Automatic transmission diagram JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 349 of 2199

The battery cables (Fig. 17) or (Fig. 18) are large

gauge, stranded copper wires sheathed within a

heavy plastic or synthetic rubber insulating jacket.

The wire used in the battery cables combines excel-

lent flexibility and reliability with high electrical cur-

rent carrying capacity. Refer toWiring Diagrams

for battery cable wire gauge information.

A clamping type female battery terminal made of

soft lead is die cast onto one end of the battery cable

wire. A square headed pinch-bolt and hex nut are

installed at the open end of the female battery termi-

nal clamp. Large eyelet type terminals are crimped

onto the opposite end of the battery cable wire and

then solder-dipped. The battery positive cable wires

have a red insulating jacket to provide visual identi-

fication and feature a larger female battery terminal

clamp to allow connection to the larger battery posi-

tive terminal post. The battery negative cable wires

have a black insulating jacket and a smaller female

battery terminal clamp.

The battery cables cannot be repaired and, if dam-

aged or faulty they must be replaced. Both the bat-

tery positive and negative cables are available for

service replacement only as a unit with the battery

wire harness, which may include portions of the wir-

ing circuits for the generator and other components

on some models. Refer toWiring Diagramsfor more

information on the various wiring circuits included in

the battery wire harness for the vehicle being ser-

viced.

OPERATION

The battery cables connect the battery terminal

posts to the vehicle electrical system. These cables

also provide a path back to the battery for electrical

current generated by the charging system for restor-

ing the voltage potential of the battery. The female

battery terminal clamps on the ends of the battery

cable wires provide a strong and reliable connection

of the battery cable to the battery terminal posts.

The terminal pinch bolts allow the female terminal

clamps to be tightened around the male terminal

posts on the top of the battery. The eyelet terminals

secured to the opposite ends of the battery cable

wires from the female battery terminal clamps pro-

vide secure and reliable connection of the battery

cables to the vehicle electrical system.

The battery positive cable terminal clamp is die

cast onto the ends of two wires. One wire has an eye-

let terminal that connects the battery positive cable

to the B(+) terminal stud of the Power Distribution

Center (PDC), and the other wire has an eyelet ter-

minal that connects the battery positive cable to the

B(+) terminal stud of the engine starter motor sole-

noid. The battery negative cable terminal clamp is

also die cast onto the ends of two wires. One wirehas an eyelet terminal that connects the battery neg-

ative cable to the vehicle powertrain through a stud

on the right side of the engine cylinder block. The

other wire has an eyelet terminal that connects the

battery negative cable to the vehicle body through a

ground screw on the right front fender inner shield,

near the battery.

DIAGNOSIS AND TESTING - BATTERY CABLES

A voltage drop test will determine if there is exces-

sive resistance in the battery cable terminal connec-

tions or the battery cable. If excessive resistance is

found in the battery cable connections, the connec-

tion point should be disassembled, cleaned of all cor-

rosion or foreign material, then reassembled.

Following reassembly, check the voltage drop for the

battery cable connection and the battery cable again

to confirm repair.

When performing the voltage drop test, it is impor-

tant to remember that the voltage drop is giving an

indication of the resistance between the two points at

which the voltmeter probes are attached.EXAM-

PLE:When testing the resistance of the battery pos-

itive cable, touch the voltmeter leads to the battery

positive cable terminal clamp and to the battery pos-

itive cable eyelet terminal at the starter solenoid

B(+) terminal stud. If you probe the battery positive

terminal post and the battery positive cable eyelet

terminal at the starter solenoid B(+) terminal stud,

you are reading the combined voltage drop in the

battery positive cable terminal clamp-to-terminal

post connection and the battery positive cable.

VOLTAGE DROP TEST

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing this

test, be certain that the following procedures are

accomplished:

²The battery is fully-charged and load tested.

Refer to Standard Procedures for the proper battery

charging and load test procedures.

²Fully engage the parking brake.

²If the vehicle is equipped with an automatic

transmission, place the gearshift selector lever in the

Park position. If the vehicle is equipped with a man-

ual transmission, place the gearshift selector lever in

the Neutral position and block the clutch pedal in the

fully depressed position.

²Verify that all lamps and accessories are turned

off.

²To prevent the engine from starting, remove the

Automatic Shut Down (ASD) relay. The ASD relay is

located in the Power Distribution Center (PDC), in

the engine compartment. See the fuse and relay lay-

out label affixed to the underside of the PDC cover

for ASD relay identification and location.

8F - 18 BATTERY SYSTEMWJ

BATTERY CABLE (Continued)

Page 363 of 2199

INSPECTION

For complete circuit diagrams, refer toStarting

Systemin the Contents of Group 8W - Wiring Dia-

grams. Before removing any unit from the starting

system for repair or diagnosis, perform the following

inspections:

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

²Battery- Visually inspect the battery for indi-

cations of physical damage and loose or corroded

cable connections. Determine the state-of-charge and

cranking capacity of the battery. Charge or replace

the battery, if required. Refer toBatteryin the

proper section of Group 8A - Battery for complete ser-

vice information for the battery.

²Ignition Switch- Visually inspect the ignition

switch for indications of physical damage and loose

or corroded wire harness connections. Refer toIgni-

tion Switch and Key Lock Cylinderin the proper

section of Group 8D - Ignition System for complete

service information for the ignition switch.

²Park/Neutral Position Switch- Visually

inspect the park/neutral position switch for indica-

tions of physical damage and loose or corroded wire

harness connections. Refer toPark/Neutral Posi-

tion Switchin the proper section of Group 21 -

Transmission for complete service information for the

park/neutral position switch.

²Starter Relay- Visually inspect the starter

relay for indications of physical damage and loose or

corroded wire harness connections.

²Starter Motor- Visually inspect the starter

motor for indications of physical damage and loose or

corroded wire harness connections.

²Starter Solenoid- Visually inspect the starter

solenoid for indications of physical damage and loose

or corroded wire harness connections.

²Wiring- Visually inspect the wire harnesses for

damage. Repair or replace any faulty wiring, as

required. Refer to the proper section ofGroup 8W -

Wiring Diagramsfor complete service information

and circuit diagrams for the starting system wiring

components.TESTING

COLD CRANKING TEST

For complete circuit diagrams, refer toStarting

Systemin the Contents of Group 8W - Wiring Dia-

grams. The battery must be fully-charged and load-

tested before proceeding. Refer toBatteryin the

Diagnosis and Testing section of Group 8A - Battery

for the procedures.

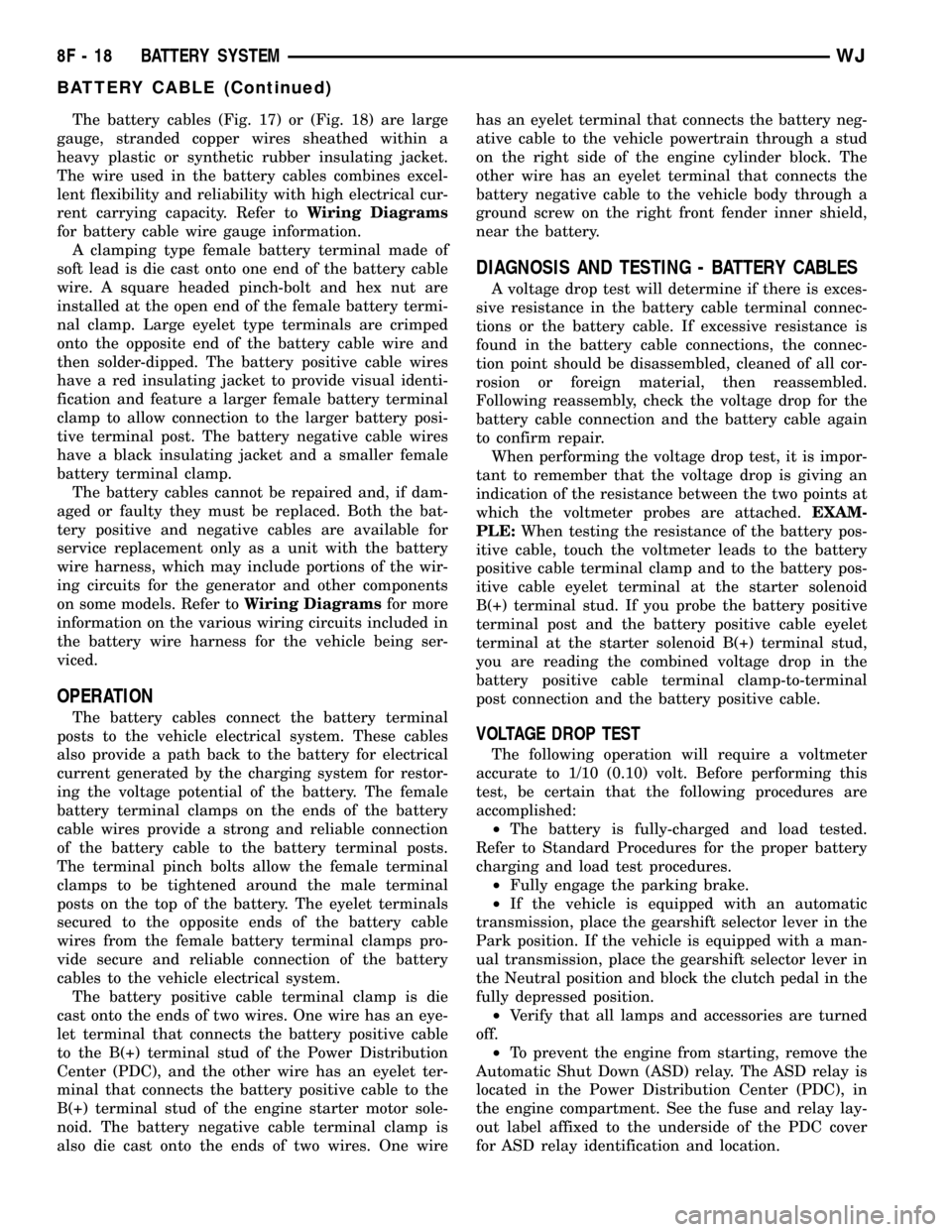

(1) Connect a suitable volt-ampere tester to the

battery terminals (Fig. 1). See the instructions pro-

vided by the manufacturer of the volt-ampere tester

being used.

(2) Fully engage the parking brake.

(3) Place the automatic transmission gearshift

selector lever in the Park position.

(4) Verify that all lamps and accessories are

turned off.

(5) To prevent the engine from starting, remove

the Automatic ShutDown (ASD) relay. The ASD relay

is located in the Power Distribution Center (PDC), in

the engine compartment. Refer to the fuse and relay

layout label affixed to the underside of the PDC cover

for ASD relay identification and location.

(6) Rotate and hold the ignition switch in the Start

position. Note the cranking voltage and current

(amperage) draw readings shown on the volt-ampere

tester.

(a) If the voltage reads below 9.6 volts, refer to

Starter Motorin the Diagnosis and Testing sec-

tion of this group. If the starter motor is OK, refer

toEngine Diagnosisin the Diagnosis and Testing

section of Group 9 - Engine for further testing of

the engine. If the starter motor is not OK, replace

the faulty starter motor.

Fig. 1 Volts-Amps Tester Connections - Typical

1 - POSITIVE CLAMP

2 - NEGATIVE CLAMP

3 - INDUCTION AMMETER CLAMP

8F - 32 STARTINGWJ

STARTING (Continued)

Page 364 of 2199

(b) If the voltage reads above 9.6 volts and the

current (amperage) draw reads below specifica-

tions, refer toFeed Circuit Testin this section.

(c) If the voltage reads 12.5 volts or greater and

the starter motor does not turn, refer toControl

Circuit Testingin this section.

(d) If the voltage reads 12.5 volts or greater and

the starter motor turns very slowly, refer toFeed

Circuit Testin this section.

NOTE: A cold engine will increase the starter cur-

rent (amperage) draw reading, and reduce the bat-

tery voltage reading.

FEED CIRCUIT TEST

The starter feed circuit test (voltage drop method)

will determine if there is excessive resistance in the

high-amperage feed circuit. For complete circuit dia-

grams, refer toStarting Systemin the Contents of

Group 8W - Wiring Diagrams.

When performing these tests, it is important to

remember that the voltage drop is giving an indica-

tion of the resistance between the two points at

which the voltmeter probes are attached.

Example:When testing the resistance of the bat-

tery positive cable, touch the voltmeter leads to the

battery positive cable clamp and the cable connector

at the starter solenoid. If you probe the battery pos-

itive terminal post and the cable connector at the

starter solenoid, you are reading the combined volt-

age drop in the battery positive cable clamp-to-termi-

nal post connection and the battery positive cable.

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing the

tests, be certain that the following procedures are

accomplished:

²Battery is fully-charged and load-tested. Refer to

Batteryin the Diagnosis and Testing section of

Group 8A - Battery for the procedures.

²Fully engage the parking brake.

²Place the automatic transmission gearshift selec-

tor lever in the Park position.

²

Verify that all lamps and accessories are turned off.

²To prevent the engine from starting, remove the

Automatic ShutDown (ASD) relay. The ASD relay is

located in the Power Distribution Center (PDC), in

the engine compartment. Refer to the fuse and relay

layout label affixed to the underside of the PDC cover

for ASD relay identification and location.

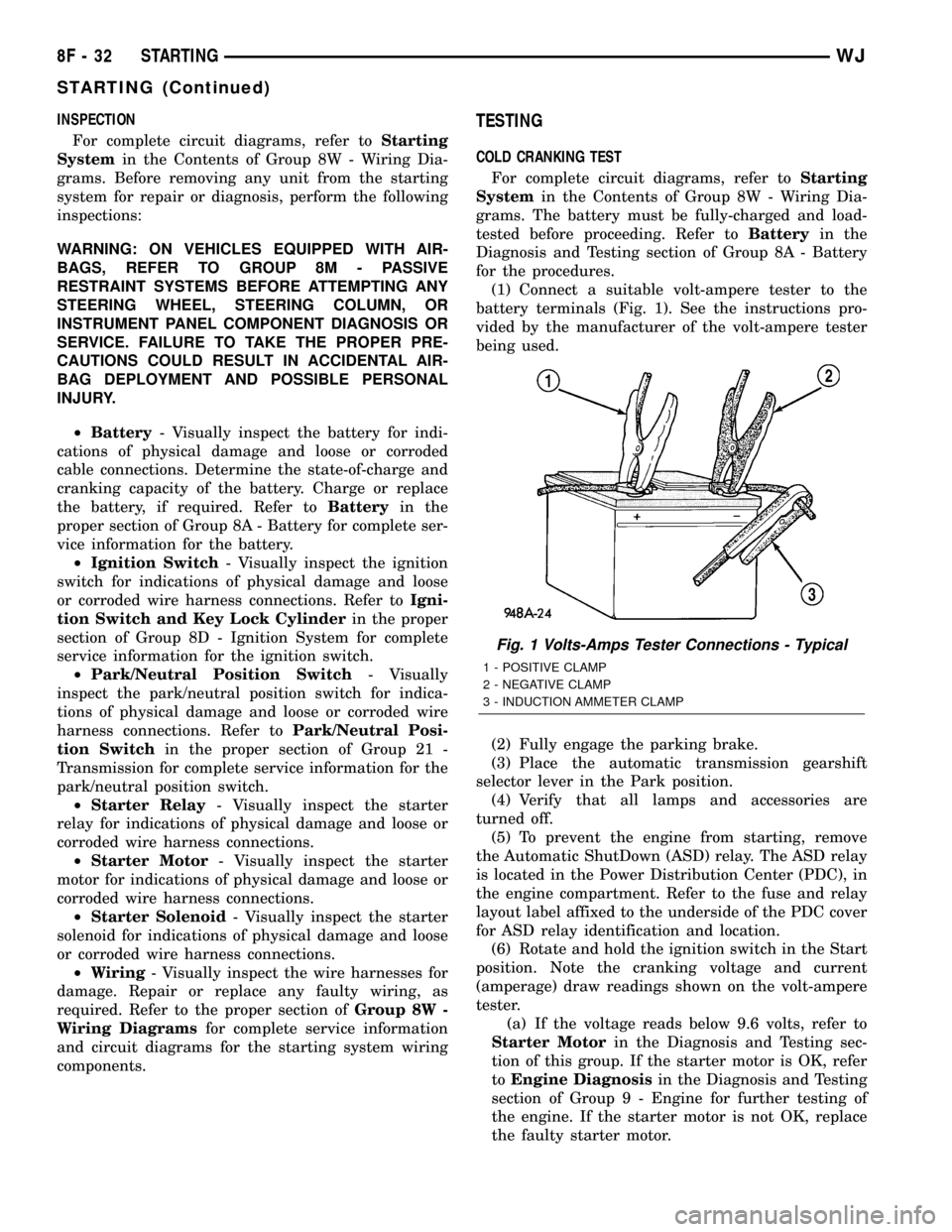

(1) Connect the positive lead of the voltmeter to

the battery negative terminal post. Connect the neg-

ative lead of the voltmeter to the battery negative

cable clamp (Fig. 2). Rotate and hold the ignition

switch in the Start position. Observe the voltmeter. If

voltage is detected, correct the poor contact between

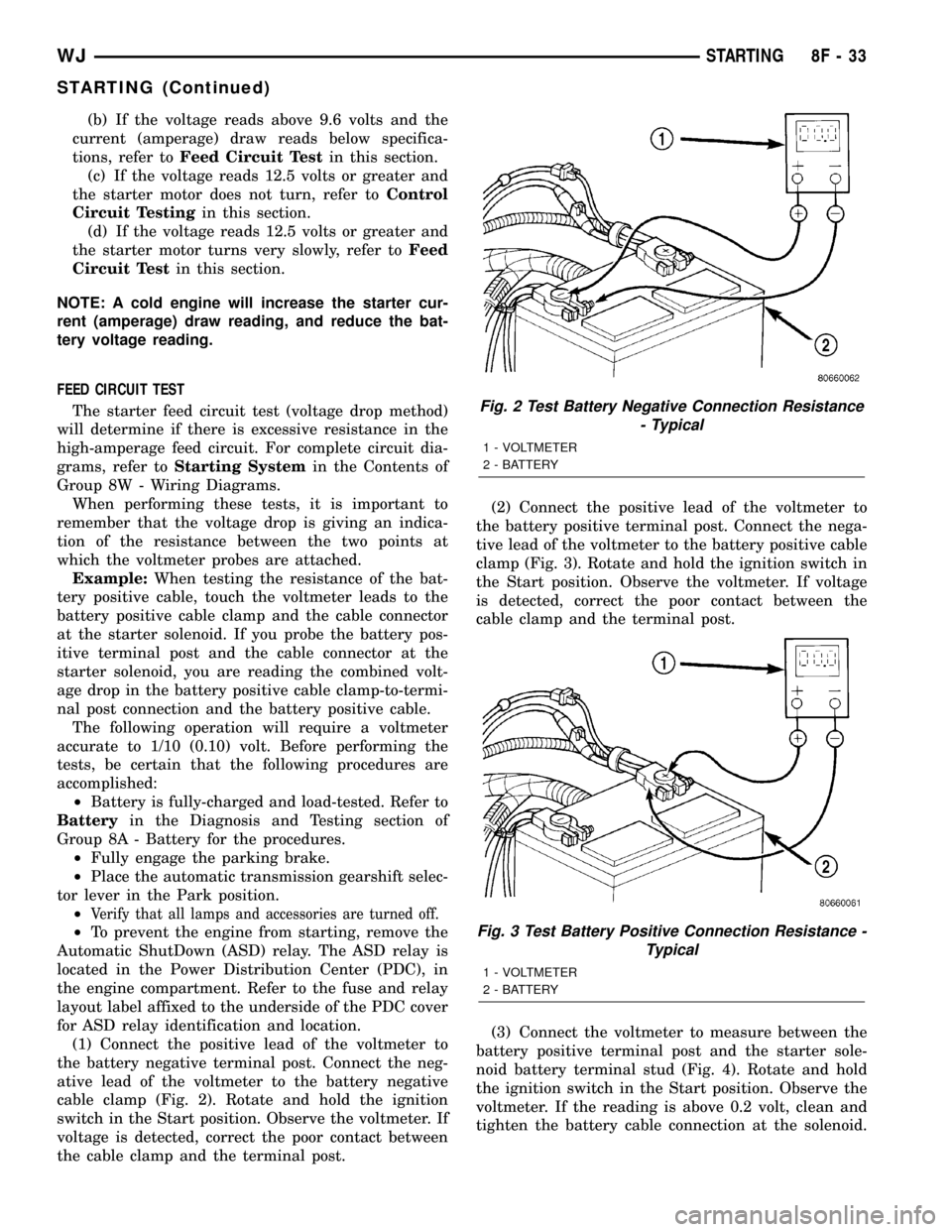

the cable clamp and the terminal post.(2) Connect the positive lead of the voltmeter to

the battery positive terminal post. Connect the nega-

tive lead of the voltmeter to the battery positive cable

clamp (Fig. 3). Rotate and hold the ignition switch in

the Start position. Observe the voltmeter. If voltage

is detected, correct the poor contact between the

cable clamp and the terminal post.

(3) Connect the voltmeter to measure between the

battery positive terminal post and the starter sole-

noid battery terminal stud (Fig. 4). Rotate and hold

the ignition switch in the Start position. Observe the

voltmeter. If the reading is above 0.2 volt, clean and

tighten the battery cable connection at the solenoid.

Fig. 2 Test Battery Negative Connection Resistance

- Typical

1 - VOLTMETER

2 - BATTERY

Fig. 3 Test Battery Positive Connection Resistance -

Typical

1 - VOLTMETER

2 - BATTERY

WJSTARTING 8F - 33

STARTING (Continued)

Page 369 of 2199

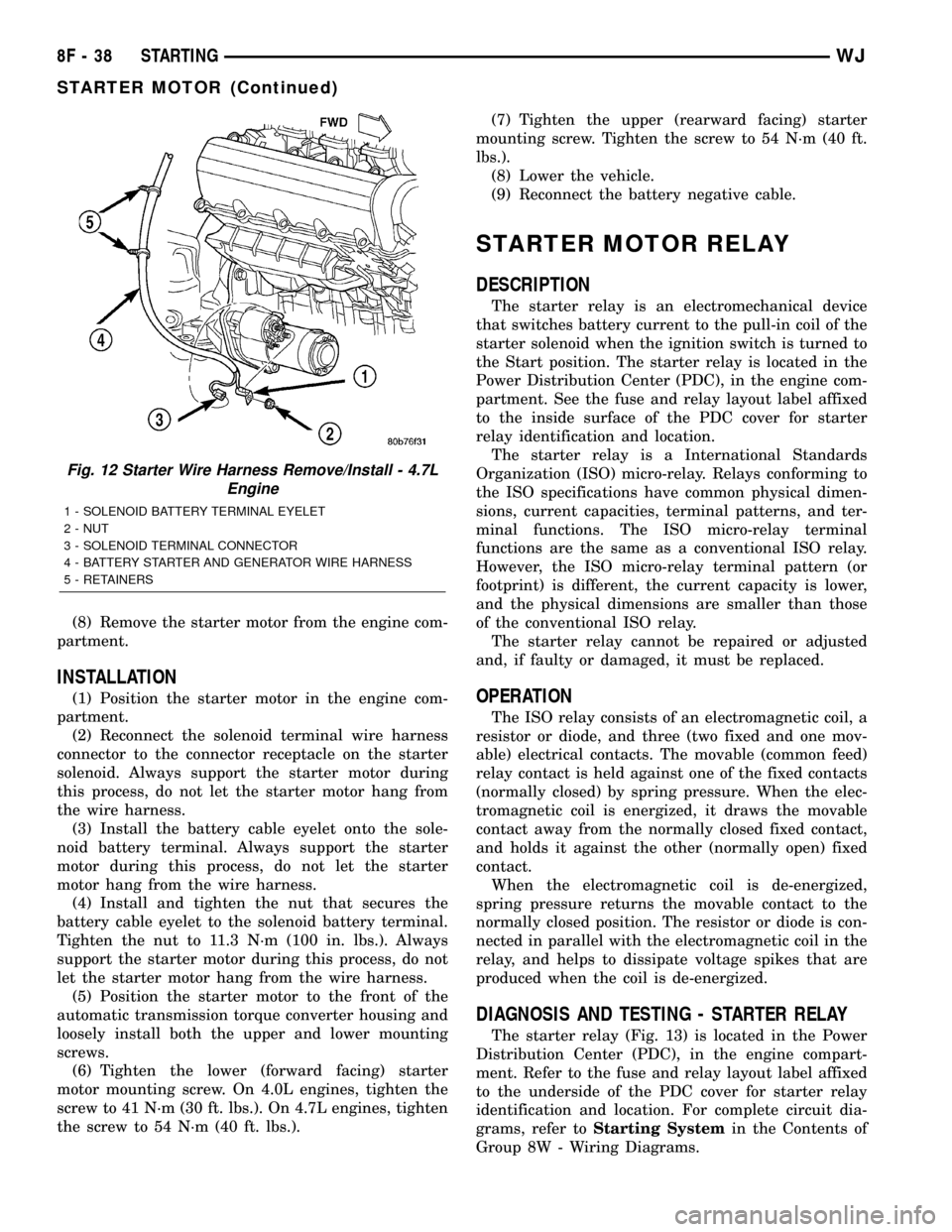

(8) Remove the starter motor from the engine com-

partment.

INSTALLATION

(1) Position the starter motor in the engine com-

partment.

(2) Reconnect the solenoid terminal wire harness

connector to the connector receptacle on the starter

solenoid. Always support the starter motor during

this process, do not let the starter motor hang from

the wire harness.

(3) Install the battery cable eyelet onto the sole-

noid battery terminal. Always support the starter

motor during this process, do not let the starter

motor hang from the wire harness.

(4) Install and tighten the nut that secures the

battery cable eyelet to the solenoid battery terminal.

Tighten the nut to 11.3 N´m (100 in. lbs.). Always

support the starter motor during this process, do not

let the starter motor hang from the wire harness.

(5) Position the starter motor to the front of the

automatic transmission torque converter housing and

loosely install both the upper and lower mounting

screws.

(6) Tighten the lower (forward facing) starter

motor mounting screw. On 4.0L engines, tighten the

screw to 41 N´m (30 ft. lbs.). On 4.7L engines, tighten

the screw to 54 N´m (40 ft. lbs.).(7) Tighten the upper (rearward facing) starter

mounting screw. Tighten the screw to 54 N´m (40 ft.

lbs.).

(8) Lower the vehicle.

(9) Reconnect the battery negative cable.

STARTER MOTOR RELAY

DESCRIPTION

The starter relay is an electromechanical device

that switches battery current to the pull-in coil of the

starter solenoid when the ignition switch is turned to

the Start position. The starter relay is located in the

Power Distribution Center (PDC), in the engine com-

partment. See the fuse and relay layout label affixed

to the inside surface of the PDC cover for starter

relay identification and location.

The starter relay is a International Standards

Organization (ISO) micro-relay. Relays conforming to

the ISO specifications have common physical dimen-

sions, current capacities, terminal patterns, and ter-

minal functions. The ISO micro-relay terminal

functions are the same as a conventional ISO relay.

However, the ISO micro-relay terminal pattern (or

footprint) is different, the current capacity is lower,

and the physical dimensions are smaller than those

of the conventional ISO relay.

The starter relay cannot be repaired or adjusted

and, if faulty or damaged, it must be replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact.

When the electromagnetic coil is de-energized,

spring pressure returns the movable contact to the

normally closed position. The resistor or diode is con-

nected in parallel with the electromagnetic coil in the

relay, and helps to dissipate voltage spikes that are

produced when the coil is de-energized.

DIAGNOSIS AND TESTING - STARTER RELAY

The starter relay (Fig. 13) is located in the Power

Distribution Center (PDC), in the engine compart-

ment. Refer to the fuse and relay layout label affixed

to the underside of the PDC cover for starter relay

identification and location. For complete circuit dia-

grams, refer toStarting Systemin the Contents of

Group 8W - Wiring Diagrams.

Fig. 12 Starter Wire Harness Remove/Install - 4.7L

Engine

1 - SOLENOID BATTERY TERMINAL EYELET

2 - NUT

3 - SOLENOID TERMINAL CONNECTOR

4 - BATTERY STARTER AND GENERATOR WIRE HARNESS

5 - RETAINERS

8F - 38 STARTINGWJ

STARTER MOTOR (Continued)

Page 510 of 2199

DESCRIPTION - OUTSIDE REAR VIEW MIRROR

An automatic dimming outside rear view mirror is

an available factory-installed option for the driver

side of the vehicle, if the vehicle is also equipped

with the automatic day/night inside rear view mirror.

The automatic dimming outside mirror is completely

controlled by the circuitry of the automatic day/night

inside rear view mirror. The automatic dimming out-

side mirror will automatically change the reflectance

of the driver side outside rear view mirror to protect

the driver from the unwanted headlight glare of

trailing vehicles while driving at night. The auto-

matic dimming outside mirror will only operate when

the ignition switch is in the On position.

The automatic dimming outside mirror sensitivity

cannot be repaired or adjusted. If any component of

this unit is faulty or damaged, the entire automatic

dimming outside mirror unit must be replaced. (Refer

to 8 - ELECTRICAL/POWER MIRRORS/SIDEVIEW

MIRROR - DIAGNOSIS AND TESTING). Refer to

the appropriate wiring information. The wiring infor-

mation includes wiring diagrams, proper wire and

connector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

OPERATION

OPERATION - REAR VIEW MIRROR

The automatic day/night mirror switch allows the

driver a manual control of whether the automatic

dimming feature is operational. This switch is a

momentary rocker-type switch located on the lower

rear-facing surface of the mirror housing. When Auto

is selected, a Light-Emitting Diode (LED) on the mir-

ror housing just to the right of the switch illuminates

to indicate that automatic day/night mirror is turned

on. When Off is selected, the LED is turned off. The

mirror also senses the backup lamp circuit, and will

automatically disable its self-dimming feature when-

ever the transmission gear selector is in the Reverse

position.

A thin layer of electrochromatic material between

two pieces of conductive glass make up the face of

the mirror. Two photocell sensors are used to monitor

light levels and adjust the reflectance of the mirror.

The ambient photocell sensor faces forward, to detect

the outside light levels. The headlamp sensor is

located on the mirror housing just to the left of the

switch and facing rearward, to detect the light level

received at the rear window side of the mirror. When

the difference between the two light levels becomes

too great (the light level received at the rear of themirror is much higher than that at the front of the

mirror), the mirror begins to darken.

On models with an optional driver side automatic

dimming outside mirror, the signal to control the

dimming of that mirror is generated by the auto-

matic day/night inside rear view mirror circuitry.

That signal is then delivered to the driver side out-

side rear view mirror on a hard wired circuit.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the automatic day/night mirror system.

OPERATION - OUTSIDE REAR VIEW MIRROR

The automatic dimming outside mirror is operated

by the same controls and circuitry as the automatic

day/night mirror. When the automatic day/night mir-

ror is turned on or off, the automatic dimming out-

side mirror is likewise turned on or off. Like in the

automatic day/night mirror, a thin layer of electro-

chromatic material between two pieces of conductive

glass make up the face of the automatic dimming

outside mirror. However, the signal to control the

dimming of the outside mirror is generated by the

automatic day/night inside rear view mirror circuitry.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the automatic dimming outside mirror.

DIAGNOSIS AND TESTING - AUTOMATIC DAY /

NIGHT MIRROR

For complete circuit diagrams, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

(1) Check the fused ignition switch output (run/

start) fuse in the junction block. If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) fuse in the junction block. If OK,

go to Step 3. If not OK, repair the open fused ignition

switch output (run/start) circuit to the ignition switch

as required.

(3) Disconnect the overhead wire harness connec-

tor from the automatic day/night mirror connector

receptacle. Check for battery voltage at the fused

ignition switch output (run/start) circuit cavity of the

overhead wire harness connector for the automatic

day/night mirror. If OK, go to Step 4. If not OK,

repair the open fused ignition switch output (run/

start) circuit to the fuse in the junction block as

required.

WJPOWER MIRRORS 8N - 13

AUTOMATIC DAY/NIGHT MIRROR (Continued)

Page 660 of 2199

TERMINOLOGY

This is a list of terms and definitions used in the

wiring diagrams.

LHD .................Left Hand Drive Vehicles

RHD................Right Hand Drive Vehicles

ATX . . Automatic Transmissions-Front Wheel Drive

MTX....Manual Transmissions-Front Wheel Drive

AT ....Automatic Transmissions-Rear Wheel Drive

MT .....Manual Transmissions-Rear Wheel Drive

SOHC...........Single Over Head Cam Engine

DOHC..........Double Over Head Cam Engine

Built-Up-Export........ Vehicles Built For Sale In

Markets Other Than North America

Except Built-Up-Export . . Vehicles Built For Sale In

North America

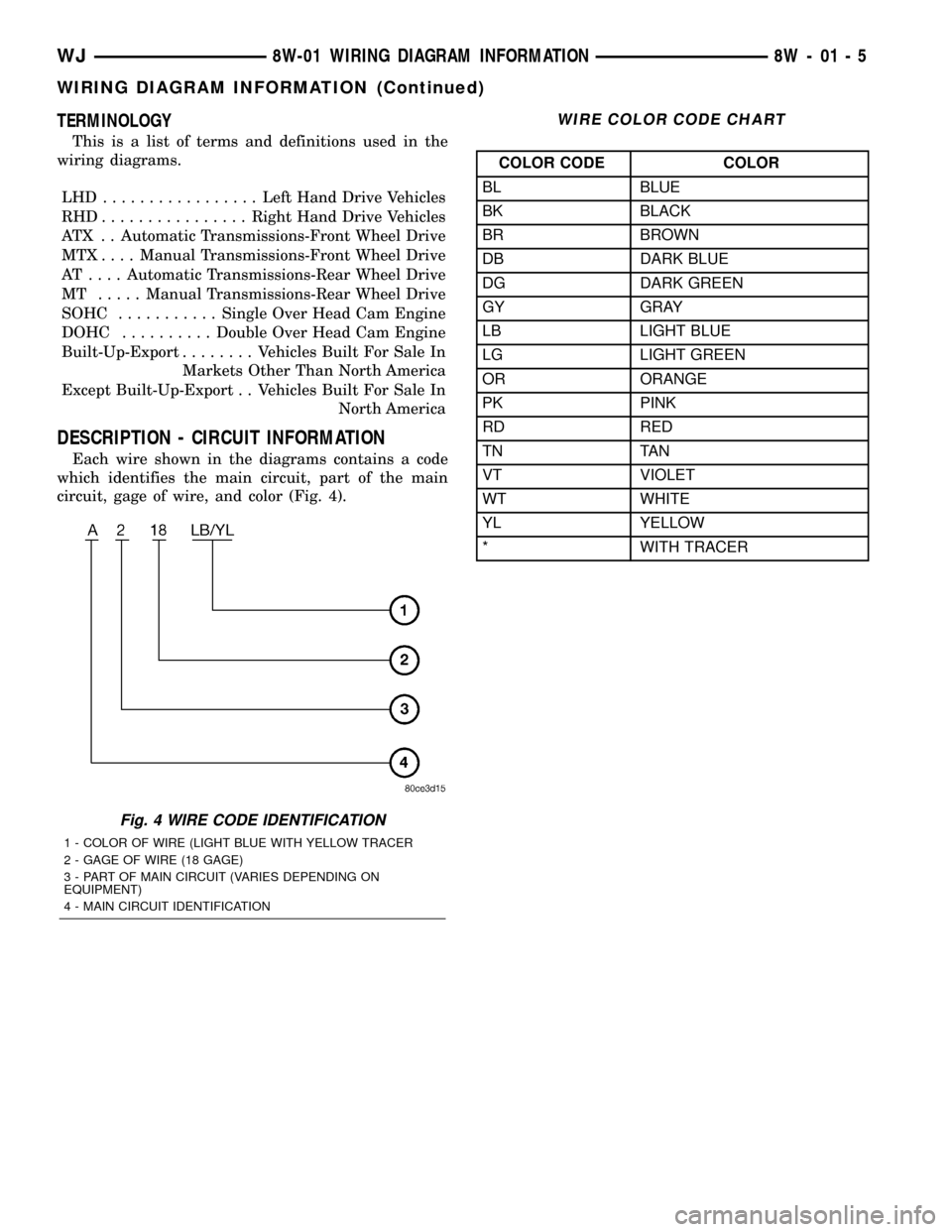

DESCRIPTION - CIRCUIT INFORMATION

Each wire shown in the diagrams contains a code

which identifies the main circuit, part of the main

circuit, gage of wire, and color (Fig. 4).

WIRE COLOR CODE CHART

COLOR CODE COLOR

BL BLUE

BK BLACK

BR BROWN

DB DARK BLUE

DG DARK GREEN

GY GRAY

LB LIGHT BLUE

LG LIGHT GREEN

OR ORANGE

PK PINK

RD RED

TN TAN

VT VIOLET

WT WHITE

YL YELLOW

* WITH TRACER

Fig. 4 WIRE CODE IDENTIFICATION

1 - COLOR OF WIRE (LIGHT BLUE WITH YELLOW TRACER

2 - GAGE OF WIRE (18 GAGE)

3 - PART OF MAIN CIRCUIT (VARIES DEPENDING ON

EQUIPMENT)

4 - MAIN CIRCUIT IDENTIFICATION

WJ8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 5

WIRING DIAGRAM INFORMATION (Continued)

Page 662 of 2199

DESCRIPTION - CONNECTOR, GROUND AND

SPLICE INFORMATION

CAUTION: Not all connectors are serviced. Some

connectors are serviced only with a harness. A typ-

ical example might be the Supplemental Restraint

System connectors. Always check parts availability

before attempting a repair.

IDENTIFICATION

In-line connectors are identified by a number, as

follows:

²In-line connectors located in the engine compart-

ment are C100 series numbers

²In-line connectors located in the Instrument

Panel area are C200 series numbers.

²In-line connectors located in the body are C300

series numbers.

²Jumper harness connectors are C400 series

numbers.

²Grounds and ground connectors are identified

with a ªGº and follow the same series numbering as

the in-line connectors.

²Splices are identified with an ªSº and follow the

same series numbering as the in-line connectors.

²Component connectors are identified by the com-

ponent name instead of a number. Multiple connec-

tors on a component use a C1, C2, etc. identifier.

LOCATIONS

Section 8W-91 contains connector/ground/splice

location illustrations. The illustrations contain the

connector name (or number)/ground number/splice

number and component identification. Connector/

ground/splice location charts in section 8W-91 refer-

ence the figure numbers of the illustrations.

The abbreviation T/O is used in the component

location section to indicate a point in which the wir-

ing harness branches out to a component. The abbre-

viation N/S means Not Shown in the illustrations

WARNING

WARNINGS - GENERAL

WARNINGSprovide information to prevent per-

sonal injury and vehicle damage. Below is a list of

general warnings that should be followed any time a

vehicle is being serviced.

WARNING: ALWAYS WEAR SAFETY GLASSES FOR

EYE PROTECTION.

WARNING: USE SAFETY STANDS ANYTIME A PRO-

CEDURE REQUIRES BEING UNDER A VEHICLE.WARNING: BE SURE THAT THE IGNITION SWITCH

ALWAYS IS IN THE OFF POSITION, UNLESS THE

PROCEDURE REQUIRES IT TO BE ON.

WARNING: SET THE PARKING BRAKE WHEN

WORKING ON ANY VEHICLE. AN AUTOMATIC

TRANSMISSION SHOULD BE IN PARK. A MANUAL

TRANSMISSION SHOULD BE IN NEUTRAL.

WARNING: OPERATE THE ENGINE ONLY IN A

WELL-VENTILATED AREA.

WARNING: KEEP AWAY FROM MOVING PARTS

WHEN THE ENGINE IS RUNNING, ESPECIALLY THE

FAN AND BELTS.

WARNING: TO PREVENT SERIOUS BURNS, AVOID

CONTACT WITH HOT PARTS SUCH AS THE RADIA-

TOR, EXHAUST MANIFOLD(S), TAIL PIPE, CATA-

LYTIC CONVERTER AND MUFFLER.

WARNING: DO NOT ALLOW FLAME OR SPARKS

NEAR THE BATTERY. GASES ARE ALWAYS

PRESENT IN AND AROUND THE BATTERY.

WARNING: ALWAYS REMOVE RINGS, WATCHES,

LOOSE HANGING JEWELRY AND AVOID LOOSE

CLOTHING.

DIAGNOSIS AND TESTING - WIRING HARNESS

TROUBLESHOOTING TOOLS

When diagnosing a problem in an electrical circuit

there are several common tools necessary. These tools

are listed and explained below.

²Jumper Wire - This is a test wire used to con-

nect two points of a circuit. It can be used to bypass

an open in a circuit.

WARNING: NEVER USE A JUMPER WIRE ACROSS

A LOAD, SUCH AS A MOTOR, CONNECTED

BETWEEN A BATTERY FEED AND GROUND.

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

voltages in these circuits, use a meter with a 10 -

megohm or greater impedance rating.

WJ8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 7

WIRING DIAGRAM INFORMATION (Continued)

Page 1489 of 2199

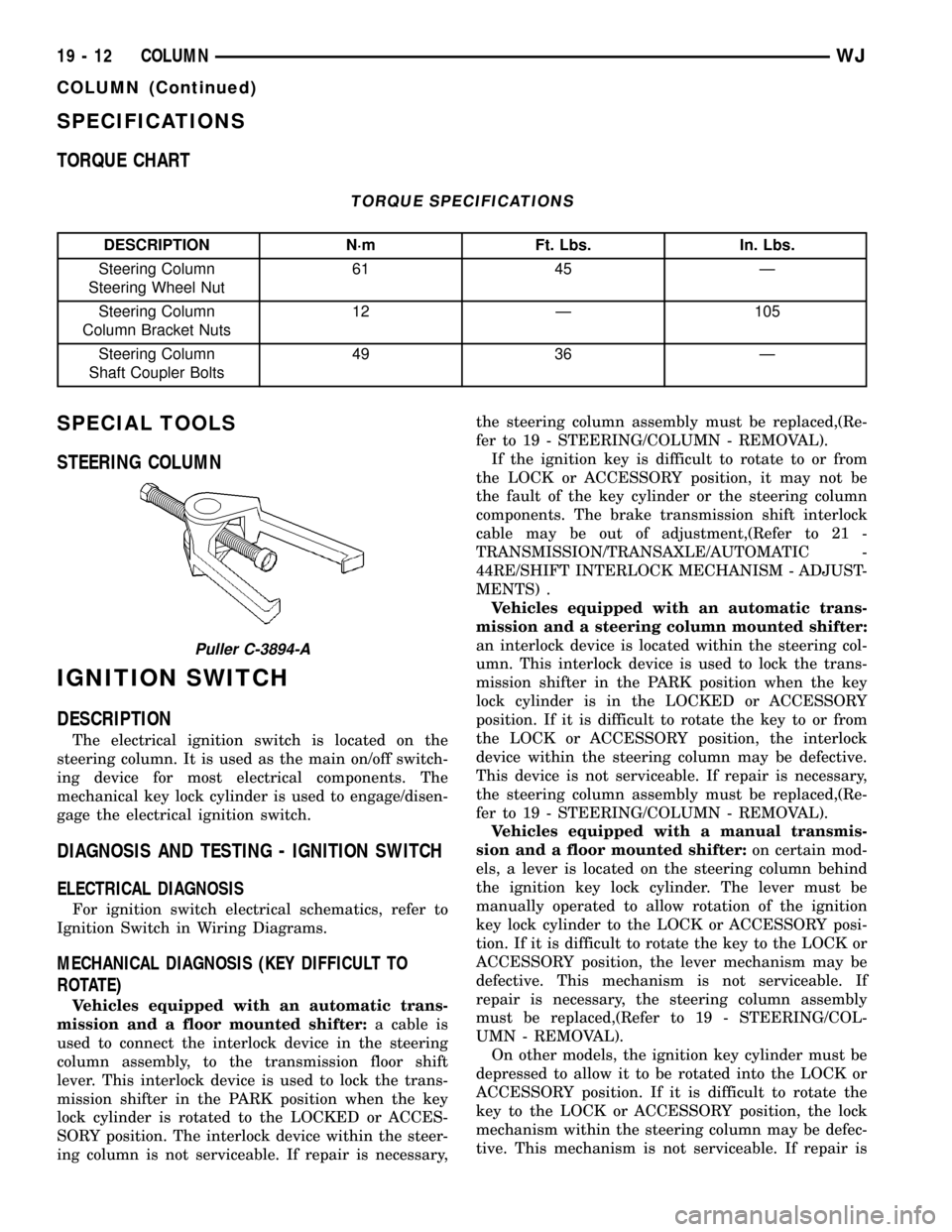

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Steering Column

Steering Wheel Nut61 45 Ð

Steering Column

Column Bracket Nuts12 Ð 105

Steering Column

Shaft Coupler Bolts49 36 Ð

SPECIAL TOOLS

STEERING COLUMN

IGNITION SWITCH

DESCRIPTION

The electrical ignition switch is located on the

steering column. It is used as the main on/off switch-

ing device for most electrical components. The

mechanical key lock cylinder is used to engage/disen-

gage the electrical ignition switch.

DIAGNOSIS AND TESTING - IGNITION SWITCH

ELECTRICAL DIAGNOSIS

For ignition switch electrical schematics, refer to

Ignition Switch in Wiring Diagrams.

MECHANICAL DIAGNOSIS (KEY DIFFICULT TO

ROTATE)

Vehicles equipped with an automatic trans-

mission and a floor mounted shifter:a cable is

used to connect the interlock device in the steering

column assembly, to the transmission floor shift

lever. This interlock device is used to lock the trans-

mission shifter in the PARK position when the key

lock cylinder is rotated to the LOCKED or ACCES-

SORY position. The interlock device within the steer-

ing column is not serviceable. If repair is necessary,the steering column assembly must be replaced,(Re-

fer to 19 - STEERING/COLUMN - REMOVAL).

If the ignition key is difficult to rotate to or from

the LOCK or ACCESSORY position, it may not be

the fault of the key cylinder or the steering column

components. The brake transmission shift interlock

cable may be out of adjustment,(Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

44RE/SHIFT INTERLOCK MECHANISM - ADJUST-

MENTS) .

Vehicles equipped with an automatic trans-

mission and a steering column mounted shifter:

an interlock device is located within the steering col-

umn. This interlock device is used to lock the trans-

mission shifter in the PARK position when the key

lock cylinder is in the LOCKED or ACCESSORY

position. If it is difficult to rotate the key to or from

the LOCK or ACCESSORY position, the interlock

device within the steering column may be defective.

This device is not serviceable. If repair is necessary,

the steering column assembly must be replaced,(Re-

fer to 19 - STEERING/COLUMN - REMOVAL).

Vehicles equipped with a manual transmis-

sion and a floor mounted shifter:on certain mod-

els, a lever is located on the steering column behind

the ignition key lock cylinder. The lever must be

manually operated to allow rotation of the ignition

key lock cylinder to the LOCK or ACCESSORY posi-

tion. If it is difficult to rotate the key to the LOCK or

ACCESSORY position, the lever mechanism may be

defective. This mechanism is not serviceable. If

repair is necessary, the steering column assembly

must be replaced,(Refer to 19 - STEERING/COL-

UMN - REMOVAL).

On other models, the ignition key cylinder must be

depressed to allow it to be rotated into the LOCK or

ACCESSORY position. If it is difficult to rotate the

key to the LOCK or ACCESSORY position, the lock

mechanism within the steering column may be defec-

tive. This mechanism is not serviceable. If repair is

Puller C-3894-A

19 - 12 COLUMNWJ

COLUMN (Continued)

Page 1491 of 2199

KEY-IN IGNITION SWITCH

DESCRIPTION

The key-in ignition switch is concealed within and

integral to the ignition switch, which is mounted on

the steering column. The key-in ignition switch is

actuated by the ignition lock cylinder mechanism,

and is hard wired between a body ground and the

Body Control Module (BCM) through the instrument

panel wire harness.

The key-in ignition switch cannot be adjusted or

repaired and, if faulty or damaged, the entire igni-

tion switch unit must be replaced,(Refer to 19 -

STEERING/COLUMN/LOCK CYLINDER HOUSING

- REMOVAL). For complete circuit diagrams, refer to

Body Control Modulein the Contents of Wiring

Diagrams.

OPERATION

The key-in ignition switch closes a path to ground

for the BCM when the ignition key is inserted in the

ignition lock cylinder, and opens the ground path

when the key is removed from the ignition lock cyl-

inder. The BCM monitors the key-in ignition switch

status through an internal pull-up, then sends the

proper switch status messages to other electronic

modules over the Programmable Communications

Interface (PCI) data bus network. The key-in ignition

switch status is also used by the BCM as an input

for chime warning system operation.

DIAGNOSIS AND TESTING

KEY-IN IGNITION SWITCH

For complete circuit diagrams, refer toBody Con-

trol Modulein the Contents of Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.(1) Disconnect and isolate the battery negative

cable. Disconnect the instrument panel wire harness

connector from the key-in ignition switch connector

receptacle on the ignition switch. Check for continu-

ity between the key-in ignition switch sense and

ground terminals of the key-in ignition switch con-

nector receptacle. There should be continuity with

the key inserted in the ignition lock cylinder, and no

continuity with the key removed from the ignition

lock cylinder. If OK, go to Step 2. If not OK, replace

the faulty ignition switch unit.

(2) Check for continuity between the ground cir-

cuit cavity of the instrument panel wire harness con-

nector for the key-in ignition switch and a good

ground. There should be continuity. If OK, go to Step

3. If not OK, repair the open ground circuit to ground

as required.

(3) Disconnect the gray 26-way instrument panel

wire harness connector from the Body Control Mod-

ule (BCM) connector receptacle. Check for continuity

between the key-in ignition switch sense circuit cav-

ity of the instrument panel wire harness connector

for the key-in ignition switch and a good ground.

There should be no continuity. If OK, go to Step 4. If

not OK, repair the shorted key-in ignition switch

sense circuit as required.

(4) Check for continuity between the key-in igni-

tion switch sense circuit cavities of the instrument

panel wire harness connector for the key-in ignition

switch and the gray 26-way instrument panel wire

harness connector for the BCM. There should be con-

tinuity. If OK, use a DRB scan tool and the proper

Diagnostic Procedures manual to test the BCM. If

not OK, repair the open key-in ignition switch sense

circuit as required.

LOCK CYLINDER

REMOVAL

The ignition key must be in the key cylinder for

cylinder removal. The key cylinder must be removed

first before removing ignition switch.

(1) Disconnect negative battery cable at battery.

(2) If equipped with an automatic transmission,

place shifter in PARK position.

(3) Rotate key to ON position.

19 - 14 COLUMNWJ

Page 1520 of 2199

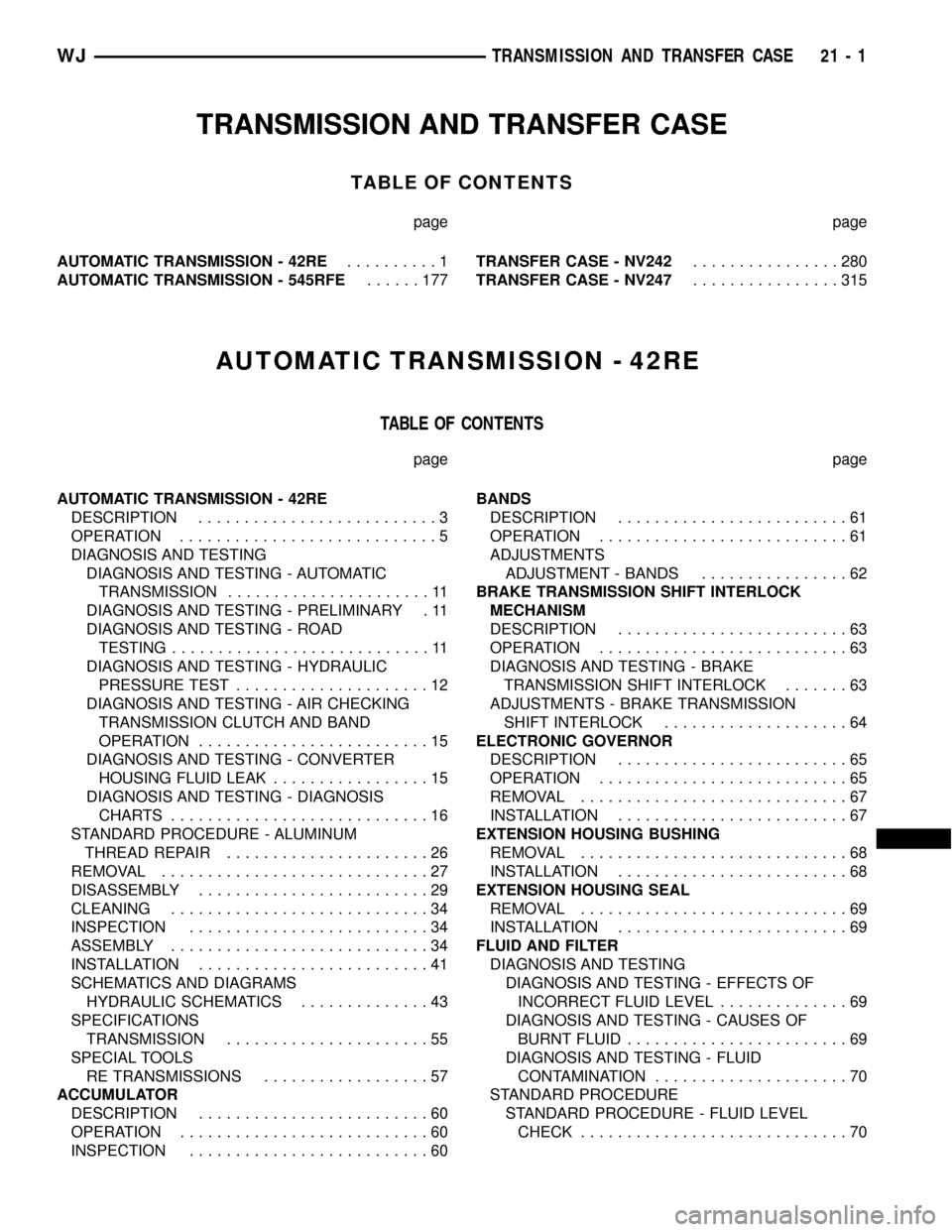

TRANSMISSION AND TRANSFER CASE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 42RE..........1

AUTOMATIC TRANSMISSION - 545RFE......177TRANSFER CASE - NV242................280

TRANSFER CASE - NV247................315

AUTOMATIC TRANSMISSION - 42RE

TABLE OF CONTENTS

page page

AUTOMATIC TRANSMISSION - 42RE

DESCRIPTION..........................3

OPERATION............................5

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - AUTOMATIC

TRANSMISSION......................11

DIAGNOSIS AND TESTING - PRELIMINARY . 11

DIAGNOSIS AND TESTING - ROAD

TESTING............................11

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TEST.....................12

DIAGNOSIS AND TESTING - AIR CHECKING

TRANSMISSION CLUTCH AND BAND

OPERATION.........................15

DIAGNOSIS AND TESTING - CONVERTER

HOUSING FLUID LEAK.................15

DIAGNOSIS AND TESTING - DIAGNOSIS

CHARTS............................16

STANDARD PROCEDURE - ALUMINUM

THREAD REPAIR......................26

REMOVAL.............................27

DISASSEMBLY.........................29

CLEANING............................34

INSPECTION..........................34

ASSEMBLY............................34

INSTALLATION.........................41

SCHEMATICS AND DIAGRAMS

HYDRAULIC SCHEMATICS..............43

SPECIFICATIONS

TRANSMISSION......................55

SPECIAL TOOLS

RE TRANSMISSIONS..................57

ACCUMULATOR

DESCRIPTION.........................60

OPERATION...........................60

INSPECTION..........................60BANDS

DESCRIPTION.........................61

OPERATION...........................61

ADJUSTMENTS

ADJUSTMENT - BANDS................62

BRAKE TRANSMISSION SHIFT INTERLOCK

MECHANISM

DESCRIPTION.........................63

OPERATION...........................63

DIAGNOSIS AND TESTING - BRAKE

TRANSMISSION SHIFT INTERLOCK.......63

ADJUSTMENTS - BRAKE TRANSMISSION

SHIFT INTERLOCK....................64

ELECTRONIC GOVERNOR

DESCRIPTION.........................65

OPERATION...........................65

REMOVAL.............................67

INSTALLATION.........................67

EXTENSION HOUSING BUSHING

REMOVAL.............................68

INSTALLATION.........................68

EXTENSION HOUSING SEAL

REMOVAL.............................69

INSTALLATION.........................69

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL..............69

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID........................69

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION.....................70

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK.............................70

WJTRANSMISSION AND TRANSFER CASE 21 - 1