Fuel JEEP GRAND CHEROKEE 2002 WJ / 2.G Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1261 of 2199

DESCRIPTION N´m Ft. In.

Lbs. Lbs.

Transmission Support Bracket

ÐBolt (Manual) 46 34 Ð

Transmission Support Bracket/

CushionÐBolt (4WD Auto) 75 55 Ð

Transmission Support Adaptor

BracketÐBolts (2WD Auto) 75 55 Ð

Exhaust Manifold/PipeÐNuts 27 20 Ð

Intake/Exhaust Manifold

Fasteners #1-5 33 24 Ð

Fasteners #6 and 7 14 Ð 126

Fasteners #8-11 33 24 Ð

Flywheel to Converter

HousingÐBolts38 28 Ð

Flywheel to CrankshaftÐBolts 143 105 Ð

Front Cover to BlockÐBolts

1/4-20 7 Ð 60

5/16-18 22 Ð 192

Fuel RailÐBolts/Stud 12 Ð 108

GeneratorÐBolts 57 42 Ð

Generator Bracket to EngineÐ

Bolts47 35 Ð

Idler Pulley to Cylinder

HeadÐBolt47 35 Ð

Main Bearing CapÐBolts 108 80 Ð

Oil Filter 18 Ð 156

Oil Filter Connector to

Adaptor 47 35 Ð

Block 68 50 Ð

Adaptor Bolts 102 50 Ð

Oil GalleyÐPlug 41 30 Ð

Oil PanÐBolts

1/4-20 9.5 Ð 84

5/16-18 15 Ð 132

Oil PanÐDrain Plug 34 25 Ð

Oil Pump

Mounting Bolts 23 Ð 204

Cover Bolts 8 Ð 70

Rocker Arm Assembly to

Cylinder

HeadÐCapscrews 30 21 Ð

Spark Plugs 37 27 ÐDESCRIPTION N´m Ft. In.

Lbs. Lbs.

Starter MotorÐMounting Bolts 45 33 Ð

Thermostat HousingÐBolts 18 Ð 156

Throttle BodyÐBolts 10 Ð 90

Vibration DamperÐBolt 108 80 Ð

Water Pump to BlockÐBolts 23 17 Ð

AIR CLEANER ELEMENT

REMOVAL - 4.0L

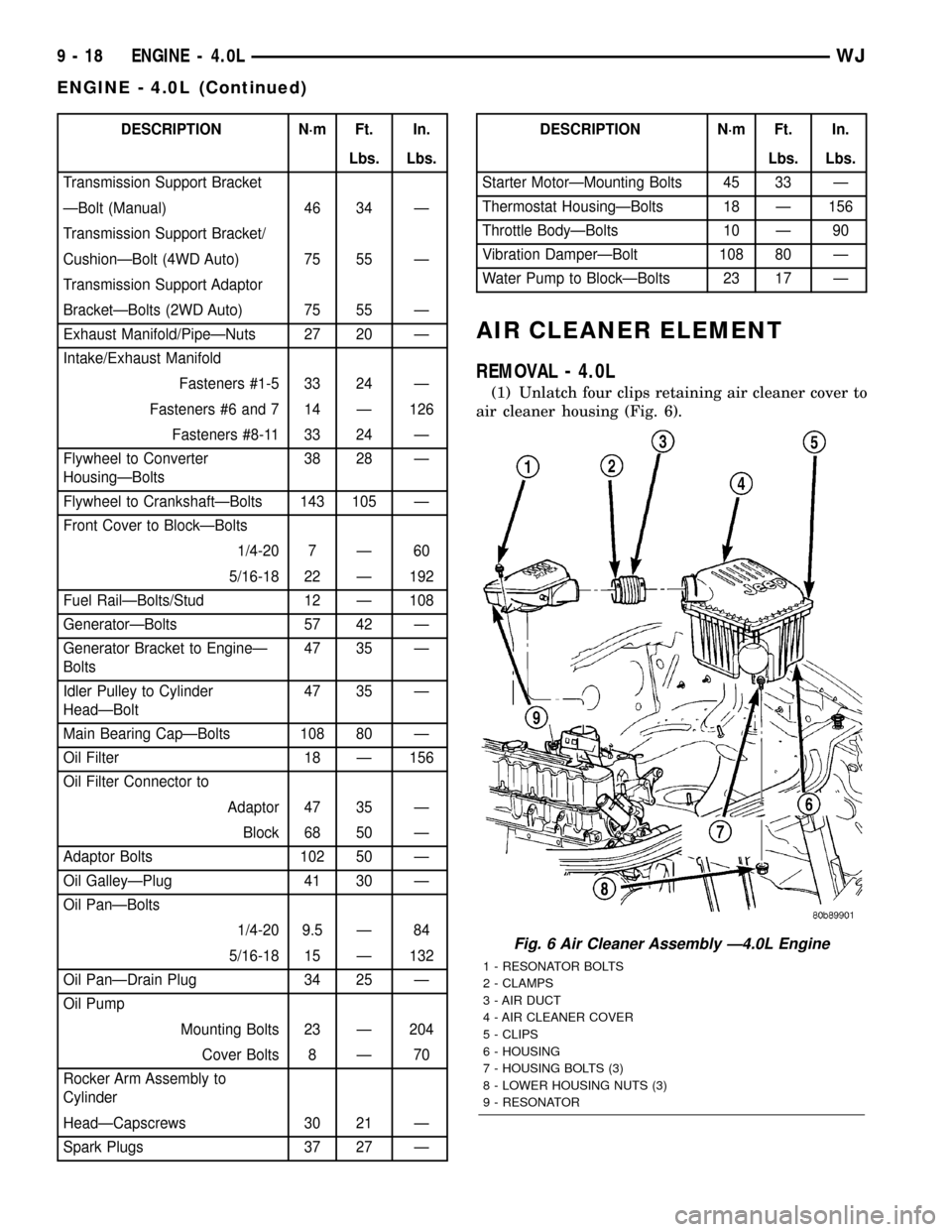

(1) Unlatch four clips retaining air cleaner cover to

air cleaner housing (Fig. 6).

Fig. 6 Air Cleaner Assembly Ð4.0L Engine

1 - RESONATOR BOLTS

2 - CLAMPS

3 - AIR DUCT

4 - AIR CLEANER COVER

5 - CLIPS

6 - HOUSING

7 - HOUSING BOLTS (3)

8 - LOWER HOUSING NUTS (3)

9 - RESONATOR

9 - 18 ENGINE - 4.0LWJ

ENGINE - 4.0L (Continued)

Page 1262 of 2199

(2) Lift cover up and position to the side.

(3) Remove air cleaner element.

INSTALLATION - 4.0L

(1) Clean inside of air cleaner housing before

installing new element.

(2) Install air cleaner element into housing.

(3) Latch clips and clamp cover down to secure. Be

sure air cleaner cover is properly seated to air

cleaner housing.

AIR CLEANER HOUSING

REMOVAL - 4.0L

(1) Disconnect air cleaner cover-to-air duct clamp

(Fig. 6).

(2) Disconnect air duct at housing.

(3)Each of the 3 air cleaner housing mount-

ing bolts is attached with 2 nuts (an upper nut

and lower nut). DO NOT REMOVE BOLTS. To

prevent stripping bolts, only remove lower

nuts. The lower housing nuts are located under

left front inner fender (Fig. 6).

(a) To gain access to lower nuts, raise vehicle.

(b) Remove clips retaining rubber inner fender

shield.

(c) Pry back shield enough to gain access to

lower nuts.

(d) Remove 3 nuts.

(e) Remove air cleaner assembly from vehicle.

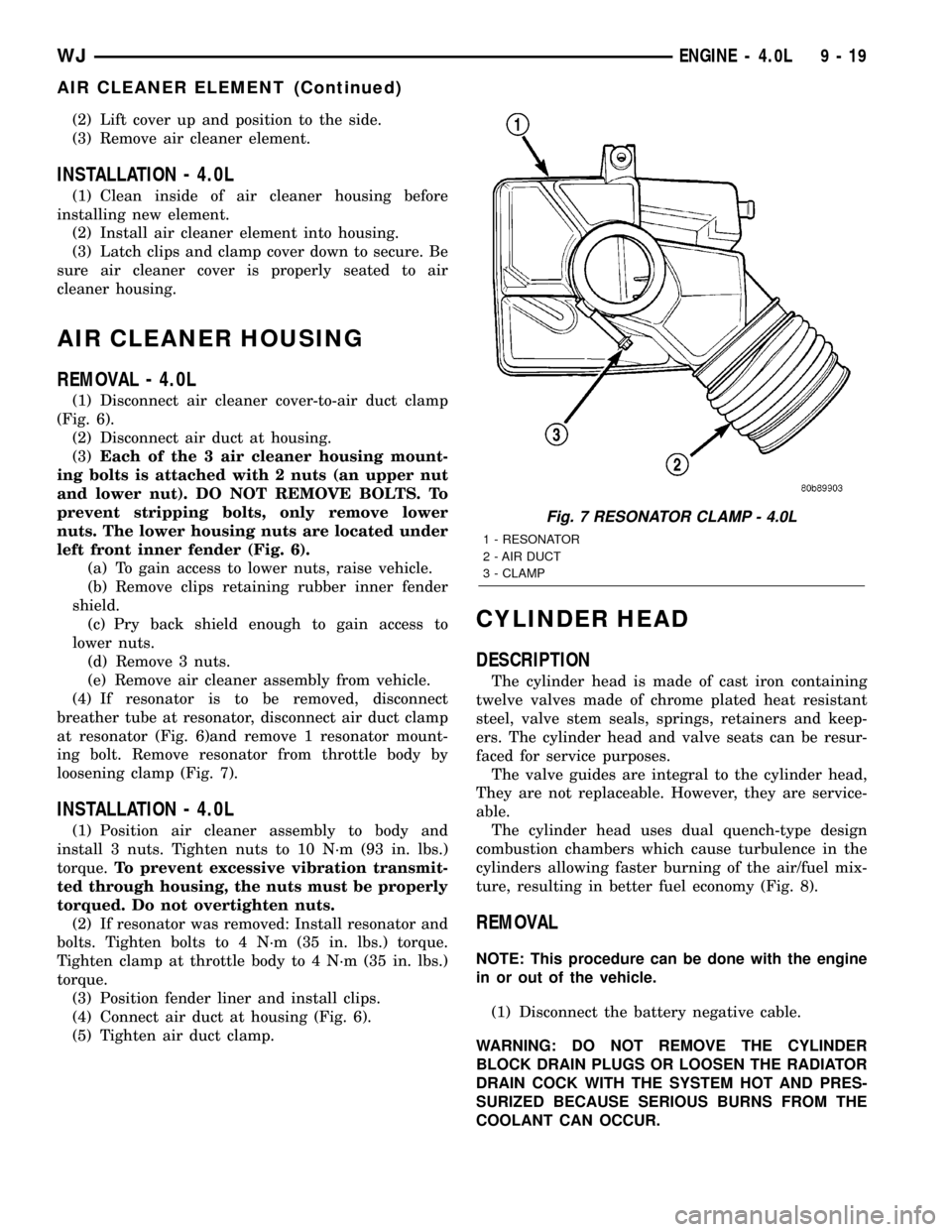

(4) If resonator is to be removed, disconnect

breather tube at resonator, disconnect air duct clamp

at resonator (Fig. 6)and remove 1 resonator mount-

ing bolt. Remove resonator from throttle body by

loosening clamp (Fig. 7).

INSTALLATION - 4.0L

(1) Position air cleaner assembly to body and

install 3 nuts. Tighten nuts to 10 N´m (93 in. lbs.)

torque.To prevent excessive vibration transmit-

ted through housing, the nuts must be properly

torqued. Do not overtighten nuts.

(2) If resonator was removed: Install resonator and

bolts. Tighten bolts to 4 N´m (35 in. lbs.) torque.

Tighten clamp at throttle body to 4 N´m (35 in. lbs.)

torque.

(3) Position fender liner and install clips.

(4) Connect air duct at housing (Fig. 6).

(5) Tighten air duct clamp.

CYLINDER HEAD

DESCRIPTION

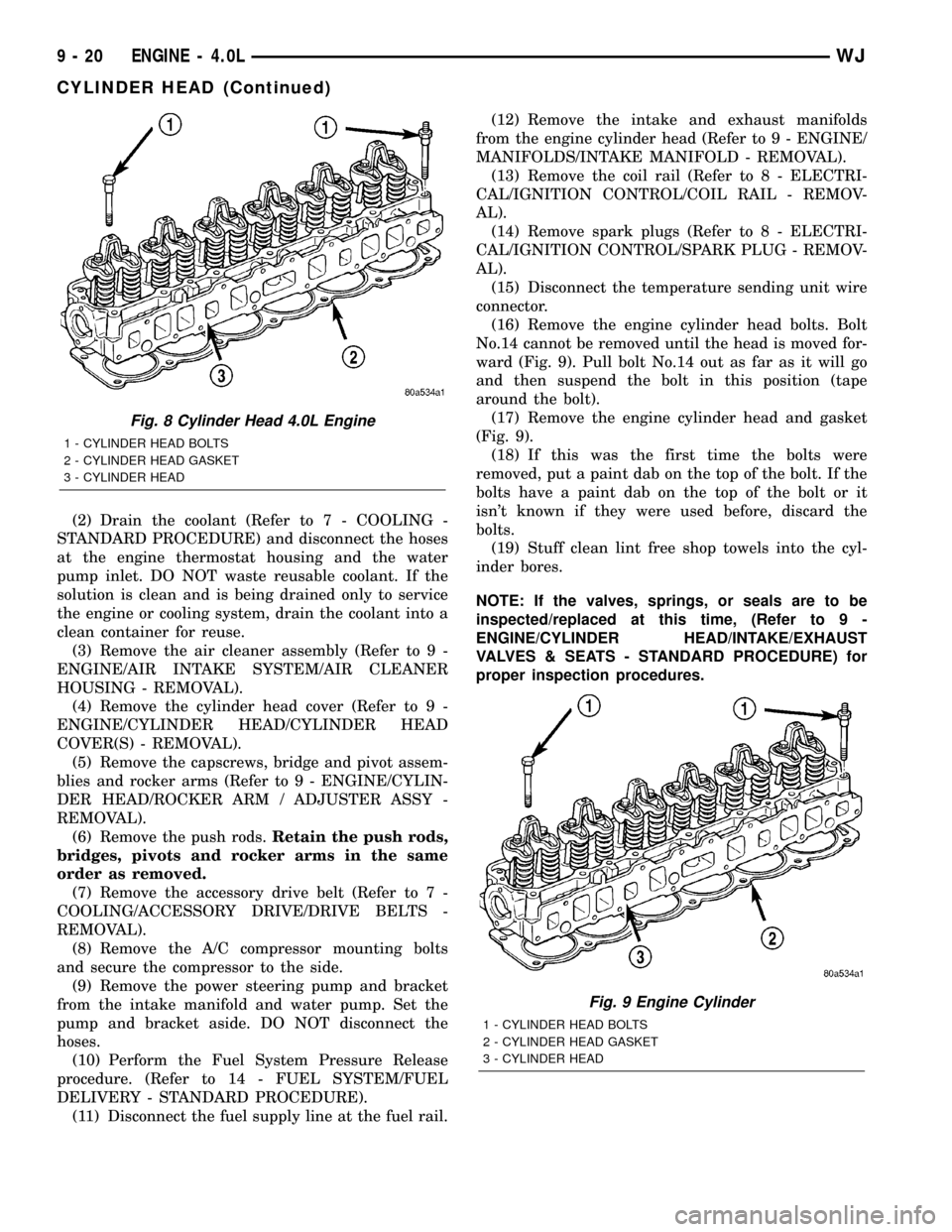

The cylinder head is made of cast iron containing

twelve valves made of chrome plated heat resistant

steel, valve stem seals, springs, retainers and keep-

ers. The cylinder head and valve seats can be resur-

faced for service purposes.

The valve guides are integral to the cylinder head,

They are not replaceable. However, they are service-

able.

The cylinder head uses dual quench-type design

combustion chambers which cause turbulence in the

cylinders allowing faster burning of the air/fuel mix-

ture, resulting in better fuel economy (Fig. 8).

REMOVAL

NOTE: This procedure can be done with the engine

in or out of the vehicle.

(1) Disconnect the battery negative cable.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAIN COCK WITH THE SYSTEM HOT AND PRES-

SURIZED BECAUSE SERIOUS BURNS FROM THE

COOLANT CAN OCCUR.

Fig. 7 RESONATOR CLAMP - 4.0L

1 - RESONATOR

2 - AIR DUCT

3 - CLAMP

WJENGINE - 4.0L 9 - 19

AIR CLEANER ELEMENT (Continued)

Page 1263 of 2199

(2) Drain the coolant (Refer to 7 - COOLING -

STANDARD PROCEDURE) and disconnect the hoses

at the engine thermostat housing and the water

pump inlet. DO NOT waste reusable coolant. If the

solution is clean and is being drained only to service

the engine or cooling system, drain the coolant into a

clean container for reuse.

(3) Remove the air cleaner assembly (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - REMOVAL).

(4) Remove the cylinder head cover (Refer to 9 -

ENGINE/CYLINDER HEAD/CYLINDER HEAD

COVER(S) - REMOVAL).

(5) Remove the capscrews, bridge and pivot assem-

blies and rocker arms (Refer to 9 - ENGINE/CYLIN-

DER HEAD/ROCKER ARM / ADJUSTER ASSY -

REMOVAL).

(6) Remove the push rods.Retain the push rods,

bridges, pivots and rocker arms in the same

order as removed.

(7) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(8) Remove the A/C compressor mounting bolts

and secure the compressor to the side.

(9) Remove the power steering pump and bracket

from the intake manifold and water pump. Set the

pump and bracket aside. DO NOT disconnect the

hoses.

(10) Perform the Fuel System Pressure Release

procedure. (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY - STANDARD PROCEDURE).

(11) Disconnect the fuel supply line at the fuel rail.(12) Remove the intake and exhaust manifolds

from the engine cylinder head (Refer to 9 - ENGINE/

MANIFOLDS/INTAKE MANIFOLD - REMOVAL).

(13) Remove the coil rail (Refer to 8 - ELECTRI-

CAL/IGNITION CONTROL/COIL RAIL - REMOV-

AL).

(14) Remove spark plugs (Refer to 8 - ELECTRI-

CAL/IGNITION CONTROL/SPARK PLUG - REMOV-

AL).

(15) Disconnect the temperature sending unit wire

connector.

(16) Remove the engine cylinder head bolts. Bolt

No.14 cannot be removed until the head is moved for-

ward (Fig. 9). Pull bolt No.14 out as far as it will go

and then suspend the bolt in this position (tape

around the bolt).

(17) Remove the engine cylinder head and gasket

(Fig. 9).

(18) If this was the first time the bolts were

removed, put a paint dab on the top of the bolt. If the

bolts have a paint dab on the top of the bolt or it

isn't known if they were used before, discard the

bolts.

(19) Stuff clean lint free shop towels into the cyl-

inder bores.

NOTE: If the valves, springs, or seals are to be

inspected/replaced at this time, (Refer to 9 -

ENGINE/CYLINDER HEAD/INTAKE/EXHAUST

VALVES & SEATS - STANDARD PROCEDURE) for

proper inspection procedures.

Fig. 8 Cylinder Head 4.0L Engine

1 - CYLINDER HEAD BOLTS

2 - CYLINDER HEAD GASKET

3 - CYLINDER HEAD

Fig. 9 Engine Cylinder

1 - CYLINDER HEAD BOLTS

2 - CYLINDER HEAD GASKET

3 - CYLINDER HEAD

9 - 20 ENGINE - 4.0LWJ

CYLINDER HEAD (Continued)

Page 1264 of 2199

CLEANING

Thoroughly clean the engine cylinder head and cyl-

inder block mating surfaces. Clean the intake and

engine exhaust manifold and engine cylinder head

mating surfaces. Remove all gasket material and car-

bon.

Check to ensure that no coolant or foreign material

has fallen into the tappet bore area.

Remove the carbon deposits from the combustion

chambers and top of the pistons.

INSPECTION

Use a straightedge and feeler gauge to check the

flatness of the engine cylinder head and block mating

surfaces.

INSTALLATION

NOTE: This procedure can be done with the engine

in or out of the vehicle.

The engine cylinder head gasket is a composition

gasket. The gasket is to be installed DRY.DO NOT

use a gasket sealing compound on the gasket.

If the engine cylinder head is to be replaced and

the original valves used, measure the valve stem

diameter. Only standard size valves can be used with

a service replacement engine cylinder head unless

the replacement head valve stem guide bores are

reamed to accommodate oversize valve stems.

Remove all carbon buildup and reface the valves.

(1) Remove the shop towels from the cylinder

bores. Coat the bores with clean engine oil.

(2) Position the engine cylinder head gasket (with

the numbers facing up) using the alignment dowels

in the cylinder block, to position the gasket.

CAUTION: Engine cylinder head bolts should be

reused only once. Replace the head bolts if they

were used before or if they have a paint dab on the

top of the bolt.

(3) With bolt No.14 held in place (tape around

bolt), install the engine cylinder head over the same

dowels used to locate the gasket. Remove the tape

from bolt No.14.

(4) Coat the threads of stud bolt No.11 with Loc-

tite 592 sealant, or equivalent.

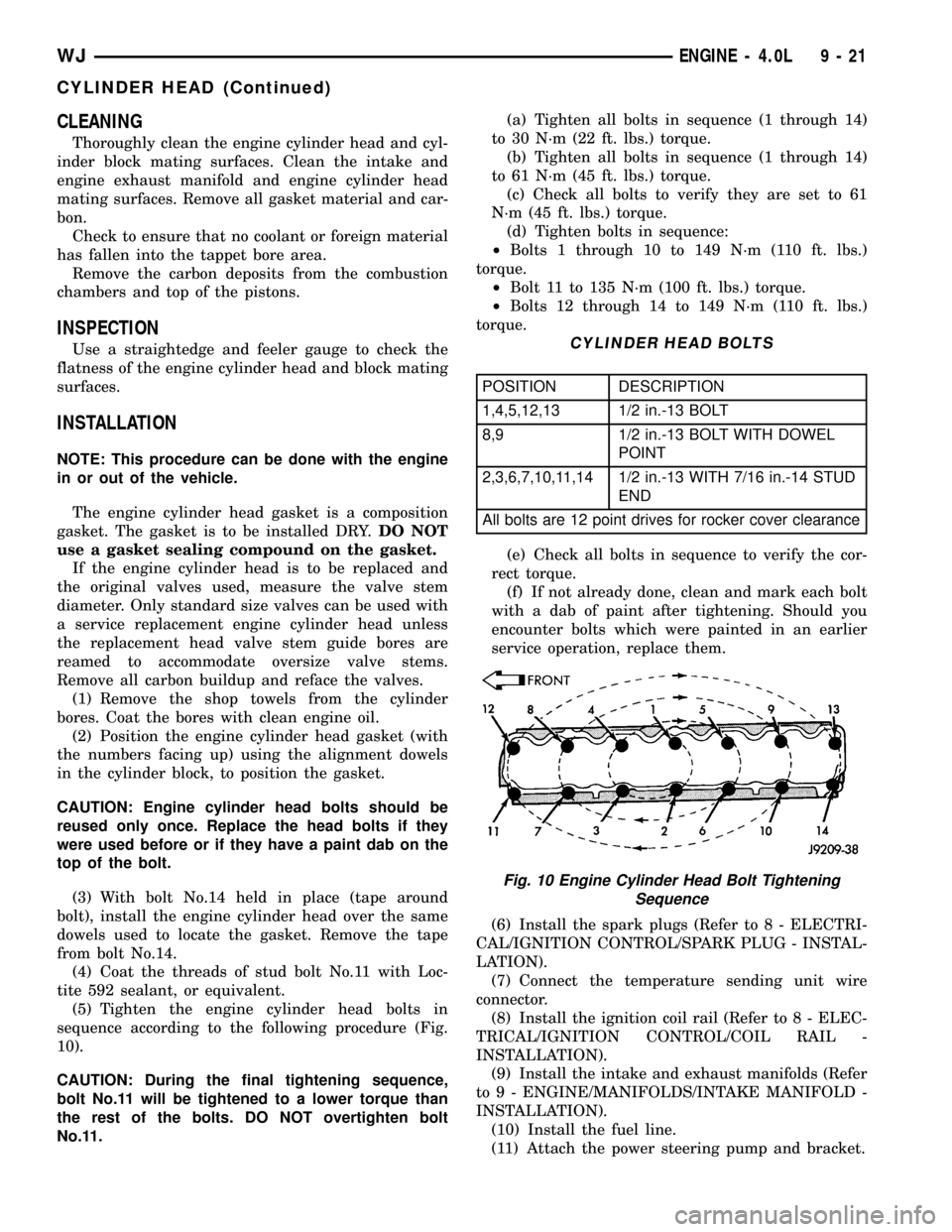

(5) Tighten the engine cylinder head bolts in

sequence according to the following procedure (Fig.

10).

CAUTION: During the final tightening sequence,

bolt No.11 will be tightened to a lower torque than

the rest of the bolts. DO NOT overtighten bolt

No.11.(a) Tighten all bolts in sequence (1 through 14)

to 30 N´m (22 ft. lbs.) torque.

(b) Tighten all bolts in sequence (1 through 14)

to 61 N´m (45 ft. lbs.) torque.

(c) Check all bolts to verify they are set to 61

N´m (45 ft. lbs.) torque.

(d) Tighten bolts in sequence:

²Bolts 1 through 10 to 149 N´m (110 ft. lbs.)

torque.

²Bolt 11 to 135 N´m (100 ft. lbs.) torque.

²Bolts 12 through 14 to 149 N´m (110 ft. lbs.)

torque.

CYLINDER HEAD BOLTS

POSITION DESCRIPTION

1,4,5,12,13 1/2 in.-13 BOLT

8,9 1/2 in.-13 BOLT WITH DOWEL

POINT

2,3,6,7,10,11,14 1/2 in.-13 WITH 7/16 in.-14 STUD

END

All bolts are 12 point drives for rocker cover clearance

(e) Check all bolts in sequence to verify the cor-

rect torque.

(f) If not already done, clean and mark each bolt

with a dab of paint after tightening. Should you

encounter bolts which were painted in an earlier

service operation, replace them.

(6) Install the spark plugs (Refer to 8 - ELECTRI-

CAL/IGNITION CONTROL/SPARK PLUG - INSTAL-

LATION).

(7) Connect the temperature sending unit wire

connector.

(8) Install the ignition coil rail (Refer to 8 - ELEC-

TRICAL/IGNITION CONTROL/COIL RAIL -

INSTALLATION).

(9) Install the intake and exhaust manifolds (Refer

to 9 - ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION).

(10) Install the fuel line.

(11) Attach the power steering pump and bracket.

Fig. 10 Engine Cylinder Head Bolt Tightening

Sequence

WJENGINE - 4.0L 9 - 21

CYLINDER HEAD (Continued)

Page 1300 of 2199

INSTALLATION

A gear-type oil pump is mounted at the underside

of the cylinder block opposite the No.4 main bearing.

(1) Install the oil pump on the cylinder block using

a replacement gasket. Tighten the bolts to 23 N´m

(17 ft. lbs.) torque.

(2) Install the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - INSTALLATION).

(3) Fill the oil pan with oil to the specified level.

INTAKE MANIFOLD

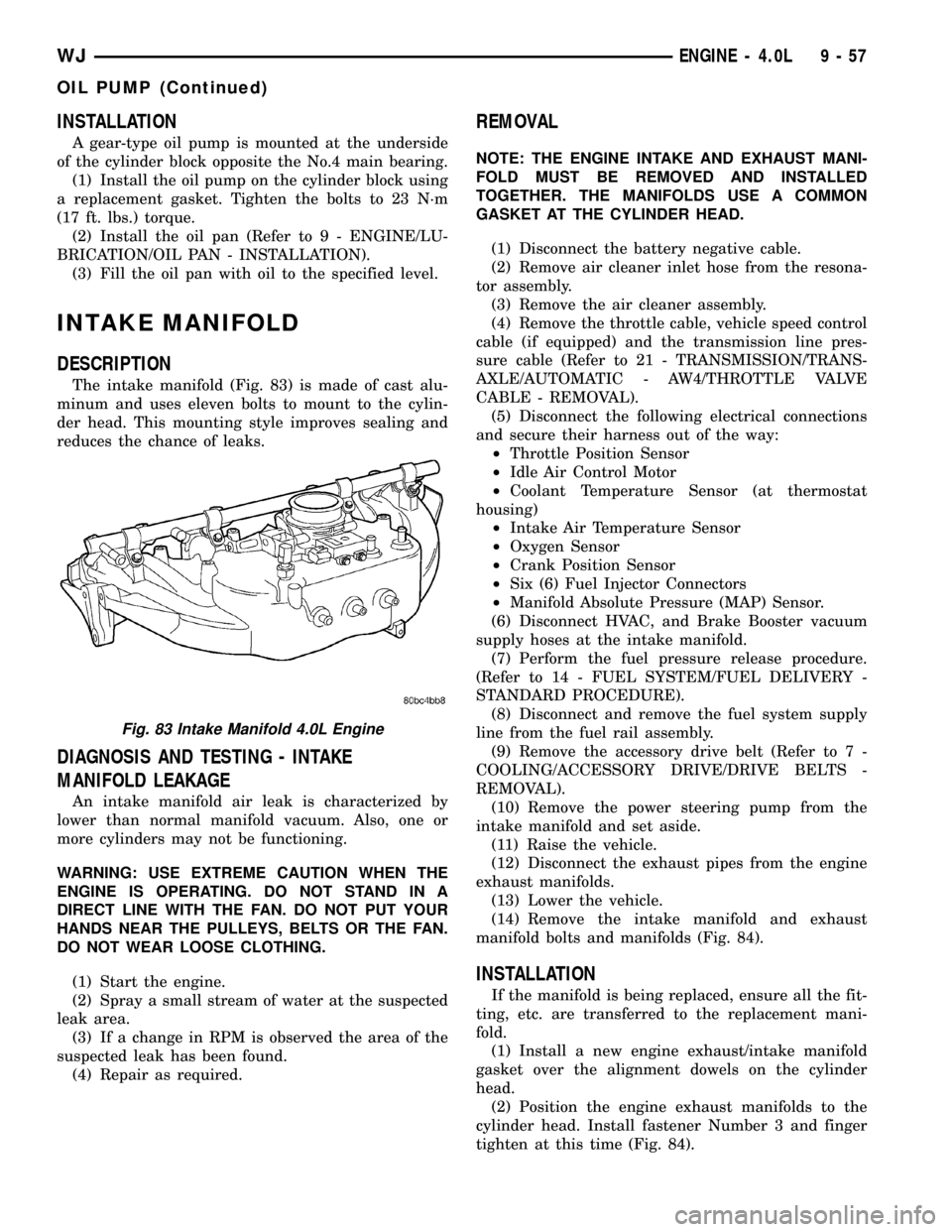

DESCRIPTION

The intake manifold (Fig. 83) is made of cast alu-

minum and uses eleven bolts to mount to the cylin-

der head. This mounting style improves sealing and

reduces the chance of leaks.

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKAGE

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water at the suspected

leak area.

(3) If a change in RPM is observed the area of the

suspected leak has been found.

(4) Repair as required.

REMOVAL

NOTE: THE ENGINE INTAKE AND EXHAUST MANI-

FOLD MUST BE REMOVED AND INSTALLED

TOGETHER. THE MANIFOLDS USE A COMMON

GASKET AT THE CYLINDER HEAD.

(1) Disconnect the battery negative cable.

(2) Remove air cleaner inlet hose from the resona-

tor assembly.

(3) Remove the air cleaner assembly.

(4) Remove the throttle cable, vehicle speed control

cable (if equipped) and the transmission line pres-

sure cable (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - AW4/THROTTLE VALVE

CABLE - REMOVAL).

(5) Disconnect the following electrical connections

and secure their harness out of the way:

²Throttle Position Sensor

²Idle Air Control Motor

²Coolant Temperature Sensor (at thermostat

housing)

²Intake Air Temperature Sensor

²Oxygen Sensor

²Crank Position Sensor

²Six (6) Fuel Injector Connectors

²Manifold Absolute Pressure (MAP) Sensor.

(6) Disconnect HVAC, and Brake Booster vacuum

supply hoses at the intake manifold.

(7) Perform the fuel pressure release procedure.

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).

(8) Disconnect and remove the fuel system supply

line from the fuel rail assembly.

(9) Remove the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(10) Remove the power steering pump from the

intake manifold and set aside.

(11) Raise the vehicle.

(12) Disconnect the exhaust pipes from the engine

exhaust manifolds.

(13) Lower the vehicle.

(14) Remove the intake manifold and exhaust

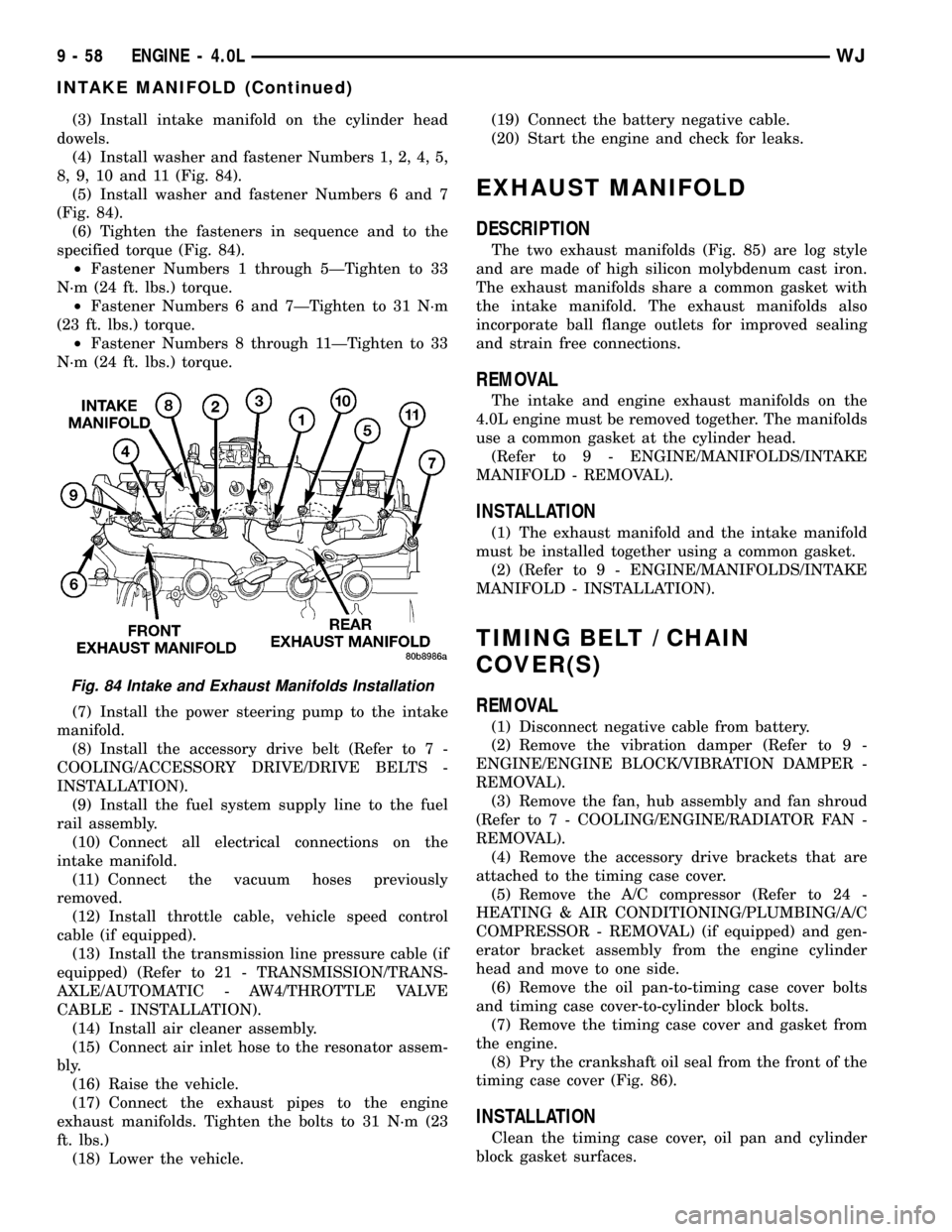

manifold bolts and manifolds (Fig. 84).

INSTALLATION

If the manifold is being replaced, ensure all the fit-

ting, etc. are transferred to the replacement mani-

fold.

(1) Install a new engine exhaust/intake manifold

gasket over the alignment dowels on the cylinder

head.

(2) Position the engine exhaust manifolds to the

cylinder head. Install fastener Number 3 and finger

tighten at this time (Fig. 84).

Fig. 83 Intake Manifold 4.0L Engine

WJENGINE - 4.0L 9 - 57

OIL PUMP (Continued)

Page 1301 of 2199

(3) Install intake manifold on the cylinder head

dowels.

(4) Install washer and fastener Numbers 1, 2, 4, 5,

8, 9, 10 and 11 (Fig. 84).

(5) Install washer and fastener Numbers 6 and 7

(Fig. 84).

(6) Tighten the fasteners in sequence and to the

specified torque (Fig. 84).

²Fastener Numbers 1 through 5ÐTighten to 33

N´m (24 ft. lbs.) torque.

²Fastener Numbers 6 and 7ÐTighten to 31 N´m

(23 ft. lbs.) torque.

²Fastener Numbers 8 through 11ÐTighten to 33

N´m (24 ft. lbs.) torque.

(7) Install the power steering pump to the intake

manifold.

(8) Install the accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(9) Install the fuel system supply line to the fuel

rail assembly.

(10) Connect all electrical connections on the

intake manifold.

(11) Connect the vacuum hoses previously

removed.

(12) Install throttle cable, vehicle speed control

cable (if equipped).

(13) Install the transmission line pressure cable (if

equipped) (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - AW4/THROTTLE VALVE

CABLE - INSTALLATION).

(14) Install air cleaner assembly.

(15) Connect air inlet hose to the resonator assem-

bly.

(16) Raise the vehicle.

(17) Connect the exhaust pipes to the engine

exhaust manifolds. Tighten the bolts to 31 N´m (23

ft. lbs.)

(18) Lower the vehicle.(19) Connect the battery negative cable.

(20) Start the engine and check for leaks.

EXHAUST MANIFOLD

DESCRIPTION

The two exhaust manifolds (Fig. 85) are log style

and are made of high silicon molybdenum cast iron.

The exhaust manifolds share a common gasket with

the intake manifold. The exhaust manifolds also

incorporate ball flange outlets for improved sealing

and strain free connections.

REMOVAL

The intake and engine exhaust manifolds on the

4.0L engine must be removed together. The manifolds

use a common gasket at the cylinder head.

(Refer to 9 - ENGINE/MANIFOLDS/INTAKE

MANIFOLD - REMOVAL).

INSTALLATION

(1) The exhaust manifold and the intake manifold

must be installed together using a common gasket.

(2) (Refer to 9 - ENGINE/MANIFOLDS/INTAKE

MANIFOLD - INSTALLATION).

TIMING BELT / CHAIN

COVER(S)

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(3) Remove the fan, hub assembly and fan shroud

(Refer to 7 - COOLING/ENGINE/RADIATOR FAN -

REMOVAL).

(4) Remove the accessory drive brackets that are

attached to the timing case cover.

(5) Remove the A/C compressor (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/A/C

COMPRESSOR - REMOVAL) (if equipped) and gen-

erator bracket assembly from the engine cylinder

head and move to one side.

(6) Remove the oil pan-to-timing case cover bolts

and timing case cover-to-cylinder block bolts.

(7) Remove the timing case cover and gasket from

the engine.

(8) Pry the crankshaft oil seal from the front of the

timing case cover (Fig. 86).

INSTALLATION

Clean the timing case cover, oil pan and cylinder

block gasket surfaces.

Fig. 84 Intake and Exhaust Manifolds Installation

9 - 58 ENGINE - 4.0LWJ

INTAKE MANIFOLD (Continued)

Page 1307 of 2199

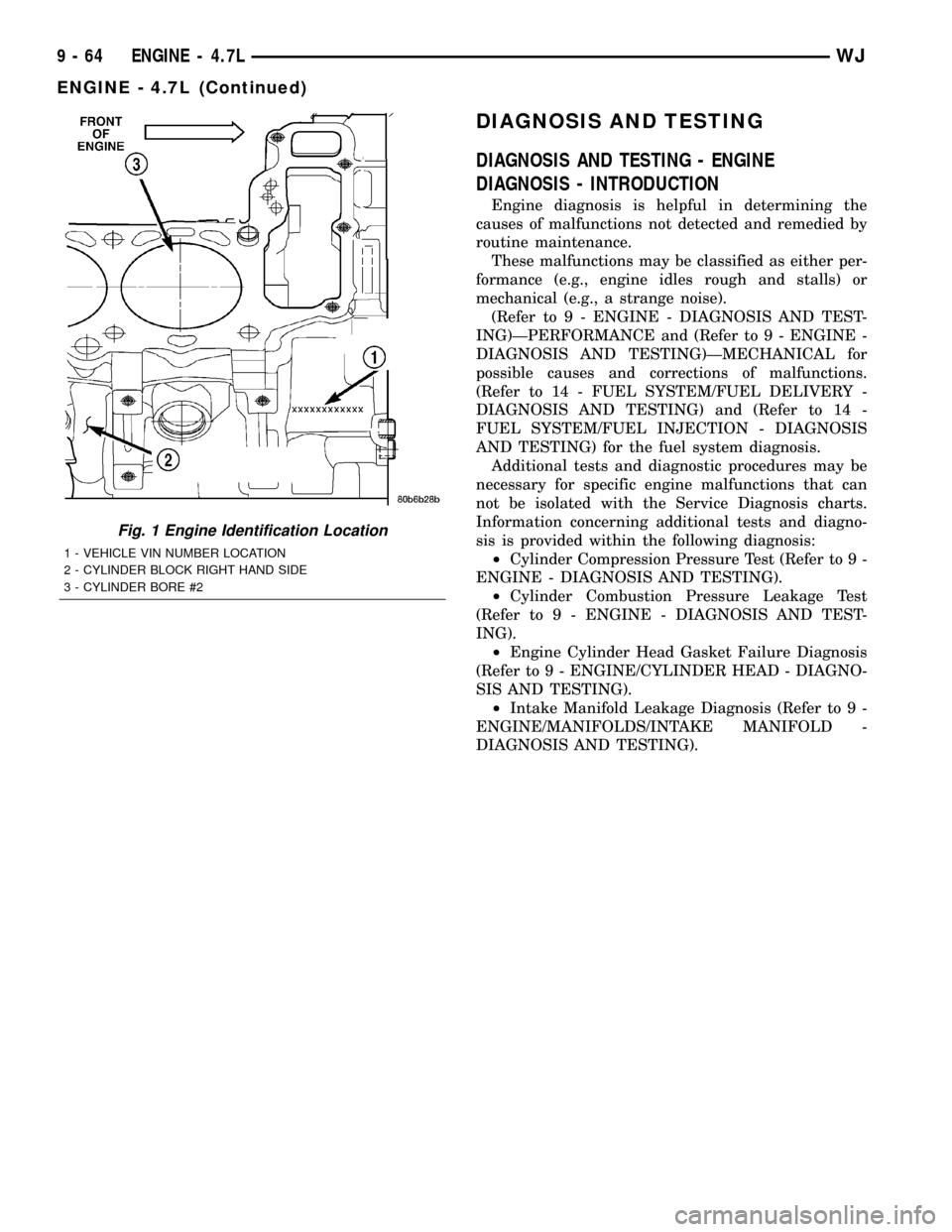

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either per-

formance (e.g., engine idles rough and stalls) or

mechanical (e.g., a strange noise).

(Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING)ÐPERFORMANCE and (Refer to 9 - ENGINE -

DIAGNOSIS AND TESTING)ÐMECHANICAL for

possible causes and corrections of malfunctions.

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

DIAGNOSIS AND TESTING) and (Refer to 14 -

FUEL SYSTEM/FUEL INJECTION - DIAGNOSIS

AND TESTING) for the fuel system diagnosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following diagnosis:

²Cylinder Compression Pressure Test (Refer to 9 -

ENGINE - DIAGNOSIS AND TESTING).

²Cylinder Combustion Pressure Leakage Test

(Refer to 9 - ENGINE - DIAGNOSIS AND TEST-

ING).

²Engine Cylinder Head Gasket Failure Diagnosis

(Refer to 9 - ENGINE/CYLINDER HEAD - DIAGNO-

SIS AND TESTING).

²Intake Manifold Leakage Diagnosis (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

DIAGNOSIS AND TESTING).

Fig. 1 Engine Identification Location

1 - VEHICLE VIN NUMBER LOCATION

2 - CYLINDER BLOCK RIGHT HAND SIDE

3 - CYLINDER BORE #2

9 - 64 ENGINE - 4.7LWJ

ENGINE - 4.7L (Continued)

Page 1308 of 2199

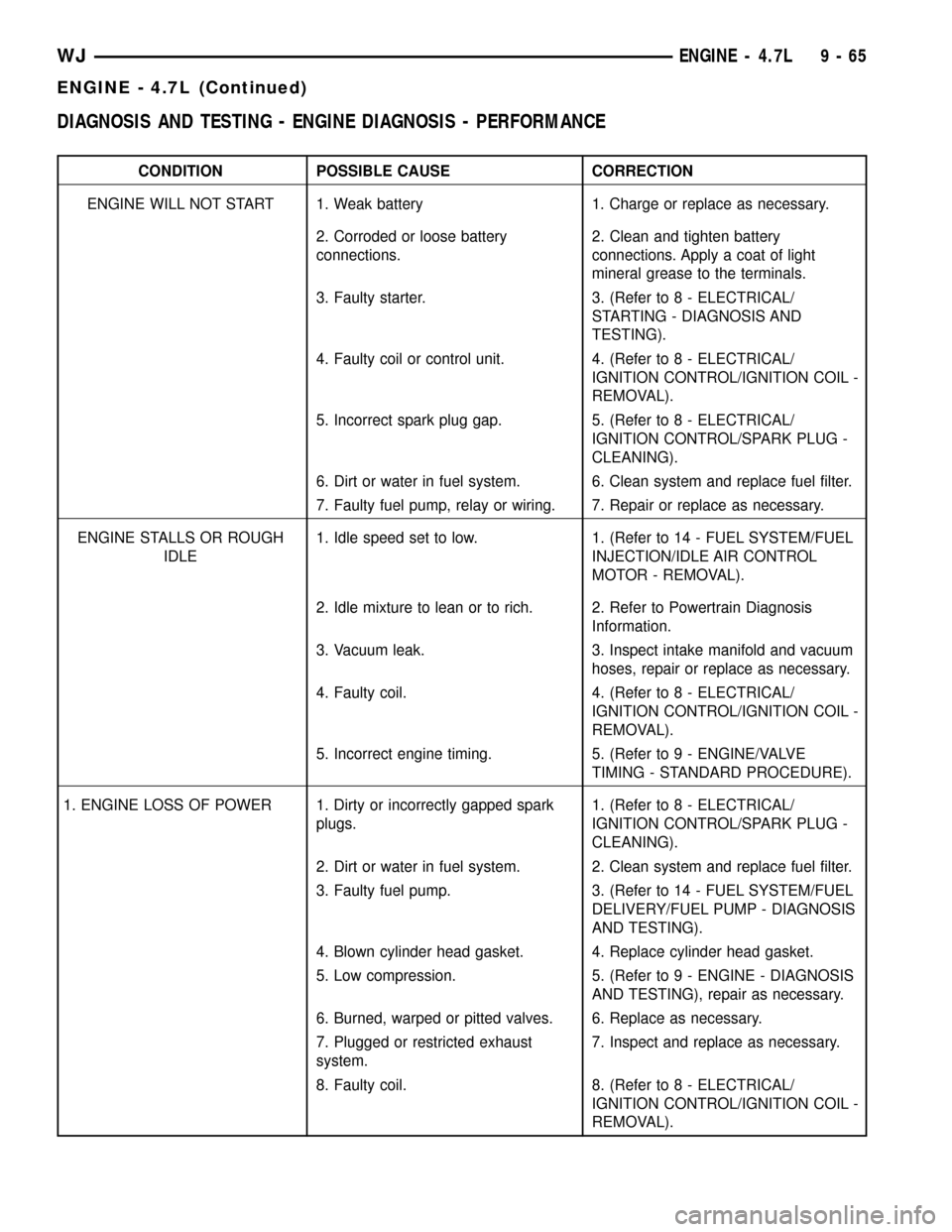

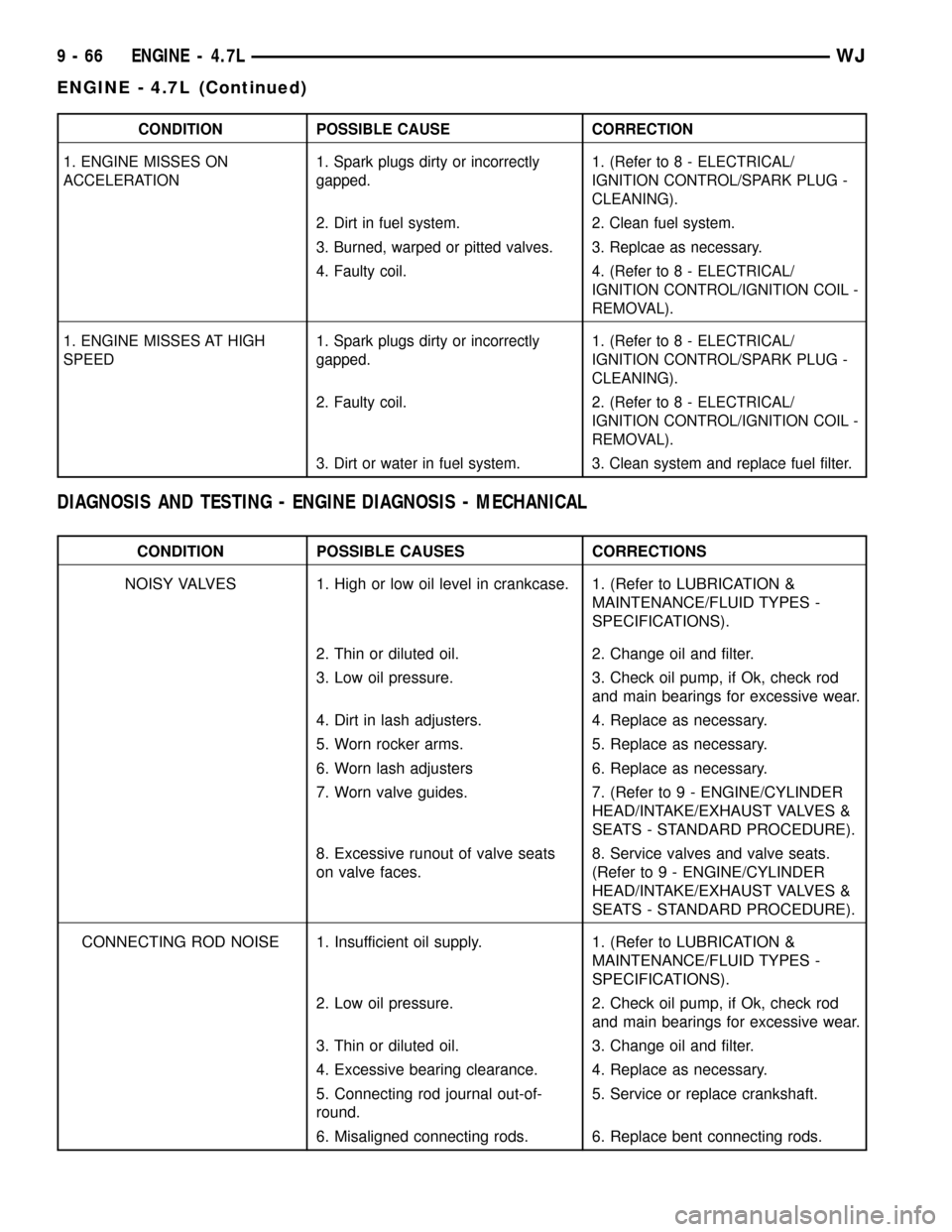

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - PERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT START 1. Weak battery 1. Charge or replace as necessary.

2. Corroded or loose battery

connections.2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to the terminals.

3. Faulty starter. 3. (Refer to 8 - ELECTRICAL/

STARTING - DIAGNOSIS AND

TESTING).

4. Faulty coil or control unit. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION COIL -

REMOVAL).

5. Incorrect spark plug gap. 5. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG -

CLEANING).

6. Dirt or water in fuel system. 6. Clean system and replace fuel filter.

7. Faulty fuel pump, relay or wiring. 7. Repair or replace as necessary.

ENGINE STALLS OR ROUGH

IDLE1. Idle speed set to low. 1. (Refer to 14 - FUEL SYSTEM/FUEL

INJECTION/IDLE AIR CONTROL

MOTOR - REMOVAL).

2. Idle mixture to lean or to rich. 2. Refer to Powertrain Diagnosis

Information.

3. Vacuum leak. 3. Inspect intake manifold and vacuum

hoses, repair or replace as necessary.

4. Faulty coil. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION COIL -

REMOVAL).

5. Incorrect engine timing. 5. (Refer to 9 - ENGINE/VALVE

TIMING - STANDARD PROCEDURE).

1. ENGINE LOSS OF POWER 1. Dirty or incorrectly gapped spark

plugs.1. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG -

CLEANING).

2. Dirt or water in fuel system. 2. Clean system and replace fuel filter.

3. Faulty fuel pump. 3. (Refer to 14 - FUEL SYSTEM/FUEL

DELIVERY/FUEL PUMP - DIAGNOSIS

AND TESTING).

4. Blown cylinder head gasket. 4. Replace cylinder head gasket.

5. Low compression. 5. (Refer to 9 - ENGINE - DIAGNOSIS

AND TESTING), repair as necessary.

6. Burned, warped or pitted valves. 6. Replace as necessary.

7. Plugged or restricted exhaust

system.7. Inspect and replace as necessary.

8. Faulty coil. 8. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION COIL -

REMOVAL).

WJENGINE - 4.7L 9 - 65

ENGINE - 4.7L (Continued)

Page 1309 of 2199

CONDITION POSSIBLE CAUSE CORRECTION

1. ENGINE MISSES ON

ACCELERATION1. Spark plugs dirty or incorrectly

gapped.1. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG -

CLEANING).

2. Dirt in fuel system. 2. Clean fuel system.

3. Burned, warped or pitted valves. 3. Replcae as necessary.

4. Faulty coil. 4. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION COIL -

REMOVAL).

1. ENGINE MISSES AT HIGH

SPEED1. Spark plugs dirty or incorrectly

gapped.1. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/SPARK PLUG -

CLEANING).

2. Faulty coil. 2. (Refer to 8 - ELECTRICAL/

IGNITION CONTROL/IGNITION COIL -

REMOVAL).

3. Dirt or water in fuel system. 3. Clean system and replace fuel filter.

DIAGNOSIS AND TESTING - ENGINE DIAGNOSIS - MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTIONS

NOISY VALVES 1. High or low oil level in crankcase. 1. (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES -

SPECIFICATIONS).

2. Thin or diluted oil. 2. Change oil and filter.

3. Low oil pressure. 3. Check oil pump, if Ok, check rod

and main bearings for excessive wear.

4. Dirt in lash adjusters. 4. Replace as necessary.

5. Worn rocker arms. 5. Replace as necessary.

6. Worn lash adjusters 6. Replace as necessary.

7. Worn valve guides. 7. (Refer to 9 - ENGINE/CYLINDER

HEAD/INTAKE/EXHAUST VALVES &

SEATS - STANDARD PROCEDURE).

8. Excessive runout of valve seats

on valve faces.8. Service valves and valve seats.

(Refer to 9 - ENGINE/CYLINDER

HEAD/INTAKE/EXHAUST VALVES &

SEATS - STANDARD PROCEDURE).

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. (Refer to LUBRICATION &

MAINTENANCE/FLUID TYPES -

SPECIFICATIONS).

2. Low oil pressure. 2. Check oil pump, if Ok, check rod

and main bearings for excessive wear.

3. Thin or diluted oil. 3. Change oil and filter.

4. Excessive bearing clearance. 4. Replace as necessary.

5. Connecting rod journal out-of-

round.5. Service or replace crankshaft.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

9 - 66 ENGINE - 4.7LWJ

ENGINE - 4.7L (Continued)

Page 1311 of 2199

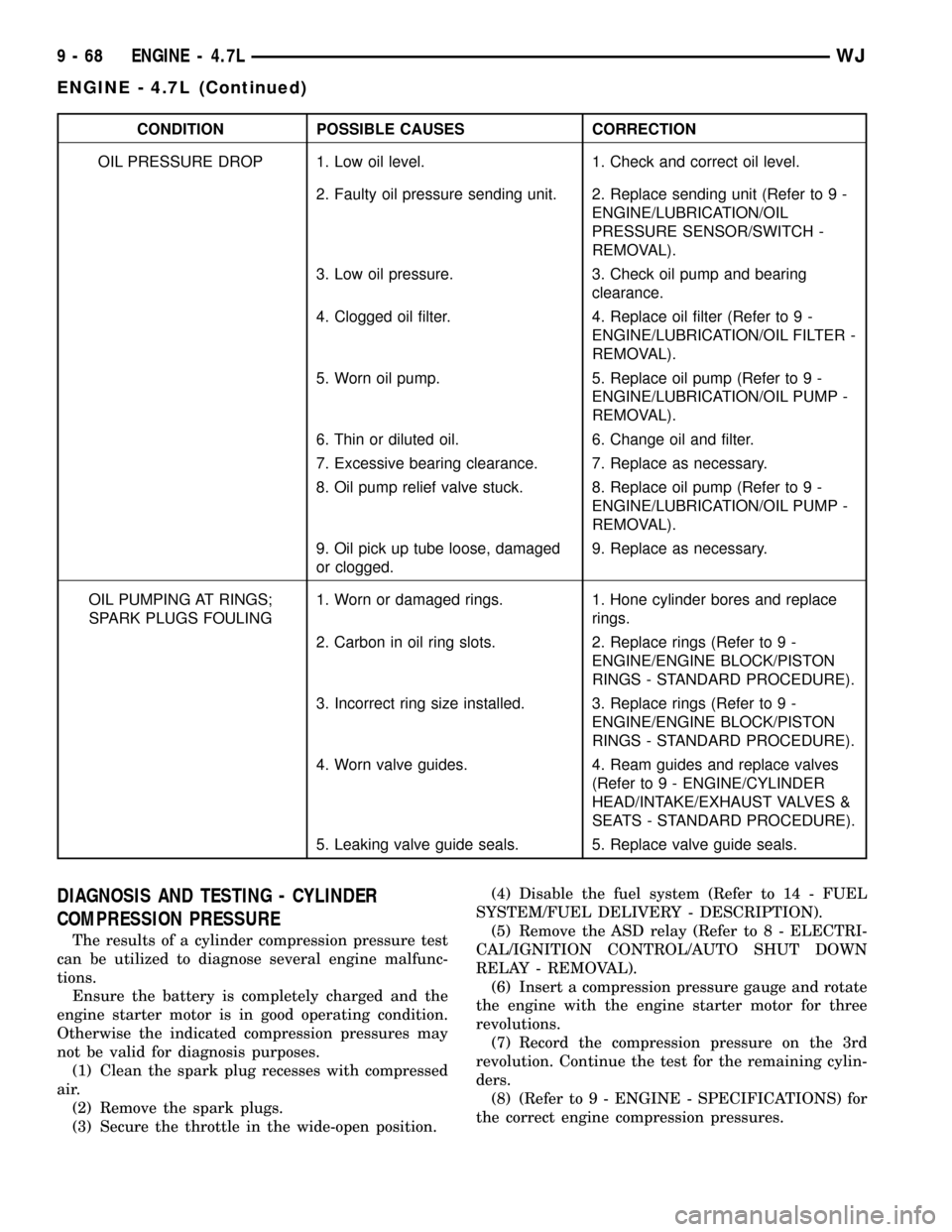

CONDITION POSSIBLE CAUSES CORRECTION

OIL PRESSURE DROP 1. Low oil level. 1. Check and correct oil level.

2. Faulty oil pressure sending unit. 2. Replace sending unit (Refer to 9 -

ENGINE/LUBRICATION/OIL

PRESSURE SENSOR/SWITCH -

REMOVAL).

3. Low oil pressure. 3. Check oil pump and bearing

clearance.

4. Clogged oil filter. 4. Replace oil filter (Refer to 9 -

ENGINE/LUBRICATION/OIL FILTER -

REMOVAL).

5. Worn oil pump. 5. Replace oil pump (Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP -

REMOVAL).

6. Thin or diluted oil. 6. Change oil and filter.

7. Excessive bearing clearance. 7. Replace as necessary.

8. Oil pump relief valve stuck. 8. Replace oil pump (Refer to 9 -

ENGINE/LUBRICATION/OIL PUMP -

REMOVAL).

9. Oil pick up tube loose, damaged

or clogged.9. Replace as necessary.

OIL PUMPING AT RINGS;

SPARK PLUGS FOULING1. Worn or damaged rings. 1. Hone cylinder bores and replace

rings.

2. Carbon in oil ring slots. 2. Replace rings (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON

RINGS - STANDARD PROCEDURE).

3. Incorrect ring size installed. 3. Replace rings (Refer to 9 -

ENGINE/ENGINE BLOCK/PISTON

RINGS - STANDARD PROCEDURE).

4. Worn valve guides. 4. Ream guides and replace valves

(Refer to 9 - ENGINE/CYLINDER

HEAD/INTAKE/EXHAUST VALVES &

SEATS - STANDARD PROCEDURE).

5. Leaking valve guide seals. 5. Replace valve guide seals.

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Clean the spark plug recesses with compressed

air.

(2) Remove the spark plugs.

(3) Secure the throttle in the wide-open position.(4) Disable the fuel system (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - DESCRIPTION).

(5) Remove the ASD relay (Refer to 8 - ELECTRI-

CAL/IGNITION CONTROL/AUTO SHUT DOWN

RELAY - REMOVAL).

(6) Insert a compression pressure gauge and rotate

the engine with the engine starter motor for three

revolutions.

(7) Record the compression pressure on the 3rd

revolution. Continue the test for the remaining cylin-

ders.

(8) (Refer to 9 - ENGINE - SPECIFICATIONS) for

the correct engine compression pressures.

9 - 68 ENGINE - 4.7LWJ

ENGINE - 4.7L (Continued)