service JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1647 of 2199

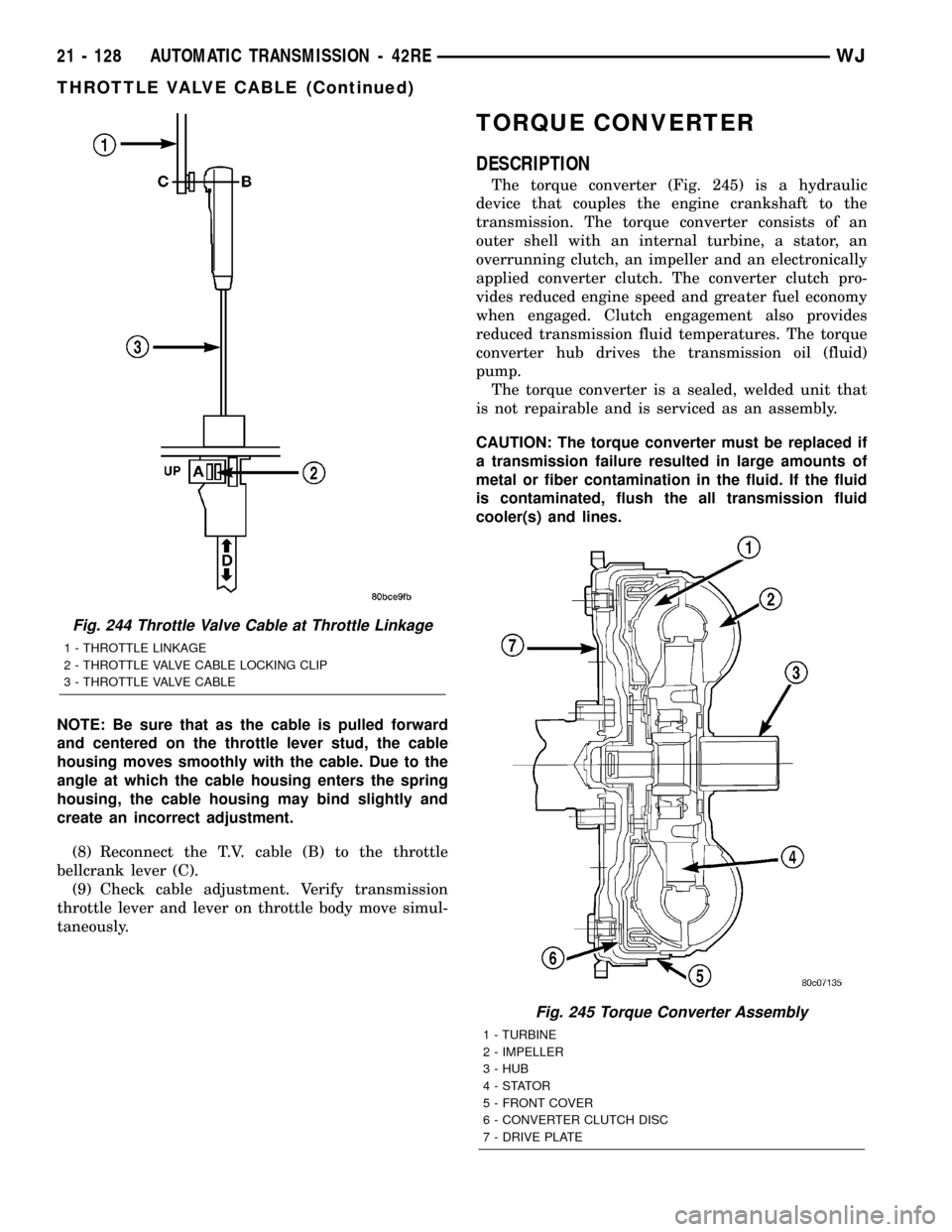

NOTE: Be sure that as the cable is pulled forward

and centered on the throttle lever stud, the cable

housing moves smoothly with the cable. Due to the

angle at which the cable housing enters the spring

housing, the cable housing may bind slightly and

create an incorrect adjustment.

(8) Reconnect the T.V. cable (B) to the throttle

bellcrank lever (C).

(9) Check cable adjustment. Verify transmission

throttle lever and lever on throttle body move simul-

taneously.

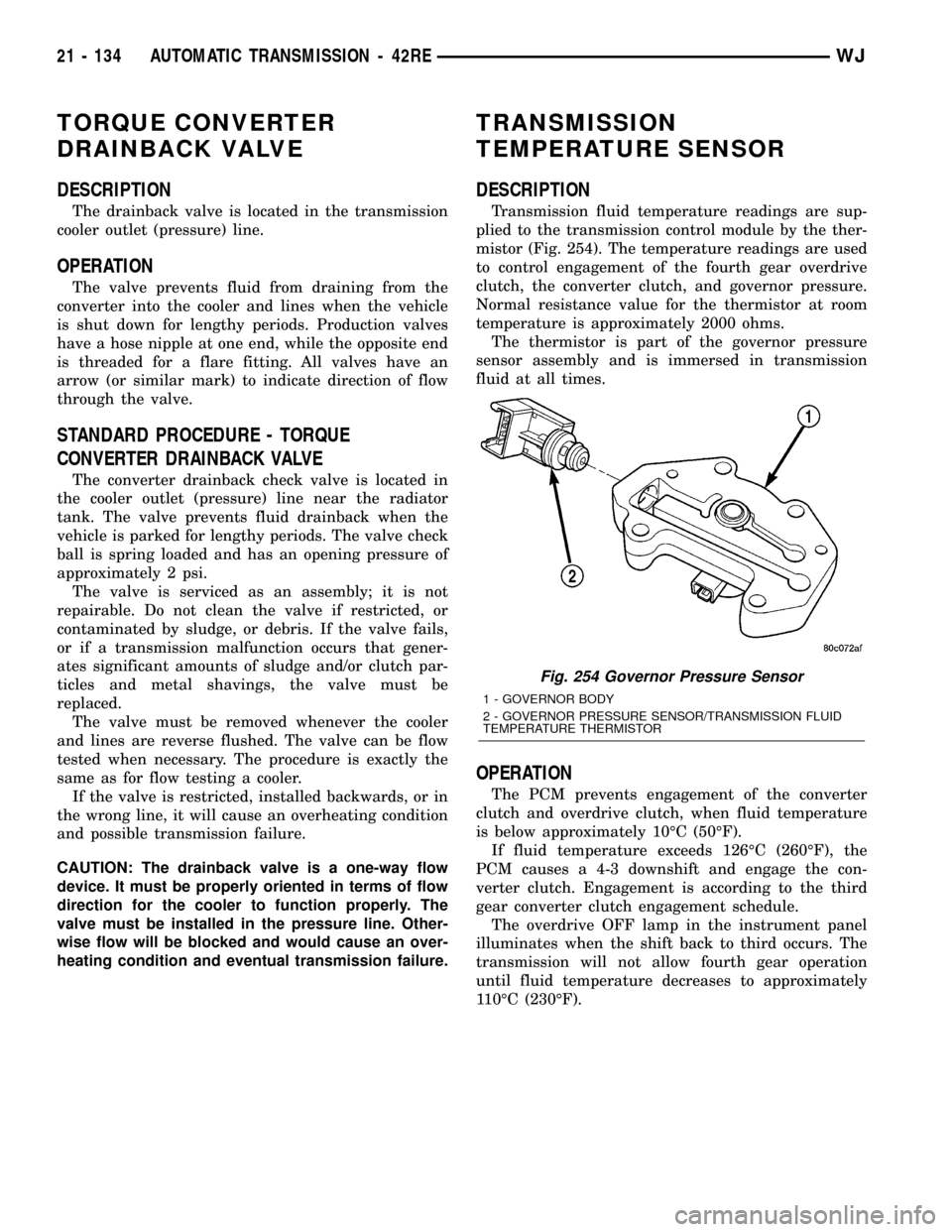

TORQUE CONVERTER

DESCRIPTION

The torque converter (Fig. 245) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, an

overrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-

vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The torque

converter hub drives the transmission oil (fluid)

pump.

The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

CAUTION: The torque converter must be replaced if

a transmission failure resulted in large amounts of

metal or fiber contamination in the fluid. If the fluid

is contaminated, flush the all transmission fluid

cooler(s) and lines.

Fig. 244 Throttle Valve Cable at Throttle Linkage

1 - THROTTLE LINKAGE

2 - THROTTLE VALVE CABLE LOCKING CLIP

3 - THROTTLE VALVE CABLE

Fig. 245 Torque Converter Assembly

1 - TURBINE

2 - IMPELLER

3 - HUB

4-STATOR

5 - FRONT COVER

6 - CONVERTER CLUTCH DISC

7 - DRIVE PLATE

21 - 128 AUTOMATIC TRANSMISSION - 42REWJ

THROTTLE VALVE CABLE (Continued)

Page 1653 of 2199

TORQUE CONVERTER

DRAINBACK VALVE

DESCRIPTION

The drainback valve is located in the transmission

cooler outlet (pressure) line.

OPERATION

The valve prevents fluid from draining from the

converter into the cooler and lines when the vehicle

is shut down for lengthy periods. Production valves

have a hose nipple at one end, while the opposite end

is threaded for a flare fitting. All valves have an

arrow (or similar mark) to indicate direction of flow

through the valve.

STANDARD PROCEDURE - TORQUE

CONVERTER DRAINBACK VALVE

The converter drainback check valve is located in

the cooler outlet (pressure) line near the radiator

tank. The valve prevents fluid drainback when the

vehicle is parked for lengthy periods. The valve check

ball is spring loaded and has an opening pressure of

approximately 2 psi.

The valve is serviced as an assembly; it is not

repairable. Do not clean the valve if restricted, or

contaminated by sludge, or debris. If the valve fails,

or if a transmission malfunction occurs that gener-

ates significant amounts of sludge and/or clutch par-

ticles and metal shavings, the valve must be

replaced.

The valve must be removed whenever the cooler

and lines are reverse flushed. The valve can be flow

tested when necessary. The procedure is exactly the

same as for flow testing a cooler.

If the valve is restricted, installed backwards, or in

the wrong line, it will cause an overheating condition

and possible transmission failure.

CAUTION: The drainback valve is a one-way flow

device. It must be properly oriented in terms of flow

direction for the cooler to function properly. The

valve must be installed in the pressure line. Other-

wise flow will be blocked and would cause an over-

heating condition and eventual transmission failure.

TRANSMISSION

TEMPERATURE SENSOR

DESCRIPTION

Transmission fluid temperature readings are sup-

plied to the transmission control module by the ther-

mistor (Fig. 254). The temperature readings are used

to control engagement of the fourth gear overdrive

clutch, the converter clutch, and governor pressure.

Normal resistance value for the thermistor at room

temperature is approximately 2000 ohms.

The thermistor is part of the governor pressure

sensor assembly and is immersed in transmission

fluid at all times.

OPERATION

The PCM prevents engagement of the converter

clutch and overdrive clutch, when fluid temperature

is below approximately 10ÉC (50ÉF).

If fluid temperature exceeds 126ÉC (260ÉF), the

PCM causes a 4-3 downshift and engage the con-

verter clutch. Engagement is according to the third

gear converter clutch engagement schedule.

The overdrive OFF lamp in the instrument panel

illuminates when the shift back to third occurs. The

transmission will not allow fourth gear operation

until fluid temperature decreases to approximately

110ÉC (230ÉF).

Fig. 254 Governor Pressure Sensor

1 - GOVERNOR BODY

2 - GOVERNOR PRESSURE SENSOR/TRANSMISSION FLUID

TEMPERATURE THERMISTOR

21 - 134 AUTOMATIC TRANSMISSION - 42REWJ

Page 1673 of 2199

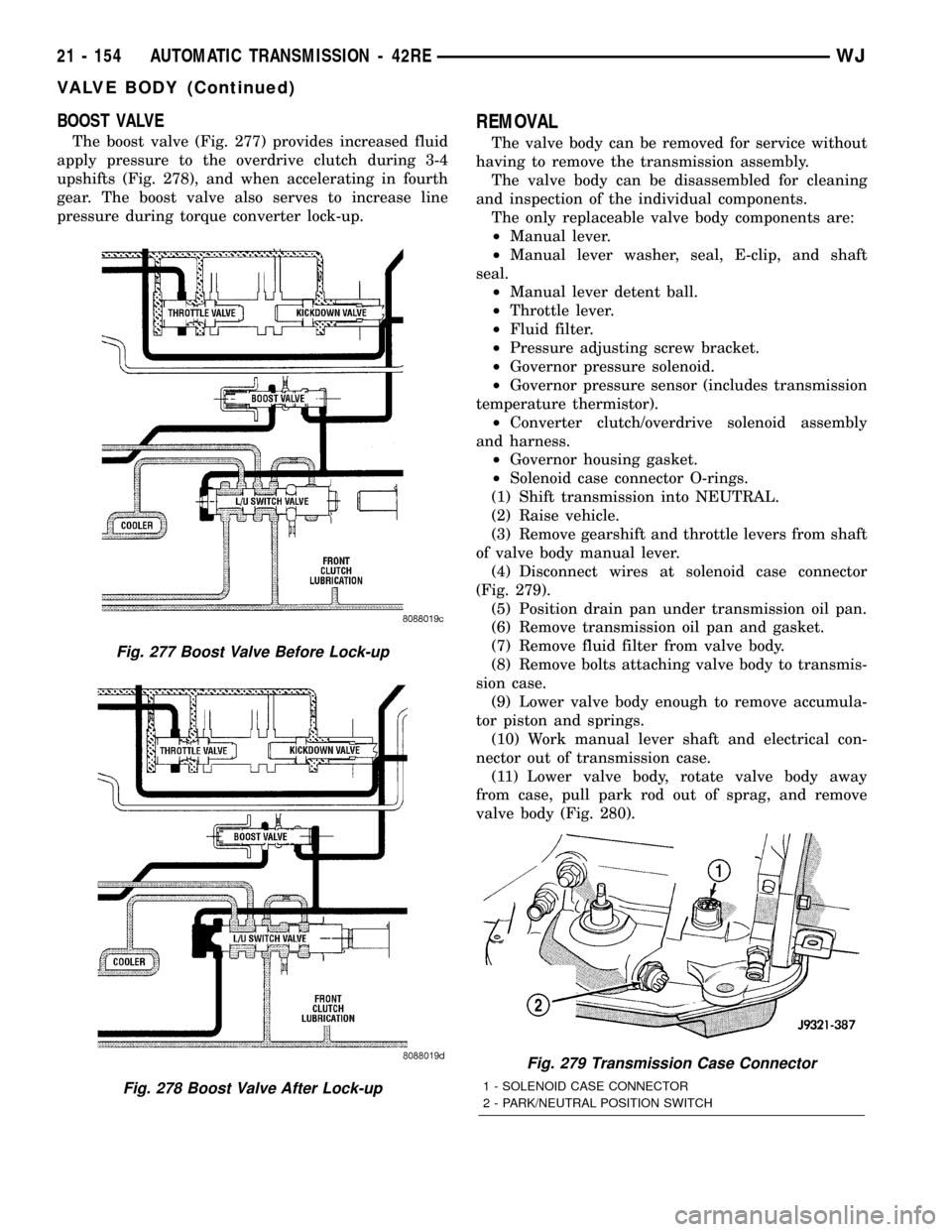

BOOST VALVE

The boost valve (Fig. 277) provides increased fluid

apply pressure to the overdrive clutch during 3-4

upshifts (Fig. 278), and when accelerating in fourth

gear. The boost valve also serves to increase line

pressure during torque converter lock-up.

REMOVAL

The valve body can be removed for service without

having to remove the transmission assembly.

The valve body can be disassembled for cleaning

and inspection of the individual components.

The only replaceable valve body components are:

²Manual lever.

²Manual lever washer, seal, E-clip, and shaft

seal.

²Manual lever detent ball.

²Throttle lever.

²Fluid filter.

²Pressure adjusting screw bracket.

²Governor pressure solenoid.

²Governor pressure sensor (includes transmission

temperature thermistor).

²Converter clutch/overdrive solenoid assembly

and harness.

²Governor housing gasket.

²Solenoid case connector O-rings.

(1) Shift transmission into NEUTRAL.

(2) Raise vehicle.

(3) Remove gearshift and throttle levers from shaft

of valve body manual lever.

(4) Disconnect wires at solenoid case connector

(Fig. 279).

(5) Position drain pan under transmission oil pan.

(6) Remove transmission oil pan and gasket.

(7) Remove fluid filter from valve body.

(8) Remove bolts attaching valve body to transmis-

sion case.

(9) Lower valve body enough to remove accumula-

tor piston and springs.

(10) Work manual lever shaft and electrical con-

nector out of transmission case.

(11) Lower valve body, rotate valve body away

from case, pull park rod out of sprag, and remove

valve body (Fig. 280).

Fig. 277 Boost Valve Before Lock-up

Fig. 278 Boost Valve After Lock-up

Fig. 279 Transmission Case Connector

1 - SOLENOID CASE CONNECTOR

2 - PARK/NEUTRAL POSITION SWITCH

21 - 154 AUTOMATIC TRANSMISSION - 42REWJ

VALVE BODY (Continued)

Page 1685 of 2199

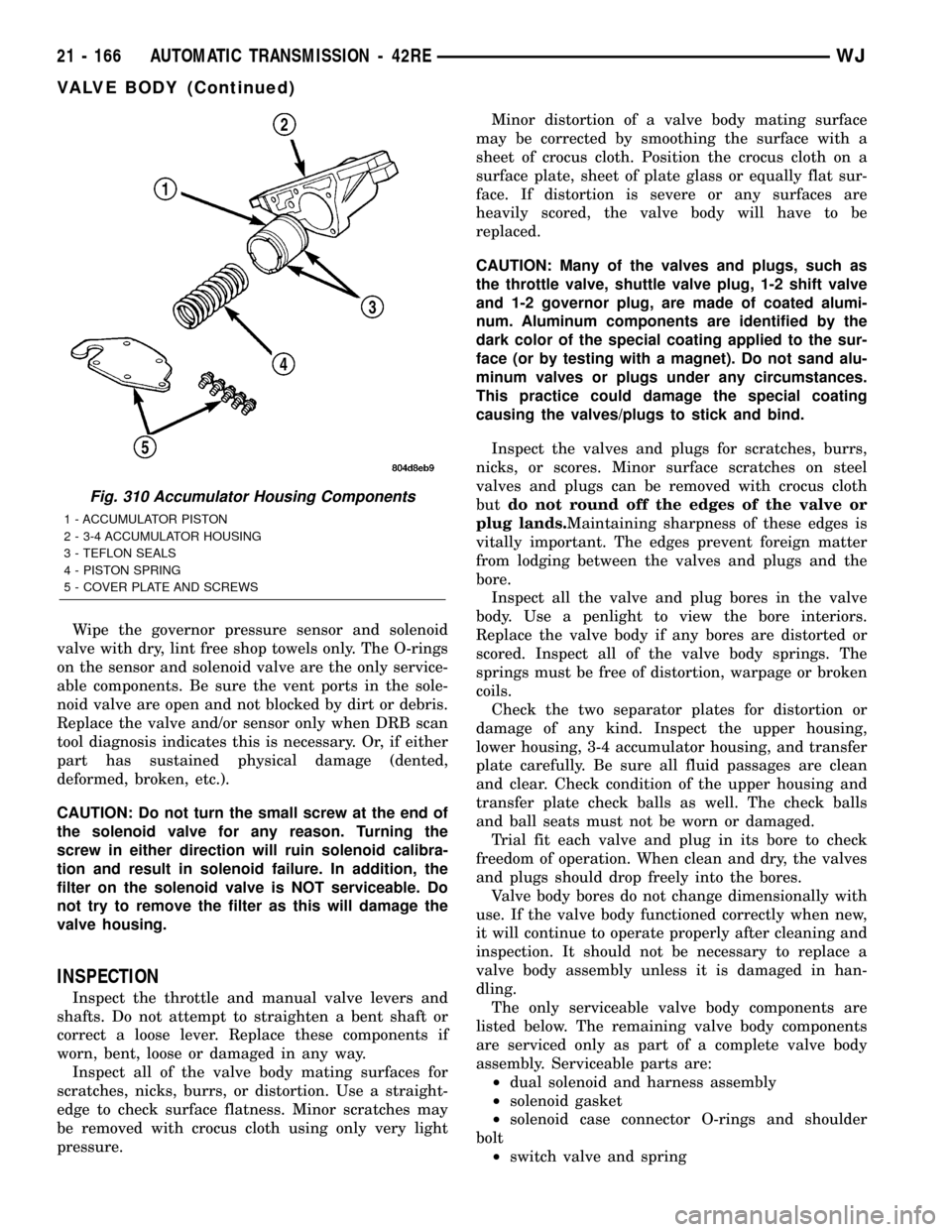

Wipe the governor pressure sensor and solenoid

valve with dry, lint free shop towels only. The O-rings

on the sensor and solenoid valve are the only service-

able components. Be sure the vent ports in the sole-

noid valve are open and not blocked by dirt or debris.

Replace the valve and/or sensor only when DRB scan

tool diagnosis indicates this is necessary. Or, if either

part has sustained physical damage (dented,

deformed, broken, etc.).

CAUTION: Do not turn the small screw at the end of

the solenoid valve for any reason. Turning the

screw in either direction will ruin solenoid calibra-

tion and result in solenoid failure. In addition, the

filter on the solenoid valve is NOT serviceable. Do

not try to remove the filter as this will damage the

valve housing.

INSPECTION

Inspect the throttle and manual valve levers and

shafts. Do not attempt to straighten a bent shaft or

correct a loose lever. Replace these components if

worn, bent, loose or damaged in any way.

Inspect all of the valve body mating surfaces for

scratches, nicks, burrs, or distortion. Use a straight-

edge to check surface flatness. Minor scratches may

be removed with crocus cloth using only very light

pressure.Minor distortion of a valve body mating surface

may be corrected by smoothing the surface with a

sheet of crocus cloth. Position the crocus cloth on a

surface plate, sheet of plate glass or equally flat sur-

face. If distortion is severe or any surfaces are

heavily scored, the valve body will have to be

replaced.

CAUTION: Many of the valves and plugs, such as

the throttle valve, shuttle valve plug, 1-2 shift valve

and 1-2 governor plug, are made of coated alumi-

num. Aluminum components are identified by the

dark color of the special coating applied to the sur-

face (or by testing with a magnet). Do not sand alu-

minum valves or plugs under any circumstances.

This practice could damage the special coating

causing the valves/plugs to stick and bind.

Inspect the valves and plugs for scratches, burrs,

nicks, or scores. Minor surface scratches on steel

valves and plugs can be removed with crocus cloth

butdo not round off the edges of the valve or

plug lands.Maintaining sharpness of these edges is

vitally important. The edges prevent foreign matter

from lodging between the valves and plugs and the

bore.

Inspect all the valve and plug bores in the valve

body. Use a penlight to view the bore interiors.

Replace the valve body if any bores are distorted or

scored. Inspect all of the valve body springs. The

springs must be free of distortion, warpage or broken

coils.

Check the two separator plates for distortion or

damage of any kind. Inspect the upper housing,

lower housing, 3-4 accumulator housing, and transfer

plate carefully. Be sure all fluid passages are clean

and clear. Check condition of the upper housing and

transfer plate check balls as well. The check balls

and ball seats must not be worn or damaged.

Trial fit each valve and plug in its bore to check

freedom of operation. When clean and dry, the valves

and plugs should drop freely into the bores.

Valve body bores do not change dimensionally with

use. If the valve body functioned correctly when new,

it will continue to operate properly after cleaning and

inspection. It should not be necessary to replace a

valve body assembly unless it is damaged in han-

dling.

The only serviceable valve body components are

listed below. The remaining valve body components

are serviced only as part of a complete valve body

assembly. Serviceable parts are:

²dual solenoid and harness assembly

²solenoid gasket

²solenoid case connector O-rings and shoulder

bolt

²switch valve and spring

Fig. 310 Accumulator Housing Components

1 - ACCUMULATOR PISTON

2 - 3-4 ACCUMULATOR HOUSING

3 - TEFLON SEALS

4 - PISTON SPRING

5 - COVER PLATE AND SCREWS

21 - 166 AUTOMATIC TRANSMISSION - 42REWJ

VALVE BODY (Continued)

Page 1703 of 2199

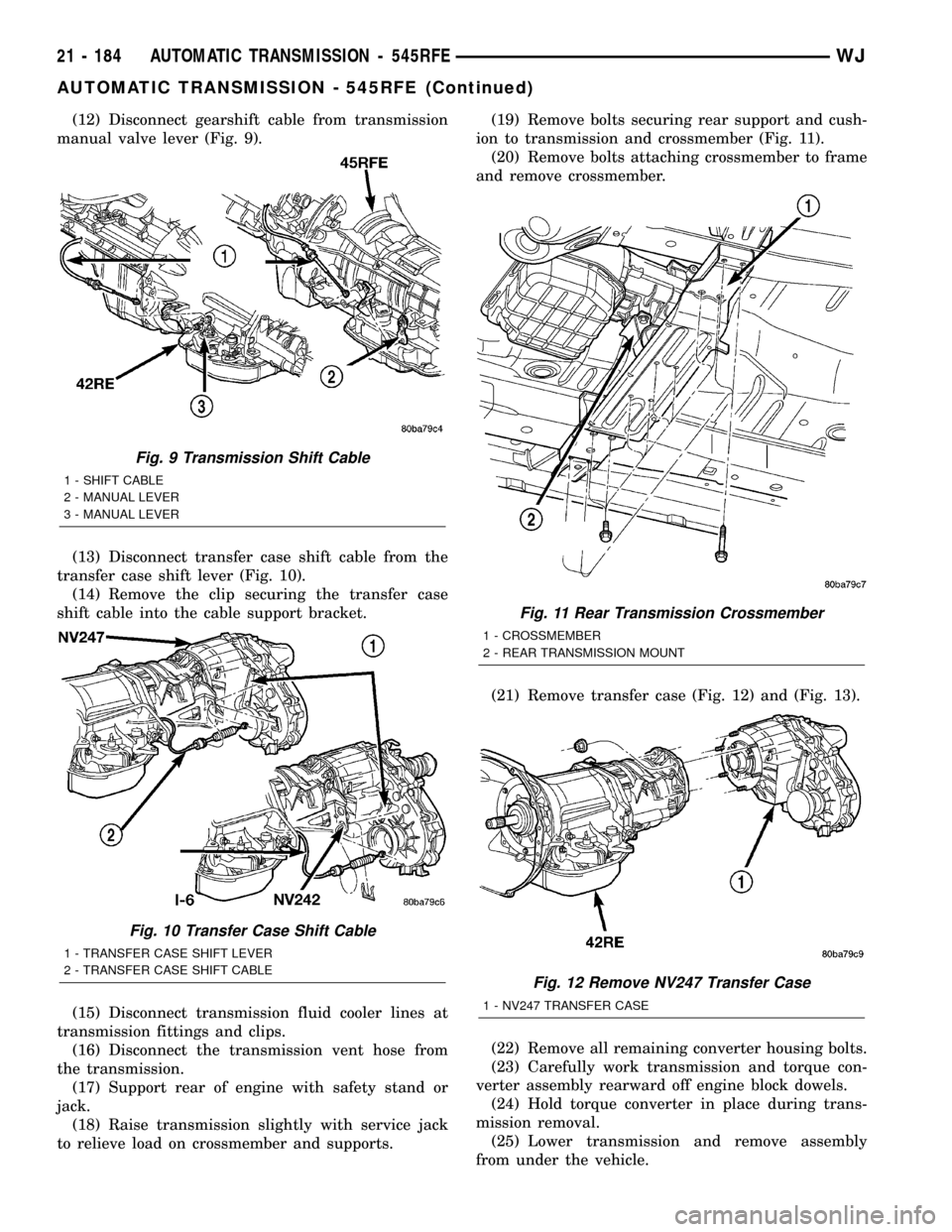

(12) Disconnect gearshift cable from transmission

manual valve lever (Fig. 9).

(13) Disconnect transfer case shift cable from the

transfer case shift lever (Fig. 10).

(14) Remove the clip securing the transfer case

shift cable into the cable support bracket.

(15) Disconnect transmission fluid cooler lines at

transmission fittings and clips.

(16) Disconnect the transmission vent hose from

the transmission.

(17) Support rear of engine with safety stand or

jack.

(18) Raise transmission slightly with service jack

to relieve load on crossmember and supports.(19) Remove bolts securing rear support and cush-

ion to transmission and crossmember (Fig. 11).

(20) Remove bolts attaching crossmember to frame

and remove crossmember.

(21) Remove transfer case (Fig. 12) and (Fig. 13).

(22) Remove all remaining converter housing bolts.

(23) Carefully work transmission and torque con-

verter assembly rearward off engine block dowels.

(24) Hold torque converter in place during trans-

mission removal.

(25) Lower transmission and remove assembly

from under the vehicle.

Fig. 9 Transmission Shift Cable

1 - SHIFT CABLE

2 - MANUAL LEVER

3 - MANUAL LEVER

Fig. 10 Transfer Case Shift Cable

1 - TRANSFER CASE SHIFT LEVER

2 - TRANSFER CASE SHIFT CABLE

Fig. 11 Rear Transmission Crossmember

1 - CROSSMEMBER

2 - REAR TRANSMISSION MOUNT

Fig. 12 Remove NV247 Transfer Case

1 - NV247 TRANSFER CASE

21 - 184 AUTOMATIC TRANSMISSION - 545RFEWJ

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1747 of 2199

(8) Engine starts must be possible with shifter

lever in PARK or NEUTRAL gate positions only.

Engine starts must not be possible in any other gate

positions other than PARK or NEUTRAL.

(9) With shifter lever handle push-button not

depressed and lever detent in:

²PARK position- apply forward force on center of

handle and remove pressure. Engine start must be

possible.

²PARK position- apply rearward force on center

of handle and remove pressure. Engine start must be

possible.

²NEUTRAL position- engine start must be possi-

ble.

²NEUTRAL position, engine running and brakes

applied- Apply forward force on center of shift han-

dle. Transmission should not be able to shift into

REVERSE detent.

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL

A low fluid level allows the pump to take in air

along with the fluid. Air in the fluid will cause fluid

pressures to be low and develop slower than normal.

If the transmission is overfilled, the gears churn the

fluid into foam. This aerates the fluid and causing

the same conditions occurring with a low level. In

either case, air bubbles cause fluid overheating, oxi-

dation and varnish buildup which interferes with

valve and clutch operation. Foaming also causes fluid

expansion which can result in fluid overflow from the

transmission vent or fill tube. Fluid overflow can eas-

ily be mistaken for a leak if inspection is not careful.

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID

Burnt, discolored fluid is a result of overheating

which has three primary causes.

(1) Internal clutch slippage, usually caused by low

line pressure, inadequate clutch apply pressure, or

clutch seal failure.

(2) A result of restricted fluid flow through the

main and/or auxiliary cooler. This condition is usu-

ally the result of a faulty or improperly installed

drainback valve, a damaged main cooler, or severe

restrictions in the coolers and lines caused by debris

or kinked lines.(3) Heavy duty operation with a vehicle not prop-

erly equipped for this type of operation. Trailer tow-

ing or similar high load operation will overheat the

transmission fluid if the vehicle is improperly

equipped. Such vehicles should have an auxiliary

transmission fluid cooler, a heavy duty cooling sys-

tem, and the engine/axle ratio combination needed to

handle heavy loads.

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION

Transmission fluid contamination is generally a

result of:

²adding incorrect fluid

²failure to clean dipstick and fill tube when

checking level

²engine coolant entering the fluid

²internal failure that generates debris

²overheat that generates sludge (fluid break-

down)

²failure to reverse flush cooler and lines after

repair

²failure to replace contaminated converter after

repair

The use of non-recommended fluids can result in

transmission failure. The usual results are erratic

shifts, slippage, abnormal wear and eventual failure

due to fluid breakdown and sludge formation. Avoid

this condition by using recommended fluids only.

The dipstick cap and fill tube should be wiped

clean before checking fluid level. Dirt, grease and

other foreign material on the cap and tube could fall

into the tube if not removed beforehand. Take the

time to wipe the cap and tube clean before withdraw-

ing the dipstick.

Engine coolant in the transmission fluid is gener-

ally caused by a cooler malfunction. The only remedy

is to replace the radiator as the cooler in the radiator

is not a serviceable part. If coolant has circulated

through the transmission, an overhaul is necessary.

The transmission cooler and lines should be

reverse flushed whenever a malfunction generates

sludge and/or debris. The torque converter should

also be replaced at the same time.

Failure to flush the cooler and lines will result in

recontamination. Flushing applies to auxiliary cool-

ers as well. The torque converter should also be

replaced whenever a failure generates sludge and

debris. This is necessary because normal converter

flushing procedures will not remove all contami-

nants.

21 - 228 AUTOMATIC TRANSMISSION - 545RFEWJ

BRAKE TRANSMISSION SHIFT INTERLOCK MECHANISM (Continued)

Page 1749 of 2199

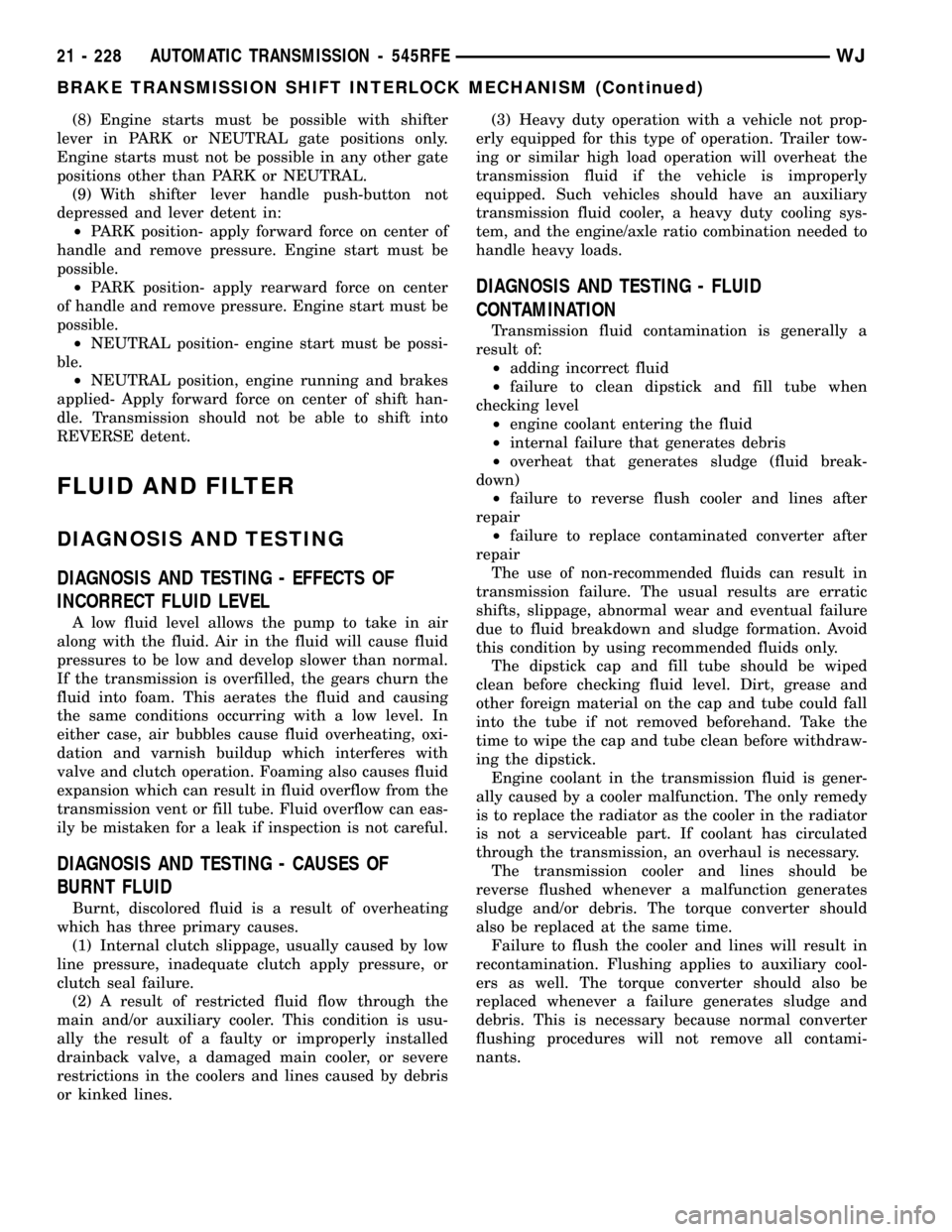

STANDARD PROCEDURE - FLUID AND FILTER

REPLACEMENT

For proper service intervals (Refer to LUBRICA-

TION & MAINTENANCE/MAINTENANCE SCHED-

ULES - DESCRIPTION).

REMOVAL

(1) Hoist and support vehicle on safety stands.

(2) Place a large diameter shallow drain pan

beneath the transmission pan.

(3) Remove bolts holding front and sides of pan to

transmission.

(4)

Loosen bolts holding rear of pan to transmission.

(5) Slowly separate front of pan away from trans-

mission allowing the fluid to drain into drain pan.

(6) Hold up pan and remove remaining bolts hold-

ing pan to transmission.

(7) While holding pan level, lower pan away from

transmission.

(8) Pour remaining fluid in pan into drain pan.

(9)

Remove screw holding filter to valve body (Fig. 60).

(10) Separate filter from valve body and oil pump

and pour fluid in filter into drain pan.

(11) Remove and discard the oil filter seal from the

bottom of the oil pump.

(12) If replacing the cooler return filter, use Oil

Filter Wrench 8321 to remove the filter from the

transmission.

(13) Dispose of used trans fluid and filter(s) prop-

erly.

INSPECTION

Inspect bottom of pan and magnet for excessive

amounts of metal. A light coating of clutch material

on the bottom of the pan does not indicate a problemunless accompanied by a slipping condition or shift

lag. If fluid and pan are contaminated with excessive

amounts of debris, refer to the diagnosis section of

this group.

CLEANING

(1) Using a suitable solvent, clean pan and mag-

net.

(2) Using a suitable gasket scraper, clean original

sealing material from surface of transmission case

and the transmission pan.

INSTALLATION

(1) Install a new primary oil filter seal in the oil

pump inlet bore. Seat the seal in the bore with the

butt end of a hammer, or other suitable tool.

CAUTION: The primary oil filter seal MUST be fully

installed flush against the oil pump body. DO NOT

install the seal onto the filter neck and attempt to

install the filter and seal as an assembly. Damage to

the transmission will result.

(2) Place replacement filter in position on valve

body and into the oil pump.

(3) Install screw to hold filter to valve body (Fig.

60). Tighten screw to 4.5 N´m (40 in. lbs.) torque.

(4) Install new cooler return filter onto the trans-

mission, if necessary. Torque the filter to 14.12 N´m

(125 in.lbs.).

(5) Place bead of MopartRTV sealant onto the

transmission case sealing surface.

(6) Place pan in position on transmission.

(7) Install bolts to hold pan to transmission.

Tighten bolts to 11.8 N´m (105 in. lbs.) torque.

(8) Lower vehicle and fill transmission with

MopartATF +4, type 9602 fluid.

STANDARD PROCEDURE - TRANSMISSION

FILL

To avoid overfilling transmission after a fluid

change or overhaul, perform the following procedure:

(1) Remove dipstick and insert clean funnel in

transmission fill tube.

(2) Add following initial quantity of MopartAT F

+4 to transmission:

(a) If only fluid and filter were changed, add10

pints (5 quarts)of ATF +4 to transmission.

(b) If transmission was completely overhauled,

torque converter was replaced or drained, and

cooler was flushed, add24 pints (12 quarts)of

ATF +4 to transmission.

(3) Check the transmission fluid (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

45RFE/FLUID - STANDARD PROCEDURE) and

adjust as required.

Fig. 60 Transmission Filters - 4X4 Shown

1 - PRIMARY OIL FILTER

2 - COOLER RETURN FILTER

3 - COOLER RETURN FILTER BYPASS VALVE

4 - VALVE BODY

21 - 230 AUTOMATIC TRANSMISSION - 545RFEWJ

FLUID AND FILTER (Continued)

Page 1779 of 2199

OPERATION

REACTION PLANETARY GEARTRAIN

The reaction planetary carrier and reverse sun

gear of the reaction planetary geartrain are a single

component which is held by the 2C clutch when

required. The reaction annulus gear is a stand alone

component that can be driven by the reverse clutch

or held by the 4C clutch. The reaction sun gear is

driven by the overdrive clutch.

REVERSE PLANETARY GEARTRAIN

The reverse planetary geartrain is the middle of

the three planetary sets. The reverse planetary car-

rier can be driven by the overdrive clutch as

required. The reverse planetary carrier is also

splined to the input annulus gear, which can be held

by the low/reverse clutch. The reverse planetary

annulus, input planetary carrier, and output shaft

are all one piece.

INPUT PLANETARY GEARTRAIN

The input sun gear of the input planetary

geartrain is driven by the underdrive clutch.

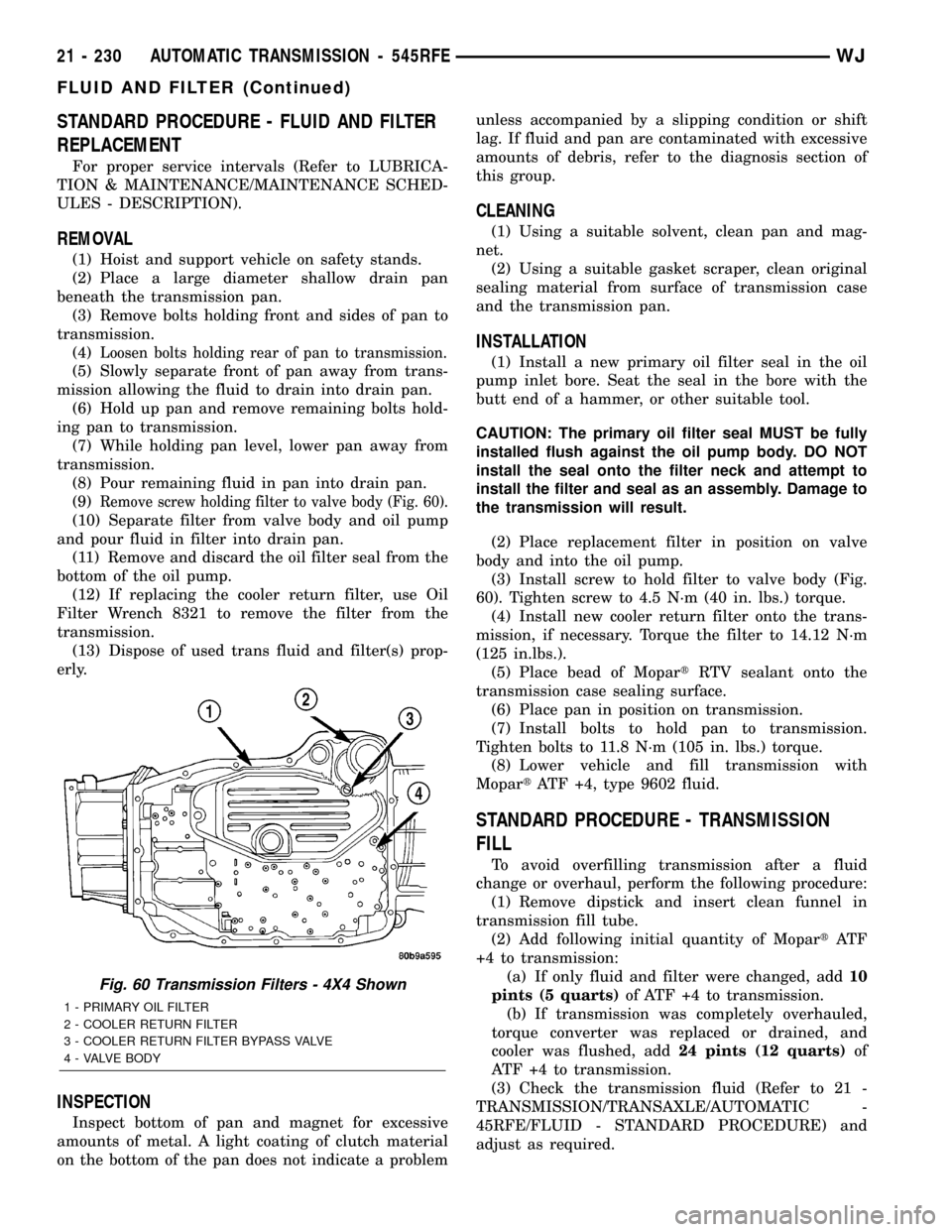

DISASSEMBLY

(1) Remove the snap-ring holding the input annu-

lus into the input carrier (Fig. 104).

(2) Remove the input annulus from the input car-

rier (Fig. 104).

(3) Remove the number 9 bearing from the reverse

planetary carrier. Note that this planetary carrier

has four pinion gears.

(4) Remove the reverse planetary gear carrier (Fig.

104).

(5) Remove the number 10 bearing from the input

sun gear (Fig. 104).

(6) Remove the input sun gear from the input car-

rier (Fig. 104).

(7) Remove the number 11 bearing from the input

carrier (Fig. 104).

CLEANING

Clean the planetary components in solvent and dry

them with compressed air.

INSPECTION

Check sun gear and driving shell condition.

Replace the gear if damaged or if the bushings are

scored or worn. The bushings are not serviceable.

Fig. 104 Reverse/Input Planetary Carrier Assembly

1 - SNAP-RING 5 - INPUT PLANETARY CARRIER

2 - BEARING NUMBER 10 6 - INPUT SUN GEAR

3 - BEARING NUMBER 11 7 - REVERSE PLANETARY CARRIER

4 - INPUT ANNULUS

21 - 260 AUTOMATIC TRANSMISSION - 545RFEWJ

PLANETARY GEARTRAIN (Continued)

Page 1783 of 2199

A solenoid can also be described by the method by

which it is controlled. Some of the possibilities

include variable force, pulse-width modulated, con-

stant ON, or duty cycle. The variable force and pulse-

width modulated versions utilize similar methods to

control the current flow through the solenoid to posi-

tion the solenoid plunger at a desired position some-

where between full ON and full OFF. The constant

ON and duty cycled versions control the voltage

across the solenoid to allow either full flow or no flow

through the solenoid's valve.

OPERATION

When an electrical current is applied to the sole-

noid coil, a magnetic field is created which produces

an attraction to the plunger, causing the plunger to

move and work against the spring pressure and the

load applied by the fluid the valve is controlling. The

plunger is normally directly attached to the valve

which it is to operate. When the current is removed

from the coil, the attraction is removed and the

plunger will return to its original position due to

spring pressure.

The plunger is made of a conductive material and

accomplishes this movement by providing a path for

the magnetic field to flow. By keeping the air gap

between the plunger and the coil to the minimum

necessary to allow free movement of the plunger, the

magnetic field is maximized.

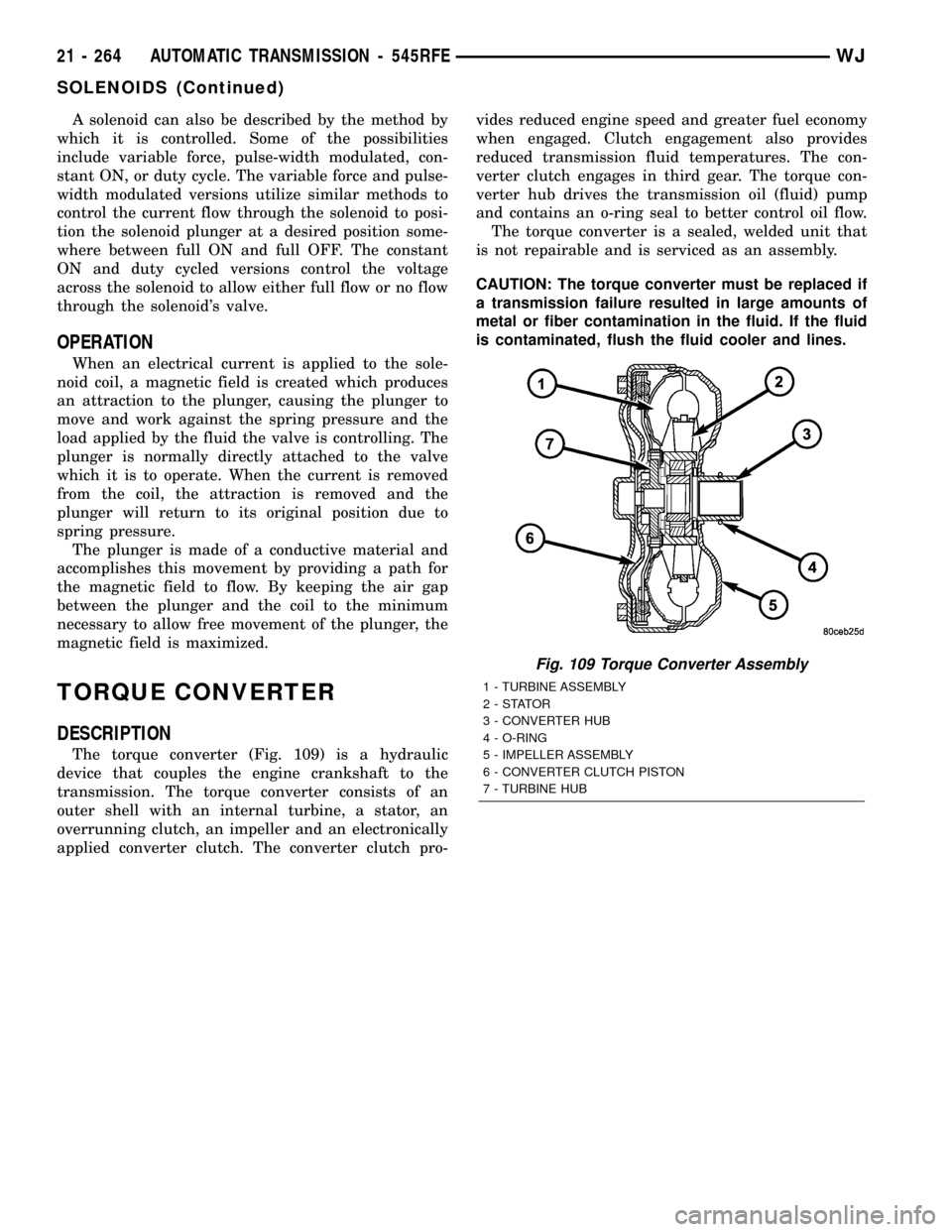

TORQUE CONVERTER

DESCRIPTION

The torque converter (Fig. 109) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, an

overrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The con-

verter clutch engages in third gear. The torque con-

verter hub drives the transmission oil (fluid) pump

and contains an o-ring seal to better control oil flow.

The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

CAUTION: The torque converter must be replaced if

a transmission failure resulted in large amounts of

metal or fiber contamination in the fluid. If the fluid

is contaminated, flush the fluid cooler and lines.

Fig. 109 Torque Converter Assembly

1 - TURBINE ASSEMBLY

2-STATOR

3 - CONVERTER HUB

4 - O-RING

5 - IMPELLER ASSEMBLY

6 - CONVERTER CLUTCH PISTON

7 - TURBINE HUB

21 - 264 AUTOMATIC TRANSMISSION - 545RFEWJ

SOLENOIDS (Continued)

Page 1793 of 2199

be in the downshifted position, thus directing fluid to

the L/R clutch circuit. In 2nd, 3rd, 4th, and fifth

gears, the solenoid switch valve will be in the

upshifted position and directs the fluid into the

torque converter clutch (TCC) circuit.

When shifting into 1st gear, a special hydraulic

sequence is performed to ensure SSV movement into

the downshifted position. The L/R pressure switch is

monitored to confirm SSV movement. If the move-

ment is not confirmed (the L/R pressure switch does

not close), 2nd gear is substituted for 1st. A DTC will

be set after three unsuccessful attempts are made to

get into 1st gear in one given key start.

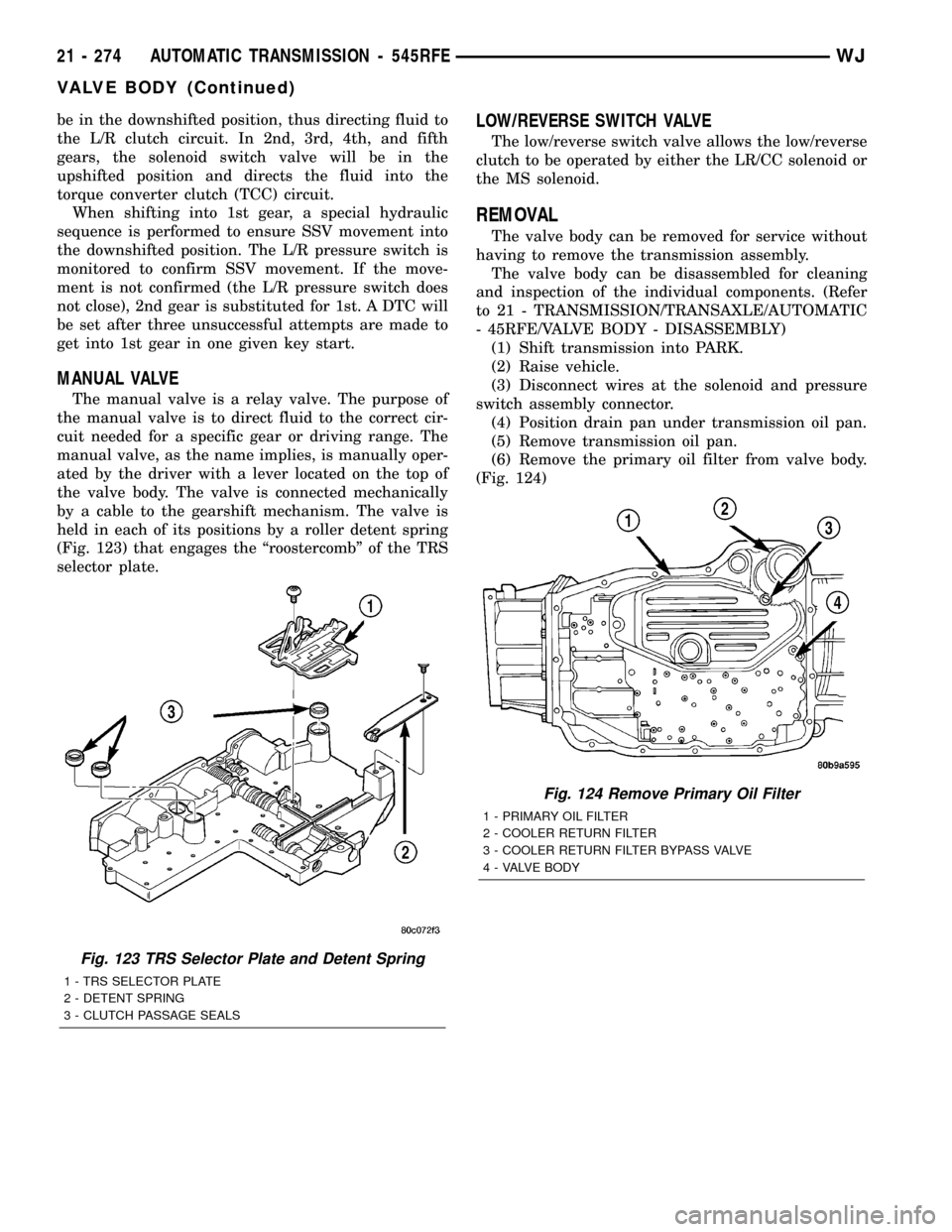

MANUAL VALVE

The manual valve is a relay valve. The purpose of

the manual valve is to direct fluid to the correct cir-

cuit needed for a specific gear or driving range. The

manual valve, as the name implies, is manually oper-

ated by the driver with a lever located on the top of

the valve body. The valve is connected mechanically

by a cable to the gearshift mechanism. The valve is

held in each of its positions by a roller detent spring

(Fig. 123) that engages the ªroostercombº of the TRS

selector plate.

LOW/REVERSE SWITCH VALVE

The low/reverse switch valve allows the low/reverse

clutch to be operated by either the LR/CC solenoid or

the MS solenoid.

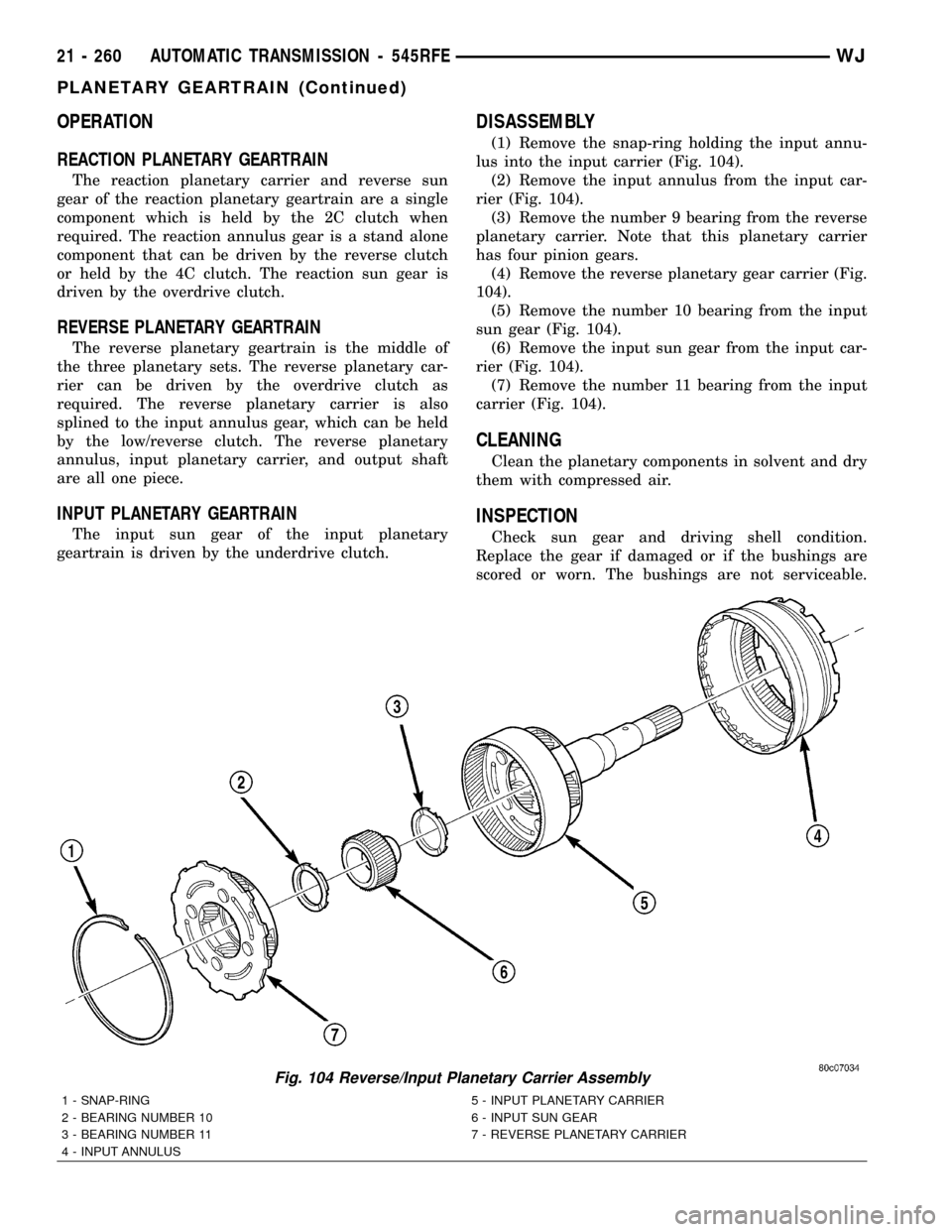

REMOVAL

The valve body can be removed for service without

having to remove the transmission assembly.

The valve body can be disassembled for cleaning

and inspection of the individual components. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 45RFE/VALVE BODY - DISASSEMBLY)

(1) Shift transmission into PARK.

(2) Raise vehicle.

(3) Disconnect wires at the solenoid and pressure

switch assembly connector.

(4) Position drain pan under transmission oil pan.

(5) Remove transmission oil pan.

(6) Remove the primary oil filter from valve body.

(Fig. 124)

Fig. 123 TRS Selector Plate and Detent Spring

1 - TRS SELECTOR PLATE

2 - DETENT SPRING

3 - CLUTCH PASSAGE SEALS

Fig. 124 Remove Primary Oil Filter

1 - PRIMARY OIL FILTER

2 - COOLER RETURN FILTER

3 - COOLER RETURN FILTER BYPASS VALVE

4 - VALVE BODY

21 - 274 AUTOMATIC TRANSMISSION - 545RFEWJ

VALVE BODY (Continued)