Motor mount JEEP GRAND CHEROKEE 2002 WJ / 2.G Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1462 of 2199

(5) Push sensor against flywheel/drive plate. With

sensor pushed against flywheel/drive plate, tighten

mounting bolt to 7 N´m (60 in. lbs.) torque.

(6) Route sensor wiring harness into wire shield.

(7) Connect sensor pigtail harness electrical con-

nector to main wiring harness.

INSTALLATION - 4.7L

(1) Clean out machined hole in engine block.

(2) Apply a small amount of engine oil to sensor

o-ring.

(3) Install sensor into engine block with a slight

rocking action. Do not twist sensor into position as

damage to o-ring may result.

CAUTION: Before tightening sensor mounting bolt,

be sure sensor is completely flush to cylinder

block. If sensor is not flush, damage to sensor

mounting tang may result.

(4) Install mounting bolt and tighten to 28 N´m

(21 ft. lbs.) torque.

(5) Connect electrical connector to sensor.

(6) Install starter motor. Refer to Starter Removal/

Installation.

FUEL INJECTOR

DESCRIPTION

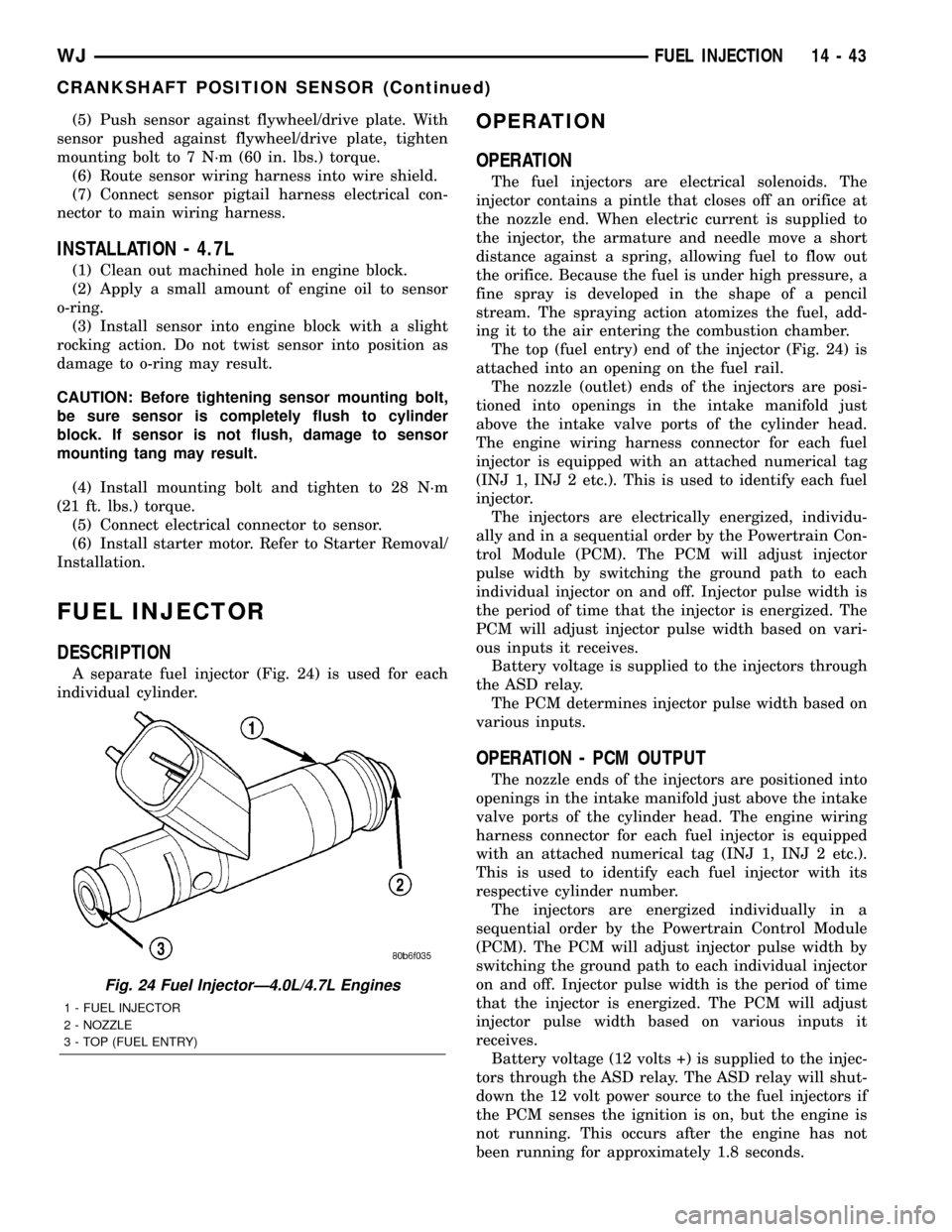

A separate fuel injector (Fig. 24) is used for each

individual cylinder.

OPERATION

OPERATION

The fuel injectors are electrical solenoids. The

injector contains a pintle that closes off an orifice at

the nozzle end. When electric current is supplied to

the injector, the armature and needle move a short

distance against a spring, allowing fuel to flow out

the orifice. Because the fuel is under high pressure, a

fine spray is developed in the shape of a pencil

stream. The spraying action atomizes the fuel, add-

ing it to the air entering the combustion chamber.

The top (fuel entry) end of the injector (Fig. 24) is

attached into an opening on the fuel rail.

The nozzle (outlet) ends of the injectors are posi-

tioned into openings in the intake manifold just

above the intake valve ports of the cylinder head.

The engine wiring harness connector for each fuel

injector is equipped with an attached numerical tag

(INJ 1, INJ 2 etc.). This is used to identify each fuel

injector.

The injectors are electrically energized, individu-

ally and in a sequential order by the Powertrain Con-

trol Module (PCM). The PCM will adjust injector

pulse width by switching the ground path to each

individual injector on and off. Injector pulse width is

the period of time that the injector is energized. The

PCM will adjust injector pulse width based on vari-

ous inputs it receives.

Battery voltage is supplied to the injectors through

the ASD relay.

The PCM determines injector pulse width based on

various inputs.

OPERATION - PCM OUTPUT

The nozzle ends of the injectors are positioned into

openings in the intake manifold just above the intake

valve ports of the cylinder head. The engine wiring

harness connector for each fuel injector is equipped

with an attached numerical tag (INJ 1, INJ 2 etc.).

This is used to identify each fuel injector with its

respective cylinder number.

The injectors are energized individually in a

sequential order by the Powertrain Control Module

(PCM). The PCM will adjust injector pulse width by

switching the ground path to each individual injector

on and off. Injector pulse width is the period of time

that the injector is energized. The PCM will adjust

injector pulse width based on various inputs it

receives.

Battery voltage (12 volts +) is supplied to the injec-

tors through the ASD relay. The ASD relay will shut-

down the 12 volt power source to the fuel injectors if

the PCM senses the ignition is on, but the engine is

not running. This occurs after the engine has not

been running for approximately 1.8 seconds.

Fig. 24 Fuel InjectorÐ4.0L/4.7L Engines

1 - FUEL INJECTOR

2 - NOZZLE

3 - TOP (FUEL ENTRY)

WJFUEL INJECTION 14 - 43

CRANKSHAFT POSITION SENSOR (Continued)

Page 1463 of 2199

The PCM determines injector on-time (pulse width)

based on various inputs.

DIAGNOSIS AND TESTING - FUEL INJECTOR

To perform a complete test of the fuel injectors and

their circuitry, use the DRB scan tool and refer to the

appropriate Powertrain Diagnostics Procedures man-

ual. To test the injector only, refer to the following:

Disconnect the fuel injector wire harness connector

from the injector. The injector is equipped with 2

electrical terminals (pins). Place an ohmmeter across

the terminals. Resistance reading should be approxi-

mately 12 ohms 1.2 ohms at 20ÉC (68ÉF).

REMOVAL

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT PRESSURE EVEN WITH ENGINE OFF.

BEFORE SERVICING FUEL INJECTOR(S), FUEL

SYSTEM PRESSURE MUST BE RELEASED.

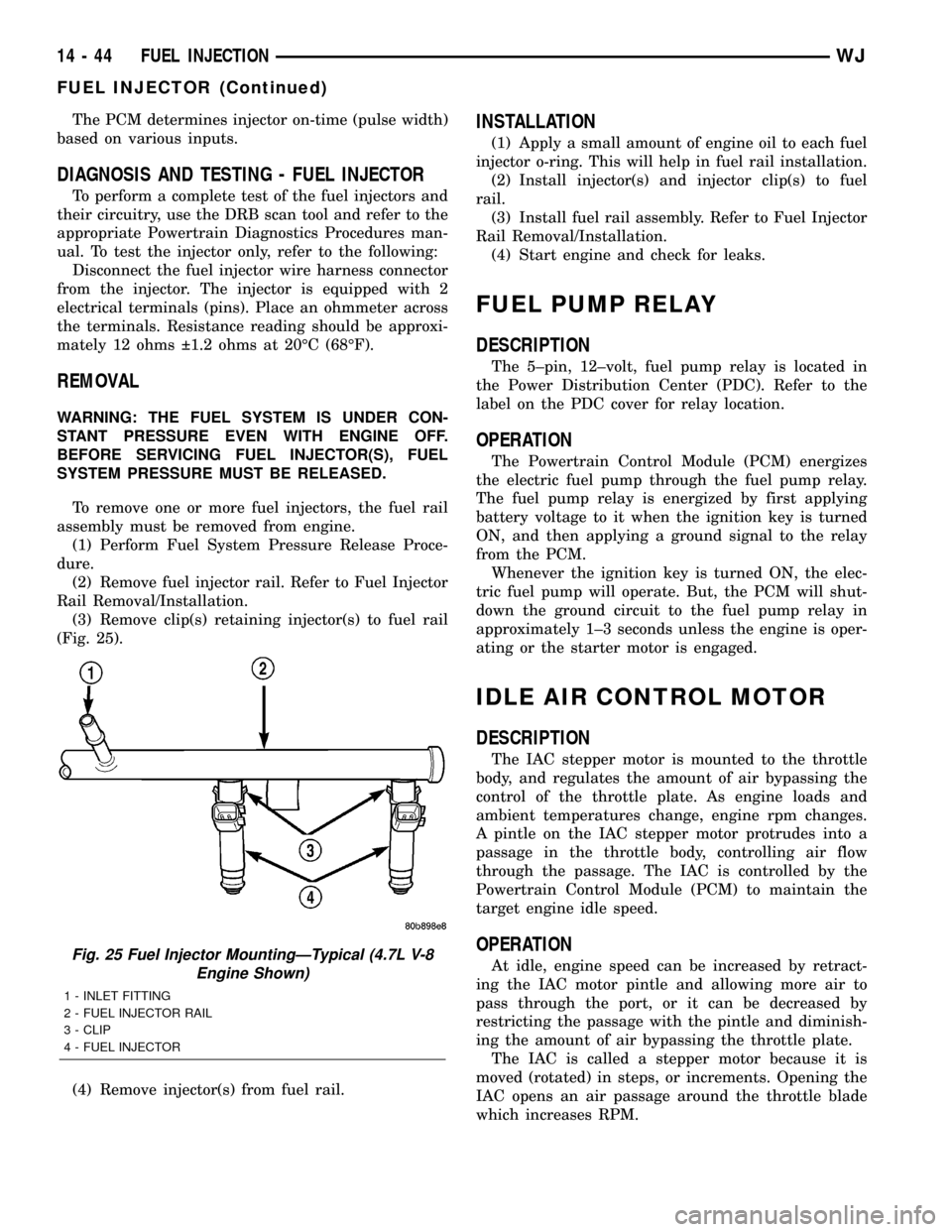

To remove one or more fuel injectors, the fuel rail

assembly must be removed from engine.

(1) Perform Fuel System Pressure Release Proce-

dure.

(2) Remove fuel injector rail. Refer to Fuel Injector

Rail Removal/Installation.

(3) Remove clip(s) retaining injector(s) to fuel rail

(Fig. 25).

(4) Remove injector(s) from fuel rail.

INSTALLATION

(1) Apply a small amount of engine oil to each fuel

injector o-ring. This will help in fuel rail installation.

(2) Install injector(s) and injector clip(s) to fuel

rail.

(3) Install fuel rail assembly. Refer to Fuel Injector

Rail Removal/Installation.

(4) Start engine and check for leaks.

FUEL PUMP RELAY

DESCRIPTION

The 5±pin, 12±volt, fuel pump relay is located in

the Power Distribution Center (PDC). Refer to the

label on the PDC cover for relay location.

OPERATION

The Powertrain Control Module (PCM) energizes

the electric fuel pump through the fuel pump relay.

The fuel pump relay is energized by first applying

battery voltage to it when the ignition key is turned

ON, and then applying a ground signal to the relay

from the PCM.

Whenever the ignition key is turned ON, the elec-

tric fuel pump will operate. But, the PCM will shut-

down the ground circuit to the fuel pump relay in

approximately 1±3 seconds unless the engine is oper-

ating or the starter motor is engaged.

IDLE AIR CONTROL MOTOR

DESCRIPTION

The IAC stepper motor is mounted to the throttle

body, and regulates the amount of air bypassing the

control of the throttle plate. As engine loads and

ambient temperatures change, engine rpm changes.

A pintle on the IAC stepper motor protrudes into a

passage in the throttle body, controlling air flow

through the passage. The IAC is controlled by the

Powertrain Control Module (PCM) to maintain the

target engine idle speed.

OPERATION

At idle, engine speed can be increased by retract-

ing the IAC motor pintle and allowing more air to

pass through the port, or it can be decreased by

restricting the passage with the pintle and diminish-

ing the amount of air bypassing the throttle plate.

The IAC is called a stepper motor because it is

moved (rotated) in steps, or increments. Opening the

IAC opens an air passage around the throttle blade

which increases RPM.Fig. 25 Fuel Injector MountingÐTypical (4.7L V-8

Engine Shown)

1 - INLET FITTING

2 - FUEL INJECTOR RAIL

3 - CLIP

4 - FUEL INJECTOR

14 - 44 FUEL INJECTIONWJ

FUEL INJECTOR (Continued)

Page 1464 of 2199

The PCM uses the IAC motor to control idle speed

(along with timing) and to reach a desired MAP dur-

ing decel (keep engine from stalling).

The IAC motor has 4 wires with 4 circuits. Two of

the wires are for 12 volts and ground to supply elec-

trical current to the motor windings to operate the

stepper motor in one direction. The other 2 wires are

also for 12 volts and ground to supply electrical cur-

rent to operate the stepper motor in the opposite

direction.

To make the IAC go in the opposite direction, the

PCM just reverses polarity on both windings. If only

1 wire is open, the IAC can only be moved 1 step

(increment) in either direction. To keep the IAC

motor in position when no movement is needed, the

PCM will energize both windings at the same time.

This locks the IAC motor in place.

In the IAC motor system, the PCM will count

every step that the motor is moved. This allows the

PCM to determine the motor pintle position. If the

memory is cleared, the PCM no longer knows the

position of the pintle. So at the first key ON, the

PCM drives the IAC motor closed, regardless of

where it was before. This zeros the counter. From

this point the PCM will back out the IAC motor and

keep track of its position again.

When engine rpm is above idle speed, the IAC is

used for the following:

²Off-idle dashpot (throttle blade will close quickly

but idle speed will not stop quickly)

²Deceleration air flow control

²A/C compressor load control (also opens the pas-

sage slightly before the compressor is engaged so

that the engine rpm does not dip down when the

compressor engages)

²Power steering load control

The PCM can control polarity of the circuit to con-

trol direction of the stepper motor.

IAC Stepper Motor Program:The PCM is also

equipped with a memory program that records the

number of steps the IAC stepper motor most recently

advanced to during a certain set of parameters. For

example: The PCM was attempting to maintain a

1000 rpm target during a cold start-up cycle. The last

recorded number of steps for that may have been

125. That value would be recorded in the memory

cell so that the next time the PCM recognizes the

identical conditions, the PCM recalls that 125 steps

were required to maintain the target. This program

allows for greater customer satisfaction due to

greater control of engine idle.

Another function of the memory program, which

occurs when the power steering switch (if equipped),

or the A/C request circuit, requires that the IAC step-

per motor control engine rpm, is the recording of the

last targeted steps into the memory cell. The PCMcan anticipate A/C compressor loads. This is accom-

plished by delaying compressor operation for approx-

imately 0.5 seconds until the PCM moves the IAC

stepper motor to the recorded steps that were loaded

into the memory cell. Using this program helps elim-

inate idle-quality changes as loads change. Finally,

the PCM incorporates a9No-Load9engine speed lim-

iter of approximately 1800 - 2000 rpm, when it rec-

ognizes that the TPS is indicating an idle signal and

IAC motor cannot maintain engine idle.

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the IAC motor through the PCM.

REMOVAL

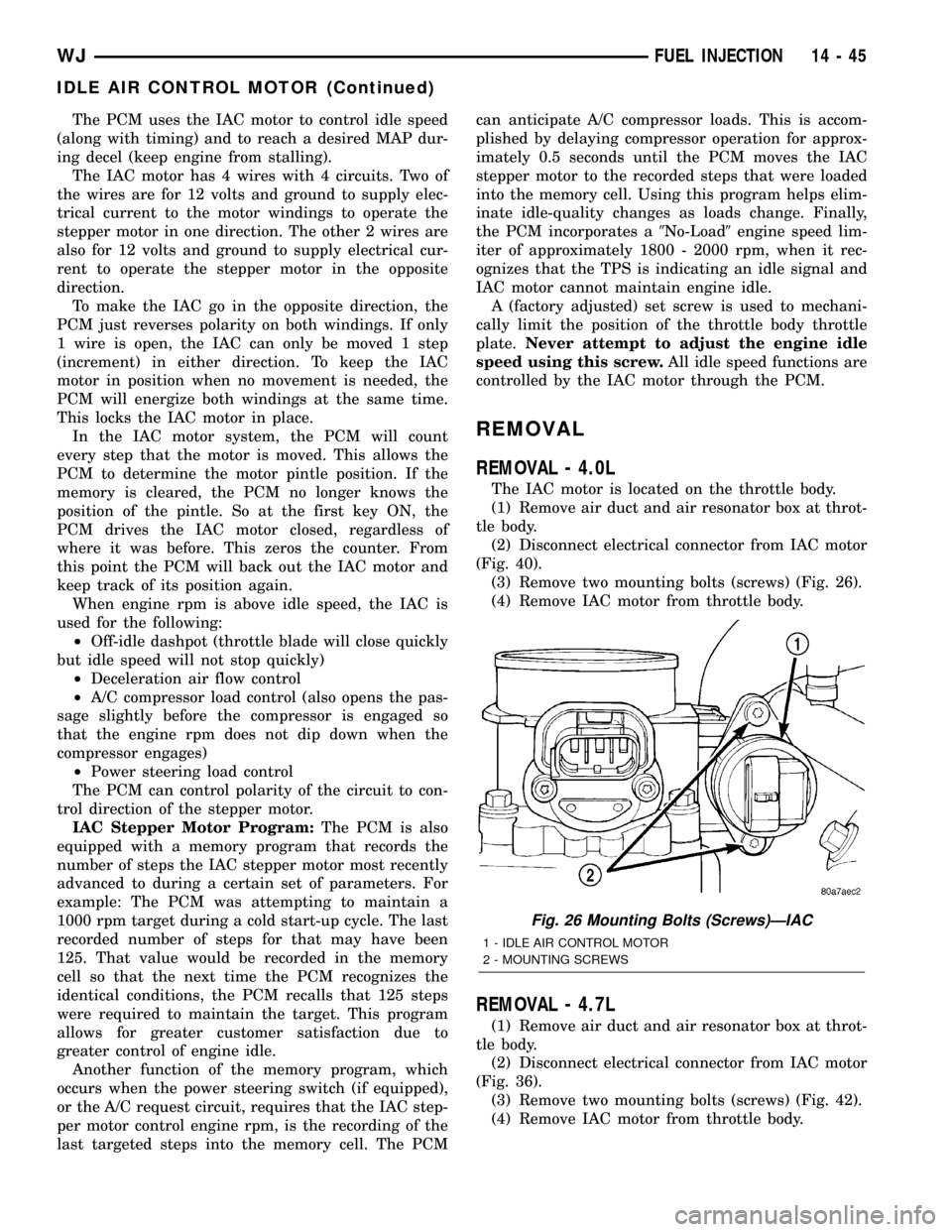

REMOVAL - 4.0L

The IAC motor is located on the throttle body.

(1) Remove air duct and air resonator box at throt-

tle body.

(2) Disconnect electrical connector from IAC motor

(Fig. 40).

(3) Remove two mounting bolts (screws) (Fig. 26).

(4) Remove IAC motor from throttle body.

REMOVAL - 4.7L

(1) Remove air duct and air resonator box at throt-

tle body.

(2) Disconnect electrical connector from IAC motor

(Fig. 36).

(3) Remove two mounting bolts (screws) (Fig. 42).

(4) Remove IAC motor from throttle body.

Fig. 26 Mounting Bolts (Screws)ÐIAC

1 - IDLE AIR CONTROL MOTOR

2 - MOUNTING SCREWS

WJFUEL INJECTION 14 - 45

IDLE AIR CONTROL MOTOR (Continued)

Page 1465 of 2199

INSTALLATION

INSTALLATION - 4.0L

The IAC motor is located on the throttle body.

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air cleaner duct/air box to throttle body.

INSTALLATION - 4.7L

(1) Install IAC motor to throttle body.

(2) Install and tighten two mounting bolts (screws)

to 7 N´m (60 in. lbs.) torque.

(3) Install electrical connector.

(4) Install air duct/air box to throttle body.

INTAKE AIR TEMPERATURE

SENSOR

DESCRIPTION

The 2±wire Intake Manifold Air Temperature (IAT)

sensor is installed in the intake manifold with the

sensor element extending into the air stream.

The IAT sensor is a two-wire Negative Thermal

Coefficient (NTC) sensor. Meaning, as intake mani-

fold temperature increases, resistance (voltage) in the

sensor decreases. As temperature decreases, resis-

tance (voltage) in the sensor increases.

OPERATION

The IAT sensor provides an input voltage to the

Powertrain Control Module (PCM) indicating the

density of the air entering the intake manifold based

upon intake manifold temperature. At key-on, a

5±volt power circuit is supplied to the sensor from

the PCM. The sensor is grounded at the PCM

through a low-noise, sensor-return circuit.

The PCM uses this input to calculate the following:

²Injector pulse-width

²Adjustment of spark timing (to help prevent

spark knock with high intake manifold air-charge

temperatures)

The resistance values of the IAT sensor is the same

as for the Engine Coolant Temperature (ECT) sensor.

REMOVAL

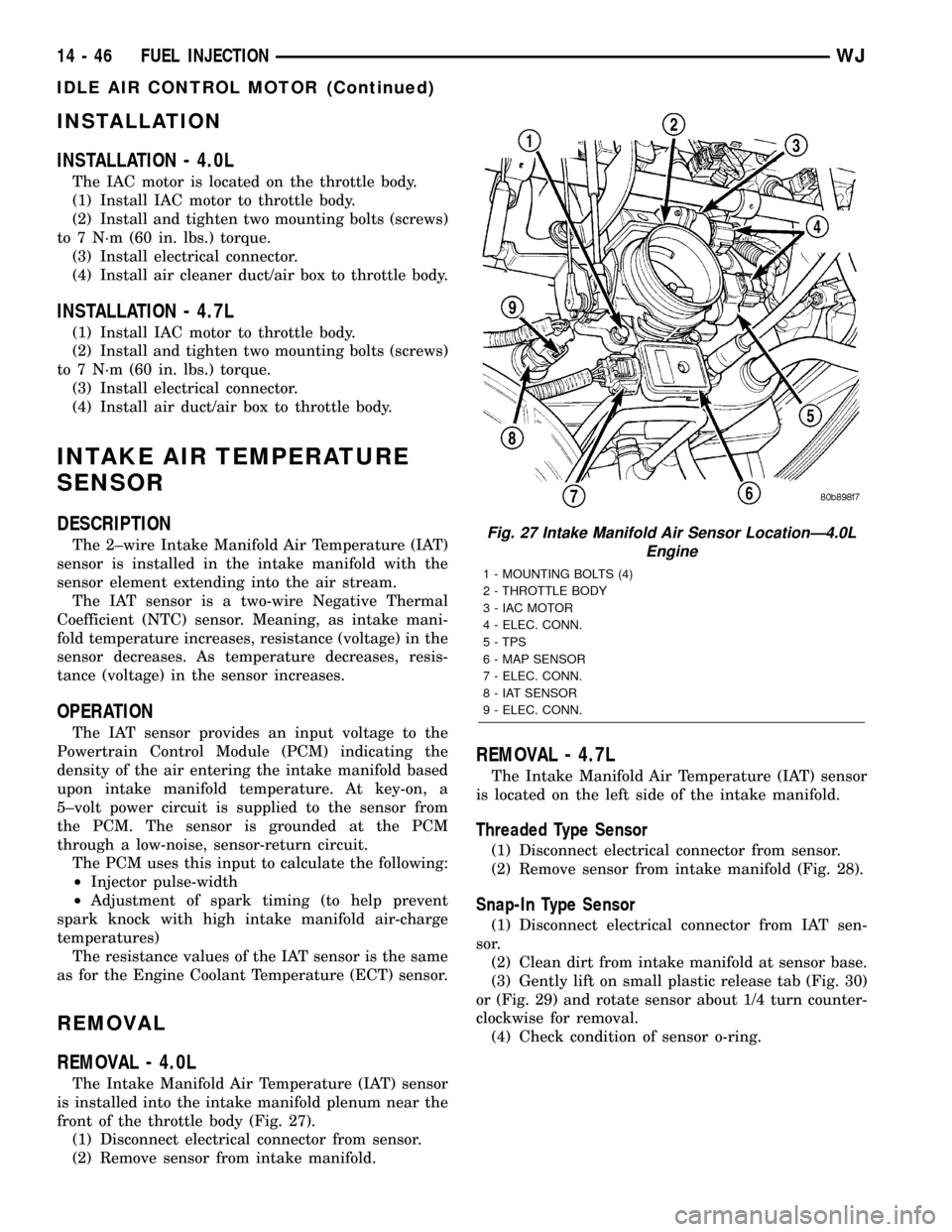

REMOVAL - 4.0L

The Intake Manifold Air Temperature (IAT) sensor

is installed into the intake manifold plenum near the

front of the throttle body (Fig. 27).

(1) Disconnect electrical connector from sensor.

(2) Remove sensor from intake manifold.

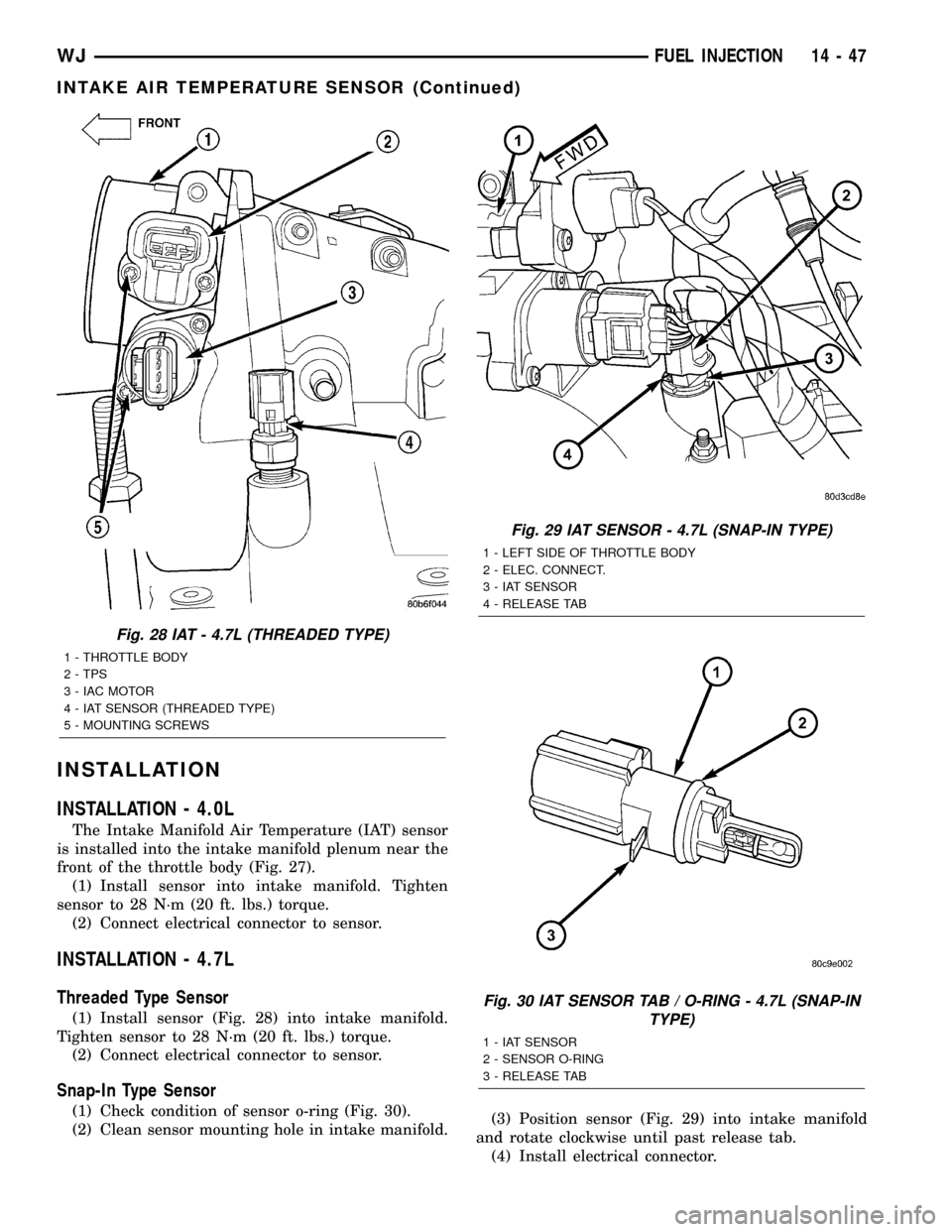

REMOVAL - 4.7L

The Intake Manifold Air Temperature (IAT) sensor

is located on the left side of the intake manifold.

Threaded Type Sensor

(1) Disconnect electrical connector from sensor.

(2) Remove sensor from intake manifold (Fig. 28).

Snap-In Type Sensor

(1) Disconnect electrical connector from IAT sen-

sor.

(2) Clean dirt from intake manifold at sensor base.

(3) Gently lift on small plastic release tab (Fig. 30)

or (Fig. 29) and rotate sensor about 1/4 turn counter-

clockwise for removal.

(4) Check condition of sensor o-ring.

Fig. 27 Intake Manifold Air Sensor LocationÐ4.0L

Engine

1 - MOUNTING BOLTS (4)

2 - THROTTLE BODY

3 - IAC MOTOR

4 - ELEC. CONN.

5 - TPS

6 - MAP SENSOR

7 - ELEC. CONN.

8 - IAT SENSOR

9 - ELEC. CONN.

14 - 46 FUEL INJECTIONWJ

IDLE AIR CONTROL MOTOR (Continued)

Page 1466 of 2199

INSTALLATION

INSTALLATION - 4.0L

The Intake Manifold Air Temperature (IAT) sensor

is installed into the intake manifold plenum near the

front of the throttle body (Fig. 27).

(1) Install sensor into intake manifold. Tighten

sensor to 28 N´m (20 ft. lbs.) torque.

(2) Connect electrical connector to sensor.

INSTALLATION - 4.7L

Threaded Type Sensor

(1) Install sensor (Fig. 28) into intake manifold.

Tighten sensor to 28 N´m (20 ft. lbs.) torque.

(2) Connect electrical connector to sensor.

Snap-In Type Sensor

(1) Check condition of sensor o-ring (Fig. 30).

(2) Clean sensor mounting hole in intake manifold.(3) Position sensor (Fig. 29) into intake manifold

and rotate clockwise until past release tab.

(4) Install electrical connector.

Fig. 28 IAT - 4.7L (THREADED TYPE)

1 - THROTTLE BODY

2 - TPS

3 - IAC MOTOR

4 - IAT SENSOR (THREADED TYPE)

5 - MOUNTING SCREWS

Fig. 29 IAT SENSOR - 4.7L (SNAP-IN TYPE)

1 - LEFT SIDE OF THROTTLE BODY

2 - ELEC. CONNECT.

3 - IAT SENSOR

4 - RELEASE TAB

Fig. 30 IAT SENSOR TAB / O-RING - 4.7L (SNAP-IN

TYPE)

1 - IAT SENSOR

2 - SENSOR O-RING

3 - RELEASE TAB

WJFUEL INJECTION 14 - 47

INTAKE AIR TEMPERATURE SENSOR (Continued)

Page 1472 of 2199

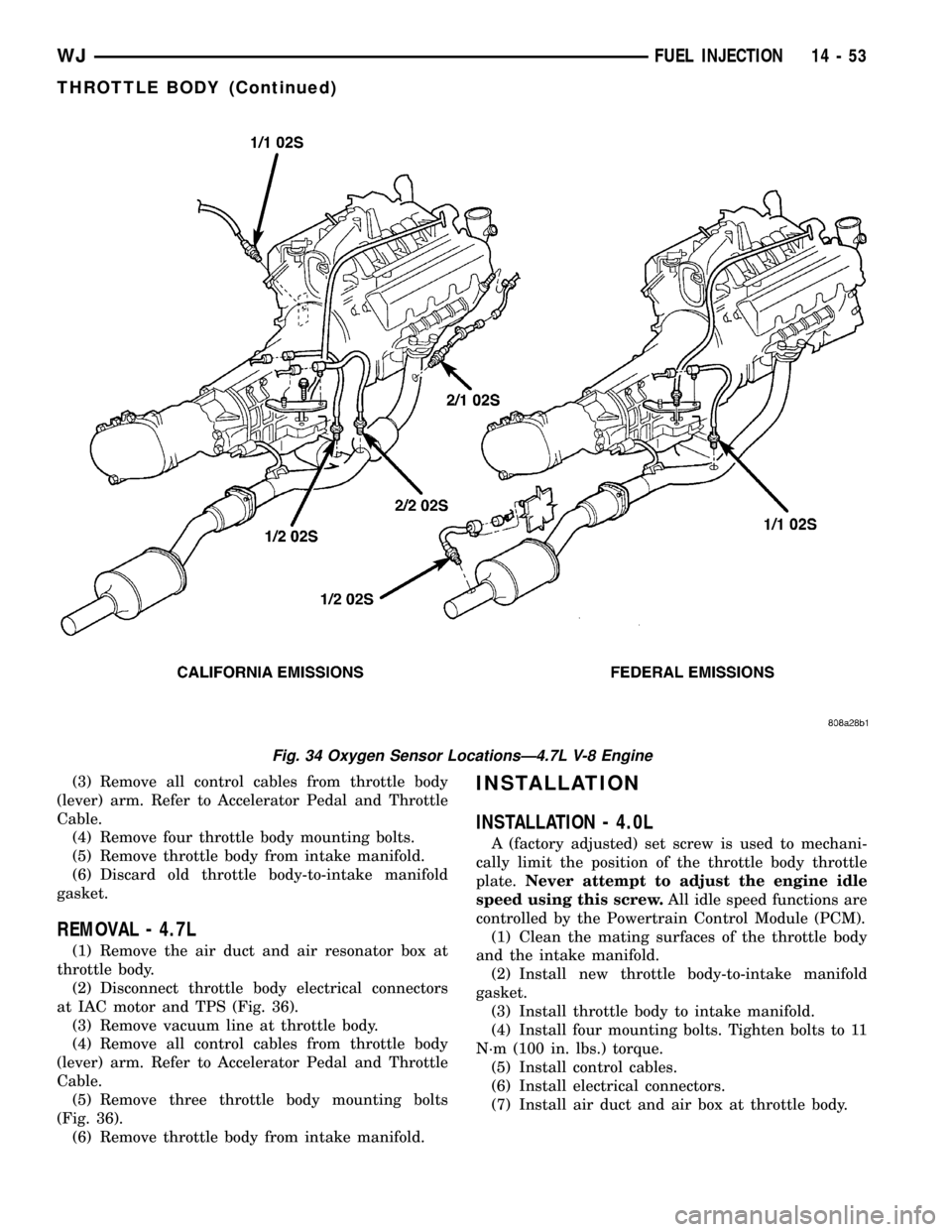

(3) Remove all control cables from throttle body

(lever) arm. Refer to Accelerator Pedal and Throttle

Cable.

(4) Remove four throttle body mounting bolts.

(5) Remove throttle body from intake manifold.

(6) Discard old throttle body-to-intake manifold

gasket.

REMOVAL - 4.7L

(1) Remove the air duct and air resonator box at

throttle body.

(2) Disconnect throttle body electrical connectors

at IAC motor and TPS (Fig. 36).

(3) Remove vacuum line at throttle body.

(4) Remove all control cables from throttle body

(lever) arm. Refer to Accelerator Pedal and Throttle

Cable.

(5) Remove three throttle body mounting bolts

(Fig. 36).

(6) Remove throttle body from intake manifold.

INSTALLATION

INSTALLATION - 4.0L

A (factory adjusted) set screw is used to mechani-

cally limit the position of the throttle body throttle

plate.Never attempt to adjust the engine idle

speed using this screw.All idle speed functions are

controlled by the Powertrain Control Module (PCM).

(1) Clean the mating surfaces of the throttle body

and the intake manifold.

(2) Install new throttle body-to-intake manifold

gasket.

(3) Install throttle body to intake manifold.

(4) Install four mounting bolts. Tighten bolts to 11

N´m (100 in. lbs.) torque.

(5) Install control cables.

(6) Install electrical connectors.

(7) Install air duct and air box at throttle body.

Fig. 34 Oxygen Sensor LocationsÐ4.7L V-8 Engine

WJFUEL INJECTION 14 - 53

THROTTLE BODY (Continued)

Page 1473 of 2199

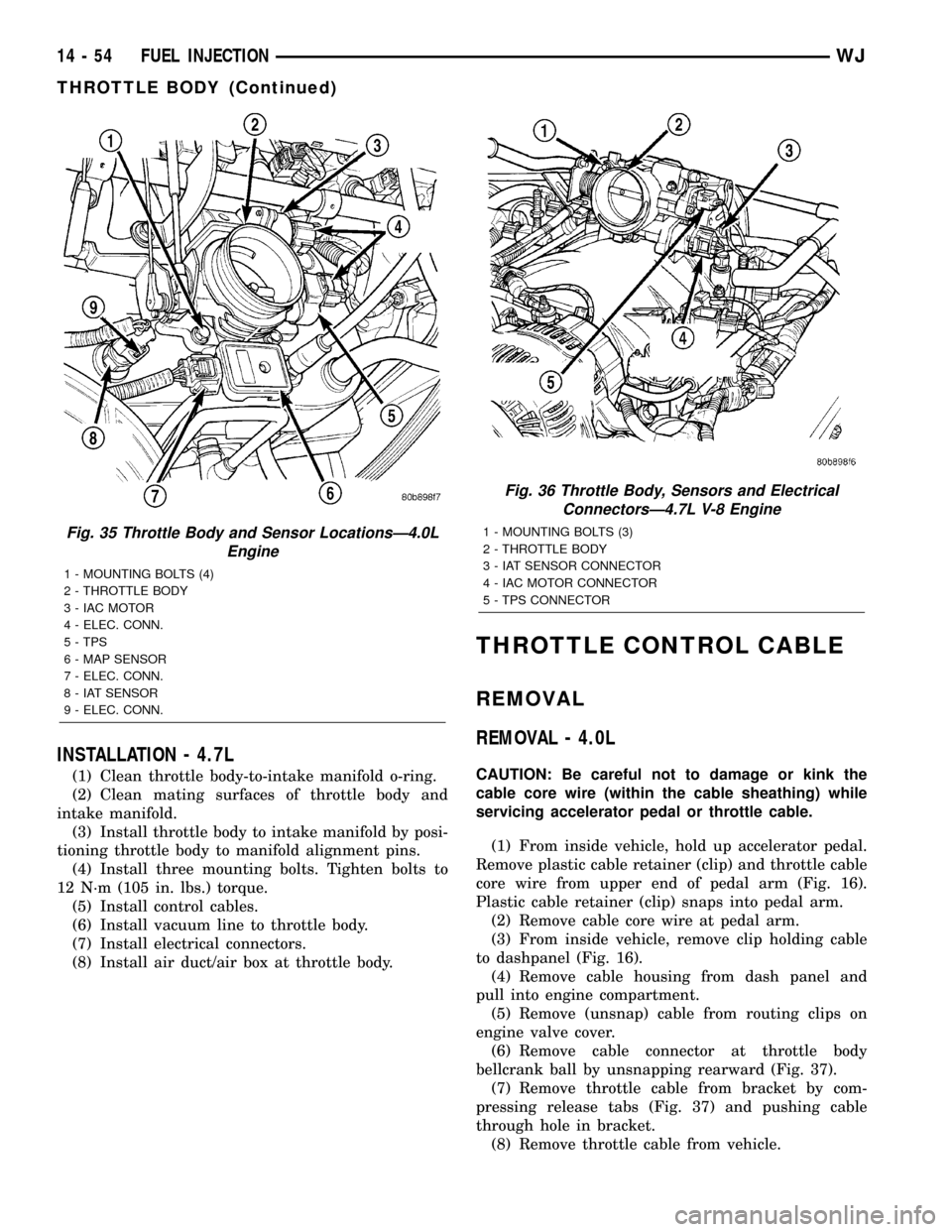

INSTALLATION - 4.7L

(1) Clean throttle body-to-intake manifold o-ring.

(2) Clean mating surfaces of throttle body and

intake manifold.

(3) Install throttle body to intake manifold by posi-

tioning throttle body to manifold alignment pins.

(4) Install three mounting bolts. Tighten bolts to

12 N´m (105 in. lbs.) torque.

(5) Install control cables.

(6) Install vacuum line to throttle body.

(7) Install electrical connectors.

(8) Install air duct/air box at throttle body.

THROTTLE CONTROL CABLE

REMOVAL

REMOVAL - 4.0L

CAUTION: Be careful not to damage or kink the

cable core wire (within the cable sheathing) while

servicing accelerator pedal or throttle cable.

(1) From inside vehicle, hold up accelerator pedal.

Remove plastic cable retainer (clip) and throttle cable

core wire from upper end of pedal arm (Fig. 16).

Plastic cable retainer (clip) snaps into pedal arm.

(2) Remove cable core wire at pedal arm.

(3) From inside vehicle, remove clip holding cable

to dashpanel (Fig. 16).

(4) Remove cable housing from dash panel and

pull into engine compartment.

(5) Remove (unsnap) cable from routing clips on

engine valve cover.

(6) Remove cable connector at throttle body

bellcrank ball by unsnapping rearward (Fig. 37).

(7) Remove throttle cable from bracket by com-

pressing release tabs (Fig. 37) and pushing cable

through hole in bracket.

(8) Remove throttle cable from vehicle.

Fig. 35 Throttle Body and Sensor LocationsÐ4.0L

Engine

1 - MOUNTING BOLTS (4)

2 - THROTTLE BODY

3 - IAC MOTOR

4 - ELEC. CONN.

5 - TPS

6 - MAP SENSOR

7 - ELEC. CONN.

8 - IAT SENSOR

9 - ELEC. CONN.

Fig. 36 Throttle Body, Sensors and Electrical

ConnectorsÐ4.7L V-8 Engine

1 - MOUNTING BOLTS (3)

2 - THROTTLE BODY

3 - IAT SENSOR CONNECTOR

4 - IAC MOTOR CONNECTOR

5 - TPS CONNECTOR

14 - 54 FUEL INJECTIONWJ

THROTTLE BODY (Continued)

Page 1476 of 2199

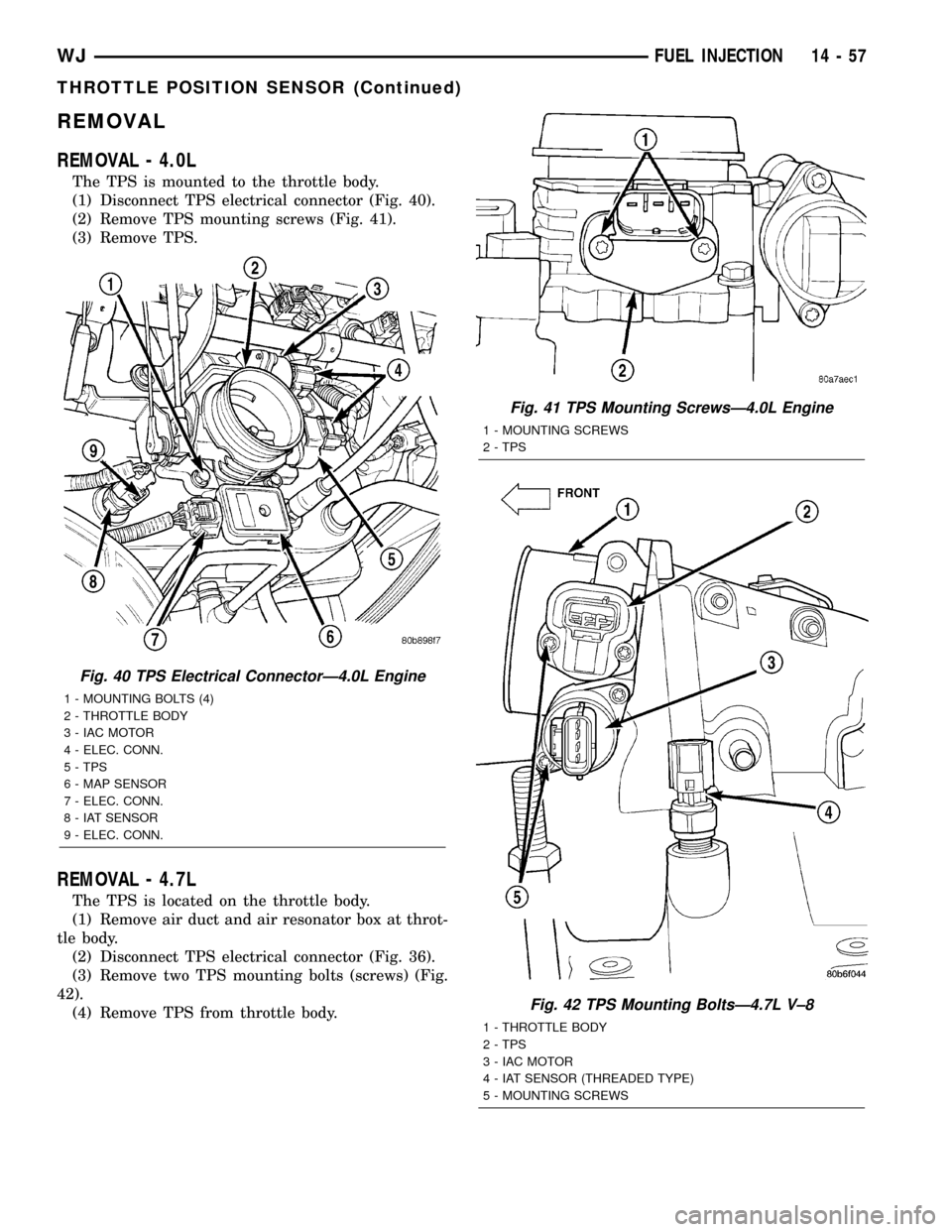

REMOVAL

REMOVAL - 4.0L

The TPS is mounted to the throttle body.

(1) Disconnect TPS electrical connector (Fig. 40).

(2) Remove TPS mounting screws (Fig. 41).

(3) Remove TPS.

REMOVAL - 4.7L

The TPS is located on the throttle body.

(1) Remove air duct and air resonator box at throt-

tle body.

(2) Disconnect TPS electrical connector (Fig. 36).

(3) Remove two TPS mounting bolts (screws) (Fig.

42).

(4) Remove TPS from throttle body.

Fig. 40 TPS Electrical ConnectorÐ4.0L Engine

1 - MOUNTING BOLTS (4)

2 - THROTTLE BODY

3 - IAC MOTOR

4 - ELEC. CONN.

5 - TPS

6 - MAP SENSOR

7 - ELEC. CONN.

8 - IAT SENSOR

9 - ELEC. CONN.

Fig. 41 TPS Mounting ScrewsÐ4.0L Engine

1 - MOUNTING SCREWS

2 - TPS

Fig. 42 TPS Mounting BoltsÐ4.7L V±8

1 - THROTTLE BODY

2 - TPS

3 - IAC MOTOR

4 - IAT SENSOR (THREADED TYPE)

5 - MOUNTING SCREWS

WJFUEL INJECTION 14 - 57

THROTTLE POSITION SENSOR (Continued)

Page 1517 of 2199

(5) Disconnect the rubber hose from the power

steering reservoir (Fig. 12).

(6) Remove the hose from the vehicle.

REMOVAL - 3/8(GEAR OUTLET HOSE

(1) Drain the power steering fluid from the reser-

voir.

(2) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Raise and support the vehicle.

(4) Disconnect the rubber hose from the steering

cooler inlet tube (Fig. 11).

(5) Disconnect the metal tube from the power

steering gear (Fig. 11).

(6) Remove the hose from the vehicle.

REMOVAL - INLET COOLER HOSE

(1) Disconnect negative battery cable at battery.

(2) Drain the power steering fluid out of the reser-

voir.

(3) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(4) Remove the front fascia grille assembly,(Refer

to 13 - FRAMES & BUMPERS/BUMPERS/FRONT

FASCIA - REMOVAL).

(5) Remove the grille opening reinforcement panel

(6) Place a drain pan under the cooler.

(7) Disconnect the lower hose at cooler (Fig. 6).

(8) Disconnect the cooler hose at the gear.

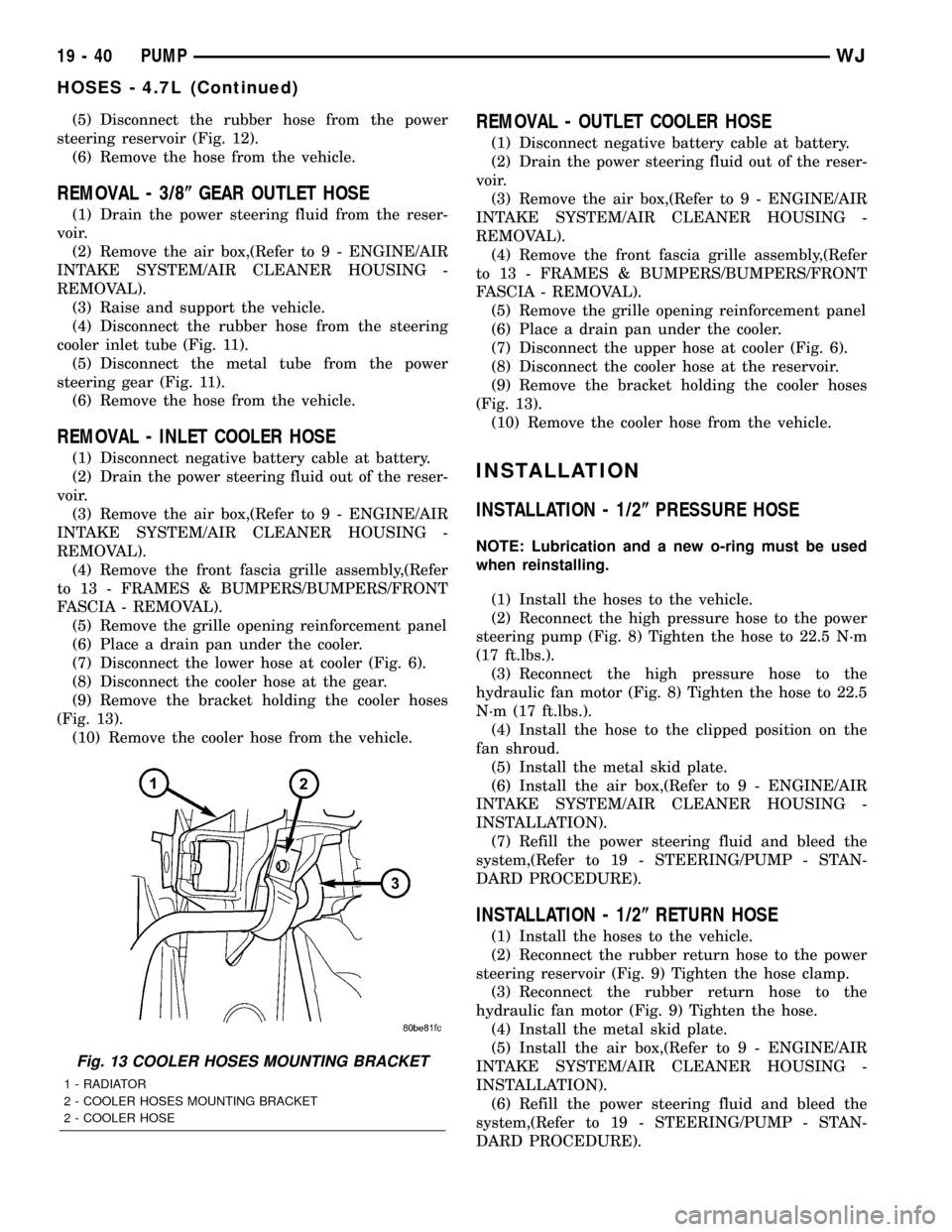

(9) Remove the bracket holding the cooler hoses

(Fig. 13).

(10) Remove the cooler hose from the vehicle.

REMOVAL - OUTLET COOLER HOSE

(1) Disconnect negative battery cable at battery.

(2) Drain the power steering fluid out of the reser-

voir.

(3) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(4) Remove the front fascia grille assembly,(Refer

to 13 - FRAMES & BUMPERS/BUMPERS/FRONT

FASCIA - REMOVAL).

(5) Remove the grille opening reinforcement panel

(6) Place a drain pan under the cooler.

(7) Disconnect the upper hose at cooler (Fig. 6).

(8) Disconnect the cooler hose at the reservoir.

(9) Remove the bracket holding the cooler hoses

(Fig. 13).

(10) Remove the cooler hose from the vehicle.

INSTALLATION

INSTALLATION - 1/2(PRESSURE HOSE

NOTE: Lubrication and a new o-ring must be used

when reinstalling.

(1) Install the hoses to the vehicle.

(2) Reconnect the high pressure hose to the power

steering pump (Fig. 8) Tighten the hose to 22.5 N´m

(17 ft.lbs.).

(3) Reconnect the high pressure hose to the

hydraulic fan motor (Fig. 8) Tighten the hose to 22.5

N´m (17 ft.lbs.).

(4) Install the hose to the clipped position on the

fan shroud.

(5) Install the metal skid plate.

(6) Install the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(7) Refill the power steering fluid and bleed the

system,(Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

INSTALLATION - 1/2(RETURN HOSE

(1) Install the hoses to the vehicle.

(2) Reconnect the rubber return hose to the power

steering reservoir (Fig. 9) Tighten the hose clamp.

(3) Reconnect the rubber return hose to the

hydraulic fan motor (Fig. 9) Tighten the hose.

(4) Install the metal skid plate.

(5) Install the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(6) Refill the power steering fluid and bleed the

system,(Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

Fig. 13 COOLER HOSES MOUNTING BRACKET

1 - RADIATOR

2 - COOLER HOSES MOUNTING BRACKET

2 - COOLER HOSE

19 - 40 PUMPWJ

HOSES - 4.7L (Continued)

Page 1561 of 2199

(11) Move transmission forward. Then raise, lower

or tilt transmission to align converter housing with

engine block dowels.

(12) Carefully work transmission forward and over

engine block dowels until converter hub is seated in

crankshaft.

(13) Install two bolts to attach converter housing

to engine.

(14) Install the upper transmission bending braces

to the torque converter housing and the overdrive

unit. Tighten the bolts to 41 N´m (30 ft.lbs.).

(15) Install remaining torque converter housing to

engine bolts. Tighten to 68 N´m (50 ft.lbs.).

(16) Install rear transmission crossmember.

Tighten crossmember to frame bolts to 68 N´m (50

ft.lbs.).

(17) Install rear support to transmission. Tighten

bolts to 47 N´m (35 ft.lbs.).

(18) Lower transmission onto crossmember and

install bolts attaching transmission mount to cross-

member. Tighten clevis bracket to crossmember bolts

to 47 N´m (35 ft.lbs.). Tighten the clevis bracket to

rear support bolt to 68 N´m (50 ft.lbs.).

(19) Remove engine support fixture.

(20) Install crankshaft position sensor. (Refer to 14

- FUEL SYSTEM/FUEL INJECTION/CRANKSHAFT

POSITION SENSOR - INSTALLATION)

(21) Install new plastic retainer grommet on any

shift cable that was disconnected. Grommets should

not be reused. Use pry tool to remove rod from grom-

met and cut away old grommet. Use pliers to snap

new grommet into cable and to snap grommet onto

lever.

(22) Connect gearshift and throttle valve cable to

transmission.

(23) Connect wires to park/neutral position switch

and transmission solenoid connector. Be sure trans-

mission harnesses are properly routed.CAUTION: It is essential that correct length bolts be

used to attach the converter to the driveplate. Bolts

that are too long will damage the clutch surface

inside the converter.

(24) Install all torque converter-to-driveplate bolts

by hand.

(25) Verify that the torque converter is pulled

flush to the driveplate. Tighten bolts to 31 N´m (270

in. lbs.).

(26) Install converter housing access cover. Tighten

bolt to 23 N´m (200 in.lbs.).

(27) Install the bell housing brace to the torque

converter cover and the engine to transmission bend-

ing brace. Tighten the bolts and nut to 41 N´m (30

ft.lbs.).

(28) Install starter motor (Refer to 8 - ELECTRI-

CAL/STARTING/STARTER MOTOR - INSTALLA-

TION) and cooler line bracket.

(29) Connect cooler lines to transmission.

(30) Install transmission fill tube. Install new seal

on tube before installation.

(31) Install exhaust components.

(32) Install transfer case. Tighten transfer case

nuts to 35 N´m (26 ft.lbs.).

(33) Install the transfer case shift cable to the

cable support bracket and the transfer case shift

lever.

(34) Align and connect propeller shaft(s).

(35) Adjust gearshift linkage and throttle valve

cable if necessary.

(36) Lower vehicle.

(37) Fill transmission with MopartATF +4, type

9602, fluid.

21 - 42 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)