ECU JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1971 of 2199

SYMPTOM STEP POSSIBLE CAUSE

2 Check mechanism for binding (result of forcing the glass closed/

broken components).

3 See motor inoperative above.

Sunroof9rattles9, anytime,

closed/open.1 Loose attachment screws (module), re-fasten and adjust module.

2 Loose glass panel, re-fasten and adjust glass panel.

3 Loose drain channel, refasten/secure to repair.

4 Broken mechanism, replace the sunroof assembly module.

5 Mechanism not fully closed.

A) Motor out of time, re-time motor/mechanism. Refer to glass

panel adjustments in this section.

B) Cable ratcheting, replace cables and motor bracket.

6 Check for sunshade out of track or for sunshade broken slide

block.

7 Loose wind deflector. Replace if broken.

8 Loose wind deflector spring. Replace if loose.

Sunshade squeaks/rattles,

anytime.1 Sunshade slide blocks out of track(s), put back in tracks.

-OR- 2 Missing felt pads on the drain channel, add felt pads.

Sunshade force high/low or

binding during operation.3 Felt on the drain channel rolling off, (sunshade rubs on adhesive),

replace felt pads.

4 Slide block binding in sunshade, free-up slide block by actuating a

couple times, grease slide block(s) and spring(s).

5 Broken slide block in sunshade, replace slide block.

6 Slide block spring missing, replace spring and slide block.

7 Sunshade interference with drain channel or trim welt, replace trim

welt and/or sunshade.

Motor/sunroof control module

operation: Auto open doesn't

work, or doesn't stop at closed

position.1 After power disconnect or replacement, sunroof module has to

complete on full cycle to program the sunroof control module. Full

cycle = close > open > close > vent > close.

23 - 98 SUNROOFWJ

SUNROOF (Continued)

Page 1973 of 2199

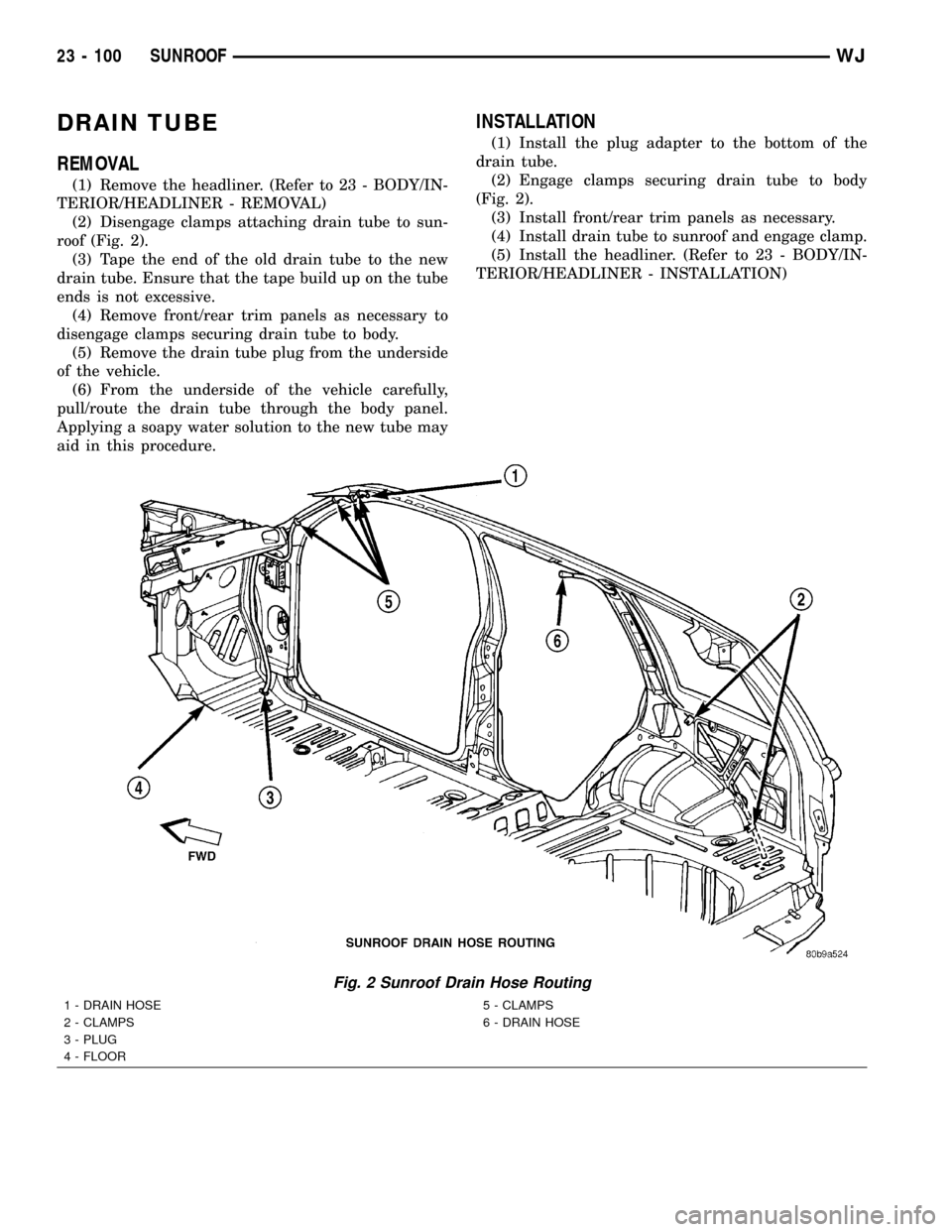

DRAIN TUBE

REMOVAL

(1) Remove the headliner. (Refer to 23 - BODY/IN-

TERIOR/HEADLINER - REMOVAL)

(2) Disengage clamps attaching drain tube to sun-

roof (Fig. 2).

(3) Tape the end of the old drain tube to the new

drain tube. Ensure that the tape build up on the tube

ends is not excessive.

(4) Remove front/rear trim panels as necessary to

disengage clamps securing drain tube to body.

(5) Remove the drain tube plug from the underside

of the vehicle.

(6) From the underside of the vehicle carefully,

pull/route the drain tube through the body panel.

Applying a soapy water solution to the new tube may

aid in this procedure.

INSTALLATION

(1) Install the plug adapter to the bottom of the

drain tube.

(2) Engage clamps securing drain tube to body

(Fig. 2).

(3) Install front/rear trim panels as necessary.

(4) Install drain tube to sunroof and engage clamp.

(5) Install the headliner. (Refer to 23 - BODY/IN-

TERIOR/HEADLINER - INSTALLATION)

Fig. 2 Sunroof Drain Hose Routing

1 - DRAIN HOSE

2 - CLAMPS

3 - PLUG

4 - FLOOR5 - CLAMPS

6 - DRAIN HOSE

23 - 100 SUNROOFWJ

Page 2090 of 2199

A/C COMPRESSOR CLUTCH

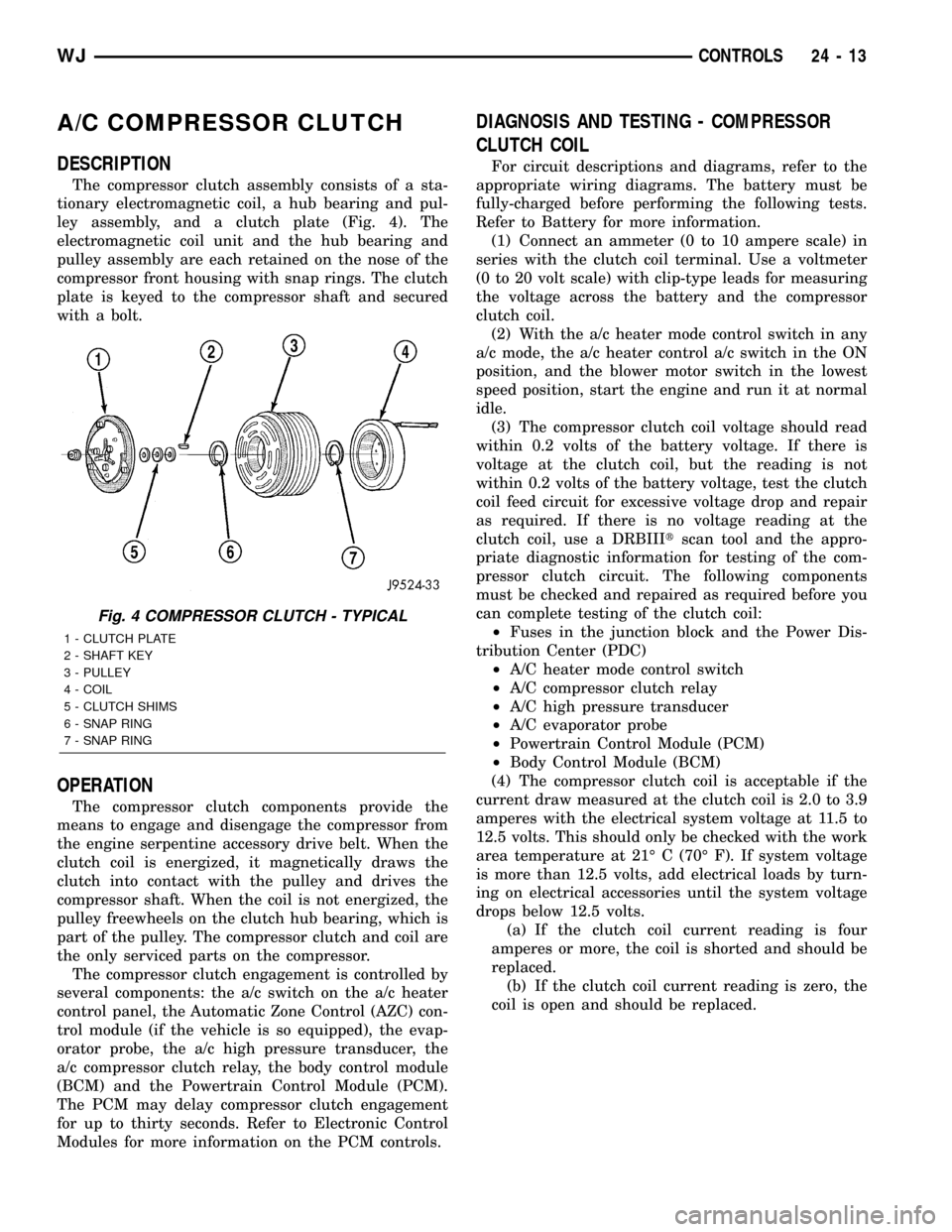

DESCRIPTION

The compressor clutch assembly consists of a sta-

tionary electromagnetic coil, a hub bearing and pul-

ley assembly, and a clutch plate (Fig. 4). The

electromagnetic coil unit and the hub bearing and

pulley assembly are each retained on the nose of the

compressor front housing with snap rings. The clutch

plate is keyed to the compressor shaft and secured

with a bolt.

OPERATION

The compressor clutch components provide the

means to engage and disengage the compressor from

the engine serpentine accessory drive belt. When the

clutch coil is energized, it magnetically draws the

clutch into contact with the pulley and drives the

compressor shaft. When the coil is not energized, the

pulley freewheels on the clutch hub bearing, which is

part of the pulley. The compressor clutch and coil are

the only serviced parts on the compressor.

The compressor clutch engagement is controlled by

several components: the a/c switch on the a/c heater

control panel, the Automatic Zone Control (AZC) con-

trol module (if the vehicle is so equipped), the evap-

orator probe, the a/c high pressure transducer, the

a/c compressor clutch relay, the body control module

(BCM) and the Powertrain Control Module (PCM).

The PCM may delay compressor clutch engagement

for up to thirty seconds. Refer to Electronic Control

Modules for more information on the PCM controls.

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH COIL

For circuit descriptions and diagrams, refer to the

appropriate wiring diagrams. The battery must be

fully-charged before performing the following tests.

Refer to Battery for more information.

(1) Connect an ammeter (0 to 10 ampere scale) in

series with the clutch coil terminal. Use a voltmeter

(0 to 20 volt scale) with clip-type leads for measuring

the voltage across the battery and the compressor

clutch coil.

(2) With the a/c heater mode control switch in any

a/c mode, the a/c heater control a/c switch in the ON

position, and the blower motor switch in the lowest

speed position, start the engine and run it at normal

idle.

(3) The compressor clutch coil voltage should read

within 0.2 volts of the battery voltage. If there is

voltage at the clutch coil, but the reading is not

within 0.2 volts of the battery voltage, test the clutch

coil feed circuit for excessive voltage drop and repair

as required. If there is no voltage reading at the

clutch coil, use a DRBIIItscan tool and the appro-

priate diagnostic information for testing of the com-

pressor clutch circuit. The following components

must be checked and repaired as required before you

can complete testing of the clutch coil:

²Fuses in the junction block and the Power Dis-

tribution Center (PDC)

²A/C heater mode control switch

²A/C compressor clutch relay

²A/C high pressure transducer

²A/C evaporator probe

²Powertrain Control Module (PCM)

²Body Control Module (BCM)

(4) The compressor clutch coil is acceptable if the

current draw measured at the clutch coil is 2.0 to 3.9

amperes with the electrical system voltage at 11.5 to

12.5 volts. This should only be checked with the work

area temperature at 21É C (70É F). If system voltage

is more than 12.5 volts, add electrical loads by turn-

ing on electrical accessories until the system voltage

drops below 12.5 volts.

(a) If the clutch coil current reading is four

amperes or more, the coil is shorted and should be

replaced.

(b) If the clutch coil current reading is zero, the

coil is open and should be replaced.

Fig. 4 COMPRESSOR CLUTCH - TYPICAL

1 - CLUTCH PLATE

2 - SHAFT KEY

3 - PULLEY

4 - COIL

5 - CLUTCH SHIMS

6 - SNAP RING

7 - SNAP RING

WJCONTROLS 24 - 13

Page 2091 of 2199

STANDARD PROCEDURE - COMPRESSOR

CLUTCH BREAK-IN

After a new compressor clutch has been installed,

cycle the compressor clutch approximately twenty

times (five seconds on, then five seconds off). During

this procedure, set the A/C Heater control in the

Recirculation Mode, the A/C button in the on posi-

tion, the blower motor switch in the highest speed

position, and the engine speed at 1500 to 2000 rpm.

This procedure (burnishing) will seat the opposing

friction surfaces and provide a higher compressor

clutch torque capability.

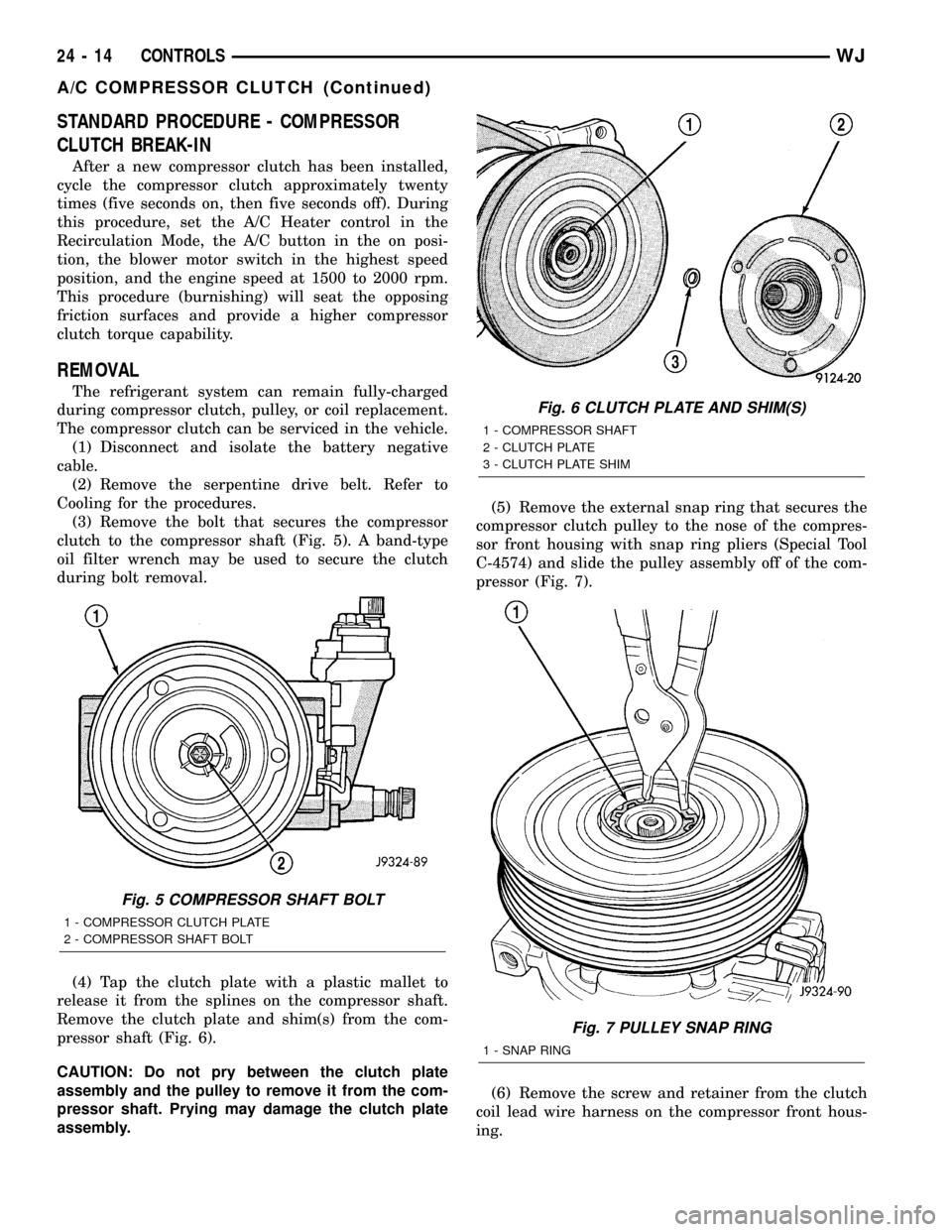

REMOVAL

The refrigerant system can remain fully-charged

during compressor clutch, pulley, or coil replacement.

The compressor clutch can be serviced in the vehicle.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the serpentine drive belt. Refer to

Cooling for the procedures.

(3) Remove the bolt that secures the compressor

clutch to the compressor shaft (Fig. 5). A band-type

oil filter wrench may be used to secure the clutch

during bolt removal.

(4) Tap the clutch plate with a plastic mallet to

release it from the splines on the compressor shaft.

Remove the clutch plate and shim(s) from the com-

pressor shaft (Fig. 6).

CAUTION: Do not pry between the clutch plate

assembly and the pulley to remove it from the com-

pressor shaft. Prying may damage the clutch plate

assembly.(5) Remove the external snap ring that secures the

compressor clutch pulley to the nose of the compres-

sor front housing with snap ring pliers (Special Tool

C-4574) and slide the pulley assembly off of the com-

pressor (Fig. 7).

(6) Remove the screw and retainer from the clutch

coil lead wire harness on the compressor front hous-

ing.

Fig. 5 COMPRESSOR SHAFT BOLT

1 - COMPRESSOR CLUTCH PLATE

2 - COMPRESSOR SHAFT BOLT

Fig. 6 CLUTCH PLATE AND SHIM(S)

1 - COMPRESSOR SHAFT

2 - CLUTCH PLATE

3 - CLUTCH PLATE SHIM

Fig. 7 PULLEY SNAP RING

1 - SNAP RING

24 - 14 CONTROLSWJ

A/C COMPRESSOR CLUTCH (Continued)

Page 2092 of 2199

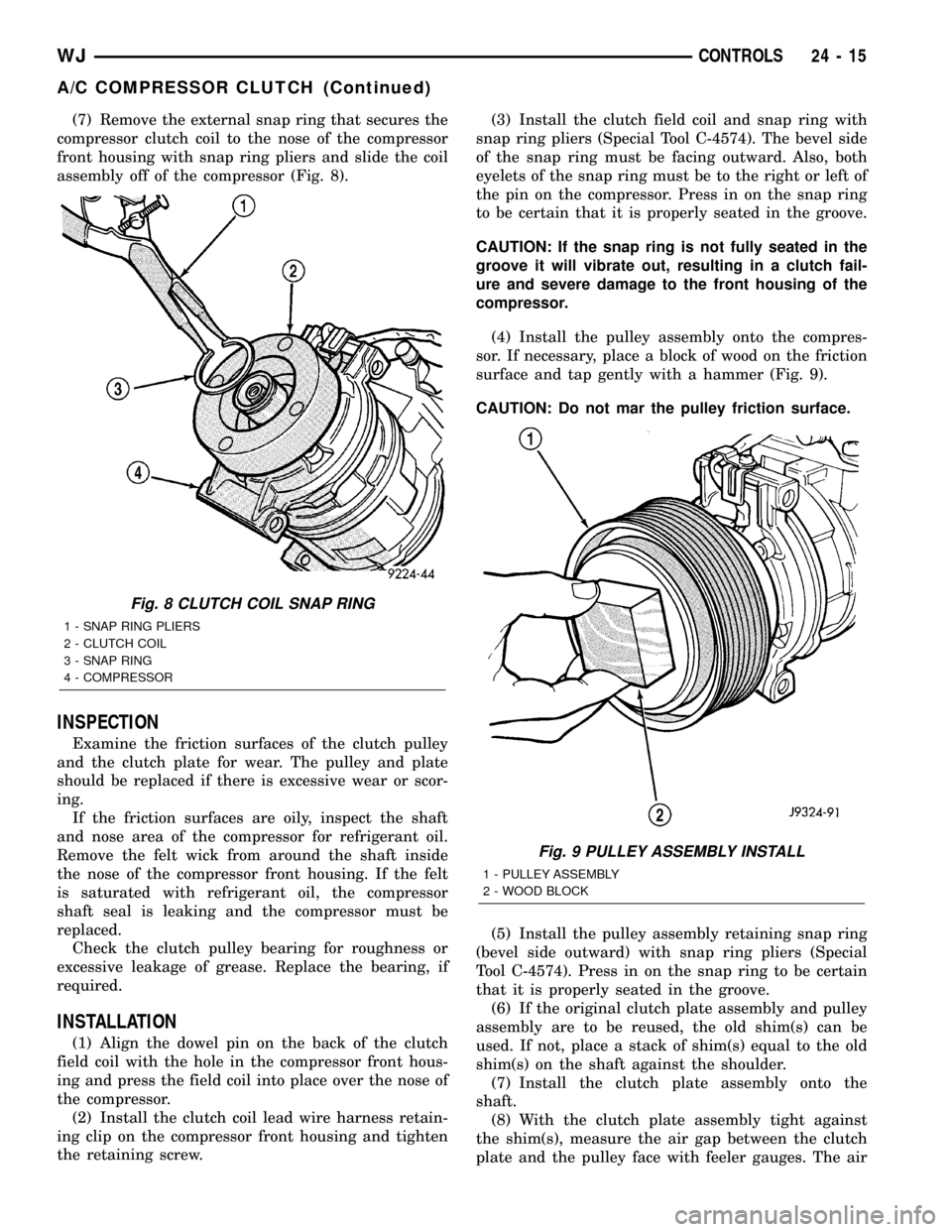

(7) Remove the external snap ring that secures the

compressor clutch coil to the nose of the compressor

front housing with snap ring pliers and slide the coil

assembly off of the compressor (Fig. 8).

INSPECTION

Examine the friction surfaces of the clutch pulley

and the clutch plate for wear. The pulley and plate

should be replaced if there is excessive wear or scor-

ing.

If the friction surfaces are oily, inspect the shaft

and nose area of the compressor for refrigerant oil.

Remove the felt wick from around the shaft inside

the nose of the compressor front housing. If the felt

is saturated with refrigerant oil, the compressor

shaft seal is leaking and the compressor must be

replaced.

Check the clutch pulley bearing for roughness or

excessive leakage of grease. Replace the bearing, if

required.

INSTALLATION

(1) Align the dowel pin on the back of the clutch

field coil with the hole in the compressor front hous-

ing and press the field coil into place over the nose of

the compressor.

(2) Install the clutch coil lead wire harness retain-

ing clip on the compressor front housing and tighten

the retaining screw.(3) Install the clutch field coil and snap ring with

snap ring pliers (Special Tool C-4574). The bevel side

of the snap ring must be facing outward. Also, both

eyelets of the snap ring must be to the right or left of

the pin on the compressor. Press in on the snap ring

to be certain that it is properly seated in the groove.

CAUTION: If the snap ring is not fully seated in the

groove it will vibrate out, resulting in a clutch fail-

ure and severe damage to the front housing of the

compressor.

(4) Install the pulley assembly onto the compres-

sor. If necessary, place a block of wood on the friction

surface and tap gently with a hammer (Fig. 9).

CAUTION: Do not mar the pulley friction surface.

(5) Install the pulley assembly retaining snap ring

(bevel side outward) with snap ring pliers (Special

Tool C-4574). Press in on the snap ring to be certain

that it is properly seated in the groove.

(6) If the original clutch plate assembly and pulley

assembly are to be reused, the old shim(s) can be

used. If not, place a stack of shim(s) equal to the old

shim(s) on the shaft against the shoulder.

(7) Install the clutch plate assembly onto the

shaft.

(8) With the clutch plate assembly tight against

the shim(s), measure the air gap between the clutch

plate and the pulley face with feeler gauges. The air

Fig. 8 CLUTCH COIL SNAP RING

1 - SNAP RING PLIERS

2 - CLUTCH COIL

3 - SNAP RING

4 - COMPRESSOR

Fig. 9 PULLEY ASSEMBLY INSTALL

1 - PULLEY ASSEMBLY

2 - WOOD BLOCK

WJCONTROLS 24 - 15

A/C COMPRESSOR CLUTCH (Continued)

Page 2101 of 2199

AIR INLET POINTER

63 Engine Intake Air Temperature

(in degrees F)-40 to

215

64 Vehicle speed in MPH 0 to 255

65 Engine RPM/100 -0 to 82

66 Engine Coolant Temp - 40 (in

degrees F)-40 to

215

67 Country Code 0 to 255

68 Not used 0 to 0

69 Not used 0 to 0

IR SENSOR POINTER

Pointer

NumberDESCRIPTION Value

Displayed

70 Thermistor temp (in degrees) -40 to

215

71 Left side sensor A/D (filtered) 0 to 255

72 Right side sensor A/D (filtered) 0 to 255

73 Left side temp (in degrees F) -40 to

140

74 Right side temp (in degrees F) -40 to

140

75 Not used 0 to 0

76 Not used 0 to 0

77 Not used 0 to 0

78 Not used 0 to 0

79 Not used 0 to 0

IDENTIFICATION POINTER

Pointer

NumberDESCRIPTION Value

Displayed

80 ROM bit pattern number (digits

1,2,3 & 4)0to

9999

81 ROM bit pattern number (digits

5,6,7 & 8)0to

9999

82 CAL bit pattern number (digits

1,2,3 & 4)0to

9999

83 CAL bit pattern number (digits

5,6,7 & 8)0to

9999

84 Not used 0 to 0

85 Not used 0 to 0

86 Not used 0 to 0

87 Not used 0 to 0

88 Not used 0 to 0

89 Not used 0 to 0

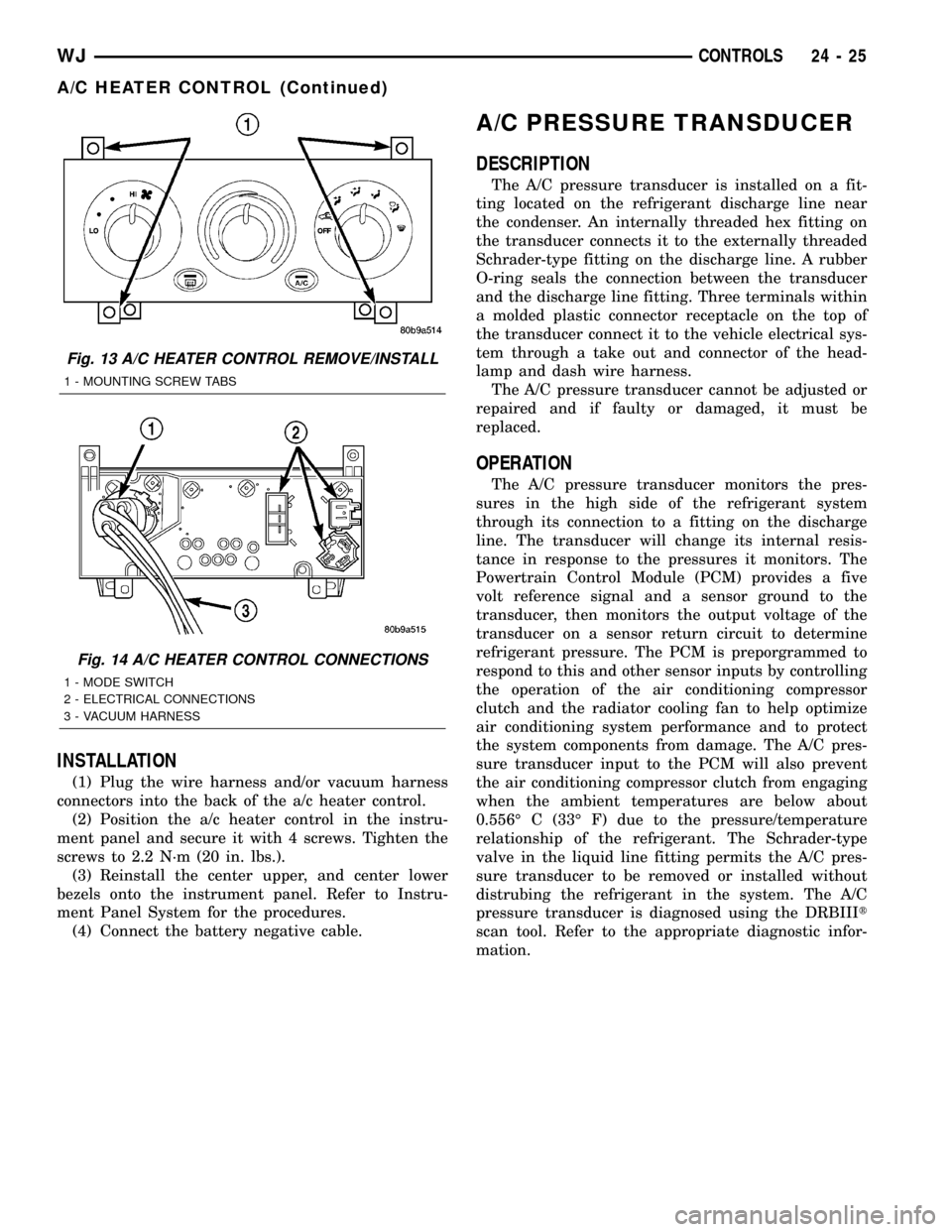

OUTPUT CIRCUIT/ACTUATOR TESTS

In the Output Circuit/Actuator Test mode, the out-

put circuits can be viewed, monitored, overridden,

and tested. If a failure occurs in an output circuit,

test the circuit by overriding the system. Test the

actuator through its full range of operation.

(1) To begin the Output Circuit/Actuator Tests you

must be in the Select Test mode.

(2) With a ª00º value displayed in the Test Selector

and no stick man, turn the rotary temperature con-

trol knob until the test number you are looking for

appears in the Test Selector display. See the Circuit

Testing charts for a listing of the test numbers, test

items, test types, system tested, and displayed val-

ues.

(3) To see the output value, depress the a/c or

recirc button. The values displayed will represent the

output from the AZC control module.

(4) To enter the actuator test, depress the a/c or

recirc button. Then, rotate the right temperature set

knob to the desired position.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

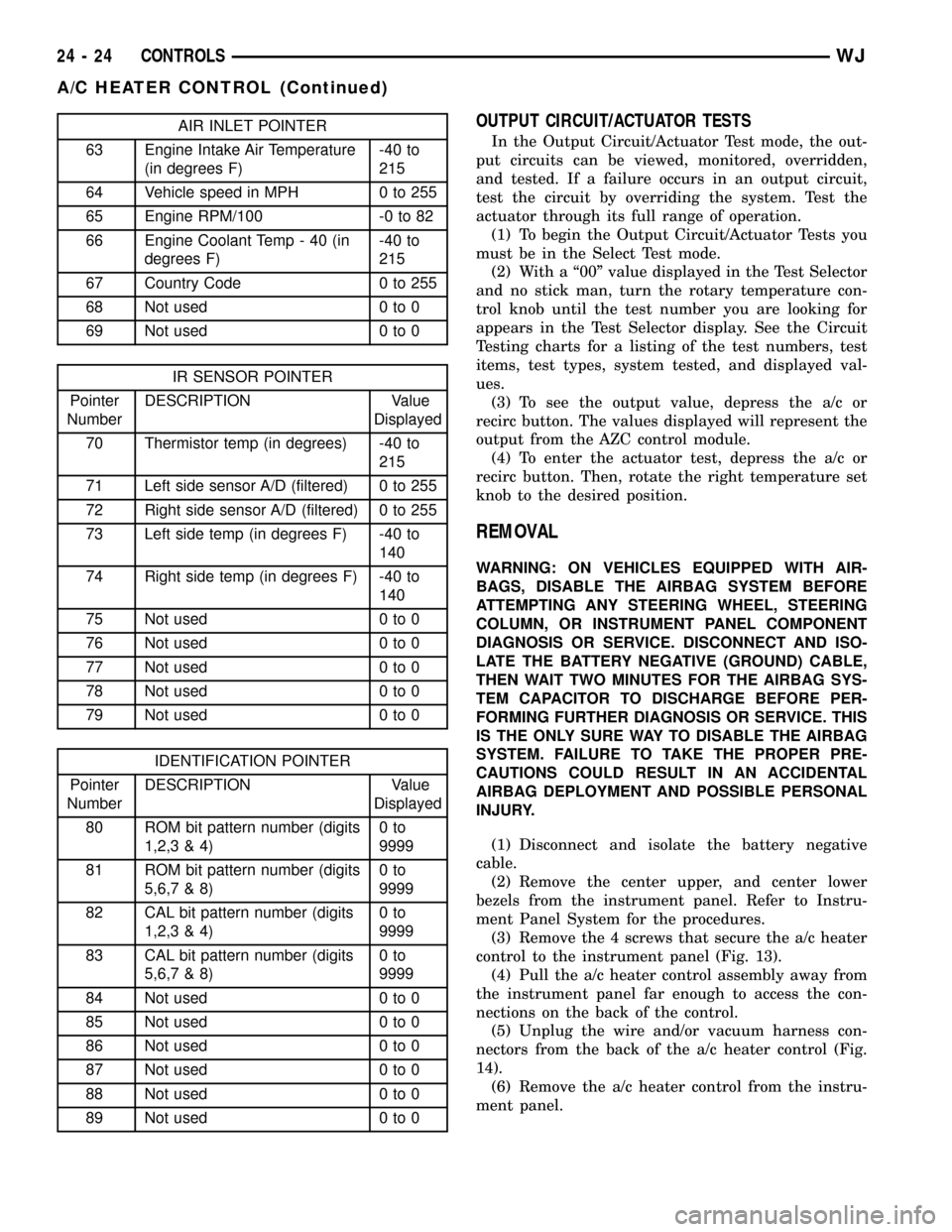

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the center upper, and center lower

bezels from the instrument panel. Refer to Instru-

ment Panel System for the procedures.

(3) Remove the 4 screws that secure the a/c heater

control to the instrument panel (Fig. 13).

(4) Pull the a/c heater control assembly away from

the instrument panel far enough to access the con-

nections on the back of the control.

(5) Unplug the wire and/or vacuum harness con-

nectors from the back of the a/c heater control (Fig.

14).

(6) Remove the a/c heater control from the instru-

ment panel.

24 - 24 CONTROLSWJ

A/C HEATER CONTROL (Continued)

Page 2102 of 2199

INSTALLATION

(1) Plug the wire harness and/or vacuum harness

connectors into the back of the a/c heater control.

(2) Position the a/c heater control in the instru-

ment panel and secure it with 4 screws. Tighten the

screws to 2.2 N´m (20 in. lbs.).

(3) Reinstall the center upper, and center lower

bezels onto the instrument panel. Refer to Instru-

ment Panel System for the procedures.

(4) Connect the battery negative cable.

A/C PRESSURE TRANSDUCER

DESCRIPTION

The A/C pressure transducer is installed on a fit-

ting located on the refrigerant discharge line near

the condenser. An internally threaded hex fitting on

the transducer connects it to the externally threaded

Schrader-type fitting on the discharge line. A rubber

O-ring seals the connection between the transducer

and the discharge line fitting. Three terminals within

a molded plastic connector receptacle on the top of

the transducer connect it to the vehicle electrical sys-

tem through a take out and connector of the head-

lamp and dash wire harness.

The A/C pressure transducer cannot be adjusted or

repaired and if faulty or damaged, it must be

replaced.

OPERATION

The A/C pressure transducer monitors the pres-

sures in the high side of the refrigerant system

through its connection to a fitting on the discharge

line. The transducer will change its internal resis-

tance in response to the pressures it monitors. The

Powertrain Control Module (PCM) provides a five

volt reference signal and a sensor ground to the

transducer, then monitors the output voltage of the

transducer on a sensor return circuit to determine

refrigerant pressure. The PCM is preporgrammed to

respond to this and other sensor inputs by controlling

the operation of the air conditioning compressor

clutch and the radiator cooling fan to help optimize

air conditioning system performance and to protect

the system components from damage. The A/C pres-

sure transducer input to the PCM will also prevent

the air conditioning compressor clutch from engaging

when the ambient temperatures are below about

0.556É C (33É F) due to the pressure/temperature

relationship of the refrigerant. The Schrader-type

valve in the liquid line fitting permits the A/C pres-

sure transducer to be removed or installed without

distrubing the refrigerant in the system. The A/C

pressure transducer is diagnosed using the DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation.

Fig. 13 A/C HEATER CONTROL REMOVE/INSTALL

1 - MOUNTING SCREW TABS

Fig. 14 A/C HEATER CONTROL CONNECTIONS

1 - MODE SWITCH

2 - ELECTRICAL CONNECTIONS

3 - VACUUM HARNESS

WJCONTROLS 24 - 25

A/C HEATER CONTROL (Continued)

Page 2104 of 2199

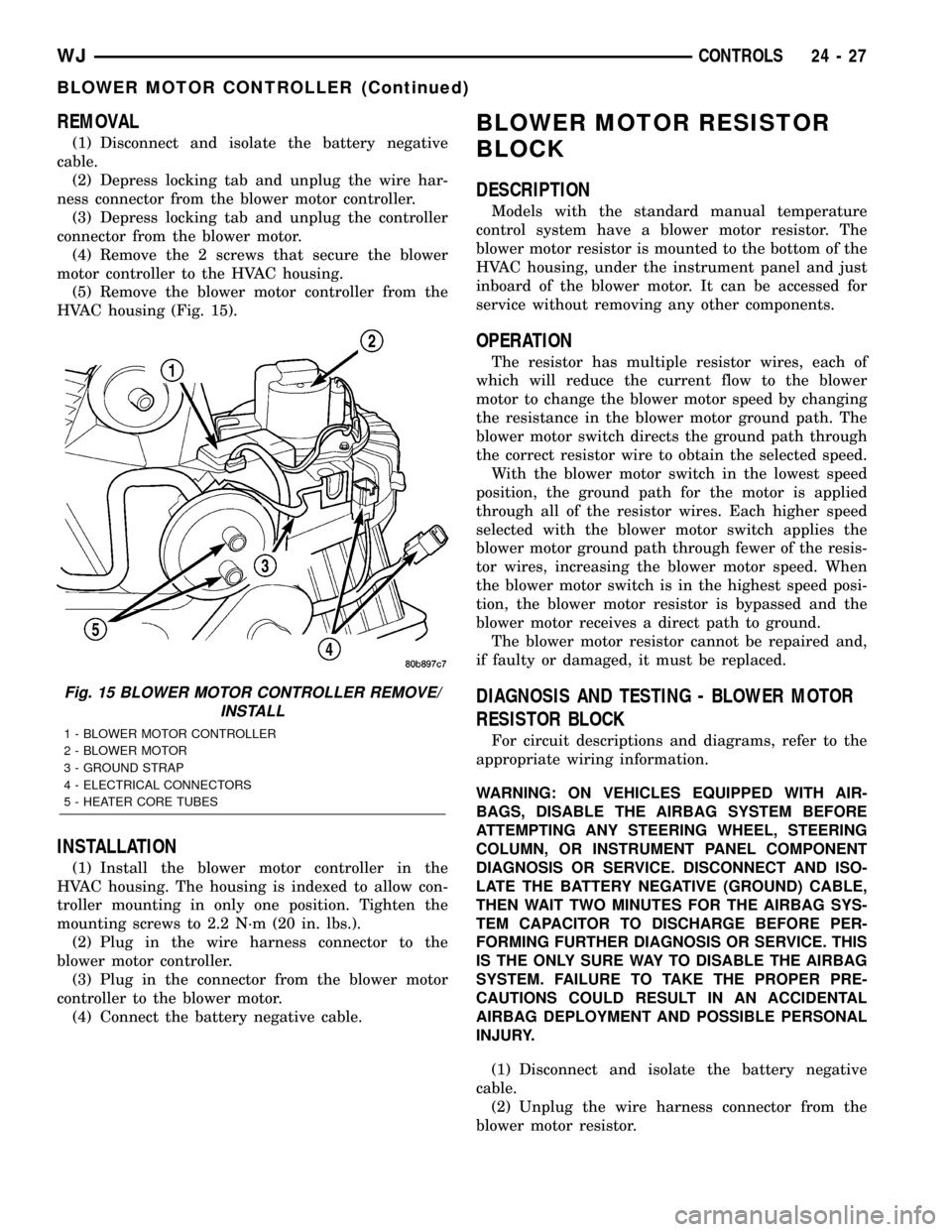

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Depress locking tab and unplug the wire har-

ness connector from the blower motor controller.

(3) Depress locking tab and unplug the controller

connector from the blower motor.

(4) Remove the 2 screws that secure the blower

motor controller to the HVAC housing.

(5) Remove the blower motor controller from the

HVAC housing (Fig. 15).

INSTALLATION

(1) Install the blower motor controller in the

HVAC housing. The housing is indexed to allow con-

troller mounting in only one position. Tighten the

mounting screws to 2.2 N´m (20 in. lbs.).

(2) Plug in the wire harness connector to the

blower motor controller.

(3) Plug in the connector from the blower motor

controller to the blower motor.

(4) Connect the battery negative cable.

BLOWER MOTOR RESISTOR

BLOCK

DESCRIPTION

Models with the standard manual temperature

control system have a blower motor resistor. The

blower motor resistor is mounted to the bottom of the

HVAC housing, under the instrument panel and just

inboard of the blower motor. It can be accessed for

service without removing any other components.

OPERATION

The resistor has multiple resistor wires, each of

which will reduce the current flow to the blower

motor to change the blower motor speed by changing

the resistance in the blower motor ground path. The

blower motor switch directs the ground path through

the correct resistor wire to obtain the selected speed.

With the blower motor switch in the lowest speed

position, the ground path for the motor is applied

through all of the resistor wires. Each higher speed

selected with the blower motor switch applies the

blower motor ground path through fewer of the resis-

tor wires, increasing the blower motor speed. When

the blower motor switch is in the highest speed posi-

tion, the blower motor resistor is bypassed and the

blower motor receives a direct path to ground.

The blower motor resistor cannot be repaired and,

if faulty or damaged, it must be replaced.

DIAGNOSIS AND TESTING - BLOWER MOTOR

RESISTOR BLOCK

For circuit descriptions and diagrams, refer to the

appropriate wiring information.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Unplug the wire harness connector from the

blower motor resistor.

Fig. 15 BLOWER MOTOR CONTROLLER REMOVE/

INSTALL

1 - BLOWER MOTOR CONTROLLER

2 - BLOWER MOTOR

3 - GROUND STRAP

4 - ELECTRICAL CONNECTORS

5 - HEATER CORE TUBES

WJCONTROLS 24 - 27

BLOWER MOTOR CONTROLLER (Continued)

Page 2105 of 2199

(3) Check for continuity between each of the

blower motor switch input terminals of the resistor

and the resistor output terminal. In each case there

should be continuity. If OK, repair the wire harness

circuits between the blower motor switch and the

blower motor resistor or blower motor as required. If

not OK, replace the faulty blower motor resistor.

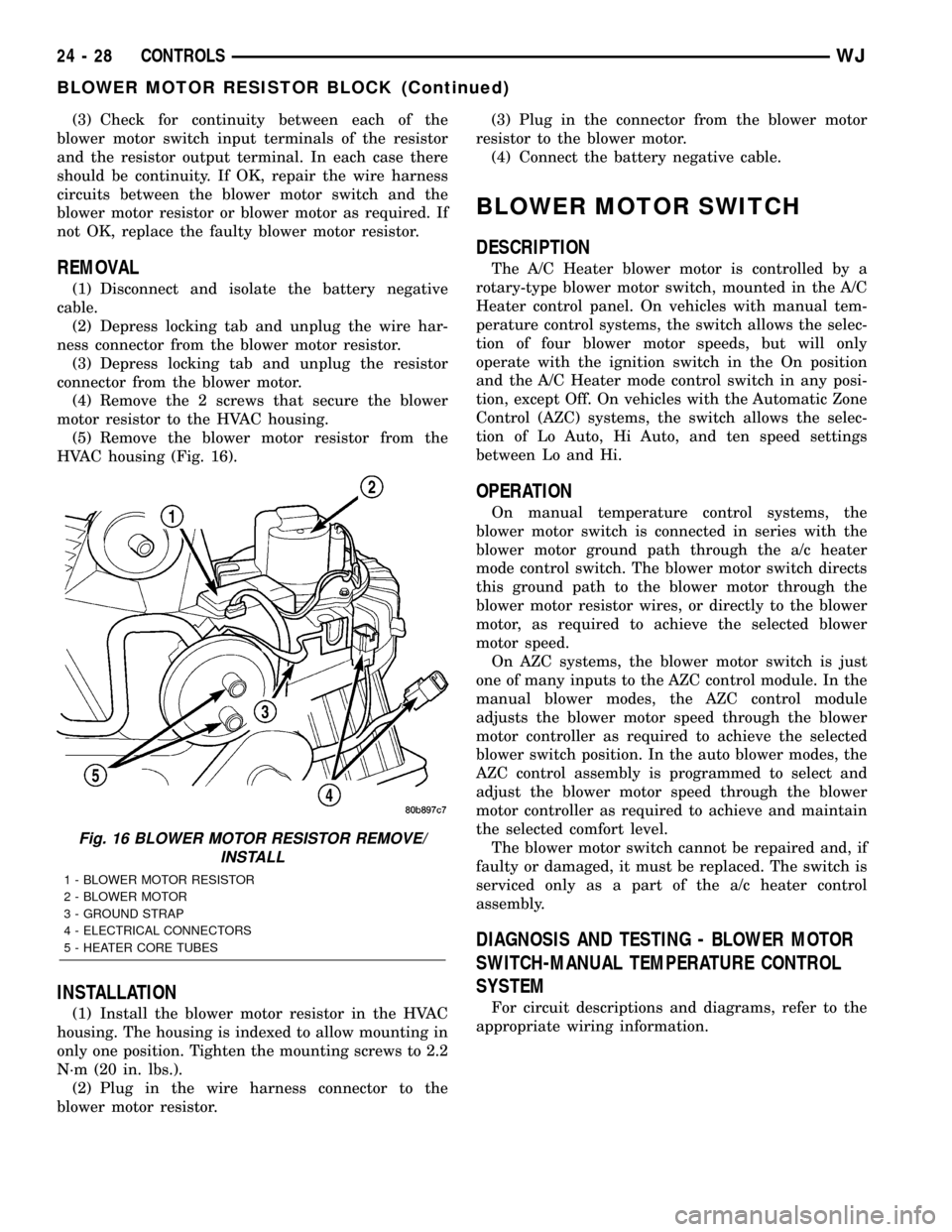

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Depress locking tab and unplug the wire har-

ness connector from the blower motor resistor.

(3) Depress locking tab and unplug the resistor

connector from the blower motor.

(4) Remove the 2 screws that secure the blower

motor resistor to the HVAC housing.

(5) Remove the blower motor resistor from the

HVAC housing (Fig. 16).

INSTALLATION

(1) Install the blower motor resistor in the HVAC

housing. The housing is indexed to allow mounting in

only one position. Tighten the mounting screws to 2.2

N´m (20 in. lbs.).

(2) Plug in the wire harness connector to the

blower motor resistor.(3) Plug in the connector from the blower motor

resistor to the blower motor.

(4) Connect the battery negative cable.

BLOWER MOTOR SWITCH

DESCRIPTION

The A/C Heater blower motor is controlled by a

rotary-type blower motor switch, mounted in the A/C

Heater control panel. On vehicles with manual tem-

perature control systems, the switch allows the selec-

tion of four blower motor speeds, but will only

operate with the ignition switch in the On position

and the A/C Heater mode control switch in any posi-

tion, except Off. On vehicles with the Automatic Zone

Control (AZC) systems, the switch allows the selec-

tion of Lo Auto, Hi Auto, and ten speed settings

between Lo and Hi.

OPERATION

On manual temperature control systems, the

blower motor switch is connected in series with the

blower motor ground path through the a/c heater

mode control switch. The blower motor switch directs

this ground path to the blower motor through the

blower motor resistor wires, or directly to the blower

motor, as required to achieve the selected blower

motor speed.

On AZC systems, the blower motor switch is just

one of many inputs to the AZC control module. In the

manual blower modes, the AZC control module

adjusts the blower motor speed through the blower

motor controller as required to achieve the selected

blower switch position. In the auto blower modes, the

AZC control assembly is programmed to select and

adjust the blower motor speed through the blower

motor controller as required to achieve and maintain

the selected comfort level.

The blower motor switch cannot be repaired and, if

faulty or damaged, it must be replaced. The switch is

serviced only as a part of the a/c heater control

assembly.

DIAGNOSIS AND TESTING - BLOWER MOTOR

SWITCH-MANUAL TEMPERATURE CONTROL

SYSTEM

For circuit descriptions and diagrams, refer to the

appropriate wiring information.

Fig. 16 BLOWER MOTOR RESISTOR REMOVE/

INSTALL

1 - BLOWER MOTOR RESISTOR

2 - BLOWER MOTOR

3 - GROUND STRAP

4 - ELECTRICAL CONNECTORS

5 - HEATER CORE TUBES

24 - 28 CONTROLSWJ

BLOWER MOTOR RESISTOR BLOCK (Continued)

Page 2107 of 2199

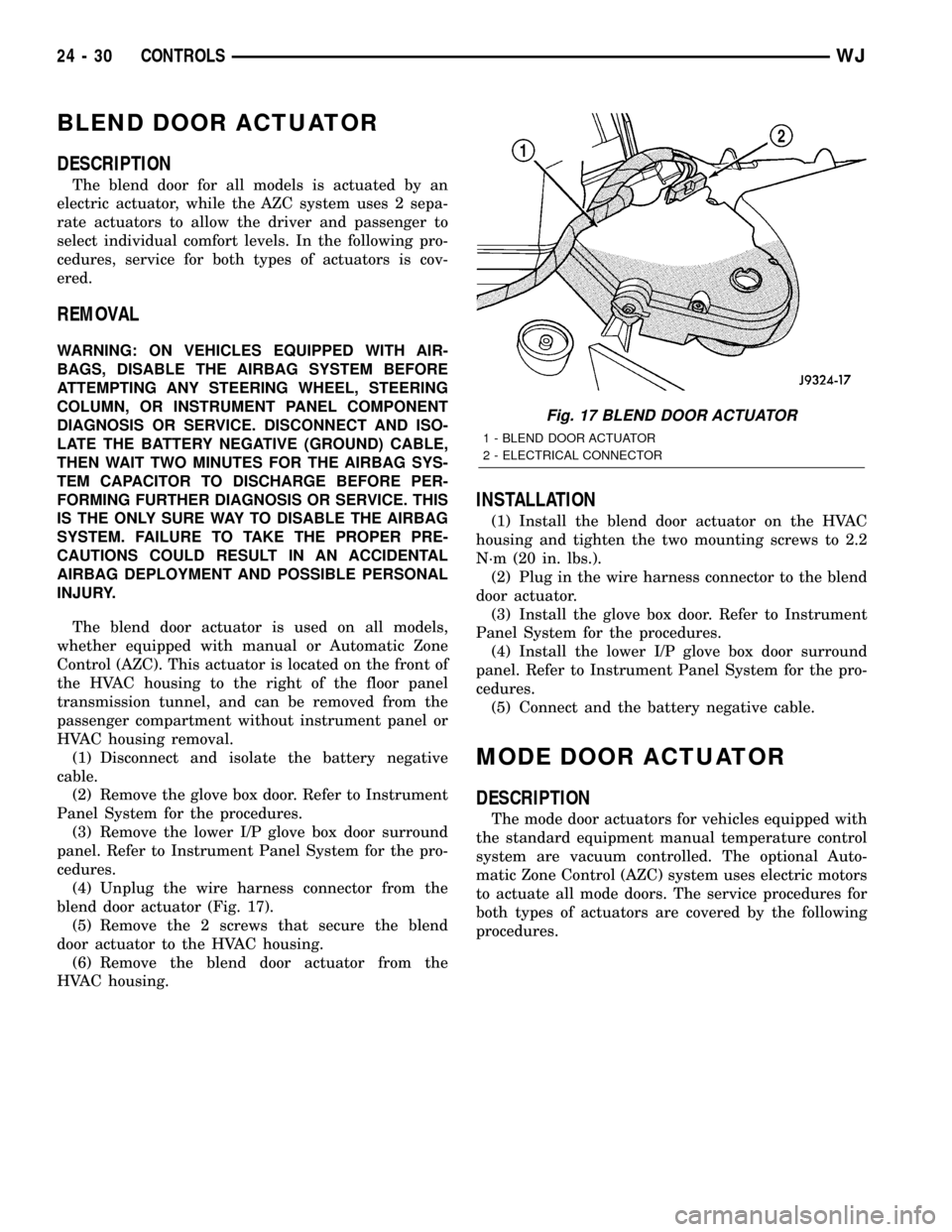

BLEND DOOR ACTUATOR

DESCRIPTION

The blend door for all models is actuated by an

electric actuator, while the AZC system uses 2 sepa-

rate actuators to allow the driver and passenger to

select individual comfort levels. In the following pro-

cedures, service for both types of actuators is cov-

ered.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The blend door actuator is used on all models,

whether equipped with manual or Automatic Zone

Control (AZC). This actuator is located on the front of

the HVAC housing to the right of the floor panel

transmission tunnel, and can be removed from the

passenger compartment without instrument panel or

HVAC housing removal.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the glove box door. Refer to Instrument

Panel System for the procedures.

(3) Remove the lower I/P glove box door surround

panel. Refer to Instrument Panel System for the pro-

cedures.

(4) Unplug the wire harness connector from the

blend door actuator (Fig. 17).

(5) Remove the 2 screws that secure the blend

door actuator to the HVAC housing.

(6) Remove the blend door actuator from the

HVAC housing.

INSTALLATION

(1) Install the blend door actuator on the HVAC

housing and tighten the two mounting screws to 2.2

N´m (20 in. lbs.).

(2) Plug in the wire harness connector to the blend

door actuator.

(3) Install the glove box door. Refer to Instrument

Panel System for the procedures.

(4) Install the lower I/P glove box door surround

panel. Refer to Instrument Panel System for the pro-

cedures.

(5) Connect and the battery negative cable.

MODE DOOR ACTUATOR

DESCRIPTION

The mode door actuators for vehicles equipped with

the standard equipment manual temperature control

system are vacuum controlled. The optional Auto-

matic Zone Control (AZC) system uses electric motors

to actuate all mode doors. The service procedures for

both types of actuators are covered by the following

procedures.

Fig. 17 BLEND DOOR ACTUATOR

1 - BLEND DOOR ACTUATOR

2 - ELECTRICAL CONNECTOR

24 - 30 CONTROLSWJ