height JEEP GRAND CHEROKEE 2002 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 571 of 2199

INSTALLATION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the rear center seat belt and retractor

unit onto the seat back panel.

(2) Install and tighten the screw that secures the

retractor to the rear seat back panel (Fig. 35).

Tighten the screw to 43 N´m (32 ft. lbs.).

(3) Position the seat back latch cable plunger

against the retractor latch lever, then engage the

cable fitting into the cable support on the retractor,

which is a light snap fit (Fig. 34).

(4) Route the rear seat belt lower anchor and belt

web guide through the top of the seat back panel.

(5) Reinstall the trim onto the right rear seat

back. (Refer to 23 - BODY/SEATS/SEAT BACK

COVER - REAR - INSTALLATION).

(6) Install and tighten the two screws that secure

the belt web guide to the top of the right rear seat

back panel. Tighten the screws to 2 N´m (20 in. lbs.).

(7) Reinstall the right rear seat back panel into

the vehicle. (Refer to 23 - BODY/SEATS/SEAT BACK

- REAR - INSTALLATION).

(8) Restore the cargo area carpet to the base of the

seat back panel and unfold the right rear seat back

to its upright position.

(9) Position the rear center seat belt lower anchor

to the right rear seat belt buckle unit bracket on the

rear floor panel (Fig. 33).

(10) Install and tighten the screw that secures the

rear center seat belt lower anchor to the right rear

seat belt buckle unit bracket on the rear floor panel.

Tighten the screw to 43 N´m (32 ft. lbs.).

(11) Fold and latch the right rear seat cushion in

its normal seating position.

REAR OUTBOARD SEAT BELT

& RETRACTOR

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Disengage the rear seat cushion latch by pull-

ing upward on the release strap.

(2) Fold the rear seat cushion forward against the

back of the front bucket seat.

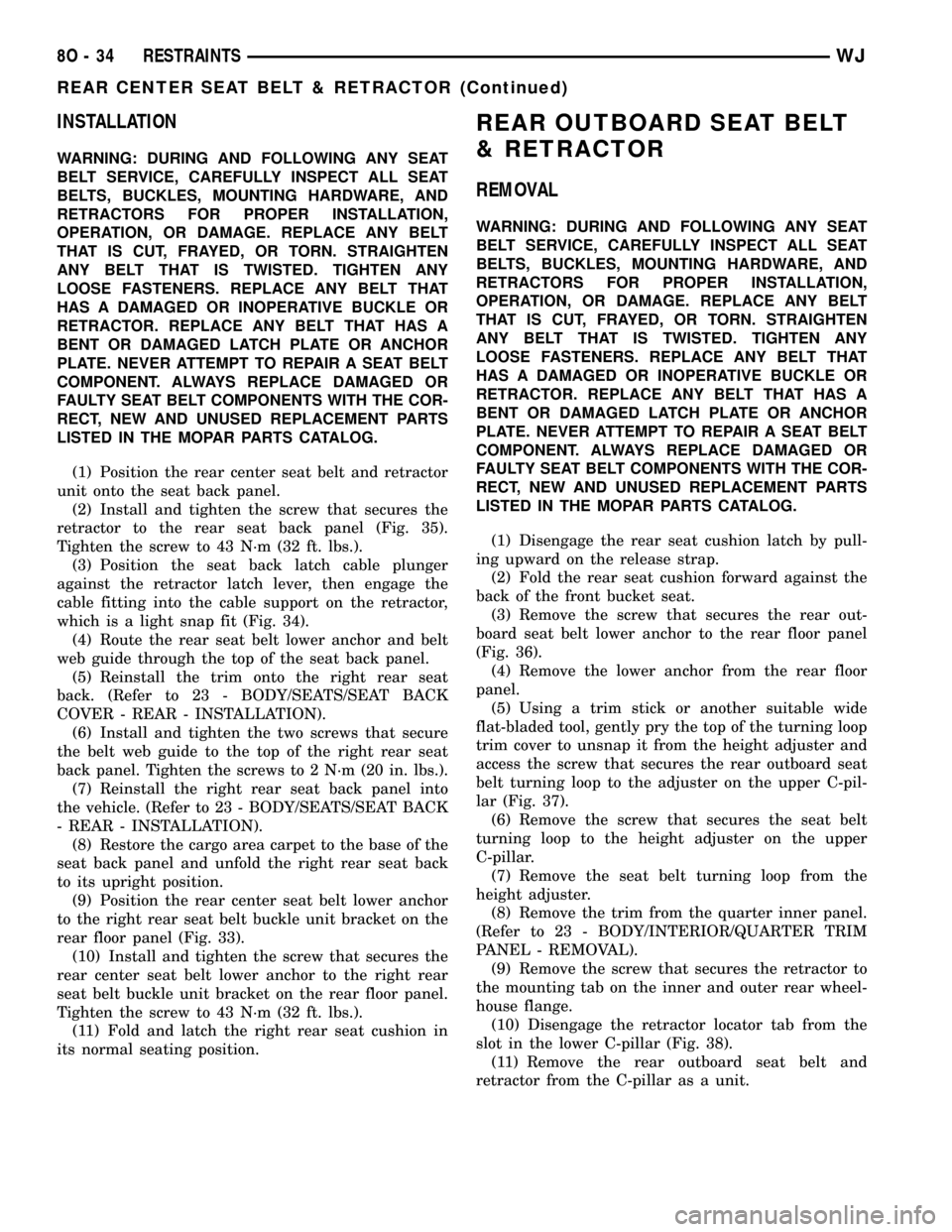

(3) Remove the screw that secures the rear out-

board seat belt lower anchor to the rear floor panel

(Fig. 36).

(4) Remove the lower anchor from the rear floor

panel.

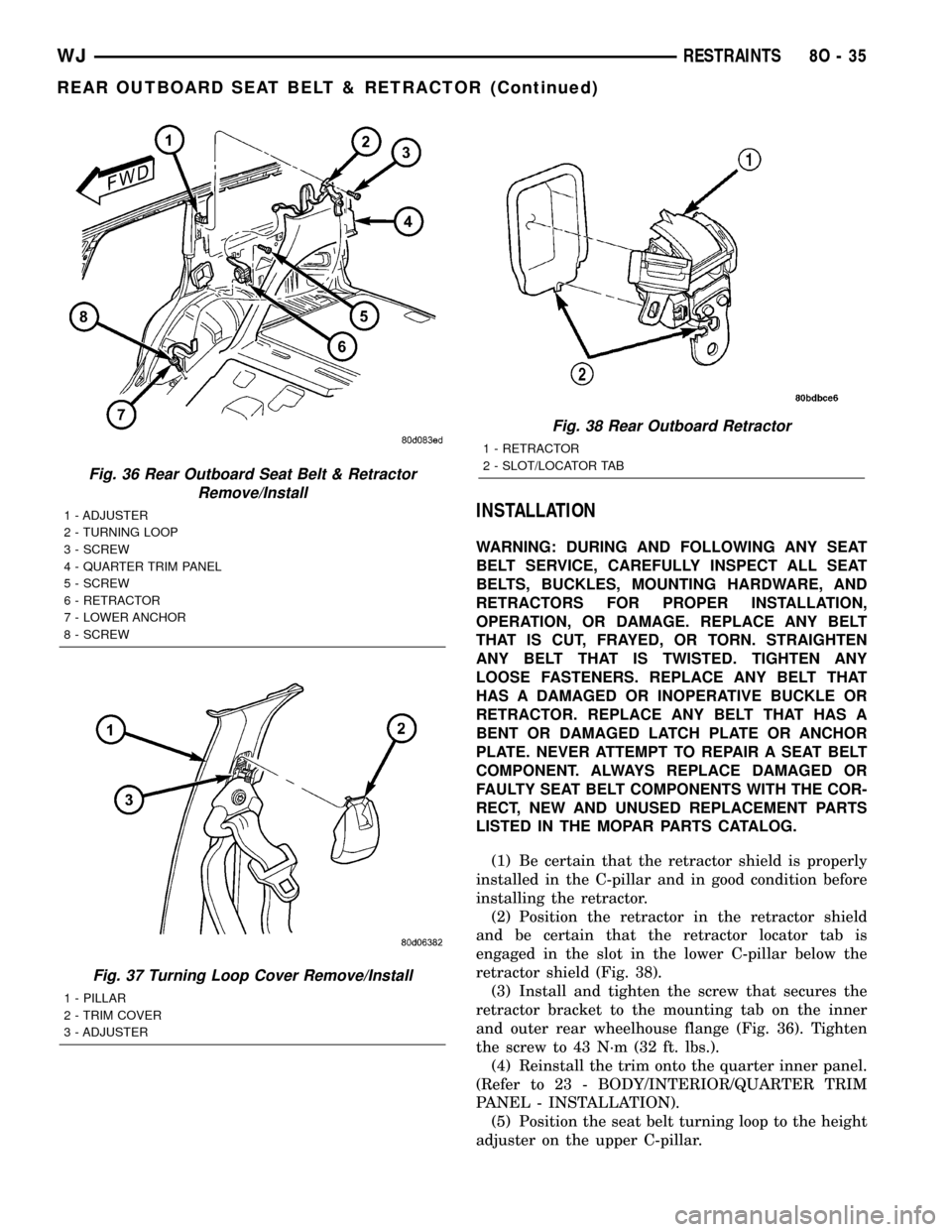

(5) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the top of the turning loop

trim cover to unsnap it from the height adjuster and

access the screw that secures the rear outboard seat

belt turning loop to the adjuster on the upper C-pil-

lar (Fig. 37).

(6) Remove the screw that secures the seat belt

turning loop to the height adjuster on the upper

C-pillar.

(7) Remove the seat belt turning loop from the

height adjuster.

(8) Remove the trim from the quarter inner panel.

(Refer to 23 - BODY/INTERIOR/QUARTER TRIM

PANEL - REMOVAL).

(9) Remove the screw that secures the retractor to

the mounting tab on the inner and outer rear wheel-

house flange.

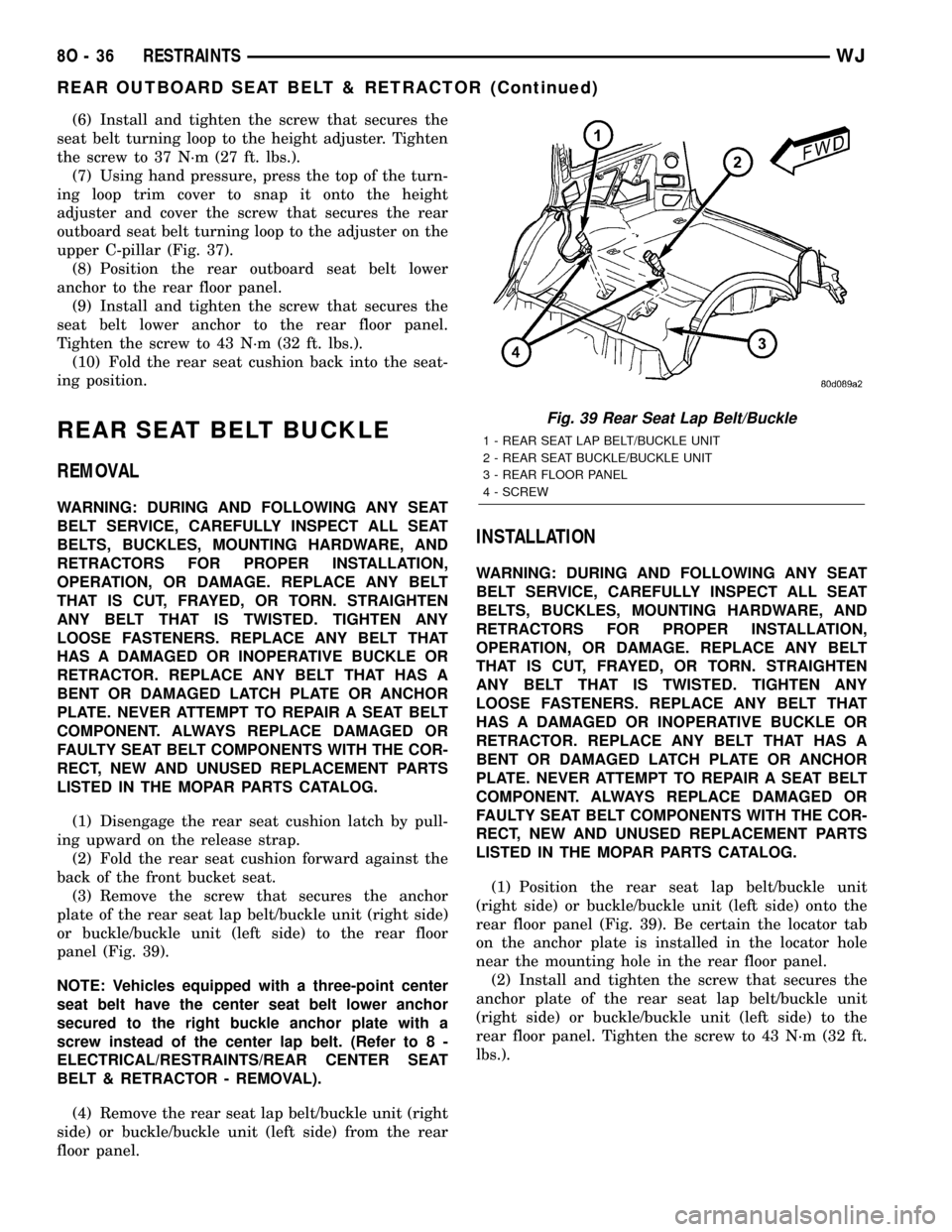

(10) Disengage the retractor locator tab from the

slot in the lower C-pillar (Fig. 38).

(11) Remove the rear outboard seat belt and

retractor from the C-pillar as a unit.

8O - 34 RESTRAINTSWJ

REAR CENTER SEAT BELT & RETRACTOR (Continued)

Page 572 of 2199

INSTALLATION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Be certain that the retractor shield is properly

installed in the C-pillar and in good condition before

installing the retractor.

(2) Position the retractor in the retractor shield

and be certain that the retractor locator tab is

engaged in the slot in the lower C-pillar below the

retractor shield (Fig. 38).

(3) Install and tighten the screw that secures the

retractor bracket to the mounting tab on the inner

and outer rear wheelhouse flange (Fig. 36). Tighten

the screw to 43 N´m (32 ft. lbs.).

(4) Reinstall the trim onto the quarter inner panel.

(Refer to 23 - BODY/INTERIOR/QUARTER TRIM

PANEL - INSTALLATION).

(5) Position the seat belt turning loop to the height

adjuster on the upper C-pillar.

Fig. 36 Rear Outboard Seat Belt & Retractor

Remove/Install

1 - ADJUSTER

2 - TURNING LOOP

3 - SCREW

4 - QUARTER TRIM PANEL

5 - SCREW

6 - RETRACTOR

7 - LOWER ANCHOR

8 - SCREW

Fig. 37 Turning Loop Cover Remove/Install

1 - PILLAR

2 - TRIM COVER

3 - ADJUSTER

Fig. 38 Rear Outboard Retractor

1 - RETRACTOR

2 - SLOT/LOCATOR TAB

WJRESTRAINTS 8O - 35

REAR OUTBOARD SEAT BELT & RETRACTOR (Continued)

Page 573 of 2199

(6) Install and tighten the screw that secures the

seat belt turning loop to the height adjuster. Tighten

the screw to 37 N´m (27 ft. lbs.).

(7) Using hand pressure, press the top of the turn-

ing loop trim cover to snap it onto the height

adjuster and cover the screw that secures the rear

outboard seat belt turning loop to the adjuster on the

upper C-pillar (Fig. 37).

(8) Position the rear outboard seat belt lower

anchor to the rear floor panel.

(9) Install and tighten the screw that secures the

seat belt lower anchor to the rear floor panel.

Tighten the screw to 43 N´m (32 ft. lbs.).

(10) Fold the rear seat cushion back into the seat-

ing position.

REAR SEAT BELT BUCKLE

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Disengage the rear seat cushion latch by pull-

ing upward on the release strap.

(2) Fold the rear seat cushion forward against the

back of the front bucket seat.

(3) Remove the screw that secures the anchor

plate of the rear seat lap belt/buckle unit (right side)

or buckle/buckle unit (left side) to the rear floor

panel (Fig. 39).

NOTE: Vehicles equipped with a three-point center

seat belt have the center seat belt lower anchor

secured to the right buckle anchor plate with a

screw instead of the center lap belt. (Refer to 8 -

ELECTRICAL/RESTRAINTS/REAR CENTER SEAT

BELT & RETRACTOR - REMOVAL).

(4) Remove the rear seat lap belt/buckle unit (right

side) or buckle/buckle unit (left side) from the rear

floor panel.

INSTALLATION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the rear seat lap belt/buckle unit

(right side) or buckle/buckle unit (left side) onto the

rear floor panel (Fig. 39). Be certain the locator tab

on the anchor plate is installed in the locator hole

near the mounting hole in the rear floor panel.

(2) Install and tighten the screw that secures the

anchor plate of the rear seat lap belt/buckle unit

(right side) or buckle/buckle unit (left side) to the

rear floor panel. Tighten the screw to 43 N´m (32 ft.

lbs.).

Fig. 39 Rear Seat Lap Belt/Buckle

1 - REAR SEAT LAP BELT/BUCKLE UNIT

2 - REAR SEAT BUCKLE/BUCKLE UNIT

3 - REAR FLOOR PANEL

4 - SCREW

8O - 36 RESTRAINTSWJ

REAR OUTBOARD SEAT BELT & RETRACTOR (Continued)

Page 575 of 2199

SEAT BELT TURNING LOOP

ADJUSTER

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Remove the turning loop from the front or rear

seat belt turning loop adjuster. (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/FRONT SEAT BELT &

RETRACTOR - REMOVAL) or (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/REAR OUTBOARD SEAT

BELT & RETRACTOR - REMOVAL).

(2) Remove the trim from the upper B-pillar (front

seat belt adjuster) or upper C-pillar (rear seat belt

adjuster). (Refer to 23 - BODY/INTERIOR/B-PILLAR

UPPER TRIM - REMOVAL) or (Refer to 23 - BODY/

INTERIOR/C-PILLAR TRIM - REMOVAL).

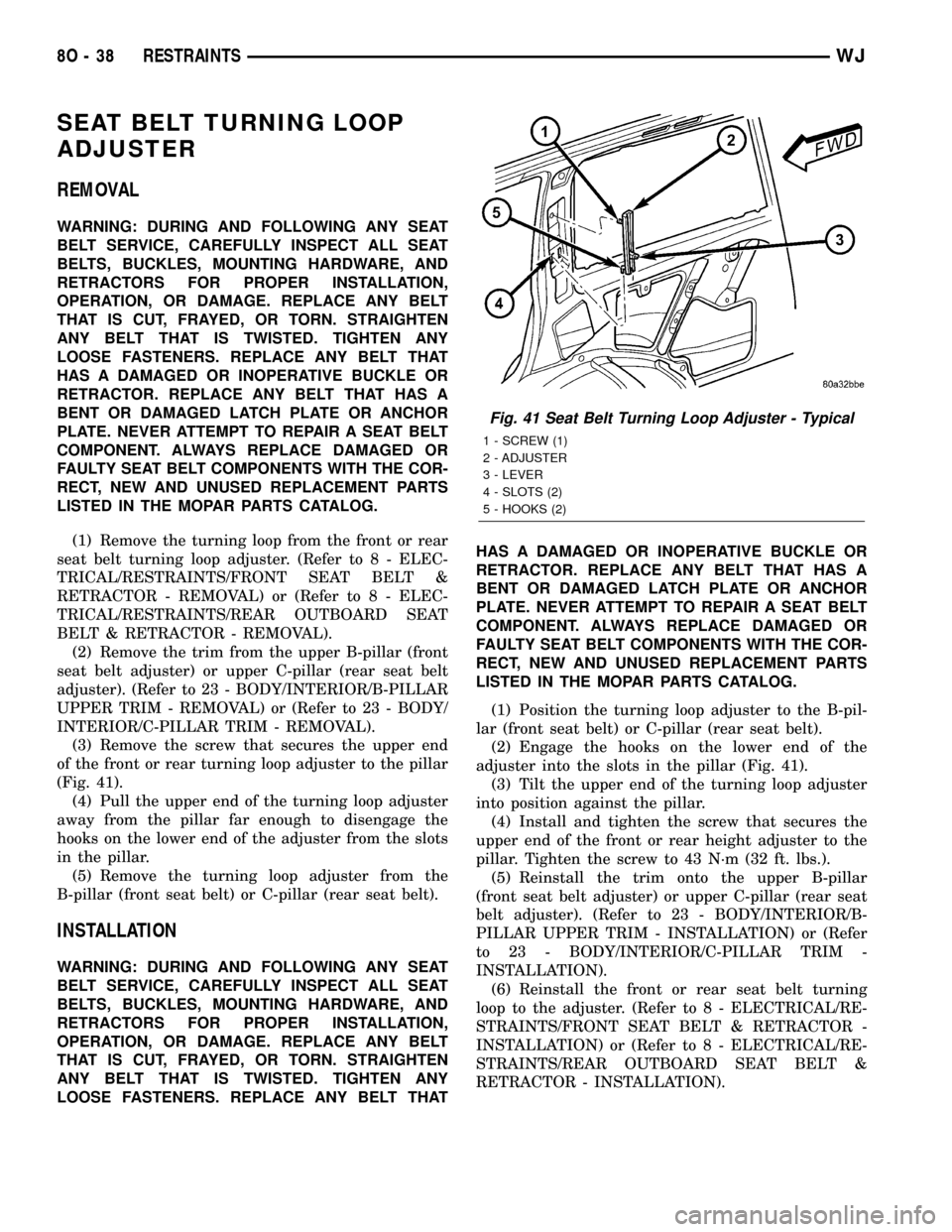

(3) Remove the screw that secures the upper end

of the front or rear turning loop adjuster to the pillar

(Fig. 41).

(4) Pull the upper end of the turning loop adjuster

away from the pillar far enough to disengage the

hooks on the lower end of the adjuster from the slots

in the pillar.

(5) Remove the turning loop adjuster from the

B-pillar (front seat belt) or C-pillar (rear seat belt).

INSTALLATION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THATHAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the turning loop adjuster to the B-pil-

lar (front seat belt) or C-pillar (rear seat belt).

(2) Engage the hooks on the lower end of the

adjuster into the slots in the pillar (Fig. 41).

(3) Tilt the upper end of the turning loop adjuster

into position against the pillar.

(4) Install and tighten the screw that secures the

upper end of the front or rear height adjuster to the

pillar. Tighten the screw to 43 N´m (32 ft. lbs.).

(5) Reinstall the trim onto the upper B-pillar

(front seat belt adjuster) or upper C-pillar (rear seat

belt adjuster). (Refer to 23 - BODY/INTERIOR/B-

PILLAR UPPER TRIM - INSTALLATION) or (Refer

to 23 - BODY/INTERIOR/C-PILLAR TRIM -

INSTALLATION).

(6) Reinstall the front or rear seat belt turning

loop to the adjuster. (Refer to 8 - ELECTRICAL/RE-

STRAINTS/FRONT SEAT BELT & RETRACTOR -

INSTALLATION) or (Refer to 8 - ELECTRICAL/RE-

STRAINTS/REAR OUTBOARD SEAT BELT &

RETRACTOR - INSTALLATION).

Fig. 41 Seat Belt Turning Loop Adjuster - Typical

1 - SCREW (1)

2 - ADJUSTER

3 - LEVER

4 - SLOTS (2)

5 - HOOKS (2)

8O - 38 RESTRAINTSWJ

Page 1258 of 2199

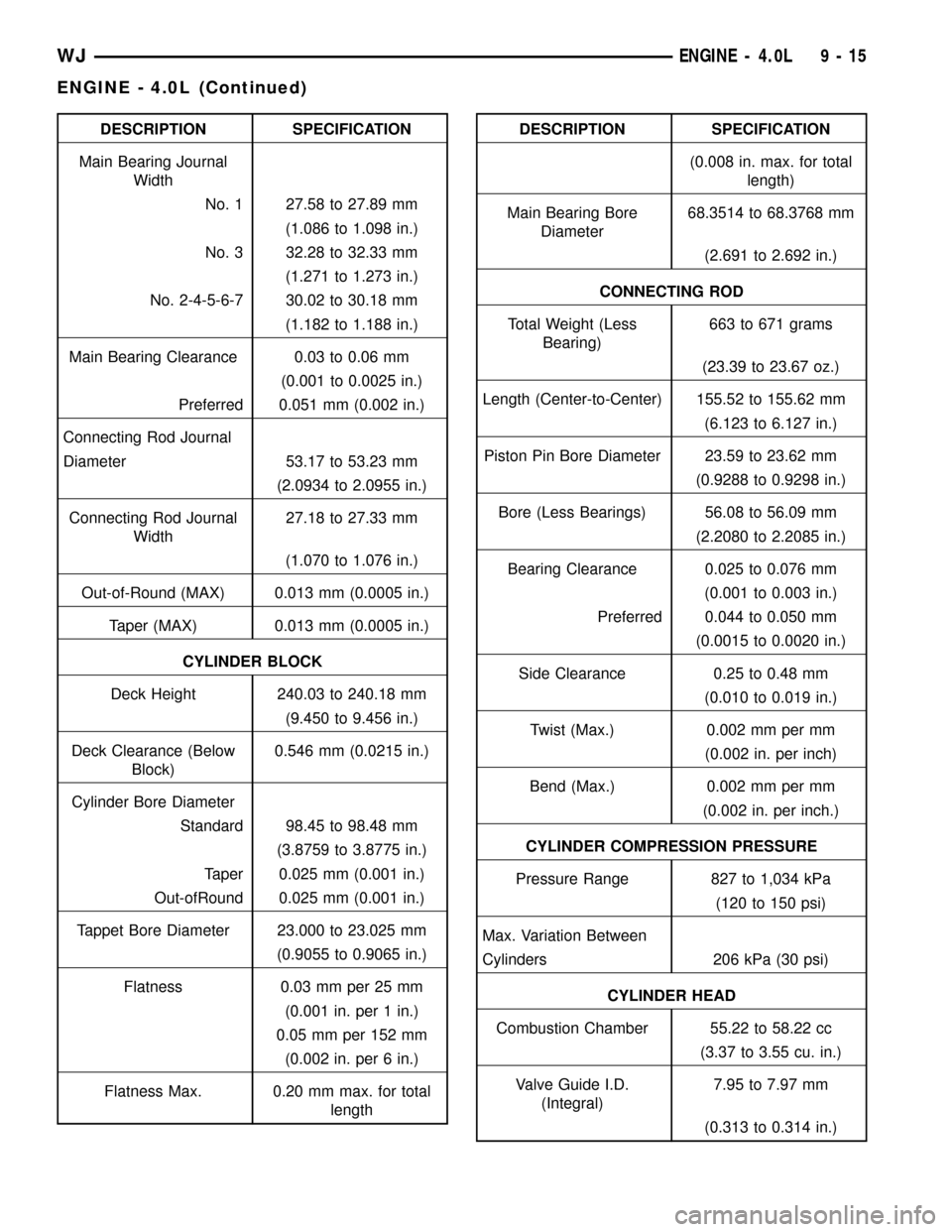

DESCRIPTION SPECIFICATION

Main Bearing Journal

Width

No. 1 27.58 to 27.89 mm

(1.086 to 1.098 in.)

No. 3 32.28 to 32.33 mm

(1.271 to 1.273 in.)

No. 2-4-5-6-7 30.02 to 30.18 mm

(1.182 to 1.188 in.)

Main Bearing Clearance 0.03 to 0.06 mm

(0.001 to 0.0025 in.)

Preferred 0.051 mm (0.002 in.)

Connecting Rod Journal

Diameter 53.17 to 53.23 mm

(2.0934 to 2.0955 in.)

Connecting Rod Journal

Width27.18 to 27.33 mm

(1.070 to 1.076 in.)

Out-of-Round (MAX) 0.013 mm (0.0005 in.)

Taper (MAX) 0.013 mm (0.0005 in.)

CYLINDER BLOCK

Deck Height 240.03 to 240.18 mm

(9.450 to 9.456 in.)

Deck Clearance (Below

Block)0.546 mm (0.0215 in.)

Cylinder Bore Diameter

Standard 98.45 to 98.48 mm

(3.8759 to 3.8775 in.)

Taper 0.025 mm (0.001 in.)

Out-ofRound 0.025 mm (0.001 in.)

Tappet Bore Diameter 23.000 to 23.025 mm

(0.9055 to 0.9065 in.)

Flatness 0.03 mm per 25 mm

(0.001 in. per 1 in.)

0.05 mm per 152 mm

(0.002 in. per 6 in.)

Flatness Max. 0.20 mm max. for total

lengthDESCRIPTION SPECIFICATION

(0.008 in. max. for total

length)

Main Bearing Bore

Diameter68.3514 to 68.3768 mm

(2.691 to 2.692 in.)

CONNECTING ROD

Total Weight (Less

Bearing)663 to 671 grams

(23.39 to 23.67 oz.)

Length (Center-to-Center) 155.52 to 155.62 mm

(6.123 to 6.127 in.)

Piston Pin Bore Diameter 23.59 to 23.62 mm

(0.9288 to 0.9298 in.)

Bore (Less Bearings) 56.08 to 56.09 mm

(2.2080 to 2.2085 in.)

Bearing Clearance 0.025 to 0.076 mm

(0.001 to 0.003 in.)

Preferred 0.044 to 0.050 mm

(0.0015 to 0.0020 in.)

Side Clearance 0.25 to 0.48 mm

(0.010 to 0.019 in.)

Twist (Max.) 0.002 mm per mm

(0.002 in. per inch)

Bend (Max.) 0.002 mm per mm

(0.002 in. per inch.)

CYLINDER COMPRESSION PRESSURE

Pressure Range 827 to 1,034 kPa

(120 to 150 psi)

Max. Variation Between

Cylinders 206 kPa (30 psi)

CYLINDER HEAD

Combustion Chamber 55.22 to 58.22 cc

(3.37 to 3.55 cu. in.)

Valve Guide I.D.

(Integral)7.95 to 7.97 mm

(0.313 to 0.314 in.)

WJENGINE - 4.0L 9 - 15

ENGINE - 4.0L (Continued)

Page 1259 of 2199

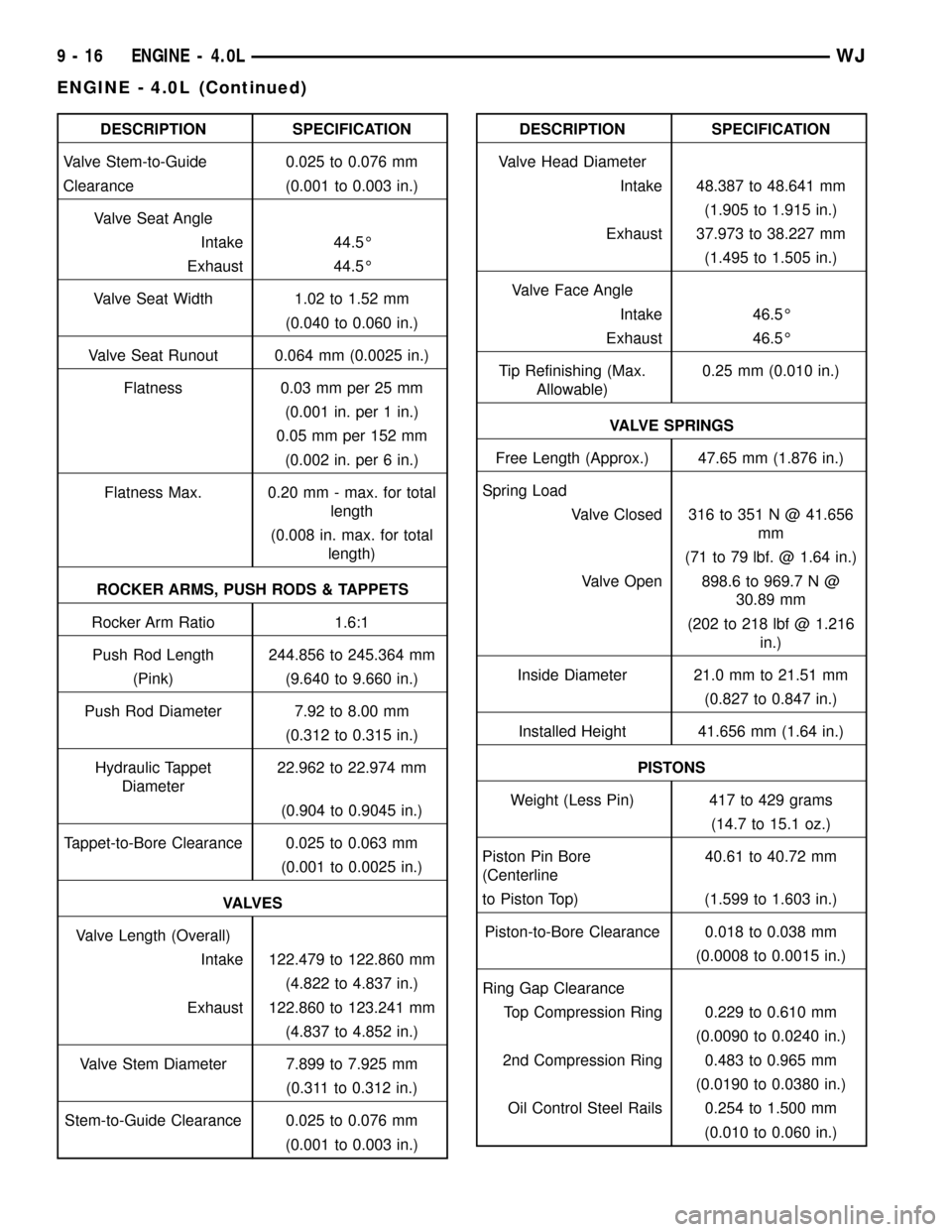

DESCRIPTION SPECIFICATION

Valve Stem-to-Guide 0.025 to 0.076 mm

Clearance (0.001 to 0.003 in.)

Valve Seat Angle

Intake 44.5É

Exhaust 44.5É

Valve Seat Width 1.02 to 1.52 mm

(0.040 to 0.060 in.)

Valve Seat Runout 0.064 mm (0.0025 in.)

Flatness 0.03 mm per 25 mm

(0.001 in. per 1 in.)

0.05 mm per 152 mm

(0.002 in. per 6 in.)

Flatness Max. 0.20 mm - max. for total

length

(0.008 in. max. for total

length)

ROCKER ARMS, PUSH RODS & TAPPETS

Rocker Arm Ratio 1.6:1

Push Rod Length 244.856 to 245.364 mm

(Pink) (9.640 to 9.660 in.)

Push Rod Diameter 7.92 to 8.00 mm

(0.312 to 0.315 in.)

Hydraulic Tappet

Diameter22.962 to 22.974 mm

(0.904 to 0.9045 in.)

Tappet-to-Bore Clearance 0.025 to 0.063 mm

(0.001 to 0.0025 in.)

VA LV E S

Valve Length (Overall)

Intake 122.479 to 122.860 mm

(4.822 to 4.837 in.)

Exhaust 122.860 to 123.241 mm

(4.837 to 4.852 in.)

Valve Stem Diameter 7.899 to 7.925 mm

(0.311 to 0.312 in.)

Stem-to-Guide Clearance 0.025 to 0.076 mm

(0.001 to 0.003 in.)DESCRIPTION SPECIFICATION

Valve Head Diameter

Intake 48.387 to 48.641 mm

(1.905 to 1.915 in.)

Exhaust 37.973 to 38.227 mm

(1.495 to 1.505 in.)

Valve Face Angle

Intake 46.5É

Exhaust 46.5É

Tip Refinishing (Max.

Allowable)0.25 mm (0.010 in.)

VALVE SPRINGS

Free Length (Approx.) 47.65 mm (1.876 in.)

Spring Load

Valve Closed 316 to 351 N @ 41.656

mm

(71 to 79 lbf. @ 1.64 in.)

Valve Open 898.6 to 969.7 N @

30.89 mm

(202 to 218 lbf @ 1.216

in.)

Inside Diameter 21.0 mm to 21.51 mm

(0.827 to 0.847 in.)

Installed Height 41.656 mm (1.64 in.)

PISTONS

Weight (Less Pin) 417 to 429 grams

(14.7 to 15.1 oz.)

Piston Pin Bore

(Centerline40.61 to 40.72 mm

to Piston Top) (1.599 to 1.603 in.)

Piston-to-Bore Clearance 0.018 to 0.038 mm

(0.0008 to 0.0015 in.)

Ring Gap Clearance

Top Compression Ring 0.229 to 0.610 mm

(0.0090 to 0.0240 in.)

2nd Compression Ring 0.483 to 0.965 mm

(0.0190 to 0.0380 in.)

Oil Control Steel Rails 0.254 to 1.500 mm

(0.010 to 0.060 in.)

9 - 16 ENGINE - 4.0LWJ

ENGINE - 4.0L (Continued)

Page 1260 of 2199

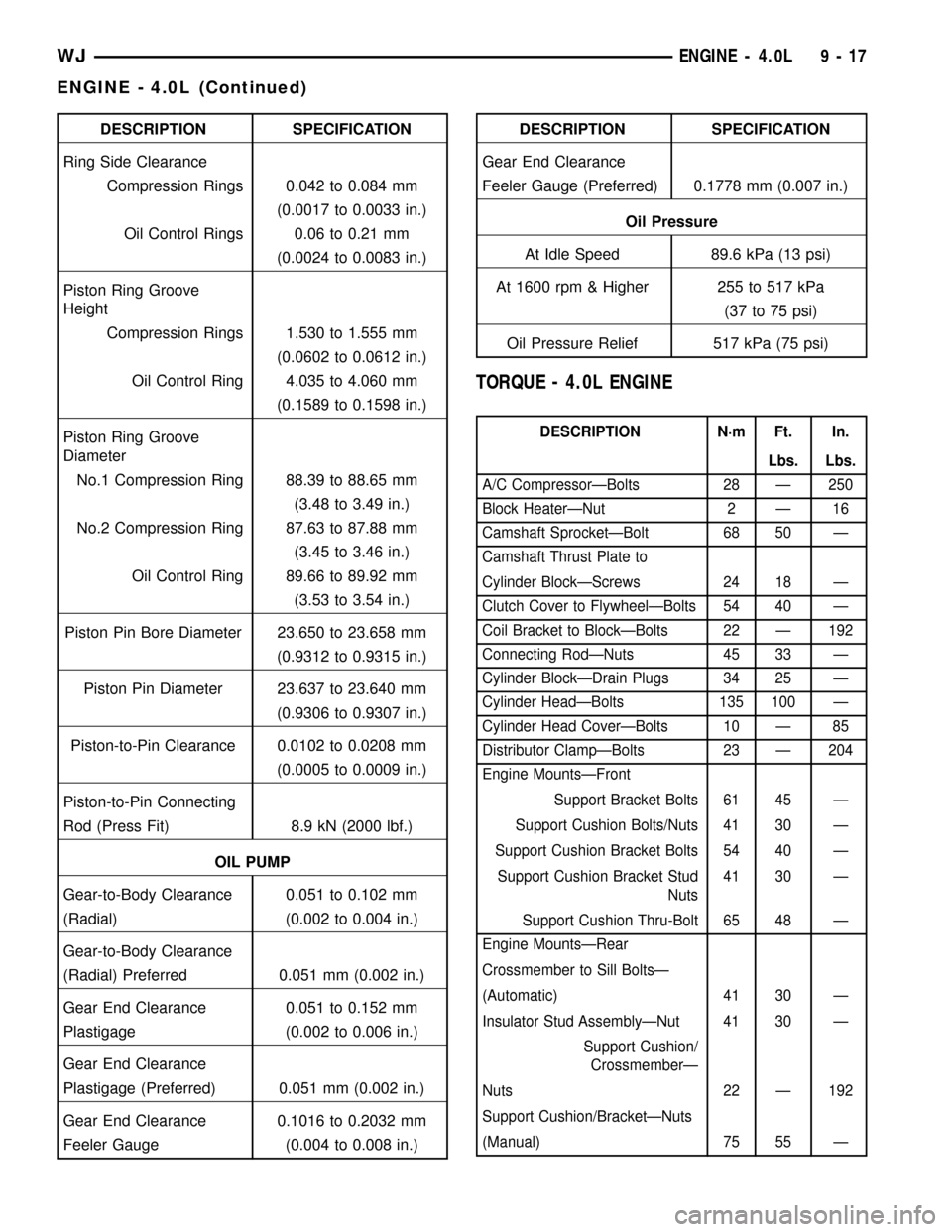

DESCRIPTION SPECIFICATION

Ring Side Clearance

Compression Rings 0.042 to 0.084 mm

(0.0017 to 0.0033 in.)

Oil Control Rings 0.06 to 0.21 mm

(0.0024 to 0.0083 in.)

Piston Ring Groove

Height

Compression Rings 1.530 to 1.555 mm

(0.0602 to 0.0612 in.)

Oil Control Ring 4.035 to 4.060 mm

(0.1589 to 0.1598 in.)

Piston Ring Groove

Diameter

No.1 Compression Ring 88.39 to 88.65 mm

(3.48 to 3.49 in.)

No.2 Compression Ring 87.63 to 87.88 mm

(3.45 to 3.46 in.)

Oil Control Ring 89.66 to 89.92 mm

(3.53 to 3.54 in.)

Piston Pin Bore Diameter 23.650 to 23.658 mm

(0.9312 to 0.9315 in.)

Piston Pin Diameter 23.637 to 23.640 mm

(0.9306 to 0.9307 in.)

Piston-to-Pin Clearance 0.0102 to 0.0208 mm

(0.0005 to 0.0009 in.)

Piston-to-Pin Connecting

Rod (Press Fit) 8.9 kN (2000 lbf.)

OIL PUMP

Gear-to-Body Clearance 0.051 to 0.102 mm

(Radial) (0.002 to 0.004 in.)

Gear-to-Body Clearance

(Radial) Preferred 0.051 mm (0.002 in.)

Gear End Clearance 0.051 to 0.152 mm

Plastigage (0.002 to 0.006 in.)

Gear End Clearance

Plastigage (Preferred) 0.051 mm (0.002 in.)

Gear End Clearance 0.1016 to 0.2032 mm

Feeler Gauge (0.004 to 0.008 in.)DESCRIPTION SPECIFICATION

Gear End Clearance

Feeler Gauge (Preferred) 0.1778 mm (0.007 in.)

Oil Pressure

At Idle Speed 89.6 kPa (13 psi)

At 1600 rpm & Higher 255 to 517 kPa

(37 to 75 psi)

Oil Pressure Relief 517 kPa (75 psi)

TORQUE - 4.0L ENGINE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

A/C CompressorÐBolts 28 Ð 250

Block HeaterÐNut 2 Ð 16

Camshaft SprocketÐBolt 68 50 Ð

Camshaft Thrust Plate to

Cylinder BlockÐScrews 24 18 Ð

Clutch Cover to FlywheelÐBolts 54 40 Ð

Coil Bracket to BlockÐBolts 22 Ð 192

Connecting RodÐNuts 45 33 Ð

Cylinder BlockÐDrain Plugs 34 25 Ð

Cylinder HeadÐBolts 135 100 Ð

Cylinder Head CoverÐBolts 10 Ð 85

Distributor ClampÐBolts 23 Ð 204

Engine MountsÐFront

Support Bracket Bolts 61 45 Ð

Support Cushion Bolts/Nuts 41 30 Ð

Support Cushion Bracket Bolts 54 40 Ð

Support Cushion Bracket Stud

Nuts41 30 Ð

Support Cushion Thru-Bolt 65 48 Ð

Engine MountsÐRear

Crossmember to Sill BoltsÐ

(Automatic) 41 30 Ð

Insulator Stud AssemblyÐNut 41 30 Ð

Support Cushion/

CrossmemberÐ

Nuts 22 Ð 192

Support Cushion/BracketÐNuts

(Manual) 75 55 Ð

WJENGINE - 4.0L 9 - 17

ENGINE - 4.0L (Continued)

Page 1266 of 2199

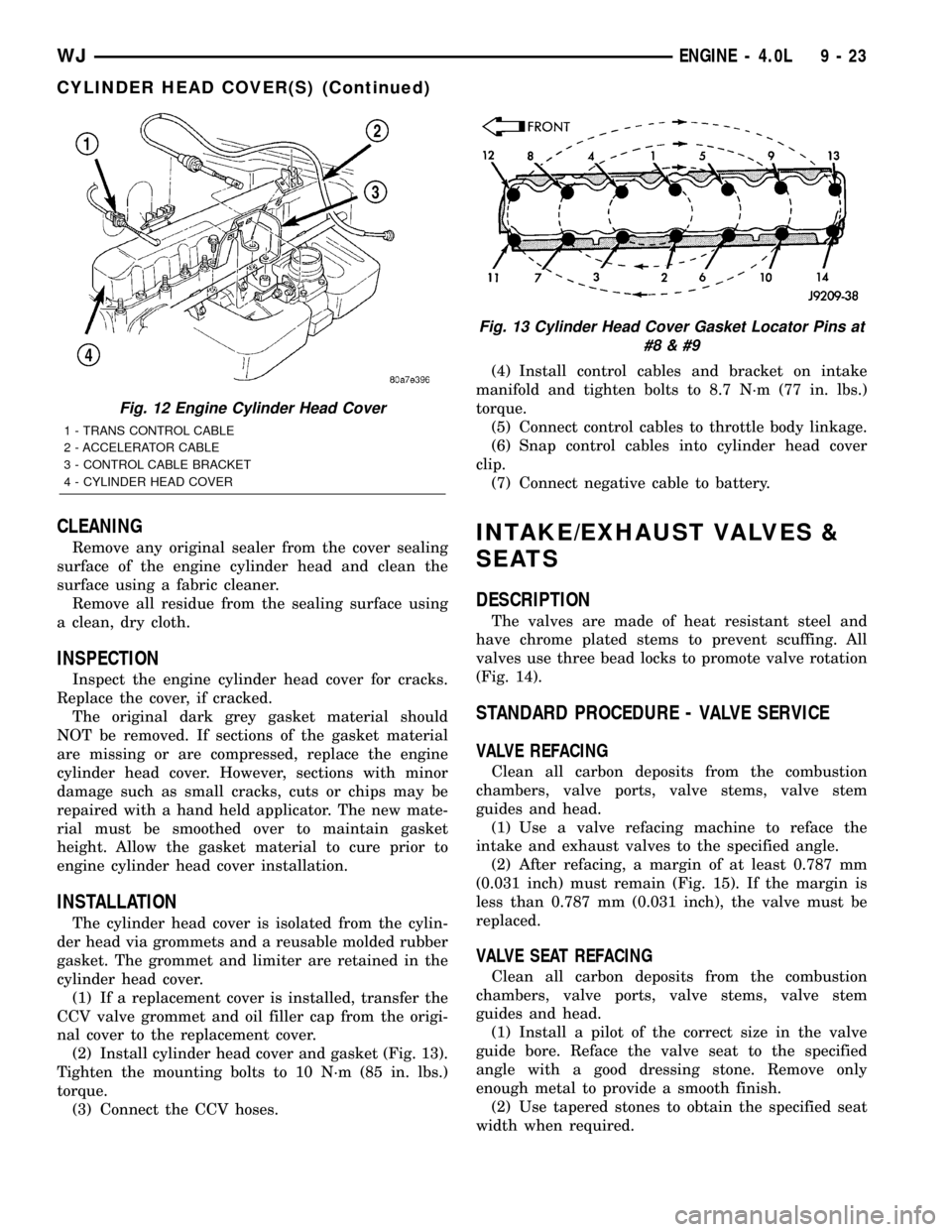

CLEANING

Remove any original sealer from the cover sealing

surface of the engine cylinder head and clean the

surface using a fabric cleaner.

Remove all residue from the sealing surface using

a clean, dry cloth.

INSPECTION

Inspect the engine cylinder head cover for cracks.

Replace the cover, if cracked.

The original dark grey gasket material should

NOT be removed. If sections of the gasket material

are missing or are compressed, replace the engine

cylinder head cover. However, sections with minor

damage such as small cracks, cuts or chips may be

repaired with a hand held applicator. The new mate-

rial must be smoothed over to maintain gasket

height. Allow the gasket material to cure prior to

engine cylinder head cover installation.

INSTALLATION

The cylinder head cover is isolated from the cylin-

der head via grommets and a reusable molded rubber

gasket. The grommet and limiter are retained in the

cylinder head cover.

(1) If a replacement cover is installed, transfer the

CCV valve grommet and oil filler cap from the origi-

nal cover to the replacement cover.

(2) Install cylinder head cover and gasket (Fig. 13).

Tighten the mounting bolts to 10 N´m (85 in. lbs.)

torque.

(3) Connect the CCV hoses.(4) Install control cables and bracket on intake

manifold and tighten bolts to 8.7 N´m (77 in. lbs.)

torque.

(5) Connect control cables to throttle body linkage.

(6) Snap control cables into cylinder head cover

clip.

(7) Connect negative cable to battery.

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The valves are made of heat resistant steel and

have chrome plated stems to prevent scuffing. All

valves use three bead locks to promote valve rotation

(Fig. 14).

STANDARD PROCEDURE - VALVE SERVICE

VALVE REFACING

Clean all carbon deposits from the combustion

chambers, valve ports, valve stems, valve stem

guides and head.

(1) Use a valve refacing machine to reface the

intake and exhaust valves to the specified angle.

(2) After refacing, a margin of at least 0.787 mm

(0.031 inch) must remain (Fig. 15). If the margin is

less than 0.787 mm (0.031 inch), the valve must be

replaced.

VALVE SEAT REFACING

Clean all carbon deposits from the combustion

chambers, valve ports, valve stems, valve stem

guides and head.

(1) Install a pilot of the correct size in the valve

guide bore. Reface the valve seat to the specified

angle with a good dressing stone. Remove only

enough metal to provide a smooth finish.

(2) Use tapered stones to obtain the specified seat

width when required.

Fig. 12 Engine Cylinder Head Cover

1 - TRANS CONTROL CABLE

2 - ACCELERATOR CABLE

3 - CONTROL CABLE BRACKET

4 - CYLINDER HEAD COVER

Fig. 13 Cylinder Head Cover Gasket Locator Pins at

#8

WJENGINE - 4.0L 9 - 23

CYLINDER HEAD COVER(S) (Continued)

Page 1319 of 2199

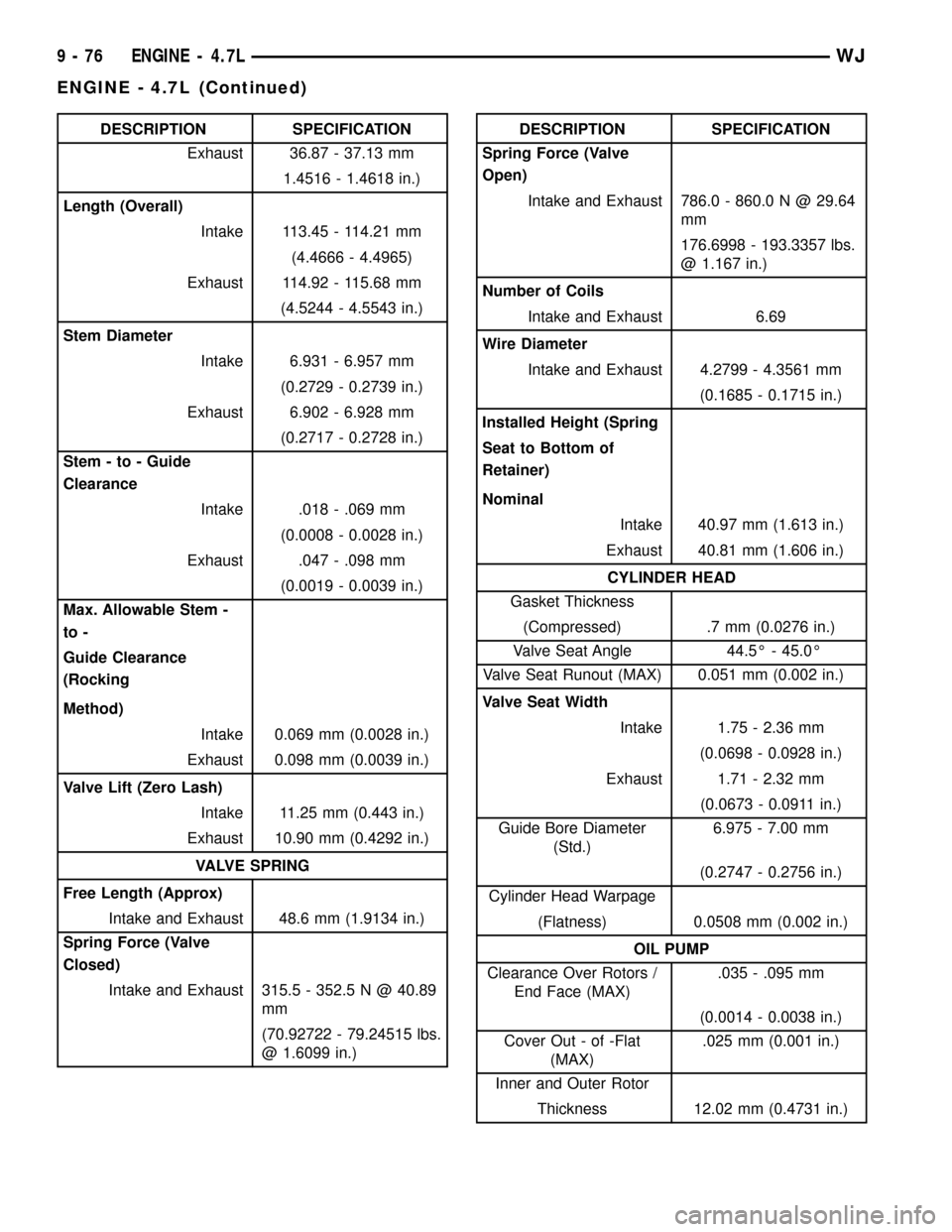

DESCRIPTION SPECIFICATION

Exhaust 36.87 - 37.13 mm

1.4516 - 1.4618 in.)

Length (Overall)

Intake 113.45 - 114.21 mm

(4.4666 - 4.4965)

Exhaust 114.92 - 115.68 mm

(4.5244 - 4.5543 in.)

Stem Diameter

Intake 6.931 - 6.957 mm

(0.2729 - 0.2739 in.)

Exhaust 6.902 - 6.928 mm

(0.2717 - 0.2728 in.)

Stem - to - Guide

Clearance

Intake .018 - .069 mm

(0.0008 - 0.0028 in.)

Exhaust .047 - .098 mm

(0.0019 - 0.0039 in.)

Max. Allowable Stem -

to -

Guide Clearance

(Rocking

Method)

Intake 0.069 mm (0.0028 in.)

Exhaust 0.098 mm (0.0039 in.)

Valve Lift (Zero Lash)

Intake 11.25 mm (0.443 in.)

Exhaust 10.90 mm (0.4292 in.)

VALVE SPRING

Free Length (Approx)

Intake and Exhaust 48.6 mm (1.9134 in.)

Spring Force (Valve

Closed)

Intake and Exhaust 315.5 - 352.5 N @ 40.89

mm

(70.92722 - 79.24515 lbs.

@ 1.6099 in.)DESCRIPTION SPECIFICATION

Spring Force (Valve

Open)

Intake and Exhaust 786.0 - 860.0 N @ 29.64

mm

176.6998 - 193.3357 lbs.

@ 1.167 in.)

Number of Coils

Intake and Exhaust 6.69

Wire Diameter

Intake and Exhaust 4.2799 - 4.3561 mm

(0.1685 - 0.1715 in.)

Installed Height (Spring

Seat to Bottom of

Retainer)

Nominal

Intake 40.97 mm (1.613 in.)

Exhaust 40.81 mm (1.606 in.)

CYLINDER HEAD

Gasket Thickness

(Compressed) .7 mm (0.0276 in.)

Valve Seat Angle 44.5É - 45.0É

Valve Seat Runout (MAX) 0.051 mm (0.002 in.)

Valve Seat Width

Intake 1.75 - 2.36 mm

(0.0698 - 0.0928 in.)

Exhaust 1.71 - 2.32 mm

(0.0673 - 0.0911 in.)

Guide Bore Diameter

(Std.)6.975 - 7.00 mm

(0.2747 - 0.2756 in.)

Cylinder Head Warpage

(Flatness) 0.0508 mm (0.002 in.)

OIL PUMP

Clearance Over Rotors /

End Face (MAX).035 - .095 mm

(0.0014 - 0.0038 in.)

Cover Out - of -Flat

(MAX).025 mm (0.001 in.)

Inner and Outer Rotor

Thickness 12.02 mm (0.4731 in.)

9 - 76 ENGINE - 4.7LWJ

ENGINE - 4.7L (Continued)

Page 1322 of 2199

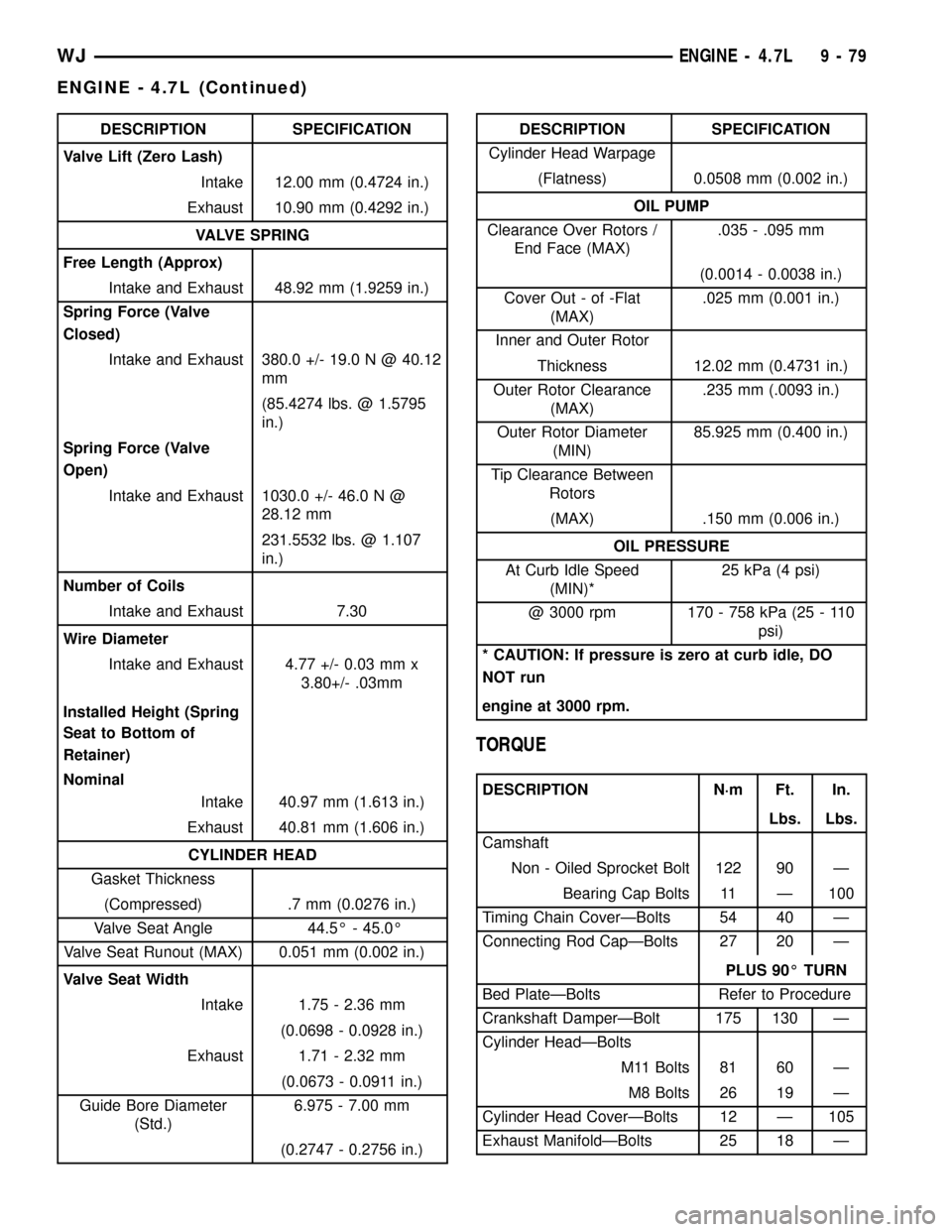

DESCRIPTION SPECIFICATION

Valve Lift (Zero Lash)

Intake 12.00 mm (0.4724 in.)

Exhaust 10.90 mm (0.4292 in.)

VALVE SPRING

Free Length (Approx)

Intake and Exhaust 48.92 mm (1.9259 in.)

Spring Force (Valve

Closed)

Intake and Exhaust 380.0 +/- 19.0 N @ 40.12

mm

(85.4274 lbs. @ 1.5795

in.)

Spring Force (Valve

Open)

Intake and Exhaust 1030.0 +/- 46.0 N @

28.12 mm

231.5532 lbs. @ 1.107

in.)

Number of Coils

Intake and Exhaust 7.30

Wire Diameter

Intake and Exhaust 4.77 +/- 0.03 mm x

3.80+/- .03mm

Installed Height (Spring

Seat to Bottom of

Retainer)

Nominal

Intake 40.97 mm (1.613 in.)

Exhaust 40.81 mm (1.606 in.)

CYLINDER HEAD

Gasket Thickness

(Compressed) .7 mm (0.0276 in.)

Valve Seat Angle 44.5É - 45.0É

Valve Seat Runout (MAX) 0.051 mm (0.002 in.)

Valve Seat Width

Intake 1.75 - 2.36 mm

(0.0698 - 0.0928 in.)

Exhaust 1.71 - 2.32 mm

(0.0673 - 0.0911 in.)

Guide Bore Diameter

(Std.)6.975 - 7.00 mm

(0.2747 - 0.2756 in.)DESCRIPTION SPECIFICATION

Cylinder Head Warpage

(Flatness) 0.0508 mm (0.002 in.)

OIL PUMP

Clearance Over Rotors /

End Face (MAX).035 - .095 mm

(0.0014 - 0.0038 in.)

Cover Out - of -Flat

(MAX).025 mm (0.001 in.)

Inner and Outer Rotor

Thickness 12.02 mm (0.4731 in.)

Outer Rotor Clearance

(MAX).235 mm (.0093 in.)

Outer Rotor Diameter

(MIN)85.925 mm (0.400 in.)

Tip Clearance Between

Rotors

(MAX) .150 mm (0.006 in.)

OIL PRESSURE

At Curb Idle Speed

(MIN)*25 kPa (4 psi)

@ 3000 rpm 170 - 758 kPa (25 - 110

psi)

* CAUTION: If pressure is zero at curb idle, DO

NOT run

engine at 3000 rpm.

TORQUE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Camshaft

Non - Oiled Sprocket Bolt 122 90 Ð

Bearing Cap Bolts 11 Ð 100

Timing Chain CoverÐBolts 54 40 Ð

Connecting Rod CapÐBolts 27 20 Ð

PLUS 90É TURN

Bed PlateÐBolts Refer to Procedure

Crankshaft DamperÐBolt 175 130 Ð

Cylinder HeadÐBolts

M11 Bolts 81 60 Ð

M8 Bolts 26 19 Ð

Cylinder Head CoverÐBolts 12 Ð 105

Exhaust ManifoldÐBolts 25 18 Ð

WJENGINE - 4.7L 9 - 79

ENGINE - 4.7L (Continued)