service JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1799 of 2199

TRANSFER CASE - NV242

TABLE OF CONTENTS

page page

TRANSFER CASE - NV242

DESCRIPTION........................280

OPERATION..........................281

DIAGNOSIS AND TESTING - TRANSFER

CASE - NV242.......................281

REMOVAL............................282

DISASSEMBLY........................282

CLEANING...........................292

INSPECTION.........................293

ASSEMBLY...........................295

INSTALLATION........................307

SPECIFICATIONS

TRANSFER CASE - NV242.............308

SPECIAL TOOLS

TRANSFER CASE - NV242.............308

FLUID

STANDARD PROCEDURE - FLUID DRAIN/

REFILL............................310FRONT OUTPUT SHAFT SEAL

REMOVAL............................310

INSTALLATION........................310

POSITION SENSOR

DESCRIPTION........................311

OPERATION..........................311

REMOVAL............................312

INSTALLATION........................312

REAR RETAINER BUSHING AND SEAL -

NV242HD

REMOVAL............................312

INSTALLATION........................312

SHIFT CABLE

REMOVAL............................313

INSTALLATION........................313

TRANSFER CASE - NV242

DESCRIPTION

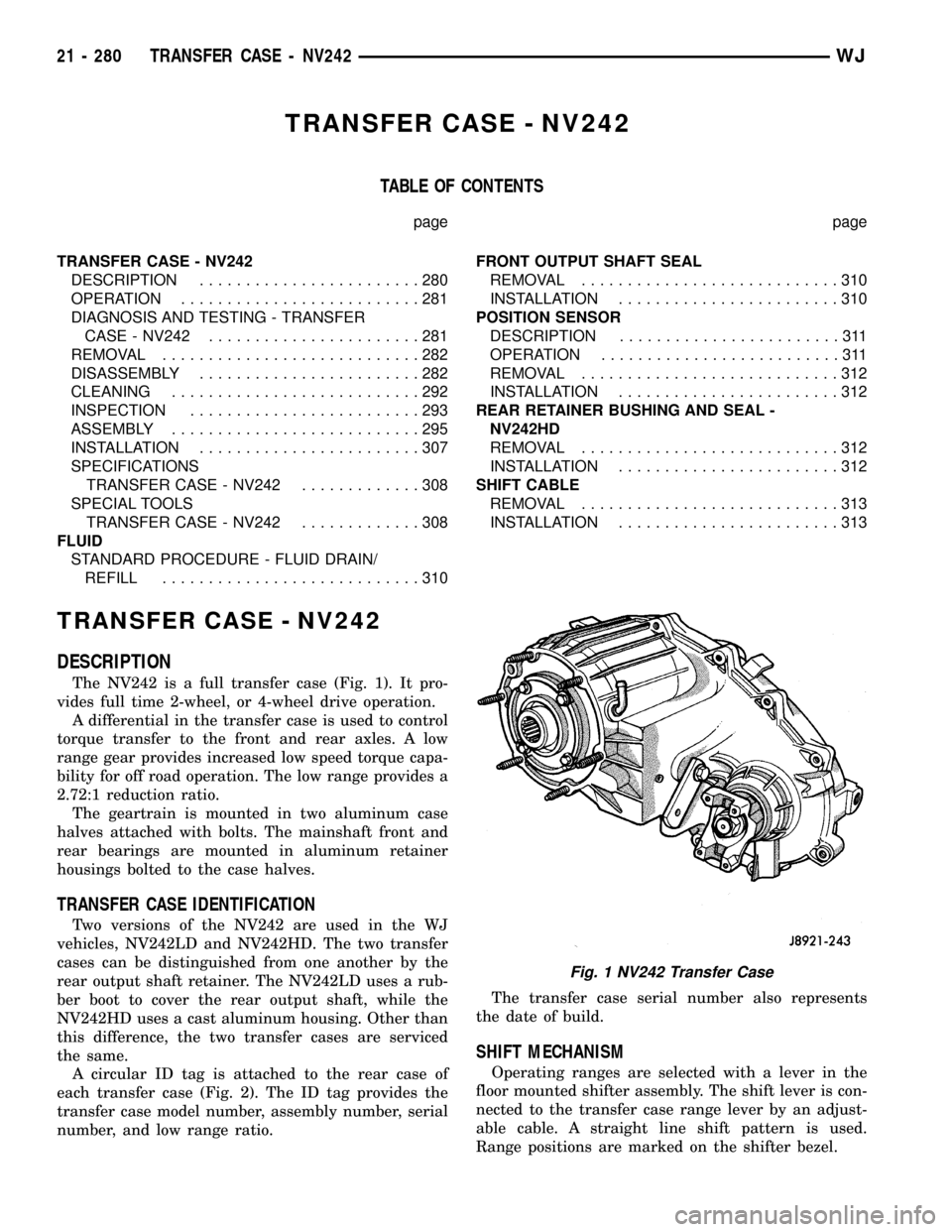

The NV242 is a full transfer case (Fig. 1). It pro-

vides full time 2-wheel, or 4-wheel drive operation.

A differential in the transfer case is used to control

torque transfer to the front and rear axles. A low

range gear provides increased low speed torque capa-

bility for off road operation. The low range provides a

2.72:1 reduction ratio.

The geartrain is mounted in two aluminum case

halves attached with bolts. The mainshaft front and

rear bearings are mounted in aluminum retainer

housings bolted to the case halves.

TRANSFER CASE IDENTIFICATION

Two versions of the NV242 are used in the WJ

vehicles, NV242LD and NV242HD. The two transfer

cases can be distinguished from one another by the

rear output shaft retainer. The NV242LD uses a rub-

ber boot to cover the rear output shaft, while the

NV242HD uses a cast aluminum housing. Other than

this difference, the two transfer cases are serviced

the same.

A circular ID tag is attached to the rear case of

each transfer case (Fig. 2). The ID tag provides the

transfer case model number, assembly number, serial

number, and low range ratio.The transfer case serial number also represents

the date of build.

SHIFT MECHANISM

Operating ranges are selected with a lever in the

floor mounted shifter assembly. The shift lever is con-

nected to the transfer case range lever by an adjust-

able cable. A straight line shift pattern is used.

Range positions are marked on the shifter bezel.

Fig. 1 NV242 Transfer Case

21 - 280 TRANSFER CASE - NV242WJ

Page 1811 of 2199

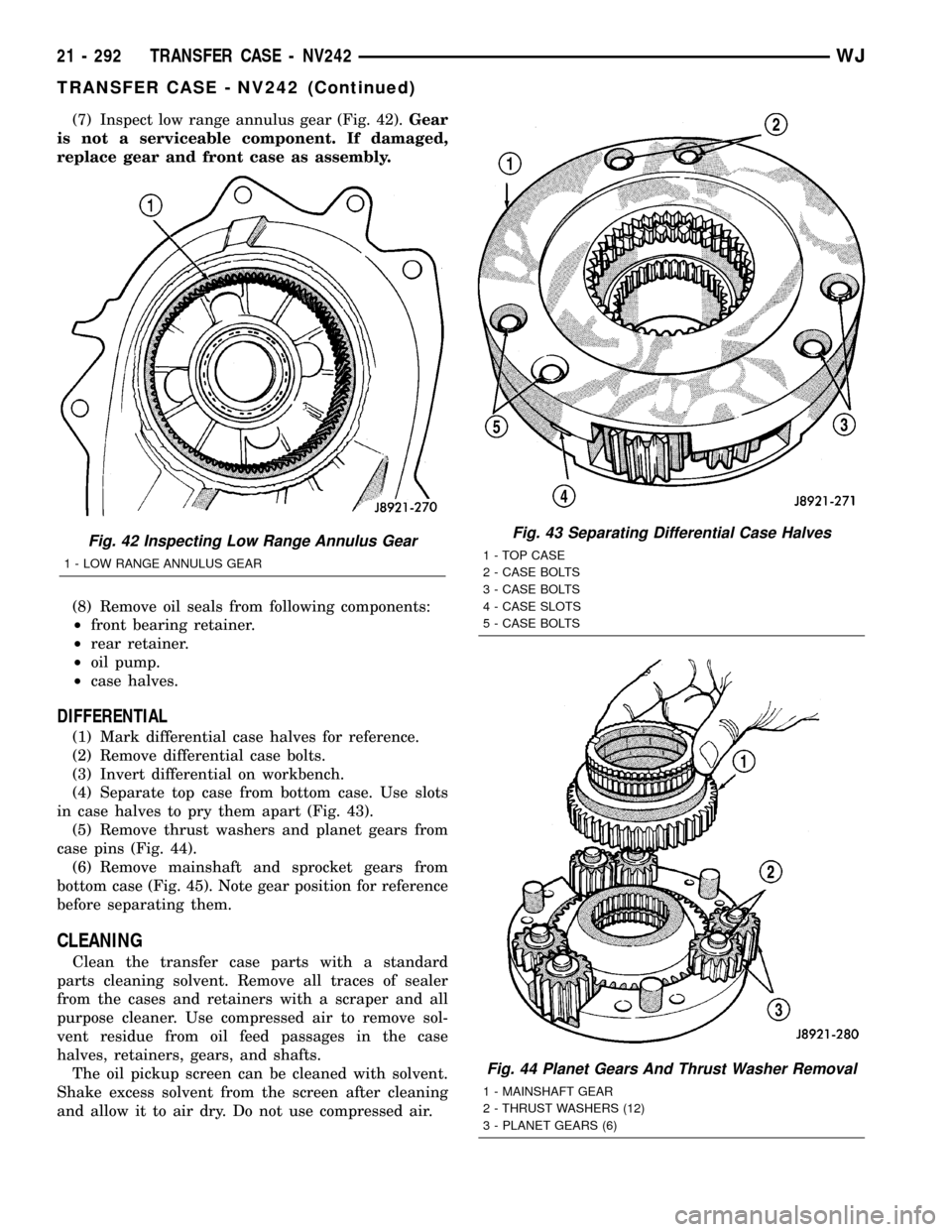

(7) Inspect low range annulus gear (Fig. 42).Gear

is not a serviceable component. If damaged,

replace gear and front case as assembly.

(8) Remove oil seals from following components:

²front bearing retainer.

²rear retainer.

²oil pump.

²case halves.

DIFFERENTIAL

(1) Mark differential case halves for reference.

(2) Remove differential case bolts.

(3) Invert differential on workbench.

(4) Separate top case from bottom case. Use slots

in case halves to pry them apart (Fig. 43).

(5) Remove thrust washers and planet gears from

case pins (Fig. 44).

(6) Remove mainshaft and sprocket gears from

bottom case (Fig. 45). Note gear position for reference

before separating them.

CLEANING

Clean the transfer case parts with a standard

parts cleaning solvent. Remove all traces of sealer

from the cases and retainers with a scraper and all

purpose cleaner. Use compressed air to remove sol-

vent residue from oil feed passages in the case

halves, retainers, gears, and shafts.

The oil pickup screen can be cleaned with solvent.

Shake excess solvent from the screen after cleaning

and allow it to air dry. Do not use compressed air.

Fig. 42 Inspecting Low Range Annulus Gear

1 - LOW RANGE ANNULUS GEAR

Fig. 43 Separating Differential Case Halves

1 - TOP CASE

2 - CASE BOLTS

3 - CASE BOLTS

4 - CASE SLOTS

5 - CASE BOLTS

Fig. 44 Planet Gears And Thrust Washer Removal

1 - MAINSHAFT GEAR

2 - THRUST WASHERS (12)

3 - PLANET GEARS (6)

21 - 292 TRANSFER CASE - NV242WJ

TRANSFER CASE - NV242 (Continued)

Page 1813 of 2199

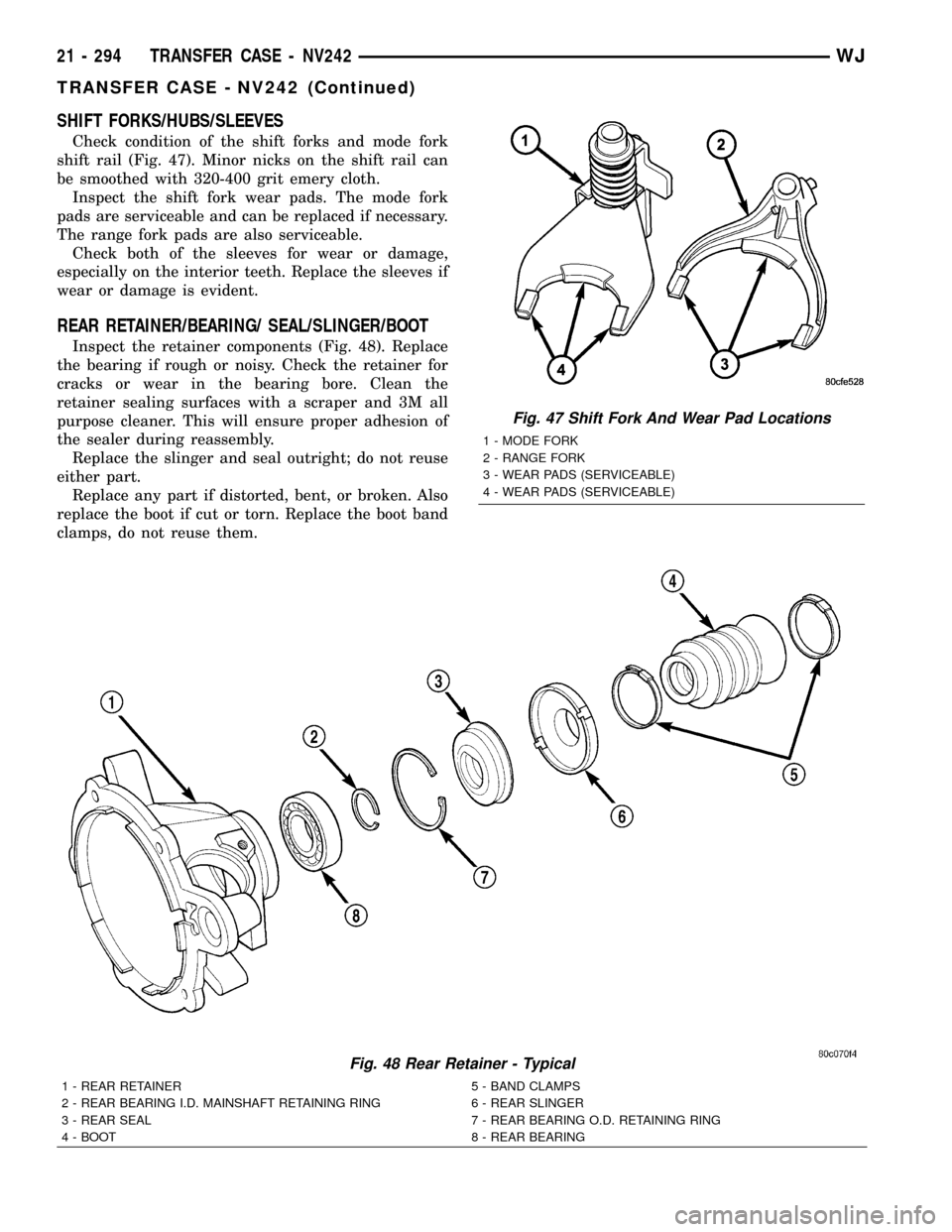

SHIFT FORKS/HUBS/SLEEVES

Check condition of the shift forks and mode fork

shift rail (Fig. 47). Minor nicks on the shift rail can

be smoothed with 320-400 grit emery cloth.

Inspect the shift fork wear pads. The mode fork

pads are serviceable and can be replaced if necessary.

The range fork pads are also serviceable.

Check both of the sleeves for wear or damage,

especially on the interior teeth. Replace the sleeves if

wear or damage is evident.

REAR RETAINER/BEARING/ SEAL/SLINGER/BOOT

Inspect the retainer components (Fig. 48). Replace

the bearing if rough or noisy. Check the retainer for

cracks or wear in the bearing bore. Clean the

retainer sealing surfaces with a scraper and 3M all

purpose cleaner. This will ensure proper adhesion of

the sealer during reassembly.

Replace the slinger and seal outright; do not reuse

either part.

Replace any part if distorted, bent, or broken. Also

replace the boot if cut or torn. Replace the boot band

clamps, do not reuse them.

Fig. 48 Rear Retainer - Typical

1 - REAR RETAINER 5 - BAND CLAMPS

2 - REAR BEARING I.D. MAINSHAFT RETAINING RING 6 - REAR SLINGER

3 - REAR SEAL 7 - REAR BEARING O.D. RETAINING RING

4 - BOOT 8 - REAR BEARING

Fig. 47 Shift Fork And Wear Pad Locations

1 - MODE FORK

2 - RANGE FORK

3 - WEAR PADS (SERVICEABLE)

4 - WEAR PADS (SERVICEABLE)

21 - 294 TRANSFER CASE - NV242WJ

TRANSFER CASE - NV242 (Continued)

Page 1814 of 2199

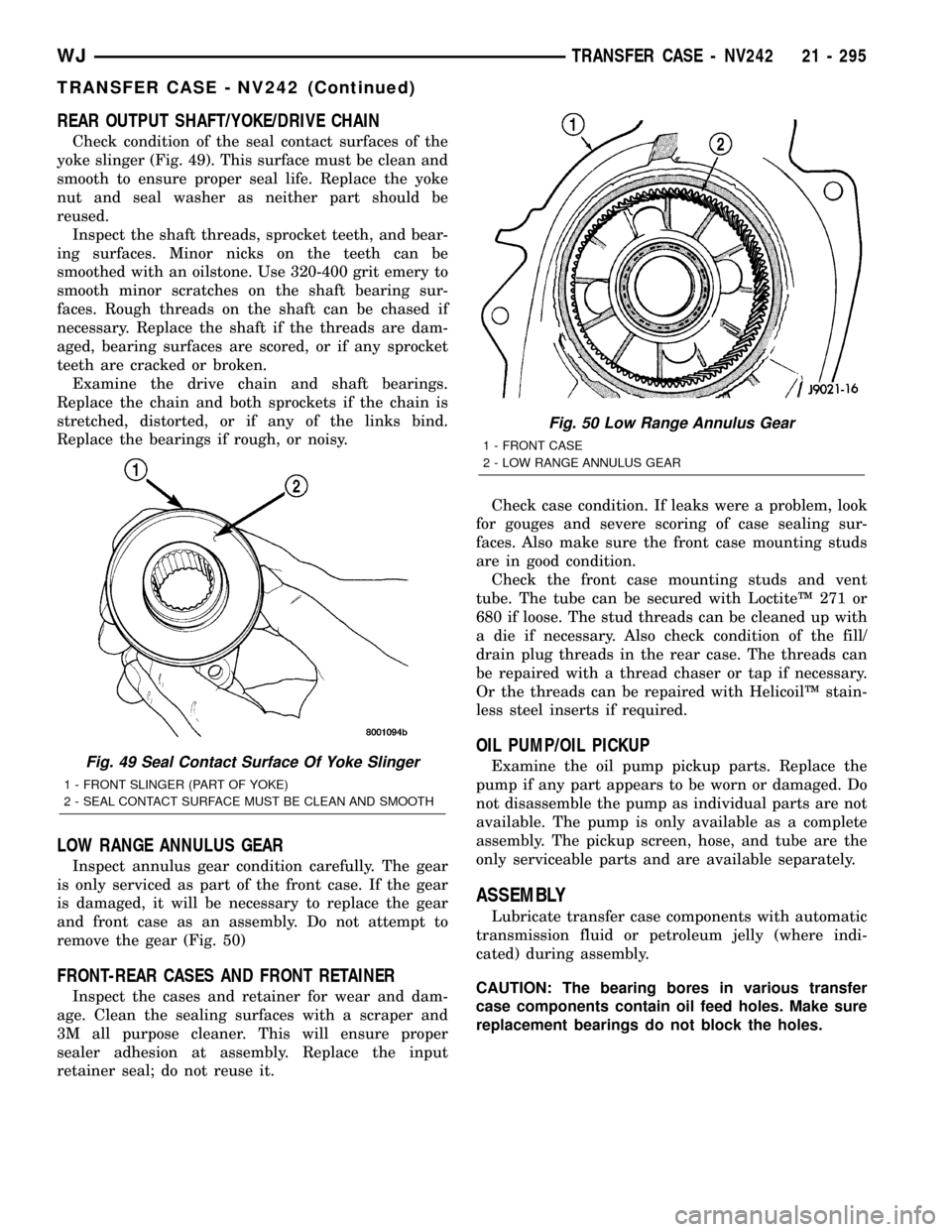

REAR OUTPUT SHAFT/YOKE/DRIVE CHAIN

Check condition of the seal contact surfaces of the

yoke slinger (Fig. 49). This surface must be clean and

smooth to ensure proper seal life. Replace the yoke

nut and seal washer as neither part should be

reused.

Inspect the shaft threads, sprocket teeth, and bear-

ing surfaces. Minor nicks on the teeth can be

smoothed with an oilstone. Use 320-400 grit emery to

smooth minor scratches on the shaft bearing sur-

faces. Rough threads on the shaft can be chased if

necessary. Replace the shaft if the threads are dam-

aged, bearing surfaces are scored, or if any sprocket

teeth are cracked or broken.

Examine the drive chain and shaft bearings.

Replace the chain and both sprockets if the chain is

stretched, distorted, or if any of the links bind.

Replace the bearings if rough, or noisy.

LOW RANGE ANNULUS GEAR

Inspect annulus gear condition carefully. The gear

is only serviced as part of the front case. If the gear

is damaged, it will be necessary to replace the gear

and front case as an assembly. Do not attempt to

remove the gear (Fig. 50)

FRONT-REAR CASES AND FRONT RETAINER

Inspect the cases and retainer for wear and dam-

age. Clean the sealing surfaces with a scraper and

3M all purpose cleaner. This will ensure proper

sealer adhesion at assembly. Replace the input

retainer seal; do not reuse it.Check case condition. If leaks were a problem, look

for gouges and severe scoring of case sealing sur-

faces. Also make sure the front case mounting studs

are in good condition.

Check the front case mounting studs and vent

tube. The tube can be secured with LoctiteŸ 271 or

680 if loose. The stud threads can be cleaned up with

a die if necessary. Also check condition of the fill/

drain plug threads in the rear case. The threads can

be repaired with a thread chaser or tap if necessary.

Or the threads can be repaired with HelicoilŸ stain-

less steel inserts if required.

OIL PUMP/OIL PICKUP

Examine the oil pump pickup parts. Replace the

pump if any part appears to be worn or damaged. Do

not disassemble the pump as individual parts are not

available. The pump is only available as a complete

assembly. The pickup screen, hose, and tube are the

only serviceable parts and are available separately.

ASSEMBLY

Lubricate transfer case components with automatic

transmission fluid or petroleum jelly (where indi-

cated) during assembly.

CAUTION: The bearing bores in various transfer

case components contain oil feed holes. Make sure

replacement bearings do not block the holes.

Fig. 49 Seal Contact Surface Of Yoke Slinger

1 - FRONT SLINGER (PART OF YOKE)

2 - SEAL CONTACT SURFACE MUST BE CLEAN AND SMOOTH

Fig. 50 Low Range Annulus Gear

1 - FRONT CASE

2 - LOW RANGE ANNULUS GEAR

WJTRANSFER CASE - NV242 21 - 295

TRANSFER CASE - NV242 (Continued)

Page 1838 of 2199

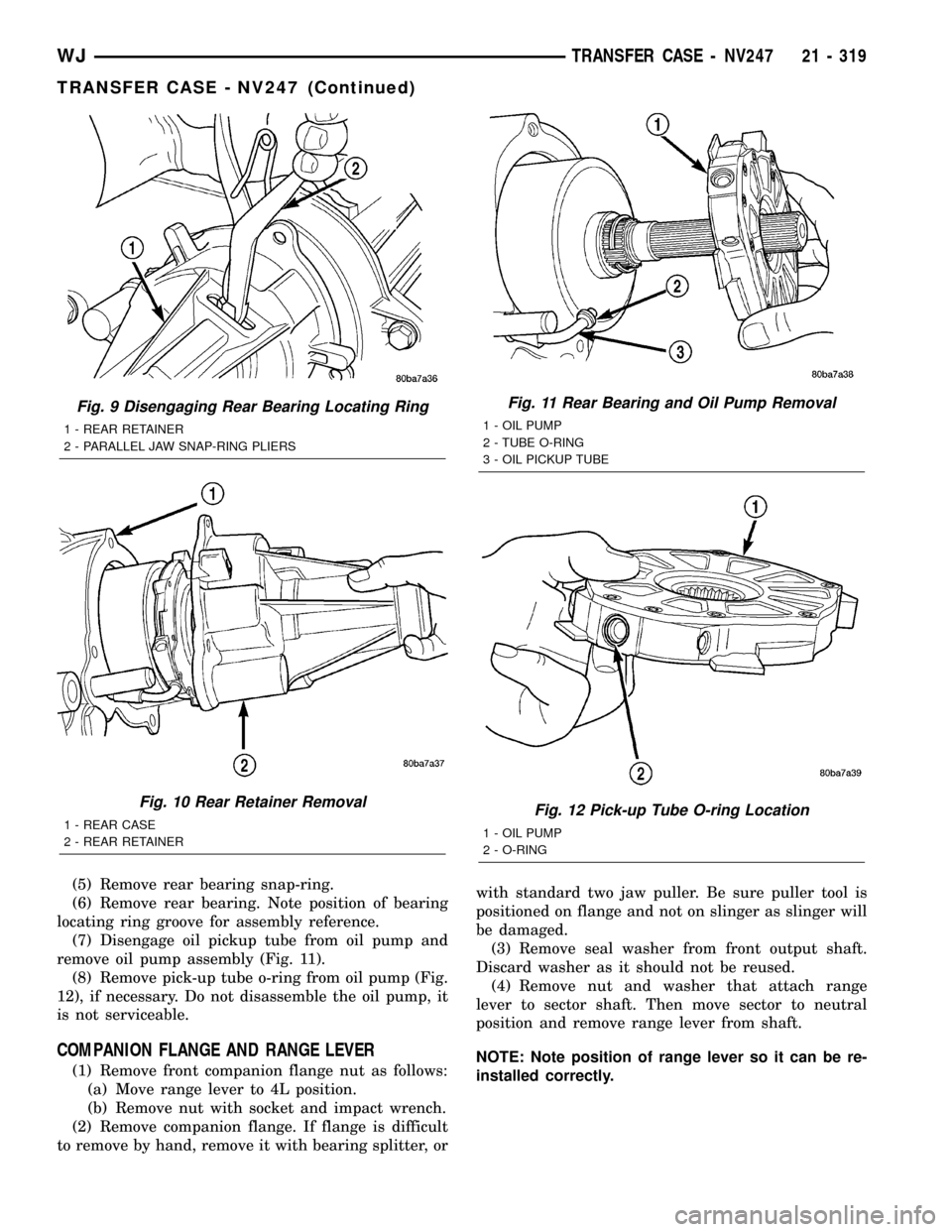

(5) Remove rear bearing snap-ring.

(6) Remove rear bearing. Note position of bearing

locating ring groove for assembly reference.

(7) Disengage oil pickup tube from oil pump and

remove oil pump assembly (Fig. 11).

(8) Remove pick-up tube o-ring from oil pump (Fig.

12), if necessary. Do not disassemble the oil pump, it

is not serviceable.

COMPANION FLANGE AND RANGE LEVER

(1) Remove front companion flange nut as follows:

(a) Move range lever to 4L position.

(b) Remove nut with socket and impact wrench.

(2) Remove companion flange. If flange is difficult

to remove by hand, remove it with bearing splitter, orwith standard two jaw puller. Be sure puller tool is

positioned on flange and not on slinger as slinger will

be damaged.

(3) Remove seal washer from front output shaft.

Discard washer as it should not be reused.

(4) Remove nut and washer that attach range

lever to sector shaft. Then move sector to neutral

position and remove range lever from shaft.

NOTE: Note position of range lever so it can be re-

installed correctly.

Fig. 9 Disengaging Rear Bearing Locating Ring

1 - REAR RETAINER

2 - PARALLEL JAW SNAP-RING PLIERS

Fig. 10 Rear Retainer Removal

1 - REAR CASE

2 - REAR RETAINER

Fig. 11 Rear Bearing and Oil Pump Removal

1 - OIL PUMP

2 - TUBE O-RING

3 - OIL PICKUP TUBE

Fig. 12 Pick-up Tube O-ring Location

1 - OIL PUMP

2 - O-RING

WJTRANSFER CASE - NV247 21 - 319

TRANSFER CASE - NV247 (Continued)

Page 1844 of 2199

INPUT AND LOW RANGE GEARS

Inspect the low range gear pinions and pinion pins.

Replace the low range gear if any of the pins or pin-

ions are worn or damaged.

Inspect the thrust washers, retainer, and snap-

ring. Replace the snap-ring if bent, or distorted.

Replace the thrust washers and retainer if worn,

cracked or damaged in any way.

Examine the input gear carefully. Be sure the gear

teeth and bearing surfaces are in good condition.

Replace the gear if wear or damage is evident.

Check the input gear pilot bearing. Rotate the

bearing and check for roughness or noise. Also check

bearing position in the bore. The bearing should be

recessed approximately 2.5 mm (0.100 in.) below the

top edge of the bore. The bearing should not be

seated at the bottom of the bore. Replace the bearing

if worn, or roughness is evident. Replace both the

gear and bearing if the bearing is a loose fit in the

bore.

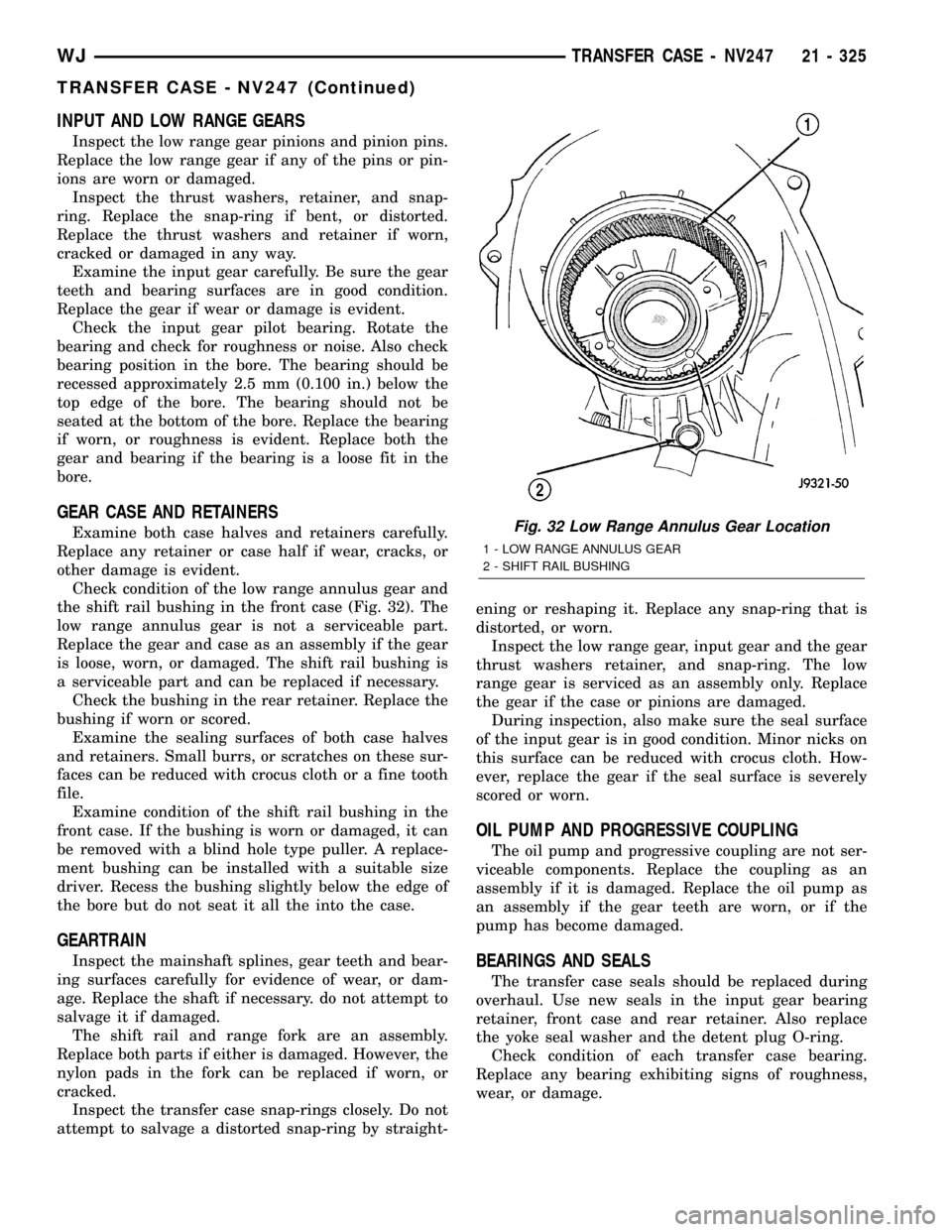

GEAR CASE AND RETAINERS

Examine both case halves and retainers carefully.

Replace any retainer or case half if wear, cracks, or

other damage is evident.

Check condition of the low range annulus gear and

the shift rail bushing in the front case (Fig. 32). The

low range annulus gear is not a serviceable part.

Replace the gear and case as an assembly if the gear

is loose, worn, or damaged. The shift rail bushing is

a serviceable part and can be replaced if necessary.

Check the bushing in the rear retainer. Replace the

bushing if worn or scored.

Examine the sealing surfaces of both case halves

and retainers. Small burrs, or scratches on these sur-

faces can be reduced with crocus cloth or a fine tooth

file.

Examine condition of the shift rail bushing in the

front case. If the bushing is worn or damaged, it can

be removed with a blind hole type puller. A replace-

ment bushing can be installed with a suitable size

driver. Recess the bushing slightly below the edge of

the bore but do not seat it all the into the case.

GEARTRAIN

Inspect the mainshaft splines, gear teeth and bear-

ing surfaces carefully for evidence of wear, or dam-

age. Replace the shaft if necessary. do not attempt to

salvage it if damaged.

The shift rail and range fork are an assembly.

Replace both parts if either is damaged. However, the

nylon pads in the fork can be replaced if worn, or

cracked.

Inspect the transfer case snap-rings closely. Do not

attempt to salvage a distorted snap-ring by straight-ening or reshaping it. Replace any snap-ring that is

distorted, or worn.

Inspect the low range gear, input gear and the gear

thrust washers retainer, and snap-ring. The low

range gear is serviced as an assembly only. Replace

the gear if the case or pinions are damaged.

During inspection, also make sure the seal surface

of the input gear is in good condition. Minor nicks on

this surface can be reduced with crocus cloth. How-

ever, replace the gear if the seal surface is severely

scored or worn.

OIL PUMP AND PROGRESSIVE COUPLING

The oil pump and progressive coupling are not ser-

viceable components. Replace the coupling as an

assembly if it is damaged. Replace the oil pump as

an assembly if the gear teeth are worn, or if the

pump has become damaged.

BEARINGS AND SEALS

The transfer case seals should be replaced during

overhaul. Use new seals in the input gear bearing

retainer, front case and rear retainer. Also replace

the yoke seal washer and the detent plug O-ring.

Check condition of each transfer case bearing.

Replace any bearing exhibiting signs of roughness,

wear, or damage.

Fig. 32 Low Range Annulus Gear Location

1 - LOW RANGE ANNULUS GEAR

2 - SHIFT RAIL BUSHING

WJTRANSFER CASE - NV247 21 - 325

TRANSFER CASE - NV247 (Continued)

Page 1861 of 2199

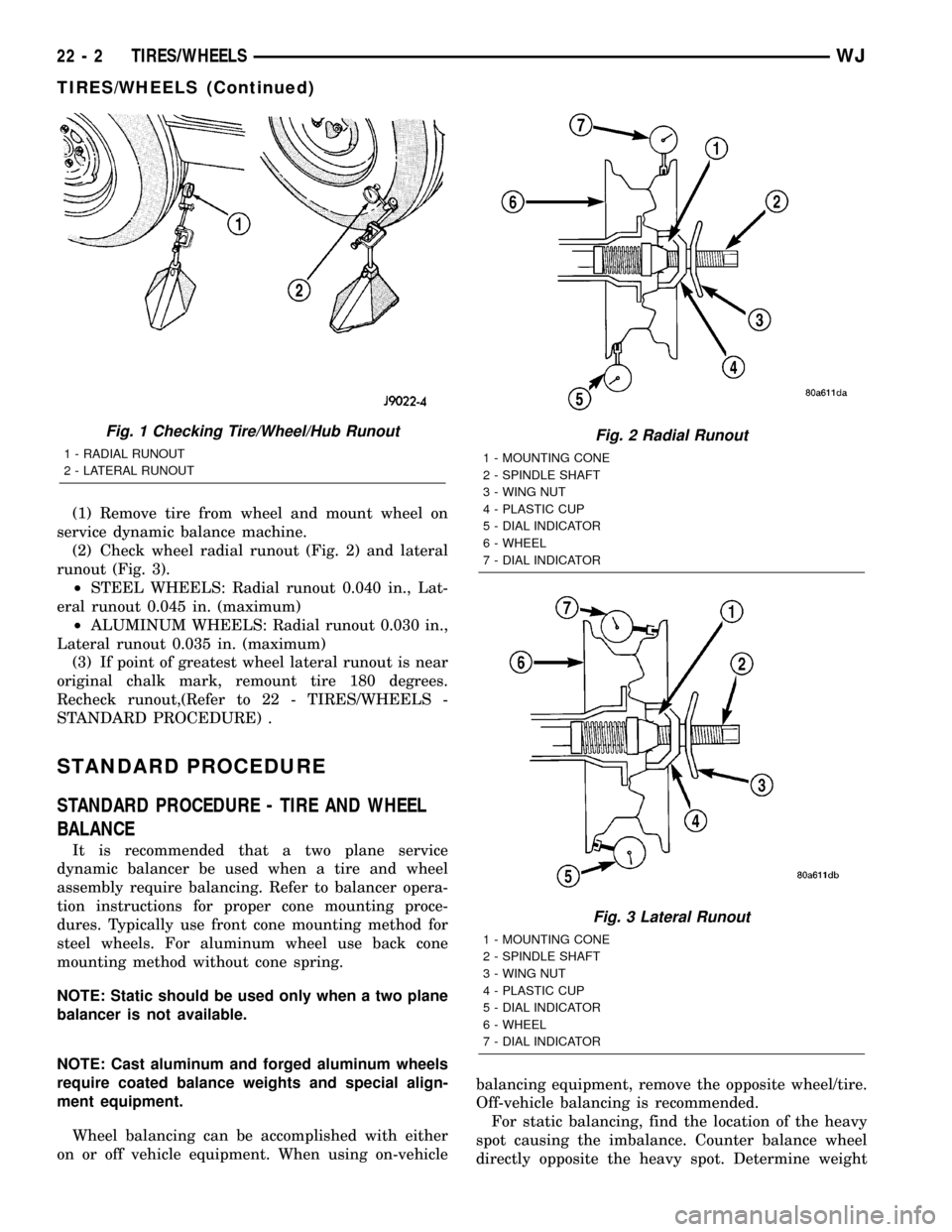

(1) Remove tire from wheel and mount wheel on

service dynamic balance machine.

(2) Check wheel radial runout (Fig. 2) and lateral

runout (Fig. 3).

²STEEL WHEELS: Radial runout 0.040 in., Lat-

eral runout 0.045 in. (maximum)

²ALUMINUM WHEELS: Radial runout 0.030 in.,

Lateral runout 0.035 in. (maximum)

(3) If point of greatest wheel lateral runout is near

original chalk mark, remount tire 180 degrees.

Recheck runout,(Refer to 22 - TIRES/WHEELS -

STANDARD PROCEDURE) .

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE AND WHEEL

BALANCE

It is recommended that a two plane service

dynamic balancer be used when a tire and wheel

assembly require balancing. Refer to balancer opera-

tion instructions for proper cone mounting proce-

dures. Typically use front cone mounting method for

steel wheels. For aluminum wheel use back cone

mounting method without cone spring.

NOTE: Static should be used only when a two plane

balancer is not available.

NOTE: Cast aluminum and forged aluminum wheels

require coated balance weights and special align-

ment equipment.

Wheel balancing can be accomplished with either

on or off vehicle equipment. When using on-vehiclebalancing equipment, remove the opposite wheel/tire.

Off-vehicle balancing is recommended.

For static balancing, find the location of the heavy

spot causing the imbalance. Counter balance wheel

directly opposite the heavy spot. Determine weight

Fig. 1 Checking Tire/Wheel/Hub Runout

1 - RADIAL RUNOUT

2 - LATERAL RUNOUT

Fig. 2 Radial Runout

1 - MOUNTING CONE

2 - SPINDLE SHAFT

3 - WING NUT

4 - PLASTIC CUP

5 - DIAL INDICATOR

6 - WHEEL

7 - DIAL INDICATOR

Fig. 3 Lateral Runout

1 - MOUNTING CONE

2 - SPINDLE SHAFT

3 - WING NUT

4 - PLASTIC CUP

5 - DIAL INDICATOR

6 - WHEEL

7 - DIAL INDICATOR

22 - 2 TIRES/WHEELSWJ

TIRES/WHEELS (Continued)

Page 1869 of 2199

SPARE TIRE

DESCRIPTION - SPARE / TEMPORARY TIRE

The temporary spare tire is designed for emer-

gency use only. The original tire should be repaired

or replaced at the first opportunity, then reinstalled.

Do not exceed speeds of 50 M.P.H. when using the

temporary spare tire. Refer to Owner's Manual for

complete details.

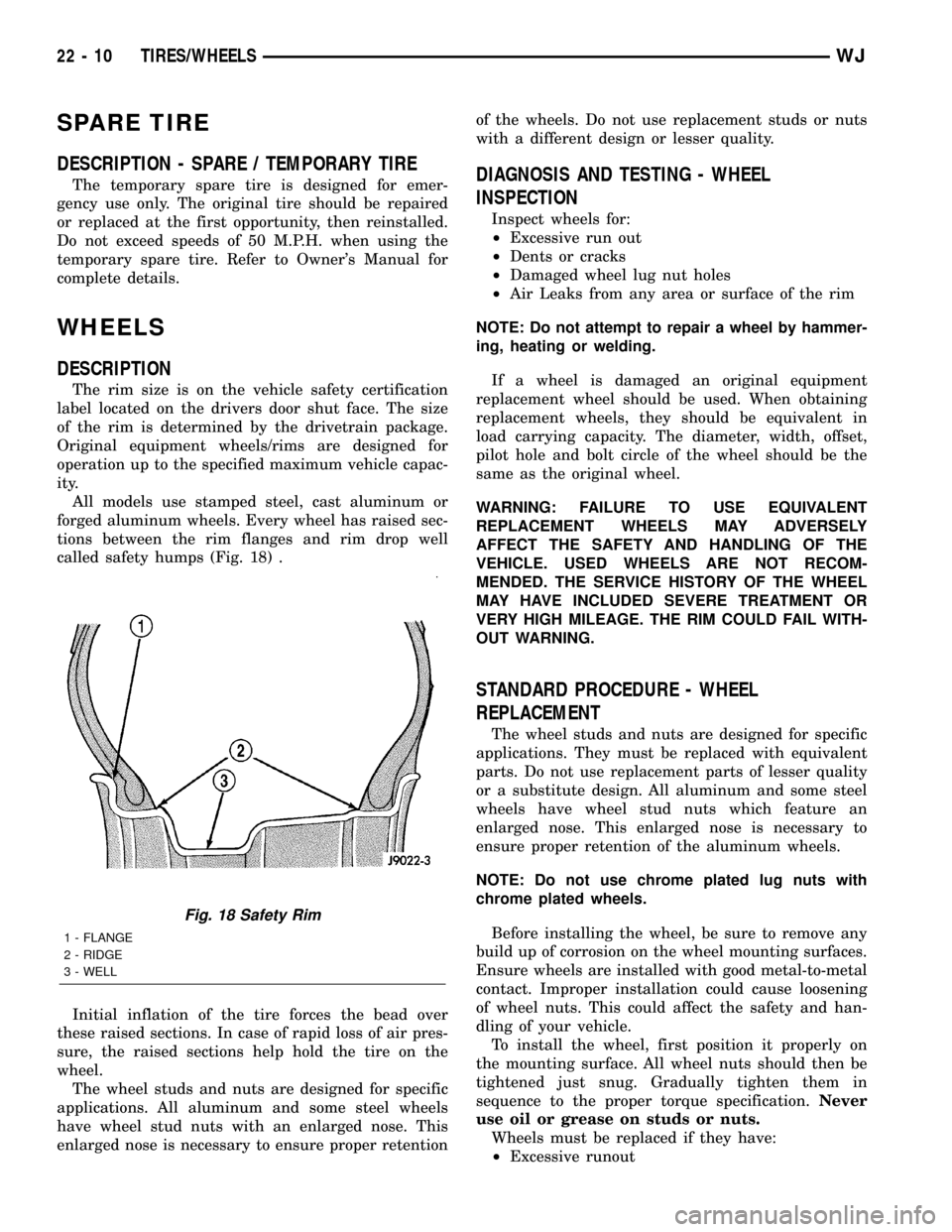

WHEELS

DESCRIPTION

The rim size is on the vehicle safety certification

label located on the drivers door shut face. The size

of the rim is determined by the drivetrain package.

Original equipment wheels/rims are designed for

operation up to the specified maximum vehicle capac-

ity.

All models use stamped steel, cast aluminum or

forged aluminum wheels. Every wheel has raised sec-

tions between the rim flanges and rim drop well

called safety humps (Fig. 18) .

Initial inflation of the tire forces the bead over

these raised sections. In case of rapid loss of air pres-

sure, the raised sections help hold the tire on the

wheel.

The wheel studs and nuts are designed for specific

applications. All aluminum and some steel wheels

have wheel stud nuts with an enlarged nose. This

enlarged nose is necessary to ensure proper retentionof the wheels. Do not use replacement studs or nuts

with a different design or lesser quality.

DIAGNOSIS AND TESTING - WHEEL

INSPECTION

Inspect wheels for:

²Excessive run out

²Dents or cracks

²Damaged wheel lug nut holes

²Air Leaks from any area or surface of the rim

NOTE: Do not attempt to repair a wheel by hammer-

ing, heating or welding.

If a wheel is damaged an original equipment

replacement wheel should be used. When obtaining

replacement wheels, they should be equivalent in

load carrying capacity. The diameter, width, offset,

pilot hole and bolt circle of the wheel should be the

same as the original wheel.

WARNING: FAILURE TO USE EQUIVALENT

REPLACEMENT WHEELS MAY ADVERSELY

AFFECT THE SAFETY AND HANDLING OF THE

VEHICLE. USED WHEELS ARE NOT RECOM-

MENDED. THE SERVICE HISTORY OF THE WHEEL

MAY HAVE INCLUDED SEVERE TREATMENT OR

VERY HIGH MILEAGE. THE RIM COULD FAIL WITH-

OUT WARNING.

STANDARD PROCEDURE - WHEEL

REPLACEMENT

The wheel studs and nuts are designed for specific

applications. They must be replaced with equivalent

parts. Do not use replacement parts of lesser quality

or a substitute design. All aluminum and some steel

wheels have wheel stud nuts which feature an

enlarged nose. This enlarged nose is necessary to

ensure proper retention of the aluminum wheels.

NOTE: Do not use chrome plated lug nuts with

chrome plated wheels.

Before installing the wheel, be sure to remove any

build up of corrosion on the wheel mounting surfaces.

Ensure wheels are installed with good metal-to-metal

contact. Improper installation could cause loosening

of wheel nuts. This could affect the safety and han-

dling of your vehicle.

To install the wheel, first position it properly on

the mounting surface. All wheel nuts should then be

tightened just snug. Gradually tighten them in

sequence to the proper torque specification.Never

use oil or grease on studs or nuts.

Wheels must be replaced if they have:

²Excessive runout

Fig. 18 Safety Rim

1 - FLANGE

2 - RIDGE

3 - WELL

22 - 10 TIRES/WHEELSWJ

Page 1870 of 2199

²Bent or dented

²Leak air through welds

²Have damaged bolt holes

Wheel repairs employing hammering, heating, or

welding are not allowed.

Original equipment wheels are available through

your dealer. Replacement wheels from any other

source should be equivalent in:

²Load carrying capacity

²Diameter

²Width²Offset

²Mounting configuration

Failure to use equivalent replacement wheels may

affect the safety and handling of your vehicle.

Replacement withusedwheels is not recommended.

Their service history may have included severe treat-

ment.

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Lug Nut

1/2 X 20 with 60É Cone115-150 85-115 Ð

STUDS

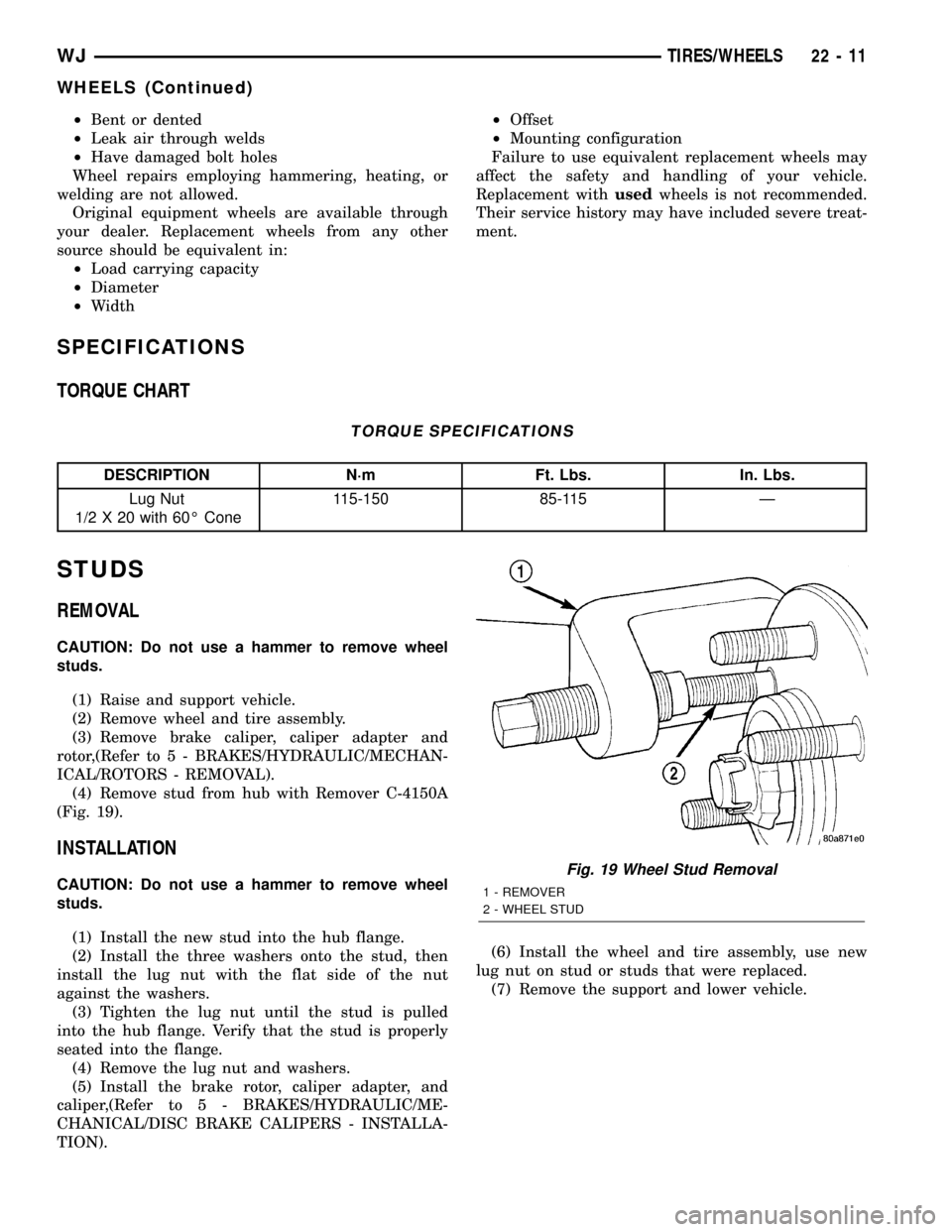

REMOVAL

CAUTION: Do not use a hammer to remove wheel

studs.

(1) Raise and support vehicle.

(2) Remove wheel and tire assembly.

(3) Remove brake caliper, caliper adapter and

rotor,(Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/ROTORS - REMOVAL).

(4) Remove stud from hub with Remover C-4150A

(Fig. 19).

INSTALLATION

CAUTION: Do not use a hammer to remove wheel

studs.

(1) Install the new stud into the hub flange.

(2) Install the three washers onto the stud, then

install the lug nut with the flat side of the nut

against the washers.

(3) Tighten the lug nut until the stud is pulled

into the hub flange. Verify that the stud is properly

seated into the flange.

(4) Remove the lug nut and washers.

(5) Install the brake rotor, caliper adapter, and

caliper,(Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/DISC BRAKE CALIPERS - INSTALLA-

TION).(6) Install the wheel and tire assembly, use new

lug nut on stud or studs that were replaced.

(7) Remove the support and lower vehicle.Fig. 19 Wheel Stud Removal

1 - REMOVER

2 - WHEEL STUD

WJTIRES/WHEELS 22 - 11

WHEELS (Continued)

Page 1871 of 2199

TIRE PRESSURE MONITORING

DESCRIPTION

The EVIC will monitor the tire pressure signals

from the five tire sensors and determine if any tire

has gone below the low pressure threshold or raised

above the high pressure threshold. Refer to the table

below.

LOW TIRE PRESSURE THRESHOLDS

SYSTEM STATUS

INDICATORTIRE PRESSURE

ON 179 kPa (26 PSI)

OFF 214 kPa (31 PSI)

HIGH TIRE PRESSURE THRESHOLDS

SYSTEM STATUS

INDICATORTIRE PRESSURE

ON 310 kPa (45 PSI)

OFF 276 kPa (40 PSI)

The Remote Tire Pressure Monitors (RTPM) are

not internally serviceable. For a Sensor Failure or

Low Battery fault, the RTPM must be replaced.

OPERATION

If equipped with the Tire Pressure Monitoring Sys-

tem, each of the vehicle's five wheels will have a

valve stem with a pressure sensor and radio trans-

mitter built in. Signals from the tire pressure sensors

are received and interpreted by the Electronic Vehi-

cle Information Center (EVIC). A sensor in a

mounted wheel will broadcast its detected pressure

once per minute when the vehicle is moving faster

than 40 km/h (25 mph). The spare tire sensor will

broadcast once every hour. Each sensor's broadcast is

uniquely coded so that the EVIC can determine loca-

tion. The individual tire pressures can be displayed

graphically on the EVIC

DIAGNOSIS AND TESTING - TIRE PRESSURE

MONITORING SYSTEM

All Tire Pressure Monitoring System Faults are

specific to one location. If a9BATTERY LOW9or

9SENSOR FAILURE9fault is detected, the location

will be displayed. The appropriate sensor/transmitter

can then be replaced. If a single sensor/transmitter

cannot be detected by the EVIC, replace that sensor

transmitter. If none of the sensors/transmitters can

be detected, refer to symptoms in the EVIC section.

For additional system description and diagnosis,

refer to Tire Pressure Monitoring in the Body Diag-

nostic manual.

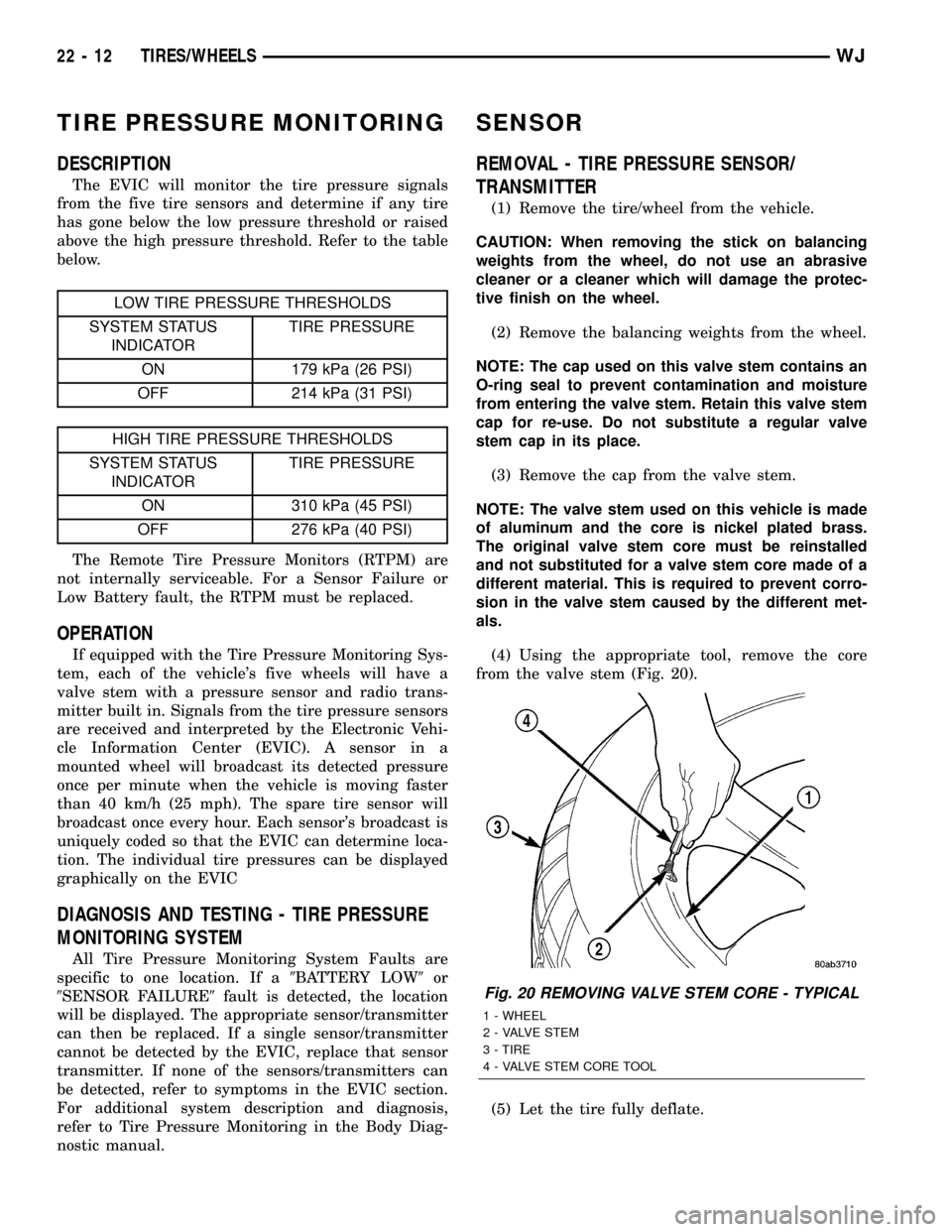

SENSOR

REMOVAL - TIRE PRESSURE SENSOR/

TRANSMITTER

(1) Remove the tire/wheel from the vehicle.

CAUTION: When removing the stick on balancing

weights from the wheel, do not use an abrasive

cleaner or a cleaner which will damage the protec-

tive finish on the wheel.

(2) Remove the balancing weights from the wheel.

NOTE: The cap used on this valve stem contains an

O-ring seal to prevent contamination and moisture

from entering the valve stem. Retain this valve stem

cap for re-use. Do not substitute a regular valve

stem cap in its place.

(3) Remove the cap from the valve stem.

NOTE: The valve stem used on this vehicle is made

of aluminum and the core is nickel plated brass.

The original valve stem core must be reinstalled

and not substituted for a valve stem core made of a

different material. This is required to prevent corro-

sion in the valve stem caused by the different met-

als.

(4) Using the appropriate tool, remove the core

from the valve stem (Fig. 20).

(5) Let the tire fully deflate.

Fig. 20 REMOVING VALVE STEM CORE - TYPICAL

1 - WHEEL

2 - VALVE STEM

3 - TIRE

4 - VALVE STEM CORE TOOL

22 - 12 TIRES/WHEELSWJ