compressor JEEP GRAND CHEROKEE 2002 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1578 of 2199

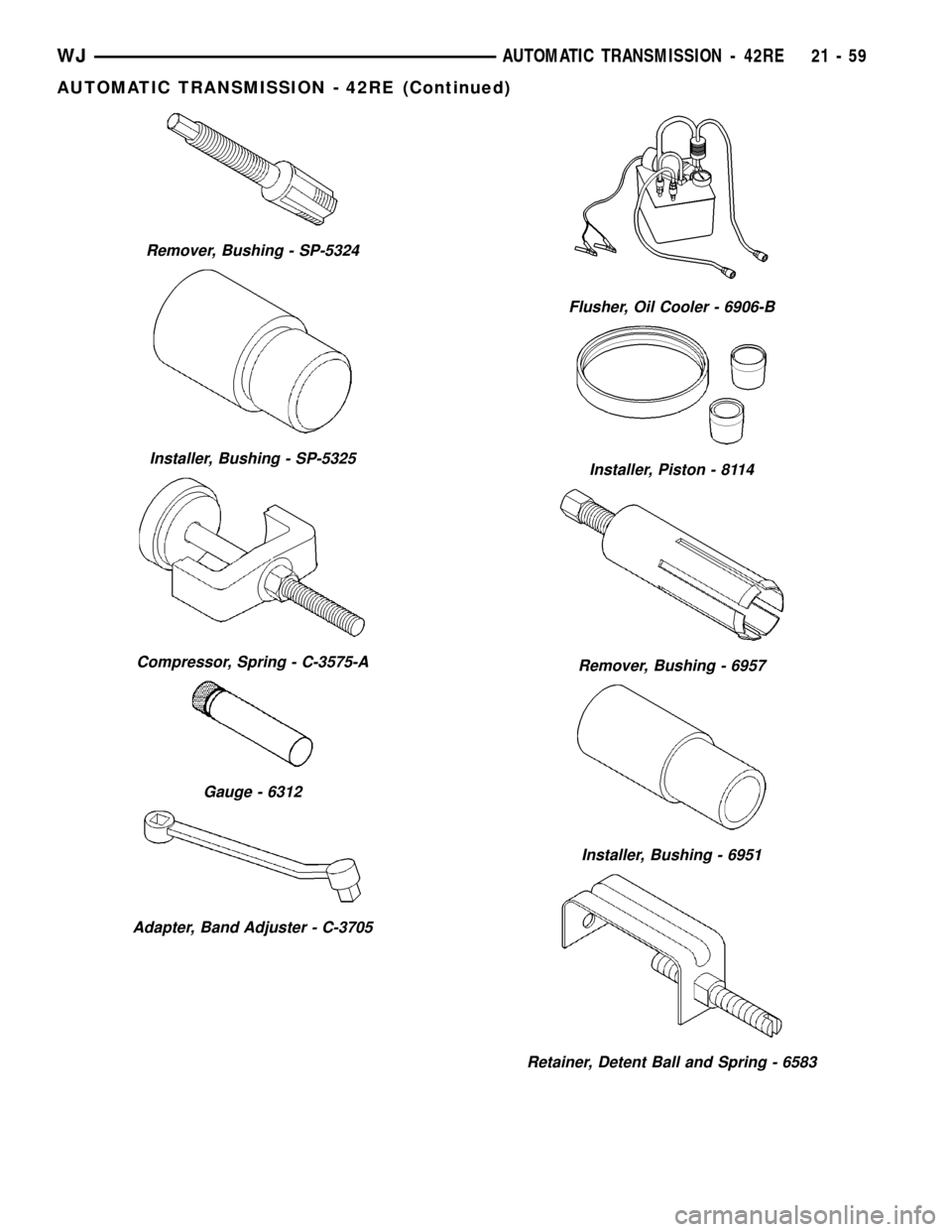

Remover, Bushing - SP-5324

Installer, Bushing - SP-5325

Compressor, Spring - C-3575-A

Gauge - 6312

Adapter, Band Adjuster - C-3705

Flusher, Oil Cooler - 6906-B

Installer, Piston - 8114

Remover, Bushing - 6957

Installer, Bushing - 6951

Retainer, Detent Ball and Spring - 6583

WJAUTOMATIC TRANSMISSION - 42RE 21 - 59

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1593 of 2199

OPERATION

To apply the clutch, pressure is applied between

the clutch retainer and piston. The fluid pressure is

provided by the oil pump, transferred through the

control valves and passageways, and enters the

clutch through the hub of the reaction shaft support.

With pressure applied between the clutch retainer

and piston, the piston moves away from the clutch

retainer and compresses the clutch pack. This action

applies the clutch pack, allowing torque to flow

through the input shaft into the driving discs, and

into the clutch plates and pressure plate that are

lugged to the clutch retainer. The waved snap-ring is

used to cushion the application of the clutch pack.

When pressure is released from the piston, the

spring returns the piston to its fully released position

and disengages the clutch. The release spring also

helps to cushion the application of the clutch assem-

bly. When the clutch is in the process of being

released by the release spring, fluid flows through a

vent and one-way ball-check-valve located in the

clutch retainer. The check-valve is needed to elimi-

nate the possibility of plate drag caused by centrifu-

gal force acting on the residual fluid trapped in the

clutch piston retainer.

DISASSEMBLY

(1) Remove waved snap-ring and remove pressure

plate, clutch plates and clutch discs (Fig. 92).

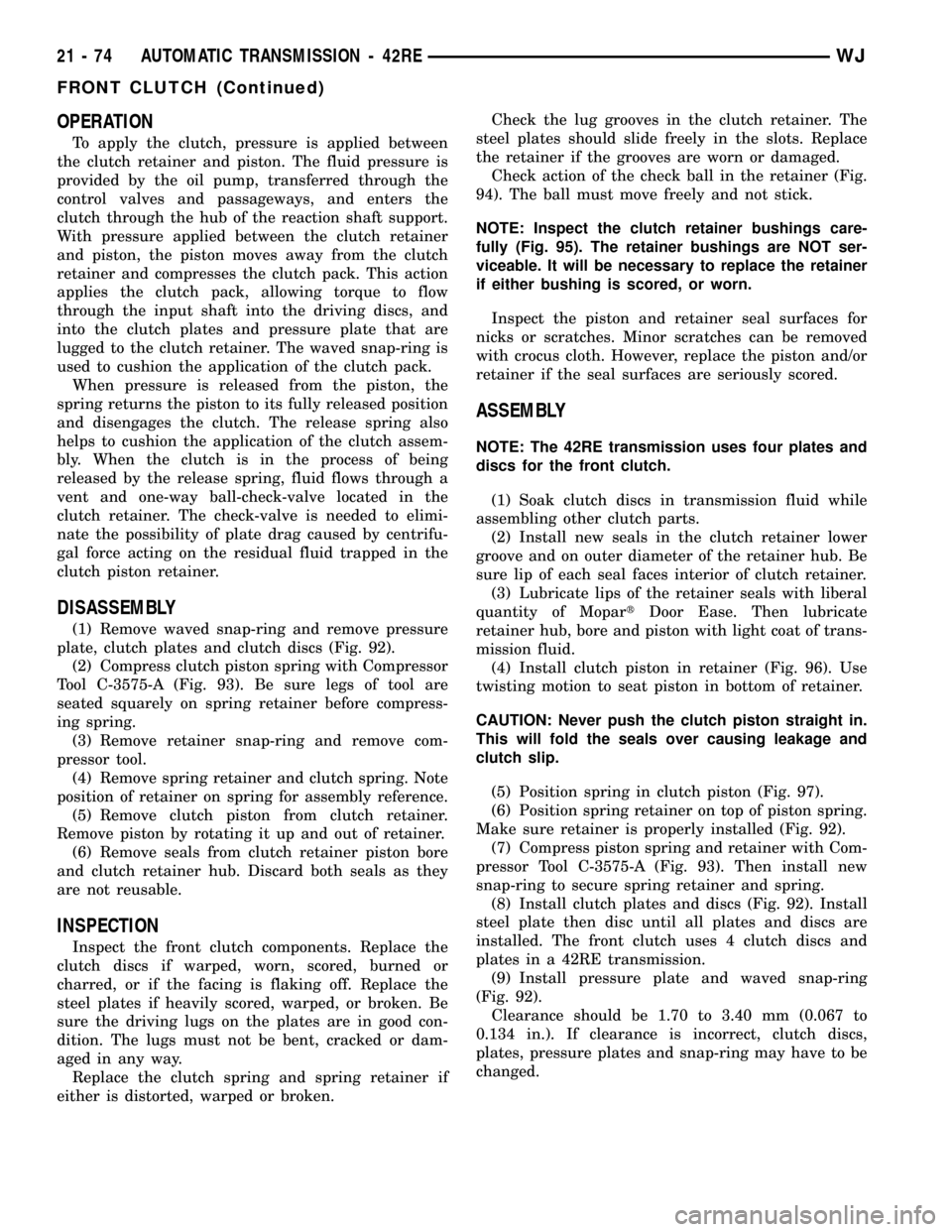

(2) Compress clutch piston spring with Compressor

Tool C-3575-A (Fig. 93). Be sure legs of tool are

seated squarely on spring retainer before compress-

ing spring.

(3) Remove retainer snap-ring and remove com-

pressor tool.

(4) Remove spring retainer and clutch spring. Note

position of retainer on spring for assembly reference.

(5) Remove clutch piston from clutch retainer.

Remove piston by rotating it up and out of retainer.

(6) Remove seals from clutch retainer piston bore

and clutch retainer hub. Discard both seals as they

are not reusable.

INSPECTION

Inspect the front clutch components. Replace the

clutch discs if warped, worn, scored, burned or

charred, or if the facing is flaking off. Replace the

steel plates if heavily scored, warped, or broken. Be

sure the driving lugs on the plates are in good con-

dition. The lugs must not be bent, cracked or dam-

aged in any way.

Replace the clutch spring and spring retainer if

either is distorted, warped or broken.Check the lug grooves in the clutch retainer. The

steel plates should slide freely in the slots. Replace

the retainer if the grooves are worn or damaged.

Check action of the check ball in the retainer (Fig.

94). The ball must move freely and not stick.

NOTE: Inspect the clutch retainer bushings care-

fully (Fig. 95). The retainer bushings are NOT ser-

viceable. It will be necessary to replace the retainer

if either bushing is scored, or worn.

Inspect the piston and retainer seal surfaces for

nicks or scratches. Minor scratches can be removed

with crocus cloth. However, replace the piston and/or

retainer if the seal surfaces are seriously scored.

ASSEMBLY

NOTE: The 42RE transmission uses four plates and

discs for the front clutch.

(1) Soak clutch discs in transmission fluid while

assembling other clutch parts.

(2) Install new seals in the clutch retainer lower

groove and on outer diameter of the retainer hub. Be

sure lip of each seal faces interior of clutch retainer.

(3) Lubricate lips of the retainer seals with liberal

quantity of MopartDoor Ease. Then lubricate

retainer hub, bore and piston with light coat of trans-

mission fluid.

(4) Install clutch piston in retainer (Fig. 96). Use

twisting motion to seat piston in bottom of retainer.

CAUTION: Never push the clutch piston straight in.

This will fold the seals over causing leakage and

clutch slip.

(5) Position spring in clutch piston (Fig. 97).

(6) Position spring retainer on top of piston spring.

Make sure retainer is properly installed (Fig. 92).

(7) Compress piston spring and retainer with Com-

pressor Tool C-3575-A (Fig. 93). Then install new

snap-ring to secure spring retainer and spring.

(8) Install clutch plates and discs (Fig. 92). Install

steel plate then disc until all plates and discs are

installed. The front clutch uses 4 clutch discs and

plates in a 42RE transmission.

(9) Install pressure plate and waved snap-ring

(Fig. 92).

Clearance should be 1.70 to 3.40 mm (0.067 to

0.134 in.). If clearance is incorrect, clutch discs,

plates, pressure plates and snap-ring may have to be

changed.

21 - 74 AUTOMATIC TRANSMISSION - 42REWJ

FRONT CLUTCH (Continued)

Page 1595 of 2199

Fig. 93 Compressing Front Clutch Piston Spring

1 - FRONT CLUTCH SPRING

2 - COMPRESSOR TOOL C-3575-A

3 - RETAINER SNAP-RING

4 - SPRING RETAINER

Fig. 94 Front Clutch Piston Retainer Check Ball

Location

1 - RETAINER CHECK BALL

Fig. 95 Retainer Bushing Location/Inspection

1 - FRONT CLUTCH RETAINER BUSHINGS (NON-

SERVICEABLE)

Fig. 96 Front Clutch Piston Installation

1 - CLUTCH PISTON

2 - FRONT CLUTCH RETAINER

Fig. 97 Clutch Piston Spring Installation

1 - RETAINER

2 - CLUTCH SPRING

3 - PISTON

21 - 76 AUTOMATIC TRANSMISSION - 42REWJ

FRONT CLUTCH (Continued)

Page 1610 of 2199

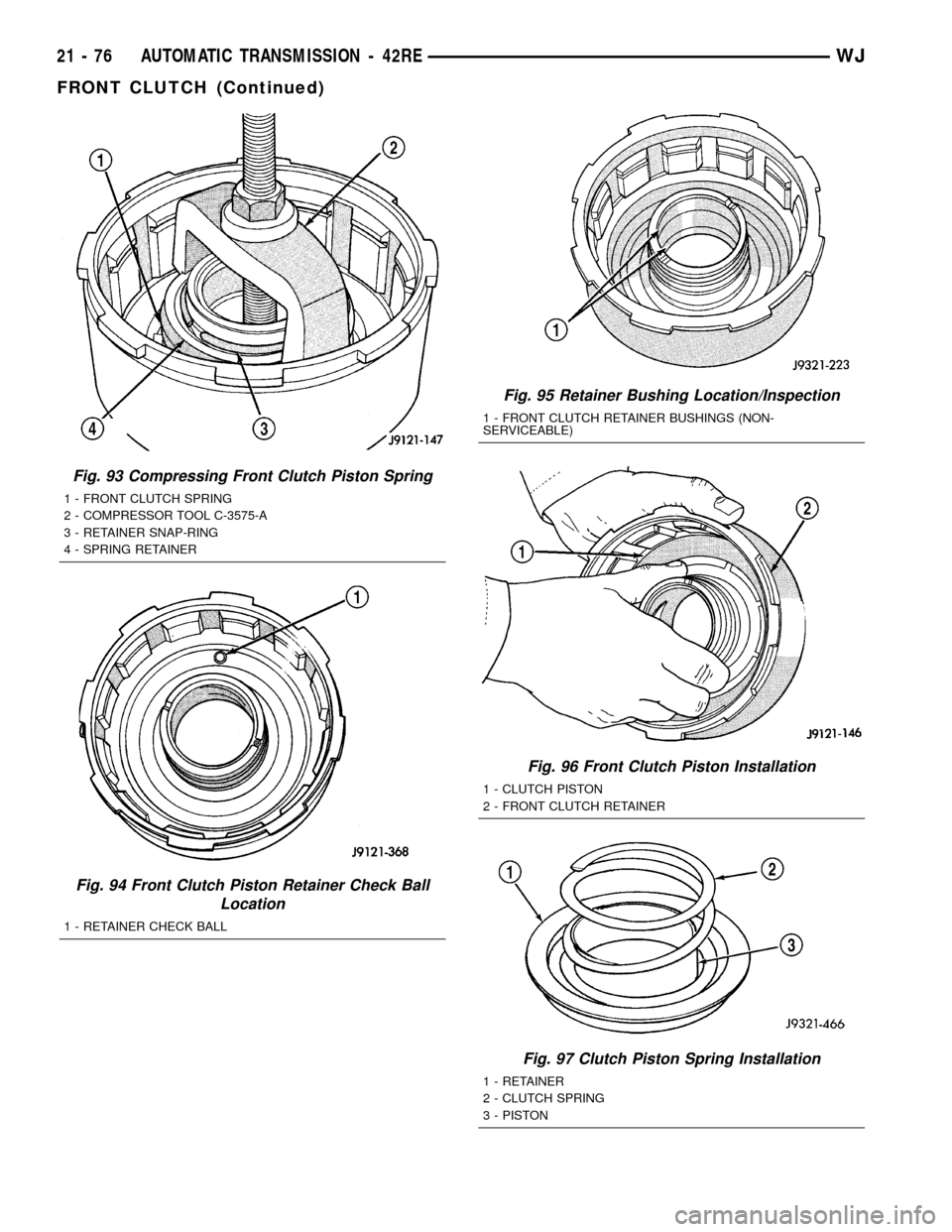

DIRECT CLUTCH, HUB AND SPRING

WARNING: THE NEXT STEP IN DISASSEMBLY

INVOLVES COMPRESSING THE DIRECT CLUTCH

SPRING. IT IS EXTREMELY IMPORTANT THAT

PROPER EQUIPMENT BE USED TO COMPRESS

THE SPRING AS SPRING FORCE IS APPROXI-

MATELY 830 POUNDS. USE SPRING COMPRESSOR

TOOL 6227-1 AND A HYDRAULIC SHOP PRESS

WITH A MINIMUM RAM TRAVEL OF 5-6 INCHES.

THE PRESS MUST ALSO HAVE A BED THAT CAN

BE ADJUSTED UP OR DOWN AS REQUIRED.

RELEASE CLUTCH SPRING TENSION SLOWLY AND

COMPLETELY TO AVOID PERSONAL INJURY.(1) Mount geartrain assembly in shop press (Fig.

142).

(2) Position Compressor Tool 6227-1 on clutch hub

(Fig. 142). Support output shaft flange with steel

press plates as shown and center assembly under

press ram.

(3) Apply press pressure slowly. Compress hub and

spring far enough to expose clutch hub retaining ring

and relieve spring pressure on clutch pack snap-ring

(Fig. 142).

(4) Remove direct clutch pack snap-ring (Fig. 143).

(5) Remove direct clutch hub retaining ring (Fig.

144).

(6) Release press load slowly and completely (Fig.

145).

(7) Remove Special Tool 6227-1. Then remove

clutch pack from hub (Fig. 145).

GEARTRAIN

(1) Remove direct clutch hub and spring (Fig. 146).

Fig. 140 Removing Gear Case From Geartrain

Assembly

1 - GEARTRAIN ASSEMBLY

2 - GEAR CASE

Fig. 141 Rear Bearing Removal

1 - OUTPUT SHAFT

2 - REAR BEARING

3 - SNAP-RING

Fig. 142 Geartrain Mounted In Shop Press

1 - PRESS RAM

2 - SPECIAL TOOL C-3995-A (OR SIMILAR TOOL)

3 - CLUTCH HUB

4 - PLATES

5 - PRESS BED

6 - SPECIAL TOOL 6227-1

WJAUTOMATIC TRANSMISSION - 42RE 21 - 91

OVERDRIVE UNIT (Continued)

Page 1619 of 2199

WARNING: THE NEXT STEP IN GEARTRAIN

ASSEMBLY INVOLVES COMPRESSING THE DIRECT

CLUTCH HUB AND SPRING. IT IS EXTREMELY

IMPORTANT THAT PROPER EQUIPMENT BE USED

TO COMPRESS THE SPRING AS SPRING FORCE IS

APPROXIMATELY 830 POUNDS. USE COMPRES-

SOR TOOL C-6227-1 AND A HYDRAULIC-TYPE

SHOP PRESS WITH A MINIMUM RAM TRAVEL OF 6

INCHES. THE PRESS MUST ALSO HAVE A BED

THAT CAN BE ADJUSTED UP OR DOWN AS

REQUIRED. RELEASE CLUTCH SPRING TENSION

SLOWLY AND COMPLETELY TO AVOID PERSONAL

INJURY.

(20) Position Compressor Tool 6227-1 on clutch

hub.

(21) Compress clutch hub and spring just enough

to place tension on hub and hold it in place.

(22) Slowly compress clutch hub and spring. Com-

press spring and hub only enough to expose ring

grooves for clutch pack snap ring and clutch hub

retaining ring.

(23) Realign clutch pack on hub and seat clutch

discs and plates in clutch drum.

(24) Install direct clutch pack snap-ring (Fig. 171).

Be very sure snap-ring is fully seated in clutch drum

ring groove.

(25) Install clutch hub retaining ring (Fig. 172). Be

very sure retaining ring is fully seated in sun gear

ring groove.

(26) Slowly release press ram, remove compressor

tools and remove geartrain assembly.

GEAR CASE

(1) Position park pawl and spring in case and

install park pawl shaft. Verify that end of spring

with 90É bend is hooked to pawl and straight end of

spring is seated against case.

(2) Install pawl shaft retaining bolt. Tighten bolt

to 27 N´m (20 ft. lbs.) torque.

(3) Install park lock reaction plug. Note that plug

has locating pin at rear (Fig. 173). Be sure pin is

seated in hole in case before installing snap-ring.

(4) Install reaction plug snap-ring (Fig. 174). Com-

press snap ring only enough for installation; do not

distort it.

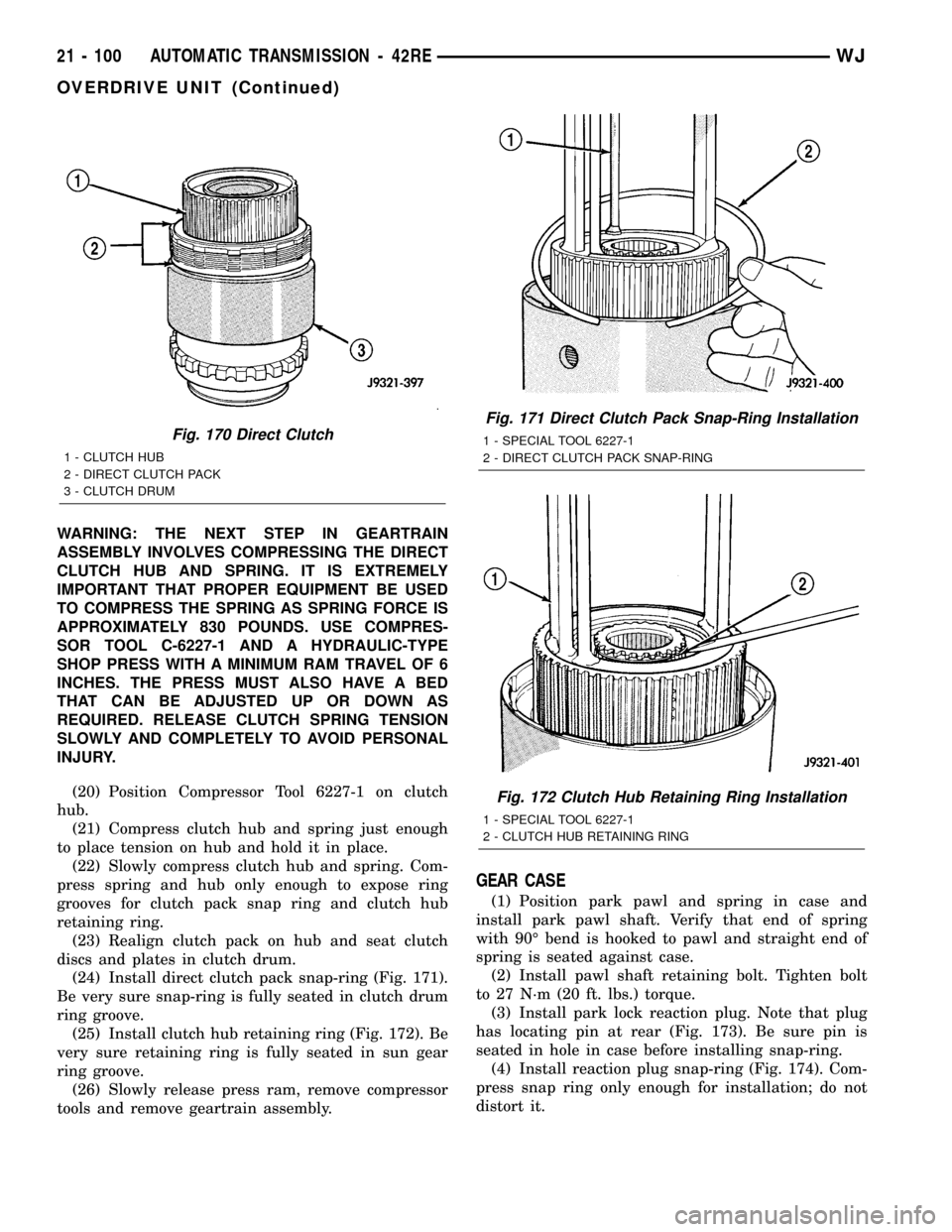

Fig. 170 Direct Clutch

1 - CLUTCH HUB

2 - DIRECT CLUTCH PACK

3 - CLUTCH DRUM

Fig. 171 Direct Clutch Pack Snap-Ring Installation

1 - SPECIAL TOOL 6227-1

2 - DIRECT CLUTCH PACK SNAP-RING

Fig. 172 Clutch Hub Retaining Ring Installation

1 - SPECIAL TOOL 6227-1

2 - CLUTCH HUB RETAINING RING

21 - 100 AUTOMATIC TRANSMISSION - 42REWJ

OVERDRIVE UNIT (Continued)

Page 1740 of 2199

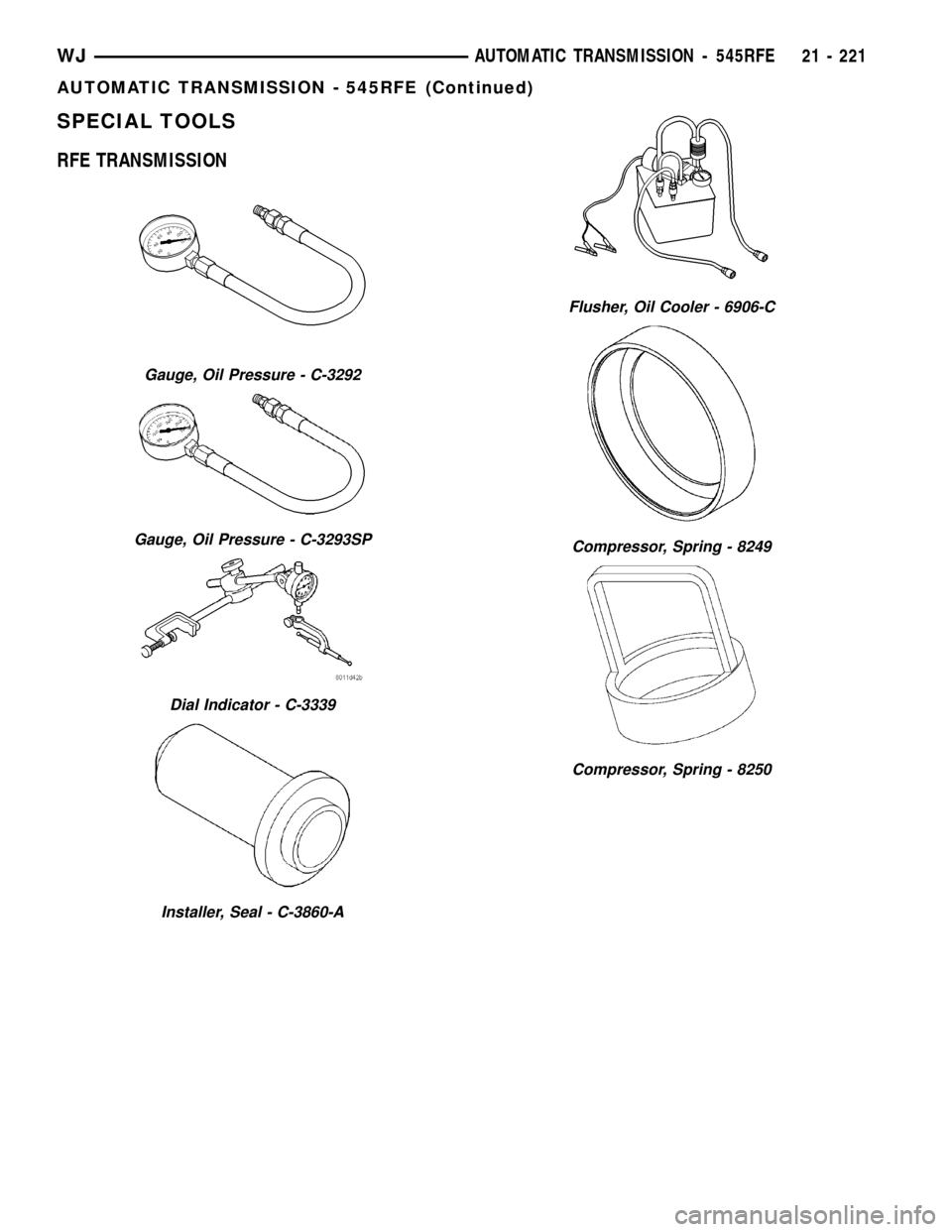

SPECIAL TOOLS

RFE TRANSMISSION

Gauge, Oil Pressure - C-3292

Gauge, Oil Pressure - C-3293SP

Dial Indicator - C-3339

Installer, Seal - C-3860-A

Flusher, Oil Cooler - 6906-C

Compressor, Spring - 8249

Compressor, Spring - 8250

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 221

AUTOMATIC TRANSMISSION - 545RFE (Continued)

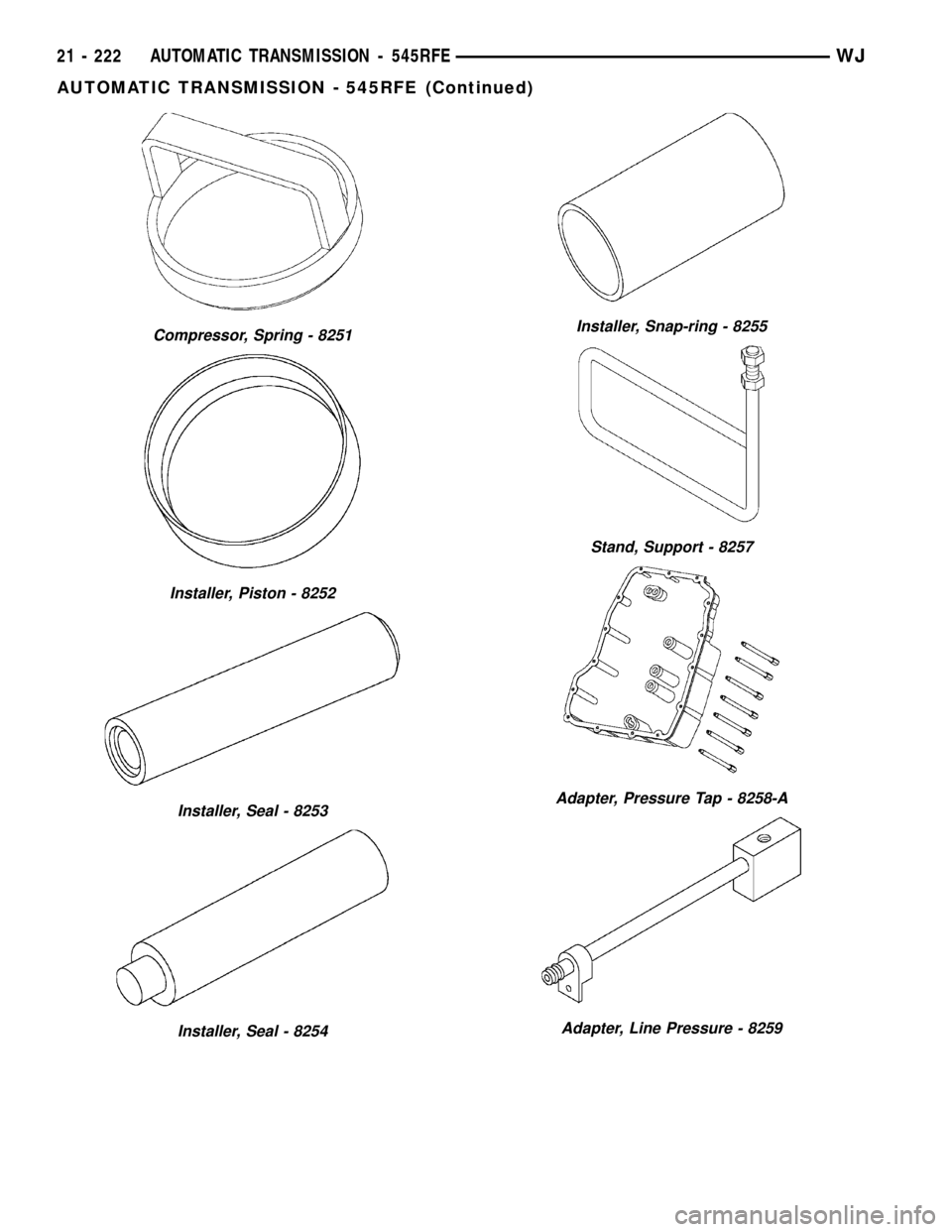

Page 1741 of 2199

Compressor, Spring - 8251

Installer, Piston - 8252

Installer, Seal - 8253

Installer, Seal - 8254

Installer, Snap-ring - 8255

Stand, Support - 8257

Adapter, Pressure Tap - 8258-A

Adapter, Line Pressure - 8259

21 - 222 AUTOMATIC TRANSMISSION - 545RFEWJ

AUTOMATIC TRANSMISSION - 545RFE (Continued)

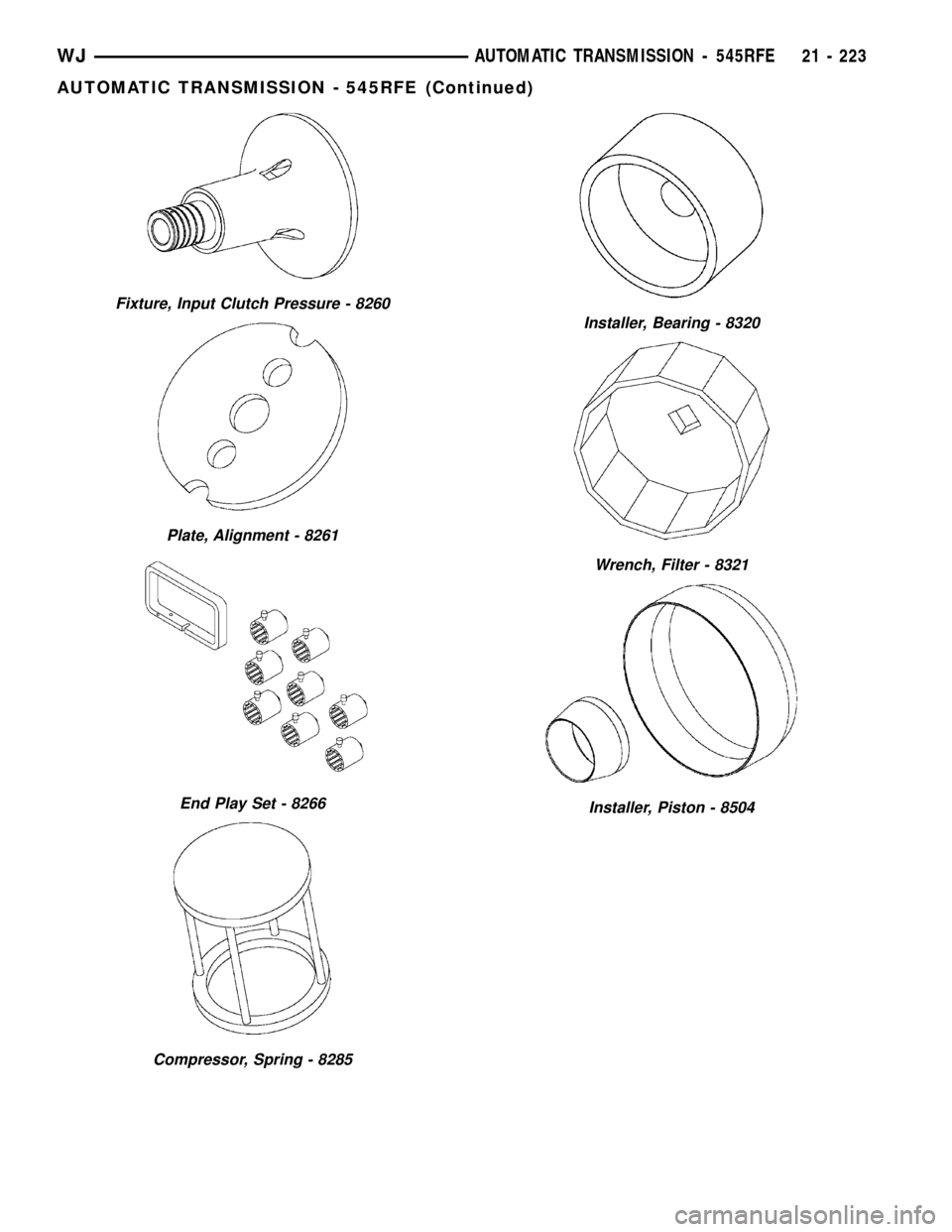

Page 1742 of 2199

Fixture, Input Clutch Pressure - 8260

Plate, Alignment - 8261

End Play Set - 8266

Compressor, Spring - 8285

Installer, Bearing - 8320

Wrench, Filter - 8321

Installer, Piston - 8504

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 223

AUTOMATIC TRANSMISSION - 545RFE (Continued)

Page 1743 of 2199

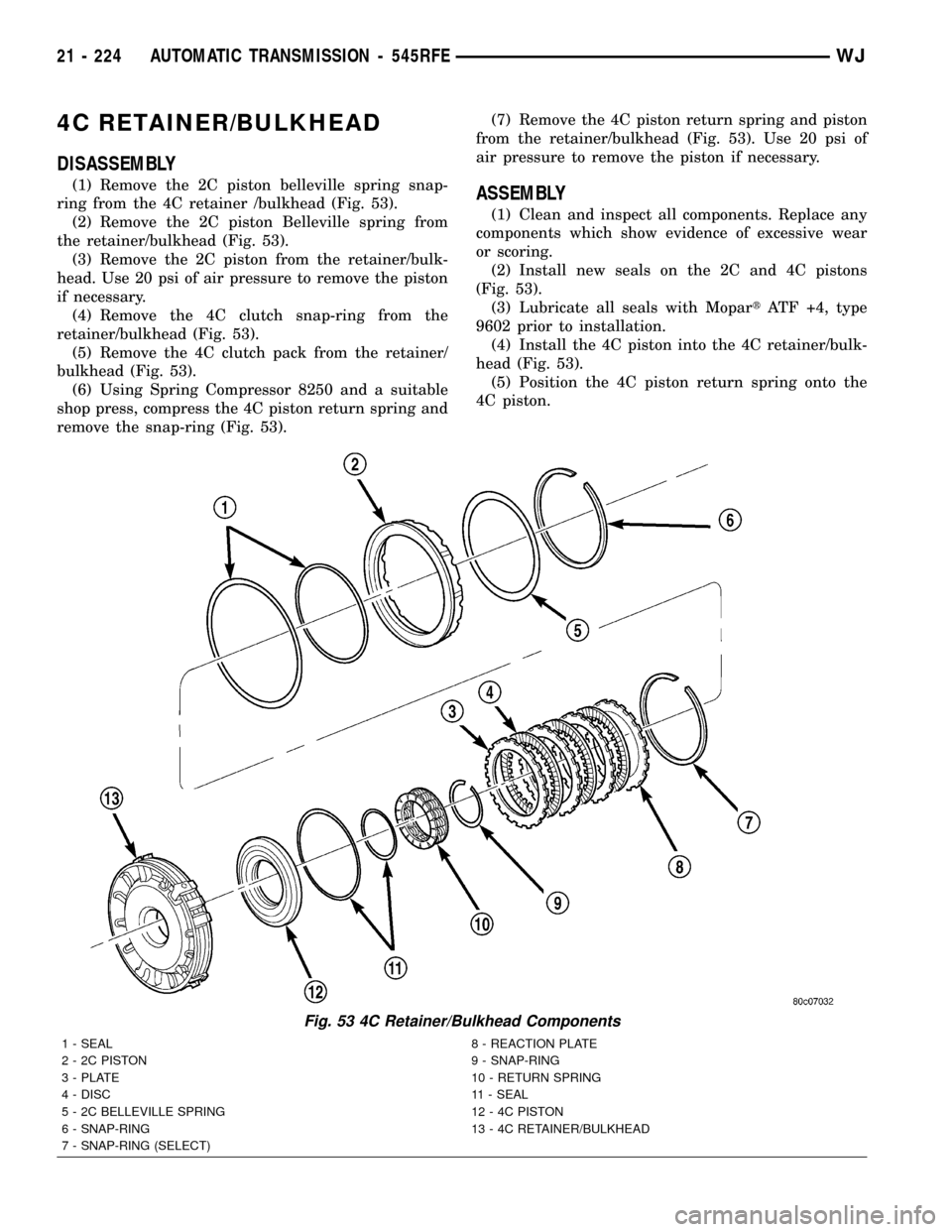

4C RETAINER/BULKHEAD

DISASSEMBLY

(1) Remove the 2C piston belleville spring snap-

ring from the 4C retainer /bulkhead (Fig. 53).

(2) Remove the 2C piston Belleville spring from

the retainer/bulkhead (Fig. 53).

(3) Remove the 2C piston from the retainer/bulk-

head. Use 20 psi of air pressure to remove the piston

if necessary.

(4) Remove the 4C clutch snap-ring from the

retainer/bulkhead (Fig. 53).

(5) Remove the 4C clutch pack from the retainer/

bulkhead (Fig. 53).

(6) Using Spring Compressor 8250 and a suitable

shop press, compress the 4C piston return spring and

remove the snap-ring (Fig. 53).(7) Remove the 4C piston return spring and piston

from the retainer/bulkhead (Fig. 53). Use 20 psi of

air pressure to remove the piston if necessary.ASSEMBLY

(1) Clean and inspect all components. Replace any

components which show evidence of excessive wear

or scoring.

(2) Install new seals on the 2C and 4C pistons

(Fig. 53).

(3) Lubricate all seals with MopartATF +4, type

9602 prior to installation.

(4) Install the 4C piston into the 4C retainer/bulk-

head (Fig. 53).

(5) Position the 4C piston return spring onto the

4C piston.

Fig. 53 4C Retainer/Bulkhead Components

1 - SEAL 8 - REACTION PLATE

2 - 2C PISTON 9 - SNAP-RING

3 - PLATE 10 - RETURN SPRING

4 - DISC 11 - SEAL

5 - 2C BELLEVILLE SPRING 12 - 4C PISTON

6 - SNAP-RING 13 - 4C RETAINER/BULKHEAD

7 - SNAP-RING (SELECT)

21 - 224 AUTOMATIC TRANSMISSION - 545RFEWJ

Page 1744 of 2199

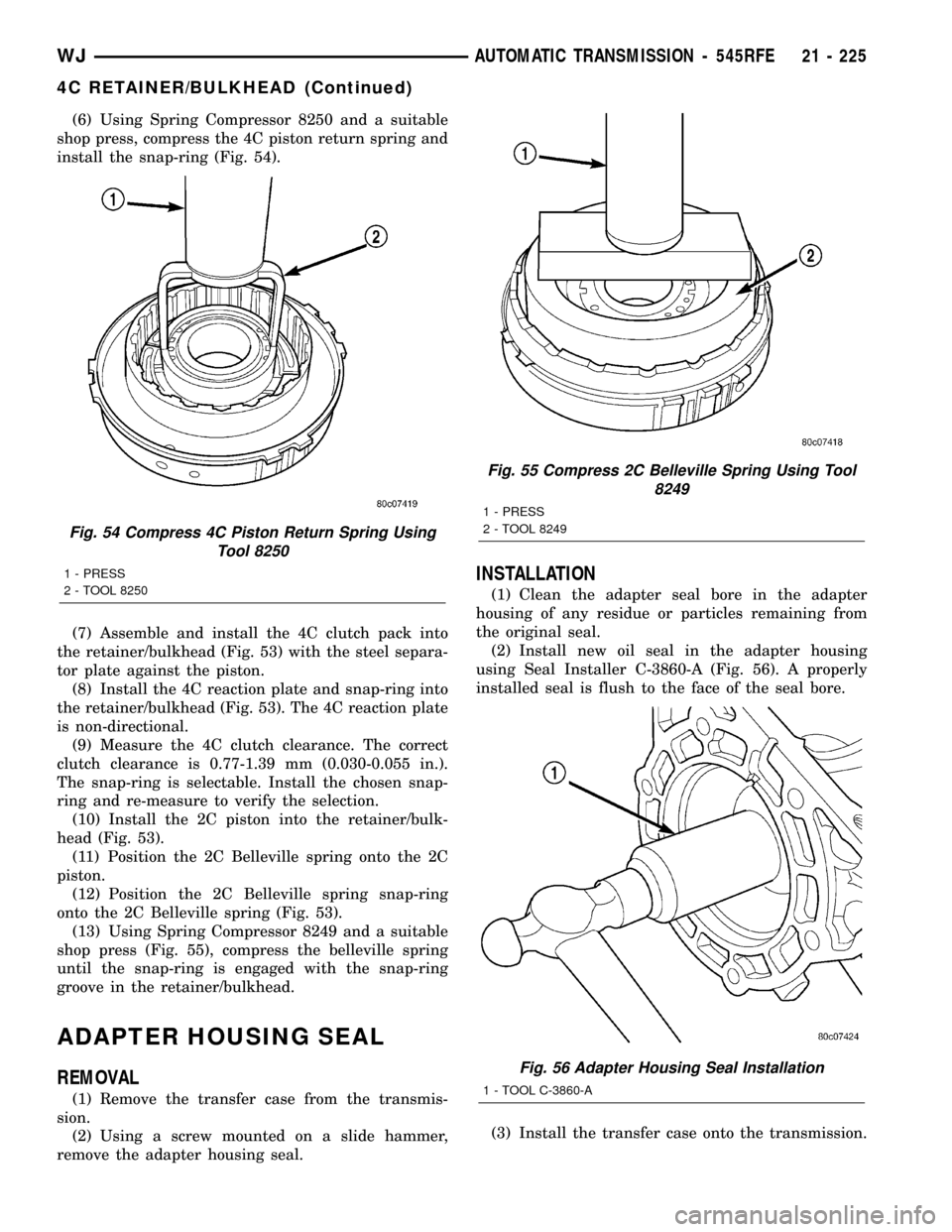

(6) Using Spring Compressor 8250 and a suitable

shop press, compress the 4C piston return spring and

install the snap-ring (Fig. 54).

(7) Assemble and install the 4C clutch pack into

the retainer/bulkhead (Fig. 53) with the steel separa-

tor plate against the piston.

(8) Install the 4C reaction plate and snap-ring into

the retainer/bulkhead (Fig. 53). The 4C reaction plate

is non-directional.

(9) Measure the 4C clutch clearance. The correct

clutch clearance is 0.77-1.39 mm (0.030-0.055 in.).

The snap-ring is selectable. Install the chosen snap-

ring and re-measure to verify the selection.

(10) Install the 2C piston into the retainer/bulk-

head (Fig. 53).

(11) Position the 2C Belleville spring onto the 2C

piston.

(12) Position the 2C Belleville spring snap-ring

onto the 2C Belleville spring (Fig. 53).

(13) Using Spring Compressor 8249 and a suitable

shop press (Fig. 55), compress the belleville spring

until the snap-ring is engaged with the snap-ring

groove in the retainer/bulkhead.

ADAPTER HOUSING SEAL

REMOVAL

(1) Remove the transfer case from the transmis-

sion.

(2) Using a screw mounted on a slide hammer,

remove the adapter housing seal.

INSTALLATION

(1) Clean the adapter seal bore in the adapter

housing of any residue or particles remaining from

the original seal.

(2) Install new oil seal in the adapter housing

using Seal Installer C-3860-A (Fig. 56). A properly

installed seal is flush to the face of the seal bore.

(3) Install the transfer case onto the transmission.

Fig. 54 Compress 4C Piston Return Spring Using

Tool 8250

1 - PRESS

2 - TOOL 8250

Fig. 55 Compress 2C Belleville Spring Using Tool

8249

1 - PRESS

2 - TOOL 8249

Fig. 56 Adapter Housing Seal Installation

1 - TOOL C-3860-A

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 225

4C RETAINER/BULKHEAD (Continued)