turn JEEP GRAND CHEROKEE 2002 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 201 of 2199

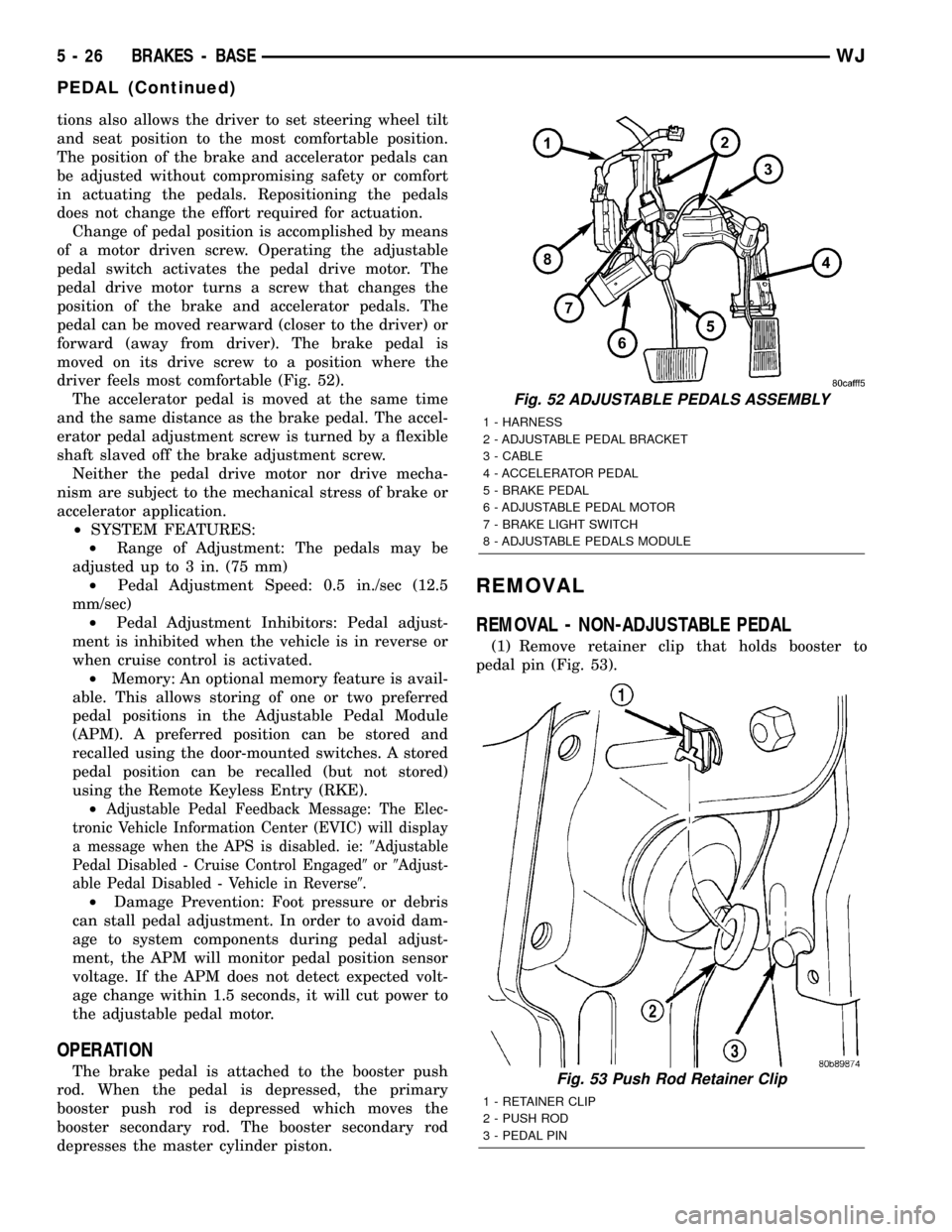

tions also allows the driver to set steering wheel tilt

and seat position to the most comfortable position.

The position of the brake and accelerator pedals can

be adjusted without compromising safety or comfort

in actuating the pedals. Repositioning the pedals

does not change the effort required for actuation.

Change of pedal position is accomplished by means

of a motor driven screw. Operating the adjustable

pedal switch activates the pedal drive motor. The

pedal drive motor turns a screw that changes the

position of the brake and accelerator pedals. The

pedal can be moved rearward (closer to the driver) or

forward (away from driver). The brake pedal is

moved on its drive screw to a position where the

driver feels most comfortable (Fig. 52).

The accelerator pedal is moved at the same time

and the same distance as the brake pedal. The accel-

erator pedal adjustment screw is turned by a flexible

shaft slaved off the brake adjustment screw.

Neither the pedal drive motor nor drive mecha-

nism are subject to the mechanical stress of brake or

accelerator application.

²SYSTEM FEATURES:

²Range of Adjustment: The pedals may be

adjusted up to 3 in. (75 mm)

²Pedal Adjustment Speed: 0.5 in./sec (12.5

mm/sec)

²Pedal Adjustment Inhibitors: Pedal adjust-

ment is inhibited when the vehicle is in reverse or

when cruise control is activated.

²Memory: An optional memory feature is avail-

able. This allows storing of one or two preferred

pedal positions in the Adjustable Pedal Module

(APM). A preferred position can be stored and

recalled using the door-mounted switches. A stored

pedal position can be recalled (but not stored)

using the Remote Keyless Entry (RKE).

²

Adjustable Pedal Feedback Message: The Elec-

tronic Vehicle Information Center (EVIC) will display

a message when the APS is disabled. ie:9Adjustable

Pedal Disabled - Cruise Control Engaged9or9Adjust-

able Pedal Disabled - Vehicle in Reverse9.

²Damage Prevention: Foot pressure or debris

can stall pedal adjustment. In order to avoid dam-

age to system components during pedal adjust-

ment, the APM will monitor pedal position sensor

voltage. If the APM does not detect expected volt-

age change within 1.5 seconds, it will cut power to

the adjustable pedal motor.

OPERATION

The brake pedal is attached to the booster push

rod. When the pedal is depressed, the primary

booster push rod is depressed which moves the

booster secondary rod. The booster secondary rod

depresses the master cylinder piston.

REMOVAL

REMOVAL - NON-ADJUSTABLE PEDAL

(1) Remove retainer clip that holds booster to

pedal pin (Fig. 53).

Fig. 52 ADJUSTABLE PEDALS ASSEMBLY

1 - HARNESS

2 - ADJUSTABLE PEDAL BRACKET

3 - CABLE

4 - ACCELERATOR PEDAL

5 - BRAKE PEDAL

6 - ADJUSTABLE PEDAL MOTOR

7 - BRAKE LIGHT SWITCH

8 - ADJUSTABLE PEDALS MODULE

Fig. 53 Push Rod Retainer Clip

1 - RETAINER CLIP

2 - PUSH ROD

3 - PEDAL PIN

5 - 26 BRAKES - BASEWJ

PEDAL (Continued)

Page 214 of 2199

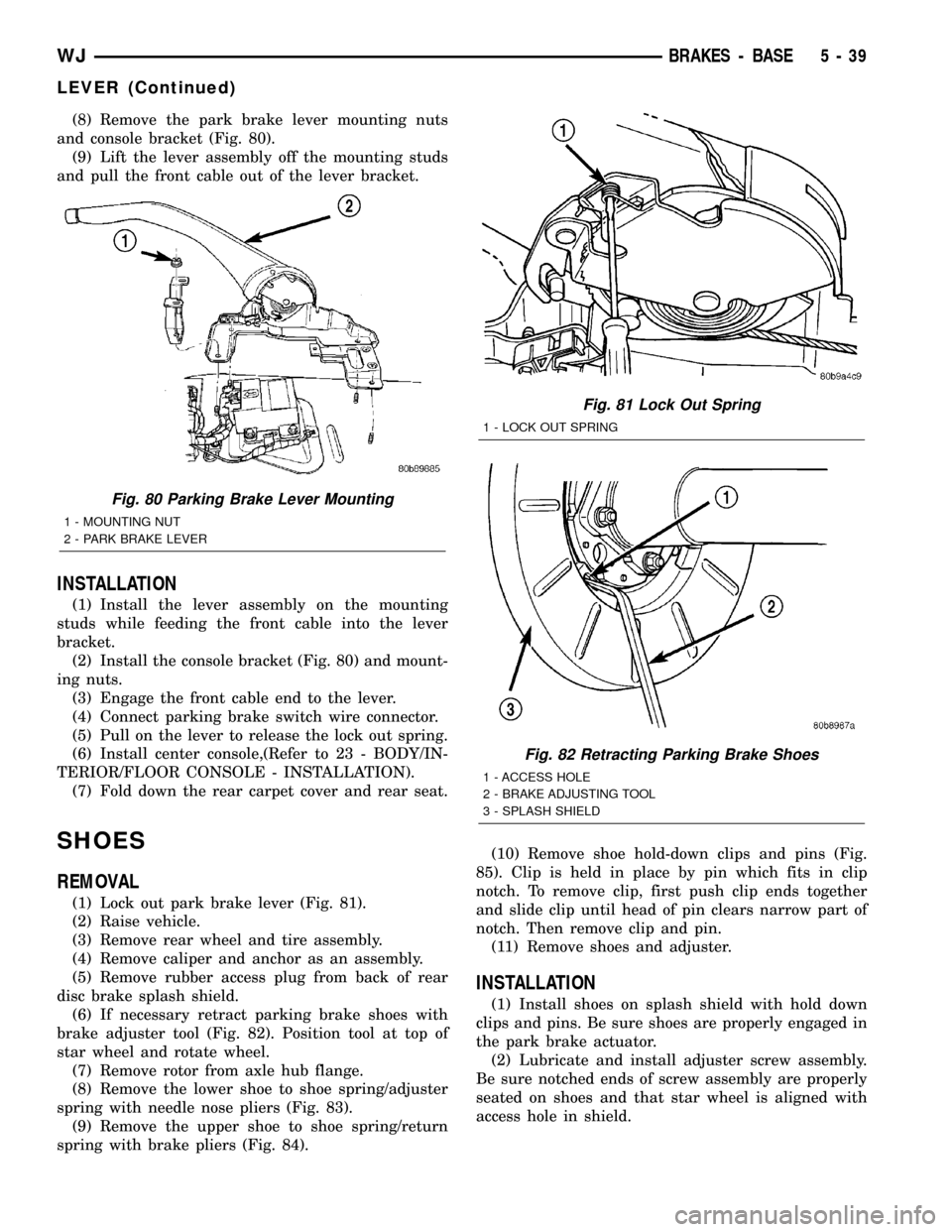

(8) Remove the park brake lever mounting nuts

and console bracket (Fig. 80).

(9) Lift the lever assembly off the mounting studs

and pull the front cable out of the lever bracket.

INSTALLATION

(1) Install the lever assembly on the mounting

studs while feeding the front cable into the lever

bracket.

(2) Install the console bracket (Fig. 80) and mount-

ing nuts.

(3) Engage the front cable end to the lever.

(4) Connect parking brake switch wire connector.

(5) Pull on the lever to release the lock out spring.

(6) Install center console,(Refer to 23 - BODY/IN-

TERIOR/FLOOR CONSOLE - INSTALLATION).

(7) Fold down the rear carpet cover and rear seat.

SHOES

REMOVAL

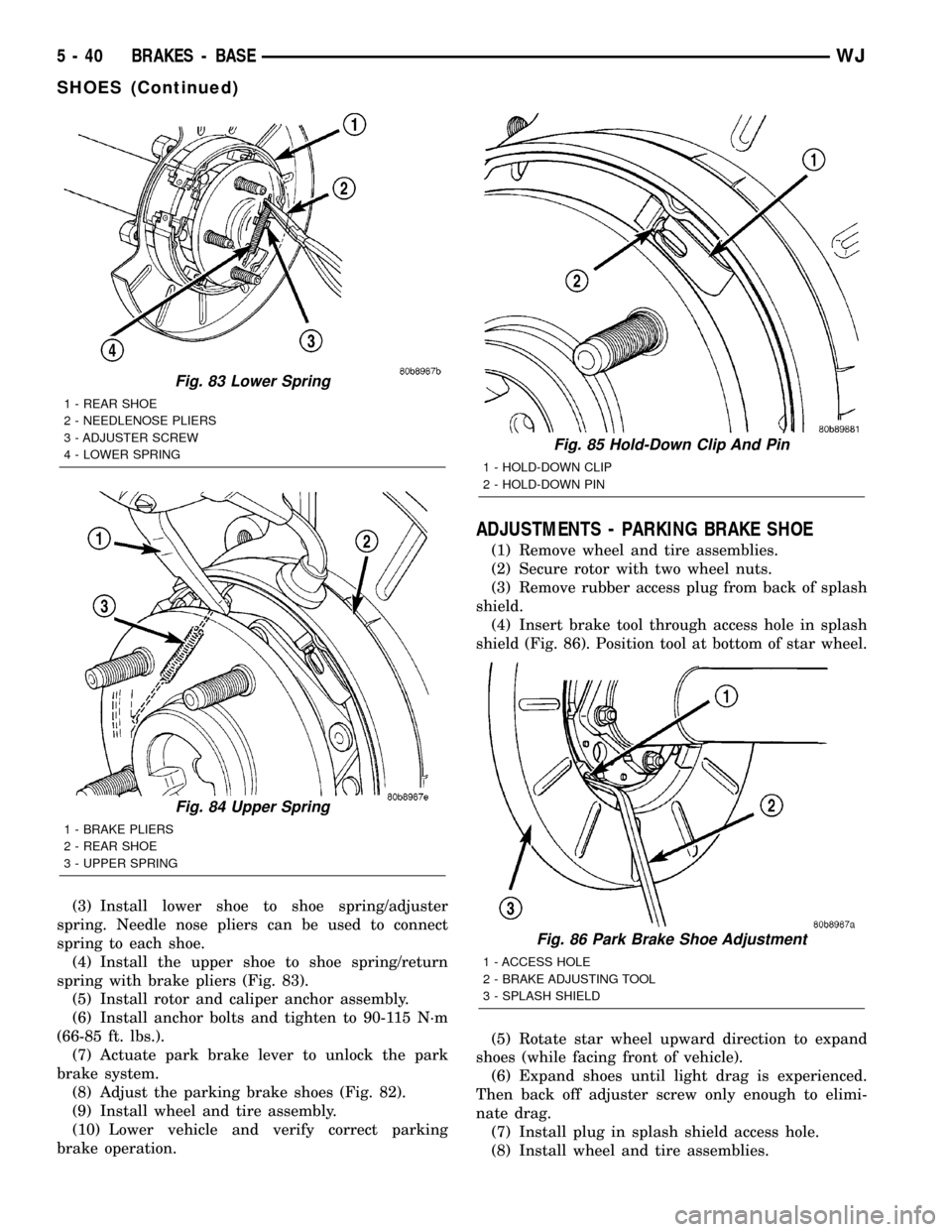

(1) Lock out park brake lever (Fig. 81).

(2) Raise vehicle.

(3) Remove rear wheel and tire assembly.

(4) Remove caliper and anchor as an assembly.

(5) Remove rubber access plug from back of rear

disc brake splash shield.

(6) If necessary retract parking brake shoes with

brake adjuster tool (Fig. 82). Position tool at top of

star wheel and rotate wheel.

(7) Remove rotor from axle hub flange.

(8) Remove the lower shoe to shoe spring/adjuster

spring with needle nose pliers (Fig. 83).

(9) Remove the upper shoe to shoe spring/return

spring with brake pliers (Fig. 84).(10) Remove shoe hold-down clips and pins (Fig.

85). Clip is held in place by pin which fits in clip

notch. To remove clip, first push clip ends together

and slide clip until head of pin clears narrow part of

notch. Then remove clip and pin.

(11) Remove shoes and adjuster.

INSTALLATION

(1) Install shoes on splash shield with hold down

clips and pins. Be sure shoes are properly engaged in

the park brake actuator.

(2) Lubricate and install adjuster screw assembly.

Be sure notched ends of screw assembly are properly

seated on shoes and that star wheel is aligned with

access hole in shield.

Fig. 80 Parking Brake Lever Mounting

1 - MOUNTING NUT

2 - PARK BRAKE LEVER

Fig. 81 Lock Out Spring

1 - LOCK OUT SPRING

Fig. 82 Retracting Parking Brake Shoes

1 - ACCESS HOLE

2 - BRAKE ADJUSTING TOOL

3 - SPLASH SHIELD

WJBRAKES - BASE 5 - 39

LEVER (Continued)

Page 215 of 2199

(3) Install lower shoe to shoe spring/adjuster

spring. Needle nose pliers can be used to connect

spring to each shoe.

(4) Install the upper shoe to shoe spring/return

spring with brake pliers (Fig. 83).

(5) Install rotor and caliper anchor assembly.

(6) Install anchor bolts and tighten to 90-115 N´m

(66-85 ft. lbs.).

(7) Actuate park brake lever to unlock the park

brake system.

(8) Adjust the parking brake shoes (Fig. 82).

(9) Install wheel and tire assembly.

(10) Lower vehicle and verify correct parking

brake operation.

ADJUSTMENTS - PARKING BRAKE SHOE

(1) Remove wheel and tire assemblies.

(2) Secure rotor with two wheel nuts.

(3) Remove rubber access plug from back of splash

shield.

(4) Insert brake tool through access hole in splash

shield (Fig. 86). Position tool at bottom of star wheel.

(5) Rotate star wheel upward direction to expand

shoes (while facing front of vehicle).

(6) Expand shoes until light drag is experienced.

Then back off adjuster screw only enough to elimi-

nate drag.

(7) Install plug in splash shield access hole.

(8) Install wheel and tire assemblies.

Fig. 83 Lower Spring

1 - REAR SHOE

2 - NEEDLENOSE PLIERS

3 - ADJUSTER SCREW

4 - LOWER SPRING

Fig. 84 Upper Spring

1 - BRAKE PLIERS

2 - REAR SHOE

3 - UPPER SPRING

Fig. 85 Hold-Down Clip And Pin

1 - HOLD-DOWN CLIP

2 - HOLD-DOWN PIN

Fig. 86 Park Brake Shoe Adjustment

1 - ACCESS HOLE

2 - BRAKE ADJUSTING TOOL

3 - SPLASH SHIELD

5 - 40 BRAKES - BASEWJ

SHOES (Continued)

Page 216 of 2199

BRAKES - ABS

TABLE OF CONTENTS

page page

BRAKES - ABS

DESCRIPTION.........................41

OPERATION...........................41

DIAGNOSIS AND TESTING - ANTILOCK

BRAKES............................42

STANDARD PROCEDURE - BLEEDING ABS

BRAKE SYSTEM......................42

SPECIFICATIONS

TORQUE CHART......................42

ELECTRIC BRAKE

DESCRIPTION.........................43

OPERATION...........................43

FRONT WHEEL SPEED SENSOR

DESCRIPTION.........................43

OPERATION...........................43

REMOVAL.............................43INSTALLATION.........................43

G-SWITCH

DESCRIPTION.........................44

OPERATION...........................44

REMOVAL.............................44

INSTALLATION.........................44

REAR WHEEL SPEED SENSOR

DESCRIPTION.........................45

OPERATION...........................45

REMOVAL.............................45

INSTALLATION.........................46

HCU (HYDRAULIC CONTROL UNIT)

DESCRIPTION.........................46

OPERATION...........................46

REMOVAL.............................47

INSTALLATION.........................47

BRAKES - ABS

DESCRIPTION

The purpose of the antilock system is to prevent

wheel lockup during periods of high wheel slip. Pre-

venting lockup helps maintain vehicle braking action

and steering control.

The hydraulic system is a three channel design.

The front brakes are controlled individually and the

rear brakes in tandem.

The ABS electrical system is separate from other

vehicle electrical circuits. A separate controller oper-

ates the system.

OPERATION

The antilock CAB activates the system whenever

sensor signals indicate periods of high wheel slip.

High wheel slip can be described as the point where

wheel rotation begins approaching 20 to 30 percent of

actual vehicle speed during braking. Periods of high

wheel slip occur when brake stops involve high pedal

pressure and rate of vehicle deceleration.

Battery voltage is supplied to the CAB ignition ter-

minal when the ignition switch is turned to Run posi-

tion. The CAB performs a system initialization

procedure at this point. Initialization consists of a

static and dynamic self check of system electrical

components.

The static check occurs after the ignition switch is

turned to Run position. The dynamic check occurs

when vehicle road speed reaches approximately 30kph (18 mph). During the dynamic check, the CAB

briefly cycles the pump and solenoids to verify oper-

ation.

If an ABS component exhibits a fault during ini-

tialization, the CAB illuminates the amber warning

light and registers a fault code in the microprocessor

memory.

ANTILOCK BRAKING

The antilock system prevents lockup during high

slip conditions by modulating fluid apply pressure to

the wheel brake units.

Brake fluid apply pressure is modulated according

to wheel speed, degree of slip and rate of decelera-

tion. A sensor at each wheel converts wheel speed

into electrical signals. These signals are transmitted

to the CAB for processing and determination of

wheel slip and deceleration rate.

The ABS system has three fluid pressure control

channels. The front brakes are controlled separately

and the rear brakes in tandem. A speed sensor input

signal indicating a high slip condition activates the

CAB antilock program.

Two solenoid valves are used in each antilock con-

trol channel. The valves are all located within the

HCU valve body and work in pairs to either increase,

hold, or decrease apply pressure as needed in the

individual control channels.

The solenoid valves are not static during antilock

braking. They are cycled continuously to modulate

pressure. Solenoid cycle time in antilock mode can be

measured in milliseconds.

WJBRAKES - ABS 5 - 41

Page 217 of 2199

DIAGNOSIS AND TESTING - ANTILOCK

BRAKES

The ABS brake system performs several self-tests

every time the ignition switch is turned on and the

vehicle is driven. The CAB monitors the systems

input and output circuits to verify the system is oper-

ating correctly. If the on board diagnostic system

senses that a circuit is malfunctioning the system

will set a trouble code in its memory.

NOTE: An audible noise may be heard during the

self-test. This noise should be considered normal.

NOTE: The MDS or DRB III scan tool is used to

diagnose the ABS system. For additional informa-

tion refer to the Electrical section. For test proce-

dures refer to the Chassis Diagnostic Manual.

STANDARD PROCEDURE - BLEEDING ABS

BRAKE SYSTEM

ABS system bleeding requires conventional bleed-

ing methods plus use of the DRB scan tool. The pro-cedure involves performing a base brake bleeding,

followed by use of the scan tool to cycle and bleed the

HCU pump and solenoids. A second base brake bleed-

ing procedure is then required to remove any air

remaining in the system.

(1) Perform base brake bleeding. (Refer to 5 -

BRAKES - STANDARD PROCEDURE) OR (Refer to

5 - BRAKES - STANDARD PROCEDURE).

(2) Connect scan tool to the Data Link Connector.

(3) Select ANTILOCK BRAKES, followed by MIS-

CELLANEOUS, then ABS BRAKES. Follow the

instructions displayed. When scan tool displays TEST

COMPLETE, disconnect scan tool and proceed.

(4) Perform base brake bleeding a second time.

(Refer to 5 - BRAKES - STANDARD PROCEDURE)

OR (Refer to 5 - BRAKES - STANDARD PROCE-

DURE).

(5) Top off master cylinder fluid level and verify

proper brake operation before moving vehicle.

SPECIFICATIONS

TORQUE CHART

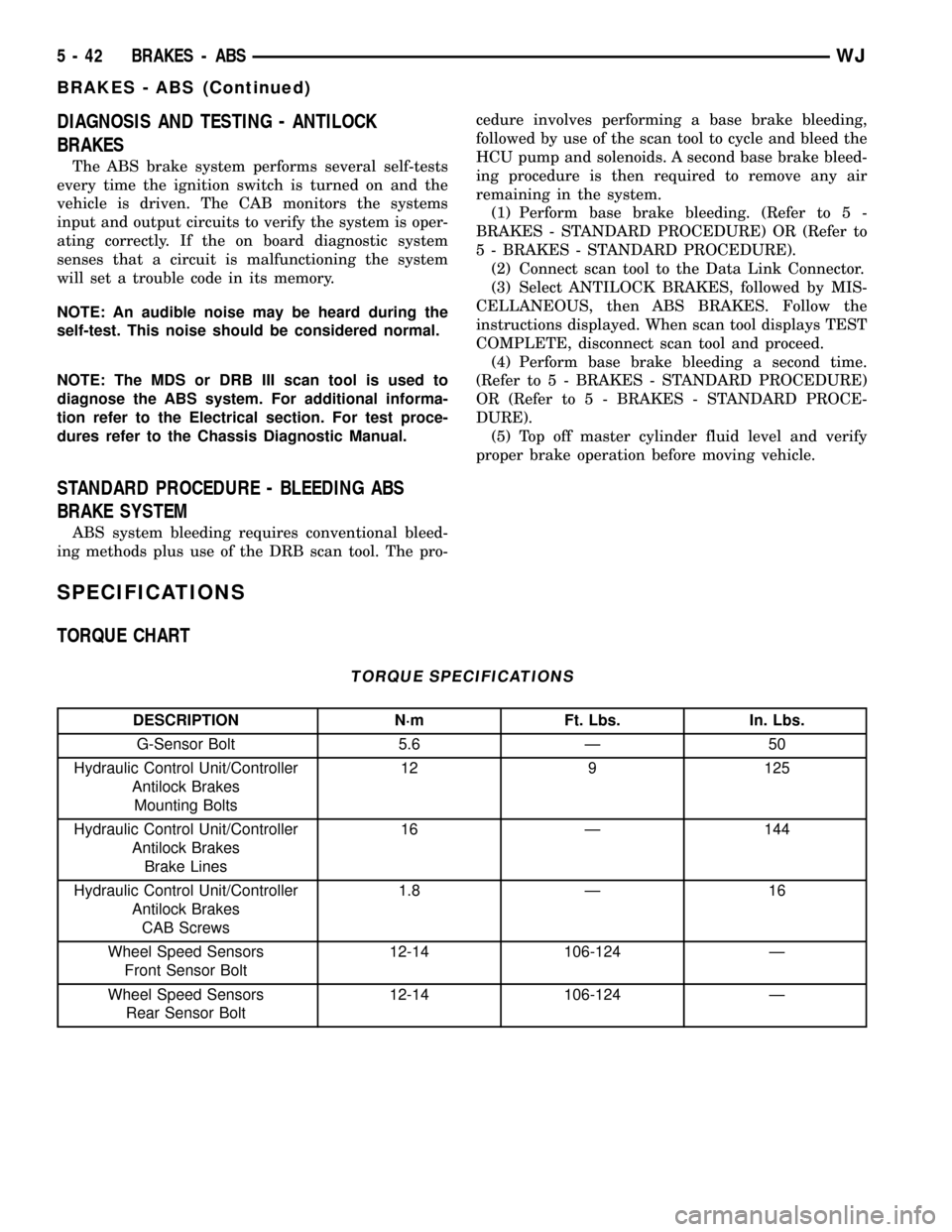

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

G-Sensor Bolt 5.6 Ð 50

Hydraulic Control Unit/Controller

Antilock Brakes

Mounting Bolts12 9 125

Hydraulic Control Unit/Controller

Antilock Brakes

Brake Lines16 Ð 144

Hydraulic Control Unit/Controller

Antilock Brakes

CAB Screws1.8 Ð 16

Wheel Speed Sensors

Front Sensor Bolt12-14 106-124 Ð

Wheel Speed Sensors

Rear Sensor Bolt12-14 106-124 Ð

5 - 42 BRAKES - ABSWJ

BRAKES - ABS (Continued)

Page 221 of 2199

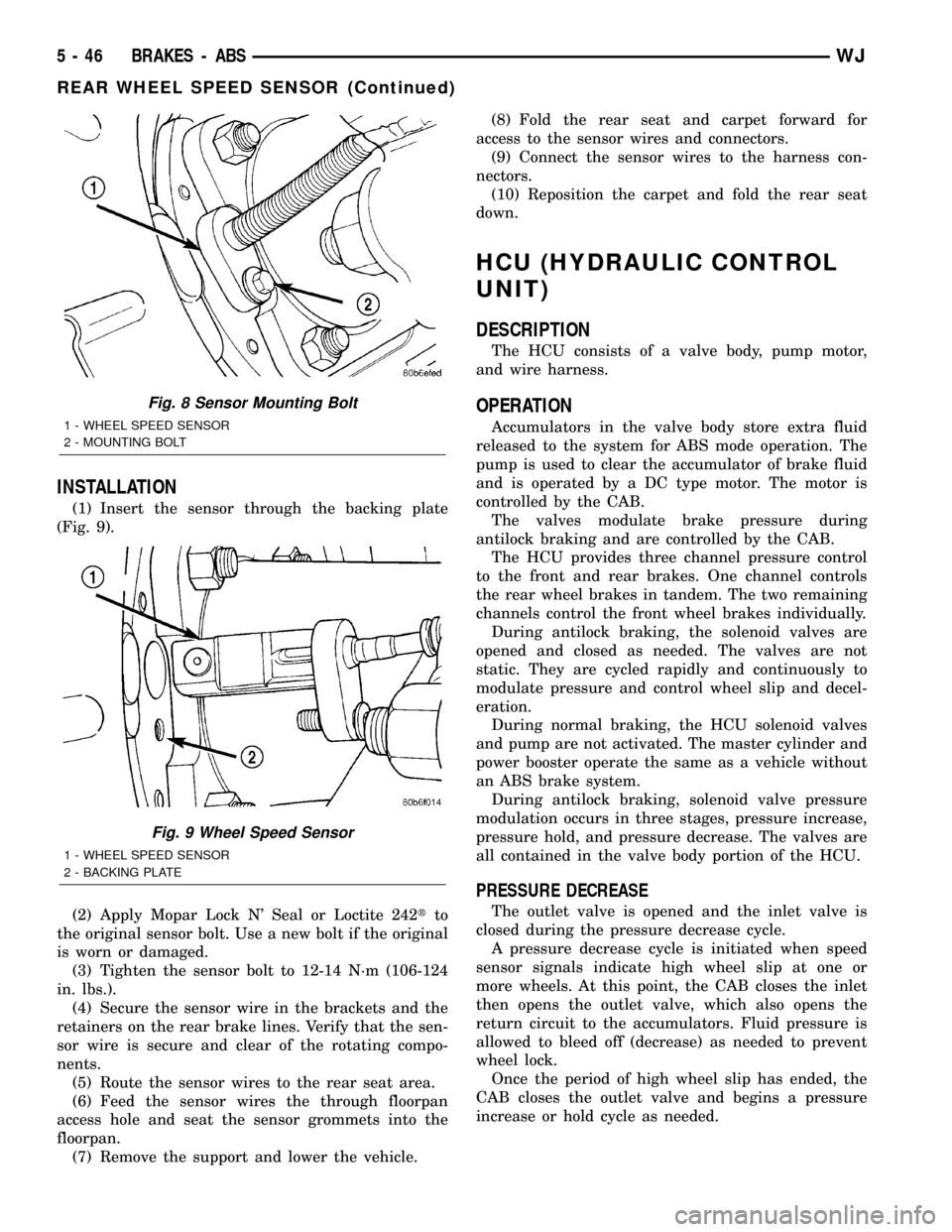

INSTALLATION

(1) Insert the sensor through the backing plate

(Fig. 9).

(2) Apply Mopar Lock N' Seal or Loctite 242tto

the original sensor bolt. Use a new bolt if the original

is worn or damaged.

(3) Tighten the sensor bolt to 12-14 N´m (106-124

in. lbs.).

(4) Secure the sensor wire in the brackets and the

retainers on the rear brake lines. Verify that the sen-

sor wire is secure and clear of the rotating compo-

nents.

(5) Route the sensor wires to the rear seat area.

(6) Feed the sensor wires the through floorpan

access hole and seat the sensor grommets into the

floorpan.

(7) Remove the support and lower the vehicle.(8) Fold the rear seat and carpet forward for

access to the sensor wires and connectors.

(9) Connect the sensor wires to the harness con-

nectors.

(10) Reposition the carpet and fold the rear seat

down.

HCU (HYDRAULIC CONTROL

UNIT)

DESCRIPTION

The HCU consists of a valve body, pump motor,

and wire harness.

OPERATION

Accumulators in the valve body store extra fluid

released to the system for ABS mode operation. The

pump is used to clear the accumulator of brake fluid

and is operated by a DC type motor. The motor is

controlled by the CAB.

The valves modulate brake pressure during

antilock braking and are controlled by the CAB.

The HCU provides three channel pressure control

to the front and rear brakes. One channel controls

the rear wheel brakes in tandem. The two remaining

channels control the front wheel brakes individually.

During antilock braking, the solenoid valves are

opened and closed as needed. The valves are not

static. They are cycled rapidly and continuously to

modulate pressure and control wheel slip and decel-

eration.

During normal braking, the HCU solenoid valves

and pump are not activated. The master cylinder and

power booster operate the same as a vehicle without

an ABS brake system.

During antilock braking, solenoid valve pressure

modulation occurs in three stages, pressure increase,

pressure hold, and pressure decrease. The valves are

all contained in the valve body portion of the HCU.

PRESSURE DECREASE

The outlet valve is opened and the inlet valve is

closed during the pressure decrease cycle.

A pressure decrease cycle is initiated when speed

sensor signals indicate high wheel slip at one or

more wheels. At this point, the CAB closes the inlet

then opens the outlet valve, which also opens the

return circuit to the accumulators. Fluid pressure is

allowed to bleed off (decrease) as needed to prevent

wheel lock.

Once the period of high wheel slip has ended, the

CAB closes the outlet valve and begins a pressure

increase or hold cycle as needed.

Fig. 8 Sensor Mounting Bolt

1 - WHEEL SPEED SENSOR

2 - MOUNTING BOLT

Fig. 9 Wheel Speed Sensor

1 - WHEEL SPEED SENSOR

2 - BACKING PLATE

5 - 46 BRAKES - ABSWJ

REAR WHEEL SPEED SENSOR (Continued)

Page 228 of 2199

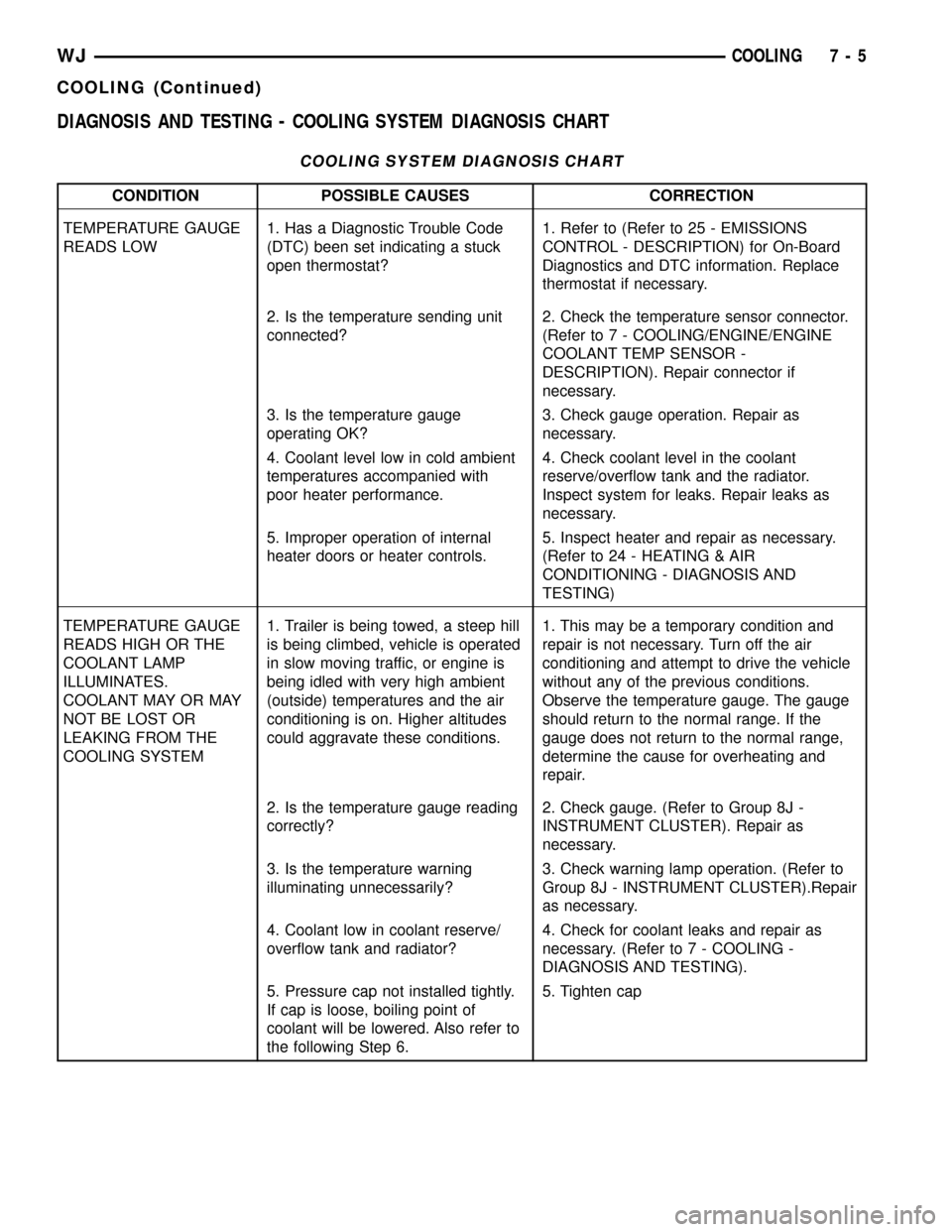

DIAGNOSIS AND TESTING - COOLING SYSTEM DIAGNOSIS CHART

COOLING SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

TEMPERATURE GAUGE

READS LOW1. Has a Diagnostic Trouble Code

(DTC) been set indicating a stuck

open thermostat?1. Refer to (Refer to 25 - EMISSIONS

CONTROL - DESCRIPTION) for On-Board

Diagnostics and DTC information. Replace

thermostat if necessary.

2. Is the temperature sending unit

connected?2. Check the temperature sensor connector.

(Refer to 7 - COOLING/ENGINE/ENGINE

COOLANT TEMP SENSOR -

DESCRIPTION). Repair connector if

necessary.

3. Is the temperature gauge

operating OK?3. Check gauge operation. Repair as

necessary.

4. Coolant level low in cold ambient

temperatures accompanied with

poor heater performance.4. Check coolant level in the coolant

reserve/overflow tank and the radiator.

Inspect system for leaks. Repair leaks as

necessary.

5. Improper operation of internal

heater doors or heater controls.5. Inspect heater and repair as necessary.

(Refer to 24 - HEATING & AIR

CONDITIONING - DIAGNOSIS AND

TESTING)

TEMPERATURE GAUGE

READS HIGH OR THE

COOLANT LAMP

ILLUMINATES.

COOLANT MAY OR MAY

NOT BE LOST OR

LEAKING FROM THE

COOLING SYSTEM1. Trailer is being towed, a steep hill

is being climbed, vehicle is operated

in slow moving traffic, or engine is

being idled with very high ambient

(outside) temperatures and the air

conditioning is on. Higher altitudes

could aggravate these conditions.1. This may be a temporary condition and

repair is not necessary. Turn off the air

conditioning and attempt to drive the vehicle

without any of the previous conditions.

Observe the temperature gauge. The gauge

should return to the normal range. If the

gauge does not return to the normal range,

determine the cause for overheating and

repair.

2. Is the temperature gauge reading

correctly?2. Check gauge. (Refer to Group 8J -

INSTRUMENT CLUSTER). Repair as

necessary.

3. Is the temperature warning

illuminating unnecessarily?3. Check warning lamp operation. (Refer to

Group 8J - INSTRUMENT CLUSTER).Repair

as necessary.

4. Coolant low in coolant reserve/

overflow tank and radiator?4. Check for coolant leaks and repair as

necessary. (Refer to 7 - COOLING -

DIAGNOSIS AND TESTING).

5. Pressure cap not installed tightly.

If cap is loose, boiling point of

coolant will be lowered. Also refer to

the following Step 6.5. Tighten cap

WJCOOLING 7 - 5

COOLING (Continued)

Page 230 of 2199

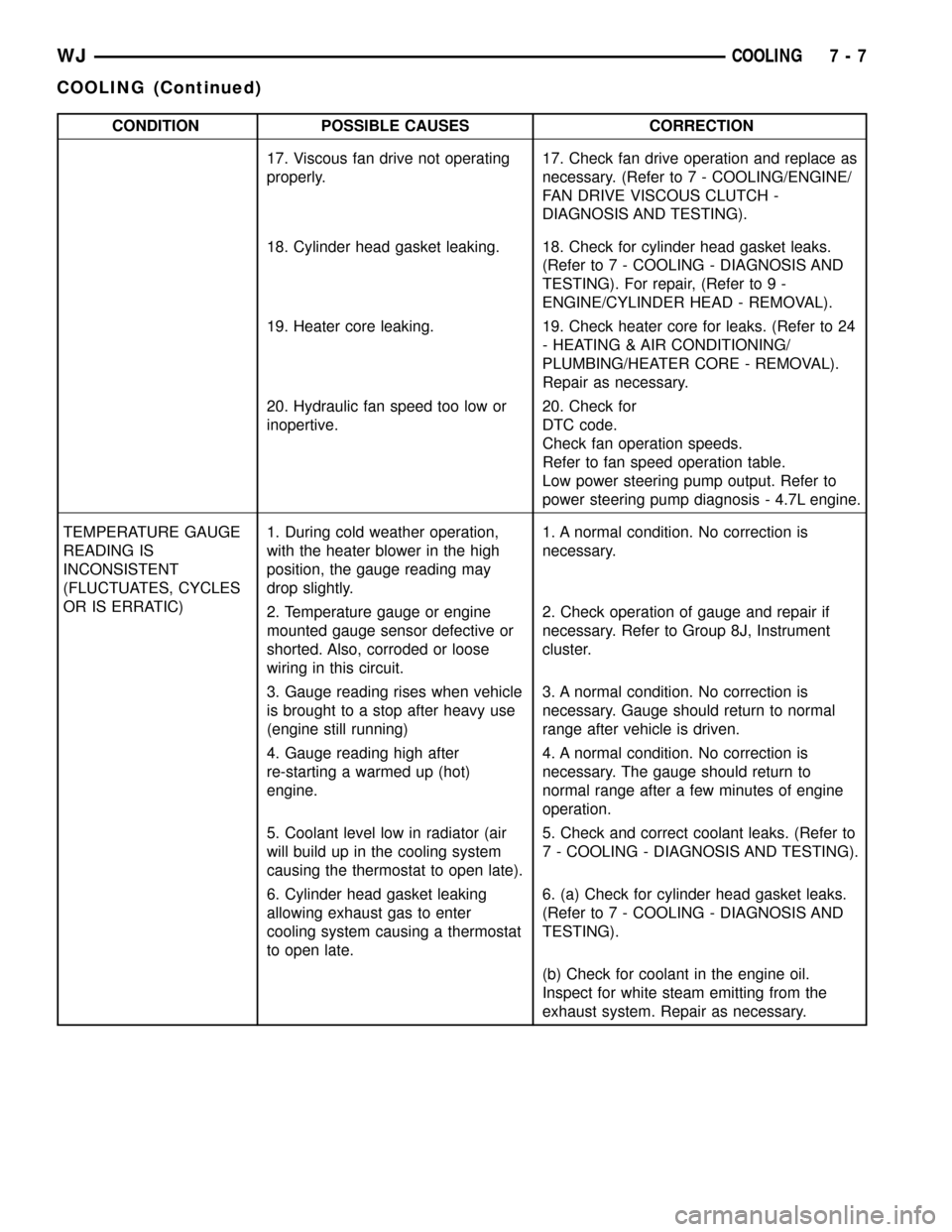

CONDITION POSSIBLE CAUSES CORRECTION

17. Viscous fan drive not operating

properly.17. Check fan drive operation and replace as

necessary. (Refer to 7 - COOLING/ENGINE/

FAN DRIVE VISCOUS CLUTCH -

DIAGNOSIS AND TESTING).

18. Cylinder head gasket leaking. 18. Check for cylinder head gasket leaks.

(Refer to 7 - COOLING - DIAGNOSIS AND

TESTING). For repair, (Refer to 9 -

ENGINE/CYLINDER HEAD - REMOVAL).

19. Heater core leaking. 19. Check heater core for leaks. (Refer to 24

- HEATING & AIR CONDITIONING/

PLUMBING/HEATER CORE - REMOVAL).

Repair as necessary.

20. Hydraulic fan speed too low or

inopertive.20. Check for

DTC code.

Check fan operation speeds.

Refer to fan speed operation table.

Low power steering pump output. Refer to

power steering pump diagnosis - 4.7L engine.

TEMPERATURE GAUGE

READING IS

INCONSISTENT

(FLUCTUATES, CYCLES

OR IS ERRATIC)1. During cold weather operation,

with the heater blower in the high

position, the gauge reading may

drop slightly.1. A normal condition. No correction is

necessary.

2. Temperature gauge or engine

mounted gauge sensor defective or

shorted. Also, corroded or loose

wiring in this circuit.2. Check operation of gauge and repair if

necessary. Refer to Group 8J, Instrument

cluster.

3. Gauge reading rises when vehicle

is brought to a stop after heavy use

(engine still running)3. A normal condition. No correction is

necessary. Gauge should return to normal

range after vehicle is driven.

4. Gauge reading high after

re-starting a warmed up (hot)

engine.4. A normal condition. No correction is

necessary. The gauge should return to

normal range after a few minutes of engine

operation.

5. Coolant level low in radiator (air

will build up in the cooling system

causing the thermostat to open late).5. Check and correct coolant leaks. (Refer to

7 - COOLING - DIAGNOSIS AND TESTING).

6. Cylinder head gasket leaking

allowing exhaust gas to enter

cooling system causing a thermostat

to open late.6. (a) Check for cylinder head gasket leaks.

(Refer to 7 - COOLING - DIAGNOSIS AND

TESTING).

(b) Check for coolant in the engine oil.

Inspect for white steam emitting from the

exhaust system. Repair as necessary.

WJCOOLING 7 - 7

COOLING (Continued)

Page 233 of 2199

CONDITION POSSIBLE CAUSES CORRECTION

COOLANT LEVEL

CHANGES IN COOLANT

RESERVE/OVERFLOW

TANK. TEMPERATURE

GAUGE IS IN NORMAL

RANGE1. Level changes are to be expected

as coolant volume fluctuates with

engine temperature. If the level in

the tank was between the FULL and

ADD marks at normal operating

temperature, the level should return

to within that range after operation

at elevated temperatures.1. A normal condition. No repair is necessary.

FAN RUNS ALL THE

TIME1. Fan control sensors inoperative. 1. Check for DTC's. Verify sensor readings.

2. Fan control solenoid stuck9on9. 2. Check fan operation speeds. Refer to fan

speed operation table.

3. Fan control solenoid harness

damaged.3. Check for DTC 1499. Repair as required.

4. Transmission temperature too

high.4. Check for transmission over temp. DTC.

5. Engine coolant temperature too

high.5. (a) Check coolant level. Correct level as

required.

(b) Thermostat stuck. Replace thermostat.

(c) Water pump failed. Replace water pump.

(d) Coolant flow restricted. Clean radiator.

(e) Air flow over radiator obstructed.Remove

obstruction.

DIAGNOSIS AND TESTING - COOLING SYSTEM

LEAKS

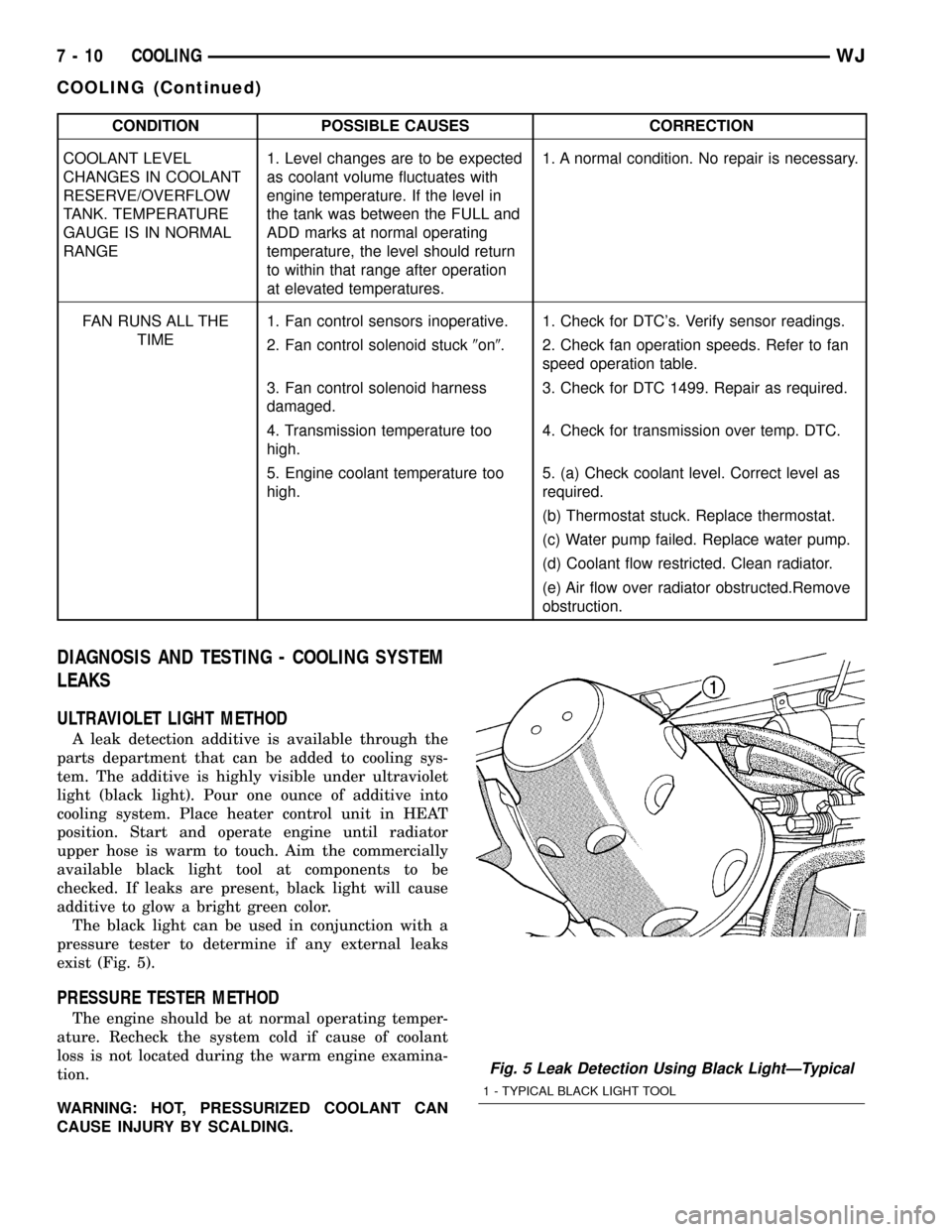

ULTRAVIOLET LIGHT METHOD

A leak detection additive is available through the

parts department that can be added to cooling sys-

tem. The additive is highly visible under ultraviolet

light (black light). Pour one ounce of additive into

cooling system. Place heater control unit in HEAT

position. Start and operate engine until radiator

upper hose is warm to touch. Aim the commercially

available black light tool at components to be

checked. If leaks are present, black light will cause

additive to glow a bright green color.

The black light can be used in conjunction with a

pressure tester to determine if any external leaks

exist (Fig. 5).

PRESSURE TESTER METHOD

The engine should be at normal operating temper-

ature. Recheck the system cold if cause of coolant

loss is not located during the warm engine examina-

tion.

WARNING: HOT, PRESSURIZED COOLANT CAN

CAUSE INJURY BY SCALDING.

Fig. 5 Leak Detection Using Black LightÐTypical

1 - TYPICAL BLACK LIGHT TOOL

7 - 10 COOLINGWJ

COOLING (Continued)

Page 234 of 2199

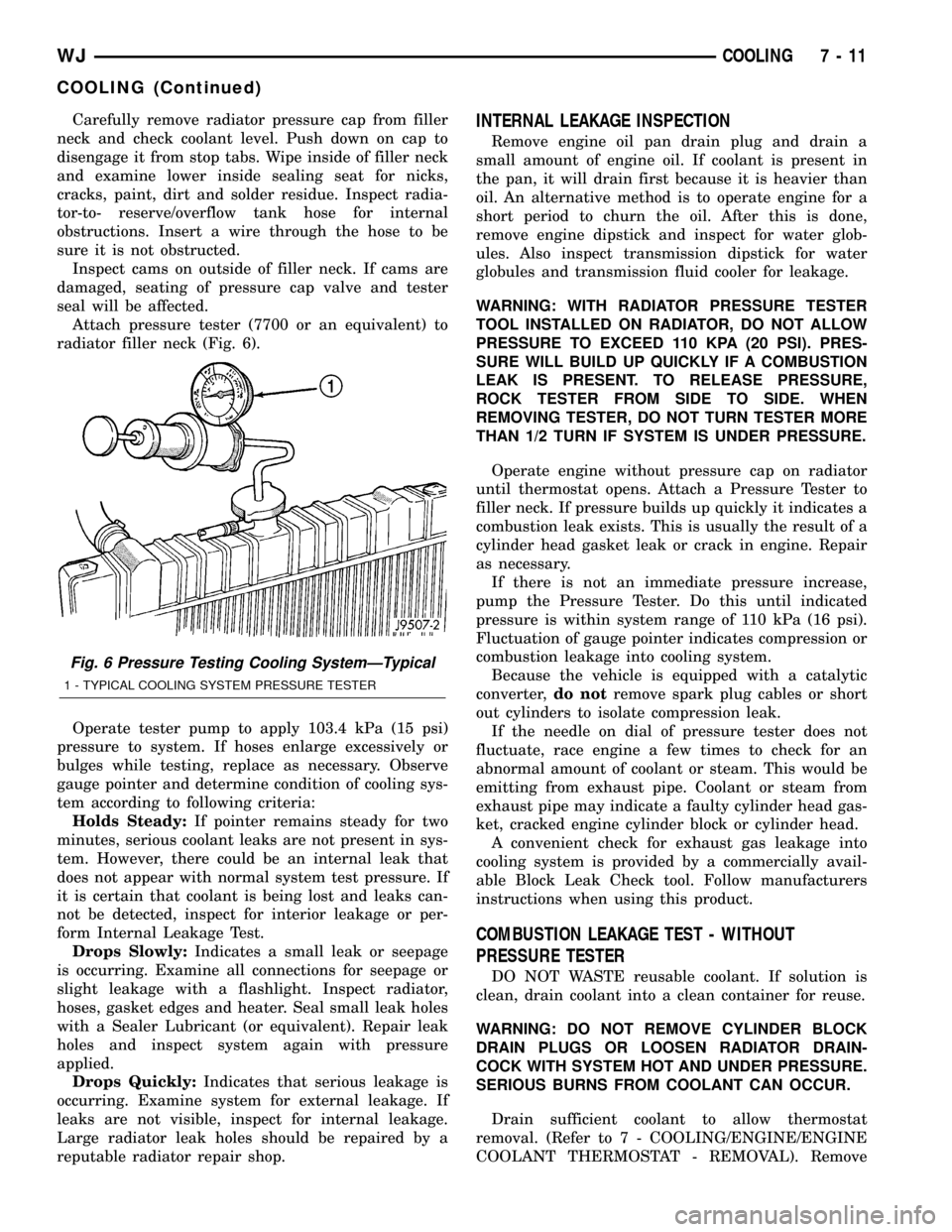

Carefully remove radiator pressure cap from filler

neck and check coolant level. Push down on cap to

disengage it from stop tabs. Wipe inside of filler neck

and examine lower inside sealing seat for nicks,

cracks, paint, dirt and solder residue. Inspect radia-

tor-to- reserve/overflow tank hose for internal

obstructions. Insert a wire through the hose to be

sure it is not obstructed.

Inspect cams on outside of filler neck. If cams are

damaged, seating of pressure cap valve and tester

seal will be affected.

Attach pressure tester (7700 or an equivalent) to

radiator filler neck (Fig. 6).

Operate tester pump to apply 103.4 kPa (15 psi)

pressure to system. If hoses enlarge excessively or

bulges while testing, replace as necessary. Observe

gauge pointer and determine condition of cooling sys-

tem according to following criteria:

Holds Steady:If pointer remains steady for two

minutes, serious coolant leaks are not present in sys-

tem. However, there could be an internal leak that

does not appear with normal system test pressure. If

it is certain that coolant is being lost and leaks can-

not be detected, inspect for interior leakage or per-

form Internal Leakage Test.

Drops Slowly:Indicates a small leak or seepage

is occurring. Examine all connections for seepage or

slight leakage with a flashlight. Inspect radiator,

hoses, gasket edges and heater. Seal small leak holes

with a Sealer Lubricant (or equivalent). Repair leak

holes and inspect system again with pressure

applied.

Drops Quickly:Indicates that serious leakage is

occurring. Examine system for external leakage. If

leaks are not visible, inspect for internal leakage.

Large radiator leak holes should be repaired by a

reputable radiator repair shop.INTERNAL LEAKAGE INSPECTION

Remove engine oil pan drain plug and drain a

small amount of engine oil. If coolant is present in

the pan, it will drain first because it is heavier than

oil. An alternative method is to operate engine for a

short period to churn the oil. After this is done,

remove engine dipstick and inspect for water glob-

ules. Also inspect transmission dipstick for water

globules and transmission fluid cooler for leakage.

WARNING: WITH RADIATOR PRESSURE TESTER

TOOL INSTALLED ON RADIATOR, DO NOT ALLOW

PRESSURE TO EXCEED 110 KPA (20 PSI). PRES-

SURE WILL BUILD UP QUICKLY IF A COMBUSTION

LEAK IS PRESENT. TO RELEASE PRESSURE,

ROCK TESTER FROM SIDE TO SIDE. WHEN

REMOVING TESTER, DO NOT TURN TESTER MORE

THAN 1/2 TURN IF SYSTEM IS UNDER PRESSURE.

Operate engine without pressure cap on radiator

until thermostat opens. Attach a Pressure Tester to

filler neck. If pressure builds up quickly it indicates a

combustion leak exists. This is usually the result of a

cylinder head gasket leak or crack in engine. Repair

as necessary.

If there is not an immediate pressure increase,

pump the Pressure Tester. Do this until indicated

pressure is within system range of 110 kPa (16 psi).

Fluctuation of gauge pointer indicates compression or

combustion leakage into cooling system.

Because the vehicle is equipped with a catalytic

converter,do notremove spark plug cables or short

out cylinders to isolate compression leak.

If the needle on dial of pressure tester does not

fluctuate, race engine a few times to check for an

abnormal amount of coolant or steam. This would be

emitting from exhaust pipe. Coolant or steam from

exhaust pipe may indicate a faulty cylinder head gas-

ket, cracked engine cylinder block or cylinder head.

A convenient check for exhaust gas leakage into

cooling system is provided by a commercially avail-

able Block Leak Check tool. Follow manufacturers

instructions when using this product.

COMBUSTION LEAKAGE TEST - WITHOUT

PRESSURE TESTER

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

WARNING: DO NOT REMOVE CYLINDER BLOCK

DRAIN PLUGS OR LOOSEN RADIATOR DRAIN-

COCK WITH SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

Drain sufficient coolant to allow thermostat

removal. (Refer to 7 - COOLING/ENGINE/ENGINE

COOLANT THERMOSTAT - REMOVAL). Remove

Fig. 6 Pressure Testing Cooling SystemÐTypical

1 - TYPICAL COOLING SYSTEM PRESSURE TESTER

WJCOOLING 7 - 11

COOLING (Continued)