE - ENGINE CORE AND

OIL GALLERY PLUGS

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 4).CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious

engine problems.

Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Lightly coat inside of cup plug hole with Mopart

Stud and Bearing Mount. Make certain the new plug

is cleaned of all oil or grease. Using proper drive

plug, drive plug into hole so that the sharp edge of

the plug is at least 0.5 mm (0.020 in.) inside the

lead-in chamfer.

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Mark the hinge locations on the hood panel for

alignment reference during installation. Remove the

engine compartment lamp. Remove the hood.

(3) Remove the radiator drain cock and radiator

cap to drain the coolant. DO NOT waste usable cool-

ant. If the solution is clean, drain the coolant into a

clean container for reuse.

(4) Remove the upper radiator hose and coolant

recovery hose.

(5) Remove the lower radiator hose.

(6) Remove upper radiator support retaining bolts

and remove radiator support.

Fig. 3 Cylinder Bore Crosshatch Pattern

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

Fig. 4 Core Hole Plug Removal

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

WJENGINE - 4.0L 9 - 11

ENGINE - 4.0L (Continued)

Page 1255 of 2199

(7) Remove the fan assembly from the water pump

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

(8) Remove the fan shroud.

(9) Disconnect the transmission fluid cooler lines

(automatic transmission).

(10) Discharge the A/C system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

(11) Remove the service valves and cap the com-

pressor ports.

(12) Remove the radiator or radiator/condenser (if

equipped with A/C).

(13) Disconnect the heater hoses at the engine

thermostat housing and water pump.

(14) Disconnect the accelerator cable, transmission

line pressure cable and speed control cable (if

equipped) from the throttle body.

(15) Remove cables from the bracket and secure

out of the way.

(16) Disconnect the body ground at the engine.

(17) Disconnect the following connectors and

secure their harness out of the way.

²Power steering pressure switch

²Coolant temperature sensor

²Six (6) fuel injector connectors

²Intake air temperature sensor

²Throttle position sensor

²Map sensor

²Crankshaft position sensor

²Oxygen sensor

²Camshaft position sensor

²Generator connector and B+ terminal wire

(18) Disconnect the coil rail electrical connections

and the oil pressure switch connector.

(19) Perform the fuel pressure release procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(20) Disconnect the fuel supply line at the injector

rail (Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

QUICK CONNECT FITTING - STANDARD PROCE-

DURE).

(21) Remove the fuel line bracket from the intake

manifold.

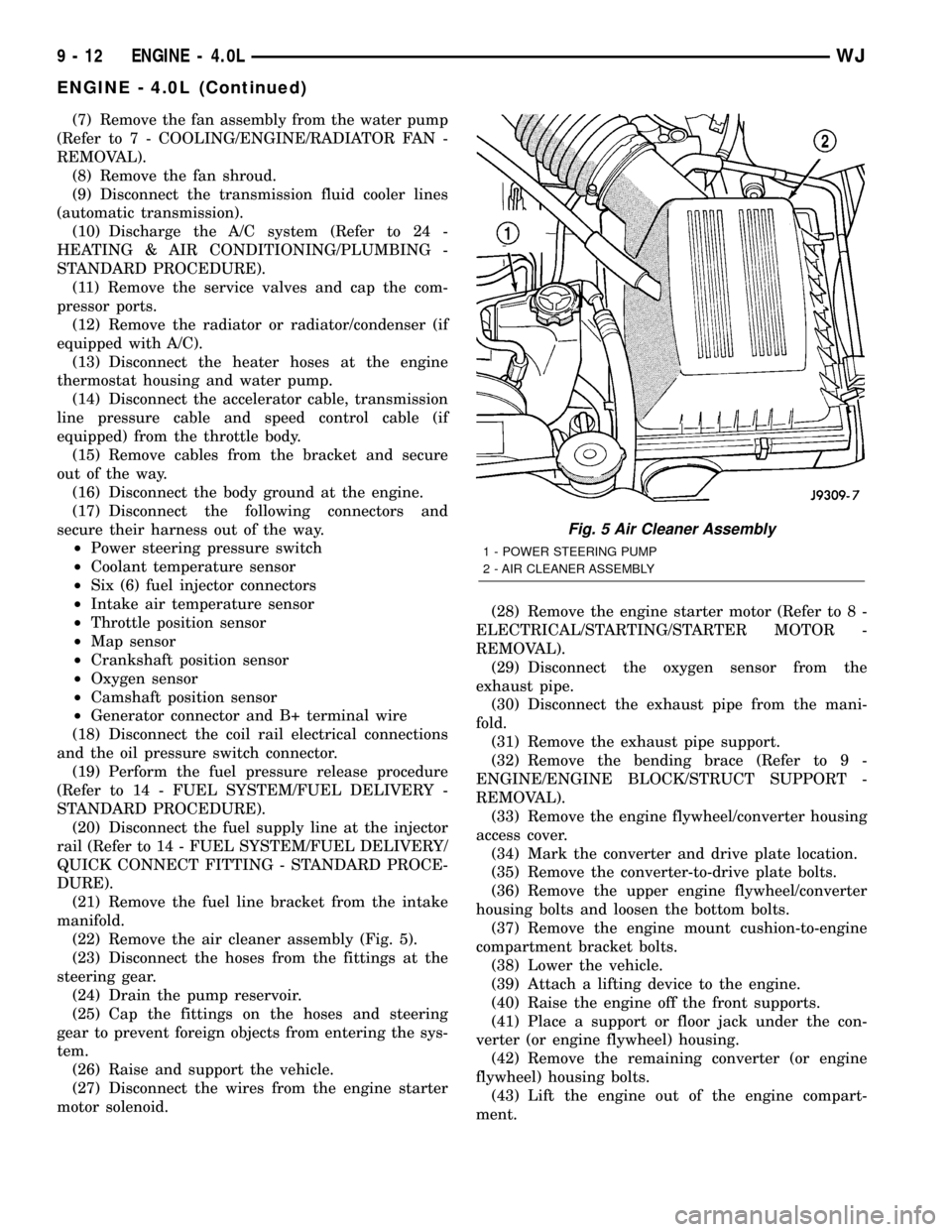

(22) Remove the air cleaner assembly (Fig. 5).

(23) Disconnect the hoses from the fittings at the

steering gear.

(24) Drain the pump reservoir.

(25) Cap the fittings on the hoses and steering

gear to prevent foreign objects from entering the sys-

tem.

(26) Raise and support the vehicle.

(27) Disconnect the wires from the engine starter

motor solenoid.(28) Remove the engine starter motor (Refer to 8 -

ELECTRICAL/STARTING/STARTER MOTOR -

REMOVAL).

(29) Disconnect the oxygen sensor from the

exhaust pipe.

(30) Disconnect the exhaust pipe from the mani-

fold.

(31) Remove the exhaust pipe support.

(32) Remove the bending brace (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCT SUPPORT -

REMOVAL).

(33) Remove the engine flywheel/converter housing

access cover.

(34) Mark the converter and drive plate location.

(35) Remove the converter-to-drive plate bolts.

(36) Remove the upper engine flywheel/converter

housing bolts and loosen the bottom bolts.

(37) Remove the engine mount cushion-to-engine

compartment bracket bolts.

(38) Lower the vehicle.

(39) Attach a lifting device to the engine.

(40) Raise the engine off the front supports.

(41) Place a support or floor jack under the con-

verter (or engine flywheel) housing.

(42) Remove the remaining converter (or engine

flywheel) housing bolts.

(43) Lift the engine out of the engine compart-

ment.

Fig. 5 Air Cleaner Assembly

1 - POWER STEERING PUMP

2 - AIR CLEANER ASSEMBLY

9 - 12 ENGINE - 4.0LWJ

ENGINE - 4.0L (Continued)

Page 1256 of 2199

INSTALLATION

CAUTION: When installing the engine into a vehicle

equipped with an automatic transmission, be care-

ful not to damage the trigger wheel on the engine

flywheel.

(1) Attach a lifting device to the engine and lower

the engine into the engine compartment. For easier

installation, it may be necessary to remove the

engine mount bracket as an aid in alignment of the

engine to the transmission.

(2) Align the transmission torque converter hous-

ing with the engine.

(3) Loosely install the converter housing lower

bolts and install the next higher bolt and nut on each

side.

(4) Tighten all 4 bolts finger tight.

(5) Install the engine mount brackets (if removed).

(6) Lower the engine and engine mount brackets

onto the engine compartment cushions. Install the

bolts and finger tighten the nuts.

(7) Remove the engine lifting device.

(8) Raise and support the vehicle.

(9) Install the remaining engine flywheel/converter

housing bolts. Tighten all bolts to 38 N´m (28 ft. lbs.)

torque.

(10) Install the converter-to-drive plate bolts.

(11) Ensure the installation reference marks are

aligned.

(12) Install the engine flywheel/converter housing

access cover.

(13) Install the exhaust pipe support and tighten

the screw.

(14) Install the engine bending brace (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCT SUPPORT -

INSTALLATION).

(15) Tighten the engine mount-to-bracket bolts.

(16) Connect the vehicle speed sensor wire connec-

tions and tighten the screws.

(17) Connect the exhaust pipe to the manifold.

(18) Install the engine starter motor (Refer to 8 -

ELECTRICAL/STARTING/STARTER MOTOR -

INSTALLATION).

(19) Connect the wires to the engine starter motor

solenoid.

(20) Lower the vehicle.

(21) Connect all the vacuum hoses and wire con-

nectors identified during engine removal.

(22) Remove protective caps from the power steer-

ing hoses.

(23) Connect the hoses to the fittings at the steer-

ing gear. Tighten the nut to 52 N´m (38 ft. lbs.)

torque.

(24) Fill the pump reservoir with fluid.(25) Inspect the fuel supply line o-ring(s) and

replace if necessary. Connect fuel supply line to injec-

tior rail and verify connection by pulling outward on

the line.

(26) Install the fuel line bracket to the intake

manifold.

(27) Connect the coil rail electrical connectors and

oil pressure switch connector.

(28) Connect the following electrical connectors:

²Power steering pressure switch

²Coolant temperature sensor

²Six (6) fuel injector connectors

²Intake air temperature sensor

²Throttle position sensor

²Map sensor

²Crankshaft position sensor

²Oxygen sensor

²Camshaft position sensor

²Generator connector and B+ terminal wire

(29) Connect all previously removed vacuum hoses.

(30) Connect the body ground strap.

(31) Install the throttle, transmission line pres-

sure, and speed control cables to their mounting

bracket and connect them to the throttle body.

(32) Connect the heater hoses at the engine ther-

mostat housing and water pump.

(33) Install the fan assembly (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - INSTALLATION).

(34) Place the fan shroud in position over the fan.

(35) Install the radiator (Refer to 7 - COOLING/

ENGINE/RADIATOR - INSTALLATION).

(36) Connect the service valves to the A/C com-

pressor ports, if equipped with A/C.

(37) Charge the air conditioner system (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

(38) Connect the radiator hoses and automatic

transmission fluid cooler pipes, if equipped.

(39) Install the fan shroud to the radiator or radi-

ator/condenser (if equipped with A/C).

(40) Install upper radiator support.

(41) Connect the upper radiator hose and tighten

the clamp.

(42) Connect the lower radiator hose and tighten

the clamp.

(43) Fill crankcase with engine oil. (Refer to

LUBRICATION & MAINTENANCE/FLUID CAPACI-

TIES - SPECIFICATIONS) for correct capacities.

(44) Fill the cooling system with reusable coolant

or new coolant (Refer to 7 - COOLING - STANDARD

PROCEDURE).

(45) Align the hood to the scribe marks. Install the

hood.

(46) Install the air cleaner assembly.

(47) Install the battery and connect the battery

cable.

WJENGINE - 4.0L 9 - 13

ENGINE - 4.0L (Continued)