Ambient temperature sensor wiring JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 313 of 2199

BCM programming then performs those tasks and

provides features through both PCI data bus commu-

nication with other electronic modules and hard

wired outputs to a number of relays. These relays

provide the BCM with the ability to control numer-

ous high current accessory systems in the vehicle.

The BCM circuitry operates on battery current

received through fuses in the Junction Block (JB) on a

non-switched fused B(+) circuit, a fused ignition switch

output (start-run) circuit, and a fused ignition switch

output (run-accessory) circuit. This arrangement allows

the BCM to provide some features regardless of the

ignition switch position. The BCM circuitry is grounded

through the chassis beneath the center console.

The BCM monitors its own internal circuitry as

well as many of its input and output circuits, and

will store a Diagnostic Trouble Code (DTC) in elec-

tronic memory for any failure it detects. These DTCs

can be retrieved and diagnosed using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

HARD WIRED INPUTS

The hard wired inputs to the BCM include the fol-

lowing:

²A/C switch signal

²Ambient temperature sensor signal

²Body control module flash enable

²Coolant level switch sense

²Door ajar switch sense (two circuits - one left

rear, and one right rear)

²Driver seat heater switch mux

²Fog lamp switch sense

²Fused B(+)

²Fused ignition switch output (run-acc)

²Fused ignition switch output (st-run)

²Ground (five circuits - two Z1, and three Z2)

²Hazard switch sense

²Headlamp switch mux

²High beam switch sense

²Hood ajar switch sense (export)

²Key-in ignition switch sense

²Liftgate ajar switch sense

²Liftgate courtesy disable

²Liftgate flip-up ajar switch sense

²Panel lamps dimmer signal

²Park lamp relay output

²Passenger seat heater switch mux

²PCI bus

²Radio control mux

²Rear window defogger switch sense

²Seat belt switch sense

²Ultralight sensor signal

²Washer fluid switch sense

²Washer pump switch sense

²Windshield wiper switch mux

²Wiper park switch sense

MESSAGING

The BCM uses the following messages received

from other electronic modules over the PCI data bus:

²Accessory Delay Control (DDM/PDM)

²Battery Temperature (PCM)

²Chime Request (EMIC, EVIC, SKIM)

²Cylinder Lock Switch Status (DDM)

²Door Ajar Status/Front Doors (DDM/PDM)

²Door Lock Status (DDM/PDM)

²Engine Model (PCM)

²Engine RPM (PCM)

²Engine Temperature (PCM)

²English/Metric Default (EMIC)

²Fuel Tank Level (PCM)

²Fuel Used/Injector Pulses (PCM)

²Panic Control (PDM)

²Programmable Features Preferences/Audible &

Optical Chirps/Headlamp Delay (EVIC)

²RKE Status (PDM)

²Vehicle Identification Number (PCM)

²Vehicle Speed (PCM)

The BCM provides the following messages to other

electronic modules over the PCI data bus:

²A/C Switch Status (PCM)

²Ambient Temperature Data (AZC/EVIC/PCM)

²Average/Instantaneous Fuel Economy (EVIC)

²Country Code (EMIC)

²Courtesy Lamp Status (DDM/PDM)

²Distance To Empty (EVIC)

²Elapsed Ignition On Timer (EVIC)

²English/Metric Status (EMIC)

²Front & Rear Door Ajar Status (EVIC)

²Front & Rear Fog Lamp Status (EMIC)

²Heated Seat Switch Status (HSM/MHSM)

²High Beam Status (EMIC)

²Ignition Off Timer (EVIC)

²Ignition Switch Position (DDM/PDM)

²Key-In Ignition Status (DDM/PDM)

²Low Beam Status (EMIC)

²Panel Lamp Status (AZC/EMIC/Radio)

²Rear Window Defogger Relay Status (DDM/

PDM)

²Remote Radio Switch Status (Radio)

²Seatbelt Status (EMIC/MHSM/MSM)

DIAGNOSIS AND TESTING - BODY CONTROL

MODULE

The hard wired inputs to and outputs from the

Body Control Module (BCM) may be diagnosed and

tested using conventional diagnostic tools and proce-

dures. Refer to the appropriate wiring information.

Conventional diagnostic methods may not prove

conclusive in the diagnosis of the BCM. In order to

obtain conclusive testing of the BCM, the Program-

mable Communications Interface (PCI) data bus net-

work and all of the electronic modules that provide

8E - 4 ELECTRONIC CONTROL MODULESWJ

BODY CONTROL MODULE (Continued)

Page 381 of 2199

these electronic modules or of the PCI data bus net-

work, the use of a DRBtscan tool and the proper

Diagnostic Procedures manual are recommended.

The electronic modules that may affect heated seat

system operation are as follows:

²Body Control Module (BCM)- Refer toBody

Control Modulein Electronic Control Modules for

more information.

²Heated Seat Module (HSM)- Refer toHeated

Seat Modulein Electronic Control Modules for more

information.

²Memory Heated Seat Module (MHSM)-If

the vehicle is equipped with the Memory System,

refer toMemory Seat Modulein Electronic Control

Modules for more information.

Refer toPower Seats Premium I/IIIin the Con-

tents of Wiring Diagrams for complete circuit dia-

grams. Following are general descriptions of the

major components in the heated seat system.

OPERATION

The heated seat system will only operate when the

ignition switch is in the On position, and the surface

temperature at the front seat heating element sen-

sors is below the designed temperature set points of

the system. The heated seat system will not operate

in ambient temperatures greater than about 41É C

(105É F). The front seat heating elements and sensors

are hard wired to the Heated Seat Module (HSM) or

the Memory Heated Seat Module (MHSM).

The heated seat switches are hard wired to the

Body Control Module (BCM). The BCM monitors the

heated seat switch inputs, then sends heated seat

switch status messages to the HSM or MHSM over

the Programmable Communications Interface (PCI)

data bus. The HSM or MHSM contains the control

logic for the heated seat system. The HSM or MHSM

responds to the heated seat switch status messages,

ignition switch status messages, and the front seat

heating element sensor inputs by controlling the out-

put to the front seat heating elements through inte-

gral solid-state relays.

When a seat heater is turned on, the sensor

located on the seat cushion electric heater element

provides the HSM or MHSM with an input indicating

the surface temperature of the seat cushion. If the

surface temperature input is below the temperature

set point for the selected Low or High heated seat

switch position, the HSM or MHSM energizes the

integral solid-state relay, which supplies battery cur-

rent to the heating elements in the seat cushion and

back. When the sensor input indicates the correct

temperature set point has been achieved, the HSM or

MHSM de-energizes the solid-state relay. The HSM

or MHSM will continue to cycle the solid-state relay

as needed to maintain the temperature set point.The HSM or MHSM and the seat heater elements

operate on non-switched battery current supplied

through the power seat circuit breaker in the junc-

tion block. However, the HSM or MHSM will auto-

matically turn off the heating elements if it detects

an open or short in the sensor circuit, a short or open

in the heating element circuit causing an excessive

current draw, or when the ignition switch is turned

to the Off position.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the heated seat system.

DIAGNOSIS AND TESTING - HEATED SEAT

SYSTEM

Following are tests that will help to diagnose the

components and circuits that are hard wired inputs

or outputs of the heated seat system. However, these

tests may not prove conclusive in the diagnosis of

this system. In order to obtain conclusive testing of

the heated seat system, the Programmable Commu-

nications Interface (PCI) data bus network and all of

the electronic modules that provide inputs to, or

receive outputs from the heated seat system compo-

nents must be checked.

The most reliable, efficient, and accurate means to

diagnose the heated seat system requires the use of a

DRB scan tool and the proper Diagnostic Procedures

manual. The DRBtscan tool can provide confirma-

tion that the PCI data bus is functional, that all of

the electronic modules are sending and receiving the

proper messages on the PCI data bus, and that the

Heated Seat Module (HSM) or Memory Heated Seat

Module (MHSM) is receiving the proper hard wired

inputs and relaying the proper hard wired outputs to

perform its heated seat system functions.

For complete circuit diagrams, refer toWiring

Diagrams.

NOTE: DO NOT ATTEMPT TO SWAP MEMORY OR

NON-MEMORY HEATED SEAT MODULES FROM

ONE VEHICLE TO ANOTHER. MOST OF THESE

MODULES ARE VEHICLE FEATURE SPECIFIC AND

THEREFORE NOT INTERCHANGEABLE. ALWAYS

USE THE CORRECT PART NUMBERED MODULE

WHEN DIAGNOSING OR REPLACING A MODULE.

WARNING: REFER TO THE RESTRAINTS SECTION

OF THIS MANUAL BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

8G - 10 HEATED SEAT SYSTEMWJ

HEATED SEAT SYSTEM (Continued)

Page 484 of 2199

MESSAGE SYSTEMS

TABLE OF CONTENTS

page page

OVERHEAD CONSOLE

DESCRIPTION..........................1

OPERATION............................1

STANDARD PROCEDURE

STANDARD PROCEDURE - MODULE LAMP

REPLACEMENT.......................1

STANDARD PROCEDURE - COURTESY

LAMP REPLACEMENT..................1

STANDARD PROCEDURE - MODULE LENS

REPLACEMENT.......................2

STANDARD PROCEDURE - ELECTRONIC

VEHICLE INFORMATION CENTER

PROGRAMMING.......................2

STANDARD PROCEDURE - COMPASS

DEMAGNETIZING......................4

STANDARD PROCEDURE - COMPASS

CALIBRATION.........................5

STANDARD PROCEDURE - COMPASS

VARIATION ADJUSTMENT................5

REMOVAL.............................5

INSTALLATION..........................6

SPECIAL TOOLS

OVERHEAD CONSOLE SYSTEMS.........6

ELECTRONIC VEHICLE INFO CENTER

DESCRIPTION..........................6OPERATION............................9

DIAGNOSIS AND TESTING - ELECTRONIC

VEHICLE INFORMATION CENTER.........9

STANDARD PROCEDURE - TIRE PRESSURE

SYSTEM TEST.......................10

REMOVAL.............................10

INSTALLATION.........................10

UNIVERSAL TRANSMITTER

DESCRIPTION.........................11

OPERATION...........................11

DIAGNOSIS AND TESTING - UNIVERSAL

TRANSMITTER.......................11

AMBIENT TEMP SENSOR

DESCRIPTION.........................12

OPERATION...........................12

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR...............12

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR CIRCUIT........12

REMOVAL.............................12

INSTALLATION.........................13

OVERHEAD CONSOLE

DESCRIPTION

An overhead console is standard factory-installed

equipment on this model. The overhead console

includes the Electronic Vehicle Information Center

(EVIC) and two reading and courtesy lamps (Fig. 1).

On vehicles equipped with a power sunroof option,

the overhead console also houses the power sunroof

switch between the two reading and courtesy lamps.

The overhead console is mounted with one screw and

two snap-clips to a molded plastic retainer bracket

located above the headliner. The retainer bracket is

secured with adhesive to the inside surface of the

roof panel.

Following are general descriptions of the major

components used in the overhead console. Refer to

Overhead Consolein Wiring Diagrams for complete

circuit diagrams.

OPERATION

See the owner's manual in the vehicle glove box for

more information on the use and operation of the

various overhead console features.

STANDARD PROCEDURE

STANDARD PROCEDURE - MODULE LAMP

REPLACEMENT

(1) Remove the overhead console (Refer to 8 -

ELECTRICAL/OVERHEAD CONSOLE - REMOV-

AL).

(2) Using a flat blade screwdriver twist out socket/

lamp (Fig. 2).

(3) Replace lamp(s) as necessary.

STANDARD PROCEDURE - COURTESY LAMP

REPLACEMENT

(1) Open hood, disconnect and isolate the negative

battery cable.

WJMESSAGE SYSTEMS 8M - 1

Page 492 of 2199

OPERATION

The EVIC has access to both non-switched and

ignition switched sources of battery current so that

some of its features remain operational at any time,

while others may only operate with the ignition

switch in the On position. When the ignition switch

is turned to the On position, the EVIC module VFD

will return to the last function being displayed before

the ignition was turned to the Off position.

The compass/temperature display is the normal

EVIC display. With the ignition switch in the On

position, momentarily depressing and releasing the

C/T (compass/temperature) push button switch will

cause the EVIC to return to the compass/tempera-

ture/trip computer display mode from any other

mode. While in the compass/temperature/trip com-

puter display mode, momentarily depressing and

releasing the Step push button will step through the

available trip computer display options.

The EVIC trip computer features several functions

that can be reset. The functions that can be reset

are: average fuel economy, trip odometer and elapsed

time. With the ignition switch in the On position and

with one of the functions of the trip computer that

can be reset currently displayed, depressing the

Reset push button twice within three seconds will

perform a global reset, and all of the trip computer

information that can be reset will be reset to zero.

With the ignition switch in the On position and the

function that is to be reset currently displayed,

momentarily depressing and releasing the Reset

push button once will perform a local reset, and only

the value of the displayed function will be reset to

zero. A global or local reset will only occur if the

function currently displayed is a function that can be

reset. The distance to service function can also be

reset using the local reset method, but it will reset

back to the Service Interval distance that is set in

the EVIC programmable features mode. Refer to

ELECTRONIC VEHICLE INFORMATION CEN-

TER PROGRAMMINGin the Service Procedures

section of this group for more information on setting

the Service Interval.

For more information on the features, control func-

tions and setting procedures for the EVIC module,

see the owner's manual in the vehicle glove box.

DIAGNOSIS AND TESTING - ELECTRONIC

VEHICLE INFORMATION CENTER

If the problem with the Electronic Vehicle Informa-

tion Center (EVIC) is a temperature reading of 130É

F or -40ÉF shown in the compass/temperature dis-

play, refer toAmbient Temperature Sensor Diag-

nosis and Testingin this group. If the problem with

the EVIC is an inaccurate or scrambled display, refer

toSelf-Diagnostic Testin this group. If the prob-lem with the EVIC is incorrect Vacuum Fluorescent

Display (VFD) dimming levels, use a DRBtscan tool

and the proper Diagnostic Procedures manual to test

for the correct dimming message inputs being

received from the Body Control Module (BCM) over

the Programmable Communications Interface (PCI)

data bus. If the problem is a no-display condition,

use the following procedures. For complete circuit

diagrams, refer toOverhead Consolein Wiring

Diagrams.

(1) Check the fused B(+) fuse in the junction block.

If OK, go to Step 2. If not OK, repair the shorted cir-

cuit or component as required and replace the faulty

fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the junction block. If OK, go to Step 3. If not OK,

repair the open fused B(+) circuit to the fused B(+)

fuse in the PDC as required.

(3) Check the fused ignition switch output (run/

start) fuse in the junction block. If OK, go to Step 4.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) fuse in the junction block. If OK,

go to Step 5. If not OK, repair the open fused ignition

switch output (run/start) circuit to the ignition switch

as required.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the overhead console. Check for continuity

between the ground circuit cavity of the roof wire

harness connector for the EVIC module and a good

ground. There should be continuity. If OK, go to Step

6. If not OK, repair the open ground circuit to ground

as required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

roof wire harness connector for the EVIC module. If

OK, go to Step 7. If not OK, repair the open fused

B(+) circuit to the fused B(+) fuse in the junction

block as required.

(7) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) circuit cavity of the roof wire har-

ness connector for the EVIC module. If OK, refer to

Self-Diagnostic Testbelow for further diagnosis of

the EVIC module and the PCI data bus. If not OK,

repair the open fused ignition switch output (run/

start) circuit to the fuse in the junction block as

required.

SELF-DIAGNOSTIC TEST

A self-diagnostic test is used to determine that the

EVIC module is operating properly, and that all PCI

WJMESSAGE SYSTEMS 8M - 9

ELECTRONIC VEHICLE INFO CENTER (Continued)

Page 495 of 2199

AMBIENT TEMP SENSOR

DESCRIPTION

Ambient air temperature is monitored by the Elec-

tronic Vehicle Information Center (EVIC) through

ambient temperature messages received from the

Body Control Module (BCM) over the Programmable

Communications Interface (PCI) data bus network.

The BCM receives a hard wired input from the ambi-

ent temperature sensor. The ambient temperature

sensor is a variable resistor mounted to a bracket

that is secured with a screw to the right side of the

headlamp mounting module grille opening, behind

the radiator grille and in front of the engine compart-

ment.

Refer toBody Control Modulein Electronic Con-

trol Modules. For complete circuit diagrams, refer to

the appropriate wiring information. The ambient

temperature sensor cannot be adjusted or repaired

and, if faulty or damaged, it must be replaced.

OPERATION

The ambient temperature sensor is a variable

resistor that operates on a five-volt reference signal

sent to it by the BCM. The resistance in the sensor

changes as temperature changes, changing the tem-

perature sensor signal circuit voltage to the BCM.

Based upon the resistance in the sensor, the BCM

senses a specific voltage on the temperature sensor

signal circuit, which it is programmed to correspond

to a specific temperature. The BCM then sends the

proper ambient temperature messages to the EVIC

over the PCI data bus.

The temperature function is supported by the

ambient temperature sensor, a wiring circuit, the

Body Control Module (BCM), the Programmable

Communications Interface (PCI) data bus, and a por-

tion of the Electronic Vehicle Information Center

(EVIC) module. If any portion of the ambient temper-

ature sensor circuit fails, the BCM will self-diagnose

the circuit. A temperature reading of 130É F will

appear in the EVIC display in place of the tempera-

ture when the sensor circuit is shorted. A tempera-

ture reading of ±40É F will appear in the EVIC

display in place of the temperature when the sensor

circuit is open.

The ambient temperature sensor circuit can also be

diagnosed by referring toDiagnosis and Testing -

Ambient Temperature Sensor, and Diagnosis

and Testing - Ambient Temperature Sensor Cir-

cuit. If the temperature sensor and circuit are con-

firmed to be OK, but the temperature display is

inoperative or incorrect, refer toDiagnosis and

Testing - Electronic Vehicle Information Center

in this group. For complete circuit diagrams, refer to

the appropriate wiring information.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the ambient temperature sensor wire har-

ness connector.

(2) Measure the resistance of the ambient temper-

ature sensor. At ±40É C (±40É F), the sensor resis-

tance is 336.6 kilohms. At 60É C (140É F), the sensor

resistance is 2.49 kilohms. The sensor resistance

should read between these two values. If OK, refer to

Diagnosis and Testing - Ambient Temperature

Sensor Circuitin this group. If not OK, replace the

faulty ambient temperature sensor.

DIAGNOSIS AND TESTING - AMBIENT

TEMPERATURE SENSOR CIRCUIT

(1) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the 2-way ambient temperature sensor

wire harness connector and the 22-way Body Control

Module (BCM) wire harness connector.

(2) Connect a jumper wire between the two termi-

nals in the body half of the 2-way ambient tempera-

ture sensor wire harness connector.

(3) Check for continuity between the sensor return

circuit and the ambient temperature sensor signal

circuit cavities of the 22-way BCM wire harness con-

nector. There should be continuity. If OK, go to Step

4. If not OK, repair the open sensor return circuit or

ambient temperature sensor signal circuit to the

ambient temperature sensor as required.

(4) Remove the jumper wire from the body half of

the 2-way ambient temperature sensor wire harness

connector. Check for continuity between the sensor

return circuit cavity of the 22-way BCM wire harness

connector and a good ground. There should be no

continuity. If OK, go to Step 5. If not OK, repair the

shorted sensor return circuit as required.

(5) Check for continuity between the ambient tem-

perature sensor signal circuit cavity of the 22-way

BCM wire harness connector and a good ground.

There should be no continuity. If OK, refer toDiag-

nosis and Testing - Electronic Vehicle Informa-

tion Centerin this group. If not OK, repair the

shorted ambient temperature sensor signal circuit as

required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

8M - 12 MESSAGE SYSTEMSWJ

Page 1176 of 2199

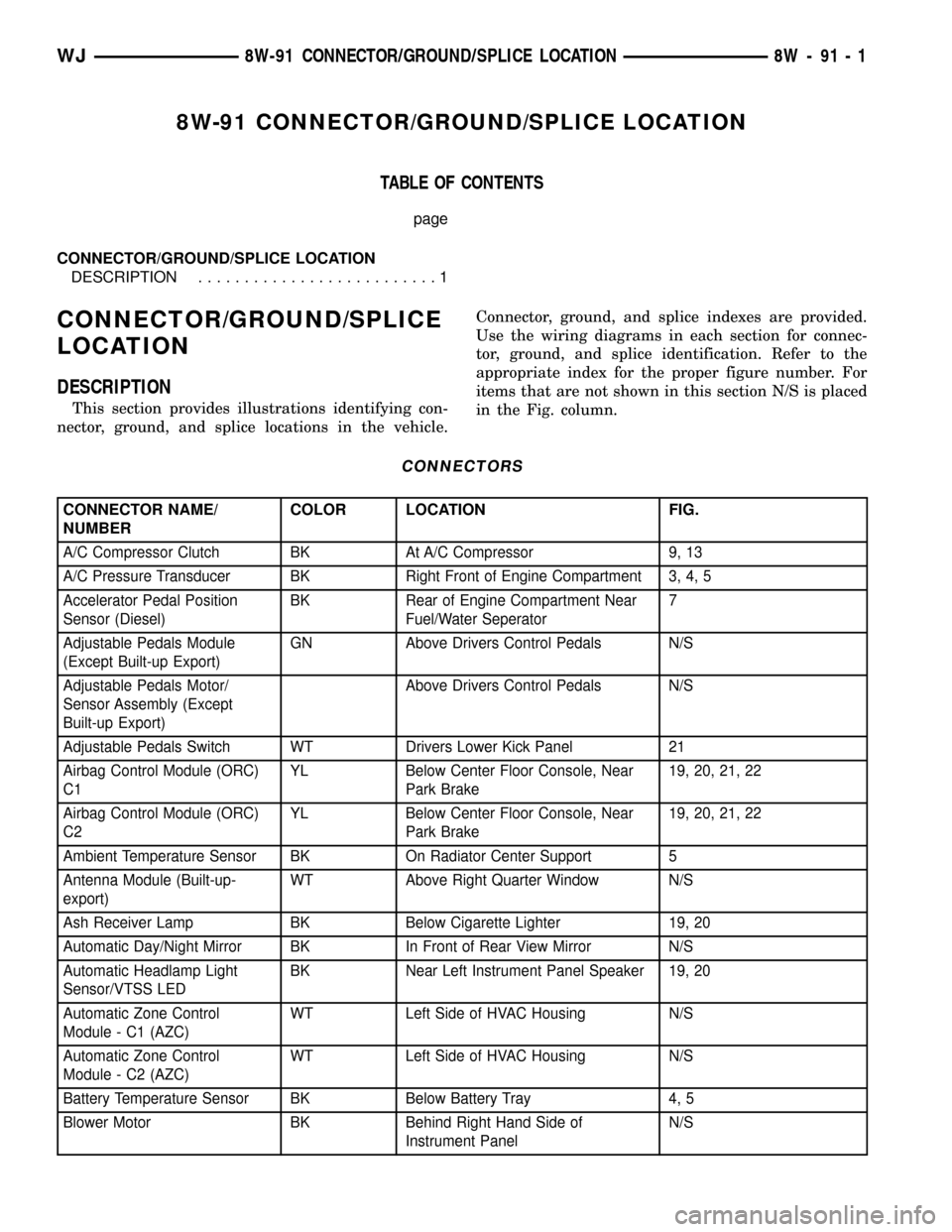

8W-91 CONNECTOR/GROUND/SPLICE LOCATION

TABLE OF CONTENTS

page

CONNECTOR/GROUND/SPLICE LOCATION

DESCRIPTION..........................1

CONNECTOR/GROUND/SPLICE

LOCATION

DESCRIPTION

This section provides illustrations identifying con-

nector, ground, and splice locations in the vehicle.Connector, ground, and splice indexes are provided.

Use the wiring diagrams in each section for connec-

tor, ground, and splice identification. Refer to the

appropriate index for the proper figure number. For

items that are not shown in this section N/S is placed

in the Fig. column.

CONNECTORS

CONNECTOR NAME/

NUMBERCOLOR LOCATION FIG.

A/C Compressor Clutch BK At A/C Compressor 9, 13

A/C Pressure Transducer BK Right Front of Engine Compartment 3, 4, 5

Accelerator Pedal Position

Sensor (Diesel)BK Rear of Engine Compartment Near

Fuel/Water Seperator7

Adjustable Pedals Module

(Except Built-up Export)GN Above Drivers Control Pedals N/S

Adjustable Pedals Motor/

Sensor Assembly (Except

Built-up Export)Above Drivers Control Pedals N/S

Adjustable Pedals Switch WT Drivers Lower Kick Panel 21

Airbag Control Module (ORC)

C1YL Below Center Floor Console, Near

Park Brake19, 20, 21, 22

Airbag Control Module (ORC)

C2YL Below Center Floor Console, Near

Park Brake19, 20, 21, 22

Ambient Temperature Sensor BK On Radiator Center Support 5

Antenna Module (Built-up-

export)WT Above Right Quarter Window N/S

Ash Receiver Lamp BK Below Cigarette Lighter 19, 20

Automatic Day/Night Mirror BK In Front of Rear View Mirror N/S

Automatic Headlamp Light

Sensor/VTSS LEDBK Near Left Instrument Panel Speaker 19, 20

Automatic Zone Control

Module - C1 (AZC)WT Left Side of HVAC Housing N/S

Automatic Zone Control

Module - C2 (AZC)WT Left Side of HVAC Housing N/S

Battery Temperature Sensor BK Below Battery Tray 4, 5

Blower Motor BK Behind Right Hand Side of

Instrument PanelN/S

WJ8W-91 CONNECTOR/GROUND/SPLICE LOCATION 8W - 91 - 1

Page 1469 of 2199

The other two heater elements (downstream sen-

sors 1/2 and 2/2) are controlled by the downstream

heater relay through output signals from the PCM.

To avoid a large simultaneous current surge, power

is delayed to the 2 downstream heater elements by

the PCM for approximately 2 seconds.

REMOVAL

(1) Remove PDC cover.

(2) Remove relay from PDC.

(3) Check condition of relay terminals and PDC

connector terminals for damage or corrosion. Repair

if necessary before installing relay.

(4) Check for pin height (pin height should be the

same for all terminals within the PDC connector).

Repair if necessary before installing relay.

INSTALLATION

(1) Install relay to PDC.

(2) Install cover to PDC.

O2S SENSOR

DESCRIPTION

The Oxygen Sensors (O2S) are attached to, and

protrude into the vehicle exhaust system. Depending

on the emission package, the vehicle may use a total

of either 2 or 4 sensors.

Federal Emissions Package:Two sensors are

used: upstream (referred to as 1/1) and downstream

(referred to as 1/2). With this emission package, the

upstream sensor (1/1) is located just before the main

catalytic convertor. The downstream sensor (1/2) is

located just after the main catalytic convertor.

4.7L V-8 With California Emissions Package:

On this emissions package, 4 sensors are used: 2

upstream (referred to as 1/1 and 2/1) and 2 down-

stream (referred to as 1/2 and 2/2). With this emis-

sion package, the right upstream sensor (2/1) is

located in the right exhaust downpipe just before the

mini-catalytic convertor. The left upstream sensor

(1/1) is located in the left exhaust downpipe just

before the mini-catalytic convertor. The right down-

stream sensor (2/2) is located in the right exhaust

downpipe just after the mini-catalytic convertor, and

before the main catalytic convertor. The left down-

stream sensor (1/2) is located in the left exhaust

downpipe just after the mini-catalytic convertor, and

before the main catalytic convertor.

4.0L 6±Cylinder With California Emissions

Package:On this emissions package, 4 sensors are

used: 2 upstream (referred to as 1/1 and 2/1) and 2

downstream (referred to as 1/2 and 2/2). With this

emission package, the rear/upper upstream sensor

(2/1) is located in the exhaust downpipe just beforethe rear mini-catalytic convertor. The front/upper

upstream sensor (1/1) is located in the exhaust down-

pipe just before the front mini-catalytic convertor.

The rear/lower downstream sensor (2/2) is located in

the exhaust downpipe just after the rear mini-cata-

lytic convertor, and before the main catalytic conver-

tor. The front/lower downstream sensor (1/2) is

located in the exhaust downpipe just after the front

mini-catalytic convertor, and before the main cata-

lytic convertor.

OPERATION

An O2 sensor is a galvanic battery that provides

the PCM with a voltage signal (0-1 volt) inversely

proportional to the amount of oxygen in the exhaust.

In other words, if the oxygen content is low, the volt-

age output is high; if the oxygen content is high the

output voltage is low. The PCM uses this information

to adjust injector pulse-width to achieve the

14.7±to±1 air/fuel ratio necessary for proper engine

operation and to control emissions.

The O2 sensor must have a source of oxygen from

outside of the exhaust stream for comparison. Cur-

rent O2 sensors receive their fresh oxygen (outside

air) supply through the O2 sensor case housing.

Four wires (circuits) are used on each O2 sensor: a

12±volt feed circuit for the sensor heating element; a

ground circuit for the heater element; a low-noise

sensor return circuit to the PCM, and an input cir-

cuit from the sensor back to the PCM to detect sen-

sor operation.

Oxygen Sensor Heaters/Heater Relays:

Depending on the emissions package, the heating ele-

ments within the sensors will be supplied voltage

from either the ASD relay, or 2 separate oxygen sen-

sor relays. Refer to Wiring Diagrams to determine

which relays are used.

The O2 sensor uses a Positive Thermal Co-efficient

(PTC) heater element. As temperature increases,

resistance increases. At ambient temperatures

around 70ÉF, the resistance of the heating element is

approximately 4.5 ohms on 4.0L engines. It is

approximately 13.5 ohms on the 4.7L engine. As the

sensor's temperature increases, resistance in the

heater element increases. This allows the heater to

maintain the optimum operating temperature of

approximately 930É-1100ÉF (500É-600É C). Although

the sensors operate the same, there are physical dif-

ferences, due to the environment that they operate

in, that keep them from being interchangeable.

Maintaining correct sensor temperature at all

times allows the system to enter into closed loop

operation sooner. Also, it allows the system to remain

in closed loop operation during periods of extended

idle.

14 - 50 FUEL INJECTIONWJ

O2S HEATER RELAY (Continued)