Ignition switch JEEP GRAND CHEROKEE 2002 WJ / 2.G Manual Online

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 450 of 2199

ing the system voltage is high (system voltage is

about sixteen volts or higher), the gauge needle is

moved to the relative voltage position in the red zone

of the gauge scale and the check gauges indicator is

illuminated. The gauge needle remains in the red

zone and the check gauges indicator remains illumi-

nated until the cluster receives a message from the

PCM indicating there is no high system voltage con-

dition (system voltage is below about sixteen volts,

but higher than about eleven volts).

²Communication Error- If the cluster fails to

receive a system voltage message, it will hold the

gauge needle at the last indication for about twelve

seconds, until a new message is received, or until the

ignition switch is turned to the Off position, which-

ever occurs first. After twelve seconds, the cluster

will return the gauge needle to the low end of the

gauge scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept across the entire gauge scale and back to con-

firm the functionality of the gauge and the cluster

control circuitry.

The PCM continually monitors the system voltage

to control the generator output. The PCM then sends

the proper system voltage messages to the instru-

ment cluster. For further diagnosis of the voltage

gauge or the instrument cluster circuitry that con-

trols the gauge, (Refer to 8 - ELECTRICAL/INSTRU-

MENT CLUSTER - DIAGNOSIS AND TESTING). If

the instrument cluster turns on the check gauges

indicator due to a system voltage low or high condi-

tion, it may indicate that the charging system

requires service. For proper diagnosis of the charging

system, the PCI data bus, or the electronic message

inputs to the instrument cluster that control the volt-

age gauge, a DRBIIItscan tool is required. Refer to

the appropriate diagnostic information.

WAIT-TO-START INDICATOR

DESCRIPTION

A wait-to-start indicator is only found in the

instrument clusters of vehicles equipped with an

optional diesel engine. The wait-to-start indicator is

located near the lower edge of the tachometer gauge

dial face, to the right of center. The wait-to-start

indicator consists of an International Control and

Display Symbol icon for ªDiesel Preheatº imprinted

on an amber lens. The lens is located behind a cutout

in the opaque layer of the tachometer gauge dial face

overlay. The dark outer layer of the gauge dial face

overlay prevents the icon from being clearly visible

when the indicator is not illuminated. The icon

appears silhouetted against an amber field throughthe translucent outer layer of the gauge dial face

overlay when the indicator is illuminated from

behind by a replaceable incandescent bulb and bulb

holder unit located on the instrument cluster elec-

tronic circuit board. The wait-to-start indicator lens

is serviced as a unit with the instrument cluster.

OPERATION

The wait-to-start indicator gives an indication to

the vehicle operator when the diesel engine glow

plugs are energized in their preheat operating mode.

This indicator is controlled by a transistor on the

instrument cluster circuit board based upon cluster

programming and electronic messages received by

the cluster from the Powertrain Control Module

(PCM) over the Programmable Communications

Interface (PCI) data bus. The wait-to-start indicator

bulb is completely controlled by the instrument clus-

ter logic circuit, and that logic will only allow this

indicator to operate when the instrument cluster

receives a battery current input on the fused ignition

switch output (run-start) circuit. Therefore, the indi-

cator will always be off when the ignition switch is in

any position except On or Start. The bulb only illu-

minates when it is switched to ground by the instru-

ment cluster transistor. The instrument cluster will

turn on the wait-to-start indicator for the following

reasons:

²Wait-To-Start Indicator Lamp-On Message-

Each time the cluster receives a wait-to-start indica-

tor lamp-on message from the PCM indicating the

glow plugs are heating and the driver must wait to

start the engine, the wait-to-start indicator will be

illuminated. The indicator remains illuminated until

the cluster receives a wait-to-start indicator lamp-off

message, or until the ignition switch is turned to the

Off position, whichever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the wait-to-start indicator

will be turned on for the duration of the test to con-

firm the functionality of the bulb and the cluster con-

trol circuitry.

The PCM continually monitors the ambient tem-

perature and the glow plug pre-heater circuits to

determine how long the glow plugs must be heated in

the pre-heat operating mode. The PCM then sends

the proper wait-to-start indicator lamp-on and lamp-

off messages to the instrument cluster. If the wait-to-

start indicator fails to light during the actuator test,

replace the bulb with a known good unit. For further

diagnosis of the wait-to-start indicator or the instru-

ment cluster circuitry that controls the indicator,

(Refer to 8 - ELECTRICAL/INSTRUMENT CLUS-

TER - DIAGNOSIS AND TESTING). For proper

diagnosis of the glow plug pre-heater control circuits,

the PCM, the PCI data bus, or the electronic message

WJINSTRUMENT CLUSTER 8J - 35

VOLTAGE GAUGE (Continued)

Page 451 of 2199

inputs to the instrument cluster that control the

wait-to-start indicator, a DRBIIItscan tool is

required. Refer to the appropriate diagnostic infor-

mation.

WATER-IN-FUEL INDICATOR

DESCRIPTION

A water-in-fuel indicator is only found in the

instrument clusters of vehicles equipped with an

optional diesel engine. The water-in-fuel indicator is

located near the left edge of the instrument cluster,

to the left of the tachometer. The water-in-fuel indi-

cator consists of an International Control and Dis-

play Symbol icon for ªWater in Fuelº imprinted on a

red lens. The lens is located behind a cutout in the

opaque layer of the instrument cluster overlay. The

dark outer layer of the overlay prevents the icon

from being clearly visible when the indicator is not

illuminated. The icon appears silhouetted against a

red field through the translucent outer layer of the

overlay when the indicator is illuminated from

behind by a Light Emitting Diode (LED), which is

soldered onto the instrument cluster electronic circuit

board. The water-in-fuel indicator lens is serviced as

a unit with the instrument cluster lens, hood and

mask unit.

OPERATION

The water-in-fuel indicator gives an indication to

the vehicle operator when there is excessive water in

the fuel system. This indicator is controlled by a

transistor on the instrument cluster circuit board

based upon cluster programming and electronic mes-

sages received by the cluster from the Powertrain

Control Module (PCM) over the Programmable Com-

munications Interface (PCI) data bus. The water-in-

fuel indicator Light Emitting Diode (LED) is

completely controlled by the instrument cluster logic

circuit, and that logic will only allow this indicator tooperate when the instrument cluster receives a bat-

tery current input on the fused ignition switch out-

put (run-start) circuit. Therefore, the indicator will

always be off when the ignition switch is in any posi-

tion except On or Start. The LED only illuminates

when it is provided a path to ground by the instru-

ment cluster transistor. The instrument cluster will

turn on the water-in-fuel indicator for the following

reasons:

²Bulb Test- Each time the ignition switch is

turned to the On position the water-in-fuel indicator

is illuminated for about three seconds as a bulb test.

²Water-In-Fuel Indicator Lamp-On Message-

Each time the cluster receives a water-in-fuel indica-

tor lamp-on message from the PCM indicating there

is excessive water in the diesel fuel system, the

water-in-fuel indicator will be illuminated. The indi-

cator remains illuminated until the cluster receives a

water-in-fuel indicator lamp-off message, or until the

ignition switch is turned to the Off position, which-

ever occurs first.

²Actuator Test- Each time the cluster is put

through the actuator test, the water-in-fuel indicator

will be turned on for the duration of the test to con-

firm the functionality of the LED and the cluster con-

trol circuitry.

The PCM continually monitors the water-in-fuel

sensor to determine whether there is excessive water

in the diesel fuel. The PCM then sends the proper

water-in-fuel indicator lamp-on and lamp-off mes-

sages to the instrument cluster. For further diagnosis

of the water-in-fuel indicator or the instrument clus-

ter circuitry that controls the indicator, (Refer to 8 -

ELECTRICAL/INSTRUMENT CLUSTER - DIAGNO-

SIS AND TESTING). For proper diagnosis of the

water-in-fuel sensor, the PCM, the PCI data bus, or

the electronic message inputs to the instrument clus-

ter that control the water-in-fuel indicator, a

DRBIIItscan tool is required. Refer to the appropri-

ate diagnostic information.

8J - 36 INSTRUMENT CLUSTERWJ

WAIT-TO-START INDICATOR (Continued)

Page 453 of 2199

LICENSE PLATE LAMP UNIT

REMOVAL.............................18

INSTALLATION.........................19

LEFT MULTI-FUNCTION SWITCH

DESCRIPTION.........................19

OPERATION...........................19

DIAGNOSIS AND TESTING - LEFT MULTI -

FUNCTION SWITCH...................20

REMOVAL

REMOVAL - LEFT MULTI-FUNCTION

SWITCH............................22

REMOVAL - MULTI-FUNCTION SWITCH

MOUNTING HOUSING..................22

INSTALLATION

INSTALLATION - LEFT MULTI-FUNCTION

SWITCH............................23

INSTALLATION - MULTI-FUNCTION SWITCH

MOUNTING HOUSING..................24

PARK/TURN SIGNAL LAMP

REMOVAL - BULBS.....................25INSTALLATION - BULBS..................25

TAIL LAMP

DESCRIPTION.........................25

OPERATION...........................25

REMOVAL

REMOVAL - BULBS....................25

REMOVAL - LAMP.....................25

INSTALLATION

INSTALLATION - BULBS................26

INSTALLATION - LAMP.................26

TURN SIGNAL CANCEL CAM

DESCRIPTION.........................26

OPERATION...........................26

UNDERHOOD LAMP

REMOVAL

REMOVAL - BULB.....................27

REMOVAL - LAMP.....................27

INSTALLATION

INSTALLATION - BULB.................27

INSTALLATION - LAMP.................27

LAMPS/LIGHTING - EXTERIOR

DESCRIPTION - TURN SIGNAL & HAZARD

WARNING SYSTEM

The turn signal and hazard warning system

includes the following major components, which are

described in further detail elsewhere in this service

information:

²Combination Flasher

²Front Side Marker Lamps

²Hazard Warning Switch

²Turn Signal Cancel Cam

²Turn Signal Indicators

²Turn Signal Lamps

²Turn Signal Switch

The turn signal and hazard warning systems also

provide the following features:

²Flash Lights with Lock- This customer pro-

grammable feature flashes the hazard warning lamps

to provide optical verification that the Remote Key-

less Entry (RKE) System has received a valid Lock or

Unlock request from an RKE transmitter. (Refer to 8

- ELECTRICAL/POWER LOCKS - DESCRIPTION -

REMOTE KEYLESS ENTRY SYSTEM).

²Panic Mode Optical Alert- This feature

flashes the hazard warning lamps to provide an opti-

cal alert when the Remote Keyless Entry (RKE) Sys-

tem panic mode is activated by depressing the Panic

button on an RKE transmitter. (Refer to 8 - ELEC-

TRICAL/POWER LOCKS - DESCRIPTION -

REMOTE KEYLESS ENTRY SYSTEM).

²Turn Signal On Warning- This feature pro-

vides the vehicle operator with both visual and audi-

ble reminders when a turn signal has been left

turned on for an extended period. (Refer to 8 - ELEC-TRICAL/OVERHEAD CONSOLE/ELECTRONIC

VEHICLE INFO CENTER - DESCRIPTION).

²Vehicle Theft Security System (VTSS) Opti-

cal Alarm- This feature flashes the hazard warning

lamps to provide an optical alarm when the VTSS is

armed and activated by an unauthorized entry into

the vehicle. (Refer to 8 - ELECTRICAL/VEHICLE

THEFT SECURITY - DESCRIPTION - VEHICLE

THEFT SECURITY SYSTEM).

OPERATION - TURN SIGNAL & HAZARD

WARNING SYSTEM

The turn signal system operates on battery current

received on a fused ignition switch output (run) cir-

cuit so that the turn signals will only operate with

the ignition switch in the On position. The hazard

warning system operates on non-switched battery

current received on a fused B(+) circuit so that the

hazard warning remains operational regardless of

the ignition switch position. When the turn signal

system is activated, the circuitry of the turn signal

switch and the combination flasher will cause the

selected (right or left) turn signal indicator, front

park/turn signal lamp, front side marker lamp and

rear tail/stop/turn signal lamp to flash on and off.

When the hazard warning system is activated, the

circuitry of the hazard warning switch and the com-

bination flasher will cause both the right side and

the left side turn signal indicators, front park/turn

signal lamps, front side marker lamps and rear tail/

stop/turn signal lamps to flash on and off.

The Body Control Module (BCM) can also activate

the hazard warning system lamps by energizing the

combination flasher through a single hard wired con-

nection to the hazard warning switch sense circuit.

The BCM grounds the circuit to energize and de-en-

8L - 2 LAMPS/LIGHTING - EXTERIORWJ

Page 454 of 2199

ergize the combination flasher in response to mes-

sage inputs received over the Programmable

Communications Interface (PCI) data bus network.

The BCM can energize the combination flasher when

the VTSS is requested.

Vehicles equipped with the optional Electronic

Vehicle Information Center (EVIC) use turn signal

status messages received from the Electro-Mechani-

cal Instrument Cluster (EMIC) and distance mes-

sages received from the Powertrain Control Module

(PCM) over the PCI data bus to determine when the

Turn Signal On warning should be activated. The

EMIC receives hard wired inputs from the combina-

tion flasher to operate the turn signal indicators,

then sends the proper turn signal status message to

the EVIC. If a turn signal is left on for more than

about 1.6 kilometers (1 mile) of driving distance, the

EVIC will display a visual ªTurn Signal Onº message

and will send a request to the BCM over the PCI

data bus to notify the vehicle operator.

During both the turn signal and the hazard warn-

ing operation, if the exterior lamps are turned Off,

the front park/turn signal lamps and the front side

marker lamps will flash in unison. If the exterior

lamps are turned On, the front park/turn signal

lamps and the front side marker lamps will flash

alternately. Refer to the owner's manual.

DIAGNOSIS AND TESTING - TURN SIGNAL &

HAZARD WARNING SYSTEMS

When diagnosing the turn signal and hazard warn-

ing circuits, remember that high generator output

can burn out bulbs rapidly and repeatedly. If this is a

concern on the vehicle being diagnosed, test the

charging system as required.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Turn the ignition switch to the On position.

Actuate the turn signal switch or the hazard warning

switch. Observe the turn signal indicator lamp(s) in

the instrument cluster. If the flash rate is very high,

check for a turn signal bulb that is not lit or is verydimly lit. Repair the circuits to that lamp or replace

the faulty bulb, as required. If the turn signal indi-

cator(s) fail to light, go to Step 2.

(2) Turn the ignition switch to the Off position.

Check the ignition run fuse and the flasher fuse in

the Junction Block (JB). If OK, go to Step 3. If not

OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).

(3) Check for battery voltage at the flasher fuse in

the JB. If OK, go to Step 4. If not OK, repair the

open fused B(+) circuit between the JB and the

Power Distribution Center (PDC).

(4) Turn the ignition switch to the On position.

Check for battery voltage at the ignition run fuse in

the JB. If OK, go to Step 5. If not OK, repair the

open fused ignition switch output (run) circuit

between the JB and the ignition switch.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the combination flasher from the JB and

replace it with a known good unit. Reconnect the bat-

tery negative cable. Test the operation of the turn

signal and hazard warning systems. If OK, discard

the faulty combination flasher. If not OK, remove the

test flasher and go to Step 6.

(6) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) circuit cavity in the JB for the combina-

tion flasher. If OK, go to Step 7. If not OK, repair the

open fused ignition switch output (run) circuit

between the combination flasher and the ignition run

fuse in the JB.

(7) Turn the ignition switch to the Off position.

Check for battery voltage at the B(+) circuit of the JB

for the combination flasher. If OK, go to Step 8. If

not OK, repair the open B(+) circuit between the

combination flasher and the flasher fuse in the JB.

(8) Disconnect and isolate the battery negative

cable. Disconnect the instrument panel wire harness

connector for the turn signal and hazard warning

switches from the multi-function switch connector.

Check for continuity between the ground circuit of

the instrument panel wire harness connector for the

left multi-function switch and a good ground. There

should be continuity. If OK, go to Step 9. If not OK,

repair the open ground circuit.

(9) Check for continuity between the hazard switch

sense circuit of the instrument panel wire harness

connector for the multi-function switch and a good

ground. There should be no continuity. If OK, go to

Step 10. If not OK, repair the shorted hazard switch

sense circuit between the multi-function switch and

the combination flasher.

(10) Check for continuity between the hazard

switch sense circuit of the JB for the combination

flasher and the instrument panel wire harness con-

WJLAMPS/LIGHTING - EXTERIOR 8L - 3

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 458 of 2199

INSTALLATION - CHMSL

(1) Connect the wire harness connector.

(2) Position the CHMSL on liftgate.

(3) Install the screws attaching the CHMSL to the

liftgate.

COMBINATION FLASHER

DESCRIPTION

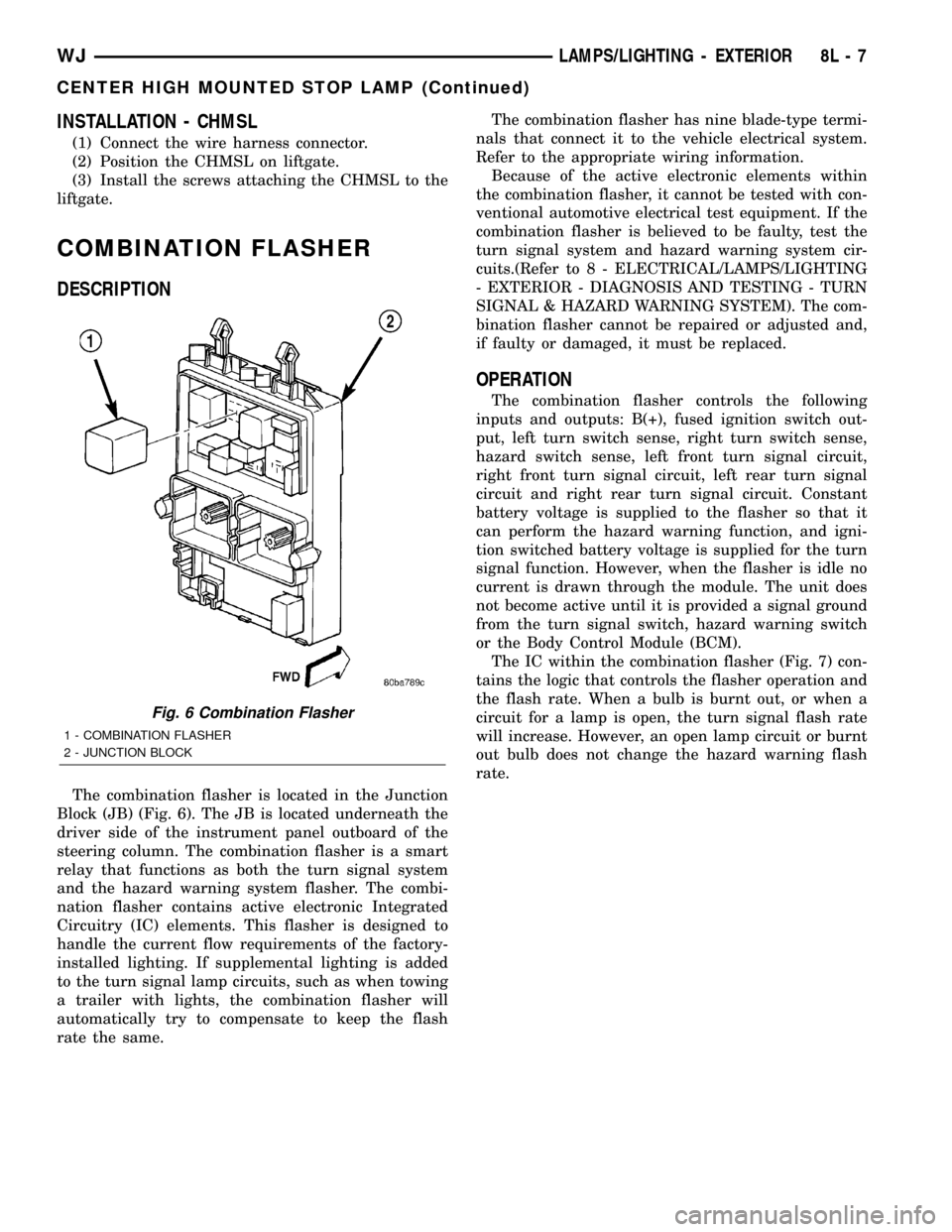

The combination flasher is located in the Junction

Block (JB) (Fig. 6). The JB is located underneath the

driver side of the instrument panel outboard of the

steering column. The combination flasher is a smart

relay that functions as both the turn signal system

and the hazard warning system flasher. The combi-

nation flasher contains active electronic Integrated

Circuitry (IC) elements. This flasher is designed to

handle the current flow requirements of the factory-

installed lighting. If supplemental lighting is added

to the turn signal lamp circuits, such as when towing

a trailer with lights, the combination flasher will

automatically try to compensate to keep the flash

rate the same.The combination flasher has nine blade-type termi-

nals that connect it to the vehicle electrical system.

Refer to the appropriate wiring information.

Because of the active electronic elements within

the combination flasher, it cannot be tested with con-

ventional automotive electrical test equipment. If the

combination flasher is believed to be faulty, test the

turn signal system and hazard warning system cir-

cuits.(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING

- EXTERIOR - DIAGNOSIS AND TESTING - TURN

SIGNAL & HAZARD WARNING SYSTEM). The com-

bination flasher cannot be repaired or adjusted and,

if faulty or damaged, it must be replaced.

OPERATION

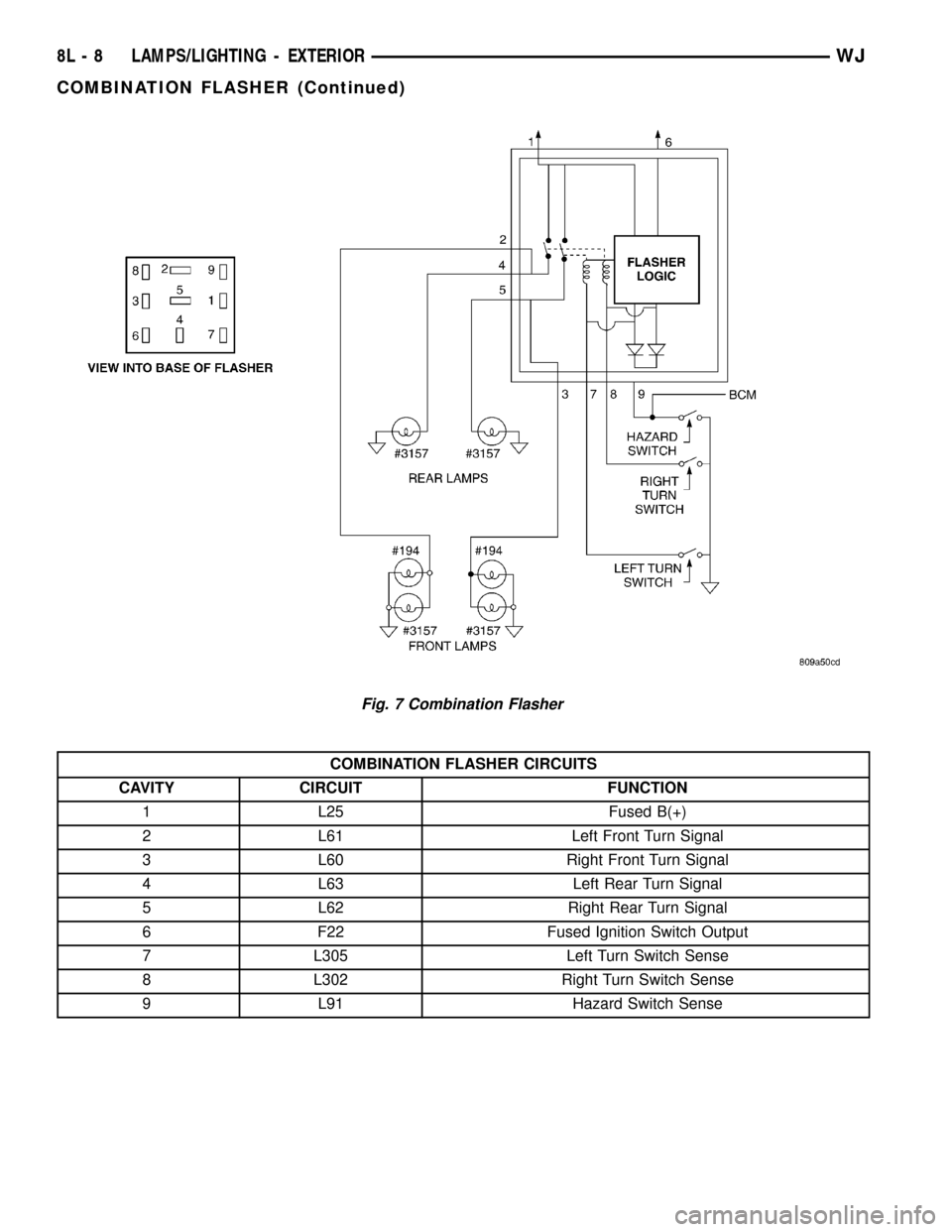

The combination flasher controls the following

inputs and outputs: B(+), fused ignition switch out-

put, left turn switch sense, right turn switch sense,

hazard switch sense, left front turn signal circuit,

right front turn signal circuit, left rear turn signal

circuit and right rear turn signal circuit. Constant

battery voltage is supplied to the flasher so that it

can perform the hazard warning function, and igni-

tion switched battery voltage is supplied for the turn

signal function. However, when the flasher is idle no

current is drawn through the module. The unit does

not become active until it is provided a signal ground

from the turn signal switch, hazard warning switch

or the Body Control Module (BCM).

The IC within the combination flasher (Fig. 7) con-

tains the logic that controls the flasher operation and

the flash rate. When a bulb is burnt out, or when a

circuit for a lamp is open, the turn signal flash rate

will increase. However, an open lamp circuit or burnt

out bulb does not change the hazard warning flash

rate.

Fig. 6 Combination Flasher

1 - COMBINATION FLASHER

2 - JUNCTION BLOCK

WJLAMPS/LIGHTING - EXTERIOR 8L - 7

CENTER HIGH MOUNTED STOP LAMP (Continued)

Page 459 of 2199

COMBINATION FLASHER CIRCUITS

CAVITY CIRCUIT FUNCTION

1 L25 Fused B(+)

2 L61 Left Front Turn Signal

3 L60 Right Front Turn Signal

4 L63 Left Rear Turn Signal

5 L62 Right Rear Turn Signal

6 F22 Fused Ignition Switch Output

7 L305 Left Turn Switch Sense

8 L302 Right Turn Switch Sense

9 L91 Hazard Switch Sense

Fig. 7 Combination Flasher

8L - 8 LAMPS/LIGHTING - EXTERIORWJ

COMBINATION FLASHER (Continued)

Page 464 of 2199

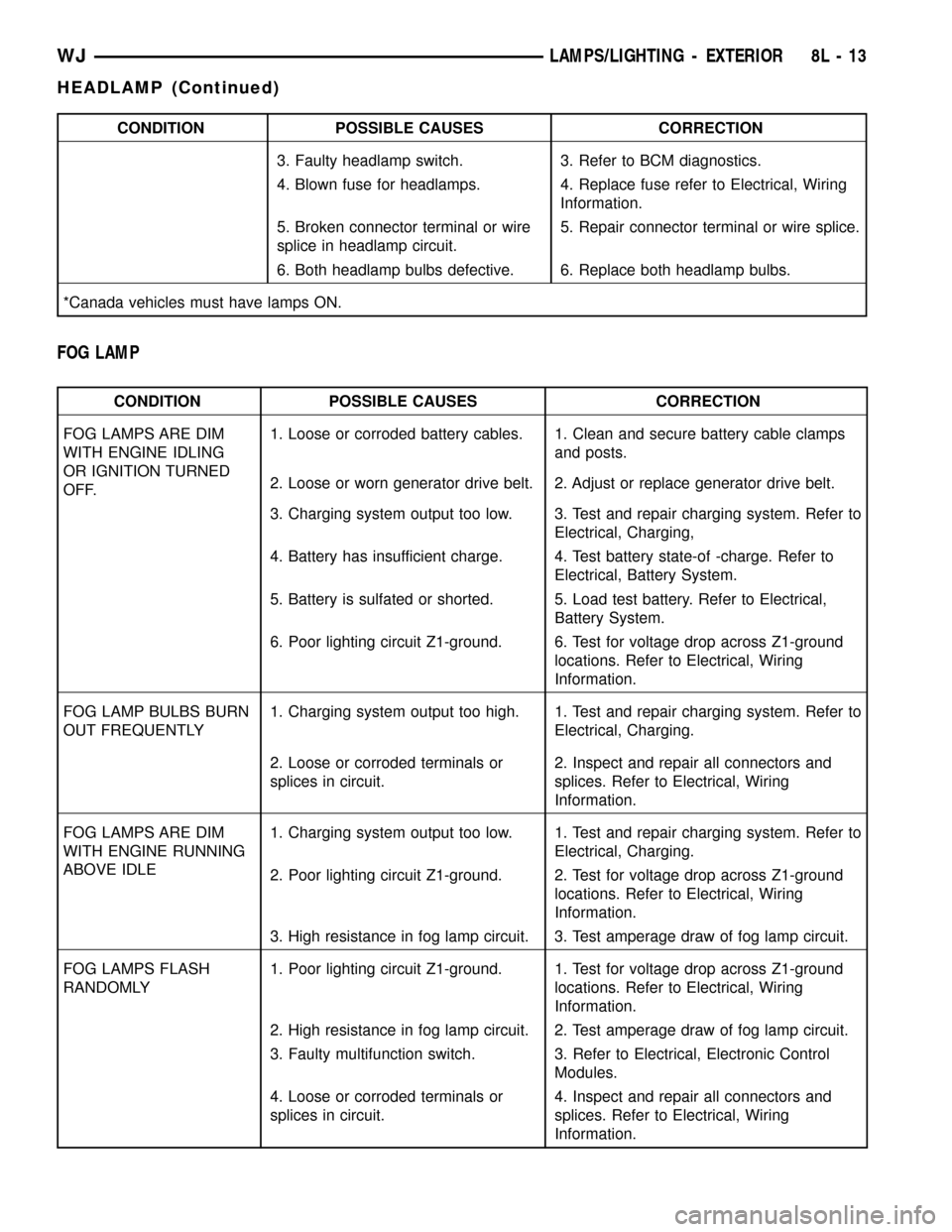

CONDITION POSSIBLE CAUSES CORRECTION

3. Faulty headlamp switch. 3. Refer to BCM diagnostics.

4. Blown fuse for headlamps. 4. Replace fuse refer to Electrical, Wiring

Information.

5. Broken connector terminal or wire

splice in headlamp circuit.5. Repair connector terminal or wire splice.

6. Both headlamp bulbs defective. 6. Replace both headlamp bulbs.

*Canada vehicles must have lamps ON.

FOG LAMP

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS ARE DIM

WITH ENGINE IDLING

OR IGNITION TURNED

OFF.1. Loose or corroded battery cables. 1. Clean and secure battery cable clamps

and posts.

2. Loose or worn generator drive belt. 2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system. Refer to

Electrical, Charging,

4. Battery has insufficient charge. 4. Test battery state-of -charge. Refer to

Electrical, Battery System.

5. Battery is sulfated or shorted. 5. Load test battery. Refer to Electrical,

Battery System.

6. Poor lighting circuit Z1-ground. 6. Test for voltage drop across Z1-ground

locations. Refer to Electrical, Wiring

Information.

FOG LAMP BULBS BURN

OUT FREQUENTLY1. Charging system output too high. 1. Test and repair charging system. Refer to

Electrical, Charging.

2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and

splices. Refer to Electrical, Wiring

Information.

FOG LAMPS ARE DIM

WITH ENGINE RUNNING

ABOVE IDLE1. Charging system output too low. 1. Test and repair charging system. Refer to

Electrical, Charging.

2. Poor lighting circuit Z1-ground. 2. Test for voltage drop across Z1-ground

locations. Refer to Electrical, Wiring

Information.

3. High resistance in fog lamp circuit. 3. Test amperage draw of fog lamp circuit.

FOG LAMPS FLASH

RANDOMLY1. Poor lighting circuit Z1-ground. 1. Test for voltage drop across Z1-ground

locations. Refer to Electrical, Wiring

Information.

2. High resistance in fog lamp circuit. 2. Test amperage draw of fog lamp circuit.

3. Faulty multifunction switch. 3. Refer to Electrical, Electronic Control

Modules.

4. Loose or corroded terminals or

splices in circuit.4. Inspect and repair all connectors and

splices. Refer to Electrical, Wiring

Information.

WJLAMPS/LIGHTING - EXTERIOR 8L - 13

HEADLAMP (Continued)

Page 470 of 2199

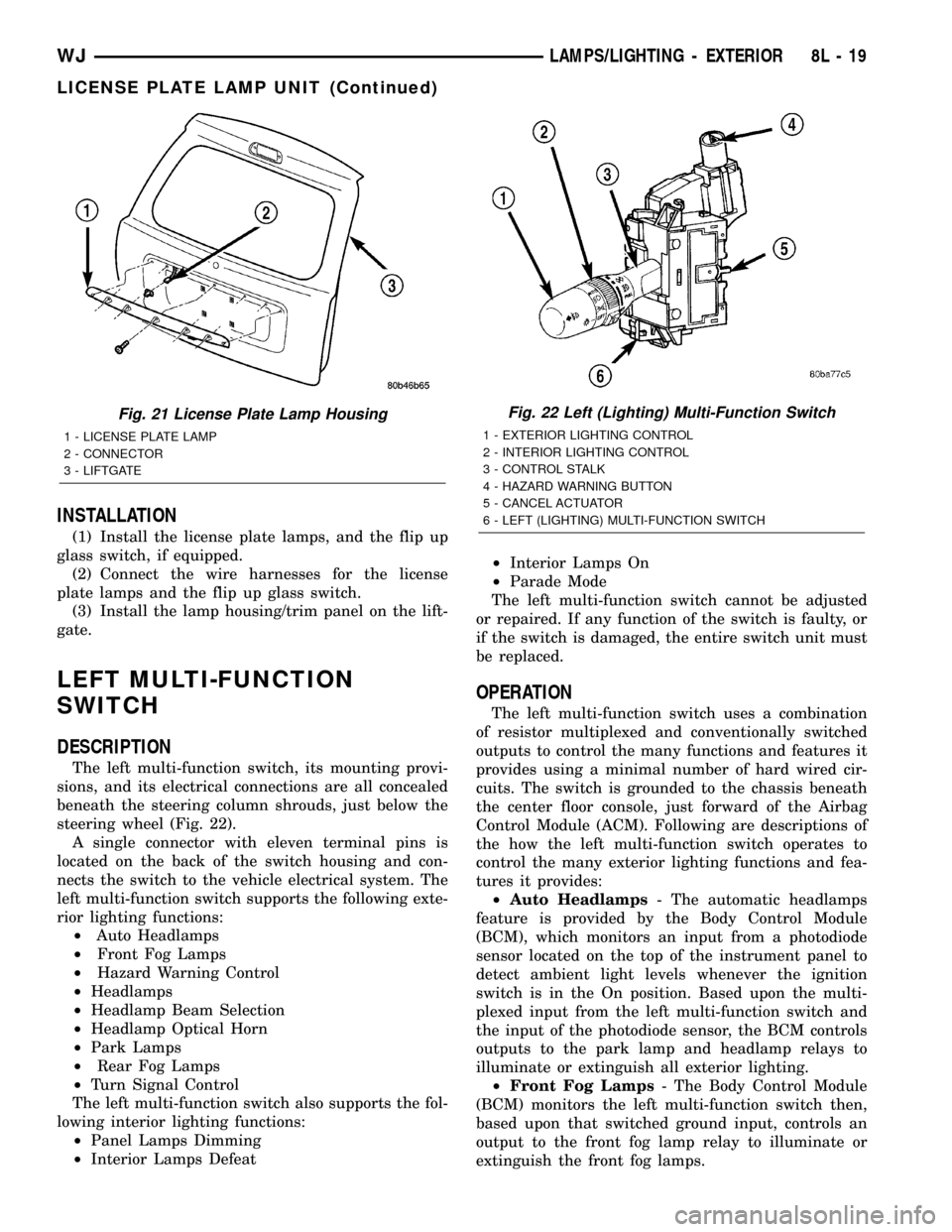

INSTALLATION

(1) Install the license plate lamps, and the flip up

glass switch, if equipped.

(2) Connect the wire harnesses for the license

plate lamps and the flip up glass switch.

(3) Install the lamp housing/trim panel on the lift-

gate.

LEFT MULTI-FUNCTION

SWITCH

DESCRIPTION

The left multi-function switch, its mounting provi-

sions, and its electrical connections are all concealed

beneath the steering column shrouds, just below the

steering wheel (Fig. 22).

A single connector with eleven terminal pins is

located on the back of the switch housing and con-

nects the switch to the vehicle electrical system. The

left multi-function switch supports the following exte-

rior lighting functions:

²Auto Headlamps

²Front Fog Lamps

²Hazard Warning Control

²Headlamps

²Headlamp Beam Selection

²Headlamp Optical Horn

²Park Lamps

²Rear Fog Lamps

²Turn Signal Control

The left multi-function switch also supports the fol-

lowing interior lighting functions:

²Panel Lamps Dimming

²Interior Lamps Defeat²Interior Lamps On

²Parade Mode

The left multi-function switch cannot be adjusted

or repaired. If any function of the switch is faulty, or

if the switch is damaged, the entire switch unit must

be replaced.

OPERATION

The left multi-function switch uses a combination

of resistor multiplexed and conventionally switched

outputs to control the many functions and features it

provides using a minimal number of hard wired cir-

cuits. The switch is grounded to the chassis beneath

the center floor console, just forward of the Airbag

Control Module (ACM). Following are descriptions of

the how the left multi-function switch operates to

control the many exterior lighting functions and fea-

tures it provides:

²Auto Headlamps- The automatic headlamps

feature is provided by the Body Control Module

(BCM), which monitors an input from a photodiode

sensor located on the top of the instrument panel to

detect ambient light levels whenever the ignition

switch is in the On position. Based upon the multi-

plexed input from the left multi-function switch and

the input of the photodiode sensor, the BCM controls

outputs to the park lamp and headlamp relays to

illuminate or extinguish all exterior lighting.

²Front Fog Lamps- The Body Control Module

(BCM) monitors the left multi-function switch then,

based upon that switched ground input, controls an

output to the front fog lamp relay to illuminate or

extinguish the front fog lamps.

Fig. 21 License Plate Lamp Housing

1 - LICENSE PLATE LAMP

2 - CONNECTOR

3 - LIFTGATE

Fig. 22 Left (Lighting) Multi-Function Switch

1 - EXTERIOR LIGHTING CONTROL

2 - INTERIOR LIGHTING CONTROL

3 - CONTROL STALK

4 - HAZARD WARNING BUTTON

5 - CANCEL ACTUATOR

6 - LEFT (LIGHTING) MULTI-FUNCTION SWITCH

WJLAMPS/LIGHTING - EXTERIOR 8L - 19

LICENSE PLATE LAMP UNIT (Continued)

Page 483 of 2199

READING LAMP

DESCRIPTION

The overhead console in this vehicle is equipped

with two individual reading and courtesy lamps.Each

lamp has its own switch, bulb, reflector and lens; but

both lamps share a common lamp housing within the

overhead console.

The overhead console reading and courtesy lamps

operate on battery current that is provided at all

times, regardless of the ignition switch position. The

ground feed for the lamps is switched through the

integral reading and courtesy lamp switches or

through the door jamb switches.

The reading and courtesy lamp lenses and the

lamp housing and reflector unit are serviced only as

a unit with the overhead console housing.The reading

and courtesy lamp switches, bulb holders and wiring

are only available as part of the overhead console

wire harness.

For service of the reading and courtesy lamp bulbs,

(Refer to 8 - ELECTRICAL/LAMPS/LIGHTING -

INTERIOR/READING LAMP - REMOVAL). For diag-

nosis of the reading and courtesy lamps, refer to the

appropriate wiring information.

OPERATION

All reading and courtesy lamps located in the over-

head console are activated by the door jamb switches.

When all of the doors are closed, these lamps can be

individually activated by depressing the correspond-

ing lens. When any door is open, depressing the lamp

lenses to activate the lamp switches will not turn the

lamps off.

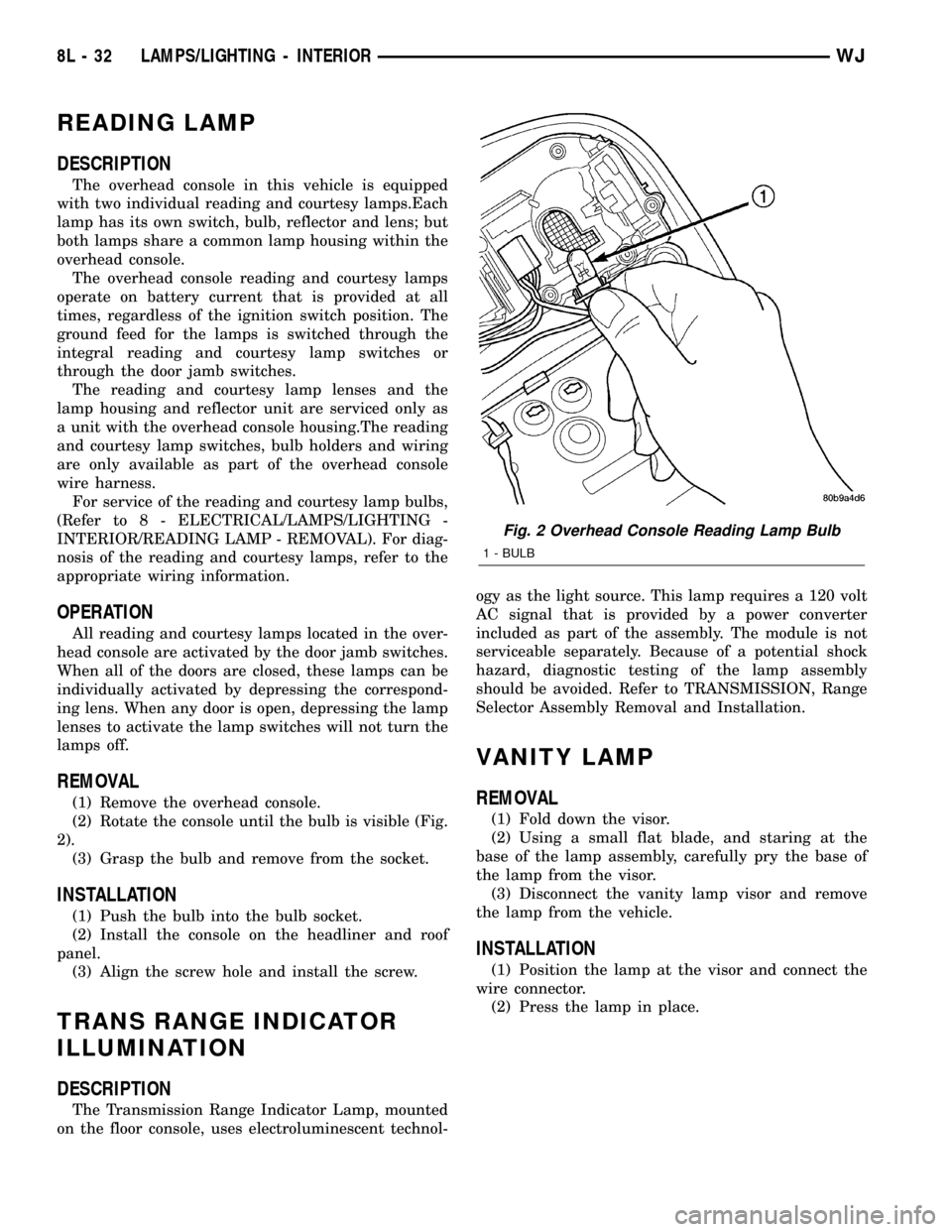

REMOVAL

(1) Remove the overhead console.

(2) Rotate the console until the bulb is visible (Fig.

2).

(3) Grasp the bulb and remove from the socket.

INSTALLATION

(1) Push the bulb into the bulb socket.

(2) Install the console on the headliner and roof

panel.

(3) Align the screw hole and install the screw.

TRANS RANGE INDICATOR

ILLUMINATION

DESCRIPTION

The Transmission Range Indicator Lamp, mounted

on the floor console, uses electroluminescent technol-ogy as the light source. This lamp requires a 120 volt

AC signal that is provided by a power converter

included as part of the assembly. The module is not

serviceable separately. Because of a potential shock

hazard, diagnostic testing of the lamp assembly

should be avoided. Refer to TRANSMISSION, Range

Selector Assembly Removal and Installation.

VANITY LAMP

REMOVAL

(1) Fold down the visor.

(2) Using a small flat blade, and staring at the

base of the lamp assembly, carefully pry the base of

the lamp from the visor.

(3) Disconnect the vanity lamp visor and remove

the lamp from the vehicle.

INSTALLATION

(1) Position the lamp at the visor and connect the

wire connector.

(2) Press the lamp in place.

Fig. 2 Overhead Console Reading Lamp Bulb

1 - BULB

8L - 32 LAMPS/LIGHTING - INTERIORWJ

Page 485 of 2199

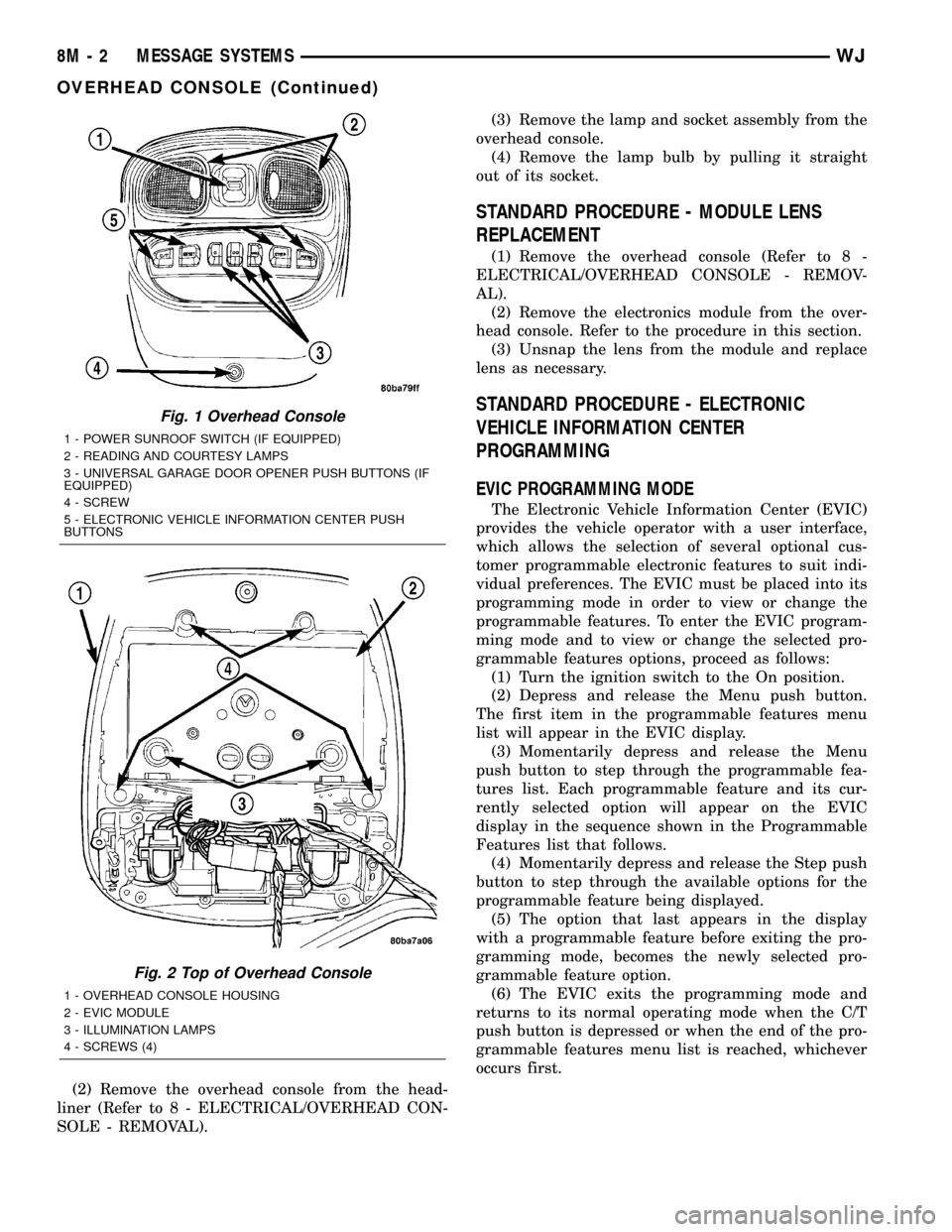

(2) Remove the overhead console from the head-

liner (Refer to 8 - ELECTRICAL/OVERHEAD CON-

SOLE - REMOVAL).(3) Remove the lamp and socket assembly from the

overhead console.

(4) Remove the lamp bulb by pulling it straight

out of its socket.

STANDARD PROCEDURE - MODULE LENS

REPLACEMENT

(1) Remove the overhead console (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - REMOV-

AL).

(2) Remove the electronics module from the over-

head console. Refer to the procedure in this section.

(3) Unsnap the lens from the module and replace

lens as necessary.

STANDARD PROCEDURE - ELECTRONIC

VEHICLE INFORMATION CENTER

PROGRAMMING

EVIC PROGRAMMING MODE

The Electronic Vehicle Information Center (EVIC)

provides the vehicle operator with a user interface,

which allows the selection of several optional cus-

tomer programmable electronic features to suit indi-

vidual preferences. The EVIC must be placed into its

programming mode in order to view or change the

programmable features. To enter the EVIC program-

ming mode and to view or change the selected pro-

grammable features options, proceed as follows:

(1) Turn the ignition switch to the On position.

(2) Depress and release the Menu push button.

The first item in the programmable features menu

list will appear in the EVIC display.

(3) Momentarily depress and release the Menu

push button to step through the programmable fea-

tures list. Each programmable feature and its cur-

rently selected option will appear on the EVIC

display in the sequence shown in the Programmable

Features list that follows.

(4) Momentarily depress and release the Step push

button to step through the available options for the

programmable feature being displayed.

(5) The option that last appears in the display

with a programmable feature before exiting the pro-

gramming mode, becomes the newly selected pro-

grammable feature option.

(6) The EVIC exits the programming mode and

returns to its normal operating mode when the C/T

push button is depressed or when the end of the pro-

grammable features menu list is reached, whichever

occurs first.

Fig. 1 Overhead Console

1 - POWER SUNROOF SWITCH (IF EQUIPPED)

2 - READING AND COURTESY LAMPS

3 - UNIVERSAL GARAGE DOOR OPENER PUSH BUTTONS (IF

EQUIPPED)

4 - SCREW

5 - ELECTRONIC VEHICLE INFORMATION CENTER PUSH

BUTTONS

Fig. 2 Top of Overhead Console

1 - OVERHEAD CONSOLE HOUSING

2 - EVIC MODULE

3 - ILLUMINATION LAMPS

4 - SCREWS (4)

8M - 2 MESSAGE SYSTEMSWJ

OVERHEAD CONSOLE (Continued)