intake JEEP GRAND CHEROKEE 2002 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1308 of 2199

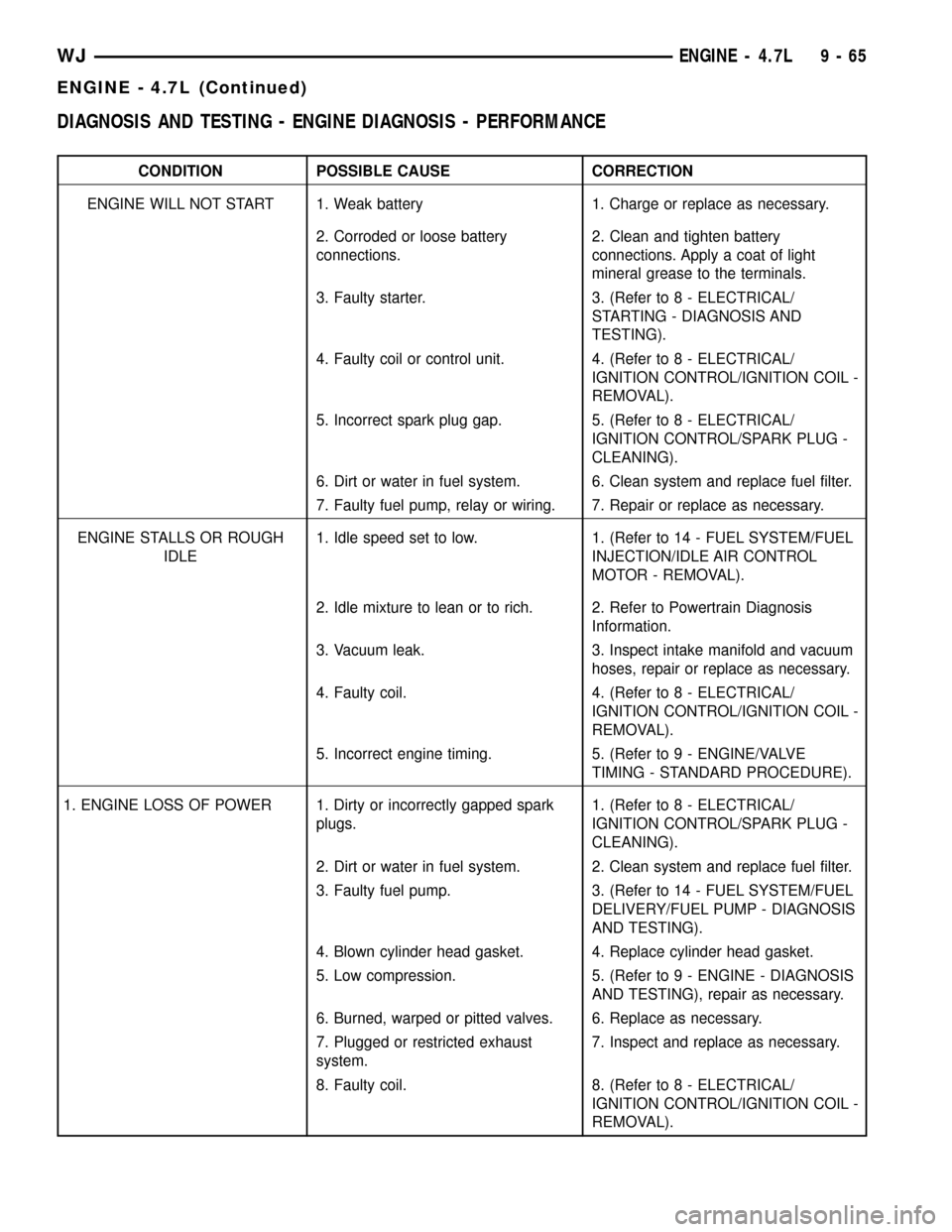

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - PERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT START 1. Weak battery 1. Charge or replace as necessary.

2. Corroded or loose battery

connections.2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to the terminals.

3. Faulty starter. 3. (Refer to 8 - ELECTRICAL/

STARTING - DIAGNOSIS AND

TESTING).

4. Faulty coil or control unit. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION COIL -

REMOVAL).

5. Incorrect spark plug gap. 5. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG -

CLEANING).

6. Dirt or water in fuel system. 6. Clean system and replace fuel filter.

7. Faulty fuel pump, relay or wiring. 7. Repair or replace as necessary.

ENGINE STALLS OR ROUGH

IDLE1. Idle speed set to low. 1. (Refer to 14 - FUEL SYSTEM/FUEL

INJECTION/IDLE AIR CONTROL

MOTOR - REMOVAL).

2. Idle mixture to lean or to rich. 2. Refer to Powertrain Diagnosis

Information.

3. Vacuum leak. 3. Inspect intake manifold and vacuum

hoses, repair or replace as necessary.

4. Faulty coil. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION COIL -

REMOVAL).

5. Incorrect engine timing. 5. (Refer to 9 - ENGINE/VALVE

TIMING - STANDARD PROCEDURE).

1. ENGINE LOSS OF POWER 1. Dirty or incorrectly gapped spark

plugs.1. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG -

CLEANING).

2. Dirt or water in fuel system. 2. Clean system and replace fuel filter.

3. Faulty fuel pump. 3. (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/FUEL PUMP - DIAGNOSIS

AND TESTING).

4. Blown cylinder head gasket. 4. Replace cylinder head gasket.

5. Low compression. 5. (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING), repair as necessary.

6. Burned, warped or pitted valves. 6. Replace as necessary.

7. Plugged or restricted exhaust

system.7. Inspect and replace as necessary.

8. Faulty coil. 8. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION COIL -

REMOVAL).

WJENGINE - 4.7L 9 - 65

ENGINE - 4.7L (Continued)

Page 1309 of 2199

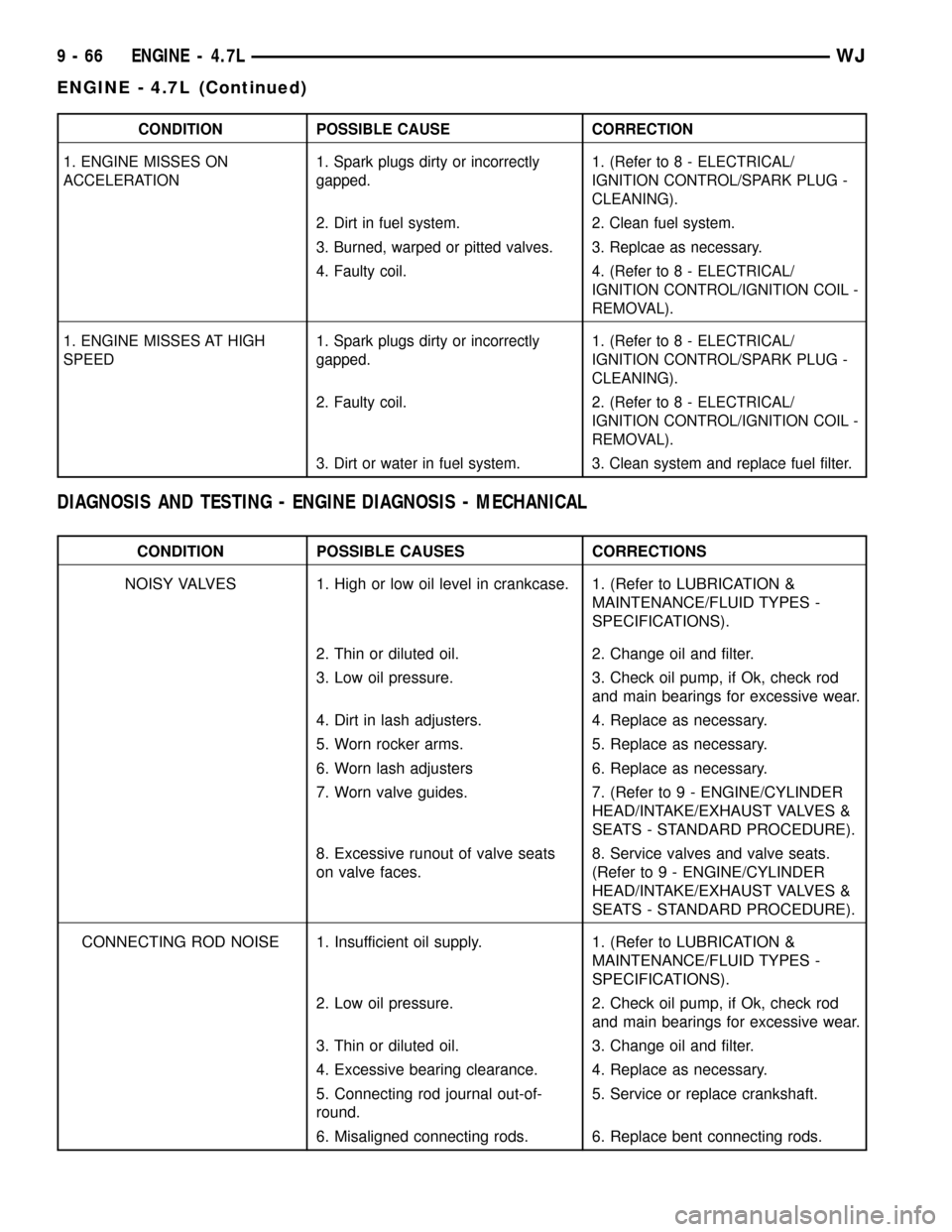

CONDITION POSSIBLE CAUSE CORRECTION

1. ENGINE MISSES ON

ACCELERATION1. Spark plugs dirty or incorrectly

gapped.1. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG -

CLEANING).

2. Dirt in fuel system. 2. Clean fuel system.

3. Burned, warped or pitted valves. 3. Replcae as necessary.

4. Faulty coil. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION COIL -

REMOVAL).

1. ENGINE MISSES AT HIGH

SPEED1. Spark plugs dirty or incorrectly

gapped.1. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG -

CLEANING).

2. Faulty coil. 2. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION COIL -

REMOVAL).

3. Dirt or water in fuel system. 3. Clean system and replace fuel filter.

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTIONS

NOISY VALVES 1. High or low oil level in crankcase. 1. (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES -

SPECIFICATIONS).

2. Thin or diluted oil. 2. Change oil and filter.

3. Low oil pressure. 3. Check oil pump, if Ok, check rod

and main bearings for excessive wear.

4. Dirt in lash adjusters. 4. Replace as necessary.

5. Worn rocker arms. 5. Replace as necessary.

6. Worn lash adjusters 6. Replace as necessary.

7. Worn valve guides. 7. (Refer to 9 - ENGINE/CYLINDER

HEAD/INTAKE/EXHAUST VALVES &

SEATS - STANDARD PROCEDURE).

8. Excessive runout of valve seats

on valve faces.8. Service valves and valve seats.

(Refer to 9 - ENGINE/CYLINDER

HEAD/INTAKE/EXHAUST VALVES &

SEATS - STANDARD PROCEDURE).

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES -

SPECIFICATIONS).

2. Low oil pressure. 2. Check oil pump, if Ok, check rod

and main bearings for excessive wear.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Connecting rod journal out-of-

round.5. Service or replace crankshaft.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

9 - 66 ENGINE - 4.7LWJ

ENGINE - 4.7L (Continued)

Page 1311 of 2199

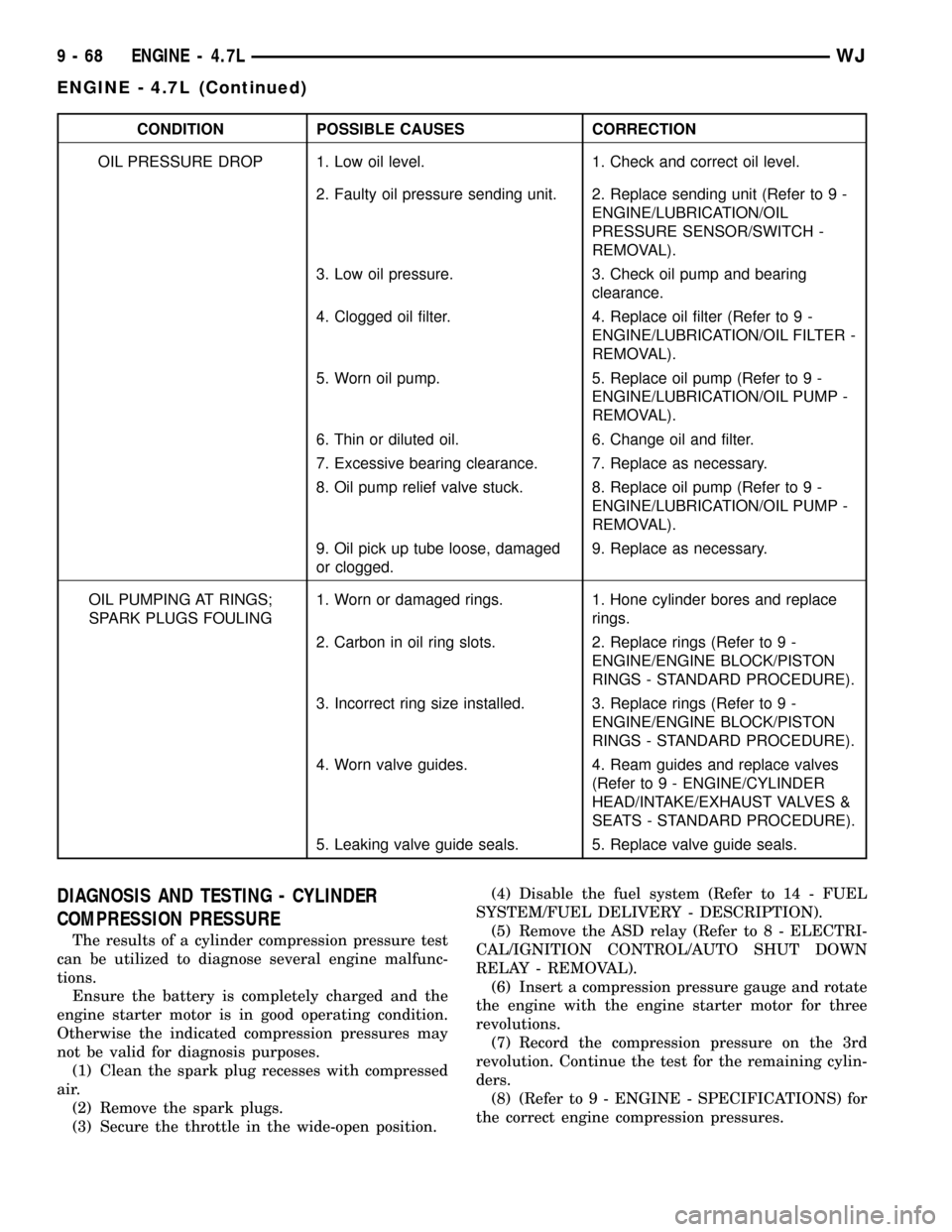

CONDITION POSSIBLE CAUSES CORRECTION

OIL PRESSURE DROP 1. Low oil level. 1. Check and correct oil level.

2. Faulty oil pressure sending unit. 2. Replace sending unit (Refer to 9 -

ENGINE/LUBRICATION/OIL

PRESSURE SENSOR/SWITCH -

REMOVAL).

3. Low oil pressure. 3. Check oil pump and bearing

clearance.

4. Clogged oil filter. 4. Replace oil filter (Refer to 9 -

ENGINE/LUBRICATION/OIL FILTER -

REMOVAL).

5. Worn oil pump. 5. Replace oil pump (Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP -

REMOVAL).

6. Thin or diluted oil. 6. Change oil and filter.

7. Excessive bearing clearance. 7. Replace as necessary.

8. Oil pump relief valve stuck. 8. Replace oil pump (Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP -

REMOVAL).

9. Oil pick up tube loose, damaged

or clogged.9. Replace as necessary.

OIL PUMPING AT RINGS;

SPARK PLUGS FOULING1. Worn or damaged rings. 1. Hone cylinder bores and replace

rings.

2. Carbon in oil ring slots. 2. Replace rings (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON

RINGS - STANDARD PROCEDURE).

3. Incorrect ring size installed. 3. Replace rings (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON

RINGS - STANDARD PROCEDURE).

4. Worn valve guides. 4. Ream guides and replace valves

(Refer to 9 - ENGINE/CYLINDER

HEAD/INTAKE/EXHAUST VALVES &

SEATS - STANDARD PROCEDURE).

5. Leaking valve guide seals. 5. Replace valve guide seals.

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Clean the spark plug recesses with compressed

air.

(2) Remove the spark plugs.

(3) Secure the throttle in the wide-open position.(4) Disable the fuel system (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - DESCRIPTION).

(5) Remove the ASD relay (Refer to 8 - ELECTRI-

CAL/IGNITION CONTROL/AUTO SHUT DOWN

RELAY - REMOVAL).

(6) Insert a compression pressure gauge and rotate

the engine with the engine starter motor for three

revolutions.

(7) Record the compression pressure on the 3rd

revolution. Continue the test for the remaining cylin-

ders.

(8) (Refer to 9 - ENGINE - SPECIFICATIONS) for

the correct engine compression pressures.

9 - 68 ENGINE - 4.7LWJ

ENGINE - 4.7L (Continued)

Page 1312 of 2199

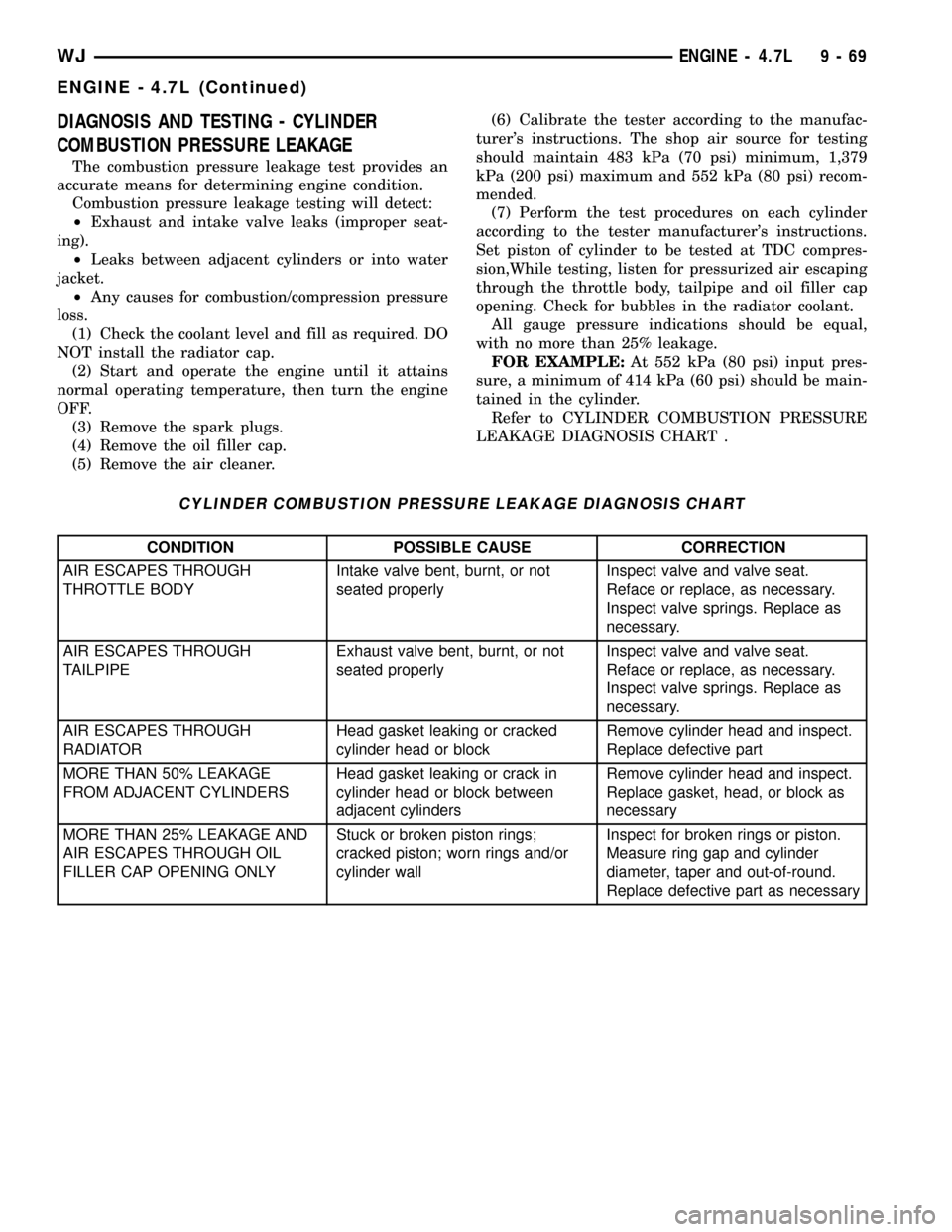

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

(1) Check the coolant level and fill as required. DO

NOT install the radiator cap.

(2) Start and operate the engine until it attains

normal operating temperature, then turn the engine

OFF.

(3) Remove the spark plugs.

(4) Remove the oil filler cap.

(5) Remove the air cleaner.(6) Calibrate the tester according to the manufac-

turer's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.

(7) Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

Set piston of cylinder to be tested at TDC compres-

sion,While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

Refer to CYLINDER COMBUSTION PRESSURE

LEAKAGE DIAGNOSIS CHART .

CYLINDER COMBUSTION PRESSURE LEAKAGE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

AIR ESCAPES THROUGH

THROTTLE BODYIntake valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

TAILPIPEExhaust valve bent, burnt, or not

seated properlyInspect valve and valve seat.

Reface or replace, as necessary.

Inspect valve springs. Replace as

necessary.

AIR ESCAPES THROUGH

RADIATORHead gasket leaking or cracked

cylinder head or blockRemove cylinder head and inspect.

Replace defective part

MORE THAN 50% LEAKAGE

FROM ADJACENT CYLINDERSHead gasket leaking or crack in

cylinder head or block between

adjacent cylindersRemove cylinder head and inspect.

Replace gasket, head, or block as

necessary

MORE THAN 25% LEAKAGE AND

AIR ESCAPES THROUGH OIL

FILLER CAP OPENING ONLYStuck or broken piston rings;

cracked piston; worn rings and/or

cylinder wallInspect for broken rings or piston.

Measure ring gap and cylinder

diameter, taper and out-of-round.

Replace defective part as necessary

WJENGINE - 4.7L 9 - 69

ENGINE - 4.7L (Continued)

Page 1315 of 2199

(13) Disconnect the engine block heater power

cable from the block heater.

(14) Lower vehicle.

(15) Remove throttle body resonator assembly and

inlet hose.

(16) Disconnect throttle and speed control cables.

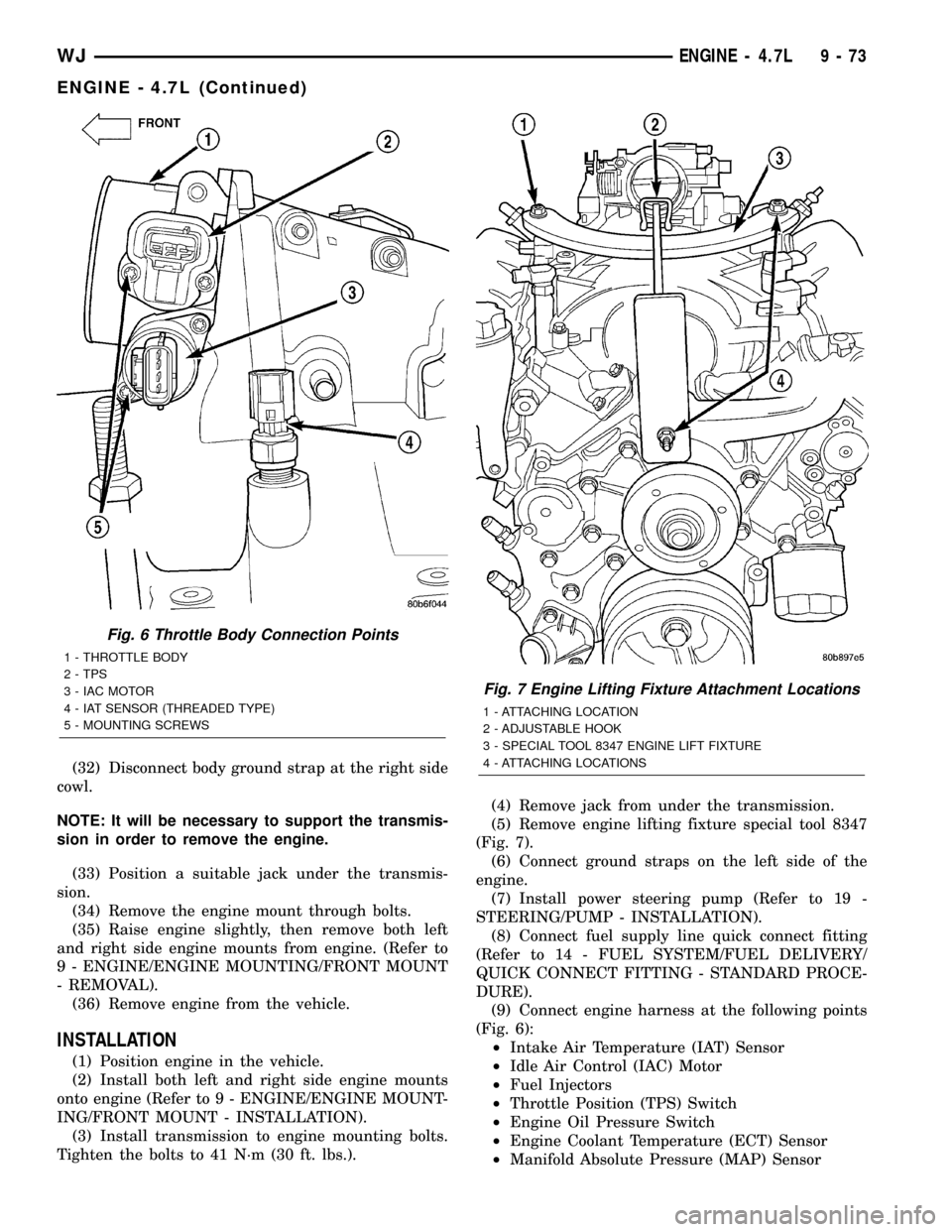

(17) Disconnect tube from both the left and right

side crankcase breathers, then remove the breathers

(Fig. 5).

(18) Discharge A/C system (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - STAN-

DARD PROCEDURE).(19) Remove radiator fan (Refer to 7 - COOLING/

ENGINE/RADIATOR FAN - REMOVAL) and acces-

sory drive belt (Refer to 7 - COOLING/ACCESSORY

DRIVE/DRIVE BELTS - REMOVAL).

(20) Remove A/C compressor (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C COM-

PRESSOR - REMOVAL).

(21) Disconnect transmission oil cooler lines at the

radiator.

(22) Disconnect radiator lower hose at the thermo-

stat housing.

(23) Remove A/C condenser (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/A/C CON-

DENSER - REMOVAL).

(24) Remove radiator (Refer to 7 - COOLING/EN-

GINE/RADIATOR - REMOVAL).

(25) Remove generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - REMOVAL).

(26) Disconnect the two heater hoses from the tim-

ing chain cover.

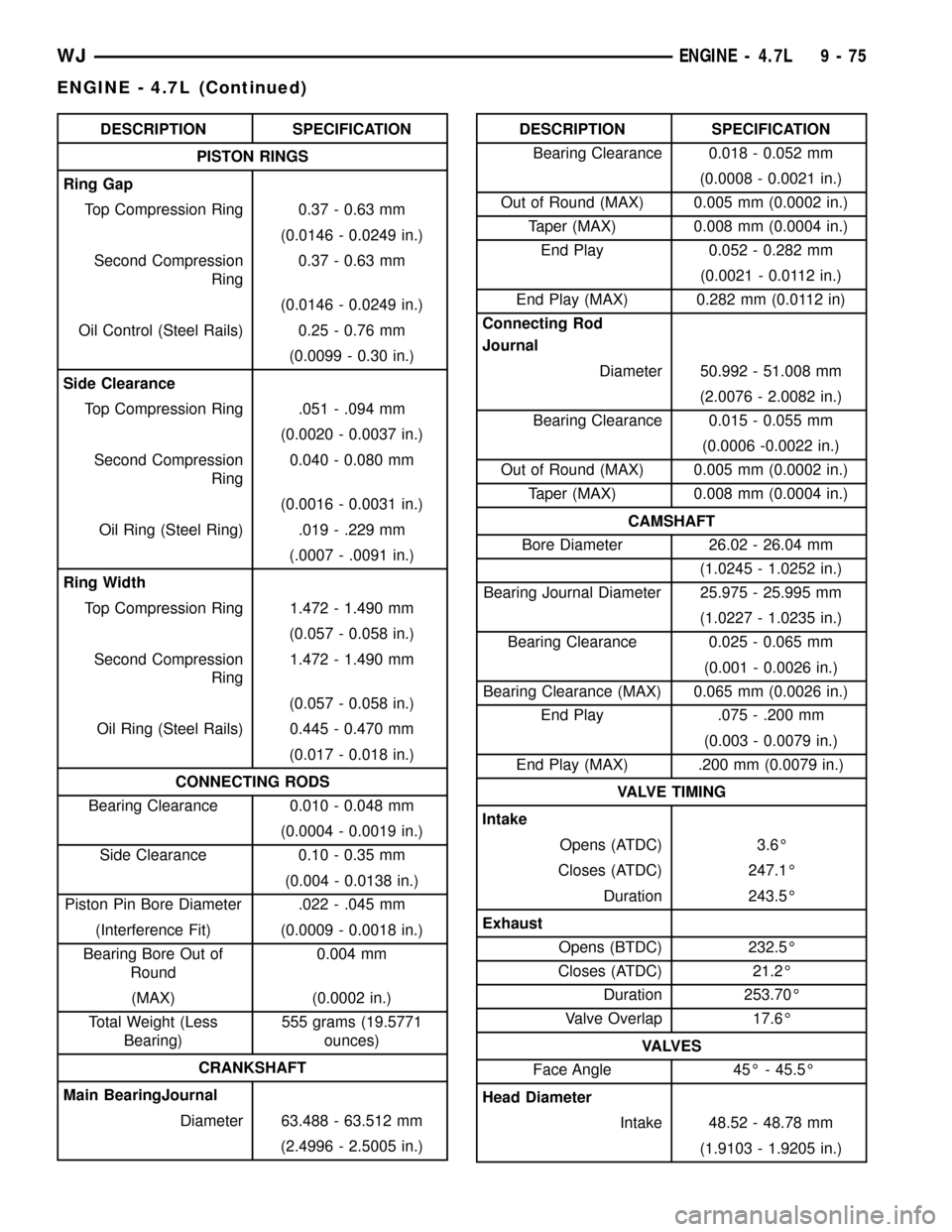

(27) Disconnect engine harness at the following

points :

²Intake air temperature (IAT) sensor (Fig. 6)

²Fuel Injectors

²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold absolute pressure (MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

(28) Release fuel rail pressure (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - STANDARD PROCE-

DURE) then disconnect the fuel supply quick connect

fitting at the fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/QUICK CONNECT FITTING -

STANDARD PROCEDURE).

(29) Remove power steering pump and position out

of the way.

(30) Disconnect ground straps from the left side of

the engine.

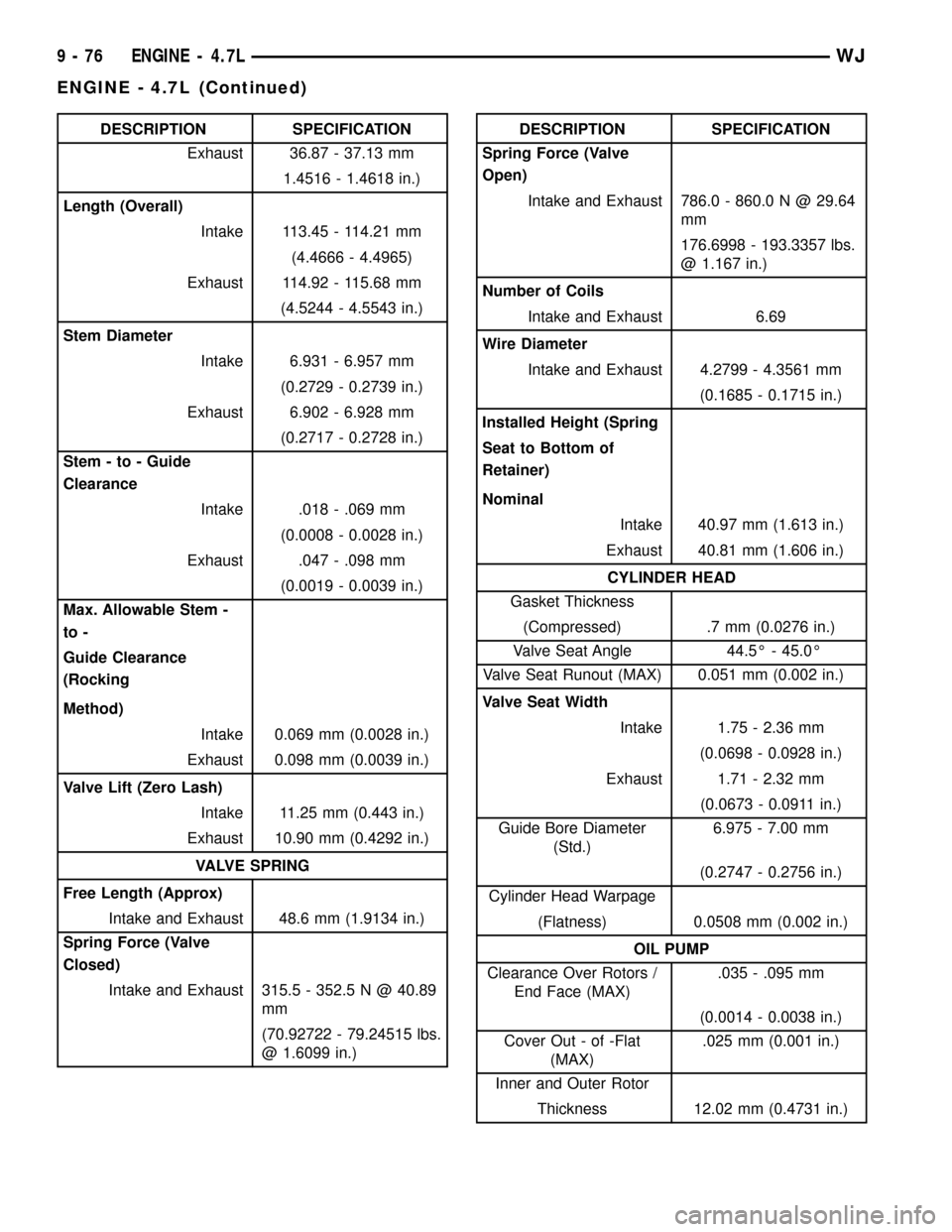

(31) Install Engine Lifting Fixture Special Tool

8347 (Fig. 7)following these steps.

²Holding the lifting fixture at a slight angle, slide

the large bore in the front plate over the hex portion

of the lifting stud.

²Position the two remaining fixture arms onto

the two lifting studs in the cylinder heads.

²Pull foward and upward on the lifting fixture so

that the lifting stud rest in the slotted area below the

large bore.

²Secure the lifting fixture to the three studs

using three 7/16 ± 14 N/C locknuts.

²Make sure the lifting loop in the lifting fixture is

in the last hole (closest to the throttle body) to min-

imize the angle of engine during removal.

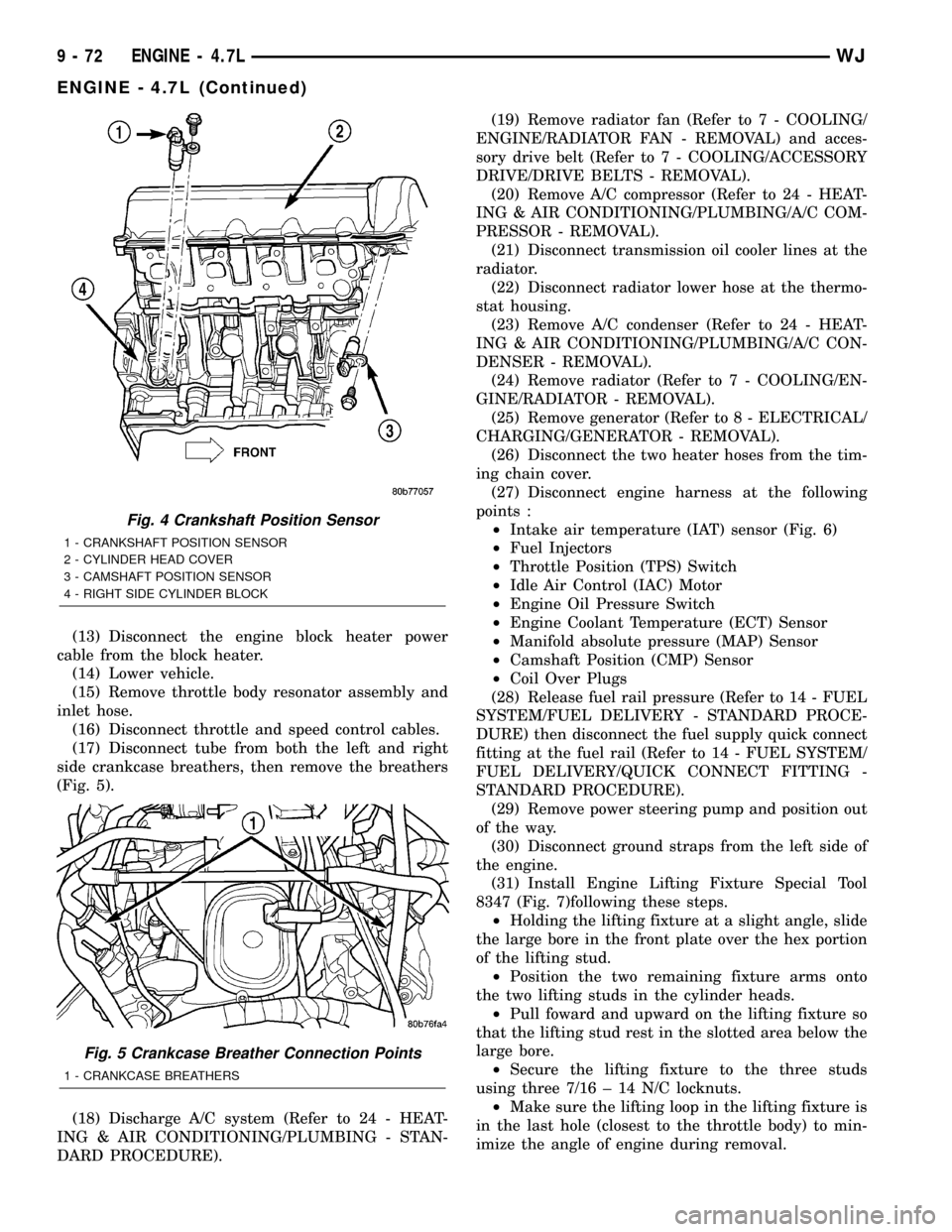

Fig. 4 Crankshaft Position Sensor

1 - CRANKSHAFT POSITION SENSOR

2 - CYLINDER HEAD COVER

3 - CAMSHAFT POSITION SENSOR

4 - RIGHT SIDE CYLINDER BLOCK

Fig. 5 Crankcase Breather Connection Points

1 - CRANKCASE BREATHERS

9 - 72 ENGINE - 4.7LWJ

ENGINE - 4.7L (Continued)

Page 1316 of 2199

(32) Disconnect body ground strap at the right side

cowl.

NOTE: It will be necessary to support the transmis-

sion in order to remove the engine.

(33) Position a suitable jack under the transmis-

sion.

(34) Remove the engine mount through bolts.

(35) Raise engine slightly, then remove both left

and right side engine mounts from engine. (Refer to

9 - ENGINE/ENGINE MOUNTING/FRONT MOUNT

- REMOVAL).

(36) Remove engine from the vehicle.

INSTALLATION

(1) Position engine in the vehicle.

(2) Install both left and right side engine mounts

onto engine (Refer to 9 - ENGINE/ENGINE MOUNT-

ING/FRONT MOUNT - INSTALLATION).

(3) Install transmission to engine mounting bolts.

Tighten the bolts to 41 N´m (30 ft. lbs.).(4) Remove jack from under the transmission.

(5) Remove engine lifting fixture special tool 8347

(Fig. 7).

(6) Connect ground straps on the left side of the

engine.

(7) Install power steering pump (Refer to 19 -

STEERING/PUMP - INSTALLATION).

(8) Connect fuel supply line quick connect fitting

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY/

QUICK CONNECT FITTING - STANDARD PROCE-

DURE).

(9) Connect engine harness at the following points

(Fig. 6):

²Intake Air Temperature (IAT) Sensor

²Idle Air Control (IAC) Motor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure (MAP) Sensor

Fig. 6 Throttle Body Connection Points

1 - THROTTLE BODY

2 - TPS

3 - IAC MOTOR

4 - IAT SENSOR (THREADED TYPE)

5 - MOUNTING SCREWS

Fig. 7 Engine Lifting Fixture Attachment Locations

1 - ATTACHING LOCATION

2 - ADJUSTABLE HOOK

3 - SPECIAL TOOL 8347 ENGINE LIFT FIXTURE

4 - ATTACHING LOCATIONS

WJENGINE - 4.7L 9 - 73

ENGINE - 4.7L (Continued)

Page 1318 of 2199

DESCRIPTION SPECIFICATION

PISTON RINGS

Ring Gap

Top Compression Ring 0.37 - 0.63 mm

(0.0146 - 0.0249 in.)

Second Compression

Ring0.37 - 0.63 mm

(0.0146 - 0.0249 in.)

Oil Control (Steel Rails) 0.25 - 0.76 mm

(0.0099 - 0.30 in.)

Side Clearance

Top Compression Ring .051 - .094 mm

(0.0020 - 0.0037 in.)

Second Compression

Ring0.040 - 0.080 mm

(0.0016 - 0.0031 in.)

Oil Ring (Steel Ring) .019 - .229 mm

(.0007 - .0091 in.)

Ring Width

Top Compression Ring 1.472 - 1.490 mm

(0.057 - 0.058 in.)

Second Compression

Ring1.472 - 1.490 mm

(0.057 - 0.058 in.)

Oil Ring (Steel Rails) 0.445 - 0.470 mm

(0.017 - 0.018 in.)

CONNECTING RODS

Bearing Clearance 0.010 - 0.048 mm

(0.0004 - 0.0019 in.)

Side Clearance 0.10 - 0.35 mm

(0.004 - 0.0138 in.)

Piston Pin Bore Diameter .022 - .045 mm

(Interference Fit) (0.0009 - 0.0018 in.)

Bearing Bore Out of

Round0.004 mm

(MAX) (0.0002 in.)

Total Weight (Less

Bearing)555 grams (19.5771

ounces)

CRANKSHAFT

Main BearingJournal

Diameter 63.488 - 63.512 mm

(2.4996 - 2.5005 in.)DESCRIPTION SPECIFICATION

Bearing Clearance 0.018 - 0.052 mm

(0.0008 - 0.0021 in.)

Out of Round (MAX) 0.005 mm (0.0002 in.)

Taper (MAX) 0.008 mm (0.0004 in.)

End Play 0.052 - 0.282 mm

(0.0021 - 0.0112 in.)

End Play (MAX) 0.282 mm (0.0112 in)

Connecting Rod

Journal

Diameter 50.992 - 51.008 mm

(2.0076 - 2.0082 in.)

Bearing Clearance 0.015 - 0.055 mm

(0.0006 -0.0022 in.)

Out of Round (MAX) 0.005 mm (0.0002 in.)

Taper (MAX) 0.008 mm (0.0004 in.)

CAMSHAFT

Bore Diameter 26.02 - 26.04 mm

(1.0245 - 1.0252 in.)

Bearing Journal Diameter 25.975 - 25.995 mm

(1.0227 - 1.0235 in.)

Bearing Clearance 0.025 - 0.065 mm

(0.001 - 0.0026 in.)

Bearing Clearance (MAX) 0.065 mm (0.0026 in.)

End Play .075 - .200 mm

(0.003 - 0.0079 in.)

End Play (MAX) .200 mm (0.0079 in.)

VALVE TIMING

Intake

Opens (ATDC) 3.6É

Closes (ATDC) 247.1É

Duration 243.5É

Exhaust

Opens (BTDC) 232.5É

Closes (ATDC) 21.2É

Duration 253.70É

Valve Overlap 17.6É

VA LV E S

Face Angle 45É - 45.5É

Head Diameter

Intake 48.52 - 48.78 mm

(1.9103 - 1.9205 in.)

WJENGINE - 4.7L 9 - 75

ENGINE - 4.7L (Continued)

Page 1319 of 2199

DESCRIPTION SPECIFICATION

Exhaust 36.87 - 37.13 mm

1.4516 - 1.4618 in.)

Length (Overall)

Intake 113.45 - 114.21 mm

(4.4666 - 4.4965)

Exhaust 114.92 - 115.68 mm

(4.5244 - 4.5543 in.)

Stem Diameter

Intake 6.931 - 6.957 mm

(0.2729 - 0.2739 in.)

Exhaust 6.902 - 6.928 mm

(0.2717 - 0.2728 in.)

Stem - to - Guide

Clearance

Intake .018 - .069 mm

(0.0008 - 0.0028 in.)

Exhaust .047 - .098 mm

(0.0019 - 0.0039 in.)

Max. Allowable Stem -

to -

Guide Clearance

(Rocking

Method)

Intake 0.069 mm (0.0028 in.)

Exhaust 0.098 mm (0.0039 in.)

Valve Lift (Zero Lash)

Intake 11.25 mm (0.443 in.)

Exhaust 10.90 mm (0.4292 in.)

VALVE SPRING

Free Length (Approx)

Intake and Exhaust 48.6 mm (1.9134 in.)

Spring Force (Valve

Closed)

Intake and Exhaust 315.5 - 352.5 N @ 40.89

mm

(70.92722 - 79.24515 lbs.

@ 1.6099 in.)DESCRIPTION SPECIFICATION

Spring Force (Valve

Open)

Intake and Exhaust 786.0 - 860.0 N @ 29.64

mm

176.6998 - 193.3357 lbs.

@ 1.167 in.)

Number of Coils

Intake and Exhaust 6.69

Wire Diameter

Intake and Exhaust 4.2799 - 4.3561 mm

(0.1685 - 0.1715 in.)

Installed Height (Spring

Seat to Bottom of

Retainer)

Nominal

Intake 40.97 mm (1.613 in.)

Exhaust 40.81 mm (1.606 in.)

CYLINDER HEAD

Gasket Thickness

(Compressed) .7 mm (0.0276 in.)

Valve Seat Angle 44.5É - 45.0É

Valve Seat Runout (MAX) 0.051 mm (0.002 in.)

Valve Seat Width

Intake 1.75 - 2.36 mm

(0.0698 - 0.0928 in.)

Exhaust 1.71 - 2.32 mm

(0.0673 - 0.0911 in.)

Guide Bore Diameter

(Std.)6.975 - 7.00 mm

(0.2747 - 0.2756 in.)

Cylinder Head Warpage

(Flatness) 0.0508 mm (0.002 in.)

OIL PUMP

Clearance Over Rotors /

End Face (MAX).035 - .095 mm

(0.0014 - 0.0038 in.)

Cover Out - of -Flat

(MAX).025 mm (0.001 in.)

Inner and Outer Rotor

Thickness 12.02 mm (0.4731 in.)

9 - 76 ENGINE - 4.7LWJ

ENGINE - 4.7L (Continued)

Page 1321 of 2199

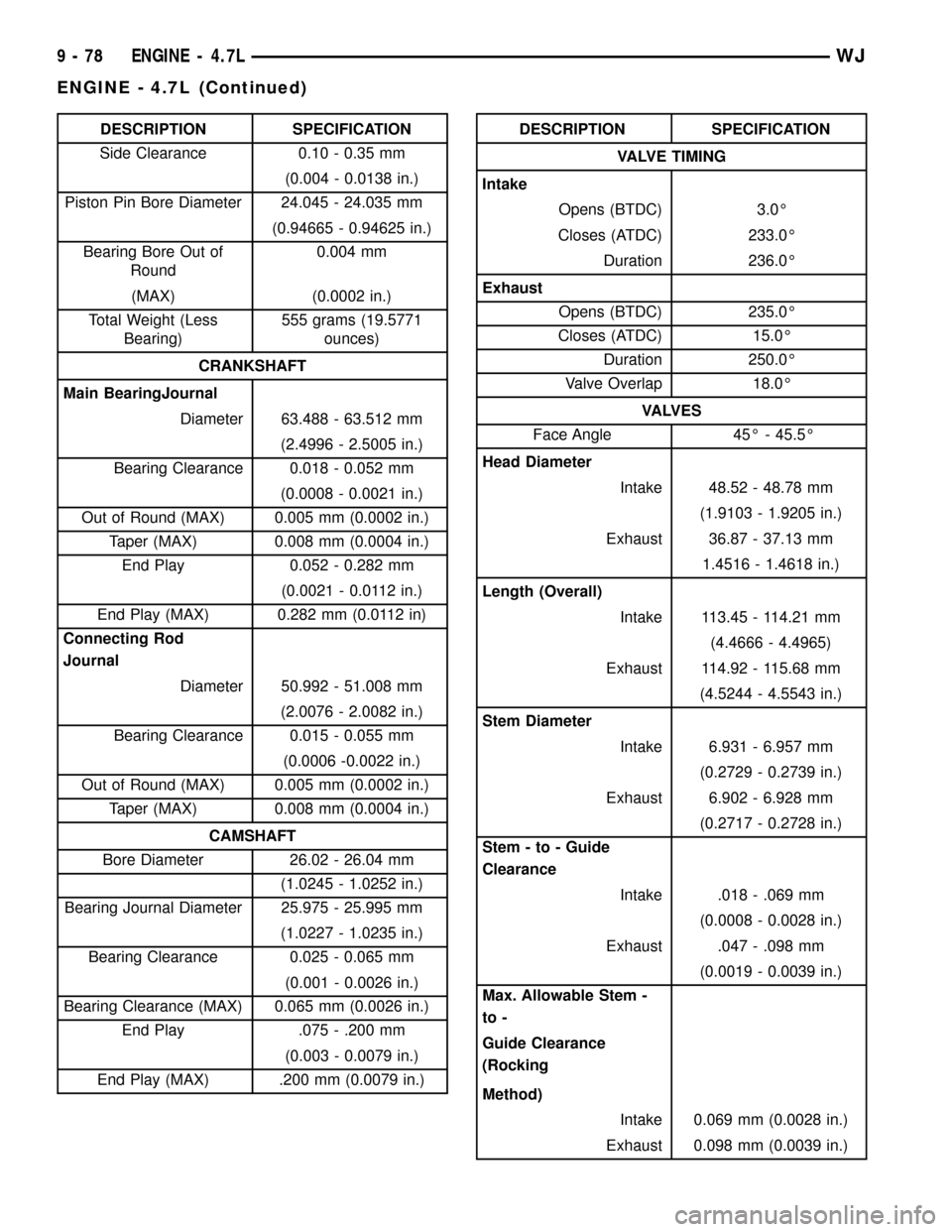

DESCRIPTION SPECIFICATION

Side Clearance 0.10 - 0.35 mm

(0.004 - 0.0138 in.)

Piston Pin Bore Diameter 24.045 - 24.035 mm

(0.94665 - 0.94625 in.)

Bearing Bore Out of

Round0.004 mm

(MAX) (0.0002 in.)

Total Weight (Less

Bearing)555 grams (19.5771

ounces)

CRANKSHAFT

Main BearingJournal

Diameter 63.488 - 63.512 mm

(2.4996 - 2.5005 in.)

Bearing Clearance 0.018 - 0.052 mm

(0.0008 - 0.0021 in.)

Out of Round (MAX) 0.005 mm (0.0002 in.)

Taper (MAX) 0.008 mm (0.0004 in.)

End Play 0.052 - 0.282 mm

(0.0021 - 0.0112 in.)

End Play (MAX) 0.282 mm (0.0112 in)

Connecting Rod

Journal

Diameter 50.992 - 51.008 mm

(2.0076 - 2.0082 in.)

Bearing Clearance 0.015 - 0.055 mm

(0.0006 -0.0022 in.)

Out of Round (MAX) 0.005 mm (0.0002 in.)

Taper (MAX) 0.008 mm (0.0004 in.)

CAMSHAFT

Bore Diameter 26.02 - 26.04 mm

(1.0245 - 1.0252 in.)

Bearing Journal Diameter 25.975 - 25.995 mm

(1.0227 - 1.0235 in.)

Bearing Clearance 0.025 - 0.065 mm

(0.001 - 0.0026 in.)

Bearing Clearance (MAX) 0.065 mm (0.0026 in.)

End Play .075 - .200 mm

(0.003 - 0.0079 in.)

End Play (MAX) .200 mm (0.0079 in.)DESCRIPTION SPECIFICATION

VALVE TIMING

Intake

Opens (BTDC) 3.0É

Closes (ATDC) 233.0É

Duration 236.0É

Exhaust

Opens (BTDC) 235.0É

Closes (ATDC) 15.0É

Duration 250.0É

Valve Overlap 18.0É

VA LV E S

Face Angle 45É - 45.5É

Head Diameter

Intake 48.52 - 48.78 mm

(1.9103 - 1.9205 in.)

Exhaust 36.87 - 37.13 mm

1.4516 - 1.4618 in.)

Length (Overall)

Intake 113.45 - 114.21 mm

(4.4666 - 4.4965)

Exhaust 114.92 - 115.68 mm

(4.5244 - 4.5543 in.)

Stem Diameter

Intake 6.931 - 6.957 mm

(0.2729 - 0.2739 in.)

Exhaust 6.902 - 6.928 mm

(0.2717 - 0.2728 in.)

Stem - to - Guide

Clearance

Intake .018 - .069 mm

(0.0008 - 0.0028 in.)

Exhaust .047 - .098 mm

(0.0019 - 0.0039 in.)

Max. Allowable Stem -

to -

Guide Clearance

(Rocking

Method)

Intake 0.069 mm (0.0028 in.)

Exhaust 0.098 mm (0.0039 in.)

9 - 78 ENGINE - 4.7LWJ

ENGINE - 4.7L (Continued)

Page 1322 of 2199

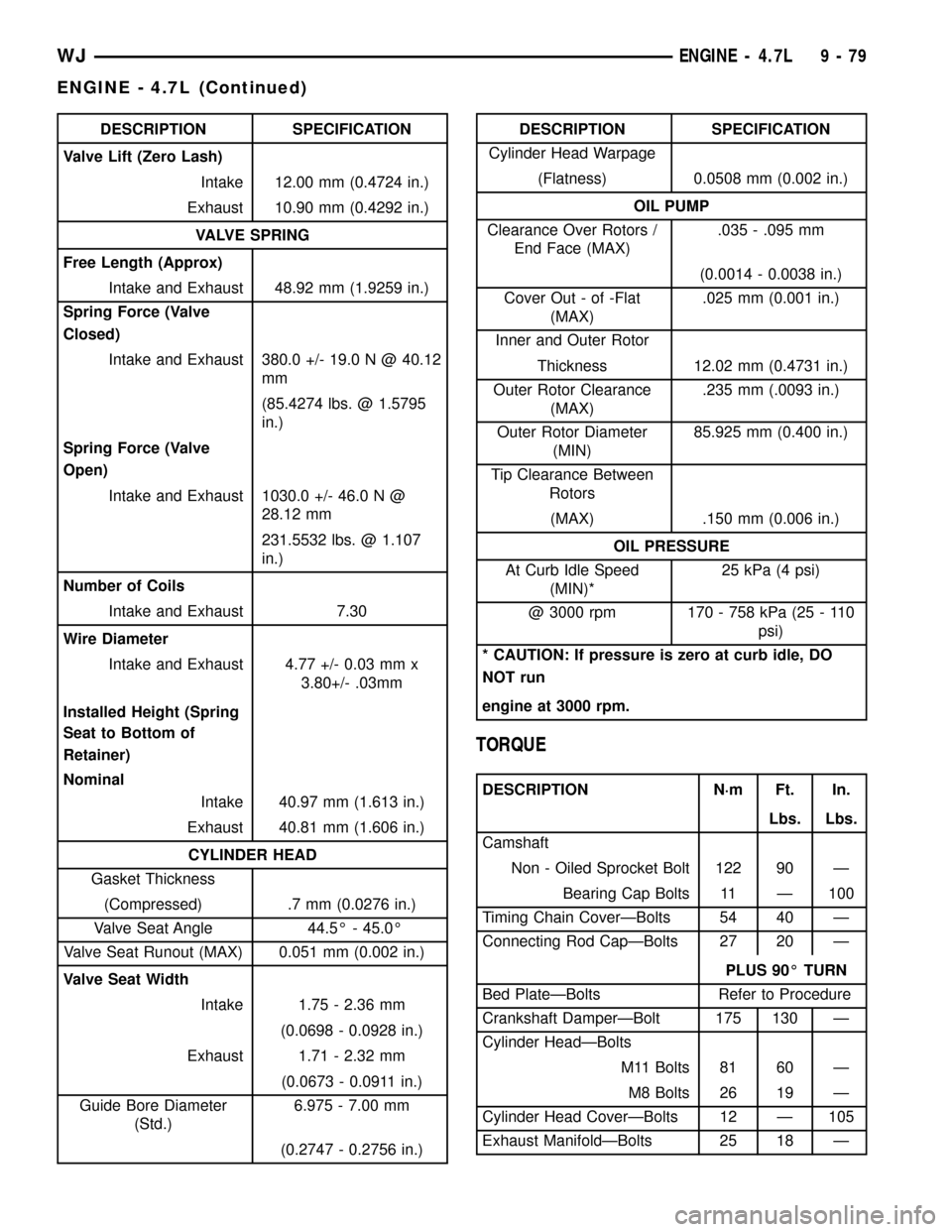

DESCRIPTION SPECIFICATION

Valve Lift (Zero Lash)

Intake 12.00 mm (0.4724 in.)

Exhaust 10.90 mm (0.4292 in.)

VALVE SPRING

Free Length (Approx)

Intake and Exhaust 48.92 mm (1.9259 in.)

Spring Force (Valve

Closed)

Intake and Exhaust 380.0 +/- 19.0 N @ 40.12

mm

(85.4274 lbs. @ 1.5795

in.)

Spring Force (Valve

Open)

Intake and Exhaust 1030.0 +/- 46.0 N @

28.12 mm

231.5532 lbs. @ 1.107

in.)

Number of Coils

Intake and Exhaust 7.30

Wire Diameter

Intake and Exhaust 4.77 +/- 0.03 mm x

3.80+/- .03mm

Installed Height (Spring

Seat to Bottom of

Retainer)

Nominal

Intake 40.97 mm (1.613 in.)

Exhaust 40.81 mm (1.606 in.)

CYLINDER HEAD

Gasket Thickness

(Compressed) .7 mm (0.0276 in.)

Valve Seat Angle 44.5É - 45.0É

Valve Seat Runout (MAX) 0.051 mm (0.002 in.)

Valve Seat Width

Intake 1.75 - 2.36 mm

(0.0698 - 0.0928 in.)

Exhaust 1.71 - 2.32 mm

(0.0673 - 0.0911 in.)

Guide Bore Diameter

(Std.)6.975 - 7.00 mm

(0.2747 - 0.2756 in.)DESCRIPTION SPECIFICATION

Cylinder Head Warpage

(Flatness) 0.0508 mm (0.002 in.)

OIL PUMP

Clearance Over Rotors /

End Face (MAX).035 - .095 mm

(0.0014 - 0.0038 in.)

Cover Out - of -Flat

(MAX).025 mm (0.001 in.)

Inner and Outer Rotor

Thickness 12.02 mm (0.4731 in.)

Outer Rotor Clearance

(MAX).235 mm (.0093 in.)

Outer Rotor Diameter

(MIN)85.925 mm (0.400 in.)

Tip Clearance Between

Rotors

(MAX) .150 mm (0.006 in.)

OIL PRESSURE

At Curb Idle Speed

(MIN)*25 kPa (4 psi)

@ 3000 rpm 170 - 758 kPa (25 - 110

psi)

* CAUTION: If pressure is zero at curb idle, DO

NOT run

engine at 3000 rpm.

TORQUE

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Camshaft

Non - Oiled Sprocket Bolt 122 90 Ð

Bearing Cap Bolts 11 Ð 100

Timing Chain CoverÐBolts 54 40 Ð

Connecting Rod CapÐBolts 27 20 Ð

PLUS 90É TURN

Bed PlateÐBolts Refer to Procedure

Crankshaft DamperÐBolt 175 130 Ð

Cylinder HeadÐBolts

M11 Bolts 81 60 Ð

M8 Bolts 26 19 Ð

Cylinder Head CoverÐBolts 12 Ð 105

Exhaust ManifoldÐBolts 25 18 Ð

WJENGINE - 4.7L 9 - 79

ENGINE - 4.7L (Continued)