Radio JEEP GRAND CHEROKEE 2002 WJ / 2.G Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1164 of 2199

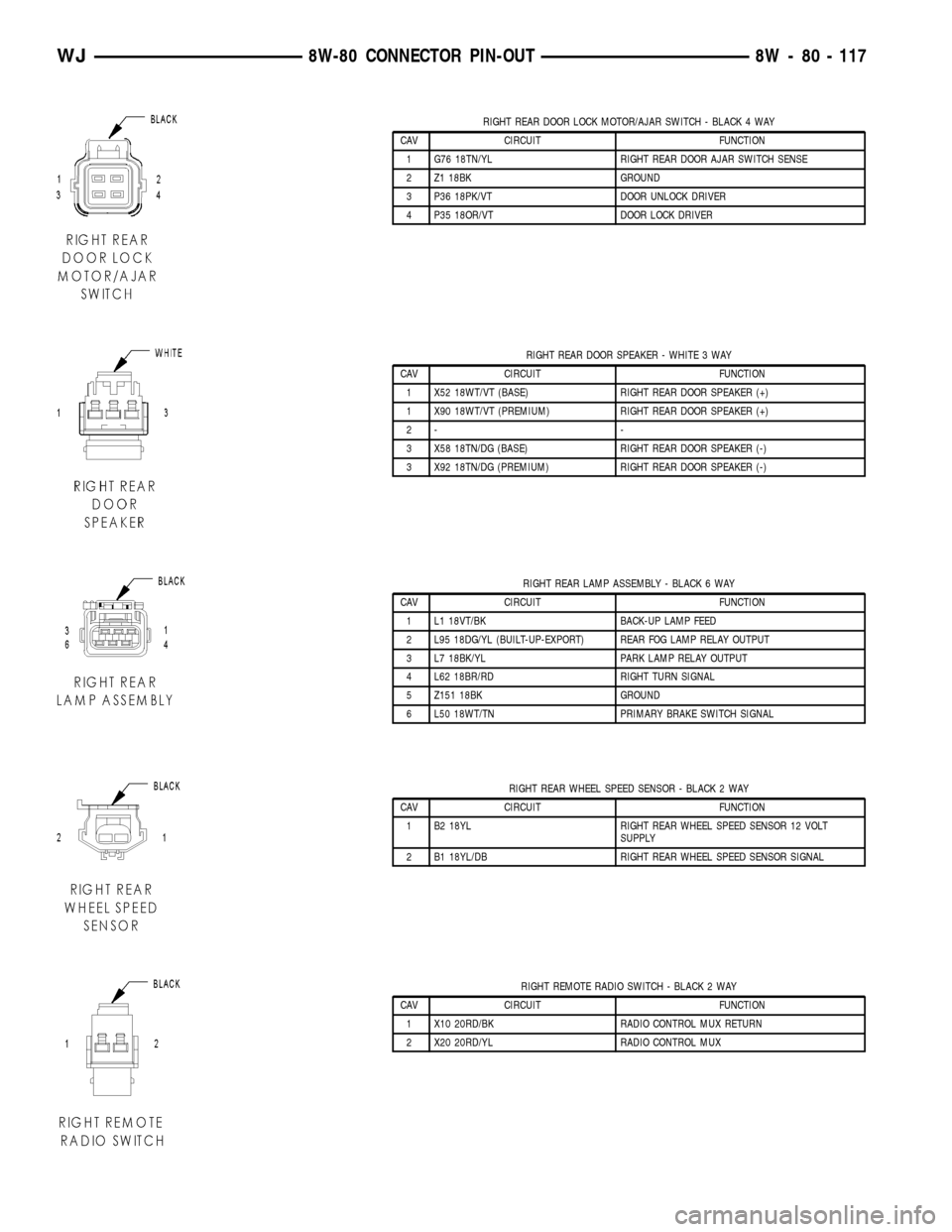

RIGHT REAR DOOR LOCK MOTOR/AJAR SWITCH - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 G76 18TN/YL RIGHT REAR DOOR AJAR SWITCH SENSE

2 Z1 18BK GROUND

3 P36 18PK/VT DOOR UNLOCK DRIVER

4 P35 18OR/VT DOOR LOCK DRIVER

RIGHT REAR DOOR SPEAKER - WHITE 3 WAY

CAV CIRCUIT FUNCTION

1 X52 18WT/VT (BASE) RIGHT REAR DOOR SPEAKER (+)

1 X90 18WT/VT (PREMIUM) RIGHT REAR DOOR SPEAKER (+)

2- -

3 X58 18TN/DG (BASE) RIGHT REAR DOOR SPEAKER (-)

3 X92 18TN/DG (PREMIUM) RIGHT REAR DOOR SPEAKER (-)

RIGHT REAR LAMP ASSEMBLY - BLACK 6 WAY

CAV CIRCUIT FUNCTION

1 L1 18VT/BK BACK-UP LAMP FEED

2 L95 18DG/YL (BUILT-UP-EXPORT) REAR FOG LAMP RELAY OUTPUT

3 L7 18BK/YL PARK LAMP RELAY OUTPUT

4 L62 18BR/RD RIGHT TURN SIGNAL

5 Z151 18BK GROUND

6 L50 18WT/TN PRIMARY BRAKE SWITCH SIGNAL

RIGHT REAR WHEEL SPEED SENSOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 B2 18YL RIGHT REAR WHEEL SPEED SENSOR 12 VOLT

SUPPLY

2 B1 18YL/DB RIGHT REAR WHEEL SPEED SENSOR SIGNAL

RIGHT REMOTE RADIO SWITCH - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 X10 20RD/BK RADIO CONTROL MUX RETURN

2 X20 20RD/YL RADIO CONTROL MUX

WJ8W-80 CONNECTOR PIN-OUT 8W - 80 - 117

Page 1179 of 2199

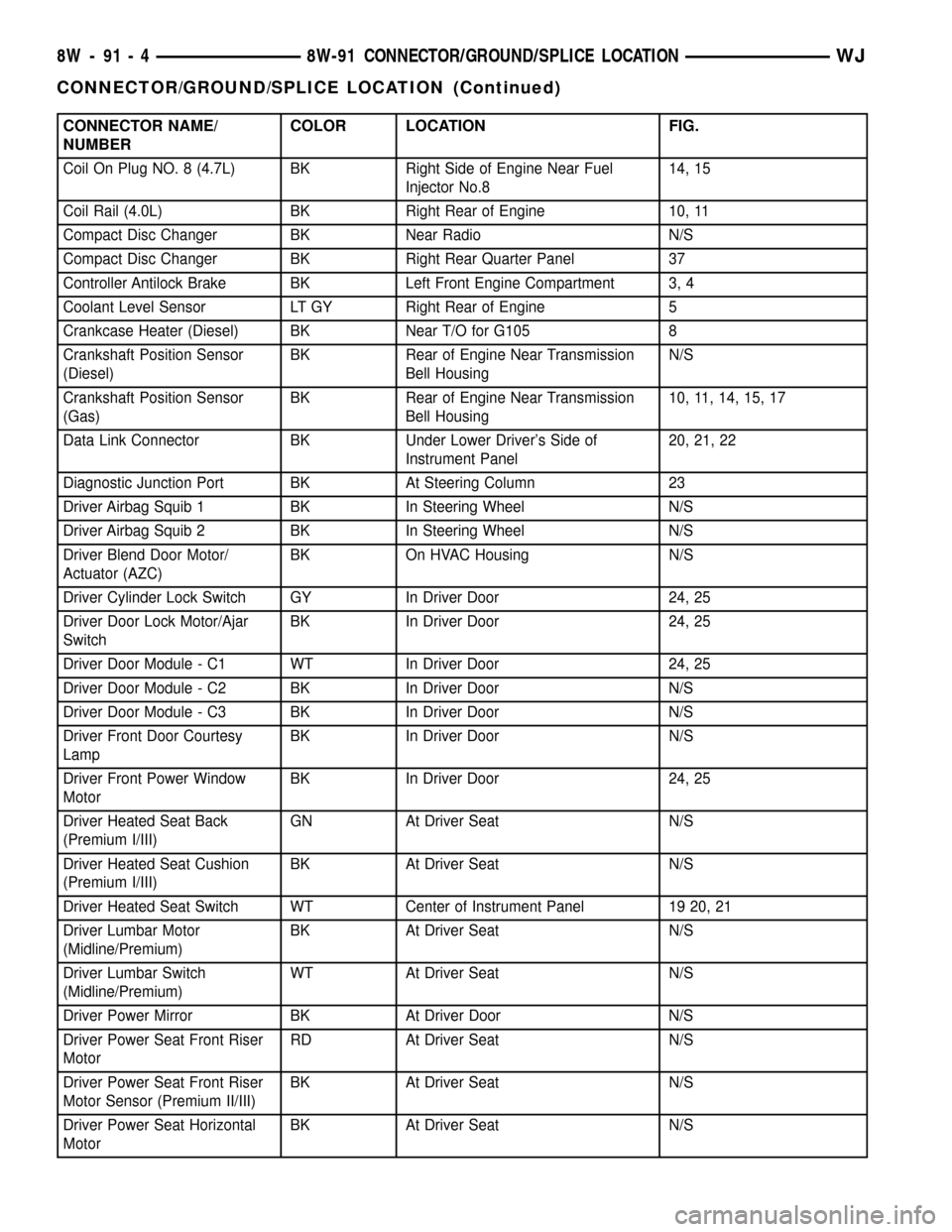

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Coil On Plug NO. 8 (4.7L) BK Right Side of Engine Near Fuel

Injector No.814, 15

Coil Rail (4.0L) BK Right Rear of Engine 10, 11

Compact Disc Changer BK Near Radio N/S

Compact Disc Changer BK Right Rear Quarter Panel 37

Controller Antilock Brake BK Left Front Engine Compartment 3, 4

Coolant Level Sensor LT GY Right Rear of Engine 5

Crankcase Heater (Diesel) BK Near T/O for G105 8

Crankshaft Position Sensor

(Diesel)BK Rear of Engine Near Transmission

Bell HousingN/S

Crankshaft Position Sensor

(Gas)BK Rear of Engine Near Transmission

Bell Housing10, 11, 14, 15, 17

Data Link Connector BK Under Lower Driver's Side of

Instrument Panel20, 21, 22

Diagnostic Junction Port BK At Steering Column 23

Driver Airbag Squib 1 BK In Steering Wheel N/S

Driver Airbag Squib 2 BK In Steering Wheel N/S

Driver Blend Door Motor/

Actuator (AZC)BK On HVAC Housing N/S

Driver Cylinder Lock Switch GY In Driver Door 24, 25

Driver Door Lock Motor/Ajar

SwitchBK In Driver Door 24, 25

Driver Door Module - C1 WT In Driver Door 24, 25

Driver Door Module - C2 BK In Driver Door N/S

Driver Door Module - C3 BK In Driver Door N/S

Driver Front Door Courtesy

LampBK In Driver Door N/S

Driver Front Power Window

MotorBK In Driver Door 24, 25

Driver Heated Seat Back

(Premium I/III)GN At Driver Seat N/S

Driver Heated Seat Cushion

(Premium I/III)BK At Driver Seat N/S

Driver Heated Seat Switch WT Center of Instrument Panel 19 20, 21

Driver Lumbar Motor

(Midline/Premium)BK At Driver Seat N/S

Driver Lumbar Switch

(Midline/Premium)WT At Driver Seat N/S

Driver Power Mirror BK At Driver Door N/S

Driver Power Seat Front Riser

MotorRD At Driver Seat N/S

Driver Power Seat Front Riser

Motor Sensor (Premium II/III)BK At Driver Seat N/S

Driver Power Seat Horizontal

MotorBK At Driver Seat N/S

8W - 91 - 4 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1182 of 2199

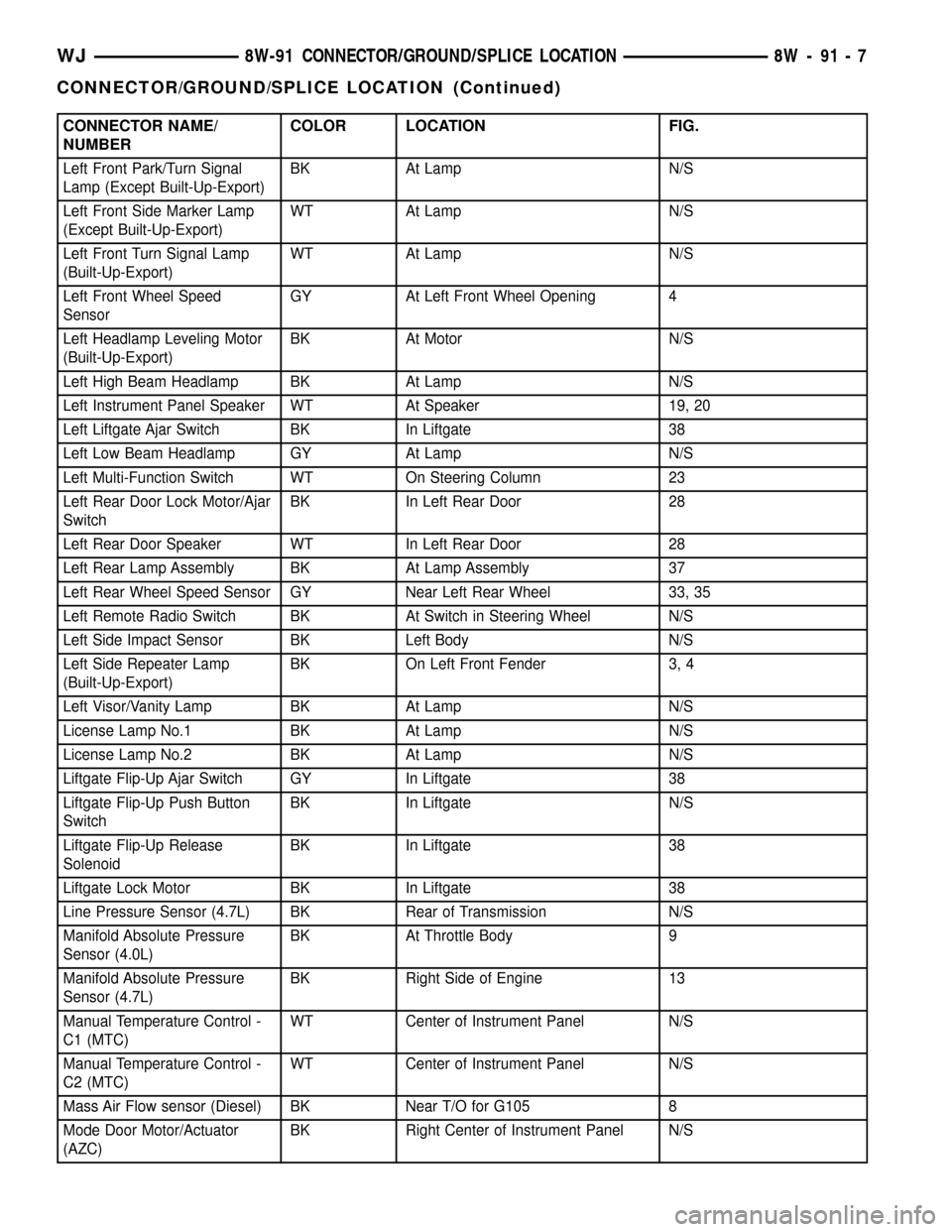

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Left Front Park/Turn Signal

Lamp (Except Built-Up-Export)BK At Lamp N/S

Left Front Side Marker Lamp

(Except Built-Up-Export)WT At Lamp N/S

Left Front Turn Signal Lamp

(Built-Up-Export)WT At Lamp N/S

Left Front Wheel Speed

SensorGY At Left Front Wheel Opening 4

Left Headlamp Leveling Motor

(Built-Up-Export)BK At Motor N/S

Left High Beam Headlamp BK At Lamp N/S

Left Instrument Panel Speaker WT At Speaker 19, 20

Left Liftgate Ajar Switch BK In Liftgate 38

Left Low Beam Headlamp GY At Lamp N/S

Left Multi-Function Switch WT On Steering Column 23

Left Rear Door Lock Motor/Ajar

SwitchBK In Left Rear Door 28

Left Rear Door Speaker WT In Left Rear Door 28

Left Rear Lamp Assembly BK At Lamp Assembly 37

Left Rear Wheel Speed Sensor GY Near Left Rear Wheel 33, 35

Left Remote Radio Switch BK At Switch in Steering Wheel N/S

Left Side Impact Sensor BK Left Body N/S

Left Side Repeater Lamp

(Built-Up-Export)BK On Left Front Fender 3, 4

Left Visor/Vanity Lamp BK At Lamp N/S

License Lamp No.1 BK At Lamp N/S

License Lamp No.2 BK At Lamp N/S

Liftgate Flip-Up Ajar Switch GY In Liftgate 38

Liftgate Flip-Up Push Button

SwitchBK In Liftgate N/S

Liftgate Flip-Up Release

SolenoidBK In Liftgate 38

Liftgate Lock Motor BK In Liftgate 38

Line Pressure Sensor (4.7L) BK Rear of Transmission N/S

Manifold Absolute Pressure

Sensor (4.0L)BK At Throttle Body 9

Manifold Absolute Pressure

Sensor (4.7L)BK Right Side of Engine 13

Manual Temperature Control -

C1 (MTC)WT Center of Instrument Panel N/S

Manual Temperature Control -

C2 (MTC)WT Center of Instrument Panel N/S

Mass Air Flow sensor (Diesel) BK Near T/O for G105 8

Mode Door Motor/Actuator

(AZC)BK Right Center of Instrument Panel N/S

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 7

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1184 of 2199

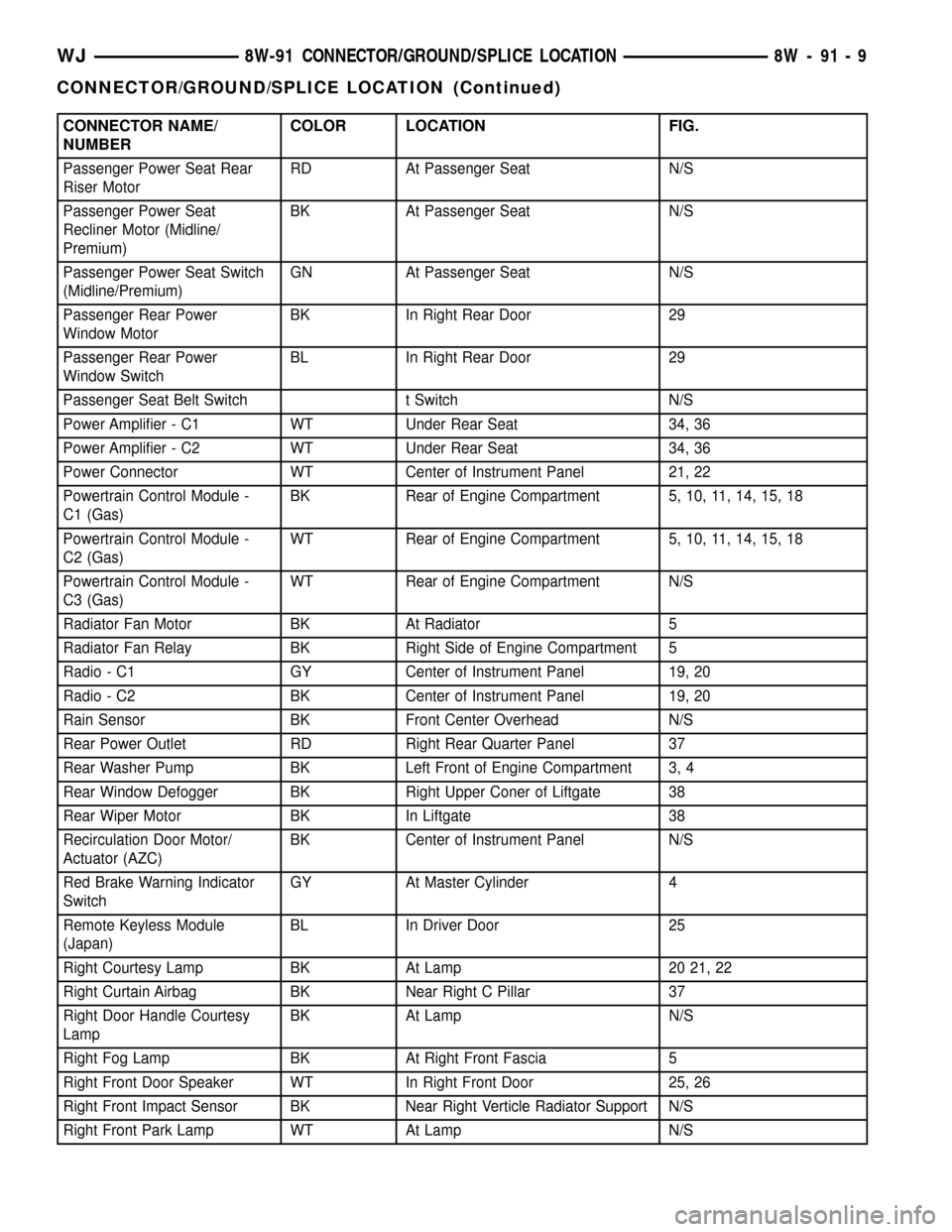

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Passenger Power Seat Rear

Riser MotorRD At Passenger Seat N/S

Passenger Power Seat

Recliner Motor (Midline/

Premium)BK At Passenger Seat N/S

Passenger Power Seat Switch

(Midline/Premium)GN At Passenger Seat N/S

Passenger Rear Power

Window MotorBK In Right Rear Door 29

Passenger Rear Power

Window SwitchBL In Right Rear Door 29

Passenger Seat Belt Switch t Switch N/S

Power Amplifier - C1 WT Under Rear Seat 34, 36

Power Amplifier - C2 WT Under Rear Seat 34, 36

Power Connector WT Center of Instrument Panel 21, 22

Powertrain Control Module -

C1 (Gas)BK Rear of Engine Compartment 5, 10, 11, 14, 15, 18

Powertrain Control Module -

C2 (Gas)WT Rear of Engine Compartment 5, 10, 11, 14, 15, 18

Powertrain Control Module -

C3 (Gas)WT Rear of Engine Compartment N/S

Radiator Fan Motor BK At Radiator 5

Radiator Fan Relay BK Right Side of Engine Compartment 5

Radio - C1 GY Center of Instrument Panel 19, 20

Radio - C2 BK Center of Instrument Panel 19, 20

Rain Sensor BK Front Center Overhead N/S

Rear Power Outlet RD Right Rear Quarter Panel 37

Rear Washer Pump BK Left Front of Engine Compartment 3, 4

Rear Window Defogger BK Right Upper Coner of Liftgate 38

Rear Wiper Motor BK In Liftgate 38

Recirculation Door Motor/

Actuator (AZC)BK Center of Instrument Panel N/S

Red Brake Warning Indicator

SwitchGY At Master Cylinder 4

Remote Keyless Module

(Japan)BL In Driver Door 25

Right Courtesy Lamp BK At Lamp 20 21, 22

Right Curtain Airbag BK Near Right C Pillar 37

Right Door Handle Courtesy

LampBK At Lamp N/S

Right Fog Lamp BK At Right Front Fascia 5

Right Front Door Speaker WT In Right Front Door 25, 26

Right Front Impact Sensor BK Near Right Verticle Radiator Support N/S

Right Front Park Lamp WT At Lamp N/S

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 9

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

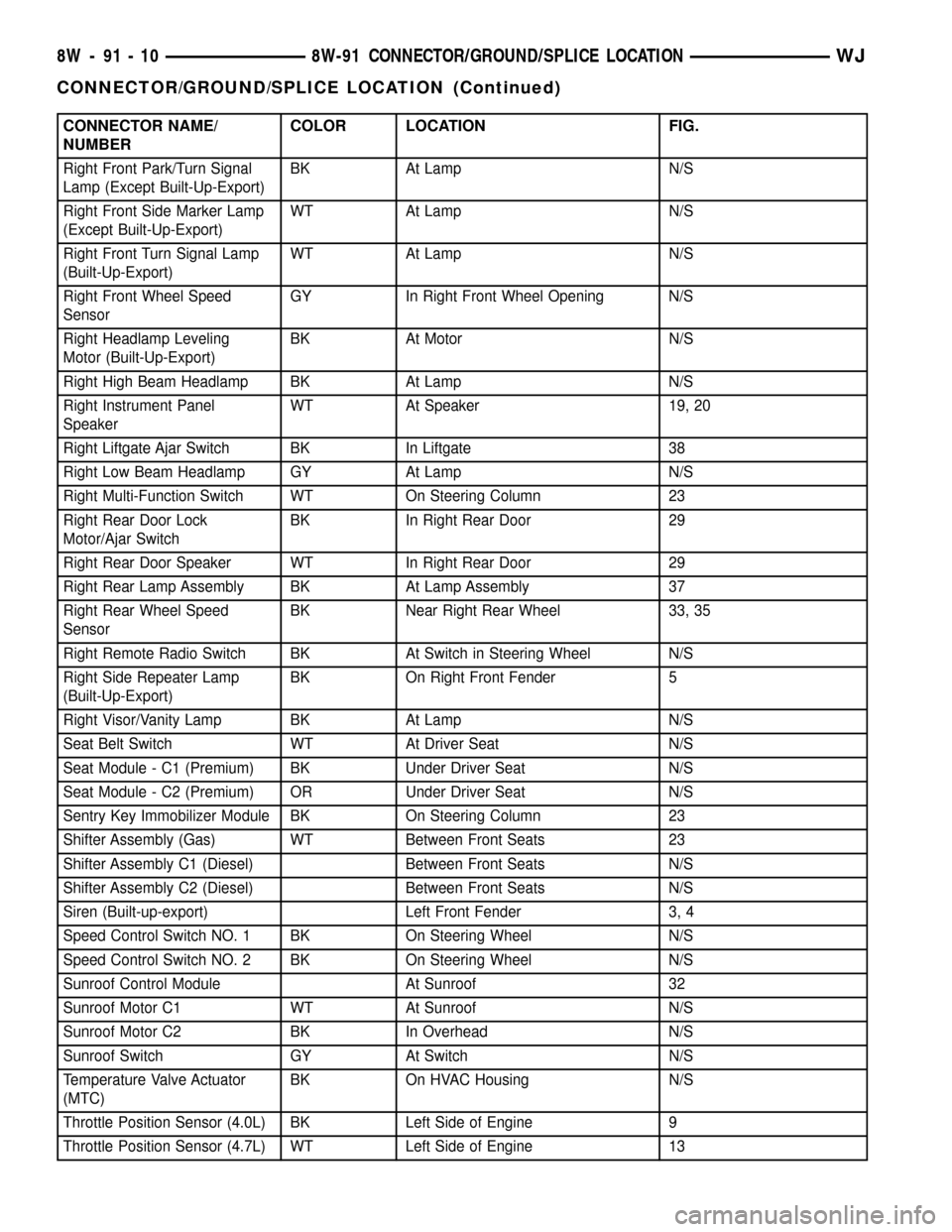

Page 1185 of 2199

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

Right Front Park/Turn Signal

Lamp (Except Built-Up-Export)BK At Lamp N/S

Right Front Side Marker Lamp

(Except Built-Up-Export)WT At Lamp N/S

Right Front Turn Signal Lamp

(Built-Up-Export)WT At Lamp N/S

Right Front Wheel Speed

SensorGY In Right Front Wheel Opening N/S

Right Headlamp Leveling

Motor (Built-Up-Export)BK At Motor N/S

Right High Beam Headlamp BK At Lamp N/S

Right Instrument Panel

SpeakerWT At Speaker 19, 20

Right Liftgate Ajar Switch BK In Liftgate 38

Right Low Beam Headlamp GY At Lamp N/S

Right Multi-Function Switch WT On Steering Column 23

Right Rear Door Lock

Motor/Ajar SwitchBK In Right Rear Door 29

Right Rear Door Speaker WT In Right Rear Door 29

Right Rear Lamp Assembly BK At Lamp Assembly 37

Right Rear Wheel Speed

SensorBK Near Right Rear Wheel 33, 35

Right Remote Radio Switch BK At Switch in Steering Wheel N/S

Right Side Repeater Lamp

(Built-Up-Export)BK On Right Front Fender 5

Right Visor/Vanity Lamp BK At Lamp N/S

Seat Belt Switch WT At Driver Seat N/S

Seat Module - C1 (Premium) BK Under Driver Seat N/S

Seat Module - C2 (Premium) OR Under Driver Seat N/S

Sentry Key Immobilizer Module BK On Steering Column 23

Shifter Assembly (Gas) WT Between Front Seats 23

Shifter Assembly C1 (Diesel) Between Front Seats N/S

Shifter Assembly C2 (Diesel) Between Front Seats N/S

Siren (Built-up-export) Left Front Fender 3, 4

Speed Control Switch NO. 1 BK On Steering Wheel N/S

Speed Control Switch NO. 2 BK On Steering Wheel N/S

Sunroof Control Module At Sunroof 32

Sunroof Motor C1 WT At Sunroof N/S

Sunroof Motor C2 BK In Overhead N/S

Sunroof Switch GY At Switch N/S

Temperature Valve Actuator

(MTC)BK On HVAC Housing N/S

Throttle Position Sensor (4.0L) BK Left Side of Engine 9

Throttle Position Sensor (4.7L) WT Left Side of Engine 13

8W - 91 - 10 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

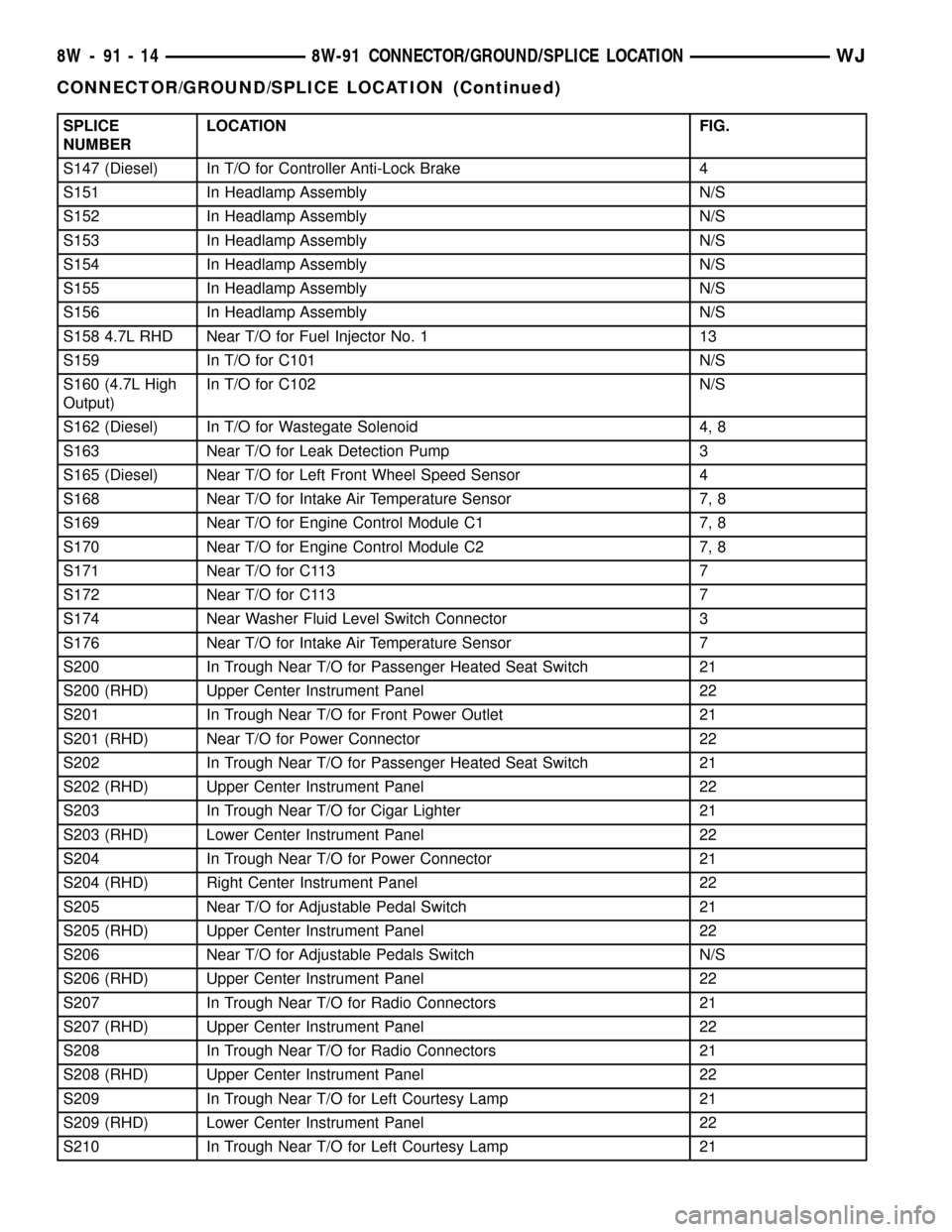

Page 1189 of 2199

SPLICE

NUMBERLOCATION FIG.

S147 (Diesel) In T/O for Controller Anti-Lock Brake 4

S151 In Headlamp Assembly N/S

S152 In Headlamp Assembly N/S

S153 In Headlamp Assembly N/S

S154 In Headlamp Assembly N/S

S155 In Headlamp Assembly N/S

S156 In Headlamp Assembly N/S

S158 4.7L RHD Near T/O for Fuel Injector No. 1 13

S159 In T/O for C101 N/S

S160 (4.7L High

Output)In T/O for C102 N/S

S162 (Diesel) In T/O for Wastegate Solenoid 4, 8

S163 Near T/O for Leak Detection Pump 3

S165 (Diesel) Near T/O for Left Front Wheel Speed Sensor 4

S168 Near T/O for Intake Air Temperature Sensor 7, 8

S169 Near T/O for Engine Control Module C1 7, 8

S170 Near T/O for Engine Control Module C2 7, 8

S171 Near T/O for C113 7

S172 Near T/O for C113 7

S174 Near Washer Fluid Level Switch Connector 3

S176 Near T/O for Intake Air Temperature Sensor 7

S200 In Trough Near T/O for Passenger Heated Seat Switch 21

S200 (RHD) Upper Center Instrument Panel 22

S201 In Trough Near T/O for Front Power Outlet 21

S201 (RHD) Near T/O for Power Connector 22

S202 In Trough Near T/O for Passenger Heated Seat Switch 21

S202 (RHD) Upper Center Instrument Panel 22

S203 In Trough Near T/O for Cigar Lighter 21

S203 (RHD) Lower Center Instrument Panel 22

S204 In Trough Near T/O for Power Connector 21

S204 (RHD) Right Center Instrument Panel 22

S205 Near T/O for Adjustable Pedal Switch 21

S205 (RHD) Upper Center Instrument Panel 22

S206 Near T/O for Adjustable Pedals Switch N/S

S206 (RHD) Upper Center Instrument Panel 22

S207 In Trough Near T/O for Radio Connectors 21

S207 (RHD) Upper Center Instrument Panel 22

S208 In Trough Near T/O for Radio Connectors 21

S208 (RHD) Upper Center Instrument Panel 22

S209 In Trough Near T/O for Left Courtesy Lamp 21

S209 (RHD) Lower Center Instrument Panel 22

S210 In Trough Near T/O for Left Courtesy Lamp 21

8W - 91 - 14 8W-91 CONNECTOR/GROUND/SPLICE LOCATIONWJ

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

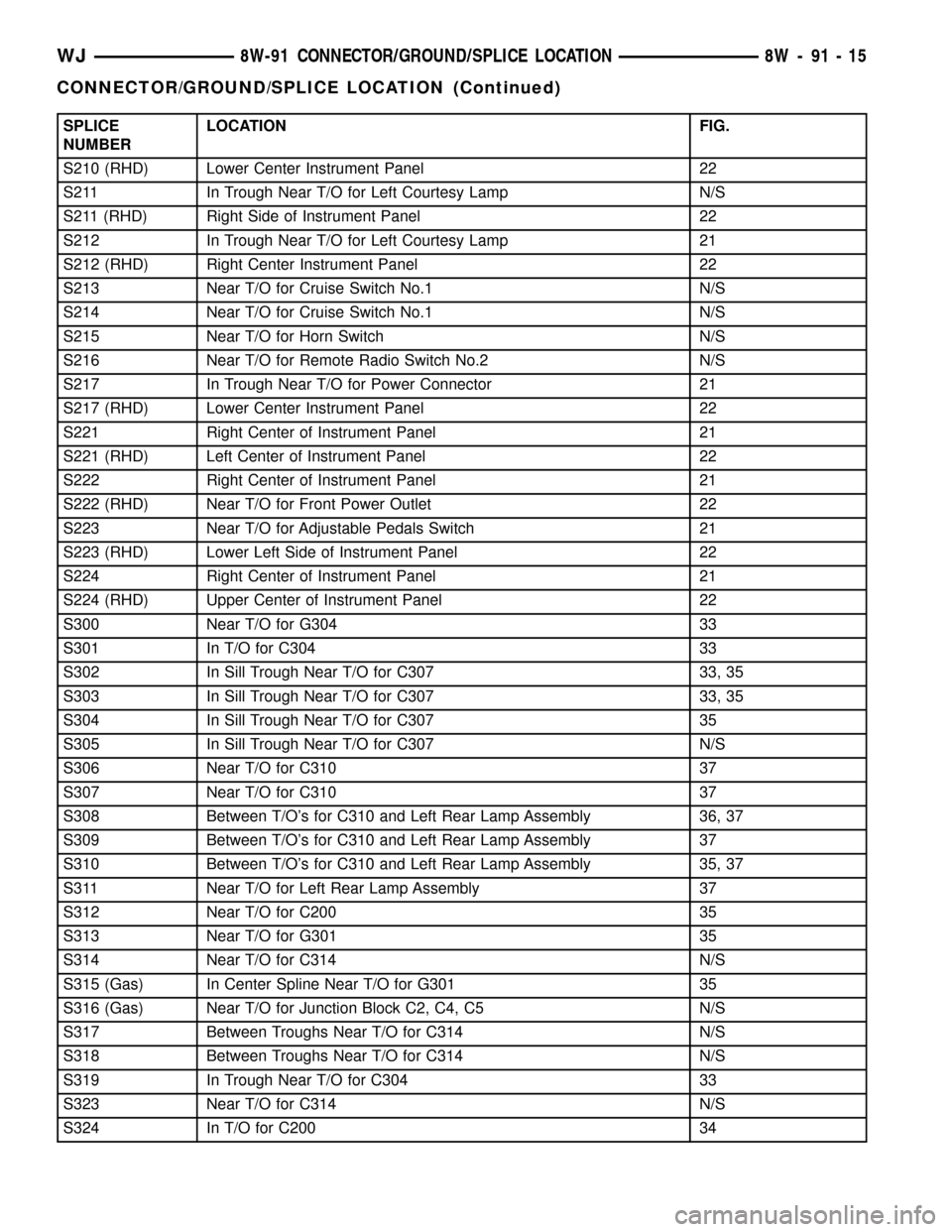

Page 1190 of 2199

SPLICE

NUMBERLOCATION FIG.

S210 (RHD) Lower Center Instrument Panel 22

S211 In Trough Near T/O for Left Courtesy Lamp N/S

S211 (RHD) Right Side of Instrument Panel 22

S212 In Trough Near T/O for Left Courtesy Lamp 21

S212 (RHD) Right Center Instrument Panel 22

S213 Near T/O for Cruise Switch No.1 N/S

S214 Near T/O for Cruise Switch No.1 N/S

S215 Near T/O for Horn Switch N/S

S216 Near T/O for Remote Radio Switch No.2 N/S

S217 In Trough Near T/O for Power Connector 21

S217 (RHD) Lower Center Instrument Panel 22

S221 Right Center of Instrument Panel 21

S221 (RHD) Left Center of Instrument Panel 22

S222 Right Center of Instrument Panel 21

S222 (RHD) Near T/O for Front Power Outlet 22

S223 Near T/O for Adjustable Pedals Switch 21

S223 (RHD) Lower Left Side of Instrument Panel 22

S224 Right Center of Instrument Panel 21

S224 (RHD) Upper Center of Instrument Panel 22

S300 Near T/O for G304 33

S301 In T/O for C304 33

S302 In Sill Trough Near T/O for C307 33, 35

S303 In Sill Trough Near T/O for C307 33, 35

S304 In Sill Trough Near T/O for C307 35

S305 In Sill Trough Near T/O for C307 N/S

S306 Near T/O for C310 37

S307 Near T/O for C310 37

S308 Between T/O's for C310 and Left Rear Lamp Assembly 36, 37

S309 Between T/O's for C310 and Left Rear Lamp Assembly 37

S310 Between T/O's for C310 and Left Rear Lamp Assembly 35, 37

S311 Near T/O for Left Rear Lamp Assembly 37

S312 Near T/O for C200 35

S313 Near T/O for G301 35

S314 Near T/O for C314 N/S

S315 (Gas) In Center Spline Near T/O for G301 35

S316 (Gas) Near T/O for Junction Block C2, C4, C5 N/S

S317 Between Troughs Near T/O for C314 N/S

S318 Between Troughs Near T/O for C314 N/S

S319 In Trough Near T/O for C304 33

S323 Near T/O for C314 N/S

S324 In T/O for C200 34

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 15

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

Page 1380 of 2199

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Disconnect generator electrical connections.

(8) Unbolt the generator and move it away from

the intake manifold for clearance.

(9) Disconnect air conditioning compressor electri-

cal connections.

(10) Unbolt the air conditioning compressor and

move it away from the intake manifold for clearance.

(11) Disconnect left and right radio suppressor

straps.

(12) Disconnect and remove ignition coil towers

(Refer to 8 - ELECTRICAL/IGNITION CONTROL/

IGNITION COIL - REMOVAL).

(13) Remove top oil dipstick tube retaining bolt

and ground strap.

(14) Bleed pressure from fuel system (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY - STANDARD

PROCEDURE).

(15) Remove fuel rail (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/FUEL RAIL - REMOVAL).

(16) Remove throttle body assembly and mounting

bracket.

(17) Drain cooling system below coolant tempera-

ture level (Refer to 7 - COOLING - STANDARD

PROCEDURE).

(18) Remove coolant temperature sensor (Refer to

7 - COOLING/ENGINE/ENGINE COOLANT TEMP

SENSOR - REMOVAL).

(19) Remove cowl to hood seal. (Refer to 23 -

BODY/WEATHERSTRIP/SEALS/COWL WEATHER-

STRIP - REMOVAL).

(20) Remove right side engine lifting stud.

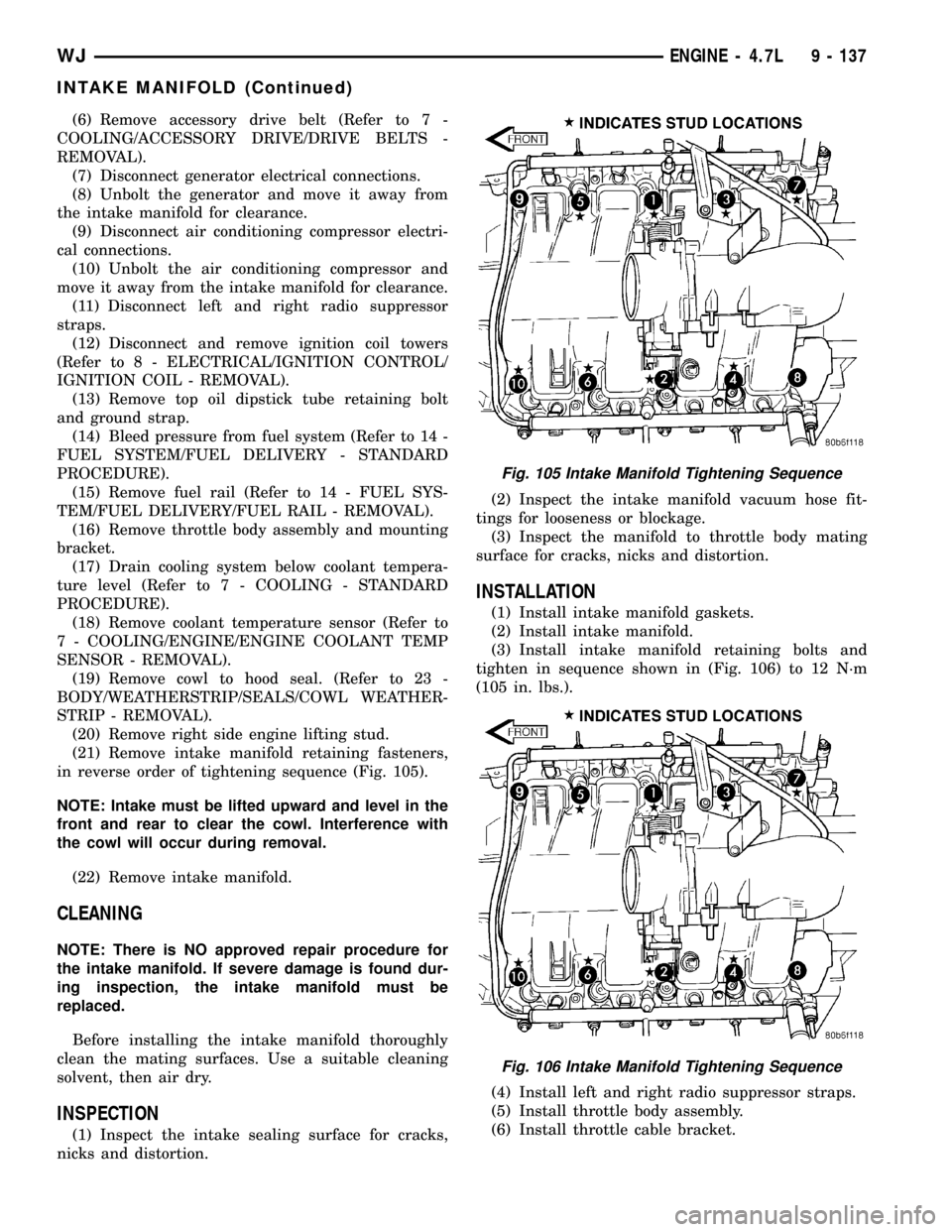

(21) Remove intake manifold retaining fasteners,

in reverse order of tightening sequence (Fig. 105).

NOTE: Intake must be lifted upward and level in the

front and rear to clear the cowl. Interference with

the cowl will occur during removal.

(22) Remove intake manifold.

CLEANING

NOTE: There is NO approved repair procedure for

the intake manifold. If severe damage is found dur-

ing inspection, the intake manifold must be

replaced.

Before installing the intake manifold thoroughly

clean the mating surfaces. Use a suitable cleaning

solvent, then air dry.

INSPECTION

(1) Inspect the intake sealing surface for cracks,

nicks and distortion.(2) Inspect the intake manifold vacuum hose fit-

tings for looseness or blockage.

(3) Inspect the manifold to throttle body mating

surface for cracks, nicks and distortion.

INSTALLATION

(1) Install intake manifold gaskets.

(2) Install intake manifold.

(3) Install intake manifold retaining bolts and

tighten in sequence shown in (Fig. 106) to 12 N´m

(105 in. lbs.).

(4) Install left and right radio suppressor straps.

(5) Install throttle body assembly.

(6) Install throttle cable bracket.

Fig. 105 Intake Manifold Tightening Sequence

Fig. 106 Intake Manifold Tightening Sequence

WJENGINE - 4.7L 9 - 137

INTAKE MANIFOLD (Continued)

Page 1871 of 2199

TIRE PRESSURE MONITORING

DESCRIPTION

The EVIC will monitor the tire pressure signals

from the five tire sensors and determine if any tire

has gone below the low pressure threshold or raised

above the high pressure threshold. Refer to the table

below.

LOW TIRE PRESSURE THRESHOLDS

SYSTEM STATUS

INDICATORTIRE PRESSURE

ON 179 kPa (26 PSI)

OFF 214 kPa (31 PSI)

HIGH TIRE PRESSURE THRESHOLDS

SYSTEM STATUS

INDICATORTIRE PRESSURE

ON 310 kPa (45 PSI)

OFF 276 kPa (40 PSI)

The Remote Tire Pressure Monitors (RTPM) are

not internally serviceable. For a Sensor Failure or

Low Battery fault, the RTPM must be replaced.

OPERATION

If equipped with the Tire Pressure Monitoring Sys-

tem, each of the vehicle's five wheels will have a

valve stem with a pressure sensor and radio trans-

mitter built in. Signals from the tire pressure sensors

are received and interpreted by the Electronic Vehi-

cle Information Center (EVIC). A sensor in a

mounted wheel will broadcast its detected pressure

once per minute when the vehicle is moving faster

than 40 km/h (25 mph). The spare tire sensor will

broadcast once every hour. Each sensor's broadcast is

uniquely coded so that the EVIC can determine loca-

tion. The individual tire pressures can be displayed

graphically on the EVIC

DIAGNOSIS AND TESTING - TIRE PRESSURE

MONITORING SYSTEM

All Tire Pressure Monitoring System Faults are

specific to one location. If a9BATTERY LOW9or

9SENSOR FAILURE9fault is detected, the location

will be displayed. The appropriate sensor/transmitter

can then be replaced. If a single sensor/transmitter

cannot be detected by the EVIC, replace that sensor

transmitter. If none of the sensors/transmitters can

be detected, refer to symptoms in the EVIC section.

For additional system description and diagnosis,

refer to Tire Pressure Monitoring in the Body Diag-

nostic manual.

SENSOR

REMOVAL - TIRE PRESSURE SENSOR/

TRANSMITTER

(1) Remove the tire/wheel from the vehicle.

CAUTION: When removing the stick on balancing

weights from the wheel, do not use an abrasive

cleaner or a cleaner which will damage the protec-

tive finish on the wheel.

(2) Remove the balancing weights from the wheel.

NOTE: The cap used on this valve stem contains an

O-ring seal to prevent contamination and moisture

from entering the valve stem. Retain this valve stem

cap for re-use. Do not substitute a regular valve

stem cap in its place.

(3) Remove the cap from the valve stem.

NOTE: The valve stem used on this vehicle is made

of aluminum and the core is nickel plated brass.

The original valve stem core must be reinstalled

and not substituted for a valve stem core made of a

different material. This is required to prevent corro-

sion in the valve stem caused by the different met-

als.

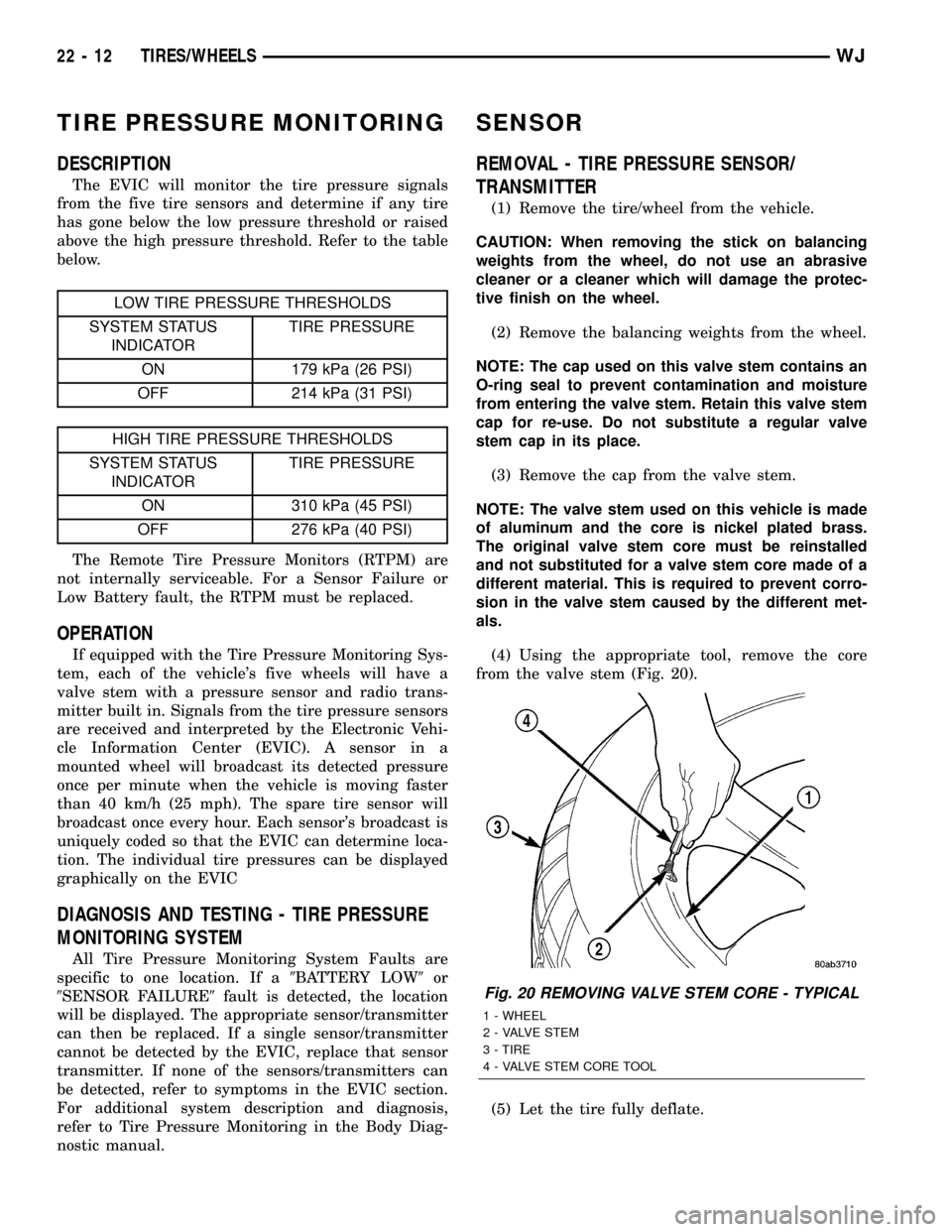

(4) Using the appropriate tool, remove the core

from the valve stem (Fig. 20).

(5) Let the tire fully deflate.

Fig. 20 REMOVING VALVE STEM CORE - TYPICAL

1 - WHEEL

2 - VALVE STEM

3 - TIRE

4 - VALVE STEM CORE TOOL

22 - 12 TIRES/WHEELSWJ

Page 1902 of 2199

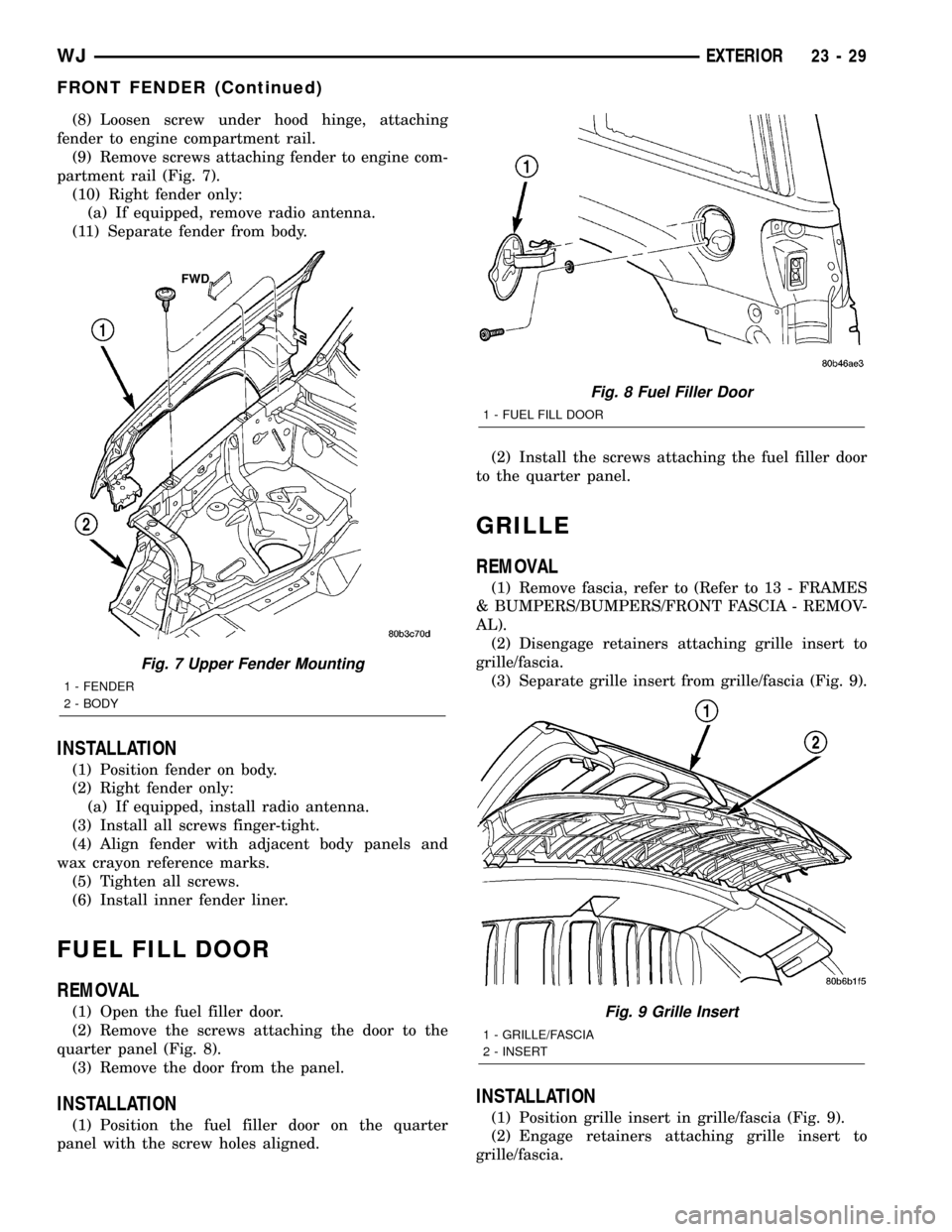

(8) Loosen screw under hood hinge, attaching

fender to engine compartment rail.

(9) Remove screws attaching fender to engine com-

partment rail (Fig. 7).

(10) Right fender only:

(a) If equipped, remove radio antenna.

(11) Separate fender from body.

INSTALLATION

(1) Position fender on body.

(2) Right fender only:

(a) If equipped, install radio antenna.

(3) Install all screws finger-tight.

(4) Align fender with adjacent body panels and

wax crayon reference marks.

(5) Tighten all screws.

(6) Install inner fender liner.

FUEL FILL DOOR

REMOVAL

(1) Open the fuel filler door.

(2) Remove the screws attaching the door to the

quarter panel (Fig. 8).

(3) Remove the door from the panel.

INSTALLATION

(1) Position the fuel filler door on the quarter

panel with the screw holes aligned.(2) Install the screws attaching the fuel filler door

to the quarter panel.

GRILLE

REMOVAL

(1) Remove fascia, refer to (Refer to 13 - FRAMES

& BUMPERS/BUMPERS/FRONT FASCIA - REMOV-

AL).

(2) Disengage retainers attaching grille insert to

grille/fascia.

(3) Separate grille insert from grille/fascia (Fig. 9).

INSTALLATION

(1) Position grille insert in grille/fascia (Fig. 9).

(2) Engage retainers attaching grille insert to

grille/fascia.

Fig. 7 Upper Fender Mounting

1 - FENDER

2 - BODY

Fig. 8 Fuel Filler Door

1 - FUEL FILL DOOR

Fig. 9 Grille Insert

1 - GRILLE/FASCIA

2 - INSERT

WJEXTERIOR 23 - 29

FRONT FENDER (Continued)