ENGINE CONTROL JEEP GRAND CHEROKEE 2002 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 362 of 2199

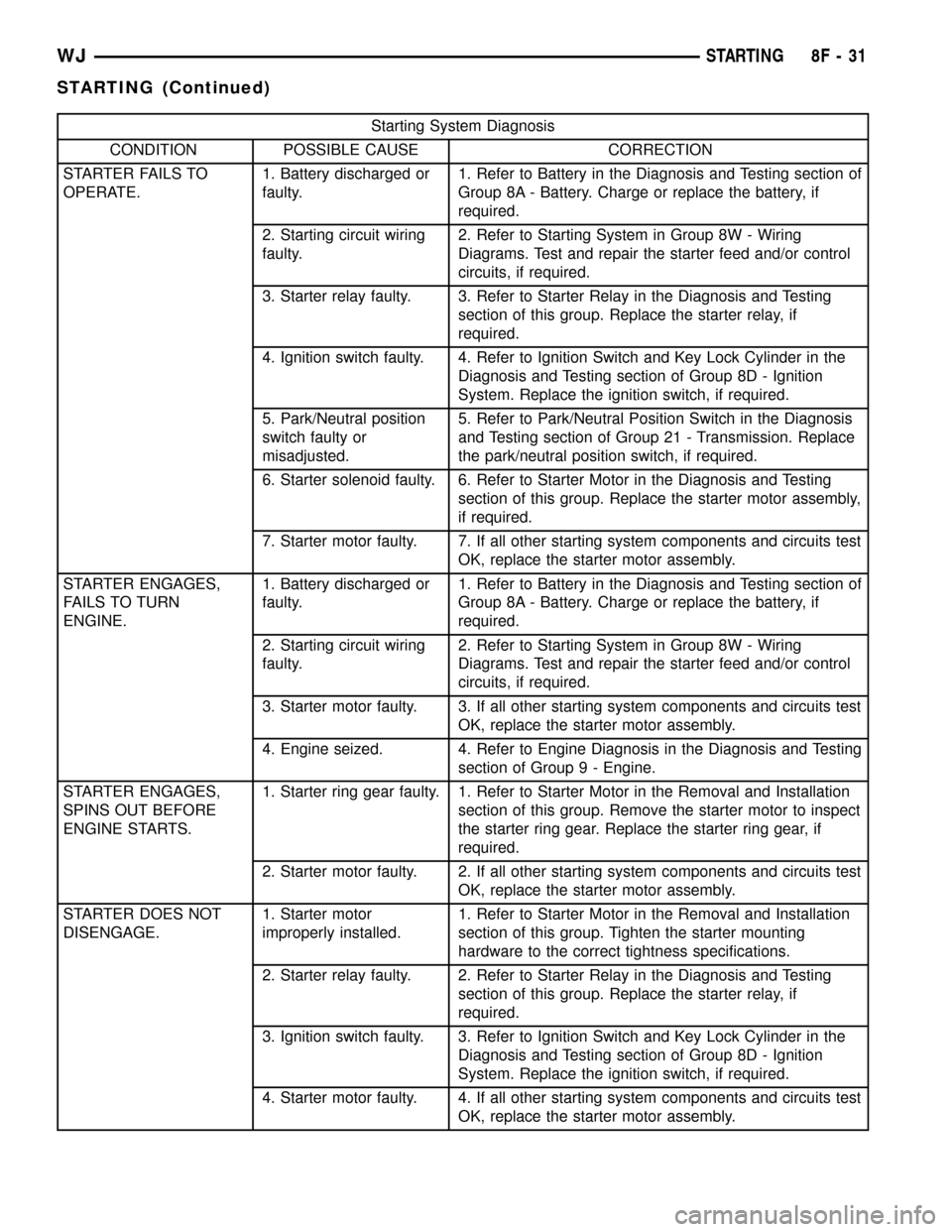

Starting System Diagnosis

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS TO

OPERATE.1. Battery discharged or

faulty.1. Refer to Battery in the Diagnosis and Testing section of

Group 8A - Battery. Charge or replace the battery, if

required.

2. Starting circuit wiring

faulty.2. Refer to Starting System in Group 8W - Wiring

Diagrams. Test and repair the starter feed and/or control

circuits, if required.

3. Starter relay faulty. 3. Refer to Starter Relay in the Diagnosis and Testing

section of this group. Replace the starter relay, if

required.

4. Ignition switch faulty. 4. Refer to Ignition Switch and Key Lock Cylinder in the

Diagnosis and Testing section of Group 8D - Ignition

System. Replace the ignition switch, if required.

5. Park/Neutral position

switch faulty or

misadjusted.5. Refer to Park/Neutral Position Switch in the Diagnosis

and Testing section of Group 21 - Transmission. Replace

the park/neutral position switch, if required.

6. Starter solenoid faulty. 6. Refer to Starter Motor in the Diagnosis and Testing

section of this group. Replace the starter motor assembly,

if required.

7. Starter motor faulty. 7. If all other starting system components and circuits test

OK, replace the starter motor assembly.

STARTER ENGAGES,

FAILS TO TURN

ENGINE.1. Battery discharged or

faulty.1. Refer to Battery in the Diagnosis and Testing section of

Group 8A - Battery. Charge or replace the battery, if

required.

2. Starting circuit wiring

faulty.2. Refer to Starting System in Group 8W - Wiring

Diagrams. Test and repair the starter feed and/or control

circuits, if required.

3. Starter motor faulty. 3. If all other starting system components and circuits test

OK, replace the starter motor assembly.

4. Engine seized. 4. Refer to Engine Diagnosis in the Diagnosis and Testing

section of Group 9 - Engine.

STARTER ENGAGES,

SPINS OUT BEFORE

ENGINE STARTS.1. Starter ring gear faulty. 1. Refer to Starter Motor in the Removal and Installation

section of this group. Remove the starter motor to inspect

the starter ring gear. Replace the starter ring gear, if

required.

2. Starter motor faulty. 2. If all other starting system components and circuits test

OK, replace the starter motor assembly.

STARTER DOES NOT

DISENGAGE.1. Starter motor

improperly installed.1. Refer to Starter Motor in the Removal and Installation

section of this group. Tighten the starter mounting

hardware to the correct tightness specifications.

2. Starter relay faulty. 2. Refer to Starter Relay in the Diagnosis and Testing

section of this group. Replace the starter relay, if

required.

3. Ignition switch faulty. 3. Refer to Ignition Switch and Key Lock Cylinder in the

Diagnosis and Testing section of Group 8D - Ignition

System. Replace the ignition switch, if required.

4. Starter motor faulty. 4. If all other starting system components and circuits test

OK, replace the starter motor assembly.

WJSTARTING 8F - 31

STARTING (Continued)

Page 364 of 2199

(b) If the voltage reads above 9.6 volts and the

current (amperage) draw reads below specifica-

tions, refer toFeed Circuit Testin this section.

(c) If the voltage reads 12.5 volts or greater and

the starter motor does not turn, refer toControl

Circuit Testingin this section.

(d) If the voltage reads 12.5 volts or greater and

the starter motor turns very slowly, refer toFeed

Circuit Testin this section.

NOTE: A cold engine will increase the starter cur-

rent (amperage) draw reading, and reduce the bat-

tery voltage reading.

FEED CIRCUIT TEST

The starter feed circuit test (voltage drop method)

will determine if there is excessive resistance in the

high-amperage feed circuit. For complete circuit dia-

grams, refer toStarting Systemin the Contents of

Group 8W - Wiring Diagrams.

When performing these tests, it is important to

remember that the voltage drop is giving an indica-

tion of the resistance between the two points at

which the voltmeter probes are attached.

Example:When testing the resistance of the bat-

tery positive cable, touch the voltmeter leads to the

battery positive cable clamp and the cable connector

at the starter solenoid. If you probe the battery pos-

itive terminal post and the cable connector at the

starter solenoid, you are reading the combined volt-

age drop in the battery positive cable clamp-to-termi-

nal post connection and the battery positive cable.

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing the

tests, be certain that the following procedures are

accomplished:

²Battery is fully-charged and load-tested. Refer to

Batteryin the Diagnosis and Testing section of

Group 8A - Battery for the procedures.

²Fully engage the parking brake.

²Place the automatic transmission gearshift selec-

tor lever in the Park position.

²

Verify that all lamps and accessories are turned off.

²To prevent the engine from starting, remove the

Automatic ShutDown (ASD) relay. The ASD relay is

located in the Power Distribution Center (PDC), in

the engine compartment. Refer to the fuse and relay

layout label affixed to the underside of the PDC cover

for ASD relay identification and location.

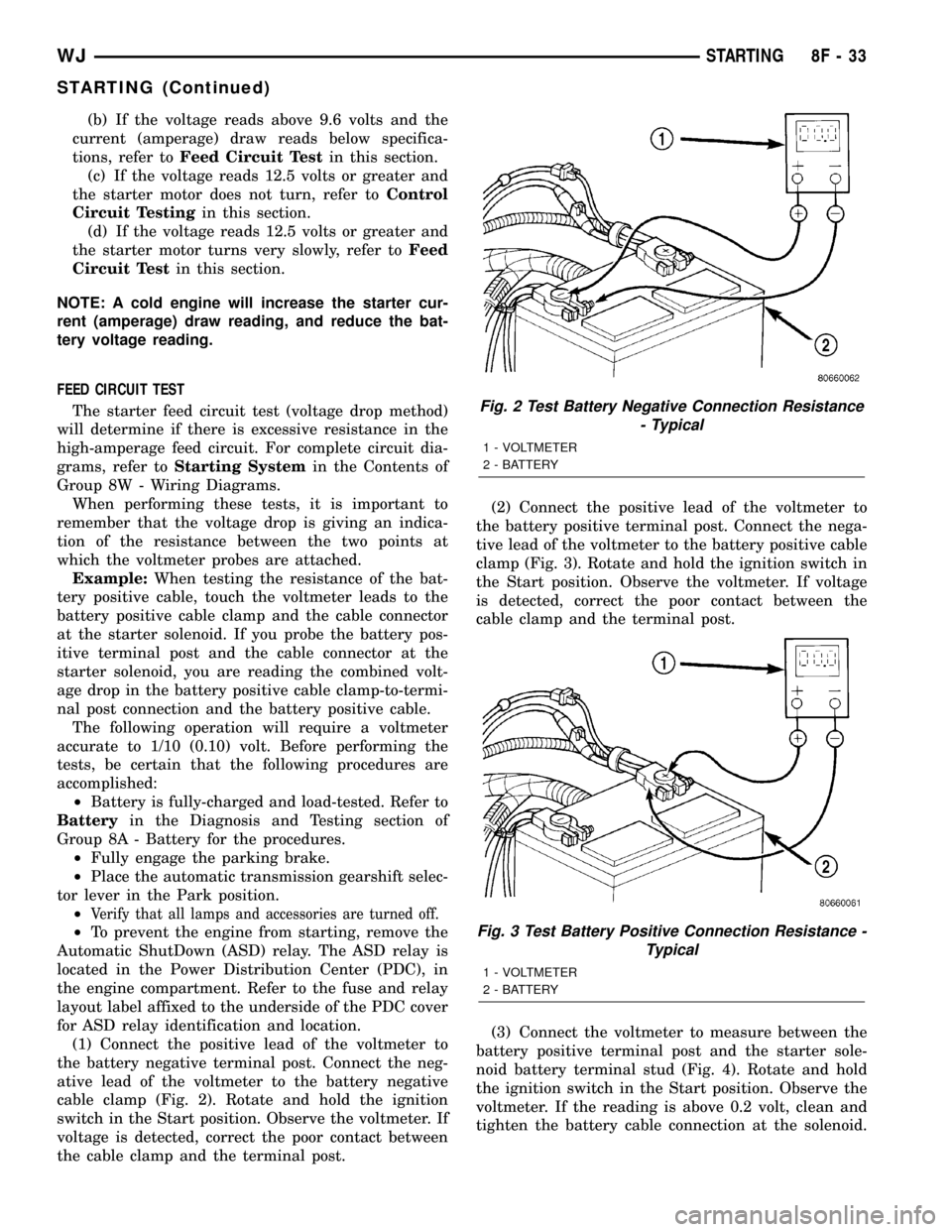

(1) Connect the positive lead of the voltmeter to

the battery negative terminal post. Connect the neg-

ative lead of the voltmeter to the battery negative

cable clamp (Fig. 2). Rotate and hold the ignition

switch in the Start position. Observe the voltmeter. If

voltage is detected, correct the poor contact between

the cable clamp and the terminal post.(2) Connect the positive lead of the voltmeter to

the battery positive terminal post. Connect the nega-

tive lead of the voltmeter to the battery positive cable

clamp (Fig. 3). Rotate and hold the ignition switch in

the Start position. Observe the voltmeter. If voltage

is detected, correct the poor contact between the

cable clamp and the terminal post.

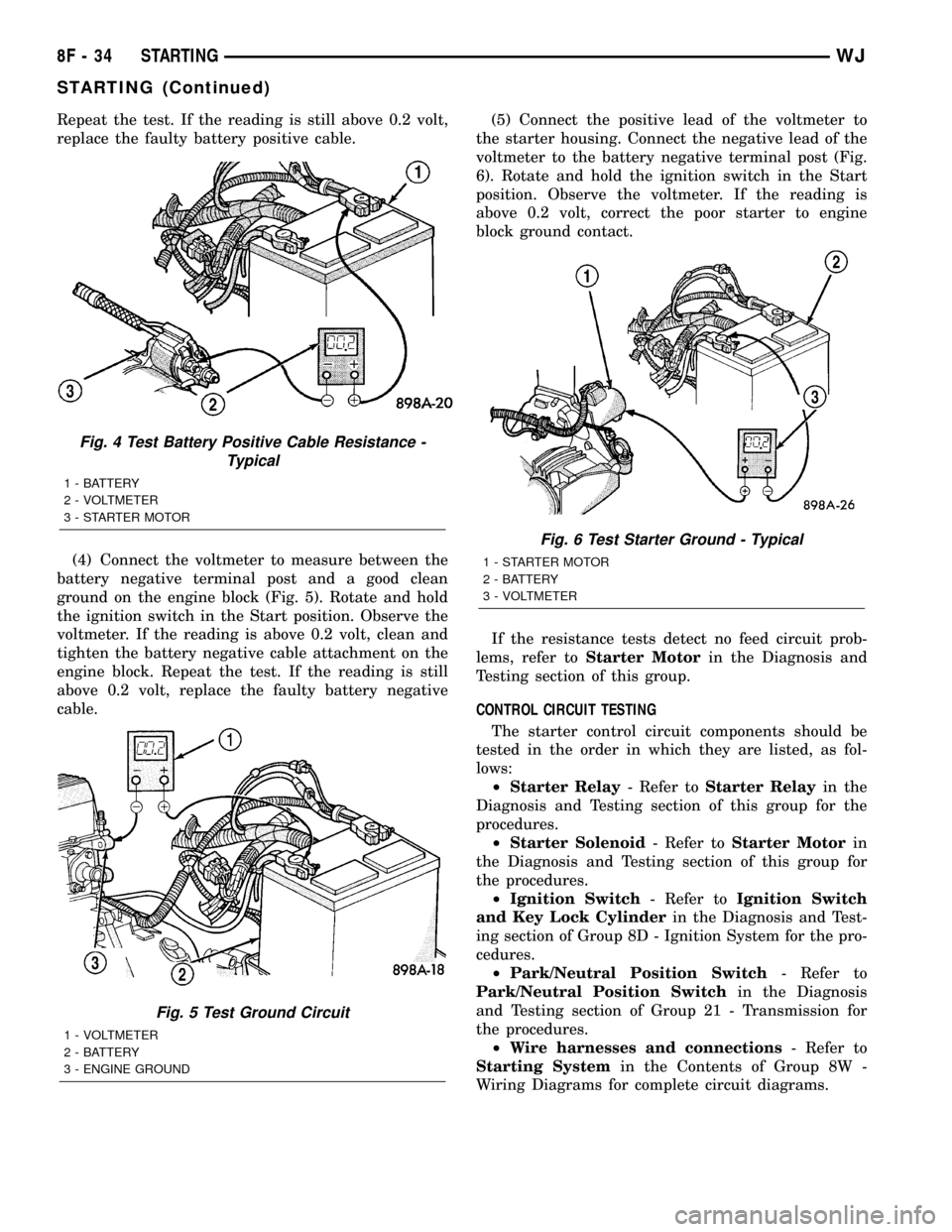

(3) Connect the voltmeter to measure between the

battery positive terminal post and the starter sole-

noid battery terminal stud (Fig. 4). Rotate and hold

the ignition switch in the Start position. Observe the

voltmeter. If the reading is above 0.2 volt, clean and

tighten the battery cable connection at the solenoid.

Fig. 2 Test Battery Negative Connection Resistance

- Typical

1 - VOLTMETER

2 - BATTERY

Fig. 3 Test Battery Positive Connection Resistance -

Typical

1 - VOLTMETER

2 - BATTERY

WJSTARTING 8F - 33

STARTING (Continued)

Page 365 of 2199

Repeat the test. If the reading is still above 0.2 volt,

replace the faulty battery positive cable.

(4) Connect the voltmeter to measure between the

battery negative terminal post and a good clean

ground on the engine block (Fig. 5). Rotate and hold

the ignition switch in the Start position. Observe the

voltmeter. If the reading is above 0.2 volt, clean and

tighten the battery negative cable attachment on the

engine block. Repeat the test. If the reading is still

above 0.2 volt, replace the faulty battery negative

cable.(5) Connect the positive lead of the voltmeter to

the starter housing. Connect the negative lead of the

voltmeter to the battery negative terminal post (Fig.

6). Rotate and hold the ignition switch in the Start

position. Observe the voltmeter. If the reading is

above 0.2 volt, correct the poor starter to engine

block ground contact.

If the resistance tests detect no feed circuit prob-

lems, refer toStarter Motorin the Diagnosis and

Testing section of this group.

CONTROL CIRCUIT TESTING

The starter control circuit components should be

tested in the order in which they are listed, as fol-

lows:

²Starter Relay- Refer toStarter Relayin the

Diagnosis and Testing section of this group for the

procedures.

²Starter Solenoid- Refer toStarter Motorin

the Diagnosis and Testing section of this group for

the procedures.

²Ignition Switch- Refer toIgnition Switch

and Key Lock Cylinderin the Diagnosis and Test-

ing section of Group 8D - Ignition System for the pro-

cedures.

²Park/Neutral Position Switch- Refer to

Park/Neutral Position Switchin the Diagnosis

and Testing section of Group 21 - Transmission for

the procedures.

²Wire harnesses and connections- Refer to

Starting Systemin the Contents of Group 8W -

Wiring Diagrams for complete circuit diagrams.

Fig. 4 Test Battery Positive Cable Resistance -

Typical

1 - BATTERY

2 - VOLTMETER

3 - STARTER MOTOR

Fig. 5 Test Ground Circuit

1 - VOLTMETER

2 - BATTERY

3 - ENGINE GROUND

Fig. 6 Test Starter Ground - Typical

1 - STARTER MOTOR

2 - BATTERY

3 - VOLTMETER

8F - 34 STARTINGWJ

STARTING (Continued)

Page 398 of 2199

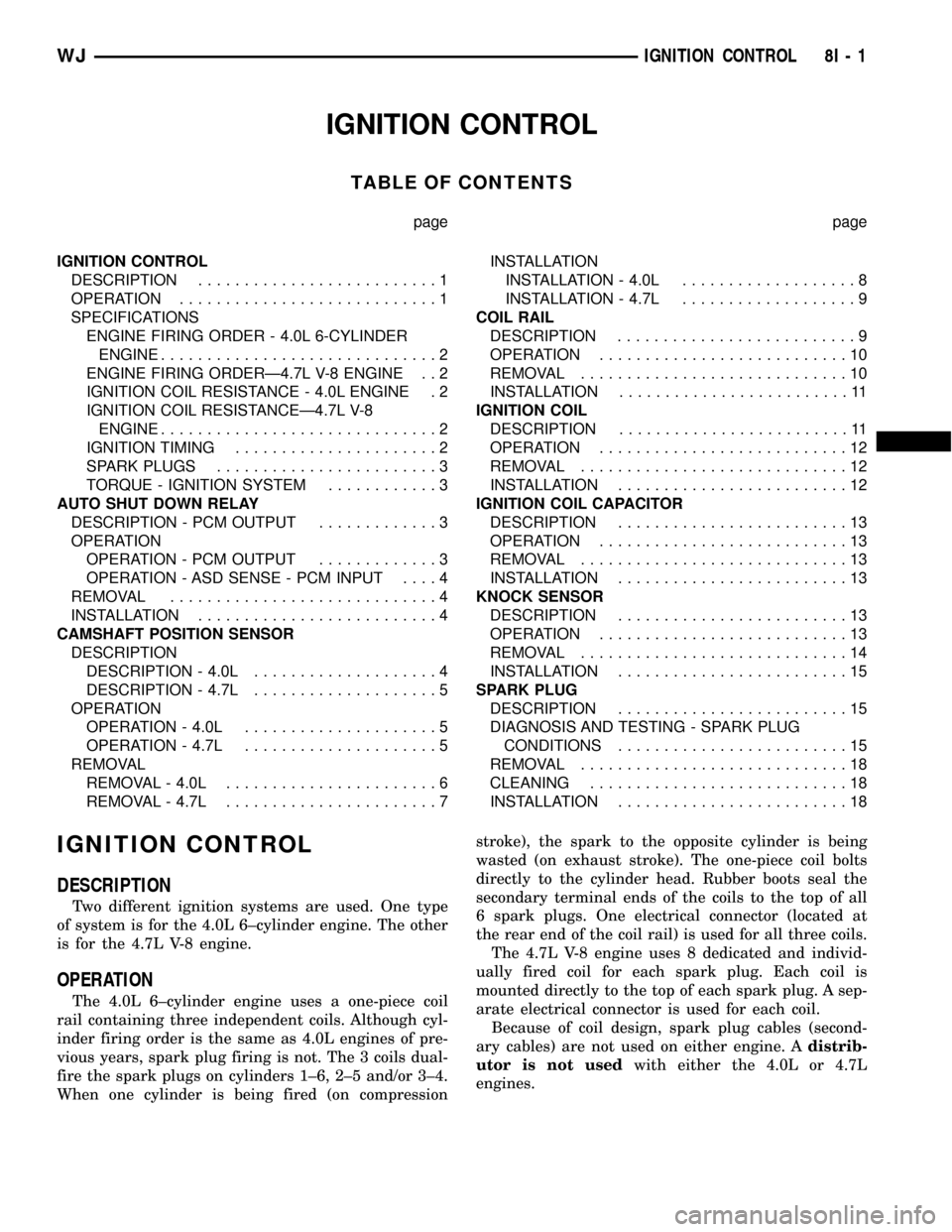

IGNITION CONTROL

TABLE OF CONTENTS

page page

IGNITION CONTROL

DESCRIPTION..........................1

OPERATION............................1

SPECIFICATIONS

ENGINE FIRING ORDER - 4.0L 6-CYLINDER

ENGINE..............................2

ENGINE FIRING ORDERÐ4.7L V-8 ENGINE . . 2

IGNITION COIL RESISTANCE - 4.0L ENGINE . 2

IGNITION COIL RESISTANCEÐ4.7L V-8

ENGINE..............................2

IGNITION TIMING......................2

SPARK PLUGS........................3

TORQUE - IGNITION SYSTEM............3

AUTO SHUT DOWN RELAY

DESCRIPTION - PCM OUTPUT.............3

OPERATION

OPERATION - PCM OUTPUT.............3

OPERATION - ASD SENSE - PCM INPUT....4

REMOVAL.............................4

INSTALLATION..........................4

CAMSHAFT POSITION SENSOR

DESCRIPTION

DESCRIPTION - 4.0L....................4

DESCRIPTION - 4.7L....................5

OPERATION

OPERATION - 4.0L.....................5

OPERATION - 4.7L.....................5

REMOVAL

REMOVAL - 4.0L.......................6

REMOVAL - 4.7L.......................7INSTALLATION

INSTALLATION - 4.0L...................8

INSTALLATION - 4.7L...................9

COIL RAIL

DESCRIPTION..........................9

OPERATION...........................10

REMOVAL.............................10

INSTALLATION.........................11

IGNITION COIL

DESCRIPTION.........................11

OPERATION...........................12

REMOVAL.............................12

INSTALLATION.........................12

IGNITION COIL CAPACITOR

DESCRIPTION.........................13

OPERATION...........................13

REMOVAL.............................13

INSTALLATION.........................13

KNOCK SENSOR

DESCRIPTION.........................13

OPERATION...........................13

REMOVAL.............................14

INSTALLATION.........................15

SPARK PLUG

DESCRIPTION.........................15

DIAGNOSIS AND TESTING - SPARK PLUG

CONDITIONS.........................15

REMOVAL.............................18

CLEANING............................18

INSTALLATION.........................18

IGNITION CONTROL

DESCRIPTION

Two different ignition systems are used. One type

of system is for the 4.0L 6±cylinder engine. The other

is for the 4.7L V-8 engine.

OPERATION

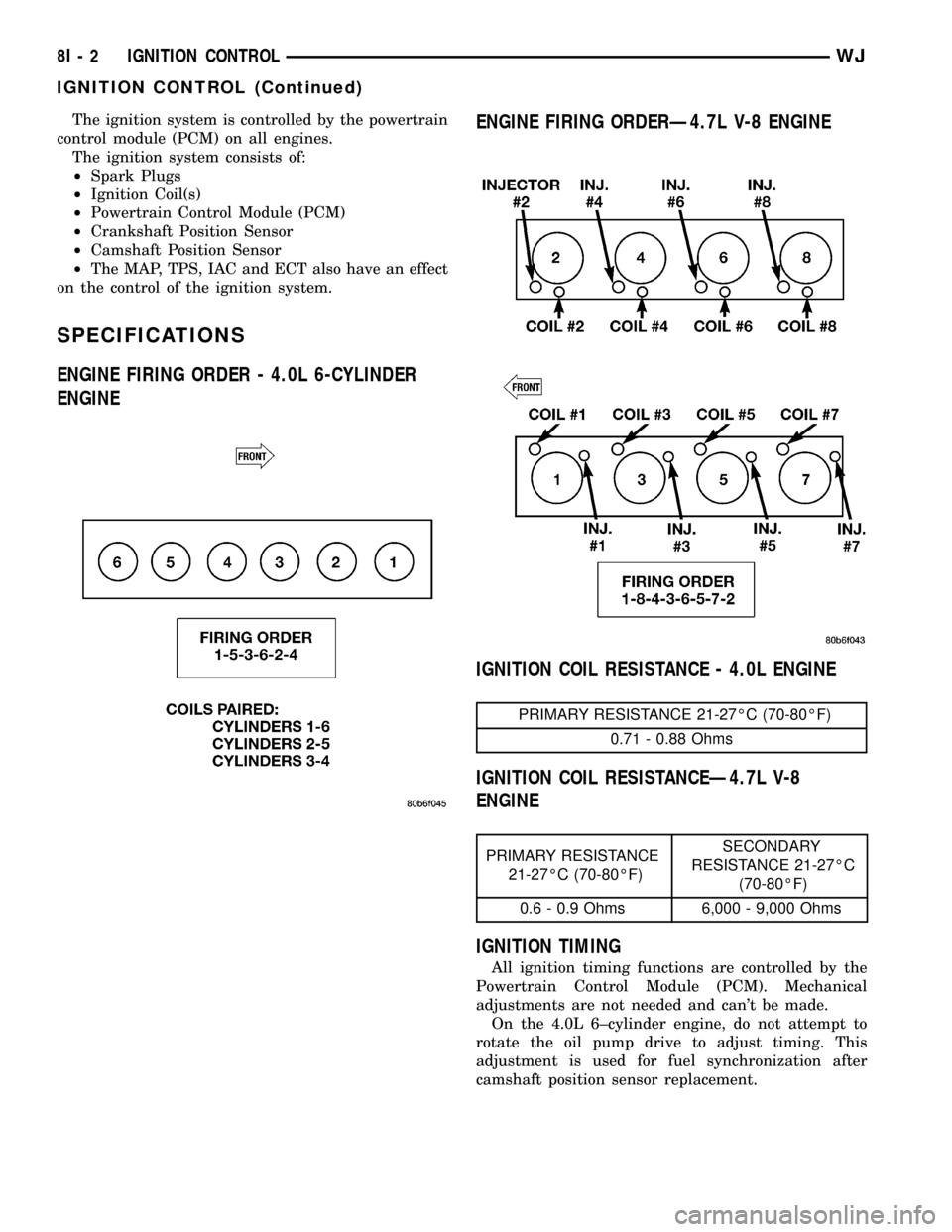

The 4.0L 6±cylinder engine uses a one-piece coil

rail containing three independent coils. Although cyl-

inder firing order is the same as 4.0L engines of pre-

vious years, spark plug firing is not. The 3 coils dual-

fire the spark plugs on cylinders 1±6, 2±5 and/or 3±4.

When one cylinder is being fired (on compressionstroke), the spark to the opposite cylinder is being

wasted (on exhaust stroke). The one-piece coil bolts

directly to the cylinder head. Rubber boots seal the

secondary terminal ends of the coils to the top of all

6 spark plugs. One electrical connector (located at

the rear end of the coil rail) is used for all three coils.

The 4.7L V-8 engine uses 8 dedicated and individ-

ually fired coil for each spark plug. Each coil is

mounted directly to the top of each spark plug. A sep-

arate electrical connector is used for each coil.

Because of coil design, spark plug cables (second-

ary cables) are not used on either engine. Adistrib-

utor is not usedwith either the 4.0L or 4.7L

engines.

WJIGNITION CONTROL 8I - 1

Page 399 of 2199

The ignition system is controlled by the powertrain

control module (PCM) on all engines.

The ignition system consists of:

²Spark Plugs

²Ignition Coil(s)

²Powertrain Control Module (PCM)

²Crankshaft Position Sensor

²Camshaft Position Sensor

²The MAP, TPS, IAC and ECT also have an effect

on the control of the ignition system.

SPECIFICATIONS

ENGINE FIRING ORDER - 4.0L 6-CYLINDER

ENGINEENGINE FIRING ORDERÐ4.7L V-8 ENGINE

IGNITION COIL RESISTANCE - 4.0L ENGINE

PRIMARY RESISTANCE 21-27ÉC (70-80ÉF)

0.71 - 0.88 Ohms

IGNITION COIL RESISTANCEÐ4.7L V-8

ENGINE

PRIMARY RESISTANCE

21-27ÉC (70-80ÉF)SECONDARY

RESISTANCE 21-27ÉC

(70-80ÉF)

0.6 - 0.9 Ohms 6,000 - 9,000 Ohms

IGNITION TIMING

All ignition timing functions are controlled by the

Powertrain Control Module (PCM). Mechanical

adjustments are not needed and can't be made.

On the 4.0L 6±cylinder engine, do not attempt to

rotate the oil pump drive to adjust timing. This

adjustment is used for fuel synchronization after

camshaft position sensor replacement.

8I - 2 IGNITION CONTROLWJ

IGNITION CONTROL (Continued)

Page 400 of 2199

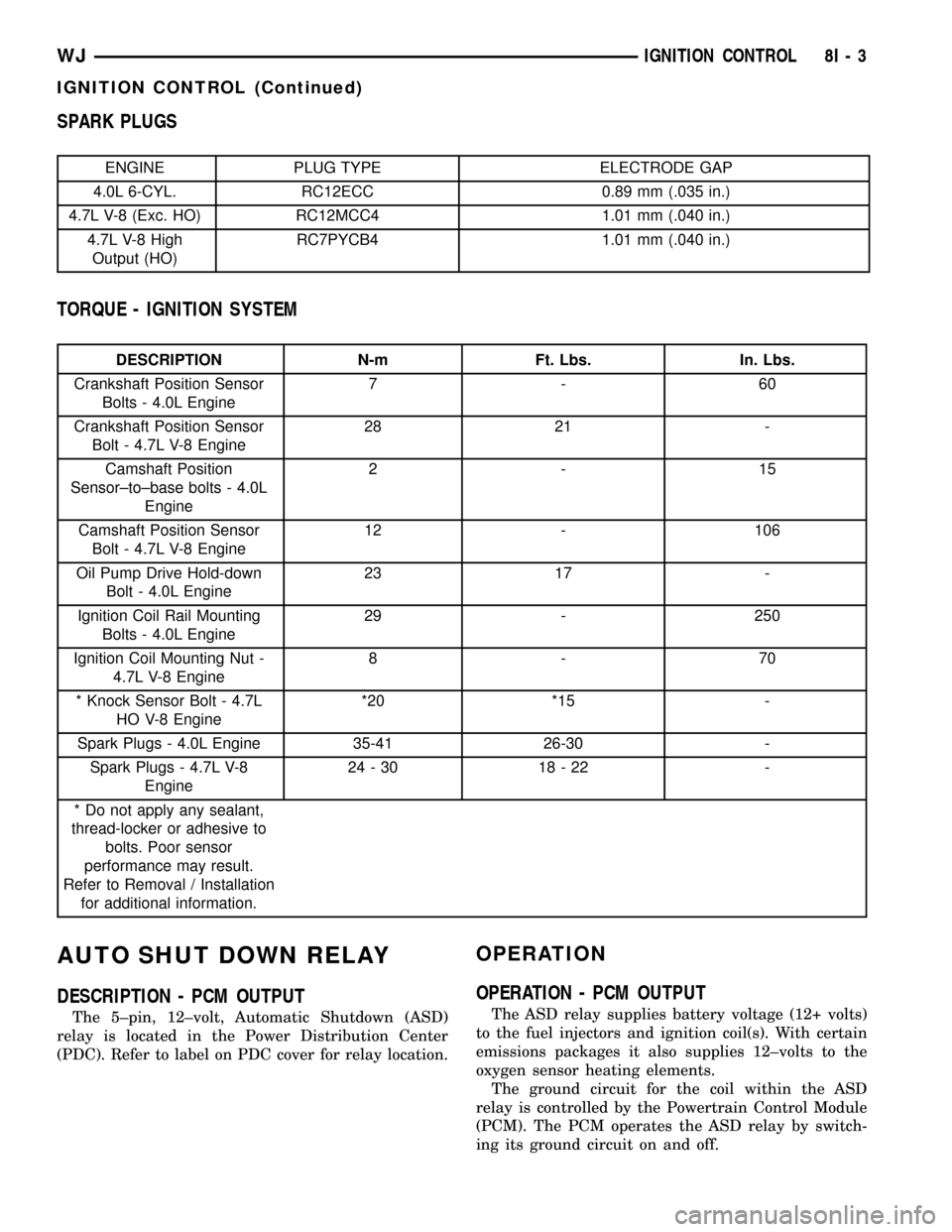

SPARK PLUGS

ENGINE PLUG TYPE ELECTRODE GAP

4.0L 6-CYL. RC12ECC 0.89 mm (.035 in.)

4.7L V-8 (Exc. HO) RC12MCC4 1.01 mm (.040 in.)

4.7L V-8 High

Output (HO)RC7PYCB4 1.01 mm (.040 in.)

TORQUE - IGNITION SYSTEM

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Crankshaft Position Sensor

Bolts - 4.0L Engine7- 60

Crankshaft Position Sensor

Bolt - 4.7L V-8 Engine28 21 -

Camshaft Position

Sensor±to±base bolts - 4.0L

Engine2- 15

Camshaft Position Sensor

Bolt - 4.7L V-8 Engine12 - 106

Oil Pump Drive Hold-down

Bolt - 4.0L Engine23 17 -

Ignition Coil Rail Mounting

Bolts - 4.0L Engine29 - 250

Ignition Coil Mounting Nut -

4.7L V-8 Engine8- 70

* Knock Sensor Bolt - 4.7L

HO V-8 Engine*20 *15 -

Spark Plugs - 4.0L Engine 35-41 26-30 -

Spark Plugs - 4.7L V-8

Engine24-30 18-22 -

* Do not apply any sealant,

thread-locker or adhesive to

bolts. Poor sensor

performance may result.

Refer to Removal / Installation

for additional information.

AUTO SHUT DOWN RELAY

DESCRIPTION - PCM OUTPUT

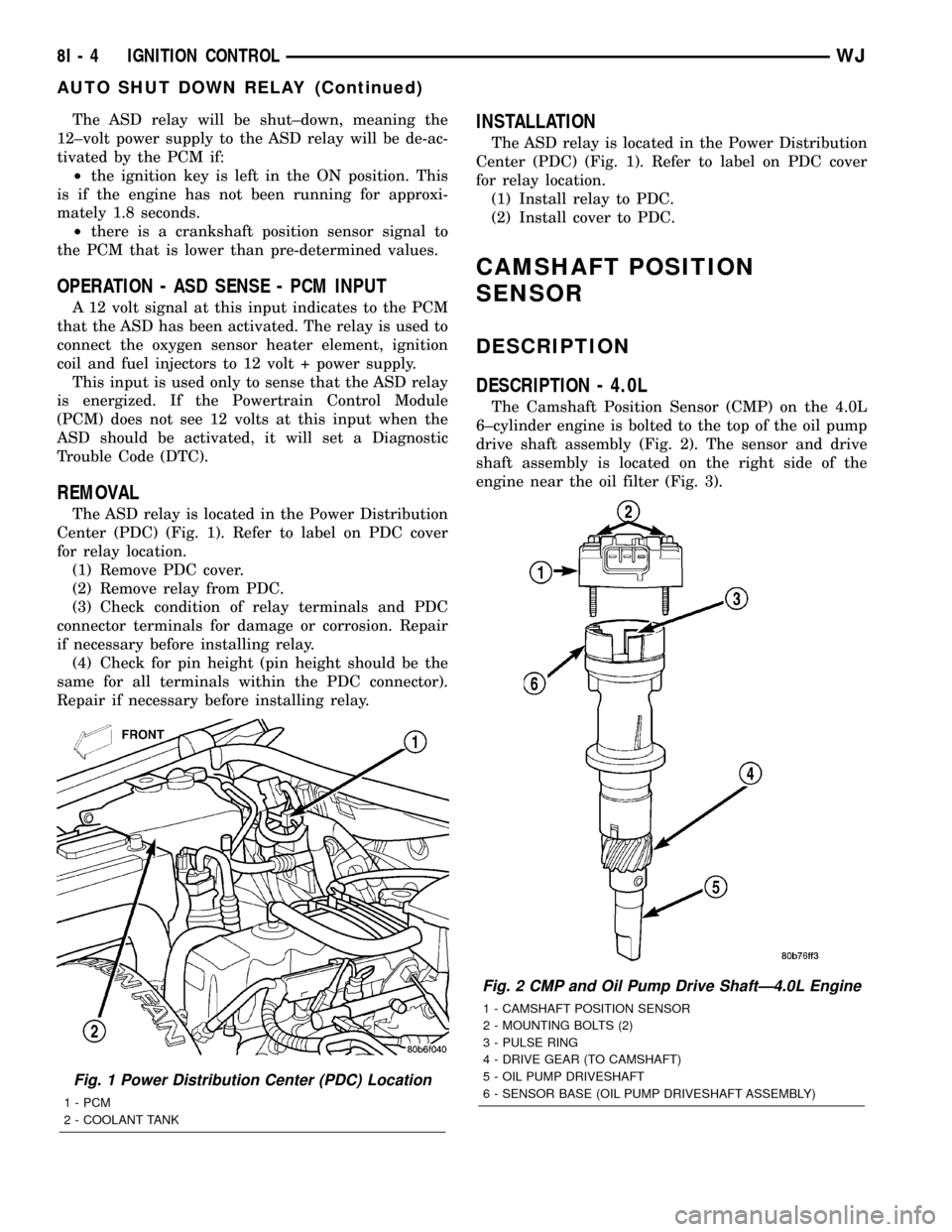

The 5±pin, 12±volt, Automatic Shutdown (ASD)

relay is located in the Power Distribution Center

(PDC). Refer to label on PDC cover for relay location.

OPERATION

OPERATION - PCM OUTPUT

The ASD relay supplies battery voltage (12+ volts)

to the fuel injectors and ignition coil(s). With certain

emissions packages it also supplies 12±volts to the

oxygen sensor heating elements.

The ground circuit for the coil within the ASD

relay is controlled by the Powertrain Control Module

(PCM). The PCM operates the ASD relay by switch-

ing its ground circuit on and off.

WJIGNITION CONTROL 8I - 3

IGNITION CONTROL (Continued)

Page 401 of 2199

The ASD relay will be shut±down, meaning the

12±volt power supply to the ASD relay will be de-ac-

tivated by the PCM if:

²the ignition key is left in the ON position. This

is if the engine has not been running for approxi-

mately 1.8 seconds.

²there is a crankshaft position sensor signal to

the PCM that is lower than pre-determined values.

OPERATION - ASD SENSE - PCM INPUT

A 12 volt signal at this input indicates to the PCM

that the ASD has been activated. The relay is used to

connect the oxygen sensor heater element, ignition

coil and fuel injectors to 12 volt + power supply.

This input is used only to sense that the ASD relay

is energized. If the Powertrain Control Module

(PCM) does not see 12 volts at this input when the

ASD should be activated, it will set a Diagnostic

Trouble Code (DTC).

REMOVAL

The ASD relay is located in the Power Distribution

Center (PDC) (Fig. 1). Refer to label on PDC cover

for relay location.

(1) Remove PDC cover.

(2) Remove relay from PDC.

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

The ASD relay is located in the Power Distribution

Center (PDC) (Fig. 1). Refer to label on PDC cover

for relay location.

(1) Install relay to PDC.

(2) Install cover to PDC.

CAMSHAFT POSITION

SENSOR

DESCRIPTION

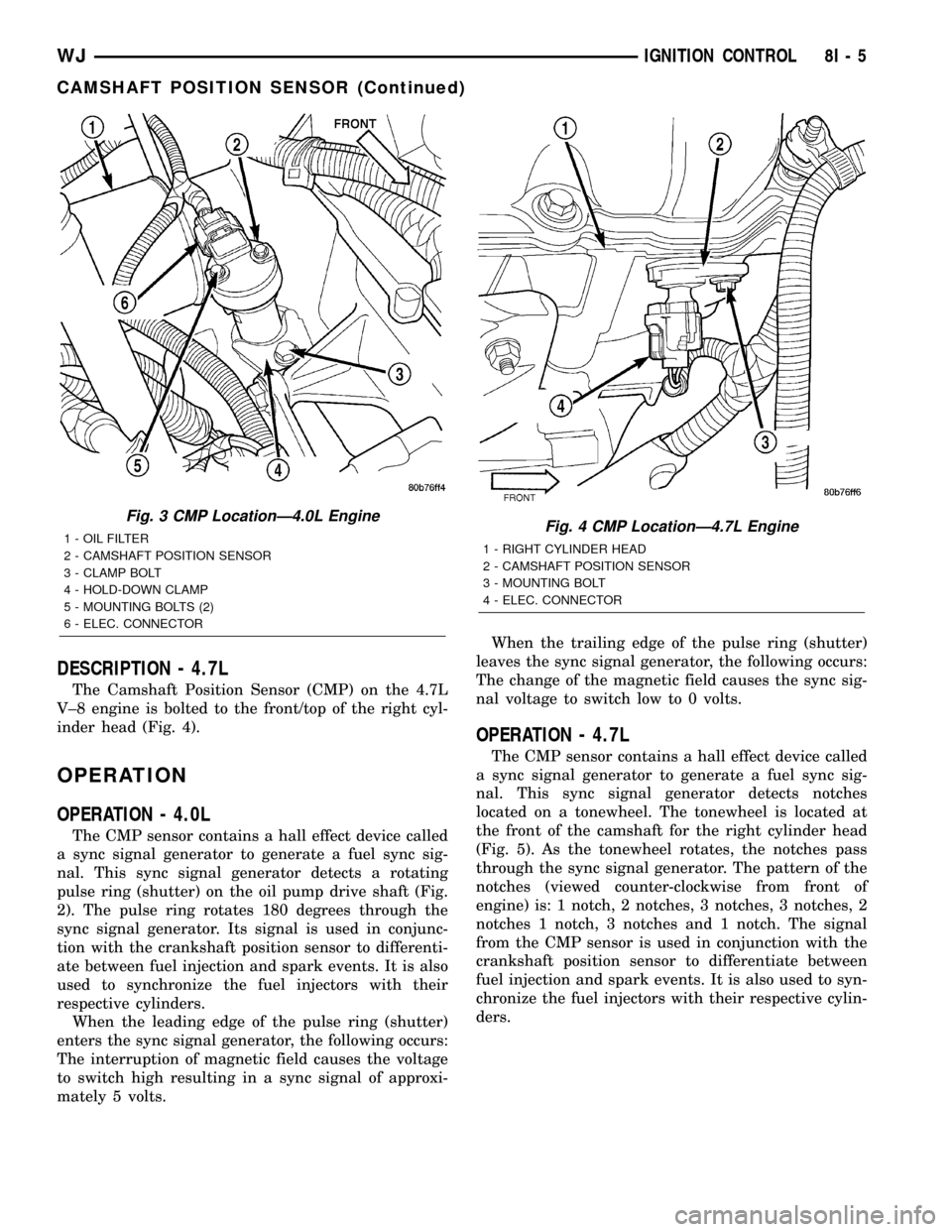

DESCRIPTION - 4.0L

The Camshaft Position Sensor (CMP) on the 4.0L

6±cylinder engine is bolted to the top of the oil pump

drive shaft assembly (Fig. 2). The sensor and drive

shaft assembly is located on the right side of the

engine near the oil filter (Fig. 3).

Fig. 1 Power Distribution Center (PDC) Location

1 - PCM

2 - COOLANT TANK

Fig. 2 CMP and Oil Pump Drive ShaftÐ4.0L Engine

1 - CAMSHAFT POSITION SENSOR

2 - MOUNTING BOLTS (2)

3 - PULSE RING

4 - DRIVE GEAR (TO CAMSHAFT)

5 - OIL PUMP DRIVESHAFT

6 - SENSOR BASE (OIL PUMP DRIVESHAFT ASSEMBLY)

8I - 4 IGNITION CONTROLWJ

AUTO SHUT DOWN RELAY (Continued)

Page 402 of 2199

DESCRIPTION - 4.7L

The Camshaft Position Sensor (CMP) on the 4.7L

V±8 engine is bolted to the front/top of the right cyl-

inder head (Fig. 4).

OPERATION

OPERATION - 4.0L

The CMP sensor contains a hall effect device called

a sync signal generator to generate a fuel sync sig-

nal. This sync signal generator detects a rotating

pulse ring (shutter) on the oil pump drive shaft (Fig.

2). The pulse ring rotates 180 degrees through the

sync signal generator. Its signal is used in conjunc-

tion with the crankshaft position sensor to differenti-

ate between fuel injection and spark events. It is also

used to synchronize the fuel injectors with their

respective cylinders.

When the leading edge of the pulse ring (shutter)

enters the sync signal generator, the following occurs:

The interruption of magnetic field causes the voltage

to switch high resulting in a sync signal of approxi-

mately 5 volts.When the trailing edge of the pulse ring (shutter)

leaves the sync signal generator, the following occurs:

The change of the magnetic field causes the sync sig-

nal voltage to switch low to 0 volts.

OPERATION - 4.7L

The CMP sensor contains a hall effect device called

a sync signal generator to generate a fuel sync sig-

nal. This sync signal generator detects notches

located on a tonewheel. The tonewheel is located at

the front of the camshaft for the right cylinder head

(Fig. 5). As the tonewheel rotates, the notches pass

through the sync signal generator. The pattern of the

notches (viewed counter-clockwise from front of

engine) is: 1 notch, 2 notches, 3 notches, 3 notches, 2

notches 1 notch, 3 notches and 1 notch. The signal

from the CMP sensor is used in conjunction with the

crankshaft position sensor to differentiate between

fuel injection and spark events. It is also used to syn-

chronize the fuel injectors with their respective cylin-

ders.

Fig. 3 CMP LocationÐ4.0L Engine

1 - OIL FILTER

2 - CAMSHAFT POSITION SENSOR

3 - CLAMP BOLT

4 - HOLD-DOWN CLAMP

5 - MOUNTING BOLTS (2)

6 - ELEC. CONNECTORFig. 4 CMP LocationÐ4.7L Engine

1 - RIGHT CYLINDER HEAD

2 - CAMSHAFT POSITION SENSOR

3 - MOUNTING BOLT

4 - ELEC. CONNECTOR

WJIGNITION CONTROL 8I - 5

CAMSHAFT POSITION SENSOR (Continued)

Page 403 of 2199

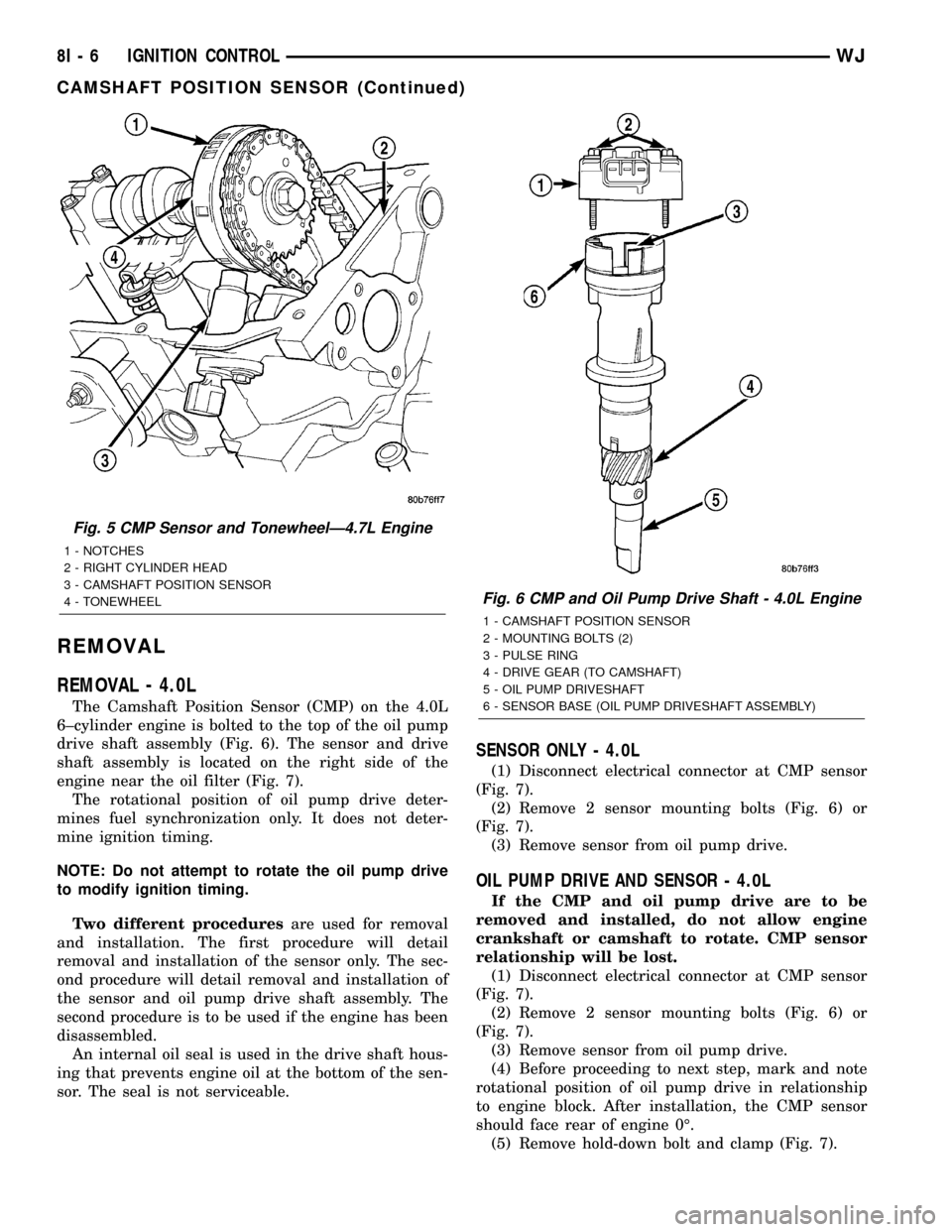

REMOVAL

REMOVAL - 4.0L

The Camshaft Position Sensor (CMP) on the 4.0L

6±cylinder engine is bolted to the top of the oil pump

drive shaft assembly (Fig. 6). The sensor and drive

shaft assembly is located on the right side of the

engine near the oil filter (Fig. 7).

The rotational position of oil pump drive deter-

mines fuel synchronization only. It does not deter-

mine ignition timing.

NOTE: Do not attempt to rotate the oil pump drive

to modify ignition timing.

Two different proceduresare used for removal

and installation. The first procedure will detail

removal and installation of the sensor only. The sec-

ond procedure will detail removal and installation of

the sensor and oil pump drive shaft assembly. The

second procedure is to be used if the engine has been

disassembled.

An internal oil seal is used in the drive shaft hous-

ing that prevents engine oil at the bottom of the sen-

sor. The seal is not serviceable.

SENSOR ONLY - 4.0L

(1) Disconnect electrical connector at CMP sensor

(Fig. 7).

(2) Remove 2 sensor mounting bolts (Fig. 6) or

(Fig. 7).

(3) Remove sensor from oil pump drive.

OIL PUMP DRIVE AND SENSOR - 4.0L

If the CMP and oil pump drive are to be

removed and installed, do not allow engine

crankshaft or camshaft to rotate. CMP sensor

relationship will be lost.

(1) Disconnect electrical connector at CMP sensor

(Fig. 7).

(2) Remove 2 sensor mounting bolts (Fig. 6) or

(Fig. 7).

(3) Remove sensor from oil pump drive.

(4) Before proceeding to next step, mark and note

rotational position of oil pump drive in relationship

to engine block. After installation, the CMP sensor

should face rear of engine 0É.

(5) Remove hold-down bolt and clamp (Fig. 7).

Fig. 5 CMP Sensor and TonewheelÐ4.7L Engine

1 - NOTCHES

2 - RIGHT CYLINDER HEAD

3 - CAMSHAFT POSITION SENSOR

4 - TONEWHEEL

Fig. 6 CMP and Oil Pump Drive Shaft - 4.0L Engine

1 - CAMSHAFT POSITION SENSOR

2 - MOUNTING BOLTS (2)

3 - PULSE RING

4 - DRIVE GEAR (TO CAMSHAFT)

5 - OIL PUMP DRIVESHAFT

6 - SENSOR BASE (OIL PUMP DRIVESHAFT ASSEMBLY)

8I - 6 IGNITION CONTROLWJ

CAMSHAFT POSITION SENSOR (Continued)

Page 404 of 2199

(6) While pulling assembly from engine, note direc-

tion and position of pulse ring (Fig. 6). After removal,

look down into top of oil pump and note direction and

position of slot at top of oil pump gear.

(7) Remove and discard old oil pump drive-to-en-

gine block gasket.

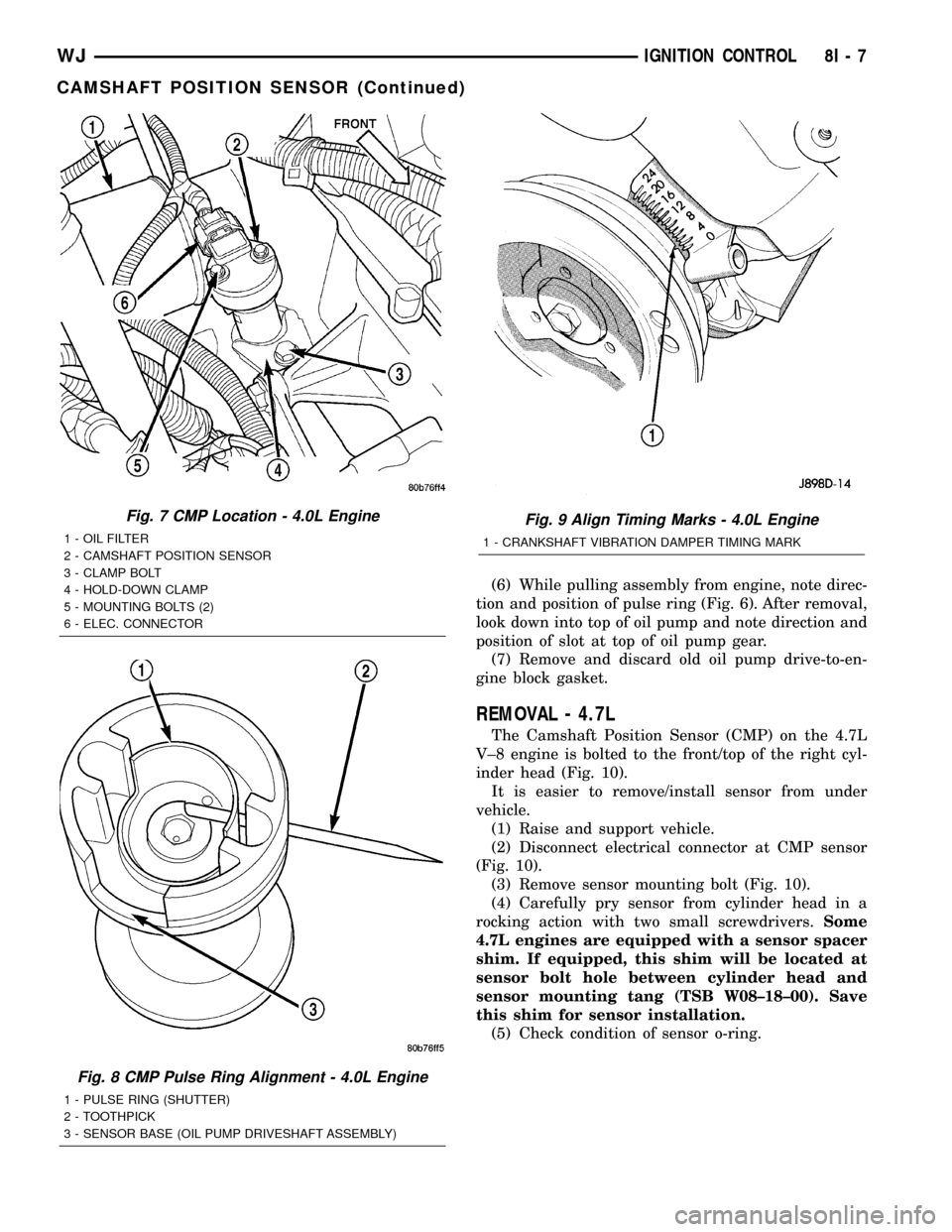

REMOVAL - 4.7L

The Camshaft Position Sensor (CMP) on the 4.7L

V±8 engine is bolted to the front/top of the right cyl-

inder head (Fig. 10).

It is easier to remove/install sensor from under

vehicle.

(1) Raise and support vehicle.

(2) Disconnect electrical connector at CMP sensor

(Fig. 10).

(3) Remove sensor mounting bolt (Fig. 10).

(4) Carefully pry sensor from cylinder head in a

rocking action with two small screwdrivers.Some

4.7L engines are equipped with a sensor spacer

shim. If equipped, this shim will be located at

sensor bolt hole between cylinder head and

sensor mounting tang (TSB W08±18±00). Save

this shim for sensor installation.

(5) Check condition of sensor o-ring.

Fig. 7 CMP Location - 4.0L Engine

1 - OIL FILTER

2 - CAMSHAFT POSITION SENSOR

3 - CLAMP BOLT

4 - HOLD-DOWN CLAMP

5 - MOUNTING BOLTS (2)

6 - ELEC. CONNECTOR

Fig. 8 CMP Pulse Ring Alignment - 4.0L Engine

1 - PULSE RING (SHUTTER)

2 - TOOTHPICK

3 - SENSOR BASE (OIL PUMP DRIVESHAFT ASSEMBLY)

Fig. 9 Align Timing Marks - 4.0L Engine

1 - CRANKSHAFT VIBRATION DAMPER TIMING MARK

WJIGNITION CONTROL 8I - 7

CAMSHAFT POSITION SENSOR (Continued)