Engine JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1876 of 2199

(2) Apply silicone lubricant to a cloth and wipe it

on door seals to avoid over-spray that can soil pas-

senger's clothing.

(3) Before applying lubricant, the component

should be wiped clean. After lubrication, any excess

lubricant should be removed.

(4) The hood latch, latch release mechanism, latch

striker, and safety latch should be lubricated period-

ically.

(5) The door lock cylinders should be lubricated

twice each year (preferably autumn and spring).

(a) Spray a small amount of lock cylinder lubri-

cant directly into the lock cylinder.

(b) Apply a small amount to the key and insert

it into the lock cylinder.

(c) Rotate it to the locked position and then back

to the unlocked position several times.(d) Remove the key. Wipe the lubricant from it

with a clean cloth to avoid soiling of clothing.

STANDARD PROCEDURE - DRILLING AND

WELDING

When holes must be drilled or punched in an inner

body panel, verify depth of space to the outer body

panel, electrical wiring, or other components. Dam-

age to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use when

welding.

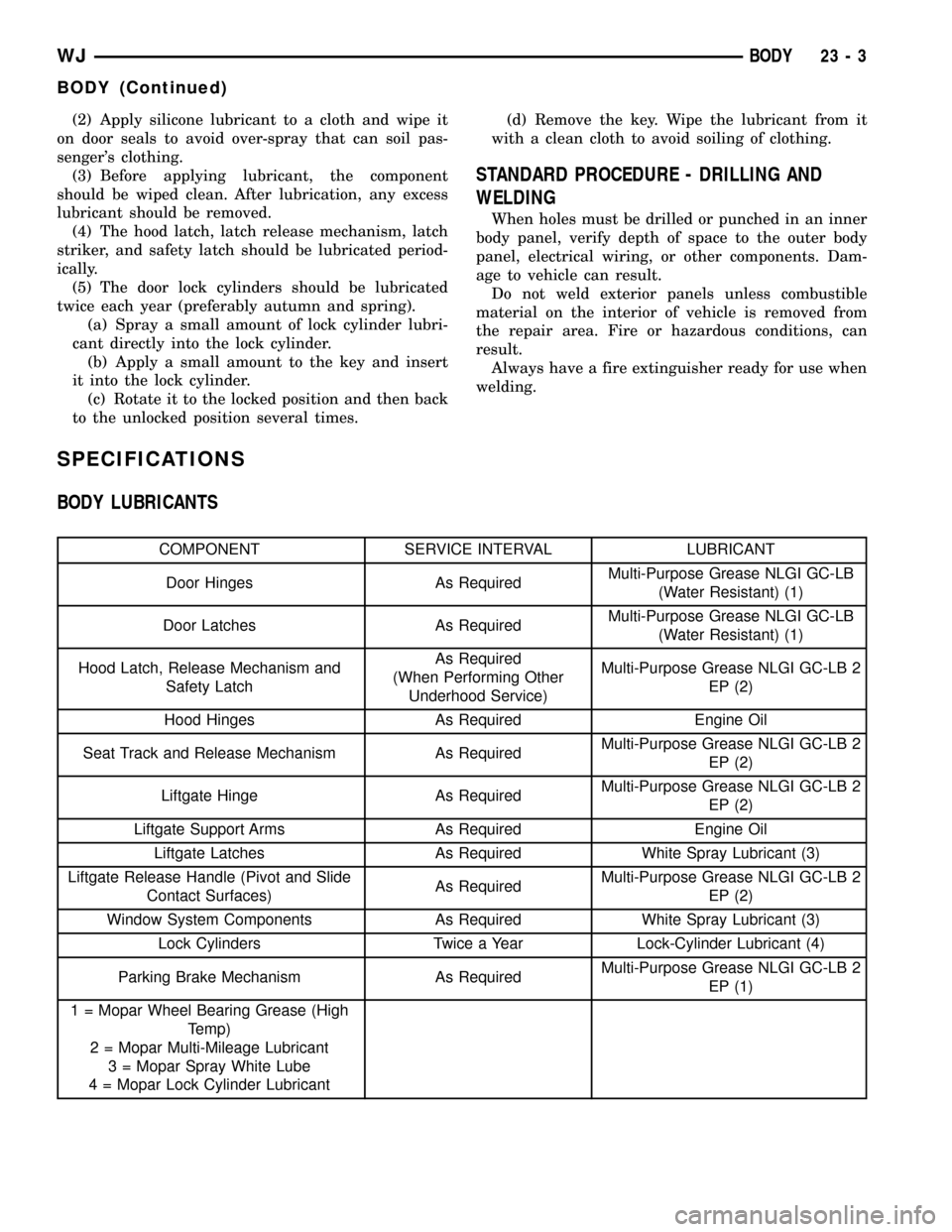

SPECIFICATIONS

BODY LUBRICANTS

COMPONENT SERVICE INTERVAL LUBRICANT

Door Hinges As RequiredMulti-Purpose Grease NLGI GC-LB

(Water Resistant) (1)

Door Latches As RequiredMulti-Purpose Grease NLGI GC-LB

(Water Resistant) (1)

Hood Latch, Release Mechanism and

Safety LatchAs Required

(When Performing Other

Underhood Service)Multi-Purpose Grease NLGI GC-LB 2

EP (2)

Hood Hinges As Required Engine Oil

Seat Track and Release Mechanism As RequiredMulti-Purpose Grease NLGI GC-LB 2

EP (2)

Liftgate Hinge As RequiredMulti-Purpose Grease NLGI GC-LB 2

EP (2)

Liftgate Support Arms As Required Engine Oil

Liftgate Latches As Required White Spray Lubricant (3)

Liftgate Release Handle (Pivot and Slide

Contact Surfaces)As RequiredMulti-Purpose Grease NLGI GC-LB 2

EP (2)

Window System Components As Required White Spray Lubricant (3)

Lock Cylinders Twice a Year Lock-Cylinder Lubricant (4)

Parking Brake Mechanism As RequiredMulti-Purpose Grease NLGI GC-LB 2

EP (1)

1 = Mopar Wheel Bearing Grease (High

Temp)

2 = Mopar Multi-Mileage Lubricant

3 = Mopar Spray White Lube

4 = Mopar Lock Cylinder Lubricant

WJBODY 23 - 3

BODY (Continued)

Page 1902 of 2199

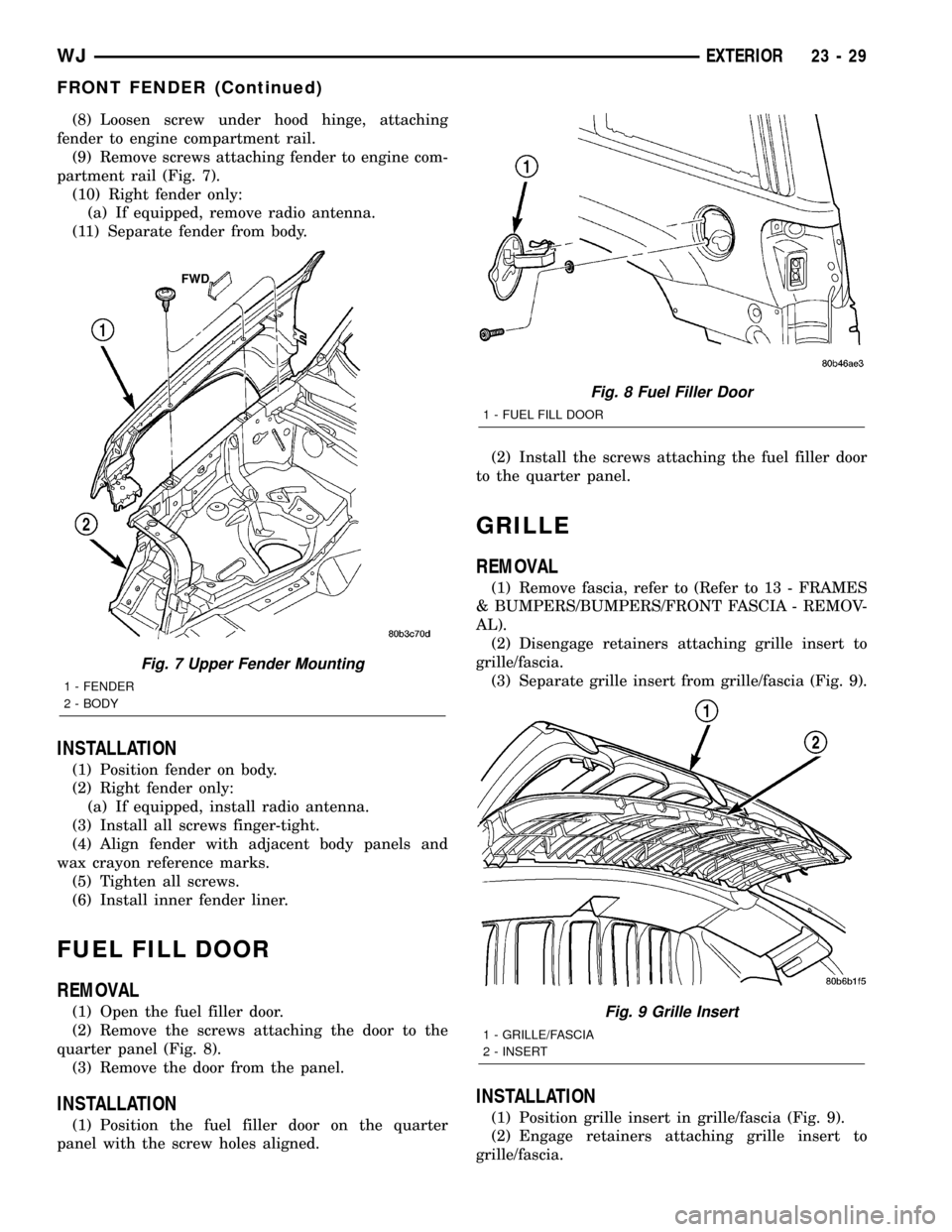

(8) Loosen screw under hood hinge, attaching

fender to engine compartment rail.

(9) Remove screws attaching fender to engine com-

partment rail (Fig. 7).

(10) Right fender only:

(a) If equipped, remove radio antenna.

(11) Separate fender from body.

INSTALLATION

(1) Position fender on body.

(2) Right fender only:

(a) If equipped, install radio antenna.

(3) Install all screws finger-tight.

(4) Align fender with adjacent body panels and

wax crayon reference marks.

(5) Tighten all screws.

(6) Install inner fender liner.

FUEL FILL DOOR

REMOVAL

(1) Open the fuel filler door.

(2) Remove the screws attaching the door to the

quarter panel (Fig. 8).

(3) Remove the door from the panel.

INSTALLATION

(1) Position the fuel filler door on the quarter

panel with the screw holes aligned.(2) Install the screws attaching the fuel filler door

to the quarter panel.

GRILLE

REMOVAL

(1) Remove fascia, refer to (Refer to 13 - FRAMES

& BUMPERS/BUMPERS/FRONT FASCIA - REMOV-

AL).

(2) Disengage retainers attaching grille insert to

grille/fascia.

(3) Separate grille insert from grille/fascia (Fig. 9).

INSTALLATION

(1) Position grille insert in grille/fascia (Fig. 9).

(2) Engage retainers attaching grille insert to

grille/fascia.

Fig. 7 Upper Fender Mounting

1 - FENDER

2 - BODY

Fig. 8 Fuel Filler Door

1 - FUEL FILL DOOR

Fig. 9 Grille Insert

1 - GRILLE/FASCIA

2 - INSERT

WJEXTERIOR 23 - 29

FRONT FENDER (Continued)

Page 1908 of 2199

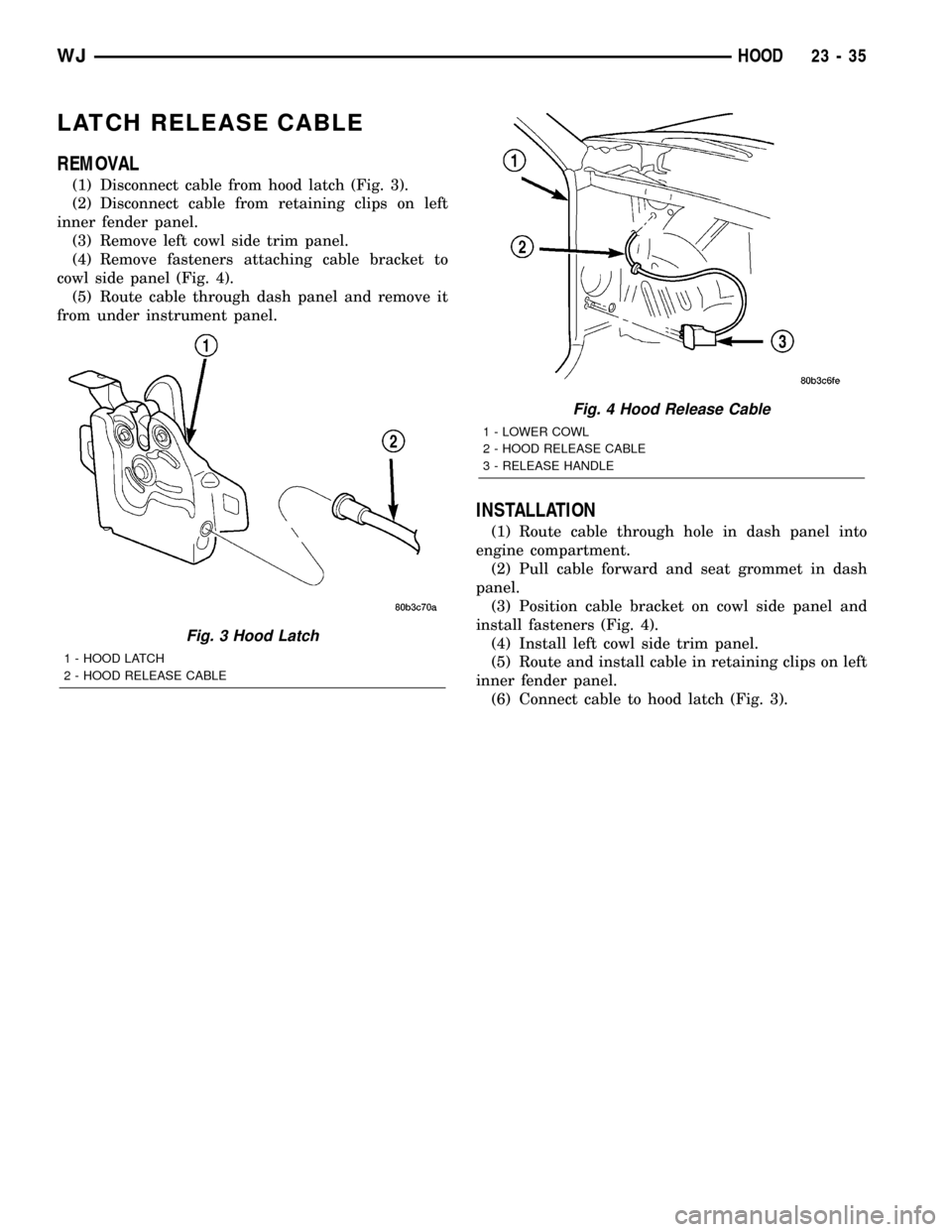

LATCH RELEASE CABLE

REMOVAL

(1) Disconnect cable from hood latch (Fig. 3).

(2) Disconnect cable from retaining clips on left

inner fender panel.

(3) Remove left cowl side trim panel.

(4) Remove fasteners attaching cable bracket to

cowl side panel (Fig. 4).

(5) Route cable through dash panel and remove it

from under instrument panel.

INSTALLATION

(1) Route cable through hole in dash panel into

engine compartment.

(2) Pull cable forward and seat grommet in dash

panel.

(3) Position cable bracket on cowl side panel and

install fasteners (Fig. 4).

(4) Install left cowl side trim panel.

(5) Route and install cable in retaining clips on left

inner fender panel.

(6) Connect cable to hood latch (Fig. 3).

Fig. 3 Hood Latch

1 - HOOD LATCH

2 - HOOD RELEASE CABLE

Fig. 4 Hood Release Cable

1 - LOWER COWL

2 - HOOD RELEASE CABLE

3 - RELEASE HANDLE

WJHOOD 23 - 35

Page 1954 of 2199

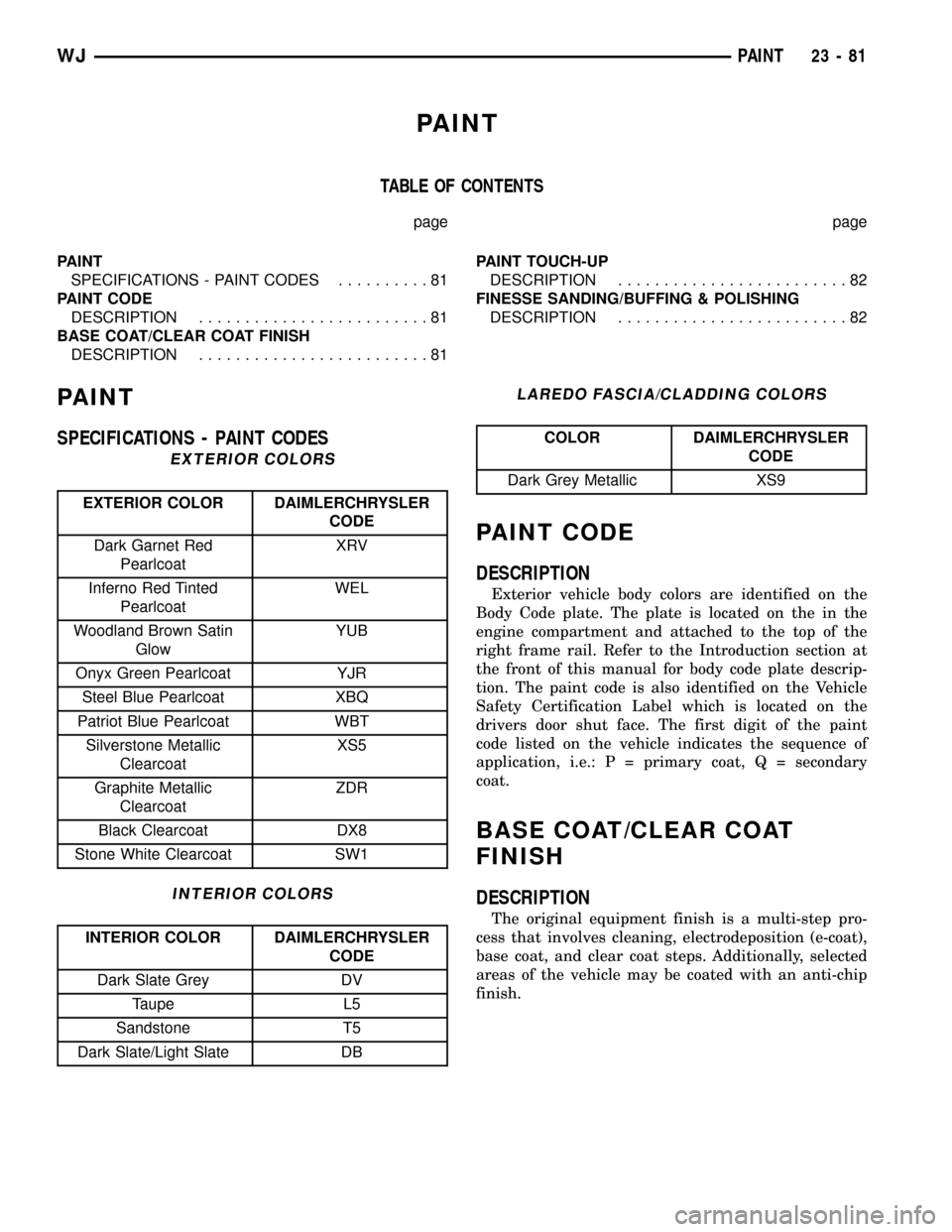

PAINT

TABLE OF CONTENTS

page page

PAINT

SPECIFICATIONS - PAINT CODES..........81

PAINT CODE

DESCRIPTION.........................81

BASE COAT/CLEAR COAT FINISH

DESCRIPTION.........................81PAINT TOUCH-UP

DESCRIPTION.........................82

FINESSE SANDING/BUFFING & POLISHING

DESCRIPTION.........................82

PAINT

SPECIFICATIONS - PAINT CODES

EXTERIOR COLORS

EXTERIOR COLOR DAIMLERCHRYSLER

CODE

Dark Garnet Red

PearlcoatXRV

Inferno Red Tinted

PearlcoatWEL

Woodland Brown Satin

GlowYUB

Onyx Green Pearlcoat YJR

Steel Blue Pearlcoat XBQ

Patriot Blue Pearlcoat WBT

Silverstone Metallic

ClearcoatXS5

Graphite Metallic

ClearcoatZDR

Black Clearcoat DX8

Stone White Clearcoat SW1

INTERIOR COLORS

INTERIOR COLOR DAIMLERCHRYSLER

CODE

Dark Slate Grey DV

Taupe L5

Sandstone T5

Dark Slate/Light Slate DB

LAREDO FASCIA/CLADDING COLORS

COLOR DAIMLERCHRYSLER

CODE

Dark Grey Metallic XS9

PAINT CODE

DESCRIPTION

Exterior vehicle body colors are identified on the

Body Code plate. The plate is located on the in the

engine compartment and attached to the top of the

right frame rail. Refer to the Introduction section at

the front of this manual for body code plate descrip-

tion. The paint code is also identified on the Vehicle

Safety Certification Label which is located on the

drivers door shut face. The first digit of the paint

code listed on the vehicle indicates the sequence of

application, i.e.: P = primary coat, Q = secondary

coat.

BASE COAT/CLEAR COAT

FINISH

DESCRIPTION

The original equipment finish is a multi-step pro-

cess that involves cleaning, electrodeposition (e-coat),

base coat, and clear coat steps. Additionally, selected

areas of the vehicle may be coated with an anti-chip

finish.

WJPAINT 23 - 81

Page 1987 of 2199

OPENING DIMENSIONS

SPECIFICATIONS - BODY OPENING

DIMENSIONS

DESCRIPTION FIGURE

WINDSHIELD AND

FRONT DOOR

OPENING3

REAR DOOR AND

QUARTER GLASS

OPENING4

LIFTGATE OPENING

AND ENGINE

COMPARTMENT5

23 - 114 BODY STRUCTUREWJ

Page 1990 of 2199

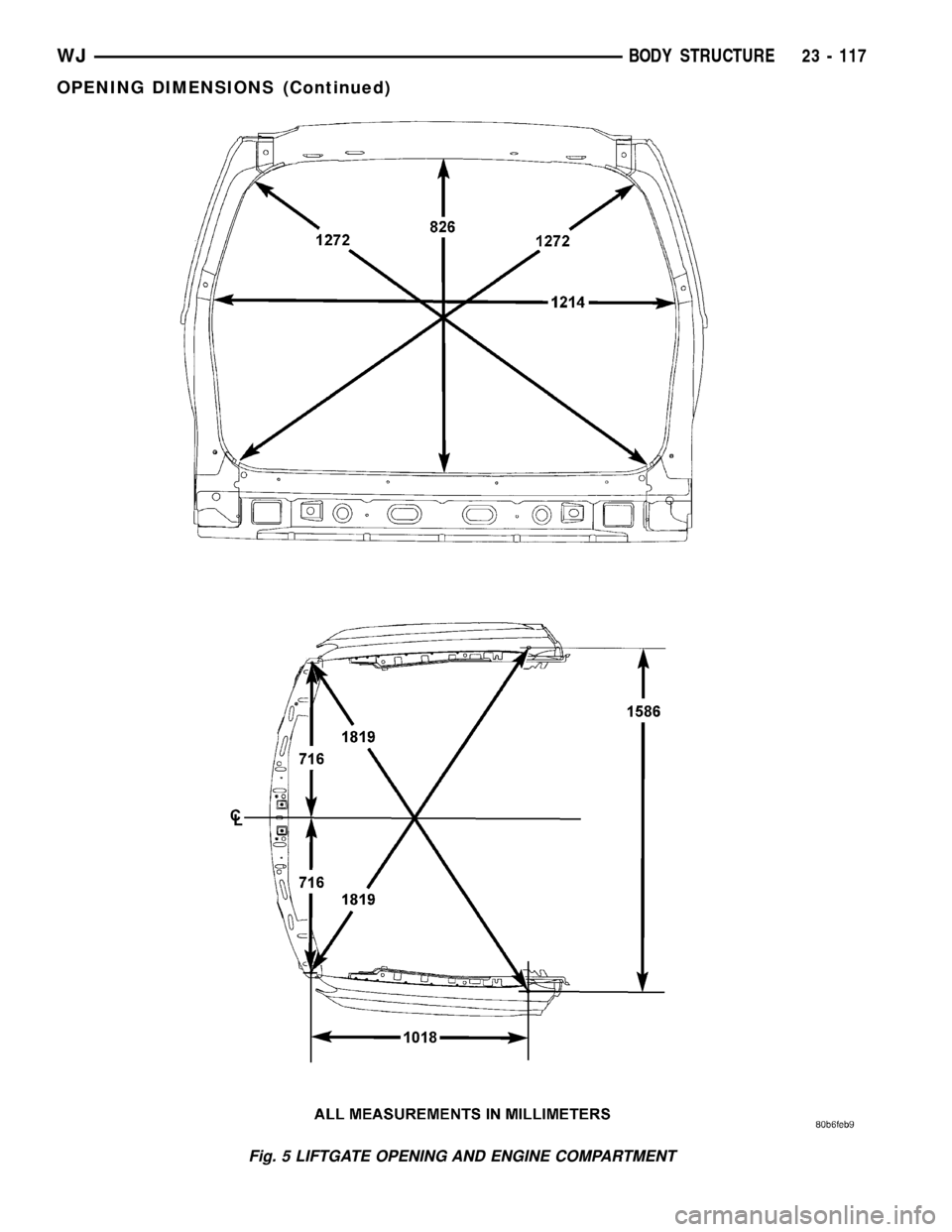

Fig. 5 LIFTGATE OPENING AND ENGINE COMPARTMENT

WJBODY STRUCTURE 23 - 117

OPENING DIMENSIONS (Continued)

Page 2027 of 2199

DESCRIPTION FIGURE

REINFORCEMENT FOR FRONT ENGINE MOUNTING AND STEERING GEAR TO

FRONT INNER SILL81

LARGE AND SMALL SWAY BAR TAPPING PLATES TO FRONT INNER SILLS 82

FRONT AND REAR DOOR HINGE TAPPING PLATES 83

REAR DOOR STRIKER REINFORCEMENT 84

TAIL LAMP MOUNTING PANELS 85

ROOF PANEL TO BODYSIDE APERTURE 86

ROOF PANEL TO REAR HEADER 87

UPPER REAR HEADER TO LOWER HEADER 88

FRONT HEADER AND ROOF BOWS TO INNER PANEL 89

FRONT SEAT/SHOULDER BELT TO INNER PANEL REINFORCEMENT 90

REAR SEAT/SHOULDER BELT TO INNER PANEL REINFORCEMENT 91

FUEL FILLER GUSSET TO INNER QUARTER PANEL 92

FRONT FLOOR PAN TO SILL REINFORCEMENT 93

CENTER FLOOR PAN TO REAR SEAT CROSSMEMBER 94

FRONT FLOOR PAN TO FRONT SEAT REINFORCEMENT AND RAILS 95

CENTER FLOOR PAN TO UPPER CONTROL ARM CROSSMEMBER AND RAILS 96

REAR FLOOR PAN TO RAILS AND SPRING GUIDE CROSSMEMBER 97

REAR RAILS 98

UPPER CONTROL ARM CROSSMEMBER TO REAR RAIL 99

REAR RAIL REINFORCEMENT TO REAR RAILS 100

UPPER CONTROL ARM REINFORCEMENTS TO REAR RAIL 101

OUTER TRANSMISSION CROSSMEMBER REINFORCEMENT TO RAIL AND

BODYSIDE SILL102

BODYSIDE SILL TO FLOOR PAN 103

REAR RAILS TO REAR CROSSMEMBER 104

INNER WHEELHOUSE TO FLOOR PAN 105

INNER WHEELHOUSE TO INNER BODYSIDE APERTURE AND FLOOR PAN 106

OUTER WHEELHOUSE TO OUTER BODYSIDE APERTURE 107

OUTER WHEELHOUSE TO INNER BODYSIDE APERTURE 108

INNER BODYSIDE APERTURE TO OUTER BODYSIDE APERTURE 109

REAR INBOARD SEAT BELT REINFORCEMENT TO FLOOR PAN 110

23 - 154 BODY STRUCTUREWJ

WELD LOCATIONS (Continued)

Page 2053 of 2199

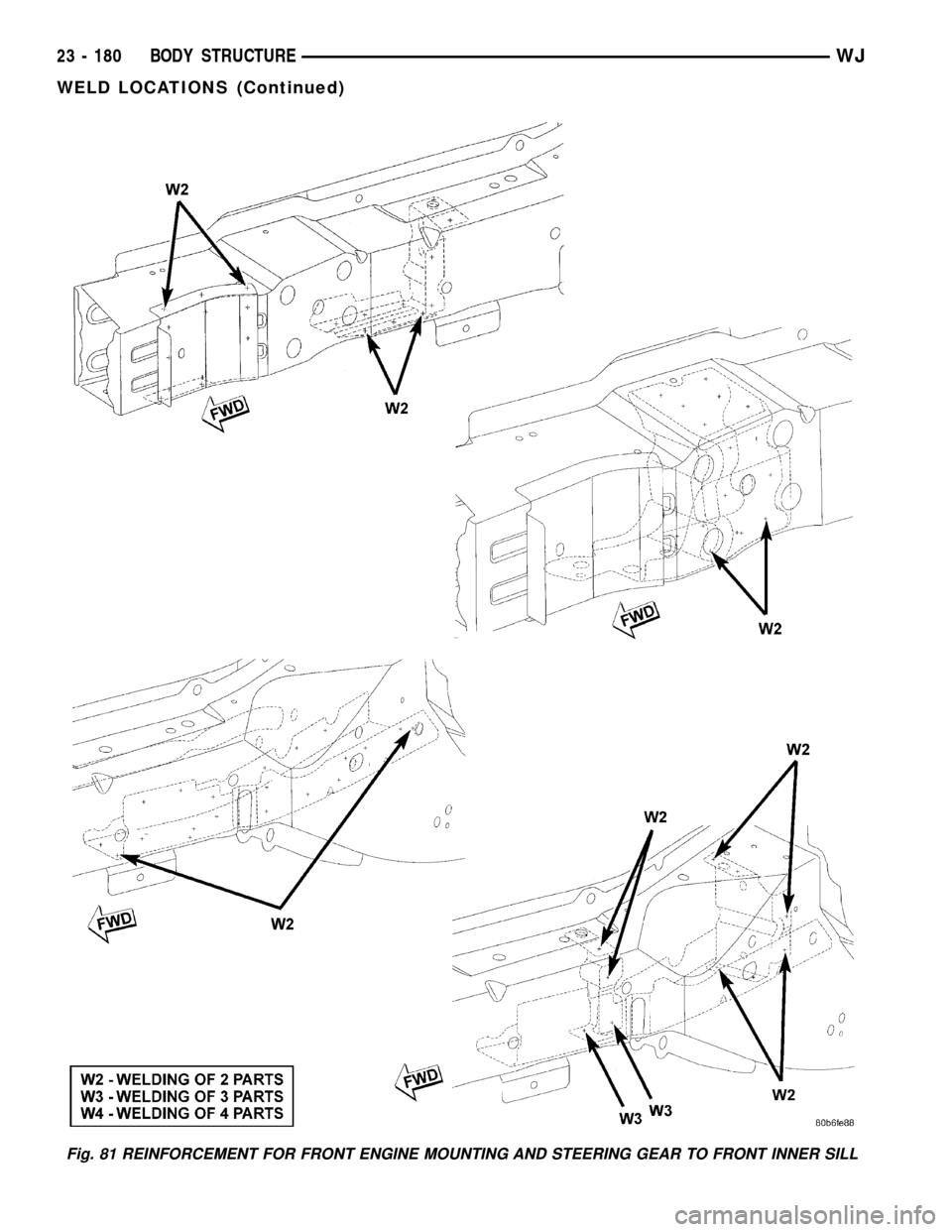

Fig. 81 REINFORCEMENT FOR FRONT ENGINE MOUNTING AND STEERING GEAR TO FRONT INNER SILL

23 - 180 BODY STRUCTUREWJ

WELD LOCATIONS (Continued)

Page 2078 of 2199

HEATING & AIR CONDITIONING

TABLE OF CONTENTS

page page

HEATING & AIR CONDITIONING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM

REQUIREMENTS.......................1

DESCRIPTION - HEATER AND AIR

CONDITIONER........................1

DESCRIPTION - REFRIGERANT SYSTEM

SERVICE PORT........................1

OPERATION

OPERATION - HEATER AND AIR

CONDITIONER........................2

OPERATION - REFRIGERANT SYSTEM

SERVICE PORT........................2DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE.......................2

DIAGNOSIS AND TESTING - HEATER

PERFORMANCE.......................6

STANDARD PROCEDURE - DIODE

REPLACEMENT.......................6

SPECIFICATIONS

A/C APPLICATION TABLE................7

TORQUE SPECIFICATIONS..............8

CONTROLS.............................9

DISTRIBUTION..........................36

PLUMBING.............................51

HEATING & AIR

CONDITIONING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM

REQUIREMENTS

To maintain the performance level of the heating-

air conditioning system, the engine cooling system

must be properly maintained. The use of a bug

screen is not recommended. Any obstructions in front

of the radiator or condenser will reduce the perfor-

mance of the air conditioning and engine cooling sys-

tems.

The engine cooling system includes the heater core

and the heater hoses. Refer to Cooling for more infor-

mation before opening, or attempting any service to

the engine cooling system.

DESCRIPTION - HEATER AND AIR

CONDITIONER

A manual temperature control type heating-air

conditioning system is standard factory-installed

equipment on this model. An electronically controlled

Automatic Zone Control (AZC) type heating-air con-

ditioning system is an available factory-installed

option.

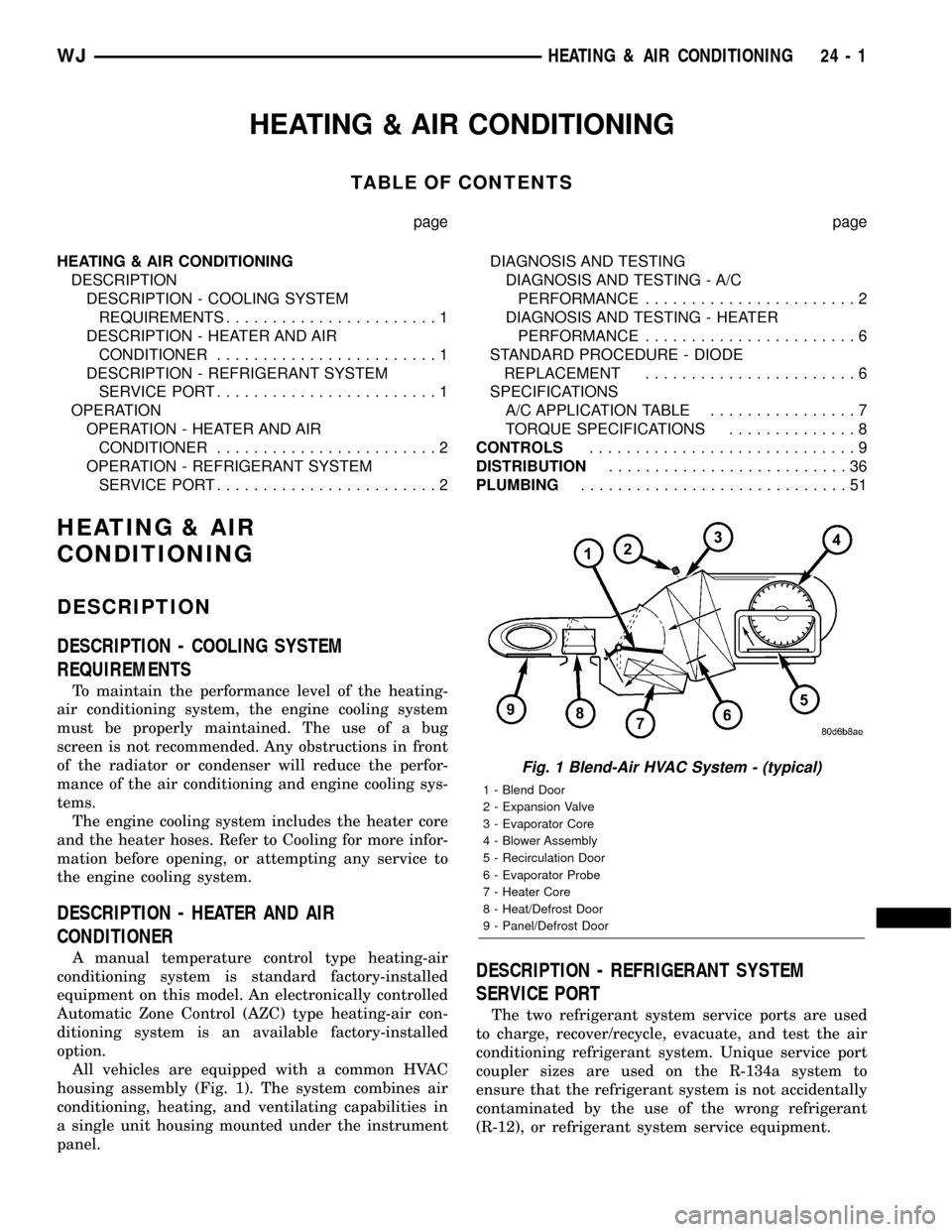

All vehicles are equipped with a common HVAC

housing assembly (Fig. 1). The system combines air

conditioning, heating, and ventilating capabilities in

a single unit housing mounted under the instrument

panel.DESCRIPTION - REFRIGERANT SYSTEM

SERVICE PORT

The two refrigerant system service ports are used

to charge, recover/recycle, evacuate, and test the air

conditioning refrigerant system. Unique service port

coupler sizes are used on the R-134a system to

ensure that the refrigerant system is not accidentally

contaminated by the use of the wrong refrigerant

(R-12), or refrigerant system service equipment.

Fig. 1 Blend-Air HVAC System - (typical)

1 - Blend Door

2 - Expansion Valve

3 - Evaporator Core

4 - Blower Assembly

5 - Recirculation Door

6 - Evaporator Probe

7 - Heater Core

8 - Heat/Defrost Door

9 - Panel/Defrost Door

WJHEATING & AIR CONDITIONING 24 - 1

Page 2079 of 2199

OPERATION

OPERATION - HEATER AND AIR CONDITIONER

Outside fresh air enters the vehicle through the

cowl top opening at the base of the windshield, and

passes through a plenum chamber to the HVAC sys-

tem blower housing. Air flow velocity can then be

adjusted with the blower motor speed selector switch

on the a/c heater control panel. The air intake open-

ings must be kept free of snow, ice, leaves, and other

obstructions for the HVAC system to receive a suffi-

cient volume of outside air.

It is also important to keep the air intake openings

clear of debris because leaf particles and other debris

that is small enough to pass through the cowl ple-

num screen can accumulate within the HVAC hous-

ing. The closed, warm, damp and dark environment

created within the HVAC housing is ideal for the

growth of certain molds, mildews and other fungi.

Any accumulation of decaying plant matter provides

an additional food source for fungal spores, which

enter the housing with the fresh air. Excess debris,

as well as objectionable odors created by decaying

plant matter and growing fungi can be discharged

into the passenger compartment during HVAC sys-

tem operation.

Both the manual and AZC heater and air condi-

tioner are blend-air type systems. In a blend-air sys-

tem, a blend door controls the amount of

unconditioned air (or cooled air from the evaporator)

that is allowed to flow through, or around, the heater

core. A temperature control knob on the a/c heater

control panel determines the discharge air tempera-

ture by energizing the blend door actuator, which

operates the blend door. This allows an almost imme-

diate control of the output air temperature of the sys-

tem. The AZC system will have separate blend doors

and temperature controls for each front seat occu-

pant.

The mode control knob on the a/c heater control

panel is used to direct the conditioned air to the

selected system outlets. On manual temperature con-

trol systems, the mode control knob switches engine

vacuum to control the mode doors, which are oper-

ated by vacuum actuators. On AZC systems, the

mode control knob switches electrical current to con-

trol the mode doors, which are operated by electronic

actuators.

The outside air intake can be shut off on manual

temperature control systems by selecting the Recircu-

lation Mode with the mode control knob. The outside

air intake can be shut off on Automatic Zone Control

(AZC) type system by pushing the Recirculation

Mode button. This will operate the recirculation door

that closes off the outside fresh air intake and recir-

culates the air that is already inside the vehicle.The air conditioner for all models is designed for

the use of non-CFC, R-134a refrigerant. The air con-

ditioning system has an evaporator to cool and dehu-

midify the incoming air prior to blending it with the

heated air. This air conditioning system uses a ther-

mal expansion valve to meter refrigerant flow to the

evaporator coil. To maintain minimum evaporator

temperature and prevent evaporator freezing, the

system utilizes an evaporator thermister probe with

the appropriate operating logic located in the body

control module (BCM).

OPERATION - REFRIGERANT SYSTEM SERVICE

PORT

The high pressure service port is located on the liq-

uid line near the receiver/drier. The low pressure ser-

vice port is located on the suction line near the

evaporator at the rear of the engine compartment.

Each of the service ports has a threaded plastic

protective cap installed over it from the factory. After

servicing the refrigerant system, always reinstall

both of the service port caps.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - A/C

PERFORMANCE

The air conditioning system is designed to provide

the passenger compartment with low temperature

and low specific humidity air. The evaporator, located

in the HVAC housing on the dash panel below the

instrument panel, is cooled to temperatures near the

freezing point. As warm damp air passes through the

cooled evaporator, the air transfers its heat to the

refrigerant in the evaporator and the moisture in the

air condenses on the evaporator fins. During periods

of high heat and humidity, an air conditioning sys-

tem will be more effective in the Recirculation Mode.

With the system in the Recirculation Mode, only air

from the passenger compartment passes through the

evaporator. As the passenger compartment air dehu-

midifies, the air conditioning system performance

levels improve.

Humidity has an important bearing on the tempera-

ture of the air delivered to the interior of the vehicle. It

is important to understand the effect that humidity has

on the performance of the air conditioning system.

When humidity is high, the evaporator has to perform a

double duty. It must lower the air temperature, and it

must lower the temperature of the moisture in the air

that condenses on the evaporator fins. Condensing the

moisture in the air transfers heat energy into the evap-

orator fins and tubing. This reduces the amount of heat

the evaporator can absorb from the air. High humidity

greatly reduces the ability of the evaporator to lower

the temperature of the air.

24 - 2 HEATING & AIR CONDITIONINGWJ

HEATING & AIR CONDITIONING (Continued)