Lubrication JEEP GRAND CHEROKEE 2002 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1245 of 2199

REMOVAL

REMOVAL - CAMSHAFT BEARINGS.......31

REMOVAL - CAMSHAFT................31

INSPECTION

INSPECTION - CAMSHAFT BEARINGS.....31

INSPECTION - CAMSHAFT..............31

INSTALLATION

INSTALLATION - CAMSHAFT BEARINGS . . . 32

INSTALLATION - CAMSHAFT............32

CONNECTING ROD BEARINGS

STANDARD PROCEDURE - FITTING

CONNECTING ROD BEARINGS..........33

CRANKSHAFT

DESCRIPTION.........................35

CRANKSHAFT MAIN BEARINGS

STANDARD PROCEDURE - FITTING

CRANKSHAFT MAIN BEARINGS..........36

REMOVAL.............................39

INSPECTION..........................40

INSTALLATION.........................40

CRANKSHAFT OIL SEAL - FRONT

REMOVAL.............................41

INSTALLATION.........................41

CRANKSHAFT OIL SEAL - REAR

REMOVAL.............................42

INSTALLATION.........................42

HYDRAULIC LIFTERS

DESCRIPTION.........................43

REMOVAL.............................43

CLEANING............................43

INSPECTION..........................43

INSTALLATION.........................43

PISTON & CONNECTING ROD

DESCRIPTION.........................44

STANDARD PROCEDURE - PISTON FITTING . 44

REMOVAL.............................45

INSTALLATION.........................46

PISTON RINGS

STANDARD PROCEDURE - PISTON RING

FITTING.............................47

VIBRATION DAMPER

REMOVAL.............................49

INSTALLATION.........................49STRUCTURAL SUPPORT

REMOVAL.............................49

INSTALLATION.........................50

LUBRICATION

DESCRIPTION.........................50

OPERATION...........................50

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE OIL

PRESSURE..........................51

DIAGNOSIS AND TESTING - ENGINE OIL

LEAK...............................51

OIL

STANDARD PROCEDURE - ENGINE OIL

SERVICE............................53

OIL FILTER

REMOVAL.............................53

INSTALLATION.........................54

OIL PAN

DESCRIPTION.........................54

REMOVAL.............................54

INSTALLATION.........................55

ENGINE OIL PRESSURE SENSOR

DESCRIPTION.........................56

OPERATION...........................56

OIL PUMP

REMOVAL.............................56

INSTALLATION.........................57

INTAKE MANIFOLD

DESCRIPTION.........................57

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKAGE..................57

REMOVAL.............................57

INSTALLATION.........................57

EXHAUST MANIFOLD

DESCRIPTION.........................58

REMOVAL.............................58

INSTALLATION.........................58

TIMING BELT / CHAIN COVER(S)

REMOVAL.............................58

INSTALLATION.........................58

TIMING BELT/CHAIN AND SPROCKETS

REMOVAL.............................60

INSTALLATION.........................60

ENGINE - 4.0L

DESCRIPTION

The 4.0 Liter (242 CID) six-cylinder engine is an

In-line, lightweight, overhead valve engine. This

engine is designed for unleaded fuel.

The engine cylinder head has dual quench-type

combustion chambers that create turbulence and fast

burning of the air/fuel mixture. This results in better

fuel economy.

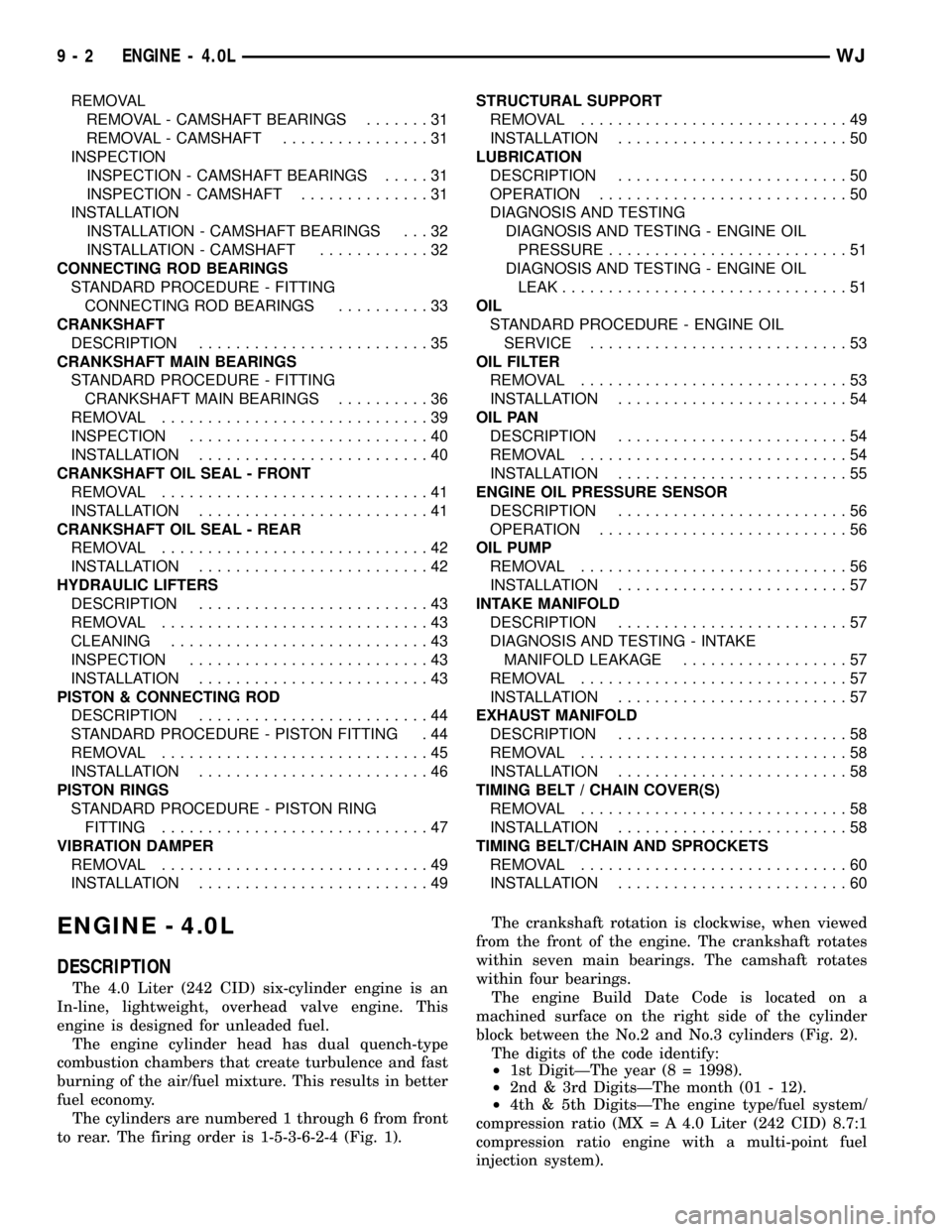

The cylinders are numbered 1 through 6 from front

to rear. The firing order is 1-5-3-6-2-4 (Fig. 1).The crankshaft rotation is clockwise, when viewed

from the front of the engine. The crankshaft rotates

within seven main bearings. The camshaft rotates

within four bearings.

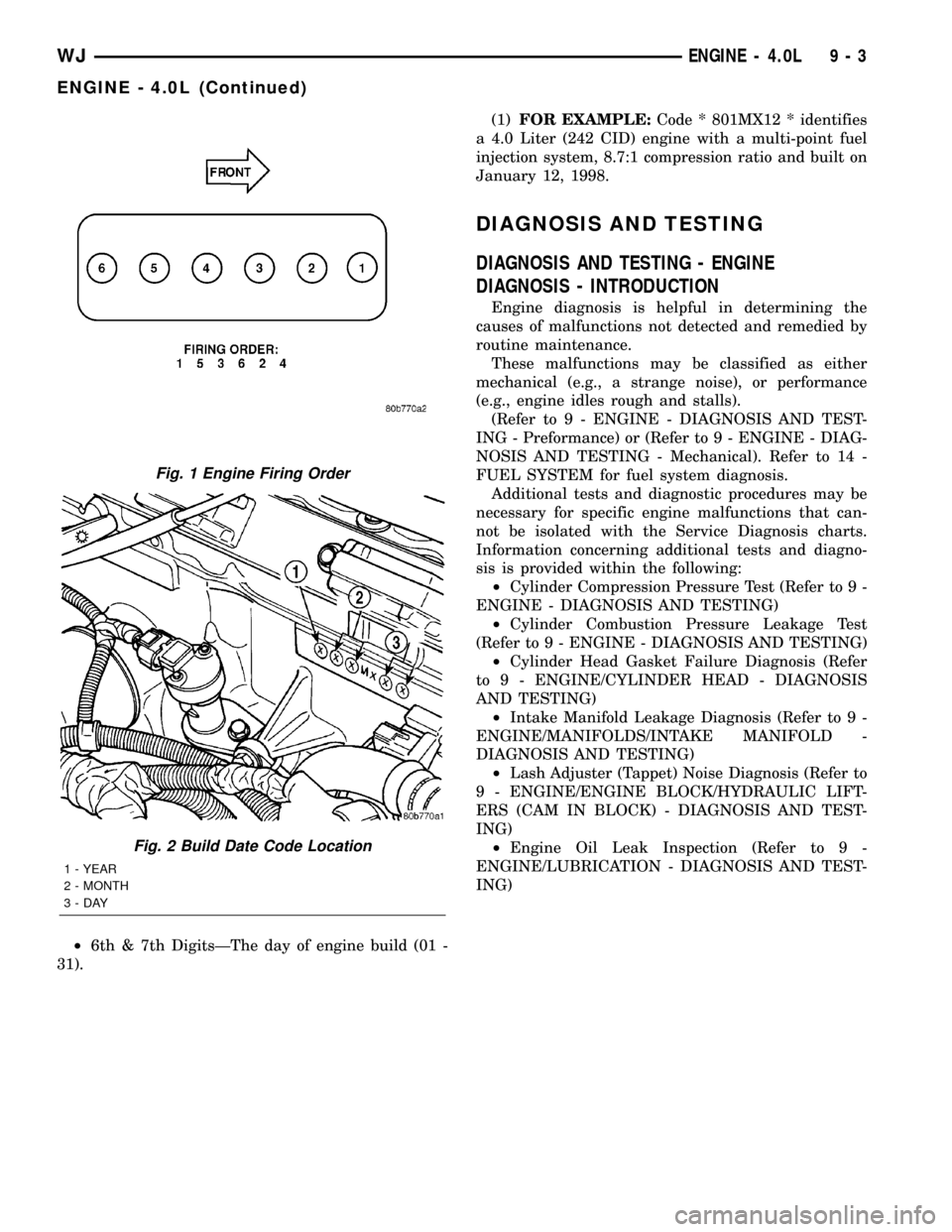

The engine Build Date Code is located on a

machined surface on the right side of the cylinder

block between the No.2 and No.3 cylinders (Fig. 2).

The digits of the code identify:

²1st DigitÐThe year (8 = 1998).

²2nd & 3rd DigitsÐThe month (01 - 12).

²4th & 5th DigitsÐThe engine type/fuel system/

compression ratio (MX = A 4.0 Liter (242 CID) 8.7:1

compression ratio engine with a multi-point fuel

injection system).

9 - 2 ENGINE - 4.0LWJ

Page 1246 of 2199

²6th & 7th DigitsÐThe day of engine build (01 -

31).(1)FOR EXAMPLE:Code * 801MX12 * identifies

a 4.0 Liter (242 CID) engine with a multi-point fuel

injection system, 8.7:1 compression ratio and built on

January 12, 1998.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

(Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING - Preformance) or (Refer to 9 - ENGINE - DIAG-

NOSIS AND TESTING - Mechanical). Refer to 14 -

FUEL SYSTEM for fuel system diagnosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test (Refer to 9 -

ENGINE - DIAGNOSIS AND TESTING)

²Cylinder Combustion Pressure Leakage Test

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING)

²Cylinder Head Gasket Failure Diagnosis (Refer

to 9 - ENGINE/CYLINDER HEAD - DIAGNOSIS

AND TESTING)

²Intake Manifold Leakage Diagnosis (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

DIAGNOSIS AND TESTING)

²Lash Adjuster (Tappet) Noise Diagnosis (Refer to

9 - ENGINE/ENGINE BLOCK/HYDRAULIC LIFT-

ERS (CAM IN BLOCK) - DIAGNOSIS AND TEST-

ING)

²Engine Oil Leak Inspection (Refer to 9 -

ENGINE/LUBRICATION - DIAGNOSIS AND TEST-

ING)

Fig. 1 Engine Firing Order

Fig. 2 Build Date Code Location

1 - YEAR

2 - MONTH

3-DAY

WJENGINE - 4.0L 9 - 3

ENGINE - 4.0L (Continued)

Page 1249 of 2199

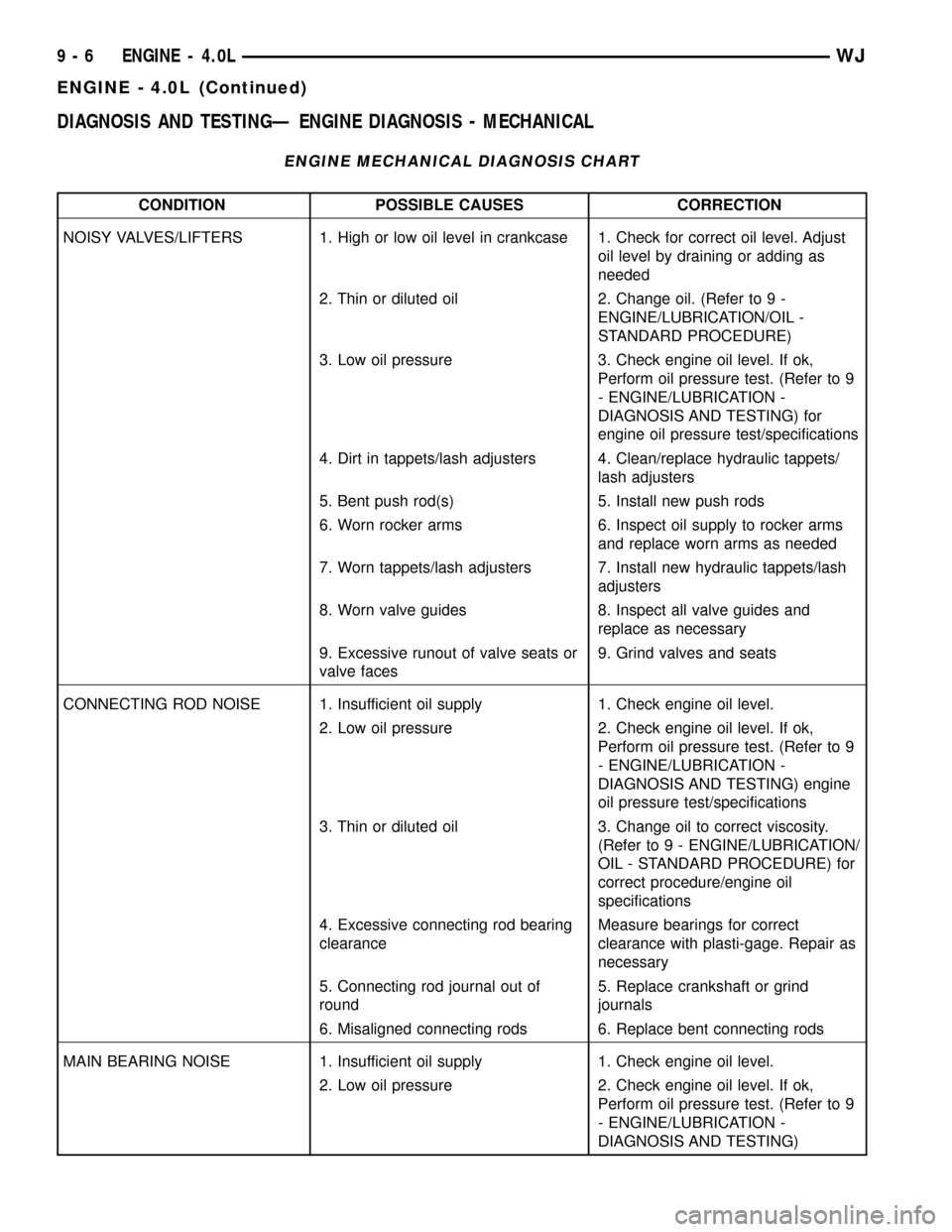

DIAGNOSIS AND TESTINGÐ ENGINE DIAGNOSIS - MECHANICAL

ENGINE MECHANICAL DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES/LIFTERS 1. High or low oil level in crankcase 1. Check for correct oil level. Adjust

oil level by draining or adding as

needed

2. Thin or diluted oil 2. Change oil. (Refer to 9 -

ENGINE/LUBRICATION/OIL -

STANDARD PROCEDURE)

3. Low oil pressure 3. Check engine oil level. If ok,

Perform oil pressure test. (Refer to 9

- ENGINE/LUBRICATION -

DIAGNOSIS AND TESTING) for

engine oil pressure test/specifications

4. Dirt in tappets/lash adjusters 4. Clean/replace hydraulic tappets/

lash adjusters

5. Bent push rod(s) 5. Install new push rods

6. Worn rocker arms 6. Inspect oil supply to rocker arms

and replace worn arms as needed

7. Worn tappets/lash adjusters 7. Install new hydraulic tappets/lash

adjusters

8. Worn valve guides 8. Inspect all valve guides and

replace as necessary

9. Excessive runout of valve seats or

valve faces9. Grind valves and seats

CONNECTING ROD NOISE 1. Insufficient oil supply 1. Check engine oil level.

2. Low oil pressure 2. Check engine oil level. If ok,

Perform oil pressure test. (Refer to 9

- ENGINE/LUBRICATION -

DIAGNOSIS AND TESTING) engine

oil pressure test/specifications

3. Thin or diluted oil 3. Change oil to correct viscosity.

(Refer to 9 - ENGINE/LUBRICATION/

OIL - STANDARD PROCEDURE) for

correct procedure/engine oil

specifications

4. Excessive connecting rod bearing

clearanceMeasure bearings for correct

clearance with plasti-gage. Repair as

necessary

5. Connecting rod journal out of

round5. Replace crankshaft or grind

journals

6. Misaligned connecting rods 6. Replace bent connecting rods

MAIN BEARING NOISE 1. Insufficient oil supply 1. Check engine oil level.

2. Low oil pressure 2. Check engine oil level. If ok,

Perform oil pressure test. (Refer to 9

- ENGINE/LUBRICATION -

DIAGNOSIS AND TESTING)

9 - 6 ENGINE - 4.0LWJ

ENGINE - 4.0L (Continued)

Page 1253 of 2199

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gaskets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐHYDROSTATIC LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).(2) Disconnect the negative cable(s) from the bat-

tery.

(3) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the spark plugs.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(7) Be sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N´m (30 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil. (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(15) Connect the negative cable(s) to the battery.

(16) Start the engine and check for any leaks.

STANDARD PROCEDURE - CYLINDER BORE

HONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1)

Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light scuff-

ing, scoring and scratches. Usually, a few strokes will

clean up a bore and maintain the required limits.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

9 - 10 ENGINE - 4.0LWJ

ENGINE - 4.0L (Continued)

Page 1256 of 2199

INSTALLATION

CAUTION: When installing the engine into a vehicle

equipped with an automatic transmission, be care-

ful not to damage the trigger wheel on the engine

flywheel.

(1) Attach a lifting device to the engine and lower

the engine into the engine compartment. For easier

installation, it may be necessary to remove the

engine mount bracket as an aid in alignment of the

engine to the transmission.

(2) Align the transmission torque converter hous-

ing with the engine.

(3) Loosely install the converter housing lower

bolts and install the next higher bolt and nut on each

side.

(4) Tighten all 4 bolts finger tight.

(5) Install the engine mount brackets (if removed).

(6) Lower the engine and engine mount brackets

onto the engine compartment cushions. Install the

bolts and finger tighten the nuts.

(7) Remove the engine lifting device.

(8) Raise and support the vehicle.

(9) Install the remaining engine flywheel/converter

housing bolts. Tighten all bolts to 38 N´m (28 ft. lbs.)

torque.

(10) Install the converter-to-drive plate bolts.

(11) Ensure the installation reference marks are

aligned.

(12) Install the engine flywheel/converter housing

access cover.

(13) Install the exhaust pipe support and tighten

the screw.

(14) Install the engine bending brace (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCT SUPPORT -

INSTALLATION).

(15) Tighten the engine mount-to-bracket bolts.

(16) Connect the vehicle speed sensor wire connec-

tions and tighten the screws.

(17) Connect the exhaust pipe to the manifold.

(18) Install the engine starter motor (Refer to 8 -

ELECTRICAL/STARTING/STARTER MOTOR -

INSTALLATION).

(19) Connect the wires to the engine starter motor

solenoid.

(20) Lower the vehicle.

(21) Connect all the vacuum hoses and wire con-

nectors identified during engine removal.

(22) Remove protective caps from the power steer-

ing hoses.

(23) Connect the hoses to the fittings at the steer-

ing gear. Tighten the nut to 52 N´m (38 ft. lbs.)

torque.

(24) Fill the pump reservoir with fluid.(25) Inspect the fuel supply line o-ring(s) and

replace if necessary. Connect fuel supply line to injec-

tior rail and verify connection by pulling outward on

the line.

(26) Install the fuel line bracket to the intake

manifold.

(27) Connect the coil rail electrical connectors and

oil pressure switch connector.

(28) Connect the following electrical connectors:

²Power steering pressure switch

²Coolant temperature sensor

²Six (6) fuel injector connectors

²Intake air temperature sensor

²Throttle position sensor

²Map sensor

²Crankshaft position sensor

²Oxygen sensor

²Camshaft position sensor

²Generator connector and B+ terminal wire

(29) Connect all previously removed vacuum hoses.

(30) Connect the body ground strap.

(31) Install the throttle, transmission line pres-

sure, and speed control cables to their mounting

bracket and connect them to the throttle body.

(32) Connect the heater hoses at the engine ther-

mostat housing and water pump.

(33) Install the fan assembly (Refer to 7 - COOL-

ING/ENGINE/RADIATOR FAN - INSTALLATION).

(34) Place the fan shroud in position over the fan.

(35) Install the radiator (Refer to 7 - COOLING/

ENGINE/RADIATOR - INSTALLATION).

(36) Connect the service valves to the A/C com-

pressor ports, if equipped with A/C.

(37) Charge the air conditioner system (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

STANDARD PROCEDURE).

(38) Connect the radiator hoses and automatic

transmission fluid cooler pipes, if equipped.

(39) Install the fan shroud to the radiator or radi-

ator/condenser (if equipped with A/C).

(40) Install upper radiator support.

(41) Connect the upper radiator hose and tighten

the clamp.

(42) Connect the lower radiator hose and tighten

the clamp.

(43) Fill crankcase with engine oil. (Refer to

LUBRICATION & MAINTENANCE/FLUID CAPACI-

TIES - SPECIFICATIONS) for correct capacities.

(44) Fill the cooling system with reusable coolant

or new coolant (Refer to 7 - COOLING - STANDARD

PROCEDURE).

(45) Align the hood to the scribe marks. Install the

hood.

(46) Install the air cleaner assembly.

(47) Install the battery and connect the battery

cable.

WJENGINE - 4.0L 9 - 13

ENGINE - 4.0L (Continued)

Page 1257 of 2199

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR FAN. DO

NOT WEAR LOOSE CLOTHING.

(48) Start the engine, inspect for leaks and correct

the fluid levels, as necessary.

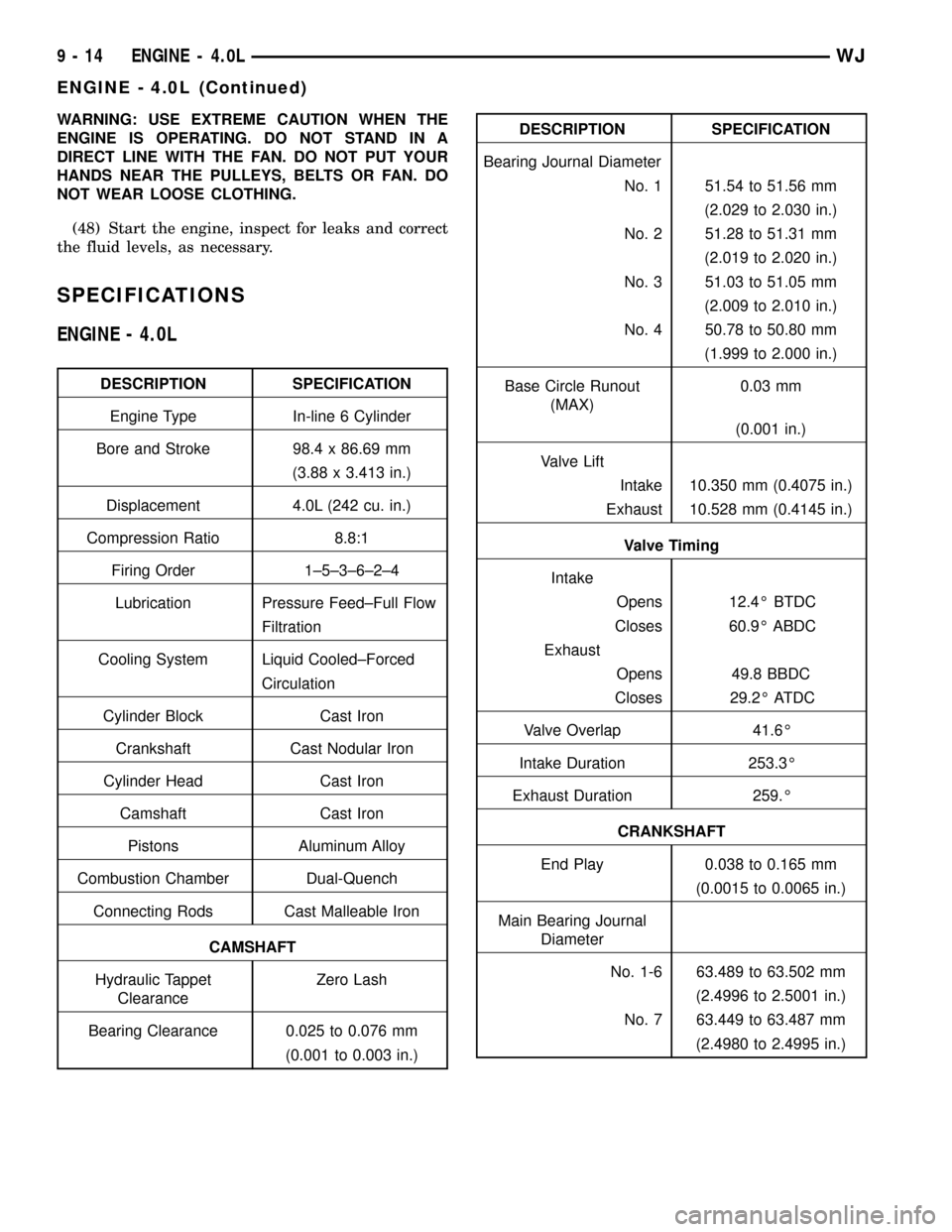

SPECIFICATIONS

ENGINE - 4.0L

DESCRIPTION SPECIFICATION

Engine Type In-line 6 Cylinder

Bore and Stroke 98.4 x 86.69 mm

(3.88 x 3.413 in.)

Displacement 4.0L (242 cu. in.)

Compression Ratio 8.8:1

Firing Order 1±5±3±6±2±4

Lubrication Pressure Feed±Full Flow

Filtration

Cooling System Liquid Cooled±Forced

Circulation

Cylinder Block Cast Iron

Crankshaft Cast Nodular Iron

Cylinder Head Cast Iron

Camshaft Cast Iron

Pistons Aluminum Alloy

Combustion Chamber Dual-Quench

Connecting Rods Cast Malleable Iron

CAMSHAFT

Hydraulic Tappet

ClearanceZero Lash

Bearing Clearance 0.025 to 0.076 mm

(0.001 to 0.003 in.)

DESCRIPTION SPECIFICATION

Bearing Journal Diameter

No. 1 51.54 to 51.56 mm

(2.029 to 2.030 in.)

No. 2 51.28 to 51.31 mm

(2.019 to 2.020 in.)

No. 3 51.03 to 51.05 mm

(2.009 to 2.010 in.)

No. 4 50.78 to 50.80 mm

(1.999 to 2.000 in.)

Base Circle Runout

(MAX)0.03 mm

(0.001 in.)

Valve Lift

Intake 10.350 mm (0.4075 in.)

Exhaust 10.528 mm (0.4145 in.)

Valve Timing

Intake

Opens 12.4É BTDC

Closes 60.9É ABDC

Exhaust

Opens 49.8 BBDC

Closes 29.2É ATDC

Valve Overlap 41.6É

Intake Duration 253.3É

Exhaust Duration 259.É

CRANKSHAFT

End Play 0.038 to 0.165 mm

(0.0015 to 0.0065 in.)

Main Bearing Journal

Diameter

No. 1-6 63.489 to 63.502 mm

(2.4996 to 2.5001 in.)

No. 7 63.449 to 63.487 mm

(2.4980 to 2.4995 in.)

9 - 14 ENGINE - 4.0LWJ

ENGINE - 4.0L (Continued)

Page 1270 of 2199

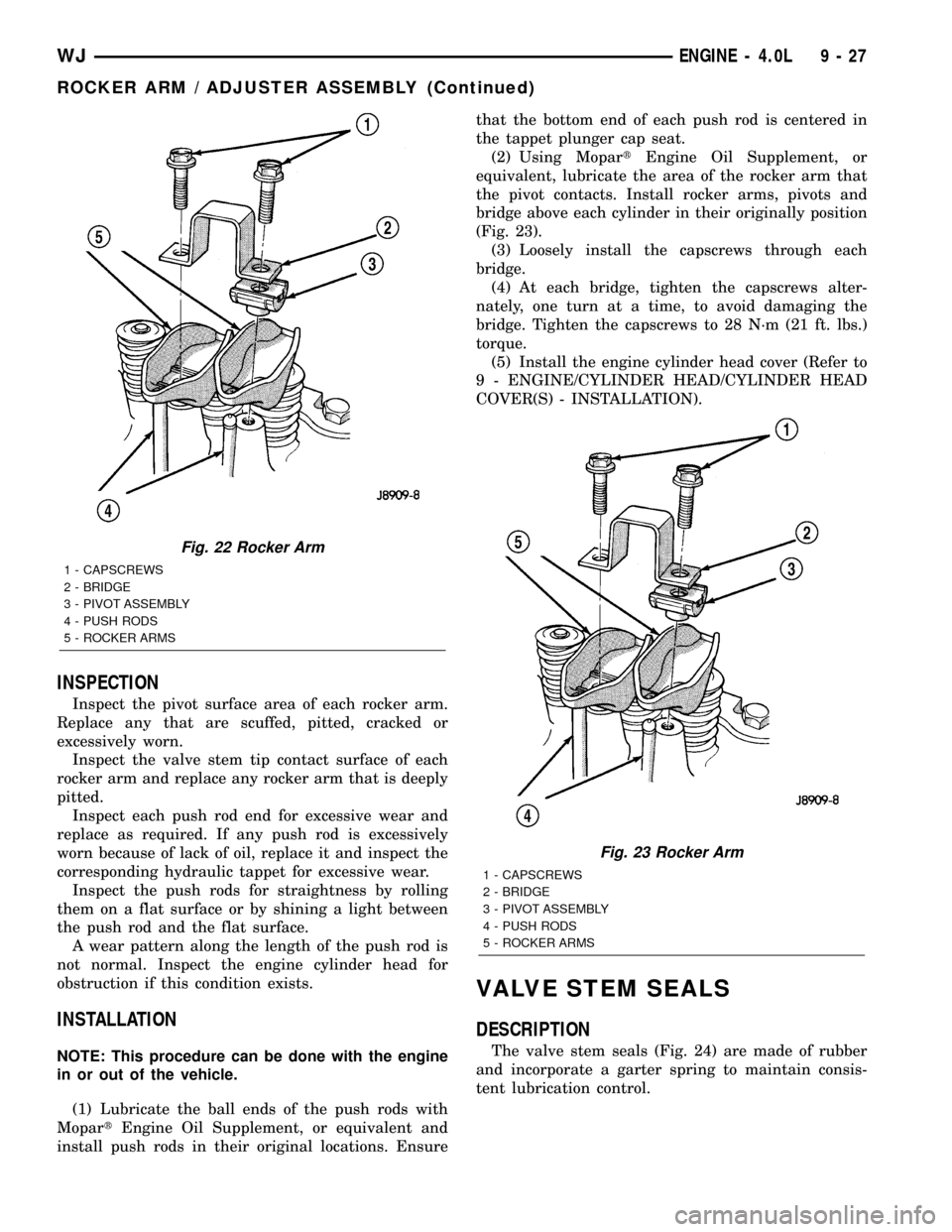

INSPECTION

Inspect the pivot surface area of each rocker arm.

Replace any that are scuffed, pitted, cracked or

excessively worn.

Inspect the valve stem tip contact surface of each

rocker arm and replace any rocker arm that is deeply

pitted.

Inspect each push rod end for excessive wear and

replace as required. If any push rod is excessively

worn because of lack of oil, replace it and inspect the

corresponding hydraulic tappet for excessive wear.

Inspect the push rods for straightness by rolling

them on a flat surface or by shining a light between

the push rod and the flat surface.

A wear pattern along the length of the push rod is

not normal. Inspect the engine cylinder head for

obstruction if this condition exists.

INSTALLATION

NOTE: This procedure can be done with the engine

in or out of the vehicle.

(1) Lubricate the ball ends of the push rods with

MopartEngine Oil Supplement, or equivalent and

install push rods in their original locations. Ensurethat the bottom end of each push rod is centered in

the tappet plunger cap seat.

(2) Using MopartEngine Oil Supplement, or

equivalent, lubricate the area of the rocker arm that

the pivot contacts. Install rocker arms, pivots and

bridge above each cylinder in their originally position

(Fig. 23).

(3) Loosely install the capscrews through each

bridge.

(4) At each bridge, tighten the capscrews alter-

nately, one turn at a time, to avoid damaging the

bridge. Tighten the capscrews to 28 N´m (21 ft. lbs.)

torque.

(5) Install the engine cylinder head cover (Refer to

9 - ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - INSTALLATION).

VALVE STEM SEALS

DESCRIPTION

The valve stem seals (Fig. 24) are made of rubber

and incorporate a garter spring to maintain consis-

tent lubrication control.

Fig. 22 Rocker Arm

1 - CAPSCREWS

2 - BRIDGE

3 - PIVOT ASSEMBLY

4 - PUSH RODS

5 - ROCKER ARMS

Fig. 23 Rocker Arm

1 - CAPSCREWS

2 - BRIDGE

3 - PIVOT ASSEMBLY

4 - PUSH RODS

5 - ROCKER ARMS

WJENGINE - 4.0L 9 - 27

ROCKER ARM / ADJUSTER ASSEMBLY (Continued)

Page 1277 of 2199

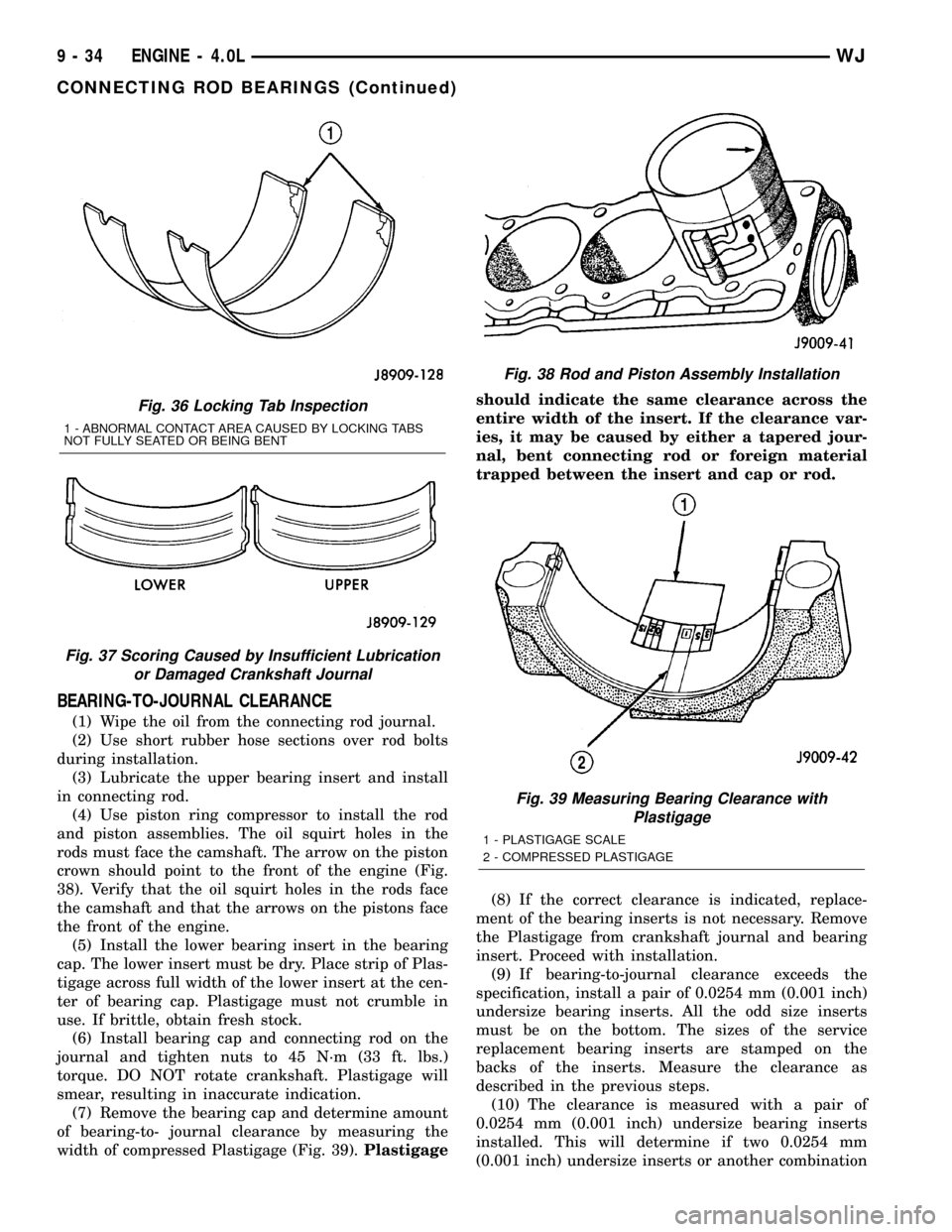

BEARING-TO-JOURNAL CLEARANCE

(1) Wipe the oil from the connecting rod journal.

(2) Use short rubber hose sections over rod bolts

during installation.

(3) Lubricate the upper bearing insert and install

in connecting rod.

(4) Use piston ring compressor to install the rod

and piston assemblies. The oil squirt holes in the

rods must face the camshaft. The arrow on the piston

crown should point to the front of the engine (Fig.

38). Verify that the oil squirt holes in the rods face

the camshaft and that the arrows on the pistons face

the front of the engine.

(5) Install the lower bearing insert in the bearing

cap. The lower insert must be dry. Place strip of Plas-

tigage across full width of the lower insert at the cen-

ter of bearing cap. Plastigage must not crumble in

use. If brittle, obtain fresh stock.

(6) Install bearing cap and connecting rod on the

journal and tighten nuts to 45 N´m (33 ft. lbs.)

torque. DO NOT rotate crankshaft. Plastigage will

smear, resulting in inaccurate indication.

(7) Remove the bearing cap and determine amount

of bearing-to- journal clearance by measuring the

width of compressed Plastigage (Fig. 39).Plastigageshould indicate the same clearance across the

entire width of the insert. If the clearance var-

ies, it may be caused by either a tapered jour-

nal, bent connecting rod or foreign material

trapped between the insert and cap or rod.

(8) If the correct clearance is indicated, replace-

ment of the bearing inserts is not necessary. Remove

the Plastigage from crankshaft journal and bearing

insert. Proceed with installation.

(9) If bearing-to-journal clearance exceeds the

specification, install a pair of 0.0254 mm (0.001 inch)

undersize bearing inserts. All the odd size inserts

must be on the bottom. The sizes of the service

replacement bearing inserts are stamped on the

backs of the inserts. Measure the clearance as

described in the previous steps.

(10) The clearance is measured with a pair of

0.0254 mm (0.001 inch) undersize bearing inserts

installed. This will determine if two 0.0254 mm

(0.001 inch) undersize inserts or another combination

Fig. 36 Locking Tab Inspection

1 - ABNORMAL CONTACT AREA CAUSED BY LOCKING TABS

NOT FULLY SEATED OR BEING BENT

Fig. 37 Scoring Caused by Insufficient Lubrication

or Damaged Crankshaft Journal

Fig. 38 Rod and Piston Assembly Installation

Fig. 39 Measuring Bearing Clearance with

Plastigage

1 - PLASTIGAGE SCALE

2 - COMPRESSED PLASTIGAGE

9 - 34 ENGINE - 4.0LWJ

CONNECTING ROD BEARINGS (Continued)

Page 1278 of 2199

is needed to provide the correct clearance. Refer to

CONNECTING ROD BEARING FITTING CHART .

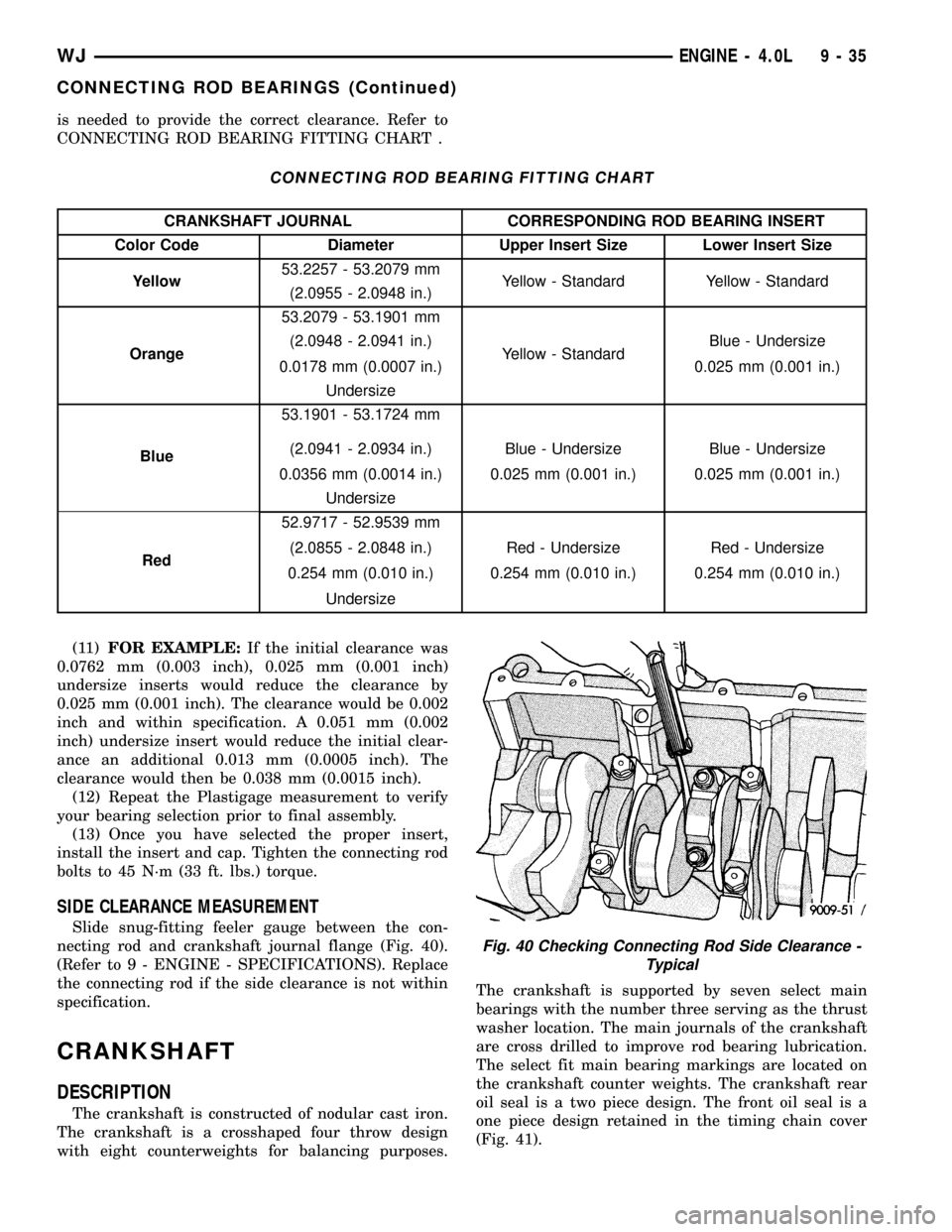

CONNECTING ROD BEARING FITTING CHART

CRANKSHAFT JOURNAL CORRESPONDING ROD BEARING INSERT

Color Code Diameter Upper Insert Size Lower Insert Size

Yellow53.2257 - 53.2079 mm

Yellow - Standard Yellow - Standard

(2.0955 - 2.0948 in.)

Orange53.2079 - 53.1901 mm

Yellow - StandardBlue - Undersize (2.0948 - 2.0941 in.)

0.0178 mm (0.0007 in.) 0.025 mm (0.001 in.)

Undersize

Blue53.1901 - 53.1724 mm

Blue - Undersize Blue - Undersize (2.0941 - 2.0934 in.)

0.0356 mm (0.0014 in.) 0.025 mm (0.001 in.) 0.025 mm (0.001 in.)

Undersize

Red52.9717 - 52.9539 mm

Red - Undersize Red - Undersize (2.0855 - 2.0848 in.)

0.254 mm (0.010 in.) 0.254 mm (0.010 in.) 0.254 mm (0.010 in.)

Undersize

(11)FOR EXAMPLE:If the initial clearance was

0.0762 mm (0.003 inch), 0.025 mm (0.001 inch)

undersize inserts would reduce the clearance by

0.025 mm (0.001 inch). The clearance would be 0.002

inch and within specification. A 0.051 mm (0.002

inch) undersize insert would reduce the initial clear-

ance an additional 0.013 mm (0.0005 inch). The

clearance would then be 0.038 mm (0.0015 inch).

(12) Repeat the Plastigage measurement to verify

your bearing selection prior to final assembly.

(13) Once you have selected the proper insert,

install the insert and cap. Tighten the connecting rod

bolts to 45 N´m (33 ft. lbs.) torque.

SIDE CLEARANCE MEASUREMENT

Slide snug-fitting feeler gauge between the con-

necting rod and crankshaft journal flange (Fig. 40).

(Refer to 9 - ENGINE - SPECIFICATIONS). Replace

the connecting rod if the side clearance is not within

specification.

CRANKSHAFT

DESCRIPTION

The crankshaft is constructed of nodular cast iron.

The crankshaft is a crosshaped four throw design

with eight counterweights for balancing purposes.The crankshaft is supported by seven select main

bearings with the number three serving as the thrust

washer location. The main journals of the crankshaft

are cross drilled to improve rod bearing lubrication.

The select fit main bearing markings are located on

the crankshaft counter weights. The crankshaft rear

oil seal is a two piece design. The front oil seal is a

one piece design retained in the timing chain cover

(Fig. 41).

Fig. 40 Checking Connecting Rod Side Clearance -

Typical

WJENGINE - 4.0L 9 - 35

CONNECTING ROD BEARINGS (Continued)

Page 1282 of 2199

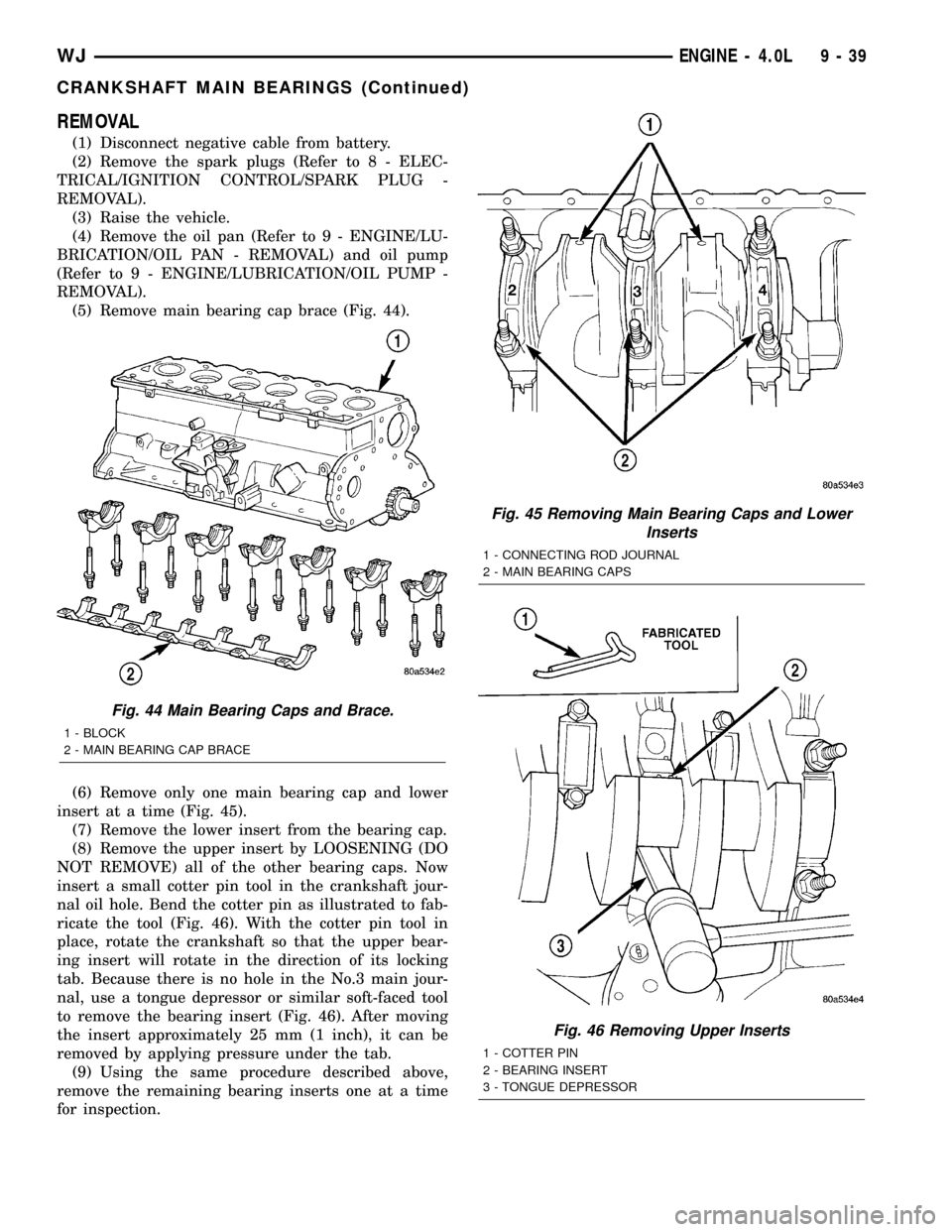

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the spark plugs (Refer to 8 - ELEC-

TRICAL/IGNITION CONTROL/SPARK PLUG -

REMOVAL).

(3) Raise the vehicle.

(4) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL) and oil pump

(Refer to 9 - ENGINE/LUBRICATION/OIL PUMP -

REMOVAL).

(5) Remove main bearing cap brace (Fig. 44).

(6) Remove only one main bearing cap and lower

insert at a time (Fig. 45).

(7) Remove the lower insert from the bearing cap.

(8) Remove the upper insert by LOOSENING (DO

NOT REMOVE) all of the other bearing caps. Now

insert a small cotter pin tool in the crankshaft jour-

nal oil hole. Bend the cotter pin as illustrated to fab-

ricate the tool (Fig. 46). With the cotter pin tool in

place, rotate the crankshaft so that the upper bear-

ing insert will rotate in the direction of its locking

tab. Because there is no hole in the No.3 main jour-

nal, use a tongue depressor or similar soft-faced tool

to remove the bearing insert (Fig. 46). After moving

the insert approximately 25 mm (1 inch), it can be

removed by applying pressure under the tab.

(9) Using the same procedure described above,

remove the remaining bearing inserts one at a time

for inspection.

Fig. 44 Main Bearing Caps and Brace.

1 - BLOCK

2 - MAIN BEARING CAP BRACE

Fig. 45 Removing Main Bearing Caps and Lower

Inserts

1 - CONNECTING ROD JOURNAL

2 - MAIN BEARING CAPS

Fig. 46 Removing Upper Inserts

1 - COTTER PIN

2 - BEARING INSERT

3 - TONGUE DEPRESSOR

WJENGINE - 4.0L 9 - 39

CRANKSHAFT MAIN BEARINGS (Continued)