shift JEEP GRAND CHEROKEE 2002 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 363 of 2199

INSPECTION

For complete circuit diagrams, refer toStarting

Systemin the Contents of Group 8W - Wiring Dia-

grams. Before removing any unit from the starting

system for repair or diagnosis, perform the following

inspections:

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

²Battery- Visually inspect the battery for indi-

cations of physical damage and loose or corroded

cable connections. Determine the state-of-charge and

cranking capacity of the battery. Charge or replace

the battery, if required. Refer toBatteryin the

proper section of Group 8A - Battery for complete ser-

vice information for the battery.

²Ignition Switch- Visually inspect the ignition

switch for indications of physical damage and loose

or corroded wire harness connections. Refer toIgni-

tion Switch and Key Lock Cylinderin the proper

section of Group 8D - Ignition System for complete

service information for the ignition switch.

²Park/Neutral Position Switch- Visually

inspect the park/neutral position switch for indica-

tions of physical damage and loose or corroded wire

harness connections. Refer toPark/Neutral Posi-

tion Switchin the proper section of Group 21 -

Transmission for complete service information for the

park/neutral position switch.

²Starter Relay- Visually inspect the starter

relay for indications of physical damage and loose or

corroded wire harness connections.

²Starter Motor- Visually inspect the starter

motor for indications of physical damage and loose or

corroded wire harness connections.

²Starter Solenoid- Visually inspect the starter

solenoid for indications of physical damage and loose

or corroded wire harness connections.

²Wiring- Visually inspect the wire harnesses for

damage. Repair or replace any faulty wiring, as

required. Refer to the proper section ofGroup 8W -

Wiring Diagramsfor complete service information

and circuit diagrams for the starting system wiring

components.TESTING

COLD CRANKING TEST

For complete circuit diagrams, refer toStarting

Systemin the Contents of Group 8W - Wiring Dia-

grams. The battery must be fully-charged and load-

tested before proceeding. Refer toBatteryin the

Diagnosis and Testing section of Group 8A - Battery

for the procedures.

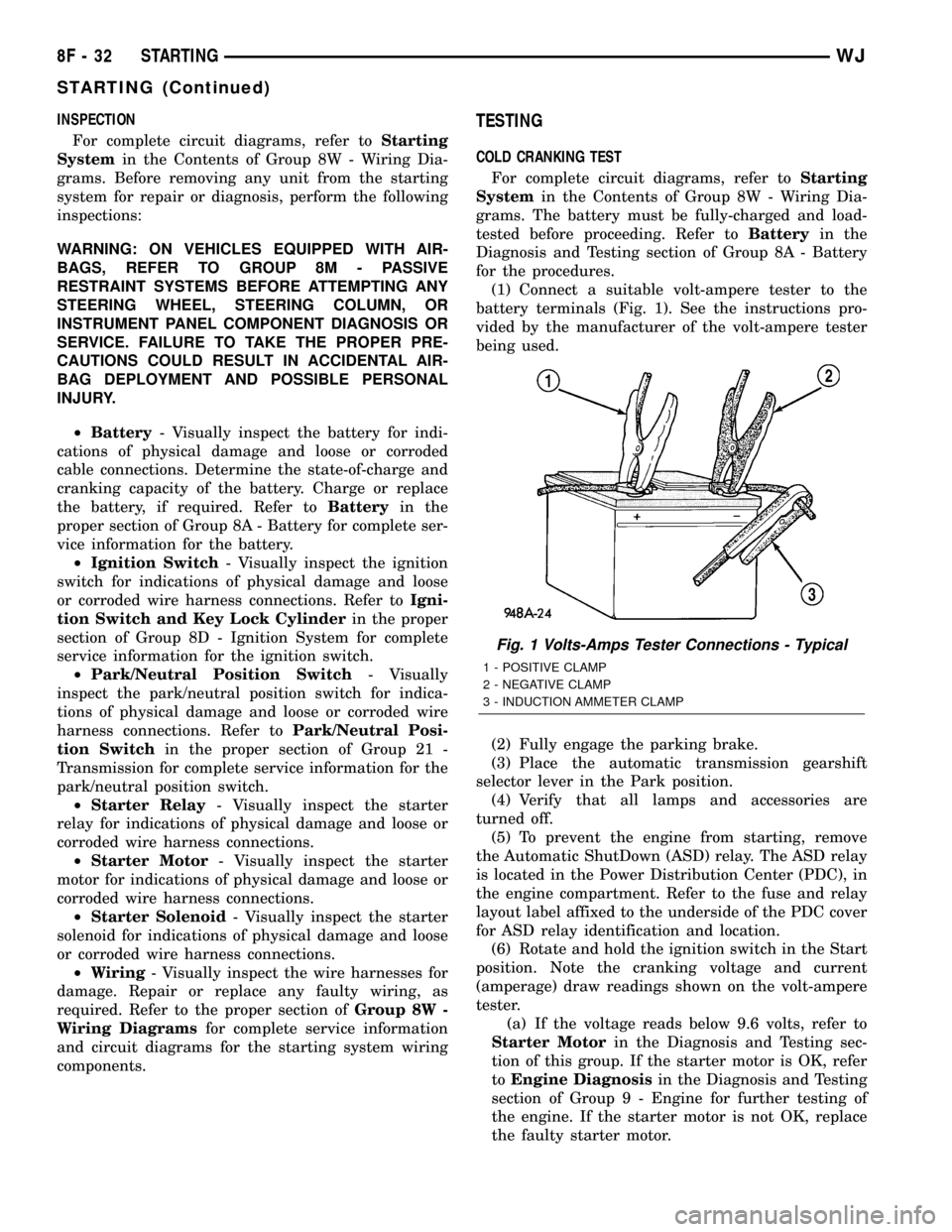

(1) Connect a suitable volt-ampere tester to the

battery terminals (Fig. 1). See the instructions pro-

vided by the manufacturer of the volt-ampere tester

being used.

(2) Fully engage the parking brake.

(3) Place the automatic transmission gearshift

selector lever in the Park position.

(4) Verify that all lamps and accessories are

turned off.

(5) To prevent the engine from starting, remove

the Automatic ShutDown (ASD) relay. The ASD relay

is located in the Power Distribution Center (PDC), in

the engine compartment. Refer to the fuse and relay

layout label affixed to the underside of the PDC cover

for ASD relay identification and location.

(6) Rotate and hold the ignition switch in the Start

position. Note the cranking voltage and current

(amperage) draw readings shown on the volt-ampere

tester.

(a) If the voltage reads below 9.6 volts, refer to

Starter Motorin the Diagnosis and Testing sec-

tion of this group. If the starter motor is OK, refer

toEngine Diagnosisin the Diagnosis and Testing

section of Group 9 - Engine for further testing of

the engine. If the starter motor is not OK, replace

the faulty starter motor.

Fig. 1 Volts-Amps Tester Connections - Typical

1 - POSITIVE CLAMP

2 - NEGATIVE CLAMP

3 - INDUCTION AMMETER CLAMP

8F - 32 STARTINGWJ

STARTING (Continued)

Page 364 of 2199

(b) If the voltage reads above 9.6 volts and the

current (amperage) draw reads below specifica-

tions, refer toFeed Circuit Testin this section.

(c) If the voltage reads 12.5 volts or greater and

the starter motor does not turn, refer toControl

Circuit Testingin this section.

(d) If the voltage reads 12.5 volts or greater and

the starter motor turns very slowly, refer toFeed

Circuit Testin this section.

NOTE: A cold engine will increase the starter cur-

rent (amperage) draw reading, and reduce the bat-

tery voltage reading.

FEED CIRCUIT TEST

The starter feed circuit test (voltage drop method)

will determine if there is excessive resistance in the

high-amperage feed circuit. For complete circuit dia-

grams, refer toStarting Systemin the Contents of

Group 8W - Wiring Diagrams.

When performing these tests, it is important to

remember that the voltage drop is giving an indica-

tion of the resistance between the two points at

which the voltmeter probes are attached.

Example:When testing the resistance of the bat-

tery positive cable, touch the voltmeter leads to the

battery positive cable clamp and the cable connector

at the starter solenoid. If you probe the battery pos-

itive terminal post and the cable connector at the

starter solenoid, you are reading the combined volt-

age drop in the battery positive cable clamp-to-termi-

nal post connection and the battery positive cable.

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing the

tests, be certain that the following procedures are

accomplished:

²Battery is fully-charged and load-tested. Refer to

Batteryin the Diagnosis and Testing section of

Group 8A - Battery for the procedures.

²Fully engage the parking brake.

²Place the automatic transmission gearshift selec-

tor lever in the Park position.

²

Verify that all lamps and accessories are turned off.

²To prevent the engine from starting, remove the

Automatic ShutDown (ASD) relay. The ASD relay is

located in the Power Distribution Center (PDC), in

the engine compartment. Refer to the fuse and relay

layout label affixed to the underside of the PDC cover

for ASD relay identification and location.

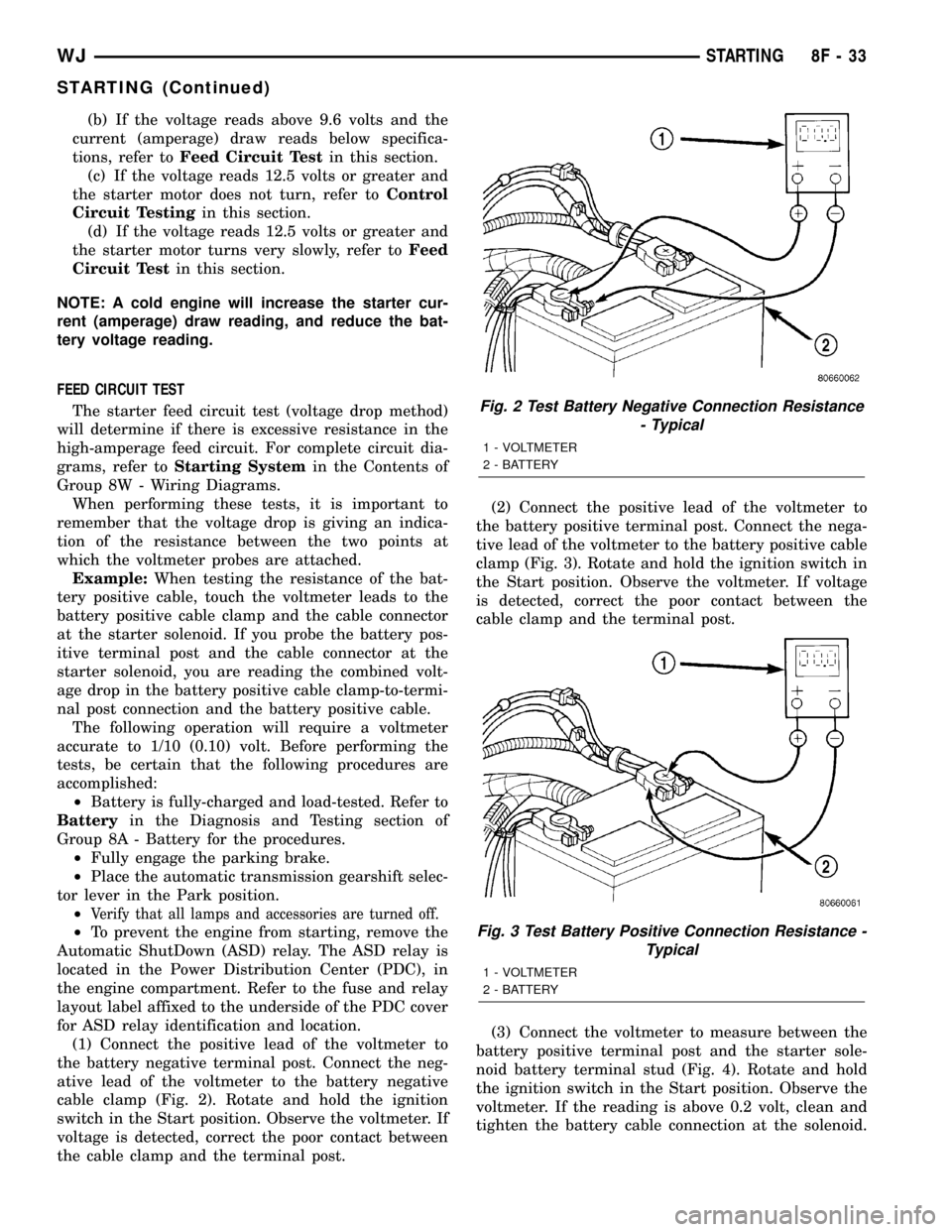

(1) Connect the positive lead of the voltmeter to

the battery negative terminal post. Connect the neg-

ative lead of the voltmeter to the battery negative

cable clamp (Fig. 2). Rotate and hold the ignition

switch in the Start position. Observe the voltmeter. If

voltage is detected, correct the poor contact between

the cable clamp and the terminal post.(2) Connect the positive lead of the voltmeter to

the battery positive terminal post. Connect the nega-

tive lead of the voltmeter to the battery positive cable

clamp (Fig. 3). Rotate and hold the ignition switch in

the Start position. Observe the voltmeter. If voltage

is detected, correct the poor contact between the

cable clamp and the terminal post.

(3) Connect the voltmeter to measure between the

battery positive terminal post and the starter sole-

noid battery terminal stud (Fig. 4). Rotate and hold

the ignition switch in the Start position. Observe the

voltmeter. If the reading is above 0.2 volt, clean and

tighten the battery cable connection at the solenoid.

Fig. 2 Test Battery Negative Connection Resistance

- Typical

1 - VOLTMETER

2 - BATTERY

Fig. 3 Test Battery Positive Connection Resistance -

Typical

1 - VOLTMETER

2 - BATTERY

WJSTARTING 8F - 33

STARTING (Continued)

Page 367 of 2199

OPERATION

These starter motors are equipped with a plane-

tary gear reduction (intermediate transmission) sys-

tem. The planetary gear reduction system consists of

a gear that is integral to the output end of the elec-

tric motor armature shaft that is in continual

engagement with a larger gear that is splined to the

input end of the starter pinion gear shaft. This fea-

ture makes it possible to reduce the dimensions of

the starter. At the same time, it allows higher arma-

ture rotational speed and delivers increased torque

through the starter pinion gear to the starter ring

gear.

The starter motors for both engines are activated

by an integral heavy duty starter solenoid switch

mounted to the overrunning clutch housing. This

electromechanical switch connects and disconnects

the feed of battery voltage to the starter motor and

actuates a shift fork that engages and disengages the

starter pinion gear with the starter ring gear.

Both starter motors use an overrunning clutch and

starter pinion gear unit to engage and drive a starter

ring gear that is integral to the torque converter

drive plate mounted on the rear crankshaft flange.

DIAGNOSIS AND TESTING - STARTER MOTOR

Correct starter motor operation can be confirmed

by performing the following free running bench test.

This test can only be performed with the starter

motor removed from the vehicle. Refer toStarting

Systemin the Specifications section of this group for

the starter motor specifications.

(1) Remove the starter motor from the vehicle.

Refer toStarter Motorin the Removal and Instal-

lation section of this group for the procedures.

(2) Mount the starter motor securely in a soft-

jawed bench vise. The vise jaws should be clamped

on the mounting flange of the starter motor. Never

clamp on the starter motor by the field frame.

(3) Connect a suitable volt-ampere tester and a

12-volt battery to the starter motor in series, and set

the ammeter to the 100 ampere scale. See the

instructions provided by the manufacturer of the

volt-ampere tester being used.

(4) Install a jumper wire from the solenoid termi-

nal to the solenoid battery terminal. The starter

motor should operate. If the starter motor fails to

operate, replace the faulty starter motor assembly.

(5) Adjust the carbon pile load of the tester to

obtain the free running test voltage. Refer toStart-

ing Systemin the Specifications section of this

group for the starter motor free running test voltage

specifications.

(6) Note the reading on the ammeter and compare

this reading to the free running test maximum

amperage draw. Refer toStarting Systemin theSpecifications section of this group for the starter

motor free running test maximum amperage draw

specifications.

(7) If the ammeter reading exceeds the maximum

amperage draw specification, replace the faulty

starter motor assembly.

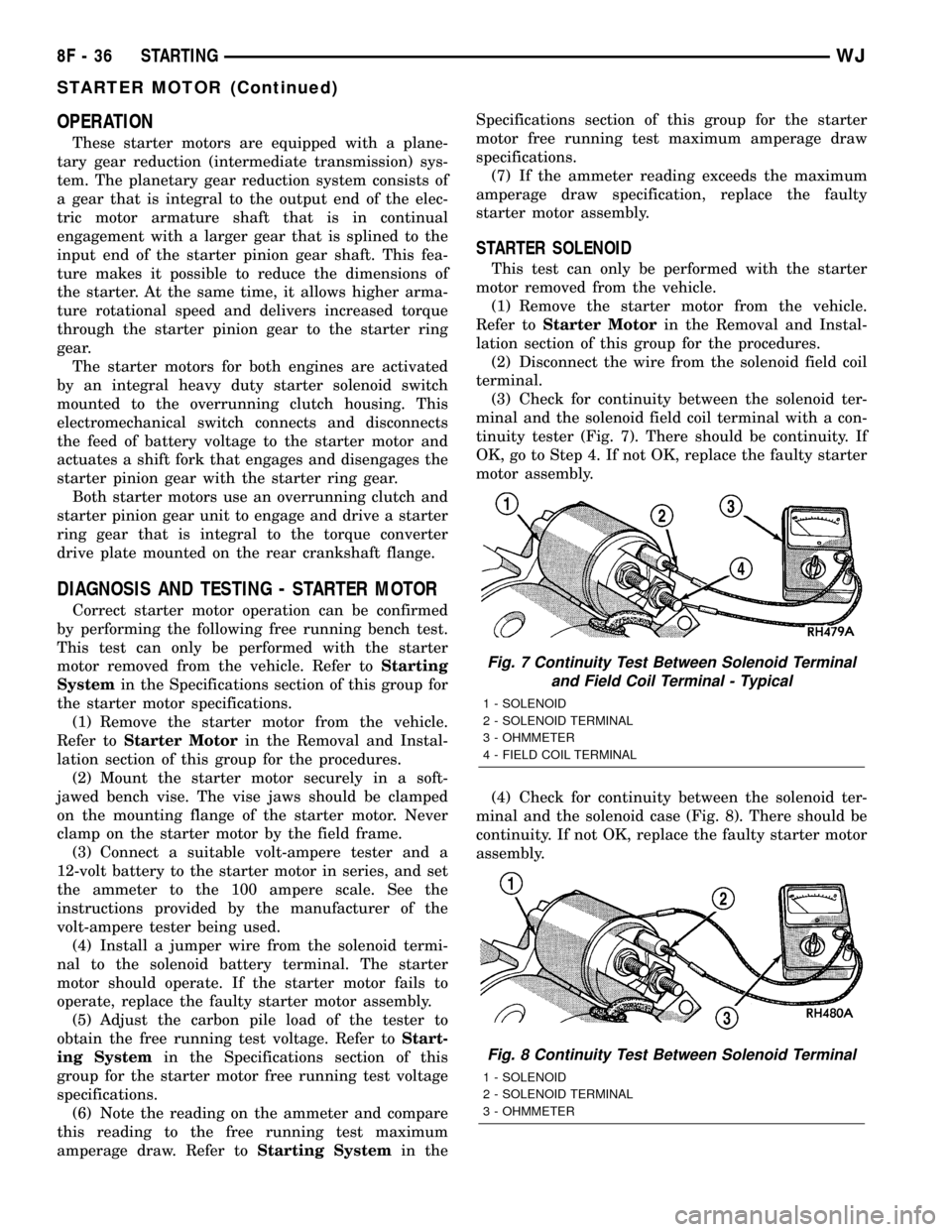

STARTER SOLENOID

This test can only be performed with the starter

motor removed from the vehicle.

(1) Remove the starter motor from the vehicle.

Refer toStarter Motorin the Removal and Instal-

lation section of this group for the procedures.

(2) Disconnect the wire from the solenoid field coil

terminal.

(3) Check for continuity between the solenoid ter-

minal and the solenoid field coil terminal with a con-

tinuity tester (Fig. 7). There should be continuity. If

OK, go to Step 4. If not OK, replace the faulty starter

motor assembly.

(4) Check for continuity between the solenoid ter-

minal and the solenoid case (Fig. 8). There should be

continuity. If not OK, replace the faulty starter motor

assembly.

Fig. 7 Continuity Test Between Solenoid Terminal

and Field Coil Terminal - Typical

1 - SOLENOID

2 - SOLENOID TERMINAL

3 - OHMMETER

4 - FIELD COIL TERMINAL

Fig. 8 Continuity Test Between Solenoid Terminal

1 - SOLENOID

2 - SOLENOID TERMINAL

3 - OHMMETER

8F - 36 STARTINGWJ

STARTER MOTOR (Continued)

Page 370 of 2199

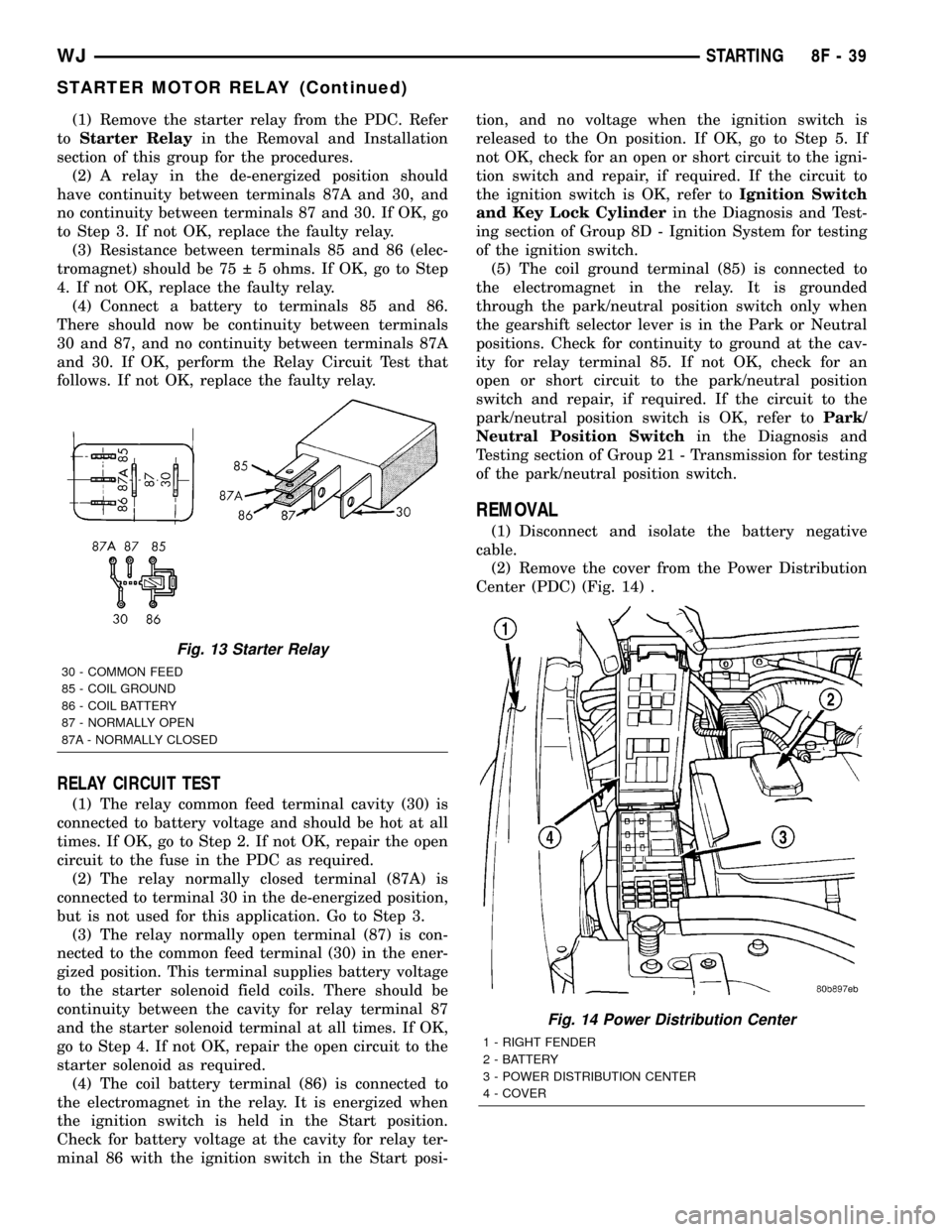

(1) Remove the starter relay from the PDC. Refer

toStarter Relayin the Removal and Installation

section of this group for the procedures.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform the Relay Circuit Test that

follows. If not OK, replace the faulty relay.

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the fuse in the PDC as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the starter solenoid field coils. There should be

continuity between the cavity for relay terminal 87

and the starter solenoid terminal at all times. If OK,

go to Step 4. If not OK, repair the open circuit to the

starter solenoid as required.

(4) The coil battery terminal (86) is connected to

the electromagnet in the relay. It is energized when

the ignition switch is held in the Start position.

Check for battery voltage at the cavity for relay ter-

minal 86 with the ignition switch in the Start posi-tion, and no voltage when the ignition switch is

released to the On position. If OK, go to Step 5. If

not OK, check for an open or short circuit to the igni-

tion switch and repair, if required. If the circuit to

the ignition switch is OK, refer toIgnition Switch

and Key Lock Cylinderin the Diagnosis and Test-

ing section of Group 8D - Ignition System for testing

of the ignition switch.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. It is grounded

through the park/neutral position switch only when

the gearshift selector lever is in the Park or Neutral

positions. Check for continuity to ground at the cav-

ity for relay terminal 85. If not OK, check for an

open or short circuit to the park/neutral position

switch and repair, if required. If the circuit to the

park/neutral position switch is OK, refer toPark/

Neutral Position Switchin the Diagnosis and

Testing section of Group 21 - Transmission for testing

of the park/neutral position switch.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 14) .

Fig. 13 Starter Relay

30 - COMMON FEED

85 - COIL GROUND

86 - COIL BATTERY

87 - NORMALLY OPEN

87A - NORMALLY CLOSED

Fig. 14 Power Distribution Center

1 - RIGHT FENDER

2 - BATTERY

3 - POWER DISTRIBUTION CENTER

4 - COVER

WJSTARTING 8F - 39

STARTER MOTOR RELAY (Continued)

Page 416 of 2199

INSTRUMENT CLUSTER

TABLE OF CONTENTS

page page

INSTRUMENT CLUSTER

DESCRIPTION..........................2

OPERATION............................4

DIAGNOSIS AND TESTING - INSTRUMENT

CLUSTER............................7

REMOVAL.............................9

DISASSEMBLY.........................10

ASSEMBLY............................11

INSTALLATION.........................12

ABS INDICATOR

DESCRIPTION.........................13

OPERATION...........................13

AIRBAG INDICATOR

DESCRIPTION.........................14

OPERATION...........................14

BRAKE/PARK BRAKE INDICATOR

DESCRIPTION.........................15

OPERATION...........................15

DIAGNOSIS AND TESTING - BRAKE

INDICATOR..........................16

CHECK GAUGES INDICATOR

DESCRIPTION.........................16

OPERATION...........................17

COOLANT LOW INDICATOR

DESCRIPTION.........................17

OPERATION...........................18

CRUISE INDICATOR

DESCRIPTION.........................18

OPERATION...........................18

ENGINE TEMPERATURE GAUGE

DESCRIPTION.........................19

OPERATION...........................19

FRONT FOG LAMP INDICATOR

DESCRIPTION.........................20

OPERATION...........................20

FUEL GAUGE

DESCRIPTION.........................21

OPERATION...........................21

HIGH BEAM INDICATOR

DESCRIPTION.........................22

OPERATION...........................22

LOW FUEL INDICATOR

DESCRIPTION.........................22

OPERATION...........................23

MALFUNCTION INDICATOR LAMP (MIL)

DESCRIPTION.........................23OPERATION...........................23

ODOMETER

DESCRIPTION.........................24

OPERATION...........................25

OIL PRESSURE GAUGE

DESCRIPTION.........................25

OPERATION...........................26

OVERDRIVE OFF INDICATOR

DESCRIPTION.........................26

OPERATION...........................26

REAR FOG LAMP INDICATOR

DESCRIPTION.........................27

OPERATION...........................27

SEATBELT INDICATOR

DESCRIPTION.........................28

OPERATION...........................28

SHIFT INDICATOR (TRANSFER CASE)

DESCRIPTION.........................29

OPERATION...........................29

SKIS INDICATOR

DESCRIPTION.........................29

OPERATION...........................29

SPEEDOMETER

DESCRIPTION.........................30

OPERATION...........................31

TACHOMETER

DESCRIPTION.........................31

OPERATION...........................31

TRANS TEMP INDICATOR

DESCRIPTION.........................32

OPERATION...........................32

TURN SIGNAL INDICATOR

DESCRIPTION.........................33

OPERATION...........................33

DIAGNOSIS AND TESTING - TURN SIGNAL

INDICATOR..........................33

VOLTAGE GAUGE

DESCRIPTION.........................34

OPERATION...........................34

WAIT-TO-START INDICATOR

DESCRIPTION.........................35

OPERATION...........................35

WATER-IN-FUEL INDICATOR

DESCRIPTION.........................36

OPERATION...........................36

WJINSTRUMENT CLUSTER 8J - 1

Page 444 of 2199

SHIFT INDICATOR (TRANSFER

CASE)

DESCRIPTION

A part time indicator is standard equipment on all

instrument clusters, but is only functional on vehi-

cles equipped with the standard equipment Selec-

Trac four-wheel drive system. The part time indicator

is located near the right edge of the instrument clus-

ter, to the right of the speedometer. The part time

indicator consists of the words ªPART TIMEº

imprinted on an amber lens. The lens is located

behind a cutout in the opaque layer of the instru-

ment cluster overlay. The dark outer layer of the

overlay prevents the indicator from being clearly vis-

ible when it is not illuminated. The words ªPART

TIMEº appear silhouetted against an amber field

through the translucent outer layer of the overlay

when the indicator is illuminated from behind by a

replaceable incandescent bulb and bulb holder unit

located on the instrument cluster electronic circuit

board. The part time indicator lens is serviced as a

unit with the instrument cluster lens, hood and mask

unit.

OPERATION

The part time indicator gives an indication to the

vehicle operator that a four-wheel drive part time

operating mode of the transfer case is selected. On

vehicles with the standard equipment Selec-Trac

four-wheel drive system, the part time indicator illu-

minates when the NV-242 transfer case is engaged in

either the4X4Part Time or 4 Lo positions. This

indicator is controlled by a transistor on the instru-

ment cluster electronic circuit board based upon clus-

ter programming and electronic messages received by

the cluster from the Powertrain Control Module

(PCM) over the Programmable Communications

Interface (PCI) data bus. The part time indicator

bulb is completely controlled by the instrument clus-

ter logic circuit, and that logic will only allow this

indicator to operate when the instrument cluster

receives a battery current input on the fused ignition

switch output (run-start) circuit. Therefore, the indi-

cator will always be off when the ignition switch is in

any position except On or Start. The bulb only illu-

minates when it is provided a path to ground by the

instrument cluster transistor. The instrument cluster

will turn on the part time indicator for the following

reasons:

²Part Time Indicator Lamp-On Message-

Each time the cluster receives a part time indicator

lamp-on message from the PCM indicating that a

four-wheel drive part time position of the transfer

case has been selected, the part time indicator will beilluminated. The indicator remains illuminated until

the cluster receives a part time indicator lamp-off

message from the PCM.

²Actuator Test- Each time the cluster is put

through the actuator test, the part time indicator will

be turned on for the duration of the test to confirm

the functionality of the bulb and the cluster control

circuitry.

The PCM continually monitors the transfer case

switch to determine the driveline operating mode.

The PCM then sends the proper part time indicator

lamp-on and lamp-off messages to the instrument

cluster. If the part time indicator fails to light during

the actuator test, replace the bulb with a known good

unit. For further diagnosis of the part time indicator

or the instrument cluster circuitry that controls the

indicator, (Refer to 8 - ELECTRICAL/INSTRUMENT

CLUSTER - DIAGNOSIS AND TESTING). For

proper diagnosis of the transfer case switch, the

PCM, the PCI data bus, or the electronic message

inputs to the instrument cluster that control the part

time indicator, a DRBIIItscan tool is required. Refer

to the appropriate diagnostic information.

SKIS INDICATOR

DESCRIPTION

A Sentry Key Immobilizer System (SKIS) indicator

is standard equipment on all instrument clusters, but

is only operational on vehicles equipped with the

optional SKIS. The SKIS indicator is located in the

upper right corner of the instrument cluster, to the

right of the speedometer. The SKIS indicator consists

of a graphical representation or icon of a circled and

crossed-out key imprinted on an amber lens. The lens

is located behind a cutout in the opaque layer of the

instrument cluster overlay. The dark outer layer of

the overlay prevents the indicator from being clearly

visible when it is not illuminated. The icon appears

silhouetted against an amber field through the trans-

lucent outer layer of the overlay when it is illumi-

nated from behind by an incandescent bulb and bulb

holder unit located on the instrument cluster elec-

tronic circuit board. The SKIS indicator lens is ser-

viced as a unit with the instrument cluster lens, hood

and mask unit.

OPERATION

The Sentry Key Immobilizer System (SKIS) indica-

tor gives an indication to the vehicle operator of the

status of the SKIS. This indicator is controlled by a

transistor on the instrument cluster electronic circuit

board based upon cluster programming and elec-

tronic messages received by the cluster from the Sen-

try Key Immobilizer Module (SKIM) over the

WJINSTRUMENT CLUSTER 8J - 29

Page 548 of 2199

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, FRONT IMPACT SENSOR,

SIDE IMPACT SENSOR, SIDE CURTAIN AIRBAG, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

WARNING: THE AIRBAG CONTROL MODULE CON-

TAINS THE IMPACT SENSOR, WHICH ENABLES

THE SYSTEM TO DEPLOY THE SUPPLEMENTAL

RESTRAINTS. NEVER STRIKE OR DROP THE AIR-

BAG CONTROL MODULE, AS IT CAN DAMAGE THE

IMPACT SENSOR OR AFFECT ITS CALIBRATION. IF

AN AIRBAG CONTROL MODULE IS ACCIDENTALLY

DROPPED DURING SERVICE, THE MODULE MUST

BE SCRAPPED AND REPLACED WITH A NEW UNIT.

FAILURE TO OBSERVE THIS WARNING COULD

RESULT IN ACCIDENTAL, INCOMPLETE, OR

IMPROPER SUPPLEMENTAL RESTRAINT DEPLOY-

MENT AND POSSIBLE OCCUPANT INJURIES.

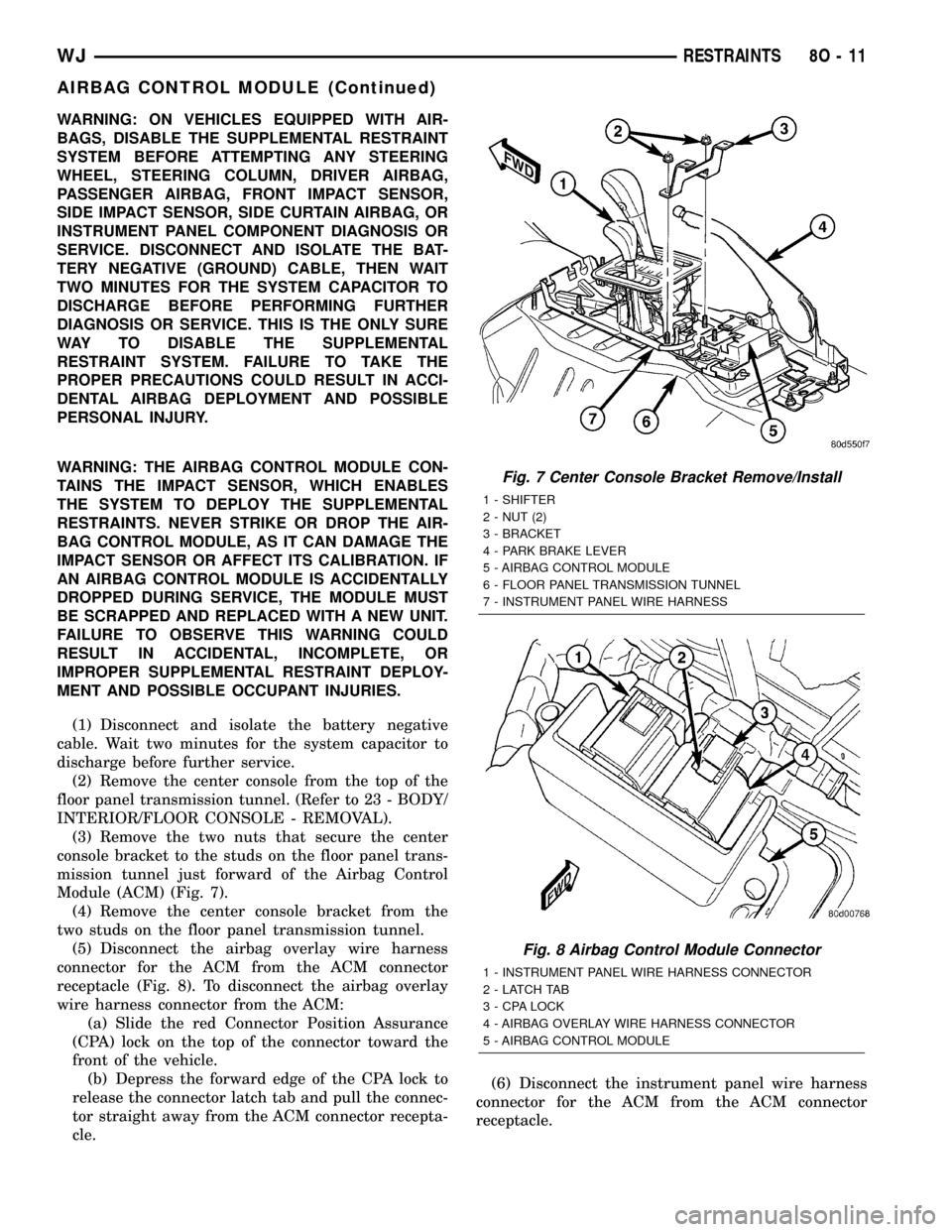

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

(2) Remove the center console from the top of the

floor panel transmission tunnel. (Refer to 23 - BODY/

INTERIOR/FLOOR CONSOLE - REMOVAL).

(3) Remove the two nuts that secure the center

console bracket to the studs on the floor panel trans-

mission tunnel just forward of the Airbag Control

Module (ACM) (Fig. 7).

(4) Remove the center console bracket from the

two studs on the floor panel transmission tunnel.

(5) Disconnect the airbag overlay wire harness

connector for the ACM from the ACM connector

receptacle (Fig. 8). To disconnect the airbag overlay

wire harness connector from the ACM:

(a) Slide the red Connector Position Assurance

(CPA) lock on the top of the connector toward the

front of the vehicle.

(b) Depress the forward edge of the CPA lock to

release the connector latch tab and pull the connec-

tor straight away from the ACM connector recepta-

cle.(6) Disconnect the instrument panel wire harness

connector for the ACM from the ACM connector

receptacle.

Fig. 7 Center Console Bracket Remove/Install

1 - SHIFTER

2 - NUT (2)

3 - BRACKET

4 - PARK BRAKE LEVER

5 - AIRBAG CONTROL MODULE

6 - FLOOR PANEL TRANSMISSION TUNNEL

7 - INSTRUMENT PANEL WIRE HARNESS

Fig. 8 Airbag Control Module Connector

1 - INSTRUMENT PANEL WIRE HARNESS CONNECTOR

2 - LATCH TAB

3 - CPA LOCK

4 - AIRBAG OVERLAY WIRE HARNESS CONNECTOR

5 - AIRBAG CONTROL MODULE

WJRESTRAINTS 8O - 11

AIRBAG CONTROL MODULE (Continued)

Page 673 of 2199

Component Page

Power Outlet......................... 8W-41

Power Seats.......................... 8W-63

Power Windows....................... 8W-60

Powertrain Control Module.............. 8W-30

Radio............................... 8W-47

Rain Sensor.......................... 8W-49

Recirculation Door Motor/Actuator........ 8W-42

Red Brake Warning Indicator Switch....... 8W-35

Remote Keyless Module................. 8W-39

Remote Radio Switches................. 8W-47

Splices.............................. 8W-10

Seat Belt Switch...................... 8W-43

Seat Module.......................... 8W-63

Sentry Key Immobilizer Module.......... 8W-39

Shifter Assembly...................... 8W-31

Side Impact Sensors................... 8W-43

Side Marker Lamps.................... 8W-50

Side Repeater Lamps................... 8W-52

Siren............................... 8W-49

Speakers............................ 8W-47Component Page

Speed Control Switches................. 8W-33

Sunroof............................. 8W-64

Temperature Valve Actuator............. 8W-42

Throttle Position Sensor................ 8W-30

Trailer Tow.......................... 8W-54

Transfer Case Position Sensor............ 8W-31

Transmission......................... 8W-31

Turn Signal Lamps.................... 8W-52

Underhood Lamp...................... 8W-44

Vehicle Information Center.............. 8W-49

Viscous/Cabin Heater................... 8W-30

Visor/Vanity Lamps.................... 8W-44

Washer Fluid Level Switch.............. 8W-53

Wastegate Solenoid.................... 8W-30

Water In Fuel Sensor................... 8W-30

Wheel Speed Sensors................... 8W-35

Window Defogger...................... 8W-48

Wiper High/Low Relay.................. 8W-53

Wiper Motor.......................... 8W-53

Washer Pump......................... 8W-5

8W - 02 - 2 8W-02 COMPONENT INDEXWJ

Page 706 of 2199

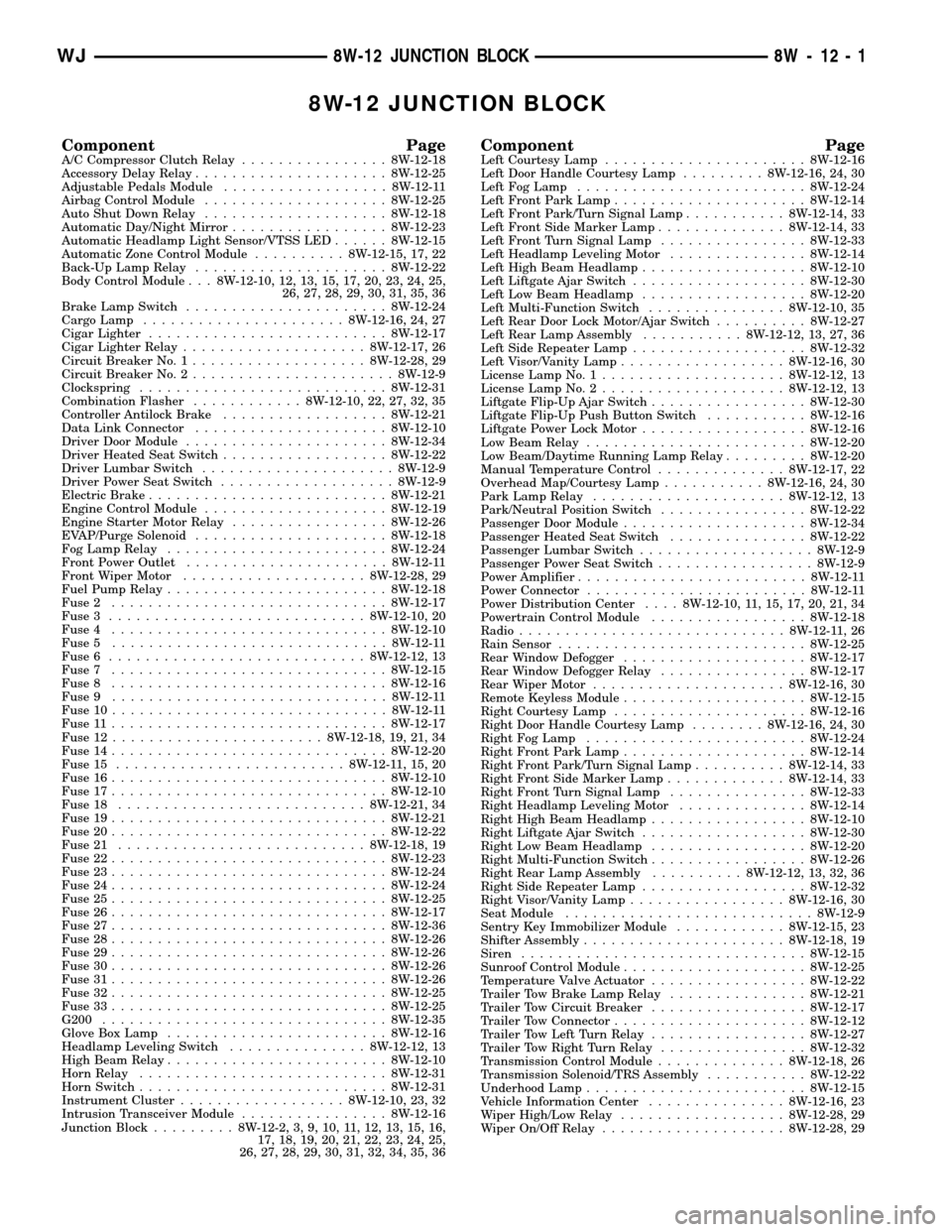

8W-12 JUNCTION BLOCK

Component PageA/C Compressor Clutch Relay................8W-12-18

Accessory Delay Relay.....................8W-12-25

Adjustable Pedals Module..................8W-12-11

Airbag Control Module....................8W-12-25

Auto Shut Down Relay....................8W-12-18

Automatic Day/Night Mirror.................8W-12-23

Automatic Headlamp Light Sensor/VTSS LED......8W-12-15

Automatic Zone Control Module..........8W-12-15, 17, 22

Back-Up Lamp Relay.....................8W-12-22

Body Control Module . . . 8W-12-10, 12, 13, 15, 17, 20, 23, 24, 25,

26, 27, 28, 29, 30, 31, 35, 36

Brake Lamp Switch......................8W-12-24

Cargo Lamp......................8W-12-16, 24, 27

Cigar Lighter..........................8W-12-17

Cigar Lighter Relay....................8W-12-17, 26

Circuit Breaker No. 1...................8W-12-28, 29

Circuit Breaker No. 2......................8W-12-9

Clockspring...........................8W-12-31

Combination Flasher............8W-12-10, 22, 27, 32, 35

Controller Antilock Brake..................8W-12-21

Data Link Connector.....................8W-12-10

Driver Door Module......................8W-12-34

Driver Heated Seat Switch..................8W-12-22

Driver Lumbar Switch.....................8W-12-9

Driver Power Seat Switch...................8W-12-9

Electric Brake..........................8W-12-21

Engine Control Module....................8W-12-19

Engine Starter Motor Relay.................8W-12-26

EVAP/Purge Solenoid.....................8W-12-18

Fog Lamp Relay........................8W-12-24

Front Power Outlet......................8W-12-11

Front Wiper Motor....................8W-12-28, 29

Fuel Pump Relay........................8W-12-18

Fuse 2..............................8W-12-17

Fuse 3............................8W-12-10, 20

Fuse 4..............................8W-12-10

Fuse 5..............................8W-12-11

Fuse 6............................8W-12-12, 13

Fuse 7..............................8W-12-15

Fuse 8..............................8W-12-16

Fuse 9..............................8W-12-11

Fuse 10..............................8W-12-11

Fuse 11..............................8W-12-17

Fuse 12.......................8W-12-18, 19, 21, 34

Fuse 14..............................8W-12-20

Fuse 15.........................8W-12-11, 15, 20

Fuse 16..............................8W-12-10

Fuse 17..............................8W-12-10

Fuse 18...........................8W-12-21, 34

Fuse 19..............................8W-12-21

Fuse 20..............................8W-12-22

Fuse 21...........................8W-12-18, 19

Fuse 22..............................8W-12-23

Fuse 23..............................8W-12-24

Fuse 24..............................8W-12-24

Fuse 25..............................8W-12-25

Fuse 26..............................8W-12-17

Fuse 27..............................8W-12-36

Fuse 28..............................8W-12-26

Fuse 29..............................8W-12-26

Fuse 30..............................8W-12-26

Fuse 31..............................8W-12-26

Fuse 32..............................8W-12-25

Fuse 33..............................8W-12-25

G200...............................8W-12-35

Glove Box Lamp........................8W-12-16

Headlamp Leveling Switch...............8W-12-12, 13

High Beam Relay........................8W-12-10

Horn Relay...........................8W-12-31

Horn Switch...........................8W-12-31

Instrument Cluster..................8W-12-10, 23, 32

Intrusion Transceiver Module................8W-12-16

Junction Block.........8W-12-2, 3, 9, 10, 11, 12, 13, 15, 16,

17, 18, 19, 20, 21, 22, 23, 24, 25,

26, 27, 28, 29, 30, 31, 32, 34, 35, 36Component PageLeft Courtesy Lamp......................8W-12-16

Left Door Handle Courtesy Lamp.........8W-12-16, 24, 30

Left Fog Lamp.........................8W-12-24

Left Front Park Lamp.....................8W-12-14

Left Front Park/Turn Signal Lamp...........8W-12-14, 33

Left Front Side Marker Lamp..............8W-12-14, 33

Left Front Turn Signal Lamp................8W-12-33

Left Headlamp Leveling Motor...............8W-12-14

Left High Beam Headlamp..................8W-12-10

Left Liftgate Ajar Switch...................8W-12-30

Left Low Beam Headlamp..................8W-12-20

Left Multi-Function Switch...............8W-12-10, 35

Left Rear Door Lock Motor/Ajar Switch..........8W-12-27

Left Rear Lamp Assembly...........8W-12-12, 13, 27, 36

Left Side Repeater Lamp...................8W-12-32

Left Visor/Vanity Lamp..................8W-12-16, 30

License Lamp No. 1....................8W-12-12, 13

License Lamp No. 2....................8W-12-12, 13

Liftgate Flip-Up Ajar Switch.................8W-12-30

Liftgate Flip-Up Push Button Switch...........8W-12-16

Liftgate Power Lock Motor..................8W-12-16

Low Beam Relay........................8W-12-20

Low Beam/Daytime Running Lamp Relay.........8W-12-20

Manual Temperature Control..............8W-12-17, 22

Overhead Map/Courtesy Lamp...........8W-12-16, 24, 30

Park Lamp Relay.....................8W-12-12, 13

Park/Neutral Position Switch................8W-12-22

Passenger Door Module....................8W-12-34

Passenger Heated Seat Switch...............8W-12-22

Passenger Lumbar Switch...................8W-12-9

Passenger Power Seat Switch.................8W-12-9

Power Amplifier.........................8W-12-11

Power Connector........................8W-12-11

Power Distribution Center....8W-12-10, 11, 15, 17, 20, 21, 34

Powertrain Control Module.................8W-12-18

Radio.............................8W-12-11, 26

Rain Sensor...........................8W-12-25

Rear Window Defogger....................8W-12-17

Rear Window Defogger Relay................8W-12-17

Rear Wiper Motor.....................8W-12-16, 30

Remote Keyless Module....................8W-12-15

Right Courtesy Lamp.....................8W-12-16

Right Door Handle Courtesy Lamp........8W-12-16, 24, 30

Right Fog Lamp........................8W-12-24

Right Front Park Lamp....................8W-12-14

Right Front Park/Turn Signal Lamp..........8W-12-14, 33

Right Front Side Marker Lamp.............8W-12-14, 33

Right Front Turn Signal Lamp...............8W-12-33

Right Headlamp Leveling Motor..............8W-12-14

Right High Beam Headlamp.................8W-12-10

Right Liftgate Ajar Switch..................8W-12-30

Right Low Beam Headlamp.................8W-12-20

Right Multi-Function Switch.................8W-12-26

Right Rear Lamp Assembly..........8W-12-12, 13, 32, 36

Right Side Repeater Lamp..................8W-12-32

Right Visor/Vanity Lamp.................8W-12-16, 30

Seat Module...........................8W-12-9

Sentry Key Immobilizer Module............8W-12-15, 23

Shifter Assembly......................8W-12-18, 19

Siren...............................8W-12-15

Sunroof Control Module....................8W-12-25

Temperature Valve Actuator.................8W-12-22

Trailer Tow Brake Lamp Relay...............8W-12-21

Trailer Tow Circuit Breaker.................8W-12-17

Trailer Tow Connector.....................8W-12-12

Trailer Tow Left Turn Relay.................8W-12-27

Trailer Tow Right Turn Relay................8W-12-32

Transmission Control Module..............8W-12-18, 26

Transmission Solenoid/TRS Assembly...........8W-12-22

Underhood Lamp........................8W-12-15

Vehicle Information Center...............8W-12-16, 23

Wiper High/Low Relay..................8W-12-28, 29

Wiper On/Off Relay....................8W-12-28, 29

WJ8W-12 JUNCTION BLOCK 8W - 12 - 1

Page 742 of 2199

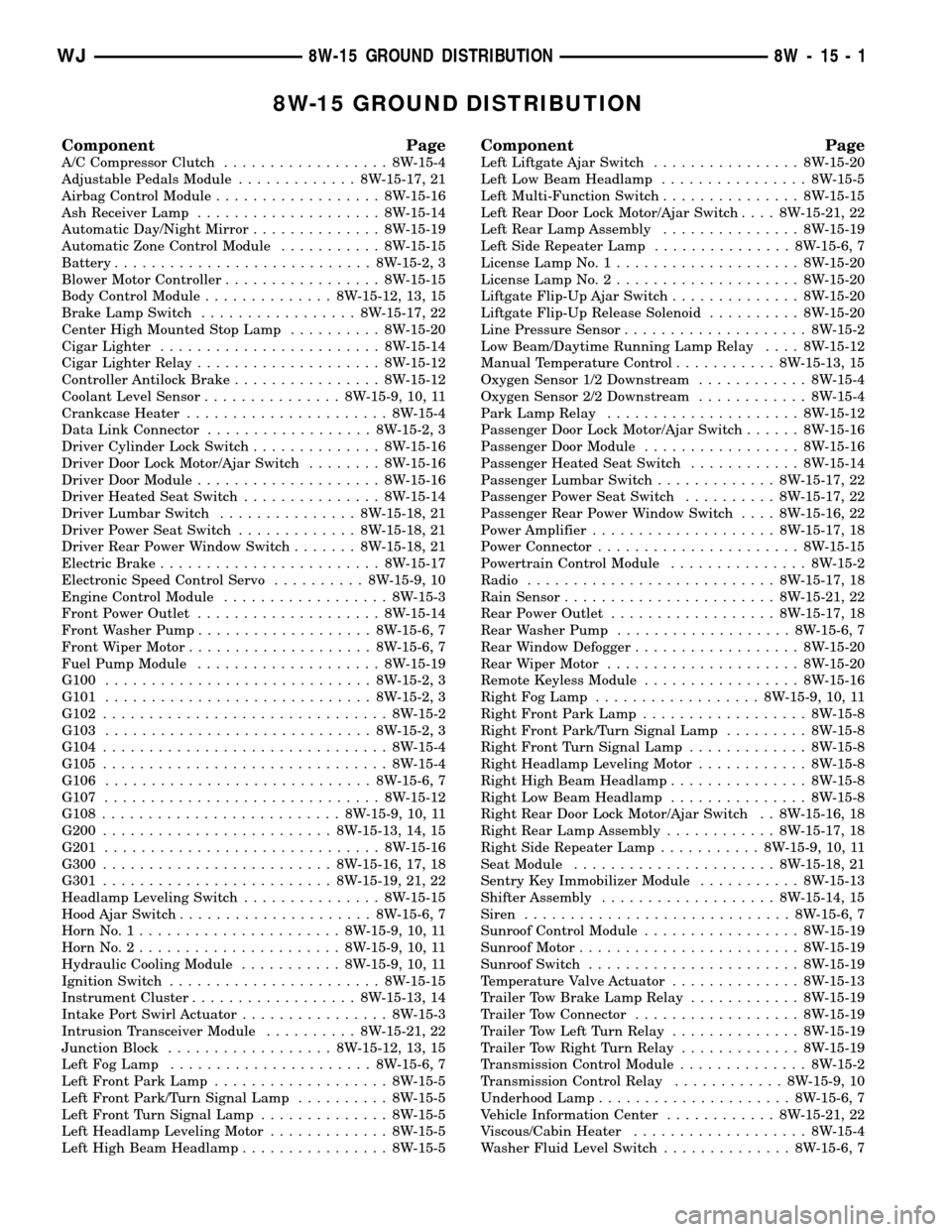

8W-15 GROUND DISTRIBUTION

Component Page

A/C Compressor Clutch.................. 8W-15-4

Adjustable Pedals Module............. 8W-15-17, 21

Airbag Control Module.................. 8W-15-16

Ash Receiver Lamp.................... 8W-15-14

Automatic Day/Night Mirror.............. 8W-15-19

Automatic Zone Control Module........... 8W-15-15

Battery............................ 8W-15-2, 3

Blower Motor Controller................. 8W-15-15

Body Control Module.............. 8W-15-12, 13, 15

Brake Lamp Switch................. 8W-15-17, 22

Center High Mounted Stop Lamp.......... 8W-15-20

Cigar Lighter........................ 8W-15-14

Cigar Lighter Relay.................... 8W-15-12

Controller Antilock Brake................ 8W-15-12

Coolant Level Sensor............... 8W-15-9, 10, 11

Crankcase Heater...................... 8W-15-4

Data Link Connector.................. 8W-15-2, 3

Driver Cylinder Lock Switch.............. 8W-15-16

Driver Door Lock Motor/Ajar Switch........ 8W-15-16

Driver Door Module.................... 8W-15-16

Driver Heated Seat Switch............... 8W-15-14

Driver Lumbar Switch............... 8W-15-18, 21

Driver Power Seat Switch............. 8W-15-18, 21

Driver Rear Power Window Switch....... 8W-15-18, 21

Electric Brake........................ 8W-15-17

Electronic Speed Control Servo.......... 8W-15-9, 10

Engine Control Module.................. 8W-15-3

Front Power Outlet.................... 8W-15-14

Front Washer Pump................... 8W-15-6, 7

Front Wiper Motor.................... 8W-15-6, 7

Fuel Pump Module.................... 8W-15-19

G100............................. 8W-15-2, 3

G101............................. 8W-15-2, 3

G102............................... 8W-15-2

G103............................. 8W-15-2, 3

G104............................... 8W-15-4

G105............................... 8W-15-4

G106............................. 8W-15-6, 7

G107.............................. 8W-15-12

G108.......................... 8W-15-9, 10, 11

G200......................... 8W-15-13, 14, 15

G201.............................. 8W-15-16

G300......................... 8W-15-16, 17, 18

G301......................... 8W-15-19, 21, 22

Headlamp Leveling Switch............... 8W-15-15

Hood Ajar Switch..................... 8W-15-6, 7

Horn No. 1...................... 8W-15-9, 10, 11

Horn No. 2...................... 8W-15-9, 10, 11

Hydraulic Cooling Module........... 8W-15-9, 10, 11

Ignition Switch....................... 8W-15-15

Instrument Cluster.................. 8W-15-13, 14

Intake Port Swirl Actuator................ 8W-15-3

Intrusion Transceiver Module.......... 8W-15-21, 22

Junction Block.................. 8W-15-12, 13, 15

Left Fog Lamp...................... 8W-15-6, 7

Left Front Park Lamp................... 8W-15-5

Left Front Park/Turn Signal Lamp.......... 8W-15-5

Left Front Turn Signal Lamp.............. 8W-15-5

Left Headlamp Leveling Motor............. 8W-15-5

Left High Beam Headlamp................ 8W-15-5

Component Page

Left Liftgate Ajar Switch................ 8W-15-20

Left Low Beam Headlamp................ 8W-15-5

Left Multi-Function Switch............... 8W-15-15

Left Rear Door Lock Motor/Ajar Switch.... 8W-15-21, 22

Left Rear Lamp Assembly............... 8W-15-19

Left Side Repeater Lamp............... 8W-15-6, 7

License Lamp No. 1.................... 8W-15-20

License Lamp No. 2.................... 8W-15-20

Liftgate Flip-Up Ajar Switch.............. 8W-15-20

Liftgate Flip-Up Release Solenoid.......... 8W-15-20

Line Pressure Sensor.................... 8W-15-2

Low Beam/Daytime Running Lamp Relay.... 8W-15-12

Manual Temperature Control........... 8W-15-13, 15

Oxygen Sensor 1/2 Downstream............ 8W-15-4

Oxygen Sensor 2/2 Downstream............ 8W-15-4

Park Lamp Relay..................... 8W-15-12

Passenger Door Lock Motor/Ajar Switch...... 8W-15-16

Passenger Door Module................. 8W-15-16

Passenger Heated Seat Switch............ 8W-15-14

Passenger Lumbar Switch............. 8W-15-17, 22

Passenger Power Seat Switch.......... 8W-15-17, 22

Passenger Rear Power Window Switch.... 8W-15-16, 22

Power Amplifier.................... 8W-15-17, 18

Power Connector...................... 8W-15-15

Powertrain Control Module............... 8W-15-2

Radio........................... 8W-15-17, 18

Rain Sensor....................... 8W-15-21, 22

Rear Power Outlet.................. 8W-15-17, 18

Rear Washer Pump................... 8W-15-6, 7

Rear Window Defogger.................. 8W-15-20

Rear Wiper Motor..................... 8W-15-20

Remote Keyless Module................. 8W-15-16

Right Fog Lamp.................. 8W-15-9, 10, 11

Right Front Park Lamp.................. 8W-15-8

Right Front Park/Turn Signal Lamp......... 8W-15-8

Right Front Turn Signal Lamp............. 8W-15-8

Right Headlamp Leveling Motor............ 8W-15-8

Right High Beam Headlamp............... 8W-15-8

Right Low Beam Headlamp............... 8W-15-8

Right Rear Door Lock Motor/Ajar Switch . . 8W-15-16, 18

Right Rear Lamp Assembly............ 8W-15-17, 18

Right Side Repeater Lamp........... 8W-15-9, 10, 11

Seat Module...................... 8W-15-18, 21

Sentry Key Immobilizer Module........... 8W-15-13

Shifter Assembly................... 8W-15-14, 15

Siren............................. 8W-15-6, 7

Sunroof Control Module................. 8W-15-19

Sunroof Motor........................ 8W-15-19

Sunroof Switch....................... 8W-15-19

Temperature Valve Actuator.............. 8W-15-13

Trailer Tow Brake Lamp Relay............ 8W-15-19

Trailer Tow Connector.................. 8W-15-19

Trailer Tow Left Turn Relay.............. 8W-15-19

Trailer Tow Right Turn Relay............. 8W-15-19

Transmission Control Module.............. 8W-15-2

Transmission Control Relay............ 8W-15-9, 10

Underhood Lamp..................... 8W-15-6, 7

Vehicle Information Center............ 8W-15-21, 22

Viscous/Cabin Heater................... 8W-15-4

Washer Fluid Level Switch.............. 8W-15-6, 7

WJ8W-15 GROUND DISTRIBUTION 8W - 15 - 1