Radio JEEP GRAND CHEROKEE 2002 WJ / 2.G Manual PDF

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1914 of 2199

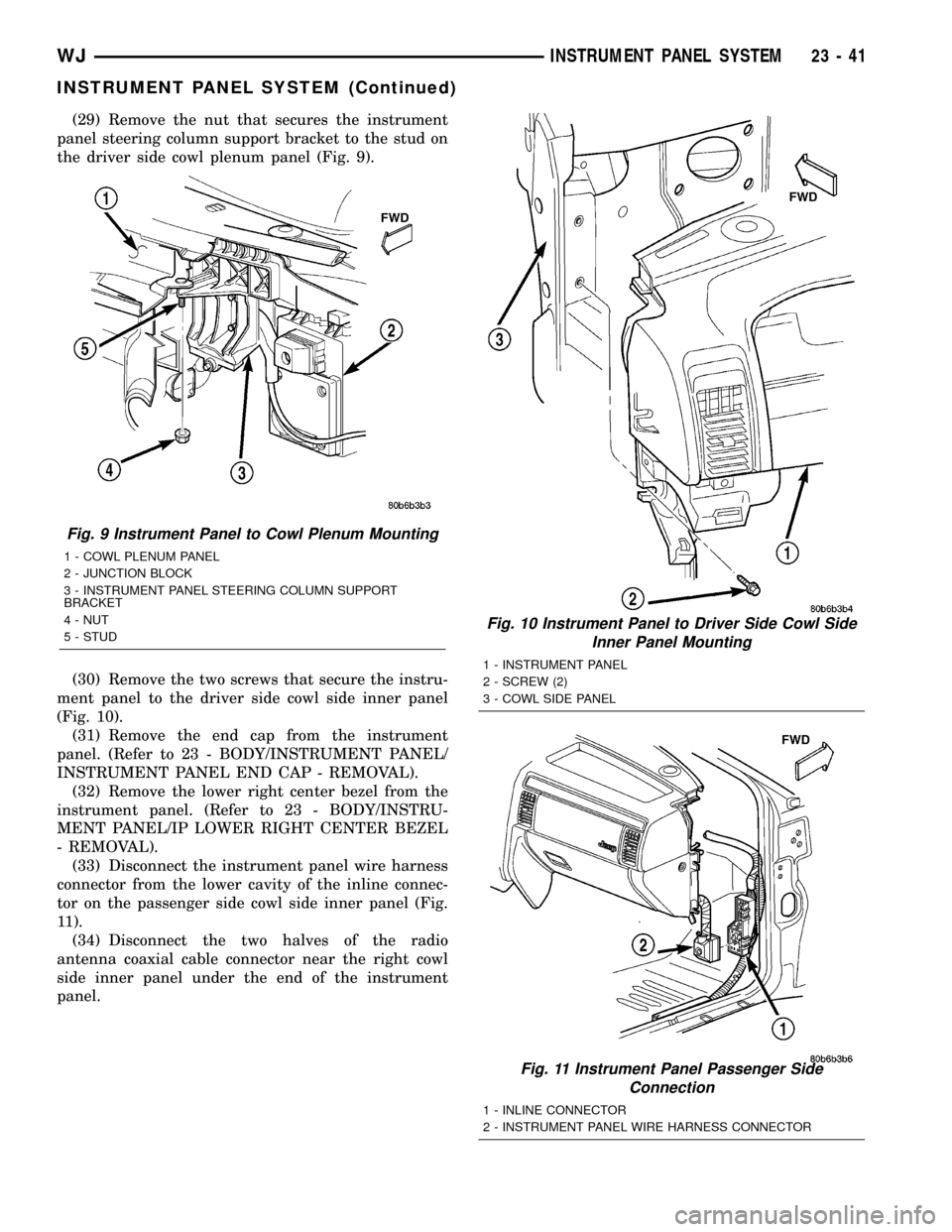

(29) Remove the nut that secures the instrument

panel steering column support bracket to the stud on

the driver side cowl plenum panel (Fig. 9).

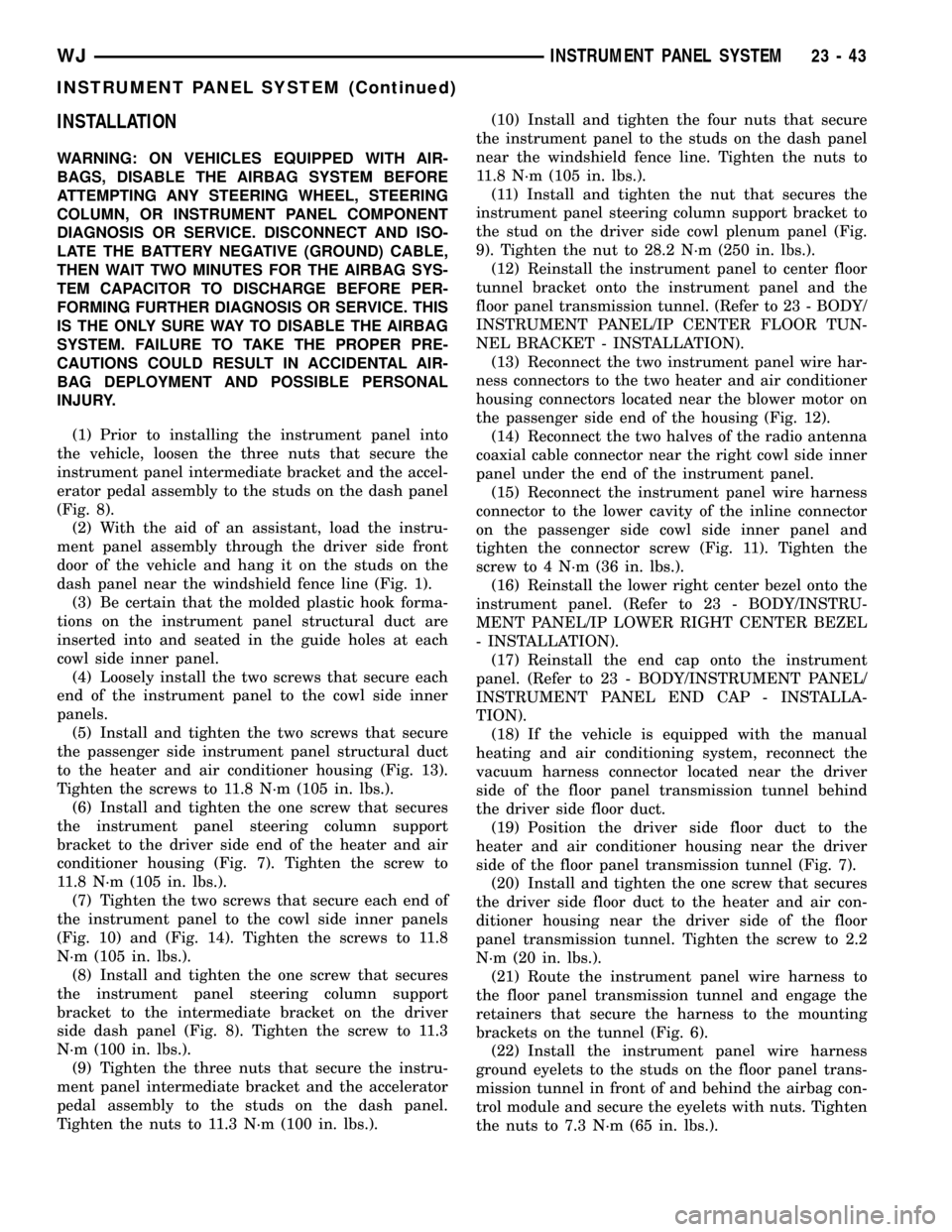

(30) Remove the two screws that secure the instru-

ment panel to the driver side cowl side inner panel

(Fig. 10).

(31) Remove the end cap from the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL END CAP - REMOVAL).

(32) Remove the lower right center bezel from the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/IP LOWER RIGHT CENTER BEZEL

- REMOVAL).

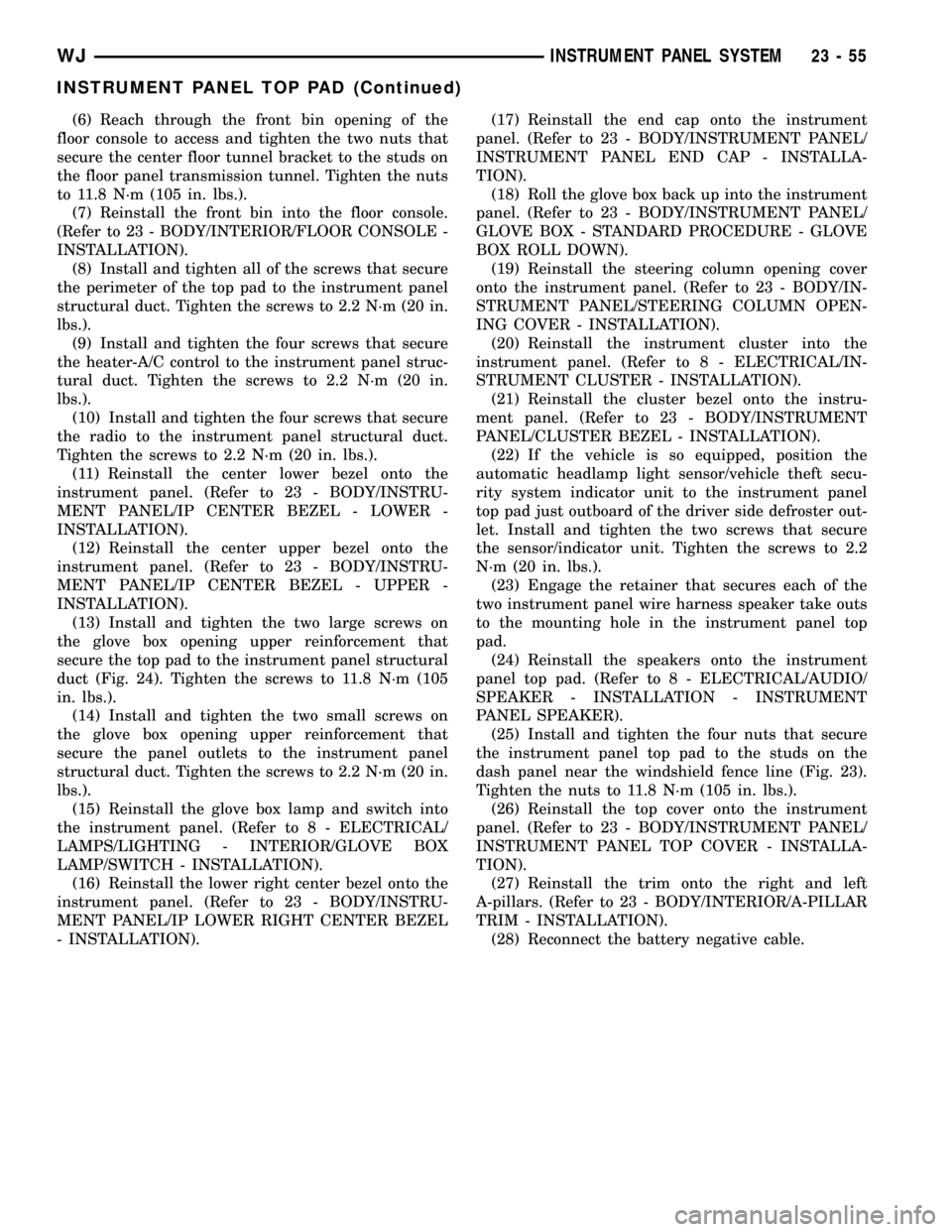

(33) Disconnect the instrument panel wire harness

connector from the lower cavity of the inline connec-

tor on the passenger side cowl side inner panel (Fig.

11).

(34) Disconnect the two halves of the radio

antenna coaxial cable connector near the right cowl

side inner panel under the end of the instrument

panel.

Fig. 9 Instrument Panel to Cowl Plenum Mounting

1 - COWL PLENUM PANEL

2 - JUNCTION BLOCK

3 - INSTRUMENT PANEL STEERING COLUMN SUPPORT

BRACKET

4 - NUT

5 - STUD

Fig. 10 Instrument Panel to Driver Side Cowl Side

Inner Panel Mounting

1 - INSTRUMENT PANEL

2 - SCREW (2)

3 - COWL SIDE PANEL

Fig. 11 Instrument Panel Passenger Side

Connection

1 - INLINE CONNECTOR

2 - INSTRUMENT PANEL WIRE HARNESS CONNECTOR

WJINSTRUMENT PANEL SYSTEM 23 - 41

INSTRUMENT PANEL SYSTEM (Continued)

Page 1916 of 2199

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Prior to installing the instrument panel into

the vehicle, loosen the three nuts that secure the

instrument panel intermediate bracket and the accel-

erator pedal assembly to the studs on the dash panel

(Fig. 8).

(2) With the aid of an assistant, load the instru-

ment panel assembly through the driver side front

door of the vehicle and hang it on the studs on the

dash panel near the windshield fence line (Fig. 1).

(3) Be certain that the molded plastic hook forma-

tions on the instrument panel structural duct are

inserted into and seated in the guide holes at each

cowl side inner panel.

(4) Loosely install the two screws that secure each

end of the instrument panel to the cowl side inner

panels.

(5) Install and tighten the two screws that secure

the passenger side instrument panel structural duct

to the heater and air conditioner housing (Fig. 13).

Tighten the screws to 11.8 N´m (105 in. lbs.).

(6) Install and tighten the one screw that secures

the instrument panel steering column support

bracket to the driver side end of the heater and air

conditioner housing (Fig. 7). Tighten the screw to

11.8 N´m (105 in. lbs.).

(7) Tighten the two screws that secure each end of

the instrument panel to the cowl side inner panels

(Fig. 10) and (Fig. 14). Tighten the screws to 11.8

N´m (105 in. lbs.).

(8) Install and tighten the one screw that secures

the instrument panel steering column support

bracket to the intermediate bracket on the driver

side dash panel (Fig. 8). Tighten the screw to 11.3

N´m (100 in. lbs.).

(9) Tighten the three nuts that secure the instru-

ment panel intermediate bracket and the accelerator

pedal assembly to the studs on the dash panel.

Tighten the nuts to 11.3 N´m (100 in. lbs.).(10) Install and tighten the four nuts that secure

the instrument panel to the studs on the dash panel

near the windshield fence line. Tighten the nuts to

11.8 N´m (105 in. lbs.).

(11) Install and tighten the nut that secures the

instrument panel steering column support bracket to

the stud on the driver side cowl plenum panel (Fig.

9). Tighten the nut to 28.2 N´m (250 in. lbs.).

(12) Reinstall the instrument panel to center floor

tunnel bracket onto the instrument panel and the

floor panel transmission tunnel. (Refer to 23 - BODY/

INSTRUMENT PANEL/IP CENTER FLOOR TUN-

NEL BRACKET - INSTALLATION).

(13) Reconnect the two instrument panel wire har-

ness connectors to the two heater and air conditioner

housing connectors located near the blower motor on

the passenger side end of the housing (Fig. 12).

(14) Reconnect the two halves of the radio antenna

coaxial cable connector near the right cowl side inner

panel under the end of the instrument panel.

(15) Reconnect the instrument panel wire harness

connector to the lower cavity of the inline connector

on the passenger side cowl side inner panel and

tighten the connector screw (Fig. 11). Tighten the

screw to 4 N´m (36 in. lbs.).

(16) Reinstall the lower right center bezel onto the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/IP LOWER RIGHT CENTER BEZEL

- INSTALLATION).

(17) Reinstall the end cap onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL END CAP - INSTALLA-

TION).

(18) If the vehicle is equipped with the manual

heating and air conditioning system, reconnect the

vacuum harness connector located near the driver

side of the floor panel transmission tunnel behind

the driver side floor duct.

(19) Position the driver side floor duct to the

heater and air conditioner housing near the driver

side of the floor panel transmission tunnel (Fig. 7).

(20) Install and tighten the one screw that secures

the driver side floor duct to the heater and air con-

ditioner housing near the driver side of the floor

panel transmission tunnel. Tighten the screw to 2.2

N´m (20 in. lbs.).

(21) Route the instrument panel wire harness to

the floor panel transmission tunnel and engage the

retainers that secure the harness to the mounting

brackets on the tunnel (Fig. 6).

(22) Install the instrument panel wire harness

ground eyelets to the studs on the floor panel trans-

mission tunnel in front of and behind the airbag con-

trol module and secure the eyelets with nuts. Tighten

the nuts to 7.3 N´m (65 in. lbs.).

WJINSTRUMENT PANEL SYSTEM 23 - 43

INSTRUMENT PANEL SYSTEM (Continued)

Page 1926 of 2199

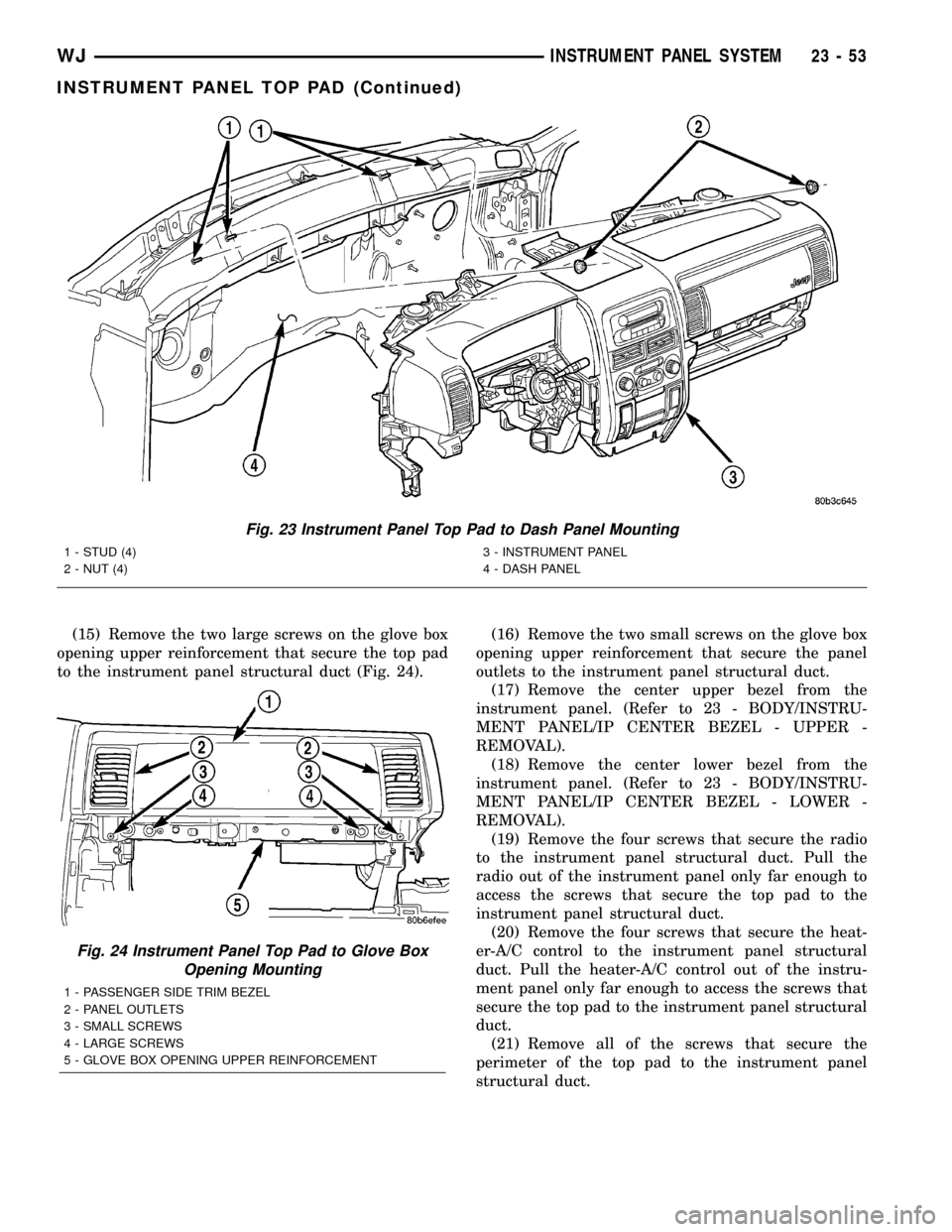

(15) Remove the two large screws on the glove box

opening upper reinforcement that secure the top pad

to the instrument panel structural duct (Fig. 24).(16) Remove the two small screws on the glove box

opening upper reinforcement that secure the panel

outlets to the instrument panel structural duct.

(17) Remove the center upper bezel from the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/IP CENTER BEZEL - UPPER -

REMOVAL).

(18) Remove the center lower bezel from the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/IP CENTER BEZEL - LOWER -

REMOVAL).

(19) Remove the four screws that secure the radio

to the instrument panel structural duct. Pull the

radio out of the instrument panel only far enough to

access the screws that secure the top pad to the

instrument panel structural duct.

(20) Remove the four screws that secure the heat-

er-A/C control to the instrument panel structural

duct. Pull the heater-A/C control out of the instru-

ment panel only far enough to access the screws that

secure the top pad to the instrument panel structural

duct.

(21) Remove all of the screws that secure the

perimeter of the top pad to the instrument panel

structural duct.

Fig. 23 Instrument Panel Top Pad to Dash Panel Mounting

1 - STUD (4)

2 - NUT (4)3 - INSTRUMENT PANEL

4 - DASH PANEL

Fig. 24 Instrument Panel Top Pad to Glove Box

Opening Mounting

1 - PASSENGER SIDE TRIM BEZEL

2 - PANEL OUTLETS

3 - SMALL SCREWS

4 - LARGE SCREWS

5 - GLOVE BOX OPENING UPPER REINFORCEMENT

WJINSTRUMENT PANEL SYSTEM 23 - 53

INSTRUMENT PANEL TOP PAD (Continued)

Page 1928 of 2199

(6) Reach through the front bin opening of the

floor console to access and tighten the two nuts that

secure the center floor tunnel bracket to the studs on

the floor panel transmission tunnel. Tighten the nuts

to 11.8 N´m (105 in. lbs.).

(7) Reinstall the front bin into the floor console.

(Refer to 23 - BODY/INTERIOR/FLOOR CONSOLE -

INSTALLATION).

(8) Install and tighten all of the screws that secure

the perimeter of the top pad to the instrument panel

structural duct. Tighten the screws to 2.2 N´m (20 in.

lbs.).

(9) Install and tighten the four screws that secure

the heater-A/C control to the instrument panel struc-

tural duct. Tighten the screws to 2.2 N´m (20 in.

lbs.).

(10) Install and tighten the four screws that secure

the radio to the instrument panel structural duct.

Tighten the screws to 2.2 N´m (20 in. lbs.).

(11) Reinstall the center lower bezel onto the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/IP CENTER BEZEL - LOWER -

INSTALLATION).

(12) Reinstall the center upper bezel onto the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/IP CENTER BEZEL - UPPER -

INSTALLATION).

(13) Install and tighten the two large screws on

the glove box opening upper reinforcement that

secure the top pad to the instrument panel structural

duct (Fig. 24). Tighten the screws to 11.8 N´m (105

in. lbs.).

(14) Install and tighten the two small screws on

the glove box opening upper reinforcement that

secure the panel outlets to the instrument panel

structural duct. Tighten the screws to 2.2 N´m (20 in.

lbs.).

(15) Reinstall the glove box lamp and switch into

the instrument panel. (Refer to 8 - ELECTRICAL/

LAMPS/LIGHTING - INTERIOR/GLOVE BOX

LAMP/SWITCH - INSTALLATION).

(16) Reinstall the lower right center bezel onto the

instrument panel. (Refer to 23 - BODY/INSTRU-

MENT PANEL/IP LOWER RIGHT CENTER BEZEL

- INSTALLATION).(17) Reinstall the end cap onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL END CAP - INSTALLA-

TION).

(18) Roll the glove box back up into the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

GLOVE BOX - STANDARD PROCEDURE - GLOVE

BOX ROLL DOWN).

(19) Reinstall the steering column opening cover

onto the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/STEERING COLUMN OPEN-

ING COVER - INSTALLATION).

(20) Reinstall the instrument cluster into the

instrument panel. (Refer to 8 - ELECTRICAL/IN-

STRUMENT CLUSTER - INSTALLATION).

(21) Reinstall the cluster bezel onto the instru-

ment panel. (Refer to 23 - BODY/INSTRUMENT

PANEL/CLUSTER BEZEL - INSTALLATION).

(22) If the vehicle is so equipped, position the

automatic headlamp light sensor/vehicle theft secu-

rity system indicator unit to the instrument panel

top pad just outboard of the driver side defroster out-

let. Install and tighten the two screws that secure

the sensor/indicator unit. Tighten the screws to 2.2

N´m (20 in. lbs.).

(23) Engage the retainer that secures each of the

two instrument panel wire harness speaker take outs

to the mounting hole in the instrument panel top

pad.

(24) Reinstall the speakers onto the instrument

panel top pad. (Refer to 8 - ELECTRICAL/AUDIO/

SPEAKER - INSTALLATION - INSTRUMENT

PANEL SPEAKER).

(25) Install and tighten the four nuts that secure

the instrument panel top pad to the studs on the

dash panel near the windshield fence line (Fig. 23).

Tighten the nuts to 11.8 N´m (105 in. lbs.).

(26) Reinstall the top cover onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL TOP COVER - INSTALLA-

TION).

(27) Reinstall the trim onto the right and left

A-pillars. (Refer to 23 - BODY/INTERIOR/A-PILLAR

TRIM - INSTALLATION).

(28) Reconnect the battery negative cable.

WJINSTRUMENT PANEL SYSTEM 23 - 55

INSTRUMENT PANEL TOP PAD (Continued)

Page 1929 of 2199

INSTRUMENT PANEL C-

CHANNEL COVER BRACKET

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE AIRBAG SYSTEM BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO MIN-

UTES FOR THE AIRBAG SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

(1)Disconnect and isolate the battery negative cable.

(2) Remove the instrument panel from the vehicle.

(Refer to 23 - BODY/INSTRUMENT PANEL -

REMOVAL).

(3) Place the instrument panel top down on a suit-

able work surface. Be certain to take the proper pre-

cautions to protect the top of the instrument panel

from any possible cosmetic damage.

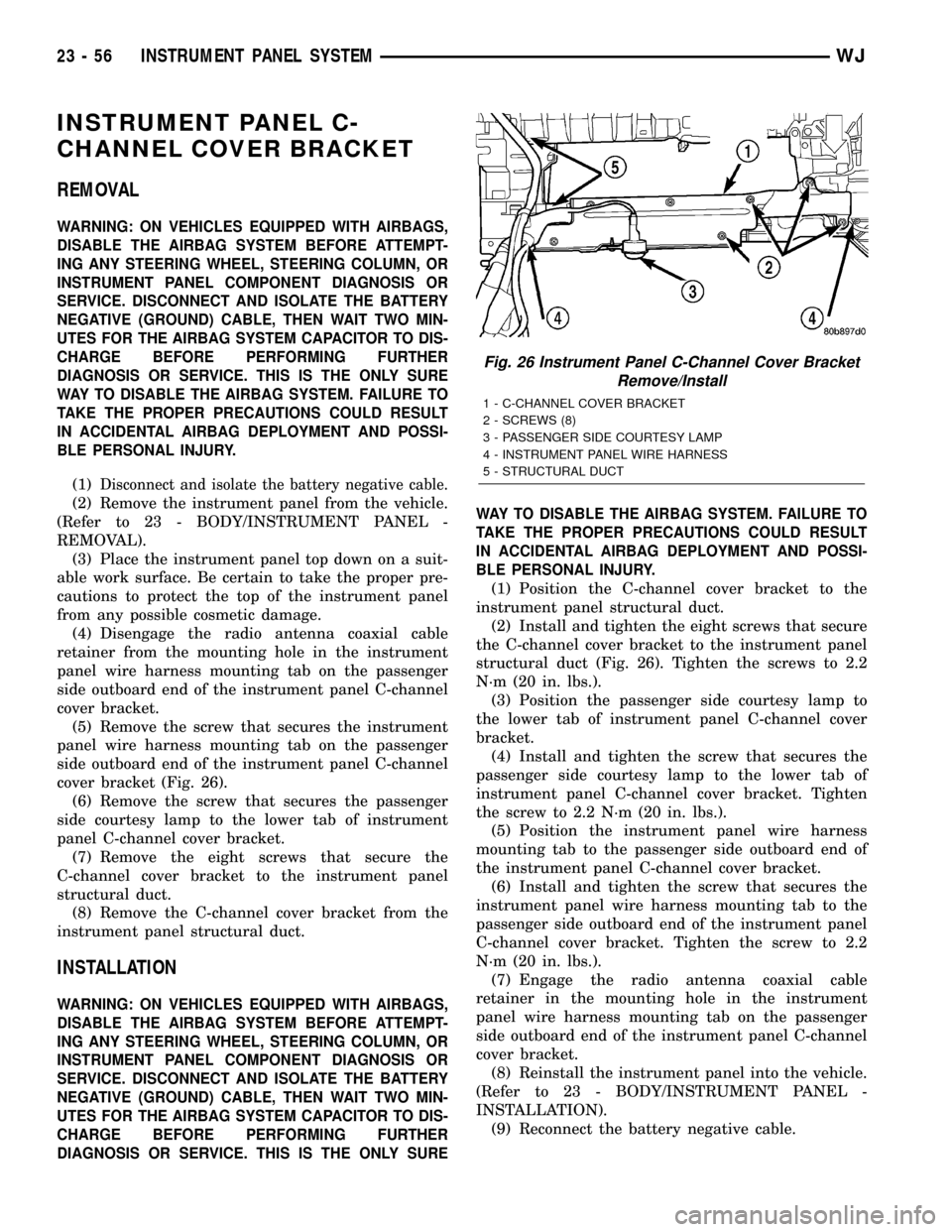

(4) Disengage the radio antenna coaxial cable

retainer from the mounting hole in the instrument

panel wire harness mounting tab on the passenger

side outboard end of the instrument panel C-channel

cover bracket.

(5) Remove the screw that secures the instrument

panel wire harness mounting tab on the passenger

side outboard end of the instrument panel C-channel

cover bracket (Fig. 26).

(6) Remove the screw that secures the passenger

side courtesy lamp to the lower tab of instrument

panel C-channel cover bracket.

(7) Remove the eight screws that secure the

C-channel cover bracket to the instrument panel

structural duct.

(8) Remove the C-channel cover bracket from the

instrument panel structural duct.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE AIRBAG SYSTEM BEFORE ATTEMPT-

ING ANY STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE, THEN WAIT TWO MIN-

UTES FOR THE AIRBAG SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SUREWAY TO DISABLE THE AIRBAG SYSTEM. FAILURE TO

TAKE THE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

(1) Position the C-channel cover bracket to the

instrument panel structural duct.

(2) Install and tighten the eight screws that secure

the C-channel cover bracket to the instrument panel

structural duct (Fig. 26). Tighten the screws to 2.2

N´m (20 in. lbs.).

(3) Position the passenger side courtesy lamp to

the lower tab of instrument panel C-channel cover

bracket.

(4) Install and tighten the screw that secures the

passenger side courtesy lamp to the lower tab of

instrument panel C-channel cover bracket. Tighten

the screw to 2.2 N´m (20 in. lbs.).

(5) Position the instrument panel wire harness

mounting tab to the passenger side outboard end of

the instrument panel C-channel cover bracket.

(6) Install and tighten the screw that secures the

instrument panel wire harness mounting tab to the

passenger side outboard end of the instrument panel

C-channel cover bracket. Tighten the screw to 2.2

N´m (20 in. lbs.).

(7) Engage the radio antenna coaxial cable

retainer in the mounting hole in the instrument

panel wire harness mounting tab on the passenger

side outboard end of the instrument panel C-channel

cover bracket.

(8) Reinstall the instrument panel into the vehicle.

(Refer to 23 - BODY/INSTRUMENT PANEL -

INSTALLATION).

(9) Reconnect the battery negative cable.

Fig. 26 Instrument Panel C-Channel Cover Bracket

Remove/Install

1 - C-CHANNEL COVER BRACKET

2 - SCREWS (8)

3 - PASSENGER SIDE COURTESY LAMP

4 - INSTRUMENT PANEL WIRE HARNESS

5 - STRUCTURAL DUCT

23 - 56 INSTRUMENT PANEL SYSTEMWJ

Page 1931 of 2199

INSTRUMENT PANEL CENTER

BEZEL - UPPER

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

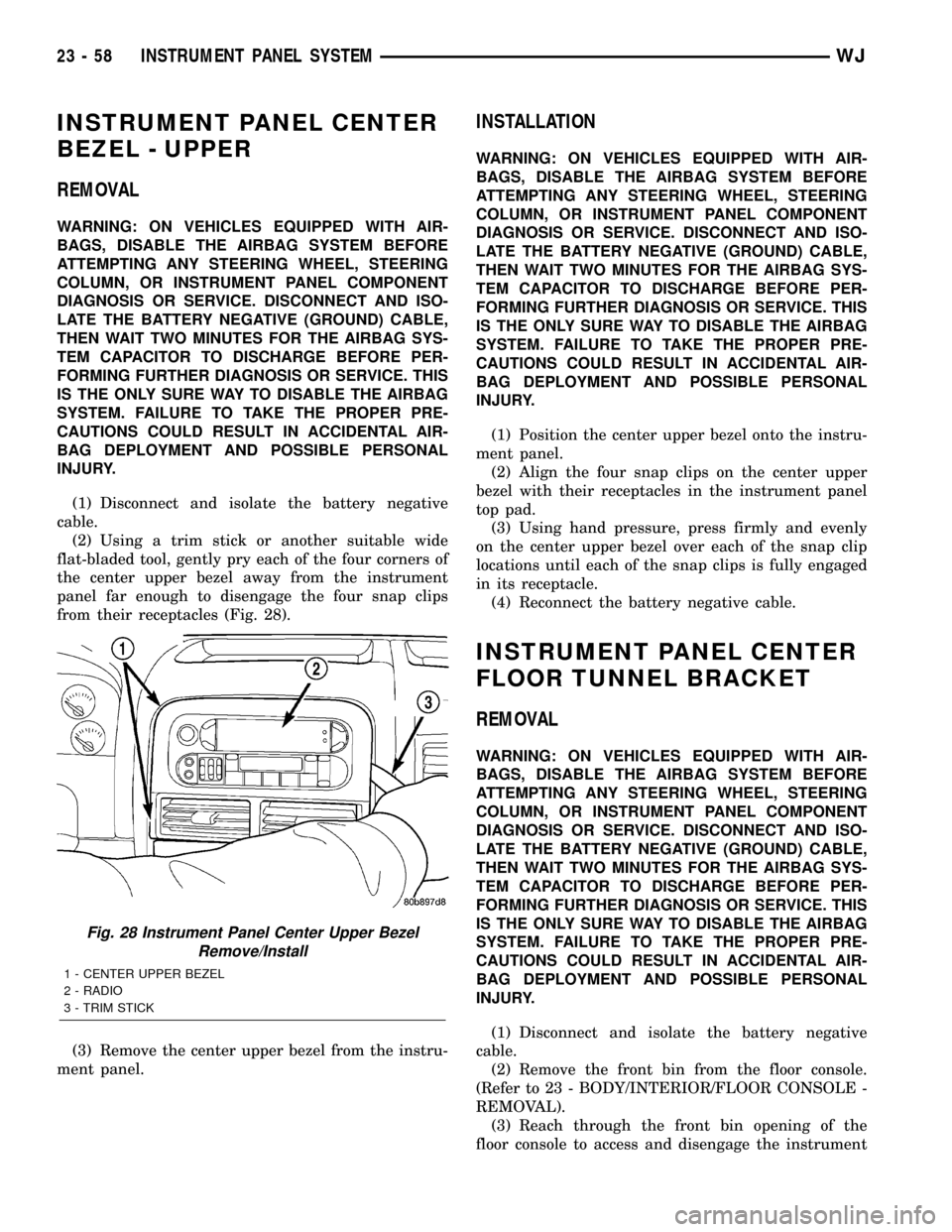

(2) Using a trim stick or another suitable wide

flat-bladed tool, gently pry each of the four corners of

the center upper bezel away from the instrument

panel far enough to disengage the four snap clips

from their receptacles (Fig. 28).

(3) Remove the center upper bezel from the instru-

ment panel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the center upper bezel onto the instru-

ment panel.

(2) Align the four snap clips on the center upper

bezel with their receptacles in the instrument panel

top pad.

(3) Using hand pressure, press firmly and evenly

on the center upper bezel over each of the snap clip

locations until each of the snap clips is fully engaged

in its receptacle.

(4) Reconnect the battery negative cable.

INSTRUMENT PANEL CENTER

FLOOR TUNNEL BRACKET

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the front bin from the floor console.

(Refer to 23 - BODY/INTERIOR/FLOOR CONSOLE -

REMOVAL).

(3) Reach through the front bin opening of the

floor console to access and disengage the instrument

Fig. 28 Instrument Panel Center Upper Bezel

Remove/Install

1 - CENTER UPPER BEZEL

2 - RADIO

3 - TRIM STICK

23 - 58 INSTRUMENT PANEL SYSTEMWJ

Page 1950 of 2199

HEADLINER

REMOVAL

CAUTION: The headliner is a one-piece, molded

component. It has limited flexibility and must not be

bent. Damage may possibly result.

(1) Record radio presets and disconnect negative

battery cable.

(2) Remove A pillar trim moldings (Refer to 23 -

BODY/INTERIOR/A-PILLAR TRIM - REMOVAL).

(3) Remove B pillar upper trim moldings (Refer to

23 - BODY/INTERIOR/B-PILLAR UPPER TRIM -

REMOVAL).

(4) Remove C pillar trim moldings (Refer to 23 -

BODY/INTERIOR/C-PILLAR TRIM - REMOVAL).

(5) Remove D pillar trim molding (Refer to 23 -

BODY/INTERIOR/D-PILLAR TRIM - REMOVAL).

(6) Remove the sun visors (Refer to 23 - BODY/IN-

TERIOR/SUN VISOR - REMOVAL).

(7) Disconnect the vanity lamp electrical connector.

(8) Remove assist handles from roof rails (Refer to

23 - BODY/INTERIOR/ASSIST HANDLE - REMOV-

AL).

(9) Remove dome lamp and overhead console, if

equipped.

(10) Remove rear cargo/dome lamp.

(11) Remove sun roof pinch welt, if equipped.

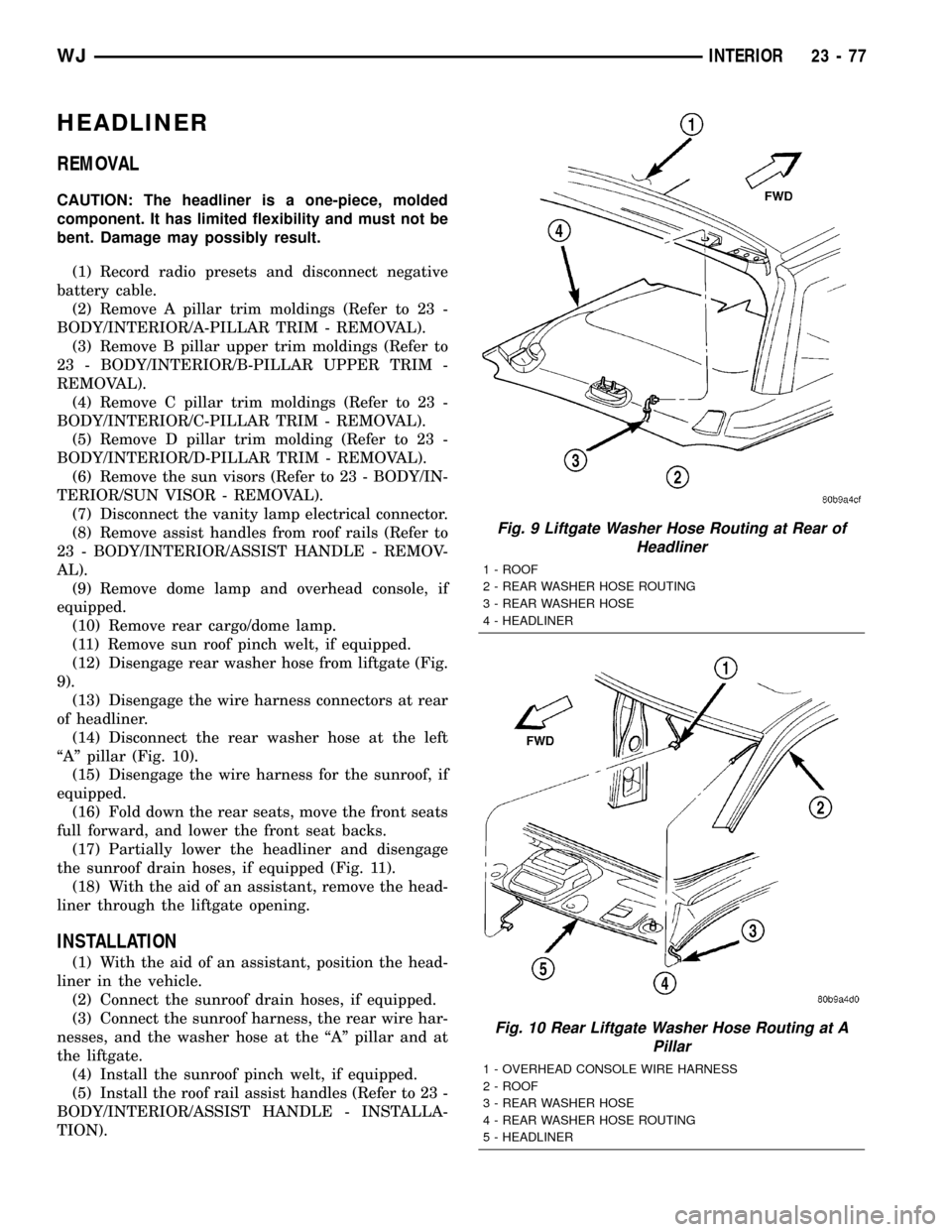

(12) Disengage rear washer hose from liftgate (Fig.

9).

(13) Disengage the wire harness connectors at rear

of headliner.

(14) Disconnect the rear washer hose at the left

ªAº pillar (Fig. 10).

(15) Disengage the wire harness for the sunroof, if

equipped.

(16) Fold down the rear seats, move the front seats

full forward, and lower the front seat backs.

(17) Partially lower the headliner and disengage

the sunroof drain hoses, if equipped (Fig. 11).

(18) With the aid of an assistant, remove the head-

liner through the liftgate opening.

INSTALLATION

(1) With the aid of an assistant, position the head-

liner in the vehicle.

(2) Connect the sunroof drain hoses, if equipped.

(3) Connect the sunroof harness, the rear wire har-

nesses, and the washer hose at the ªAº pillar and at

the liftgate.

(4) Install the sunroof pinch welt, if equipped.

(5) Install the roof rail assist handles (Refer to 23 -

BODY/INTERIOR/ASSIST HANDLE - INSTALLA-

TION).

Fig. 9 Liftgate Washer Hose Routing at Rear of

Headliner

1 - ROOF

2 - REAR WASHER HOSE ROUTING

3 - REAR WASHER HOSE

4 - HEADLINER

Fig. 10 Rear Liftgate Washer Hose Routing at A

Pillar

1 - OVERHEAD CONSOLE WIRE HARNESS

2 - ROOF

3 - REAR WASHER HOSE

4 - REAR WASHER HOSE ROUTING

5 - HEADLINER

WJINTERIOR 23 - 77

Page 2094 of 2199

open circuit to the fuse in the junction block as

required.

(5) The coil ground terminal cavity (85) is switched

to ground through the Powertrain Control Module

(PCM). There should be continuity between this cav-

ity and the A/C compressor clutch relay control cir-

cuit cavity of the PCM wire harness connector C

(gray) at all times. If not OK, repair the open circuit

as required.

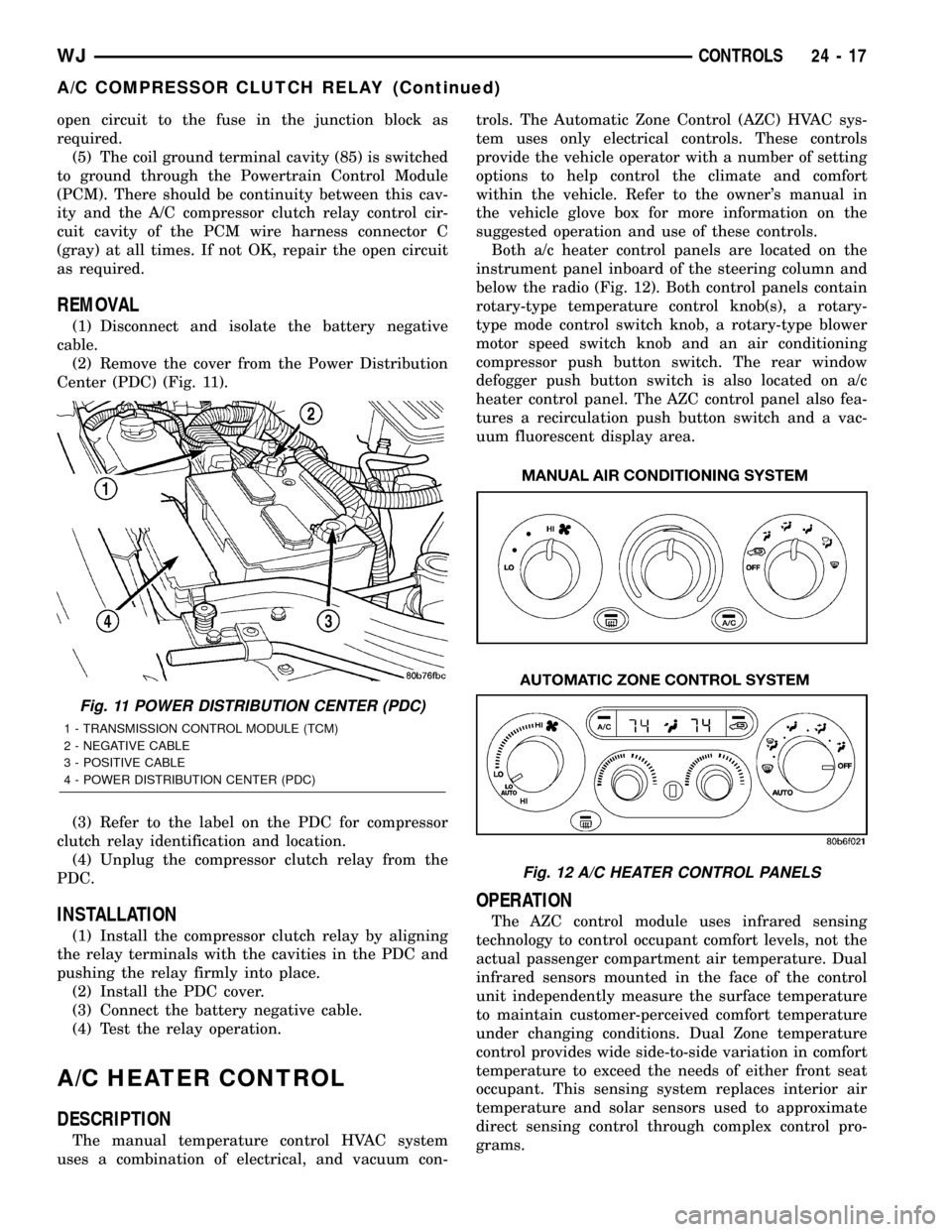

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the cover from the Power Distribution

Center (PDC) (Fig. 11).

(3) Refer to the label on the PDC for compressor

clutch relay identification and location.

(4) Unplug the compressor clutch relay from the

PDC.

INSTALLATION

(1) Install the compressor clutch relay by aligning

the relay terminals with the cavities in the PDC and

pushing the relay firmly into place.

(2) Install the PDC cover.

(3) Connect the battery negative cable.

(4) Test the relay operation.

A/C HEATER CONTROL

DESCRIPTION

The manual temperature control HVAC system

uses a combination of electrical, and vacuum con-trols. The Automatic Zone Control (AZC) HVAC sys-

tem uses only electrical controls. These controls

provide the vehicle operator with a number of setting

options to help control the climate and comfort

within the vehicle. Refer to the owner's manual in

the vehicle glove box for more information on the

suggested operation and use of these controls.

Both a/c heater control panels are located on the

instrument panel inboard of the steering column and

below the radio (Fig. 12). Both control panels contain

rotary-type temperature control knob(s), a rotary-

type mode control switch knob, a rotary-type blower

motor speed switch knob and an air conditioning

compressor push button switch. The rear window

defogger push button switch is also located on a/c

heater control panel. The AZC control panel also fea-

tures a recirculation push button switch and a vac-

uum fluorescent display area.

OPERATION

The AZC control module uses infrared sensing

technology to control occupant comfort levels, not the

actual passenger compartment air temperature. Dual

infrared sensors mounted in the face of the control

unit independently measure the surface temperature

to maintain customer-perceived comfort temperature

under changing conditions. Dual Zone temperature

control provides wide side-to-side variation in comfort

temperature to exceed the needs of either front seat

occupant. This sensing system replaces interior air

temperature and solar sensors used to approximate

direct sensing control through complex control pro-

grams.

Fig. 11 POWER DISTRIBUTION CENTER (PDC)

1 - TRANSMISSION CONTROL MODULE (TCM)

2 - NEGATIVE CABLE

3 - POSITIVE CABLE

4 - POWER DISTRIBUTION CENTER (PDC)

Fig. 12 A/C HEATER CONTROL PANELS

WJCONTROLS 24 - 17

A/C COMPRESSOR CLUTCH RELAY (Continued)