Transmission pan JEEP GRAND CHEROKEE 2002 WJ / 2.G Owner's Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 623 of 2199

(3) Insert the hook formation on the tip of the

wiper arm through the opening in the wiper blade

superstructure ahead of the wiper blade pivot block/

latch unit far enough to engage the pivot block with

the hook (Fig. 10).

(4) Slide the wiper blade pivot block/latch up into

the hook formation on the tip of the wiper arm until

the latch release tab snaps into its locked position.

Latch engagement will be accompanied by an audible

click.

(5) Gently lower the wiper blade onto the glass.

FRONT WIPER MODULE

DESCRIPTION

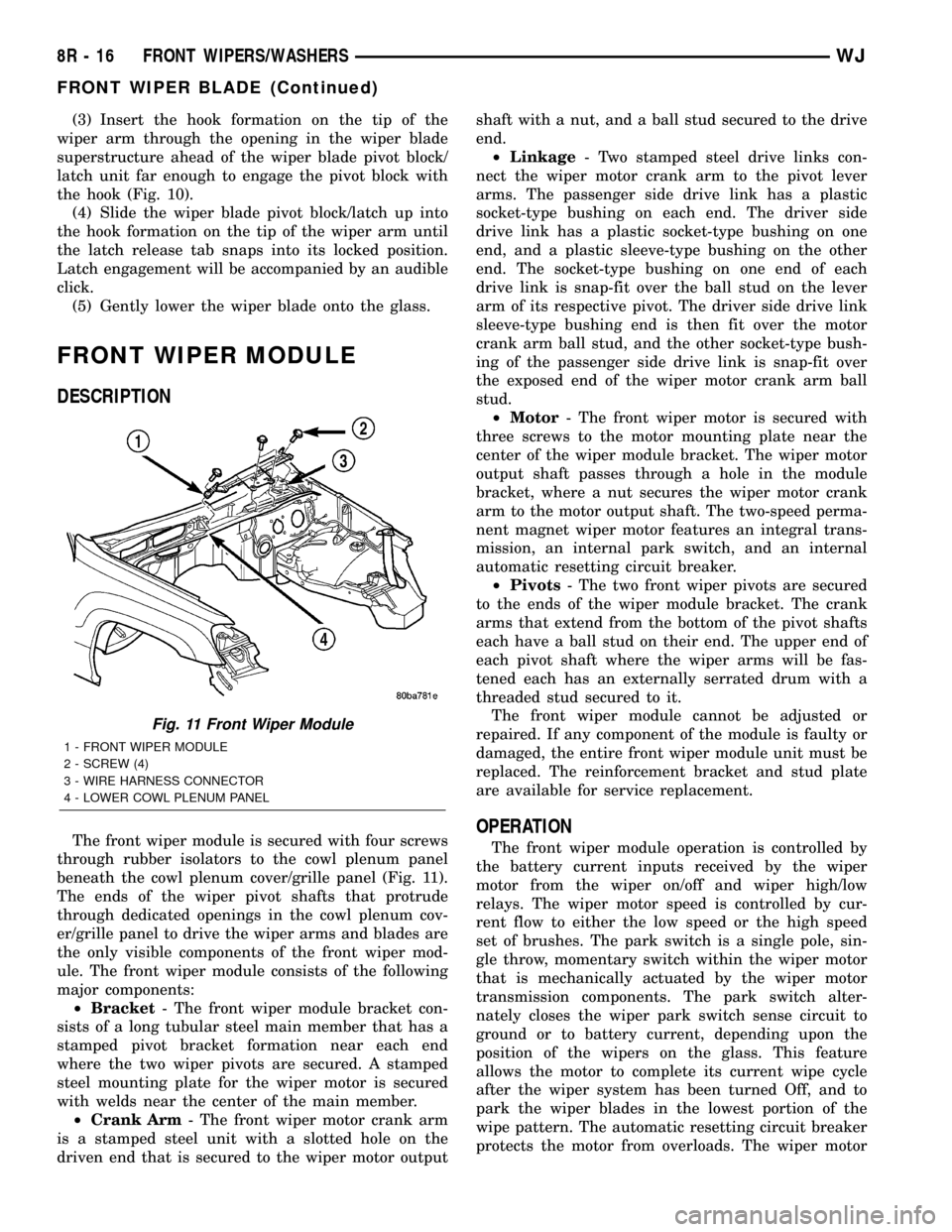

The front wiper module is secured with four screws

through rubber isolators to the cowl plenum panel

beneath the cowl plenum cover/grille panel (Fig. 11).

The ends of the wiper pivot shafts that protrude

through dedicated openings in the cowl plenum cov-

er/grille panel to drive the wiper arms and blades are

the only visible components of the front wiper mod-

ule. The front wiper module consists of the following

major components:

²Bracket- The front wiper module bracket con-

sists of a long tubular steel main member that has a

stamped pivot bracket formation near each end

where the two wiper pivots are secured. A stamped

steel mounting plate for the wiper motor is secured

with welds near the center of the main member.

²Crank Arm- The front wiper motor crank arm

is a stamped steel unit with a slotted hole on the

driven end that is secured to the wiper motor outputshaft with a nut, and a ball stud secured to the drive

end.

²Linkage- Two stamped steel drive links con-

nect the wiper motor crank arm to the pivot lever

arms. The passenger side drive link has a plastic

socket-type bushing on each end. The driver side

drive link has a plastic socket-type bushing on one

end, and a plastic sleeve-type bushing on the other

end. The socket-type bushing on one end of each

drive link is snap-fit over the ball stud on the lever

arm of its respective pivot. The driver side drive link

sleeve-type bushing end is then fit over the motor

crank arm ball stud, and the other socket-type bush-

ing of the passenger side drive link is snap-fit over

the exposed end of the wiper motor crank arm ball

stud.

²Motor- The front wiper motor is secured with

three screws to the motor mounting plate near the

center of the wiper module bracket. The wiper motor

output shaft passes through a hole in the module

bracket, where a nut secures the wiper motor crank

arm to the motor output shaft. The two-speed perma-

nent magnet wiper motor features an integral trans-

mission, an internal park switch, and an internal

automatic resetting circuit breaker.

²Pivots- The two front wiper pivots are secured

to the ends of the wiper module bracket. The crank

arms that extend from the bottom of the pivot shafts

each have a ball stud on their end. The upper end of

each pivot shaft where the wiper arms will be fas-

tened each has an externally serrated drum with a

threaded stud secured to it.

The front wiper module cannot be adjusted or

repaired. If any component of the module is faulty or

damaged, the entire front wiper module unit must be

replaced. The reinforcement bracket and stud plate

are available for service replacement.OPERATION

The front wiper module operation is controlled by

the battery current inputs received by the wiper

motor from the wiper on/off and wiper high/low

relays. The wiper motor speed is controlled by cur-

rent flow to either the low speed or the high speed

set of brushes. The park switch is a single pole, sin-

gle throw, momentary switch within the wiper motor

that is mechanically actuated by the wiper motor

transmission components. The park switch alter-

nately closes the wiper park switch sense circuit to

ground or to battery current, depending upon the

position of the wipers on the glass. This feature

allows the motor to complete its current wipe cycle

after the wiper system has been turned Off, and to

park the wiper blades in the lowest portion of the

wipe pattern. The automatic resetting circuit breaker

protects the motor from overloads. The wiper motor

Fig. 11 Front Wiper Module

1 - FRONT WIPER MODULE

2 - SCREW (4)

3 - WIRE HARNESS CONNECTOR

4 - LOWER COWL PLENUM PANEL

8R - 16 FRONT WIPERS/WASHERSWJ

FRONT WIPER BLADE (Continued)

Page 652 of 2199

motor that is secured with screws to the wiper motor

and to the liftgate inner panel.

²Electronic Controls- The rear wiper module

electronic controls include the rear wiper system

electronic logic and rear wiper motor electronic con-

trols. The electronic controls for the motor include an

electronic speed control that speeds the wiper blade

near the center of the glass, but slows the wiper

blade during directional reversals at each end of the

wipe pattern and during wiper blade off-the-glass

parking for quieter operation.

²Motor- The permanent magnet rear wiper

motor is secured with screws to the rear wiper mod-

ule bracket. The wiper motor includes an integral

transmission, and the motor output shaft.

The rear wiper module cannot be adjusted or

repaired. If any component of the module is faulty or

damaged, the entire rear wiper module unit must be

replaced. The motor output shaft gasket, bezel, nut,

and nut cover are available for service replacement.

OPERATION

The rear wiper module receives non-switched bat-

tery current through a fuse in the Junction Block

(JB) and is grounded at all times. The rear wiper

module operation is controlled by the vehicle operator

through battery current signal inputs received by the

rear wiper module electronic controls from the right

multi-function switch on the steering column. The

module also receives an external control input from

the liftgate flip-up glass ajar switch circuit. The rear

wiper module electronic control logic uses these

inputs, its internal inputs, and its programming to

provide continuous wipe, delay wipe, wipe-after-wash

and off-the-glass wiper blade parking. The wiper

blade cycling is controlled by the rear wiper module

electronic controls, which control current flow to the

wiper motor brushes. The wiper motor transmission

converts the rotary output of the wiper motor to the

back and forth wiping motion of the rear wiper arm

and blade on the liftgate glass.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the rear wiper arm from the rear

wiper motor output shaft. (Refer to 8 - ELECTRI-

CAL/REAR WIPERS/WASHERS/REAR WIPER ARM

- REMOVAL).

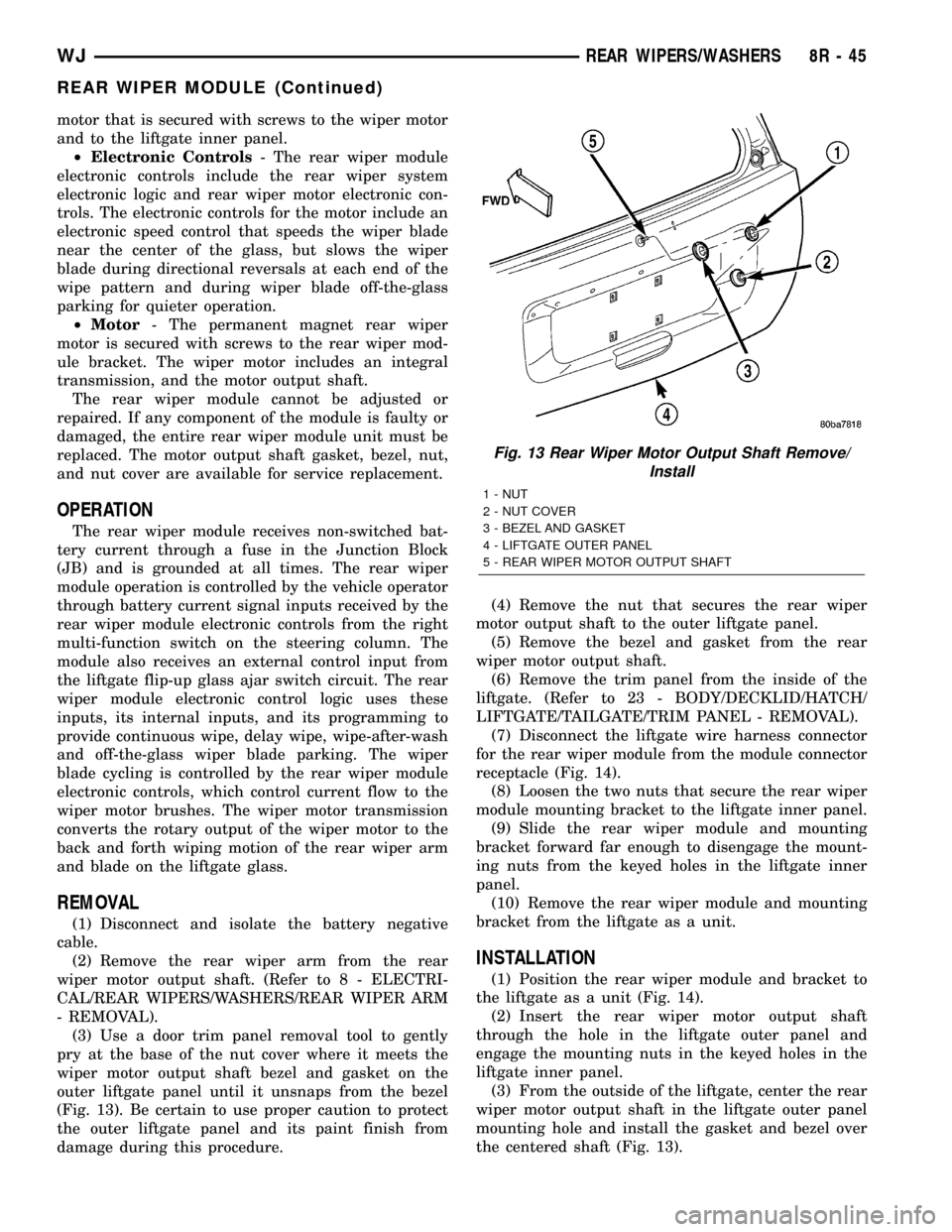

(3) Use a door trim panel removal tool to gently

pry at the base of the nut cover where it meets the

wiper motor output shaft bezel and gasket on the

outer liftgate panel until it unsnaps from the bezel

(Fig. 13). Be certain to use proper caution to protect

the outer liftgate panel and its paint finish from

damage during this procedure.(4) Remove the nut that secures the rear wiper

motor output shaft to the outer liftgate panel.

(5) Remove the bezel and gasket from the rear

wiper motor output shaft.

(6) Remove the trim panel from the inside of the

liftgate. (Refer to 23 - BODY/DECKLID/HATCH/

LIFTGATE/TAILGATE/TRIM PANEL - REMOVAL).

(7) Disconnect the liftgate wire harness connector

for the rear wiper module from the module connector

receptacle (Fig. 14).

(8) Loosen the two nuts that secure the rear wiper

module mounting bracket to the liftgate inner panel.

(9) Slide the rear wiper module and mounting

bracket forward far enough to disengage the mount-

ing nuts from the keyed holes in the liftgate inner

panel.

(10) Remove the rear wiper module and mounting

bracket from the liftgate as a unit.

INSTALLATION

(1) Position the rear wiper module and bracket to

the liftgate as a unit (Fig. 14).

(2) Insert the rear wiper motor output shaft

through the hole in the liftgate outer panel and

engage the mounting nuts in the keyed holes in the

liftgate inner panel.

(3) From the outside of the liftgate, center the rear

wiper motor output shaft in the liftgate outer panel

mounting hole and install the gasket and bezel over

the centered shaft (Fig. 13).

Fig. 13 Rear Wiper Motor Output Shaft Remove/

Install

1 - NUT

2 - NUT COVER

3 - BEZEL AND GASKET

4 - LIFTGATE OUTER PANEL

5 - REAR WIPER MOTOR OUTPUT SHAFT

WJREAR WIPERS/WASHERS 8R - 45

REAR WIPER MODULE (Continued)

Page 662 of 2199

DESCRIPTION - CONNECTOR, GROUND AND

SPLICE INFORMATION

CAUTION: Not all connectors are serviced. Some

connectors are serviced only with a harness. A typ-

ical example might be the Supplemental Restraint

System connectors. Always check parts availability

before attempting a repair.

IDENTIFICATION

In-line connectors are identified by a number, as

follows:

²In-line connectors located in the engine compart-

ment are C100 series numbers

²In-line connectors located in the Instrument

Panel area are C200 series numbers.

²In-line connectors located in the body are C300

series numbers.

²Jumper harness connectors are C400 series

numbers.

²Grounds and ground connectors are identified

with a ªGº and follow the same series numbering as

the in-line connectors.

²Splices are identified with an ªSº and follow the

same series numbering as the in-line connectors.

²Component connectors are identified by the com-

ponent name instead of a number. Multiple connec-

tors on a component use a C1, C2, etc. identifier.

LOCATIONS

Section 8W-91 contains connector/ground/splice

location illustrations. The illustrations contain the

connector name (or number)/ground number/splice

number and component identification. Connector/

ground/splice location charts in section 8W-91 refer-

ence the figure numbers of the illustrations.

The abbreviation T/O is used in the component

location section to indicate a point in which the wir-

ing harness branches out to a component. The abbre-

viation N/S means Not Shown in the illustrations

WARNING

WARNINGS - GENERAL

WARNINGSprovide information to prevent per-

sonal injury and vehicle damage. Below is a list of

general warnings that should be followed any time a

vehicle is being serviced.

WARNING: ALWAYS WEAR SAFETY GLASSES FOR

EYE PROTECTION.

WARNING: USE SAFETY STANDS ANYTIME A PRO-

CEDURE REQUIRES BEING UNDER A VEHICLE.WARNING: BE SURE THAT THE IGNITION SWITCH

ALWAYS IS IN THE OFF POSITION, UNLESS THE

PROCEDURE REQUIRES IT TO BE ON.

WARNING: SET THE PARKING BRAKE WHEN

WORKING ON ANY VEHICLE. AN AUTOMATIC

TRANSMISSION SHOULD BE IN PARK. A MANUAL

TRANSMISSION SHOULD BE IN NEUTRAL.

WARNING: OPERATE THE ENGINE ONLY IN A

WELL-VENTILATED AREA.

WARNING: KEEP AWAY FROM MOVING PARTS

WHEN THE ENGINE IS RUNNING, ESPECIALLY THE

FAN AND BELTS.

WARNING: TO PREVENT SERIOUS BURNS, AVOID

CONTACT WITH HOT PARTS SUCH AS THE RADIA-

TOR, EXHAUST MANIFOLD(S), TAIL PIPE, CATA-

LYTIC CONVERTER AND MUFFLER.

WARNING: DO NOT ALLOW FLAME OR SPARKS

NEAR THE BATTERY. GASES ARE ALWAYS

PRESENT IN AND AROUND THE BATTERY.

WARNING: ALWAYS REMOVE RINGS, WATCHES,

LOOSE HANGING JEWELRY AND AVOID LOOSE

CLOTHING.

DIAGNOSIS AND TESTING - WIRING HARNESS

TROUBLESHOOTING TOOLS

When diagnosing a problem in an electrical circuit

there are several common tools necessary. These tools

are listed and explained below.

²Jumper Wire - This is a test wire used to con-

nect two points of a circuit. It can be used to bypass

an open in a circuit.

WARNING: NEVER USE A JUMPER WIRE ACROSS

A LOAD, SUCH AS A MOTOR, CONNECTED

BETWEEN A BATTERY FEED AND GROUND.

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

voltages in these circuits, use a meter with a 10 -

megohm or greater impedance rating.

WJ8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 7

WIRING DIAGRAM INFORMATION (Continued)

Page 1052 of 2199

Component Page

RIGHT FRONT WHEEL SPEED

SENSOR....................... 8W-80-115

RIGHT HEADLAMP LEVELING MOTOR

(BUILT-UP-EXPORT)............. 8W-80-115

RIGHT HIGH BEAM HEADLAMP..... 8W-80-116

RIGHT INSTRUMENT PANEL

SPEAKER...................... 8W-80-116

RIGHT LIFTGATE AJAR SWITCH..... 8W-80-116

RIGHT LOW BEAM HEADLAMP..... 8W-80-116

RIGHT MULTI-FUNCTION SWITCH . . . 8W-80-116

RIGHT REAR DOOR LOCK

MOTOR/AJAR SWITCH........... 8W-80-117

RIGHT REAR DOOR SPEAKER....... 8W-80-117

RIGHT REAR LAMP ASSEMBLY...... 8W-80-117

RIGHT REAR WHEEL SPEED

SENSOR....................... 8W-80-117

RIGHT REMOTE RADIO SWITCH.... 8W-80-117

RIGHT SIDE REPEATER LAMP

(BUILT-UP-EXPORT)............. 8W-80-118

RIGHT VISOR/VANITY LAMP........ 8W-80-118

SEAT BELT SWITCH............... 8W-80-118

SEAT MODULE C1 (PREMIUM)...... 8W-80-118

SEAT MODULE C2 (PREMIUM)...... 8W-80-119

SENTRY KEY IMMOBILIZER

MODULE...................... 8W-80-119

SHIFTER ASSEMBLY

(C201 DIESEL).................. 8W-80-119

SHIFTER ASSEMBLY (GAS)......... 8W-80-120

SHIFTER ASSEMBLY C1 (DIESEL).... 8W-80-120

SHIFTER ASSEMBLY C2 (DIESEL).... 8W-80-120

SIREN (BUILT-UP-EXPORT)......... 8W-80-120

SPEED CONTROL SWITCH NO. 1.... 8W-80-120

SPEED CONTROL SWITCH NO. 2.... 8W-80-121

SUNROOF CONTROL MODULE...... 8W-80-121

SUNROOF MOTOR C1.............. 8W-80-121

SUNROOF MOTOR C2.............. 8W-80-121

SUNROOF SWITCH................ 8W-80-121Component Page

TEMPERATURE VALVE

ACTUATOR (MTC)............... 8W-80-122

THROTTLE POSITION

SENSOR (4.0L).................. 8W-80-122

THROTTLE POSITION

SENSOR (4.7L).................. 8W-80-122

TRAILER TOW BRAKE

LAMP RELAY................... 8W-80-122

TRAILER TOW CIRCUIT

BREAKER...................... 8W-80-122

TRAILER TOW CONNECTOR........ 8W-80-123

TRAILER TOW LEFT TURN

RELAY........................ 8W-80-123

TRAILER TOW RIGHT TURN

RELAY........................ 8W-80-123

TRANSFER CASE POSITION

SENSOR....................... 8W-80-123

TRANSMISSION CONTROL

MODULE (4.7L)................. 8W-80-124

TRANSMISSION CONTROL

MODULE C1 (DIESEL)........... 8W-80-125

TRANSMISSION CONTROL

MODULE C2 (DIESEL)........... 8W-80-125

TRANSMISSION SOLENOID (4.0L).... 8W-80-125

TRANSMISSION SOLENOID

ASSEMBLY (DIESEL)............ 8W-80-126

TRANSMISSION SOLENOID/TRS

ASSEMBLY (4.7L)................ 8W-80-126

UNDERHOOD LAMP............... 8W-80-126

VEHICLE INFORMATION CENTER . . . 8W-80-127

VISCOUS/CABIN HEATER

(DIESEL)...................... 8W-80-127

WASHER FLUID LEVEL SWITCH.... 8W-80-127

WASTEGATE SOLENOID

(DIESEL)...................... 8W-80-127

WATER IN FUEL SENSOR

(DIESEL)...................... 8W-80-127

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 5

Page 1179 of 2199

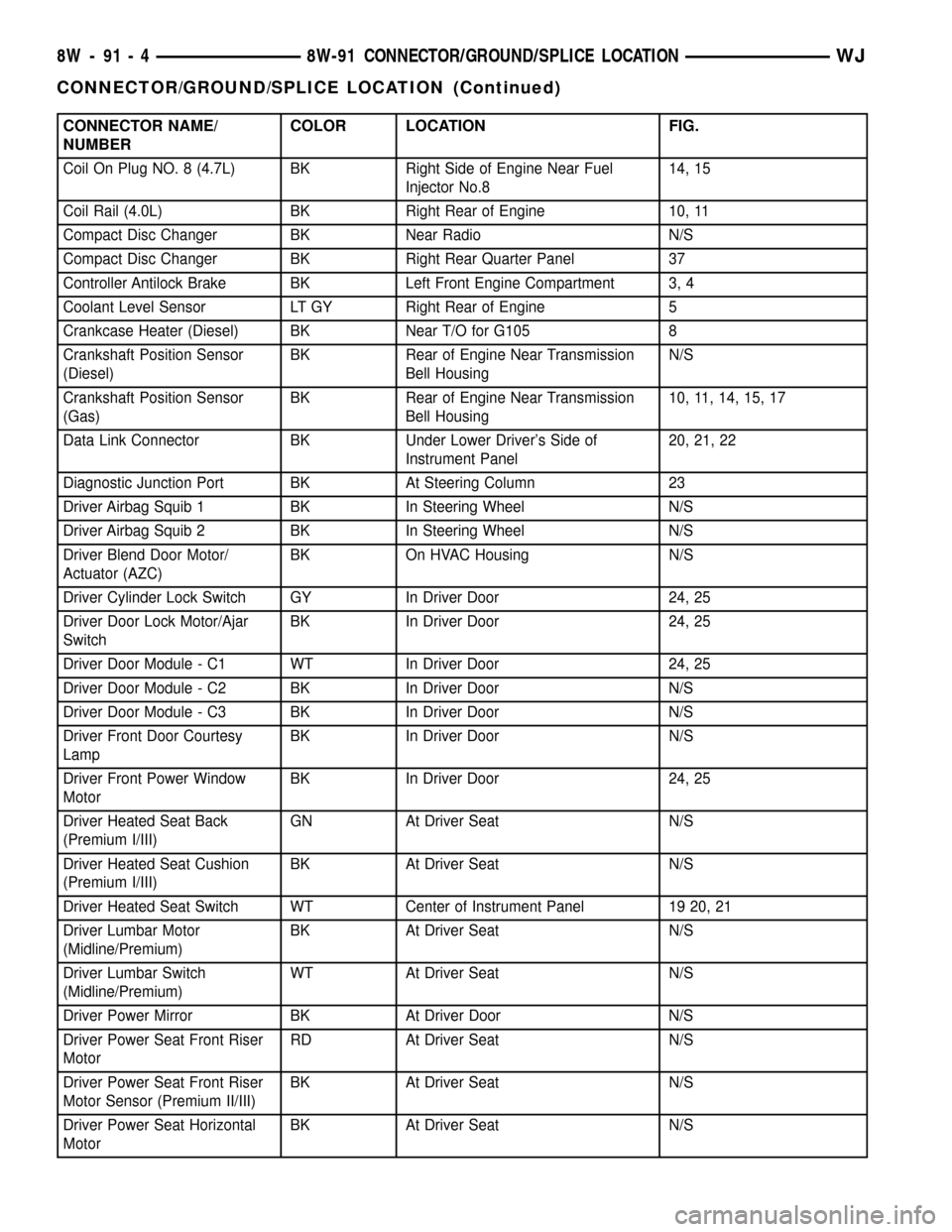

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Coil On Plug NO. 8 (4.7L) BK Right Side of Engine Near Fuel

Injector No.814, 15

Coil Rail (4.0L) BK Right Rear of Engine 10, 11

Compact Disc Changer BK Near Radio N/S

Compact Disc Changer BK Right Rear Quarter Panel 37

Controller Antilock Brake BK Left Front Engine Compartment 3, 4

Coolant Level Sensor LT GY Right Rear of Engine 5

Crankcase Heater (Diesel) BK Near T/O for G105 8

Crankshaft Position Sensor

(Diesel)BK Rear of Engine Near Transmission

Bell HousingN/S

Crankshaft Position Sensor

(Gas)BK Rear of Engine Near Transmission

Bell Housing10, 11, 14, 15, 17

Data Link Connector BK Under Lower Driver's Side of

Instrument Panel20, 21, 22

Diagnostic Junction Port BK At Steering Column 23

Driver Airbag Squib 1 BK In Steering Wheel N/S

Driver Airbag Squib 2 BK In Steering Wheel N/S

Driver Blend Door Motor/

Actuator (AZC)BK On HVAC Housing N/S

Driver Cylinder Lock Switch GY In Driver Door 24, 25

Driver Door Lock Motor/Ajar

SwitchBK In Driver Door 24, 25

Driver Door Module - C1 WT In Driver Door 24, 25

Driver Door Module - C2 BK In Driver Door N/S

Driver Door Module - C3 BK In Driver Door N/S

Driver Front Door Courtesy

LampBK In Driver Door N/S

Driver Front Power Window

MotorBK In Driver Door 24, 25

Driver Heated Seat Back

(Premium I/III)GN At Driver Seat N/S

Driver Heated Seat Cushion

(Premium I/III)BK At Driver Seat N/S

Driver Heated Seat Switch WT Center of Instrument Panel 19 20, 21

Driver Lumbar Motor

(Midline/Premium)BK At Driver Seat N/S

Driver Lumbar Switch

(Midline/Premium)WT At Driver Seat N/S

Driver Power Mirror BK At Driver Door N/S

Driver Power Seat Front Riser

MotorRD At Driver Seat N/S

Driver Power Seat Front Riser

Motor Sensor (Premium II/III)BK At Driver Seat N/S

Driver Power Seat Horizontal

MotorBK At Driver Seat N/S

8W - 91 - 4 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

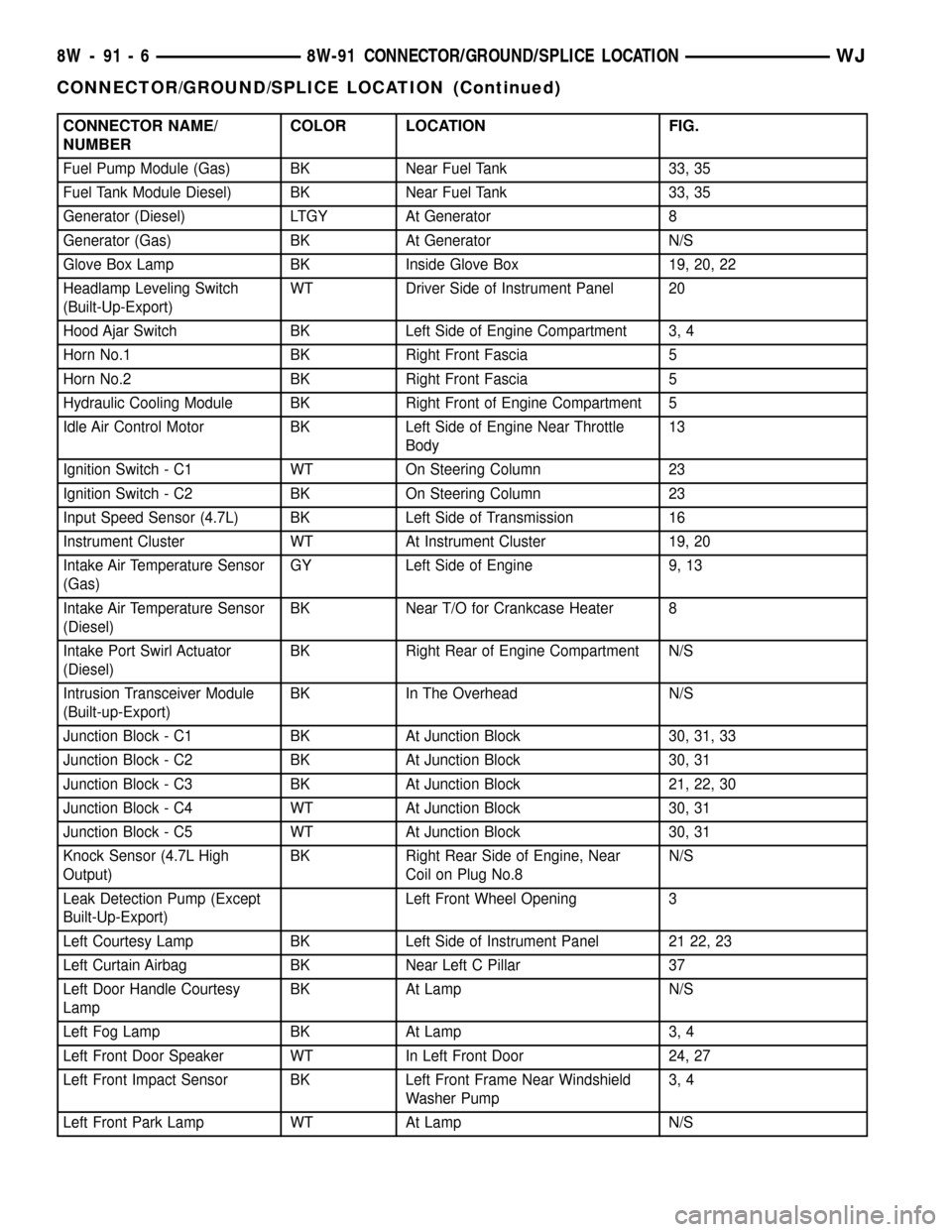

Page 1181 of 2199

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Fuel Pump Module (Gas) BK Near Fuel Tank 33, 35

Fuel Tank Module Diesel) BK Near Fuel Tank 33, 35

Generator (Diesel) LTGY At Generator 8

Generator (Gas) BK At Generator N/S

Glove Box Lamp BK Inside Glove Box 19, 20, 22

Headlamp Leveling Switch

(Built-Up-Export)WT Driver Side of Instrument Panel 20

Hood Ajar Switch BK Left Side of Engine Compartment 3, 4

Horn No.1 BK Right Front Fascia 5

Horn No.2 BK Right Front Fascia 5

Hydraulic Cooling Module BK Right Front of Engine Compartment 5

Idle Air Control Motor BK Left Side of Engine Near Throttle

Body13

Ignition Switch - C1 WT On Steering Column 23

Ignition Switch - C2 BK On Steering Column 23

Input Speed Sensor (4.7L) BK Left Side of Transmission 16

Instrument Cluster WT At Instrument Cluster 19, 20

Intake Air Temperature Sensor

(Gas)GY Left Side of Engine 9, 13

Intake Air Temperature Sensor

(Diesel)BK Near T/O for Crankcase Heater 8

Intake Port Swirl Actuator

(Diesel)BK Right Rear of Engine Compartment N/S

Intrusion Transceiver Module

(Built-up-Export)BK In The Overhead N/S

Junction Block - C1 BK At Junction Block 30, 31, 33

Junction Block - C2 BK At Junction Block 30, 31

Junction Block - C3 BK At Junction Block 21, 22, 30

Junction Block - C4 WT At Junction Block 30, 31

Junction Block - C5 WT At Junction Block 30, 31

Knock Sensor (4.7L High

Output)BK Right Rear Side of Engine, Near

Coil on Plug No.8N/S

Leak Detection Pump (Except

Built-Up-Export)Left Front Wheel Opening 3

Left Courtesy Lamp BK Left Side of Instrument Panel 21 22, 23

Left Curtain Airbag BK Near Left C Pillar 37

Left Door Handle Courtesy

LampBK At Lamp N/S

Left Fog Lamp BK At Lamp 3, 4

Left Front Door Speaker WT In Left Front Door 24, 27

Left Front Impact Sensor BK Left Front Frame Near Windshield

Washer Pump3, 4

Left Front Park Lamp WT At Lamp N/S

8W - 91 - 6 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

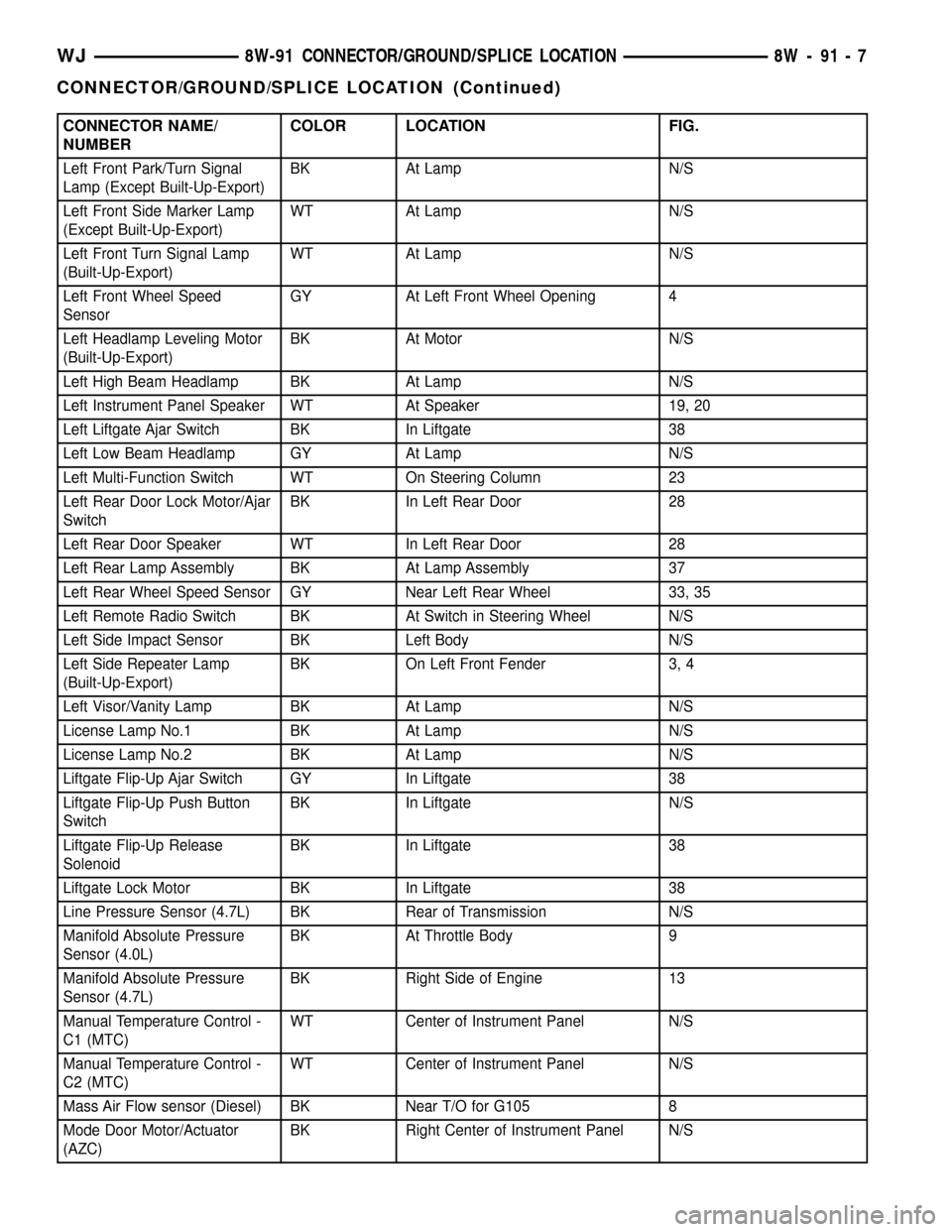

Page 1182 of 2199

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Left Front Park/Turn Signal

Lamp (Except Built-Up-Export)BK At Lamp N/S

Left Front Side Marker Lamp

(Except Built-Up-Export)WT At Lamp N/S

Left Front Turn Signal Lamp

(Built-Up-Export)WT At Lamp N/S

Left Front Wheel Speed

SensorGY At Left Front Wheel Opening 4

Left Headlamp Leveling Motor

(Built-Up-Export)BK At Motor N/S

Left High Beam Headlamp BK At Lamp N/S

Left Instrument Panel Speaker WT At Speaker 19, 20

Left Liftgate Ajar Switch BK In Liftgate 38

Left Low Beam Headlamp GY At Lamp N/S

Left Multi-Function Switch WT On Steering Column 23

Left Rear Door Lock Motor/Ajar

SwitchBK In Left Rear Door 28

Left Rear Door Speaker WT In Left Rear Door 28

Left Rear Lamp Assembly BK At Lamp Assembly 37

Left Rear Wheel Speed Sensor GY Near Left Rear Wheel 33, 35

Left Remote Radio Switch BK At Switch in Steering Wheel N/S

Left Side Impact Sensor BK Left Body N/S

Left Side Repeater Lamp

(Built-Up-Export)BK On Left Front Fender 3, 4

Left Visor/Vanity Lamp BK At Lamp N/S

License Lamp No.1 BK At Lamp N/S

License Lamp No.2 BK At Lamp N/S

Liftgate Flip-Up Ajar Switch GY In Liftgate 38

Liftgate Flip-Up Push Button

SwitchBK In Liftgate N/S

Liftgate Flip-Up Release

SolenoidBK In Liftgate 38

Liftgate Lock Motor BK In Liftgate 38

Line Pressure Sensor (4.7L) BK Rear of Transmission N/S

Manifold Absolute Pressure

Sensor (4.0L)BK At Throttle Body 9

Manifold Absolute Pressure

Sensor (4.7L)BK Right Side of Engine 13

Manual Temperature Control -

C1 (MTC)WT Center of Instrument Panel N/S

Manual Temperature Control -

C2 (MTC)WT Center of Instrument Panel N/S

Mass Air Flow sensor (Diesel) BK Near T/O for G105 8

Mode Door Motor/Actuator

(AZC)BK Right Center of Instrument Panel N/S

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 7

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

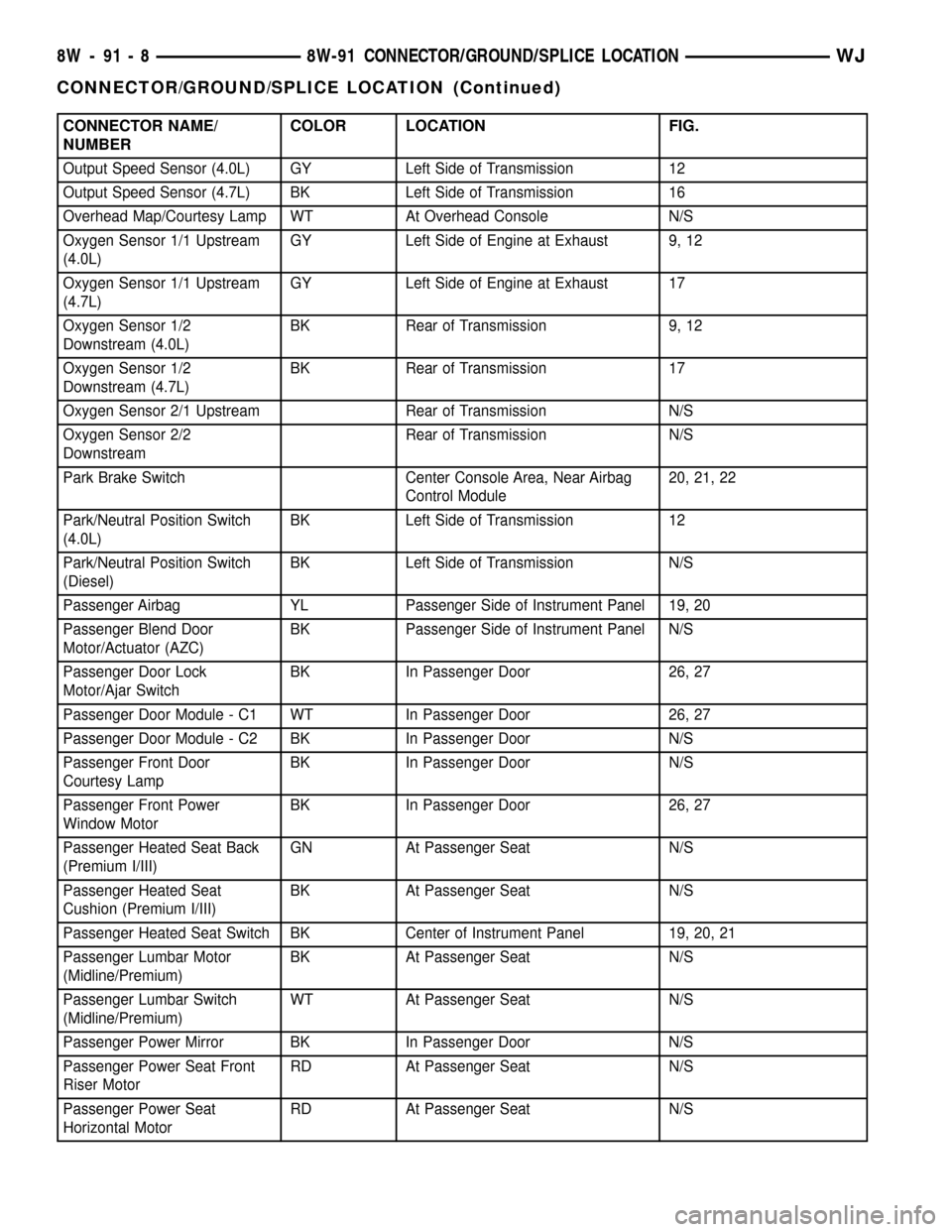

Page 1183 of 2199

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Output Speed Sensor (4.0L) GY Left Side of Transmission 12

Output Speed Sensor (4.7L) BK Left Side of Transmission 16

Overhead Map/Courtesy Lamp WT At Overhead Console N/S

Oxygen Sensor 1/1 Upstream

(4.0L)GY Left Side of Engine at Exhaust 9, 12

Oxygen Sensor 1/1 Upstream

(4.7L)GY Left Side of Engine at Exhaust 17

Oxygen Sensor 1/2

Downstream (4.0L)BK Rear of Transmission 9, 12

Oxygen Sensor 1/2

Downstream (4.7L)BK Rear of Transmission 17

Oxygen Sensor 2/1 Upstream Rear of Transmission N/S

Oxygen Sensor 2/2

DownstreamRear of Transmission N/S

Park Brake Switch Center Console Area, Near Airbag

Control Module20, 21, 22

Park/Neutral Position Switch

(4.0L)BK Left Side of Transmission 12

Park/Neutral Position Switch

(Diesel)BK Left Side of Transmission N/S

Passenger Airbag YL Passenger Side of Instrument Panel 19, 20

Passenger Blend Door

Motor/Actuator (AZC)BK Passenger Side of Instrument Panel N/S

Passenger Door Lock

Motor/Ajar SwitchBK In Passenger Door 26, 27

Passenger Door Module - C1 WT In Passenger Door 26, 27

Passenger Door Module - C2 BK In Passenger Door N/S

Passenger Front Door

Courtesy LampBK In Passenger Door N/S

Passenger Front Power

Window MotorBK In Passenger Door 26, 27

Passenger Heated Seat Back

(Premium I/III)GN At Passenger Seat N/S

Passenger Heated Seat

Cushion (Premium I/III)BK At Passenger Seat N/S

Passenger Heated Seat Switch BK Center of Instrument Panel 19, 20, 21

Passenger Lumbar Motor

(Midline/Premium)BK At Passenger Seat N/S

Passenger Lumbar Switch

(Midline/Premium)WT At Passenger Seat N/S

Passenger Power Mirror BK In Passenger Door N/S

Passenger Power Seat Front

Riser MotorRD At Passenger Seat N/S

Passenger Power Seat

Horizontal MotorRD At Passenger Seat N/S

8W - 91 - 8 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

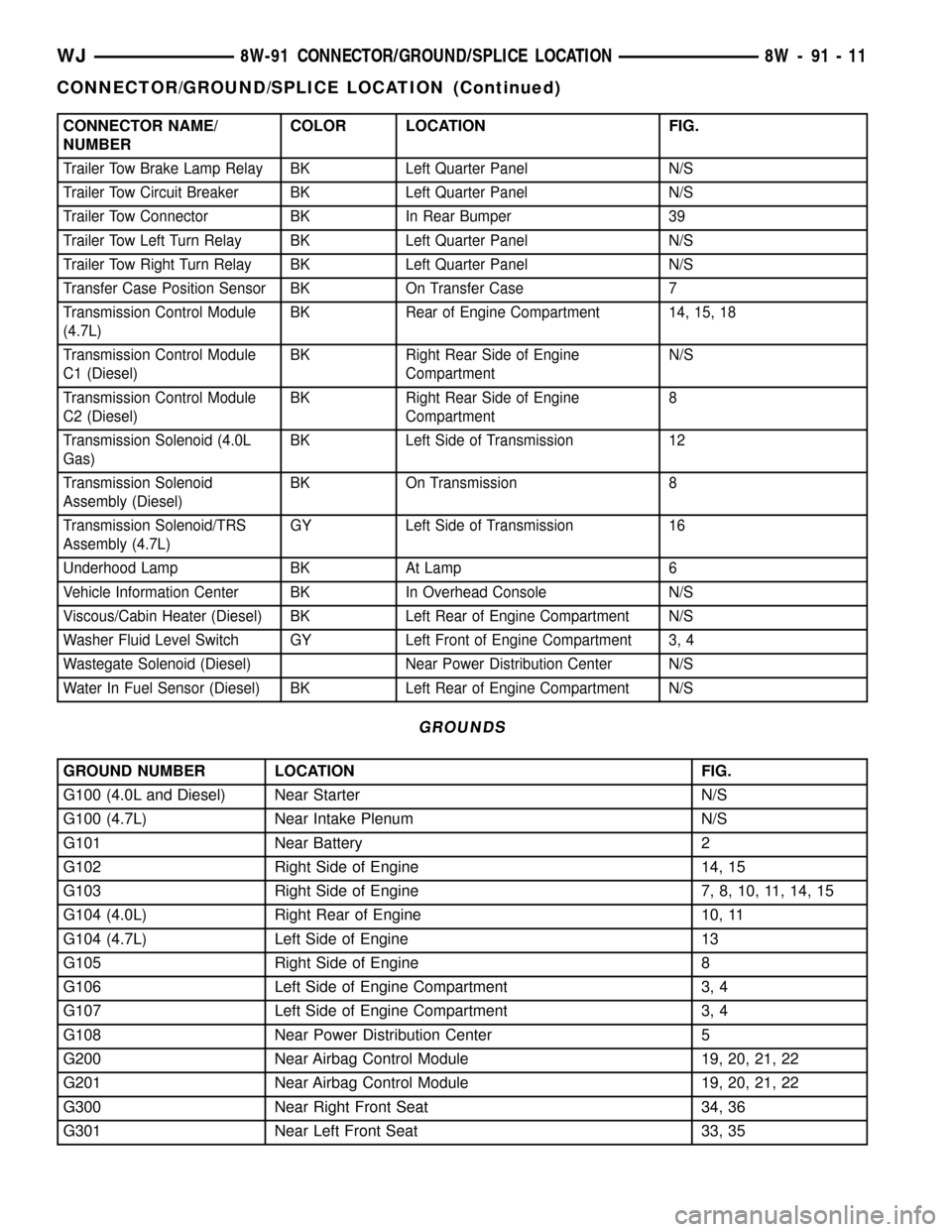

Page 1186 of 2199

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Trailer Tow Brake Lamp Relay BK Left Quarter Panel N/S

Trailer Tow Circuit Breaker BK Left Quarter Panel N/S

Trailer Tow Connector BK In Rear Bumper 39

Trailer Tow Left Turn Relay BK Left Quarter Panel N/S

Trailer Tow Right Turn Relay BK Left Quarter Panel N/S

Transfer Case Position Sensor BK On Transfer Case 7

Transmission Control Module

(4.7L)BK Rear of Engine Compartment 14, 15, 18

Transmission Control Module

C1 (Diesel)BK Right Rear Side of Engine

CompartmentN/S

Transmission Control Module

C2 (Diesel)BK Right Rear Side of Engine

Compartment8

Transmission Solenoid (4.0L

Gas)BK Left Side of Transmission 12

Transmission Solenoid

Assembly (Diesel)BK On Transmission 8

Transmission Solenoid/TRS

Assembly (4.7L)GY Left Side of Transmission 16

Underhood Lamp BK At Lamp 6

Vehicle Information Center BK In Overhead Console N/S

Viscous/Cabin Heater (Diesel) BK Left Rear of Engine Compartment N/S

Washer Fluid Level Switch GY Left Front of Engine Compartment 3, 4

Wastegate Solenoid (Diesel) Near Power Distribution Center N/S

Water In Fuel Sensor (Diesel) BK Left Rear of Engine Compartment N/S

GROUNDS

GROUND NUMBER LOCATION FIG.

G100 (4.0L and Diesel) Near Starter N/S

G100 (4.7L) Near Intake Plenum N/S

G101 Near Battery 2

G102 Right Side of Engine 14, 15

G103 Right Side of Engine 7, 8, 10, 11, 14, 15

G104 (4.0L) Right Rear of Engine 10, 11

G104 (4.7L) Left Side of Engine 13

G105 Right Side of Engine 8

G106 Left Side of Engine Compartment 3, 4

G107 Left Side of Engine Compartment 3, 4

G108 Near Power Distribution Center 5

G200 Near Airbag Control Module 19, 20, 21, 22

G201 Near Airbag Control Module 19, 20, 21, 22

G300 Near Right Front Seat 34, 36

G301 Near Left Front Seat 33, 35

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 11

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1254 of 2199

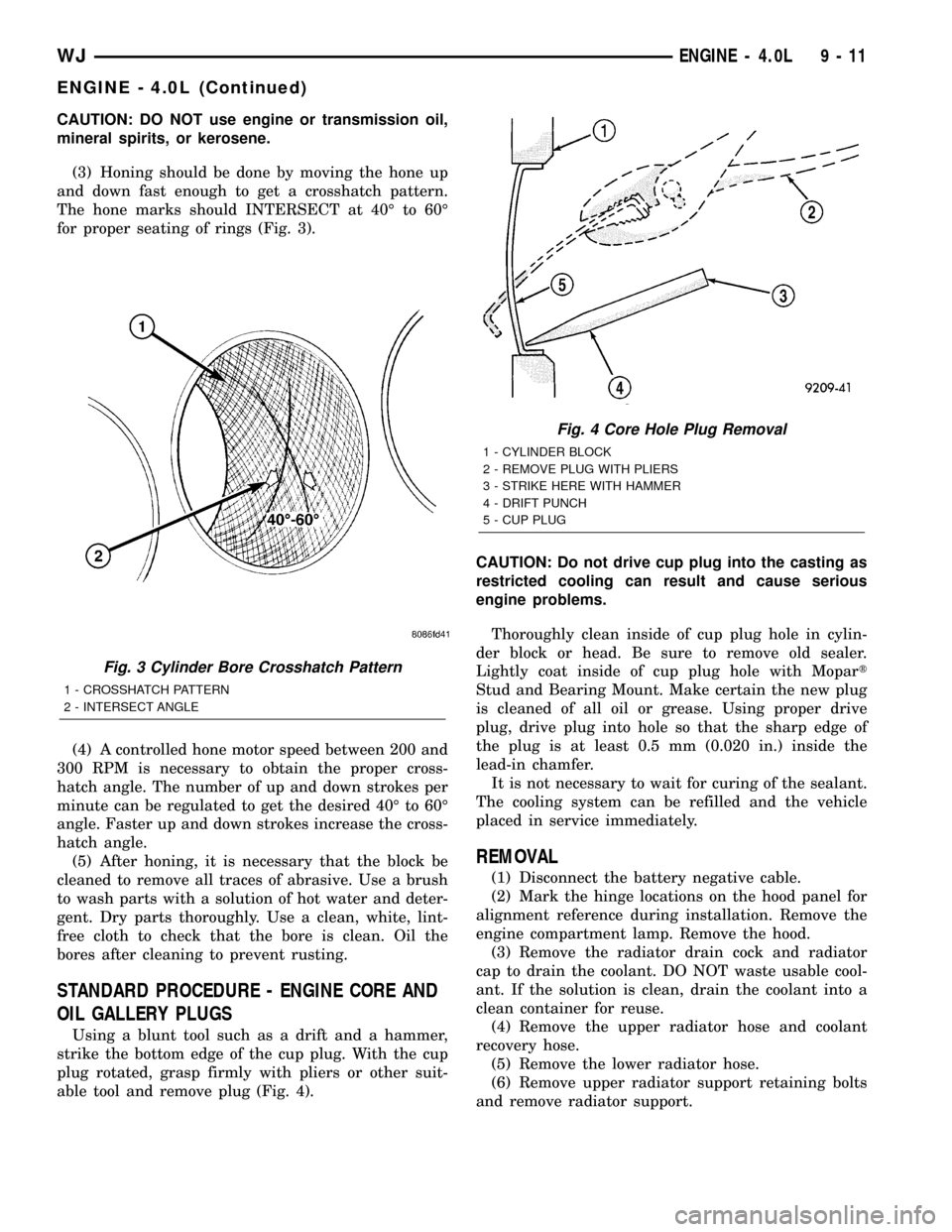

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 40É to 60É

for proper seating of rings (Fig. 3).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 40É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

STANDARD PROCEDURE - ENGINE CORE AND

OIL GALLERY PLUGS

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 4).CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious

engine problems.

Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Lightly coat inside of cup plug hole with Mopart

Stud and Bearing Mount. Make certain the new plug

is cleaned of all oil or grease. Using proper drive

plug, drive plug into hole so that the sharp edge of

the plug is at least 0.5 mm (0.020 in.) inside the

lead-in chamfer.

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Mark the hinge locations on the hood panel for

alignment reference during installation. Remove the

engine compartment lamp. Remove the hood.

(3) Remove the radiator drain cock and radiator

cap to drain the coolant. DO NOT waste usable cool-

ant. If the solution is clean, drain the coolant into a

clean container for reuse.

(4) Remove the upper radiator hose and coolant

recovery hose.

(5) Remove the lower radiator hose.

(6) Remove upper radiator support retaining bolts

and remove radiator support.

Fig. 3 Cylinder Bore Crosshatch Pattern

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

Fig. 4 Core Hole Plug Removal

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

WJENGINE - 4.0L 9 - 11

ENGINE - 4.0L (Continued)