wheel JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1870 of 2199

²Bent or dented

²Leak air through welds

²Have damaged bolt holes

Wheel repairs employing hammering, heating, or

welding are not allowed.

Original equipment wheels are available through

your dealer. Replacement wheels from any other

source should be equivalent in:

²Load carrying capacity

²Diameter

²Width²Offset

²Mounting configuration

Failure to use equivalent replacement wheels may

affect the safety and handling of your vehicle.

Replacement withusedwheels is not recommended.

Their service history may have included severe treat-

ment.

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Lug Nut

1/2 X 20 with 60É Cone115-150 85-115 Ð

STUDS

REMOVAL

CAUTION: Do not use a hammer to remove wheel

studs.

(1) Raise and support vehicle.

(2) Remove wheel and tire assembly.

(3) Remove brake caliper, caliper adapter and

rotor,(Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/ROTORS - REMOVAL).

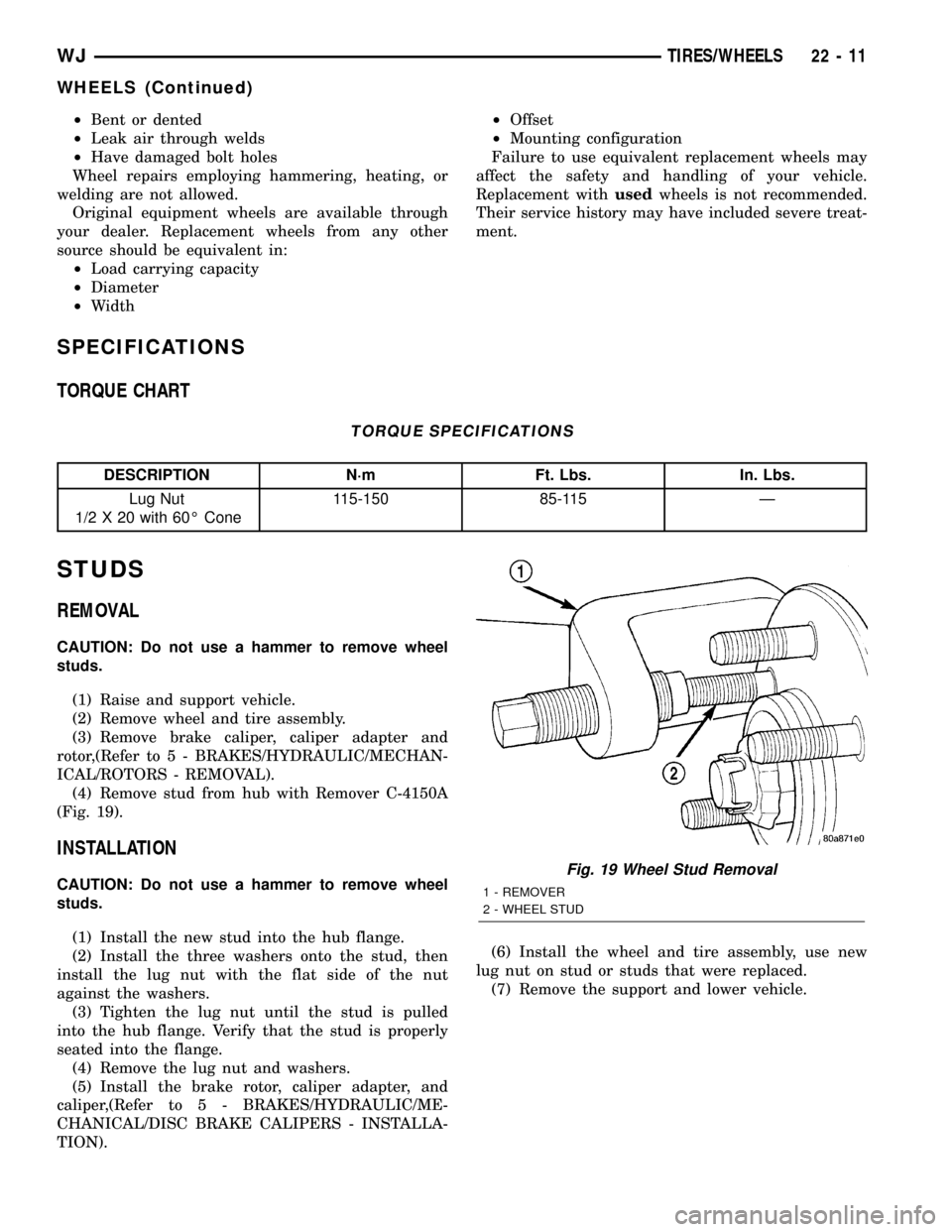

(4) Remove stud from hub with Remover C-4150A

(Fig. 19).

INSTALLATION

CAUTION: Do not use a hammer to remove wheel

studs.

(1) Install the new stud into the hub flange.

(2) Install the three washers onto the stud, then

install the lug nut with the flat side of the nut

against the washers.

(3) Tighten the lug nut until the stud is pulled

into the hub flange. Verify that the stud is properly

seated into the flange.

(4) Remove the lug nut and washers.

(5) Install the brake rotor, caliper adapter, and

caliper,(Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/DISC BRAKE CALIPERS - INSTALLA-

TION).(6) Install the wheel and tire assembly, use new

lug nut on stud or studs that were replaced.

(7) Remove the support and lower vehicle.Fig. 19 Wheel Stud Removal

1 - REMOVER

2 - WHEEL STUD

WJTIRES/WHEELS 22 - 11

WHEELS (Continued)

Page 1871 of 2199

TIRE PRESSURE MONITORING

DESCRIPTION

The EVIC will monitor the tire pressure signals

from the five tire sensors and determine if any tire

has gone below the low pressure threshold or raised

above the high pressure threshold. Refer to the table

below.

LOW TIRE PRESSURE THRESHOLDS

SYSTEM STATUS

INDICATORTIRE PRESSURE

ON 179 kPa (26 PSI)

OFF 214 kPa (31 PSI)

HIGH TIRE PRESSURE THRESHOLDS

SYSTEM STATUS

INDICATORTIRE PRESSURE

ON 310 kPa (45 PSI)

OFF 276 kPa (40 PSI)

The Remote Tire Pressure Monitors (RTPM) are

not internally serviceable. For a Sensor Failure or

Low Battery fault, the RTPM must be replaced.

OPERATION

If equipped with the Tire Pressure Monitoring Sys-

tem, each of the vehicle's five wheels will have a

valve stem with a pressure sensor and radio trans-

mitter built in. Signals from the tire pressure sensors

are received and interpreted by the Electronic Vehi-

cle Information Center (EVIC). A sensor in a

mounted wheel will broadcast its detected pressure

once per minute when the vehicle is moving faster

than 40 km/h (25 mph). The spare tire sensor will

broadcast once every hour. Each sensor's broadcast is

uniquely coded so that the EVIC can determine loca-

tion. The individual tire pressures can be displayed

graphically on the EVIC

DIAGNOSIS AND TESTING - TIRE PRESSURE

MONITORING SYSTEM

All Tire Pressure Monitoring System Faults are

specific to one location. If a9BATTERY LOW9or

9SENSOR FAILURE9fault is detected, the location

will be displayed. The appropriate sensor/transmitter

can then be replaced. If a single sensor/transmitter

cannot be detected by the EVIC, replace that sensor

transmitter. If none of the sensors/transmitters can

be detected, refer to symptoms in the EVIC section.

For additional system description and diagnosis,

refer to Tire Pressure Monitoring in the Body Diag-

nostic manual.

SENSOR

REMOVAL - TIRE PRESSURE SENSOR/

TRANSMITTER

(1) Remove the tire/wheel from the vehicle.

CAUTION: When removing the stick on balancing

weights from the wheel, do not use an abrasive

cleaner or a cleaner which will damage the protec-

tive finish on the wheel.

(2) Remove the balancing weights from the wheel.

NOTE: The cap used on this valve stem contains an

O-ring seal to prevent contamination and moisture

from entering the valve stem. Retain this valve stem

cap for re-use. Do not substitute a regular valve

stem cap in its place.

(3) Remove the cap from the valve stem.

NOTE: The valve stem used on this vehicle is made

of aluminum and the core is nickel plated brass.

The original valve stem core must be reinstalled

and not substituted for a valve stem core made of a

different material. This is required to prevent corro-

sion in the valve stem caused by the different met-

als.

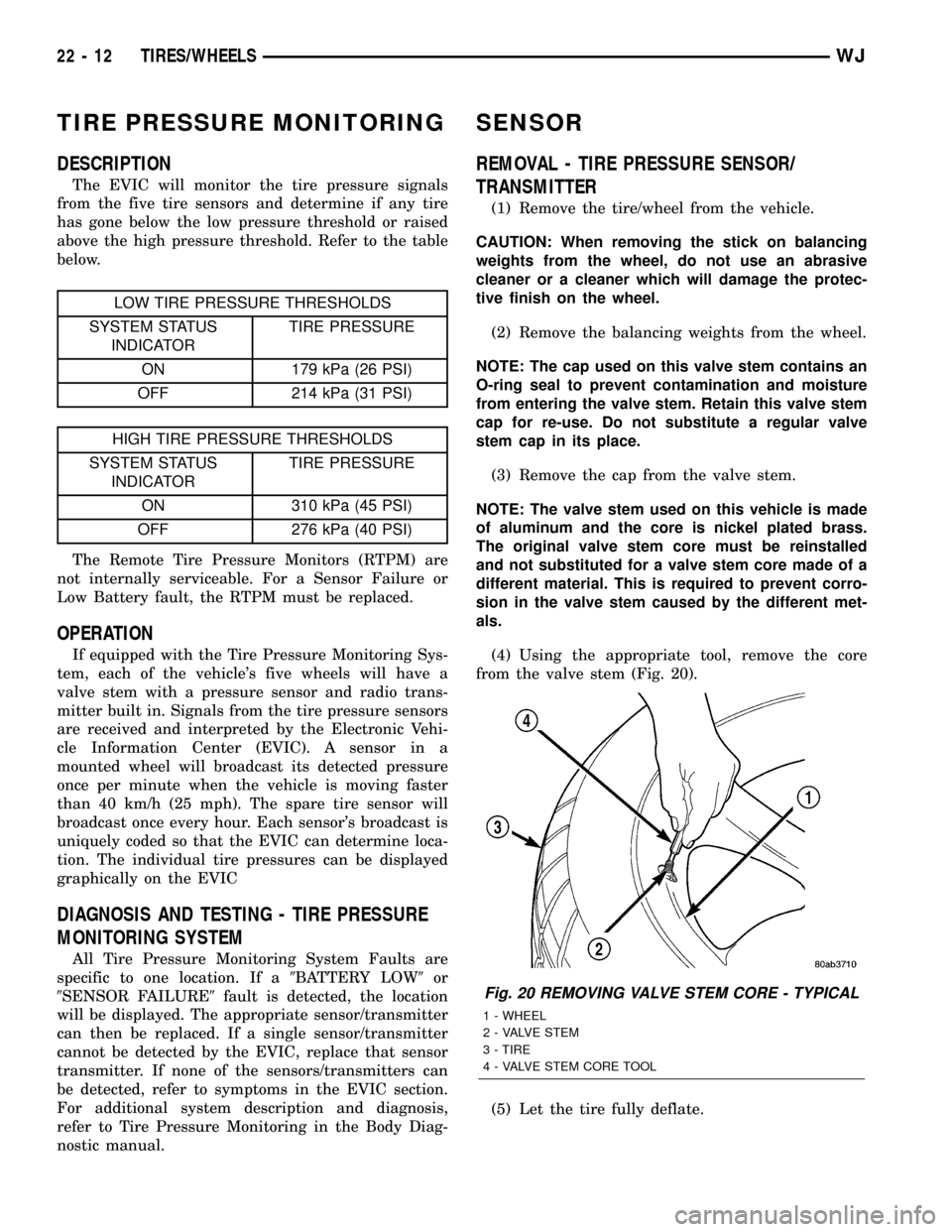

(4) Using the appropriate tool, remove the core

from the valve stem (Fig. 20).

(5) Let the tire fully deflate.

Fig. 20 REMOVING VALVE STEM CORE - TYPICAL

1 - WHEEL

2 - VALVE STEM

3 - TIRE

4 - VALVE STEM CORE TOOL

22 - 12 TIRES/WHEELSWJ

Page 1872 of 2199

CAUTION: The pressure transmitter must be

removed from the wheel and dropped into the tire

prior to breaking the bead and dismounting the tire.

Failure to do this will greatly increase the risk of

damaging the pressure transducer when servicing

the tire.

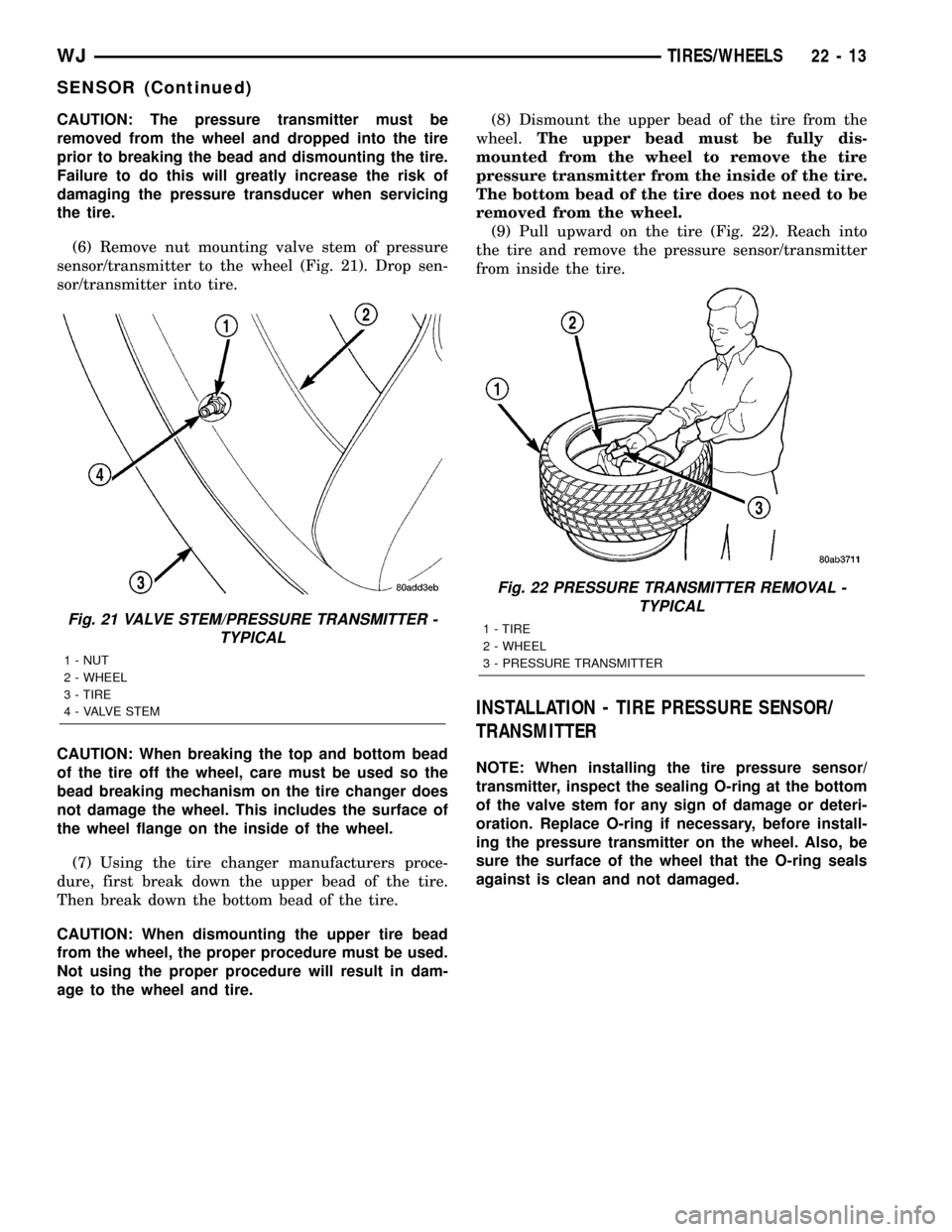

(6) Remove nut mounting valve stem of pressure

sensor/transmitter to the wheel (Fig. 21). Drop sen-

sor/transmitter into tire.

CAUTION: When breaking the top and bottom bead

of the tire off the wheel, care must be used so the

bead breaking mechanism on the tire changer does

not damage the wheel. This includes the surface of

the wheel flange on the inside of the wheel.

(7) Using the tire changer manufacturers proce-

dure, first break down the upper bead of the tire.

Then break down the bottom bead of the tire.

CAUTION: When dismounting the upper tire bead

from the wheel, the proper procedure must be used.

Not using the proper procedure will result in dam-

age to the wheel and tire.(8) Dismount the upper bead of the tire from the

wheel.The upper bead must be fully dis-

mounted from the wheel to remove the tire

pressure transmitter from the inside of the tire.

The bottom bead of the tire does not need to be

removed from the wheel.

(9) Pull upward on the tire (Fig. 22). Reach into

the tire and remove the pressure sensor/transmitter

from inside the tire.

INSTALLATION - TIRE PRESSURE SENSOR/

TRANSMITTER

NOTE: When installing the tire pressure sensor/

transmitter, inspect the sealing O-ring at the bottom

of the valve stem for any sign of damage or deteri-

oration. Replace O-ring if necessary, before install-

ing the pressure transmitter on the wheel. Also, be

sure the surface of the wheel that the O-ring seals

against is clean and not damaged.

Fig. 21 VALVE STEM/PRESSURE TRANSMITTER -

TYPICAL

1 - NUT

2 - WHEEL

3 - TIRE

4 - VALVE STEM

Fig. 22 PRESSURE TRANSMITTER REMOVAL -

TYPICAL

1 - TIRE

2 - WHEEL

3 - PRESSURE TRANSMITTER

WJTIRES/WHEELS 22 - 13

SENSOR (Continued)

Page 1873 of 2199

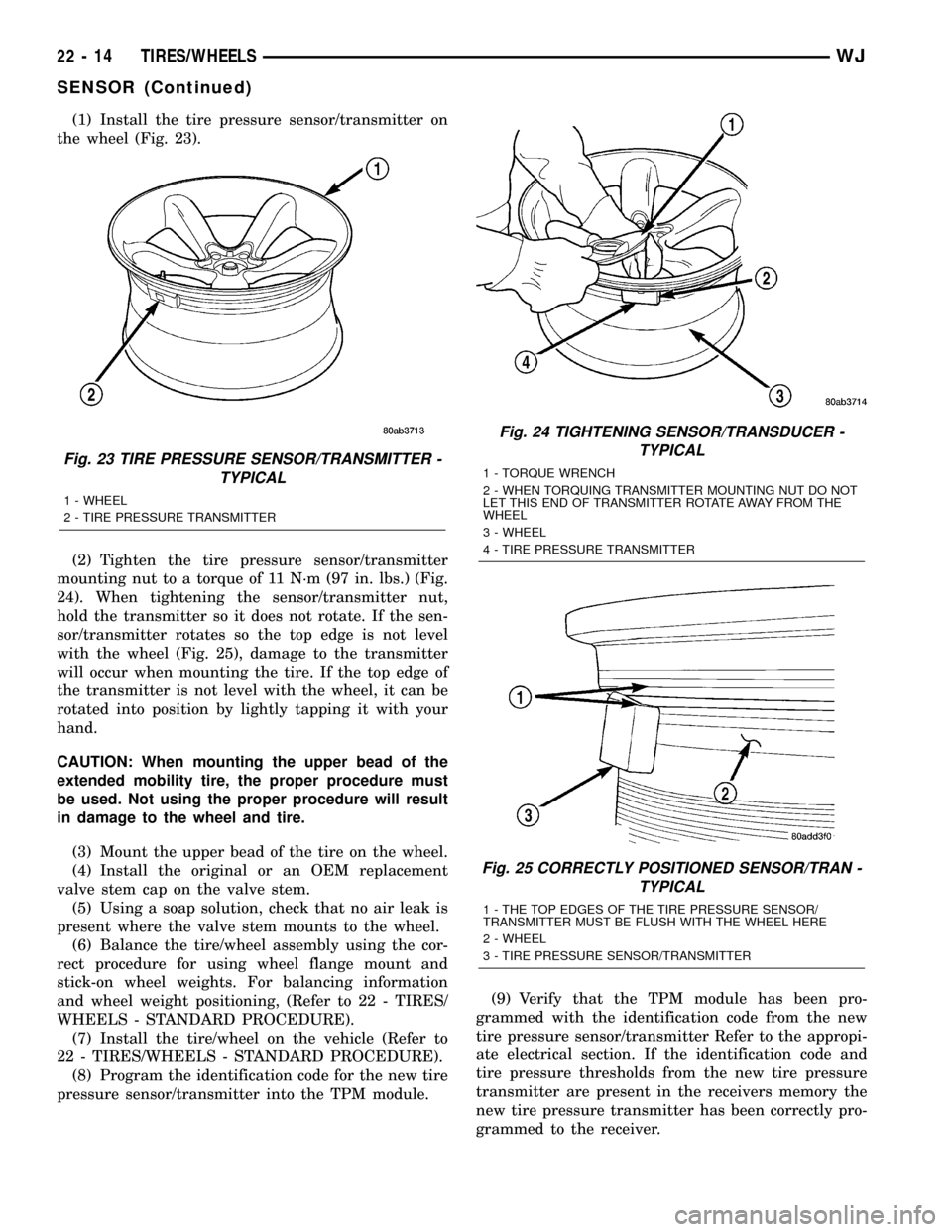

(1) Install the tire pressure sensor/transmitter on

the wheel (Fig. 23).

(2) Tighten the tire pressure sensor/transmitter

mounting nut to a torque of 11 N´m (97 in. lbs.) (Fig.

24). When tightening the sensor/transmitter nut,

hold the transmitter so it does not rotate. If the sen-

sor/transmitter rotates so the top edge is not level

with the wheel (Fig. 25), damage to the transmitter

will occur when mounting the tire. If the top edge of

the transmitter is not level with the wheel, it can be

rotated into position by lightly tapping it with your

hand.

CAUTION: When mounting the upper bead of the

extended mobility tire, the proper procedure must

be used. Not using the proper procedure will result

in damage to the wheel and tire.

(3) Mount the upper bead of the tire on the wheel.

(4) Install the original or an OEM replacement

valve stem cap on the valve stem.

(5) Using a soap solution, check that no air leak is

present where the valve stem mounts to the wheel.

(6) Balance the tire/wheel assembly using the cor-

rect procedure for using wheel flange mount and

stick-on wheel weights. For balancing information

and wheel weight positioning, (Refer to 22 - TIRES/

WHEELS - STANDARD PROCEDURE).

(7) Install the tire/wheel on the vehicle (Refer to

22 - TIRES/WHEELS - STANDARD PROCEDURE).

(8) Program the identification code for the new tire

pressure sensor/transmitter into the TPM module.(9) Verify that the TPM module has been pro-

grammed with the identification code from the new

tire pressure sensor/transmitter Refer to the appropi-

ate electrical section. If the identification code and

tire pressure thresholds from the new tire pressure

transmitter are present in the receivers memory the

new tire pressure transmitter has been correctly pro-

grammed to the receiver.

Fig. 23 TIRE PRESSURE SENSOR/TRANSMITTER -

TYPICAL

1 - WHEEL

2 - TIRE PRESSURE TRANSMITTER

Fig. 24 TIGHTENING SENSOR/TRANSDUCER -

TYPICAL

1 - TORQUE WRENCH

2 - WHEN TORQUING TRANSMITTER MOUNTING NUT DO NOT

LET THIS END OF TRANSMITTER ROTATE AWAY FROM THE

WHEEL

3 - WHEEL

4 - TIRE PRESSURE TRANSMITTER

Fig. 25 CORRECTLY POSITIONED SENSOR/TRAN -

TYPICAL

1 - THE TOP EDGES OF THE TIRE PRESSURE SENSOR/

TRANSMITTER MUST BE FLUSH WITH THE WHEEL HERE

2 - WHEEL

3 - TIRE PRESSURE SENSOR/TRANSMITTER

22 - 14 TIRES/WHEELSWJ

SENSOR (Continued)

Page 1876 of 2199

(2) Apply silicone lubricant to a cloth and wipe it

on door seals to avoid over-spray that can soil pas-

senger's clothing.

(3) Before applying lubricant, the component

should be wiped clean. After lubrication, any excess

lubricant should be removed.

(4) The hood latch, latch release mechanism, latch

striker, and safety latch should be lubricated period-

ically.

(5) The door lock cylinders should be lubricated

twice each year (preferably autumn and spring).

(a) Spray a small amount of lock cylinder lubri-

cant directly into the lock cylinder.

(b) Apply a small amount to the key and insert

it into the lock cylinder.

(c) Rotate it to the locked position and then back

to the unlocked position several times.(d) Remove the key. Wipe the lubricant from it

with a clean cloth to avoid soiling of clothing.

STANDARD PROCEDURE - DRILLING AND

WELDING

When holes must be drilled or punched in an inner

body panel, verify depth of space to the outer body

panel, electrical wiring, or other components. Dam-

age to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use when

welding.

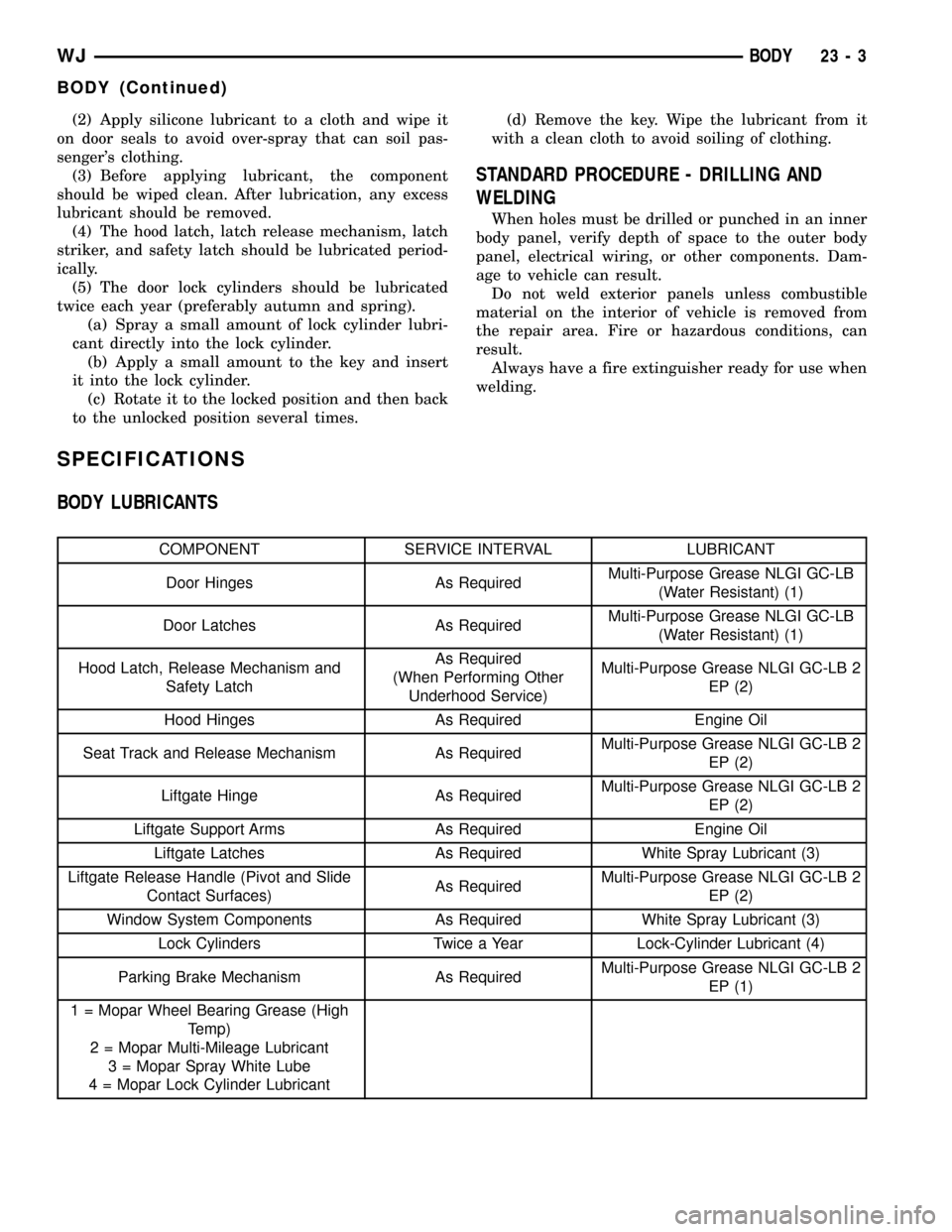

SPECIFICATIONS

BODY LUBRICANTS

COMPONENT SERVICE INTERVAL LUBRICANT

Door Hinges As RequiredMulti-Purpose Grease NLGI GC-LB

(Water Resistant) (1)

Door Latches As RequiredMulti-Purpose Grease NLGI GC-LB

(Water Resistant) (1)

Hood Latch, Release Mechanism and

Safety LatchAs Required

(When Performing Other

Underhood Service)Multi-Purpose Grease NLGI GC-LB 2

EP (2)

Hood Hinges As Required Engine Oil

Seat Track and Release Mechanism As RequiredMulti-Purpose Grease NLGI GC-LB 2

EP (2)

Liftgate Hinge As RequiredMulti-Purpose Grease NLGI GC-LB 2

EP (2)

Liftgate Support Arms As Required Engine Oil

Liftgate Latches As Required White Spray Lubricant (3)

Liftgate Release Handle (Pivot and Slide

Contact Surfaces)As RequiredMulti-Purpose Grease NLGI GC-LB 2

EP (2)

Window System Components As Required White Spray Lubricant (3)

Lock Cylinders Twice a Year Lock-Cylinder Lubricant (4)

Parking Brake Mechanism As RequiredMulti-Purpose Grease NLGI GC-LB 2

EP (1)

1 = Mopar Wheel Bearing Grease (High

Temp)

2 = Mopar Multi-Mileage Lubricant

3 = Mopar Spray White Lube

4 = Mopar Lock Cylinder Lubricant

WJBODY 23 - 3

BODY (Continued)

Page 1899 of 2199

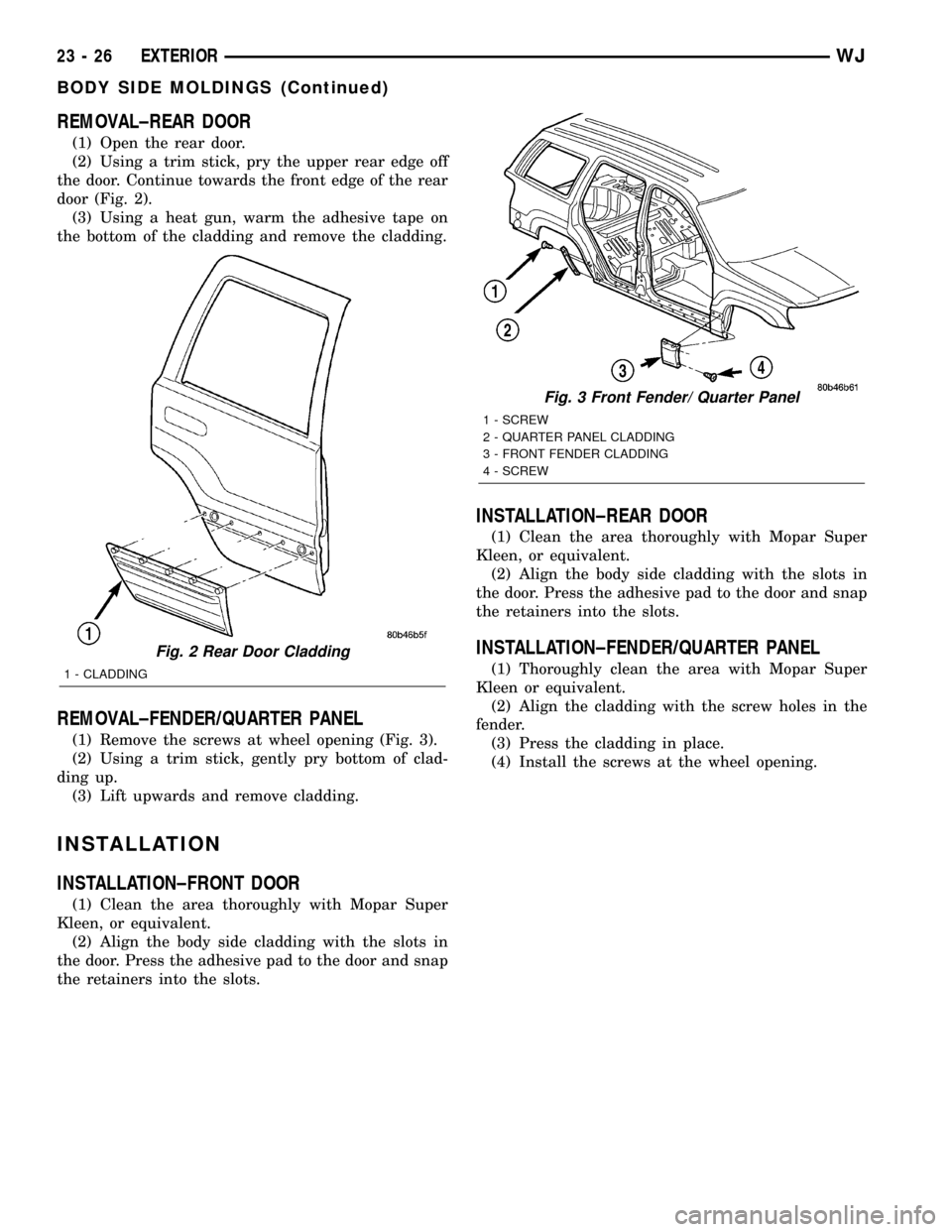

REMOVAL±REAR DOOR

(1) Open the rear door.

(2) Using a trim stick, pry the upper rear edge off

the door. Continue towards the front edge of the rear

door (Fig. 2).

(3) Using a heat gun, warm the adhesive tape on

the bottom of the cladding and remove the cladding.

REMOVAL±FENDER/QUARTER PANEL

(1) Remove the screws at wheel opening (Fig. 3).

(2) Using a trim stick, gently pry bottom of clad-

ding up.

(3) Lift upwards and remove cladding.

INSTALLATION

INSTALLATION±FRONT DOOR

(1) Clean the area thoroughly with Mopar Super

Kleen, or equivalent.

(2) Align the body side cladding with the slots in

the door. Press the adhesive pad to the door and snap

the retainers into the slots.

INSTALLATION±REAR DOOR

(1) Clean the area thoroughly with Mopar Super

Kleen, or equivalent.

(2) Align the body side cladding with the slots in

the door. Press the adhesive pad to the door and snap

the retainers into the slots.

INSTALLATION±FENDER/QUARTER PANEL

(1) Thoroughly clean the area with Mopar Super

Kleen or equivalent.

(2) Align the cladding with the screw holes in the

fender.

(3) Press the cladding in place.

(4) Install the screws at the wheel opening.

Fig. 2 Rear Door Cladding

1 - CLADDING

Fig. 3 Front Fender/ Quarter Panel

1 - SCREW

2 - QUARTER PANEL CLADDING

3 - FRONT FENDER CLADDING

4 - SCREW

23 - 26 EXTERIORWJ

BODY SIDE MOLDINGS (Continued)

Page 1903 of 2199

(3) Install fascia, refer to (Refer to 13 - FRAMES

& BUMPERS/BUMPERS/FRONT FASCIA - INSTAL-

LATION).

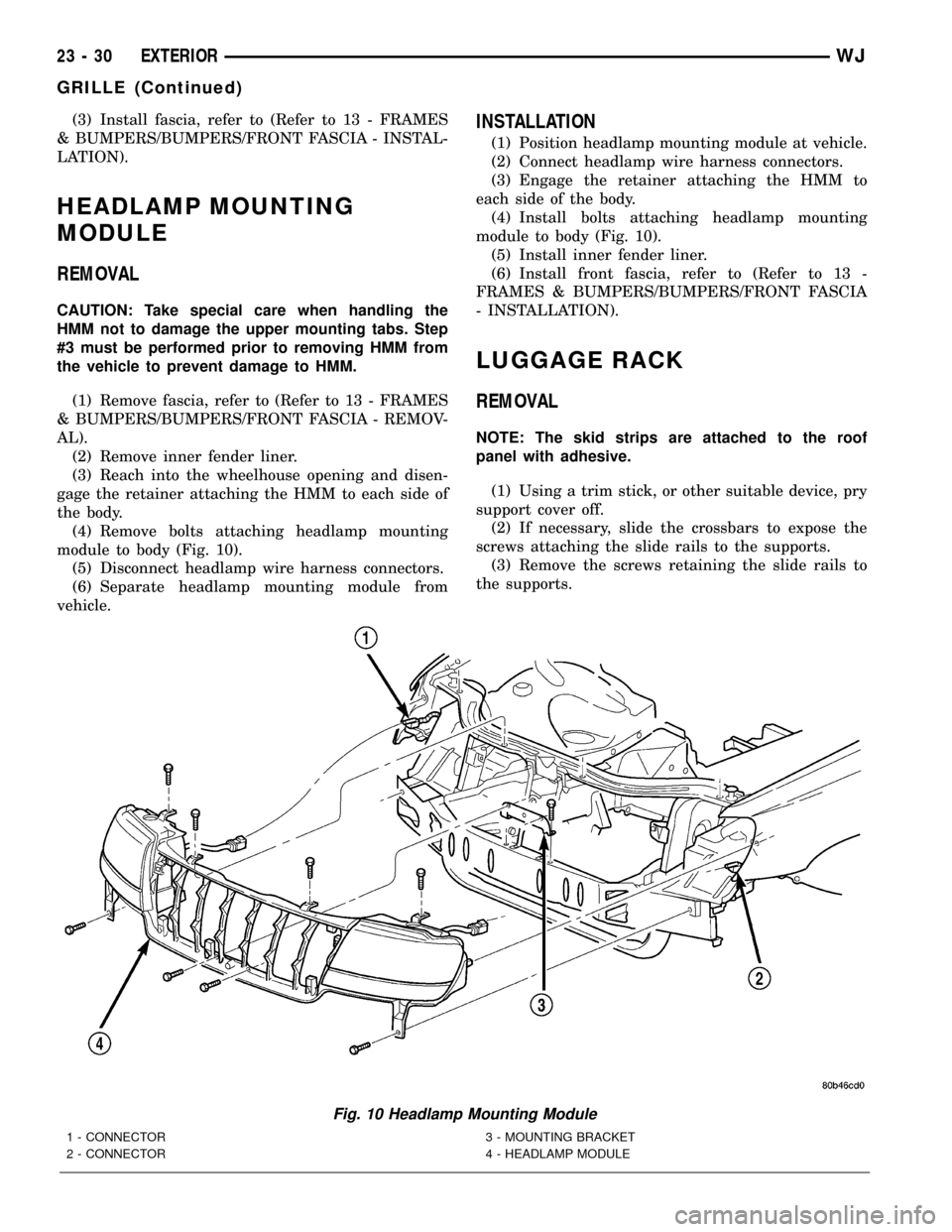

HEADLAMP MOUNTING

MODULE

REMOVAL

CAUTION: Take special care when handling the

HMM not to damage the upper mounting tabs. Step

#3 must be performed prior to removing HMM from

the vehicle to prevent damage to HMM.

(1) Remove fascia, refer to (Refer to 13 - FRAMES

& BUMPERS/BUMPERS/FRONT FASCIA - REMOV-

AL).

(2) Remove inner fender liner.

(3) Reach into the wheelhouse opening and disen-

gage the retainer attaching the HMM to each side of

the body.

(4) Remove bolts attaching headlamp mounting

module to body (Fig. 10).

(5) Disconnect headlamp wire harness connectors.

(6) Separate headlamp mounting module from

vehicle.

INSTALLATION

(1) Position headlamp mounting module at vehicle.

(2) Connect headlamp wire harness connectors.

(3) Engage the retainer attaching the HMM to

each side of the body.

(4) Install bolts attaching headlamp mounting

module to body (Fig. 10).

(5) Install inner fender liner.

(6) Install front fascia, refer to (Refer to 13 -

FRAMES & BUMPERS/BUMPERS/FRONT FASCIA

- INSTALLATION).

LUGGAGE RACK

REMOVAL

NOTE: The skid strips are attached to the roof

panel with adhesive.

(1) Using a trim stick, or other suitable device, pry

support cover off.

(2) If necessary, slide the crossbars to expose the

screws attaching the slide rails to the supports.

(3) Remove the screws retaining the slide rails to

the supports.

Fig. 10 Headlamp Mounting Module

1 - CONNECTOR

2 - CONNECTOR3 - MOUNTING BRACKET

4 - HEADLAMP MODULE

23 - 30 EXTERIORWJ

GRILLE (Continued)

Page 1910 of 2199

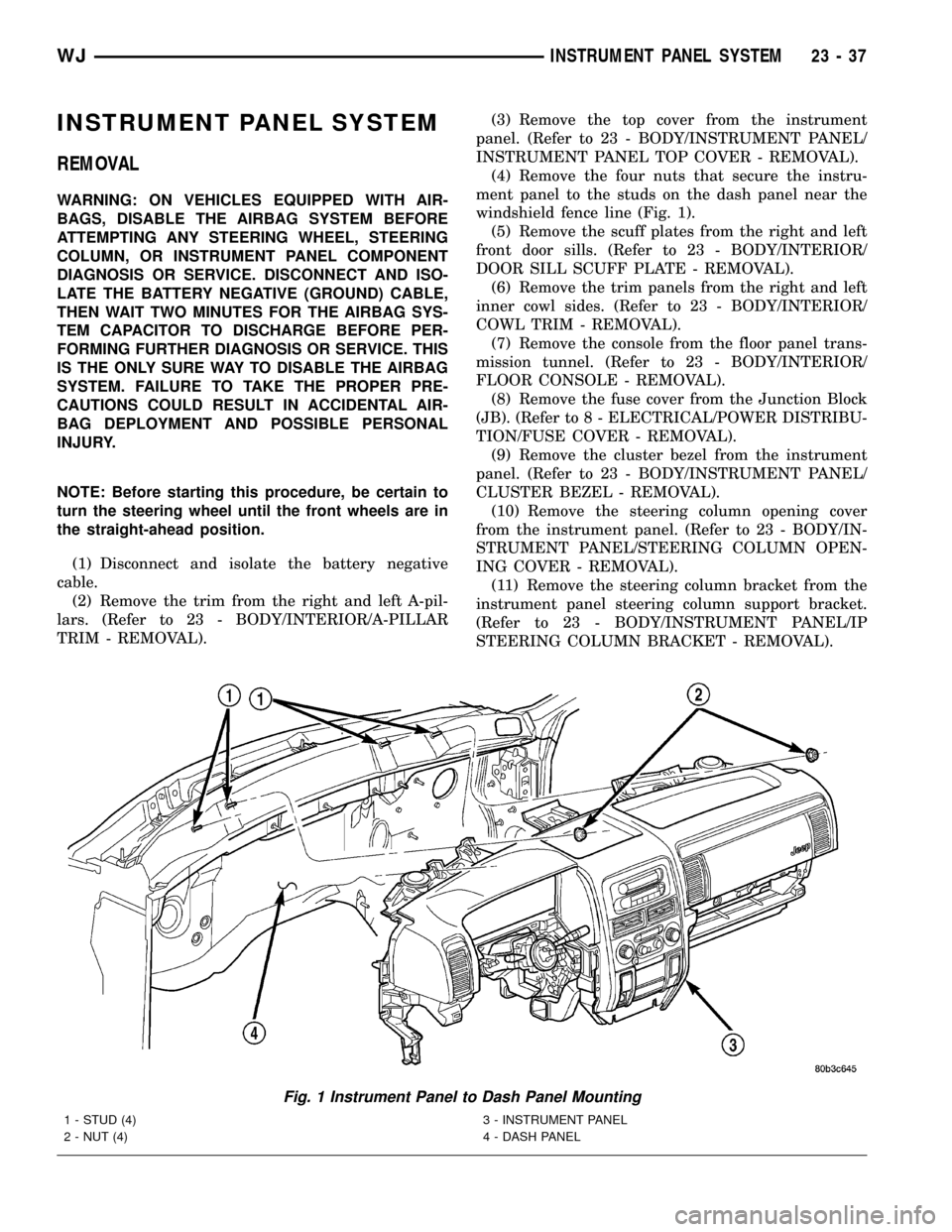

INSTRUMENT PANEL SYSTEM

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: Before starting this procedure, be certain to

turn the steering wheel until the front wheels are in

the straight-ahead position.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the trim from the right and left A-pil-

lars. (Refer to 23 - BODY/INTERIOR/A-PILLAR

TRIM - REMOVAL).(3) Remove the top cover from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL TOP COVER - REMOVAL).

(4) Remove the four nuts that secure the instru-

ment panel to the studs on the dash panel near the

windshield fence line (Fig. 1).

(5) Remove the scuff plates from the right and left

front door sills. (Refer to 23 - BODY/INTERIOR/

DOOR SILL SCUFF PLATE - REMOVAL).

(6) Remove the trim panels from the right and left

inner cowl sides. (Refer to 23 - BODY/INTERIOR/

COWL TRIM - REMOVAL).

(7) Remove the console from the floor panel trans-

mission tunnel. (Refer to 23 - BODY/INTERIOR/

FLOOR CONSOLE - REMOVAL).

(8) Remove the fuse cover from the Junction Block

(JB). (Refer to 8 - ELECTRICAL/POWER DISTRIBU-

TION/FUSE COVER - REMOVAL).

(9) Remove the cluster bezel from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

CLUSTER BEZEL - REMOVAL).

(10) Remove the steering column opening cover

from the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - REMOVAL).

(11) Remove the steering column bracket from the

instrument panel steering column support bracket.

(Refer to 23 - BODY/INSTRUMENT PANEL/IP

STEERING COLUMN BRACKET - REMOVAL).

Fig. 1 Instrument Panel to Dash Panel Mounting

1 - STUD (4)

2 - NUT (4)3 - INSTRUMENT PANEL

4 - DASH PANEL

WJINSTRUMENT PANEL SYSTEM 23 - 37

Page 1911 of 2199

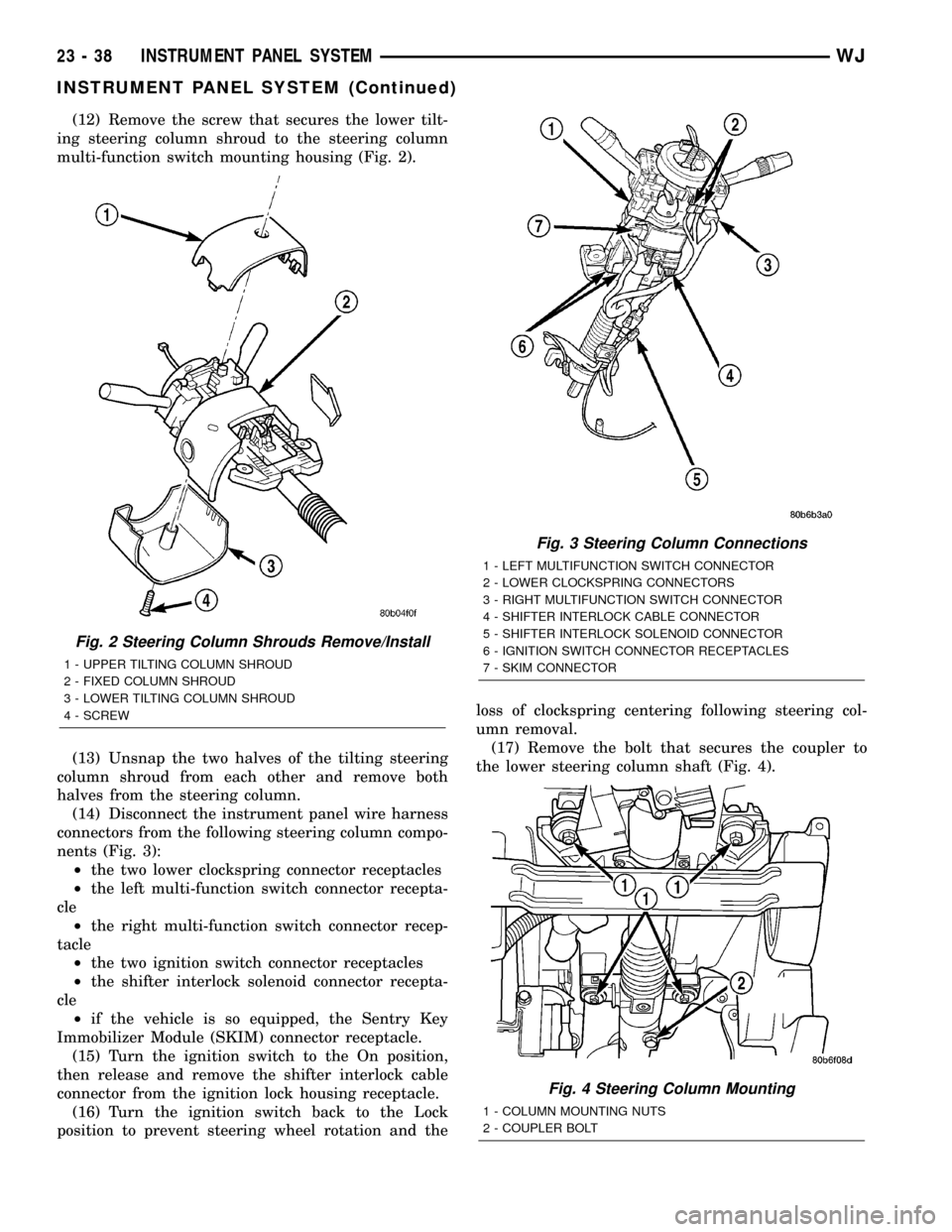

(12) Remove the screw that secures the lower tilt-

ing steering column shroud to the steering column

multi-function switch mounting housing (Fig. 2).

(13) Unsnap the two halves of the tilting steering

column shroud from each other and remove both

halves from the steering column.

(14) Disconnect the instrument panel wire harness

connectors from the following steering column compo-

nents (Fig. 3):

²the two lower clockspring connector receptacles

²the left multi-function switch connector recepta-

cle

²the right multi-function switch connector recep-

tacle

²the two ignition switch connector receptacles

²the shifter interlock solenoid connector recepta-

cle

²if the vehicle is so equipped, the Sentry Key

Immobilizer Module (SKIM) connector receptacle.

(15) Turn the ignition switch to the On position,

then release and remove the shifter interlock cable

connector from the ignition lock housing receptacle.

(16) Turn the ignition switch back to the Lock

position to prevent steering wheel rotation and theloss of clockspring centering following steering col-

umn removal.

(17) Remove the bolt that secures the coupler to

the lower steering column shaft (Fig. 4).

Fig. 2 Steering Column Shrouds Remove/Install

1 - UPPER TILTING COLUMN SHROUD

2 - FIXED COLUMN SHROUD

3 - LOWER TILTING COLUMN SHROUD

4 - SCREW

Fig. 3 Steering Column Connections

1 - LEFT MULTIFUNCTION SWITCH CONNECTOR

2 - LOWER CLOCKSPRING CONNECTORS

3 - RIGHT MULTIFUNCTION SWITCH CONNECTOR

4 - SHIFTER INTERLOCK CABLE CONNECTOR

5 - SHIFTER INTERLOCK SOLENOID CONNECTOR

6 - IGNITION SWITCH CONNECTOR RECEPTACLES

7 - SKIM CONNECTOR

Fig. 4 Steering Column Mounting

1 - COLUMN MOUNTING NUTS

2 - COUPLER BOLT

23 - 38 INSTRUMENT PANEL SYSTEMWJ

INSTRUMENT PANEL SYSTEM (Continued)

Page 1912 of 2199

(18) Remove the four nuts that secure the steering

column to the studs on the instrument panel steering

column support bracket.

(19) Remove the steering column from the instru-

ment panel. Be certain that the steering wheel is

locked and secured from rotation to prevent the loss

of clockspring centering.

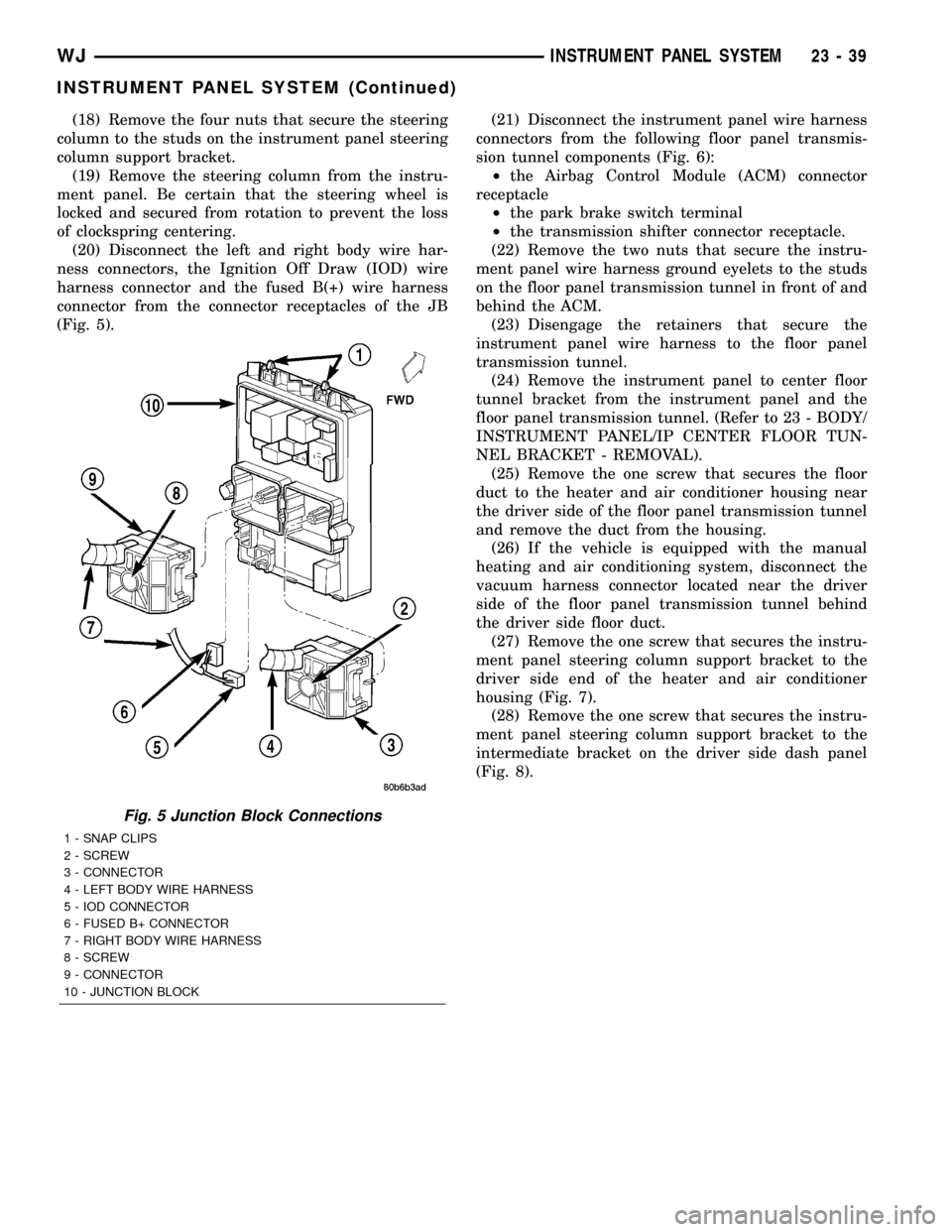

(20) Disconnect the left and right body wire har-

ness connectors, the Ignition Off Draw (IOD) wire

harness connector and the fused B(+) wire harness

connector from the connector receptacles of the JB

(Fig. 5).(21) Disconnect the instrument panel wire harness

connectors from the following floor panel transmis-

sion tunnel components (Fig. 6):

²the Airbag Control Module (ACM) connector

receptacle

²the park brake switch terminal

²the transmission shifter connector receptacle.

(22) Remove the two nuts that secure the instru-

ment panel wire harness ground eyelets to the studs

on the floor panel transmission tunnel in front of and

behind the ACM.

(23) Disengage the retainers that secure the

instrument panel wire harness to the floor panel

transmission tunnel.

(24) Remove the instrument panel to center floor

tunnel bracket from the instrument panel and the

floor panel transmission tunnel. (Refer to 23 - BODY/

INSTRUMENT PANEL/IP CENTER FLOOR TUN-

NEL BRACKET - REMOVAL).

(25) Remove the one screw that secures the floor

duct to the heater and air conditioner housing near

the driver side of the floor panel transmission tunnel

and remove the duct from the housing.

(26) If the vehicle is equipped with the manual

heating and air conditioning system, disconnect the

vacuum harness connector located near the driver

side of the floor panel transmission tunnel behind

the driver side floor duct.

(27) Remove the one screw that secures the instru-

ment panel steering column support bracket to the

driver side end of the heater and air conditioner

housing (Fig. 7).

(28) Remove the one screw that secures the instru-

ment panel steering column support bracket to the

intermediate bracket on the driver side dash panel

(Fig. 8).

Fig. 5 Junction Block Connections

1 - SNAP CLIPS

2 - SCREW

3 - CONNECTOR

4 - LEFT BODY WIRE HARNESS

5 - IOD CONNECTOR

6 - FUSED B+ CONNECTOR

7 - RIGHT BODY WIRE HARNESS

8 - SCREW

9 - CONNECTOR

10 - JUNCTION BLOCK

WJINSTRUMENT PANEL SYSTEM 23 - 39

INSTRUMENT PANEL SYSTEM (Continued)