Dash removal JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 200 of 2199

STANDARD PROCEDURE - MASTER CYLINDER

BLEEDING PROCEDURE

A new master cylinder should be bled before instal-

lation on the vehicle. Required bleeding tools include

bleed tubes and a wood dowel to stroke the pistons.

Bleed tubes can be fabricated from brake line.

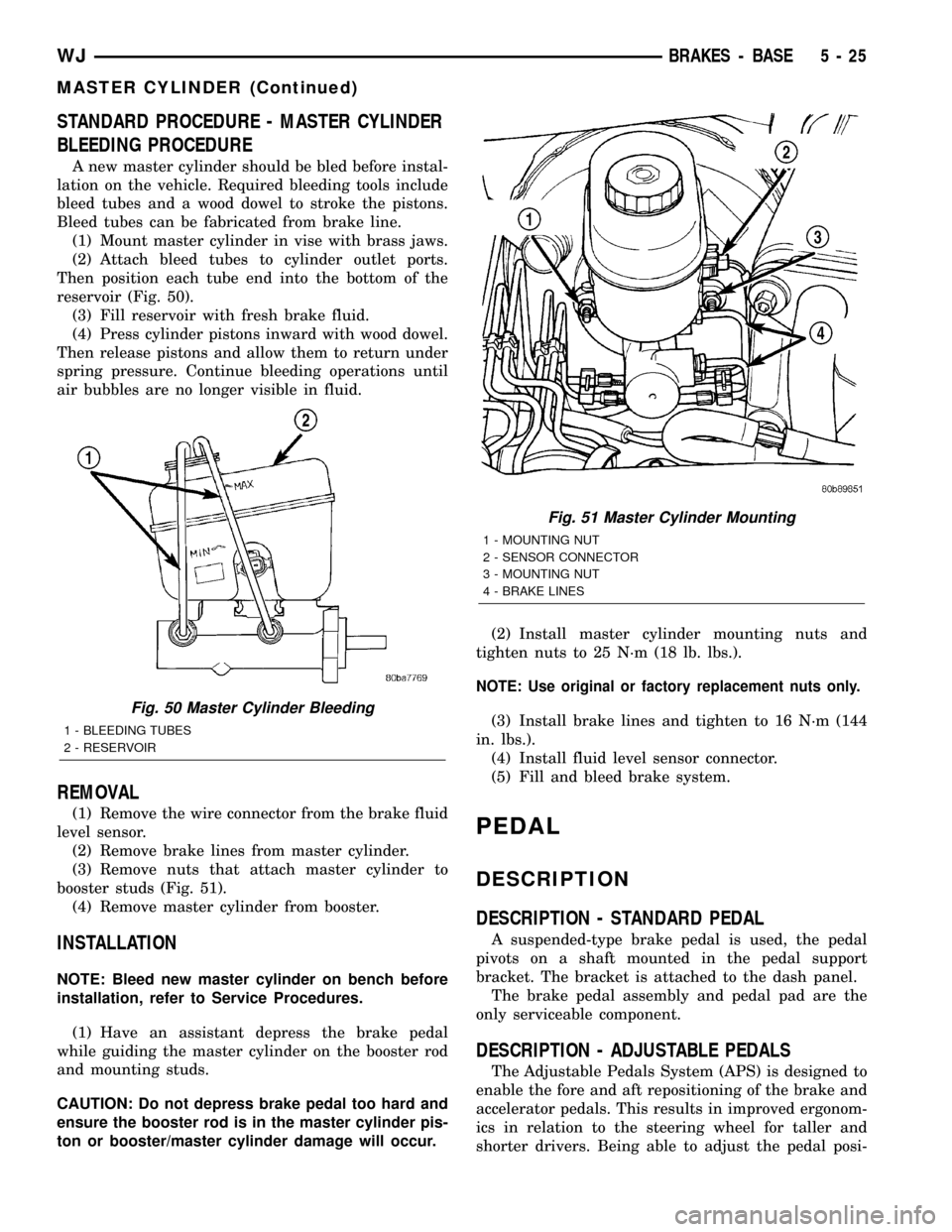

(1) Mount master cylinder in vise with brass jaws.

(2) Attach bleed tubes to cylinder outlet ports.

Then position each tube end into the bottom of the

reservoir (Fig. 50).

(3) Fill reservoir with fresh brake fluid.

(4) Press cylinder pistons inward with wood dowel.

Then release pistons and allow them to return under

spring pressure. Continue bleeding operations until

air bubbles are no longer visible in fluid.

REMOVAL

(1) Remove the wire connector from the brake fluid

level sensor.

(2) Remove brake lines from master cylinder.

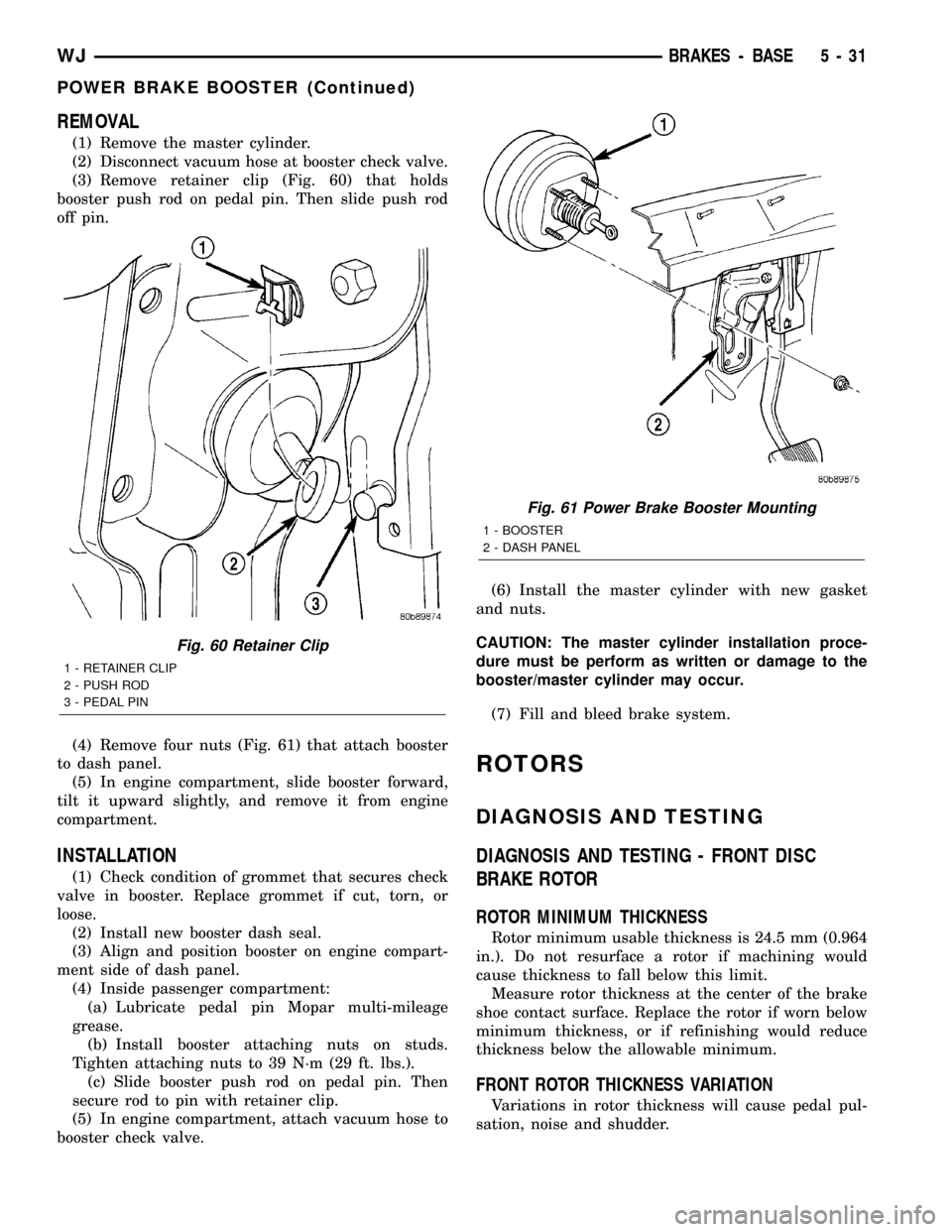

(3) Remove nuts that attach master cylinder to

booster studs (Fig. 51).

(4) Remove master cylinder from booster.

INSTALLATION

NOTE: Bleed new master cylinder on bench before

installation, refer to Service Procedures.

(1) Have an assistant depress the brake pedal

while guiding the master cylinder on the booster rod

and mounting studs.

CAUTION: Do not depress brake pedal too hard and

ensure the booster rod is in the master cylinder pis-

ton or booster/master cylinder damage will occur.(2) Install master cylinder mounting nuts and

tighten nuts to 25 N´m (18 lb. lbs.).

NOTE: Use original or factory replacement nuts only.

(3) Install brake lines and tighten to 16 N´m (144

in. lbs.).

(4) Install fluid level sensor connector.

(5) Fill and bleed brake system.

PEDAL

DESCRIPTION

DESCRIPTION - STANDARD PEDAL

A suspended-type brake pedal is used, the pedal

pivots on a shaft mounted in the pedal support

bracket. The bracket is attached to the dash panel.

The brake pedal assembly and pedal pad are the

only serviceable component.

DESCRIPTION - ADJUSTABLE PEDALS

The Adjustable Pedals System (APS) is designed to

enable the fore and aft repositioning of the brake and

accelerator pedals. This results in improved ergonom-

ics in relation to the steering wheel for taller and

shorter drivers. Being able to adjust the pedal posi-

Fig. 50 Master Cylinder Bleeding

1 - BLEEDING TUBES

2 - RESERVOIR

Fig. 51 Master Cylinder Mounting

1 - MOUNTING NUT

2 - SENSOR CONNECTOR

3 - MOUNTING NUT

4 - BRAKE LINES

WJBRAKES - BASE 5 - 25

MASTER CYLINDER (Continued)

Page 206 of 2199

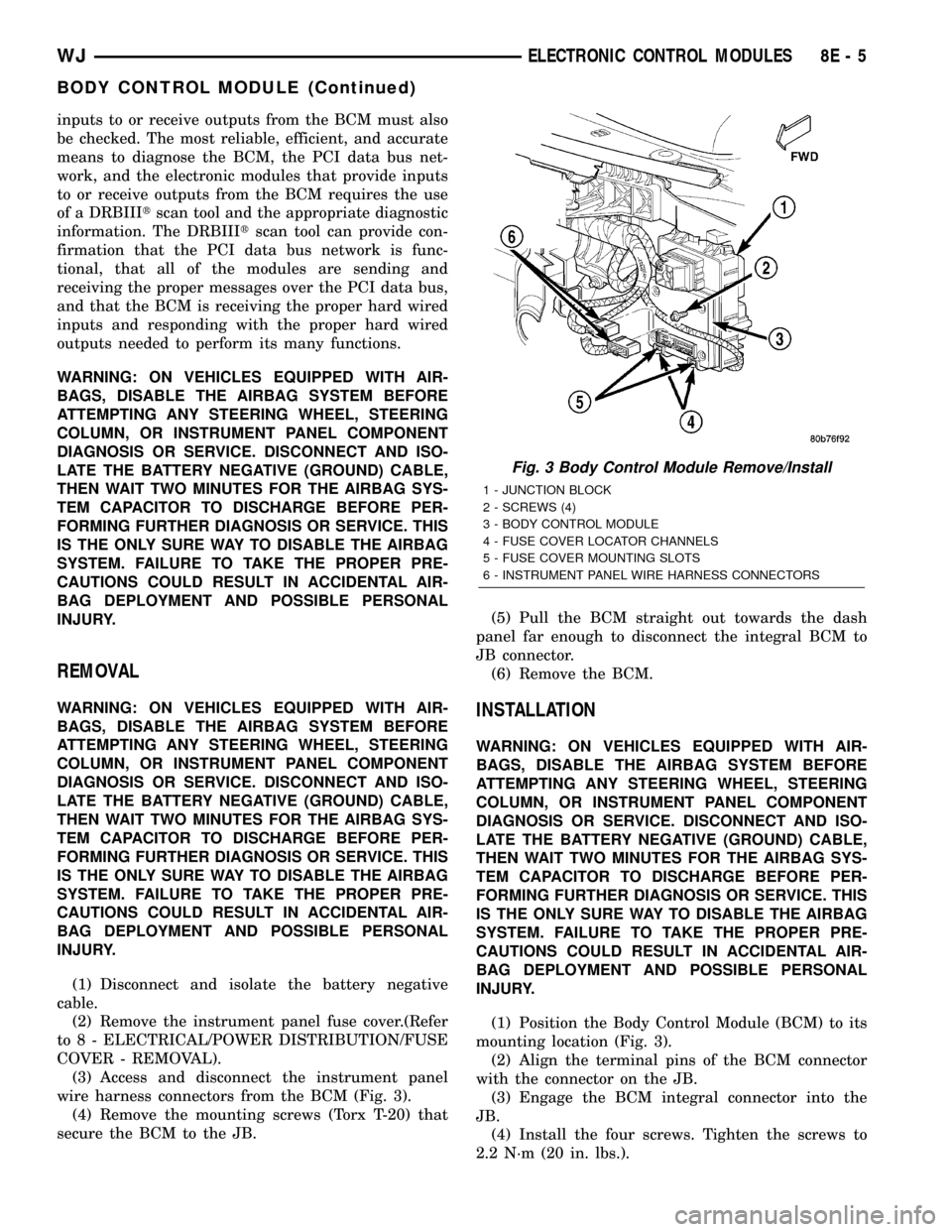

REMOVAL

(1) Remove the master cylinder.

(2) Disconnect vacuum hose at booster check valve.

(3) Remove retainer clip (Fig. 60) that holds

booster push rod on pedal pin. Then slide push rod

off pin.

(4) Remove four nuts (Fig. 61) that attach booster

to dash panel.

(5) In engine compartment, slide booster forward,

tilt it upward slightly, and remove it from engine

compartment.

INSTALLATION

(1) Check condition of grommet that secures check

valve in booster. Replace grommet if cut, torn, or

loose.

(2) Install new booster dash seal.

(3) Align and position booster on engine compart-

ment side of dash panel.

(4) Inside passenger compartment:

(a) Lubricate pedal pin Mopar multi-mileage

grease.

(b) Install booster attaching nuts on studs.

Tighten attaching nuts to 39 N´m (29 ft. lbs.).

(c) Slide booster push rod on pedal pin. Then

secure rod to pin with retainer clip.

(5) In engine compartment, attach vacuum hose to

booster check valve.(6) Install the master cylinder with new gasket

and nuts.

CAUTION: The master cylinder installation proce-

dure must be perform as written or damage to the

booster/master cylinder may occur.

(7) Fill and bleed brake system.

ROTORS

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - FRONT DISC

BRAKE ROTOR

ROTOR MINIMUM THICKNESS

Rotor minimum usable thickness is 24.5 mm (0.964

in.). Do not resurface a rotor if machining would

cause thickness to fall below this limit.

Measure rotor thickness at the center of the brake

shoe contact surface. Replace the rotor if worn below

minimum thickness, or if refinishing would reduce

thickness below the allowable minimum.

FRONT ROTOR THICKNESS VARIATION

Variations in rotor thickness will cause pedal pul-

sation, noise and shudder.

Fig. 60 Retainer Clip

1 - RETAINER CLIP

2 - PUSH ROD

3 - PEDAL PIN

Fig. 61 Power Brake Booster Mounting

1 - BOOSTER

2 - DASH PANEL

WJBRAKES - BASE 5 - 31

POWER BRAKE BOOSTER (Continued)

Page 314 of 2199

inputs to or receive outputs from the BCM must also

be checked. The most reliable, efficient, and accurate

means to diagnose the BCM, the PCI data bus net-

work, and the electronic modules that provide inputs

to or receive outputs from the BCM requires the use

of a DRBIIItscan tool and the appropriate diagnostic

information. The DRBIIItscan tool can provide con-

firmation that the PCI data bus network is func-

tional, that all of the modules are sending and

receiving the proper messages over the PCI data bus,

and that the BCM is receiving the proper hard wired

inputs and responding with the proper hard wired

outputs needed to perform its many functions.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

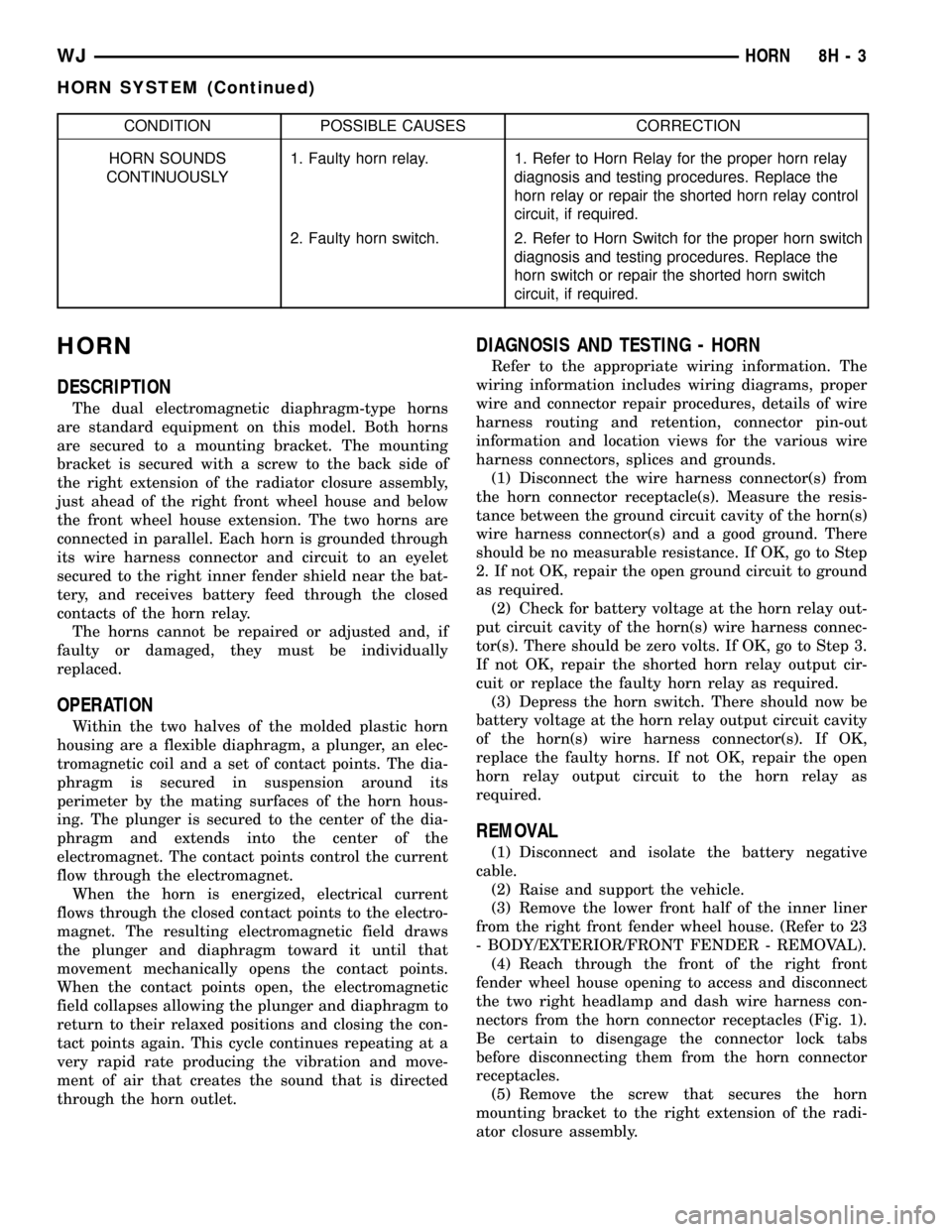

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel fuse cover.(Refer

to 8 - ELECTRICAL/POWER DISTRIBUTION/FUSE

COVER - REMOVAL).

(3) Access and disconnect the instrument panel

wire harness connectors from the BCM (Fig. 3).

(4) Remove the mounting screws (Torx T-20) that

secure the BCM to the JB.(5) Pull the BCM straight out towards the dash

panel far enough to disconnect the integral BCM to

JB connector.

(6) Remove the BCM.INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the Body Control Module (BCM) to its

mounting location (Fig. 3).

(2) Align the terminal pins of the BCM connector

with the connector on the JB.

(3) Engage the BCM integral connector into the

JB.

(4) Install the four screws. Tighten the screws to

2.2 N´m (20 in. lbs.).

Fig. 3 Body Control Module Remove/Install

1 - JUNCTION BLOCK

2 - SCREWS (4)

3 - BODY CONTROL MODULE

4 - FUSE COVER LOCATOR CHANNELS

5 - FUSE COVER MOUNTING SLOTS

6 - INSTRUMENT PANEL WIRE HARNESS CONNECTORS

WJELECTRONIC CONTROL MODULES 8E - 5

BODY CONTROL MODULE (Continued)

Page 392 of 2199

CONDITION POSSIBLE CAUSES CORRECTION

HORN SOUNDS

CONTINUOUSLY1. Faulty horn relay. 1. Refer to Horn Relay for the proper horn relay

diagnosis and testing procedures. Replace the

horn relay or repair the shorted horn relay control

circuit, if required.

2. Faulty horn switch. 2. Refer to Horn Switch for the proper horn switch

diagnosis and testing procedures. Replace the

horn switch or repair the shorted horn switch

circuit, if required.

HORN

DESCRIPTION

The dual electromagnetic diaphragm-type horns

are standard equipment on this model. Both horns

are secured to a mounting bracket. The mounting

bracket is secured with a screw to the back side of

the right extension of the radiator closure assembly,

just ahead of the right front wheel house and below

the front wheel house extension. The two horns are

connected in parallel. Each horn is grounded through

its wire harness connector and circuit to an eyelet

secured to the right inner fender shield near the bat-

tery, and receives battery feed through the closed

contacts of the horn relay.

The horns cannot be repaired or adjusted and, if

faulty or damaged, they must be individually

replaced.

OPERATION

Within the two halves of the molded plastic horn

housing are a flexible diaphragm, a plunger, an elec-

tromagnetic coil and a set of contact points. The dia-

phragm is secured in suspension around its

perimeter by the mating surfaces of the horn hous-

ing. The plunger is secured to the center of the dia-

phragm and extends into the center of the

electromagnet. The contact points control the current

flow through the electromagnet.

When the horn is energized, electrical current

flows through the closed contact points to the electro-

magnet. The resulting electromagnetic field draws

the plunger and diaphragm toward it until that

movement mechanically opens the contact points.

When the contact points open, the electromagnetic

field collapses allowing the plunger and diaphragm to

return to their relaxed positions and closing the con-

tact points again. This cycle continues repeating at a

very rapid rate producing the vibration and move-

ment of air that creates the sound that is directed

through the horn outlet.

DIAGNOSIS AND TESTING - HORN

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

(1) Disconnect the wire harness connector(s) from

the horn connector receptacle(s). Measure the resis-

tance between the ground circuit cavity of the horn(s)

wire harness connector(s) and a good ground. There

should be no measurable resistance. If OK, go to Step

2. If not OK, repair the open ground circuit to ground

as required.

(2) Check for battery voltage at the horn relay out-

put circuit cavity of the horn(s) wire harness connec-

tor(s). There should be zero volts. If OK, go to Step 3.

If not OK, repair the shorted horn relay output cir-

cuit or replace the faulty horn relay as required.

(3) Depress the horn switch. There should now be

battery voltage at the horn relay output circuit cavity

of the horn(s) wire harness connector(s). If OK,

replace the faulty horns. If not OK, repair the open

horn relay output circuit to the horn relay as

required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Raise and support the vehicle.

(3) Remove the lower front half of the inner liner

from the right front fender wheel house. (Refer to 23

- BODY/EXTERIOR/FRONT FENDER - REMOVAL).

(4) Reach through the front of the right front

fender wheel house opening to access and disconnect

the two right headlamp and dash wire harness con-

nectors from the horn connector receptacles (Fig. 1).

Be certain to disengage the connector lock tabs

before disconnecting them from the horn connector

receptacles.

(5) Remove the screw that secures the horn

mounting bracket to the right extension of the radi-

ator closure assembly.

WJHORN 8H - 3

HORN SYSTEM (Continued)

Page 460 of 2199

Turn signal inputs that actuate the combination

flasher are low current grounds, each drawing a

maximum of 300 milliamperes.The hazard warning

signal input is a low current ground drawing a max-

imum of 600 milliamperes.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the steering column cover. (Refer to 23

- BODY/INSTRUMENT PANEL/STEERING COL-

UMN OPENING COVER - REMOVAL).

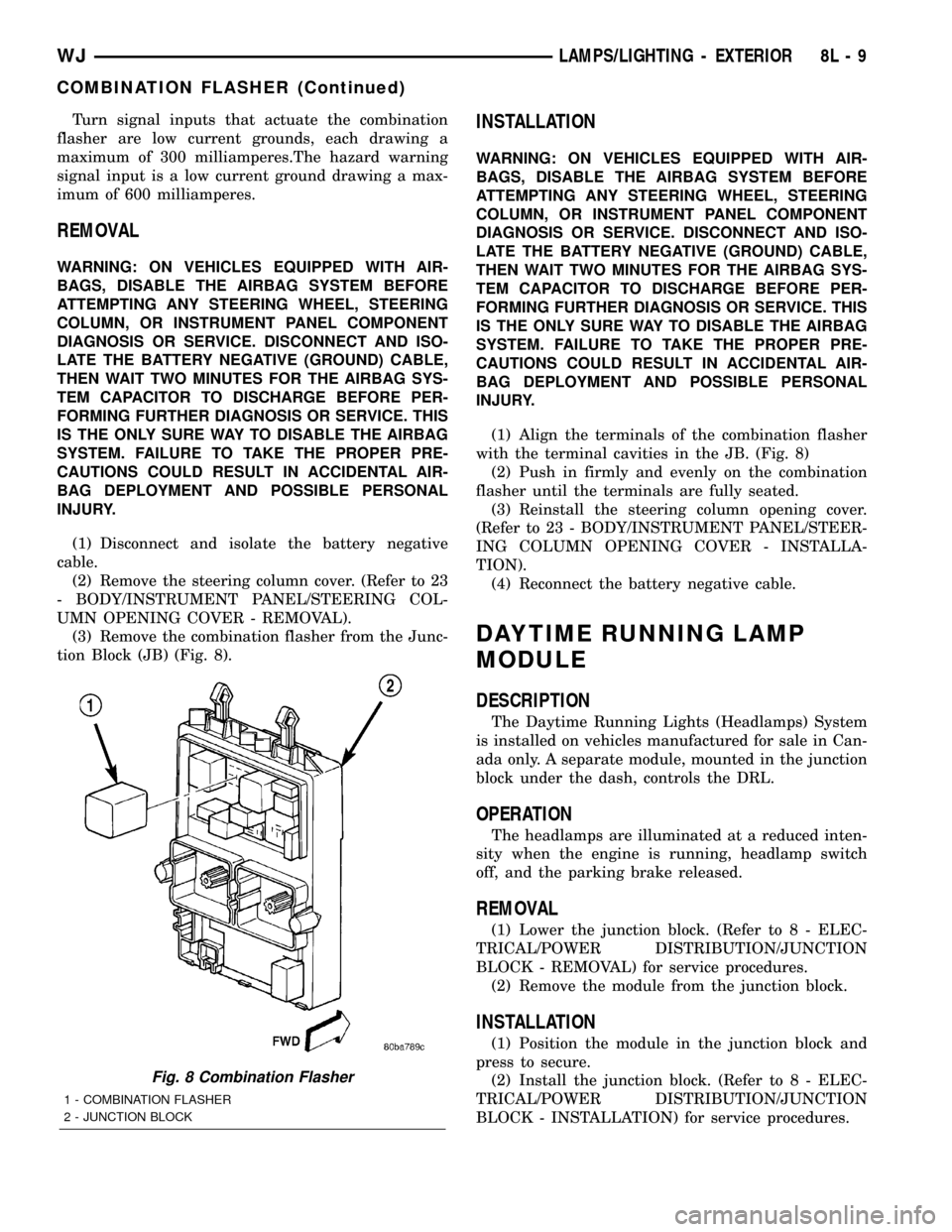

(3) Remove the combination flasher from the Junc-

tion Block (JB) (Fig. 8).

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Align the terminals of the combination flasher

with the terminal cavities in the JB. (Fig. 8)

(2) Push in firmly and evenly on the combination

flasher until the terminals are fully seated.

(3) Reinstall the steering column opening cover.

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

(4) Reconnect the battery negative cable.

DAYTIME RUNNING LAMP

MODULE

DESCRIPTION

The Daytime Running Lights (Headlamps) System

is installed on vehicles manufactured for sale in Can-

ada only. A separate module, mounted in the junction

block under the dash, controls the DRL.

OPERATION

The headlamps are illuminated at a reduced inten-

sity when the engine is running, headlamp switch

off, and the parking brake released.

REMOVAL

(1) Lower the junction block. (Refer to 8 - ELEC-

TRICAL/POWER DISTRIBUTION/JUNCTION

BLOCK - REMOVAL) for service procedures.

(2) Remove the module from the junction block.

INSTALLATION

(1) Position the module in the junction block and

press to secure.

(2) Install the junction block. (Refer to 8 - ELEC-

TRICAL/POWER DISTRIBUTION/JUNCTION

BLOCK - INSTALLATION) for service procedures.

Fig. 8 Combination Flasher

1 - COMBINATION FLASHER

2 - JUNCTION BLOCK

WJLAMPS/LIGHTING - EXTERIOR 8L - 9

COMBINATION FLASHER (Continued)

Page 561 of 2199

OPERATION

The front impact sensors are electronic accelerom-

eters that sense the rate of vehicle deceleration,

which provides verification of the direction and sever-

ity of an impact. Each sensor also contains an elec-

tronic communication chip that allows the unit to

communicate the sensor status as well as sensor

fault information to the microprocessor in the Airbag

Control Module (ACM). The ACM microprocessor con-

tinuously monitors all of the passive restraint system

electrical circuits to determine the system readiness.

If the ACM detects a monitored system fault, it sets

a Diagnostic Trouble Code (DTC) and controls the

airbag indicator operation accordingly.

The impact sensors each receive battery current

and ground through dedicated left and right sensor

plus and minus circuits from the ACM. The impact

sensors and the ACM communicate by modulating

the voltage in the sensor plus circuit. The hard wired

circuits between the front impact sensors and the

ACM may be diagnosed and tested using conven-

tional diagnostic tools and procedures. However, con-

ventional diagnostic methods will not prove

conclusive in the diagnosis of the ACM or the impact

sensors. The most reliable, efficient, and accurate

means to diagnose the impact sensors, the ACM, and

the electronic message communication between the

sensors and the ACM requires the use of a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation.

REMOVAL

The front and side impact sensors are interchange-

able except that the front impact sensors are serviced

with a right or left mounting bracket, while the side

impact sensors use no mounting bracket. If a front

impact sensor is faulty, but not damaged, the sensor

may be removed from the sensor mounting bracket

and replaced with a side impact sensor. If the front

impact sensor or the sensor mounting bracket are

damaged in any way, or if proper tightening torque of

the screws that secure the sensor to the bracket can-

not be achieved, the front impact sensor and bracket

must be replaced as a unit.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, FRONT IMPACT SENSOR,

SIDE IMPACT SENSOR, SIDE CURTAIN AIRBAG, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHERDIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

WARNING: THE FRONT IMPACT SENSOR ENABLES

THE SYSTEM TO DEPLOY THE FRONT SUPPLE-

MENTAL RESTRAINTS. NEVER STRIKE OR DROP

THE FRONT IMPACT SENSOR, AS IT CAN DAMAGE

THE IMPACT SENSOR OR AFFECT ITS CALIBRA-

TION. IF AN IMPACT SENSOR IS ACCIDENTALLY

DROPPED DURING SERVICE, THE SENSOR MUST

BE SCRAPPED AND REPLACED WITH A NEW UNIT.

FAILURE TO OBSERVE THIS WARNING COULD

RESULT IN ACCIDENTAL, INCOMPLETE, OR

IMPROPER FRONT SUPPLEMENTAL RESTRAINT

DEPLOYMENT AND POSSIBLE OCCUPANT INJU-

RIES.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

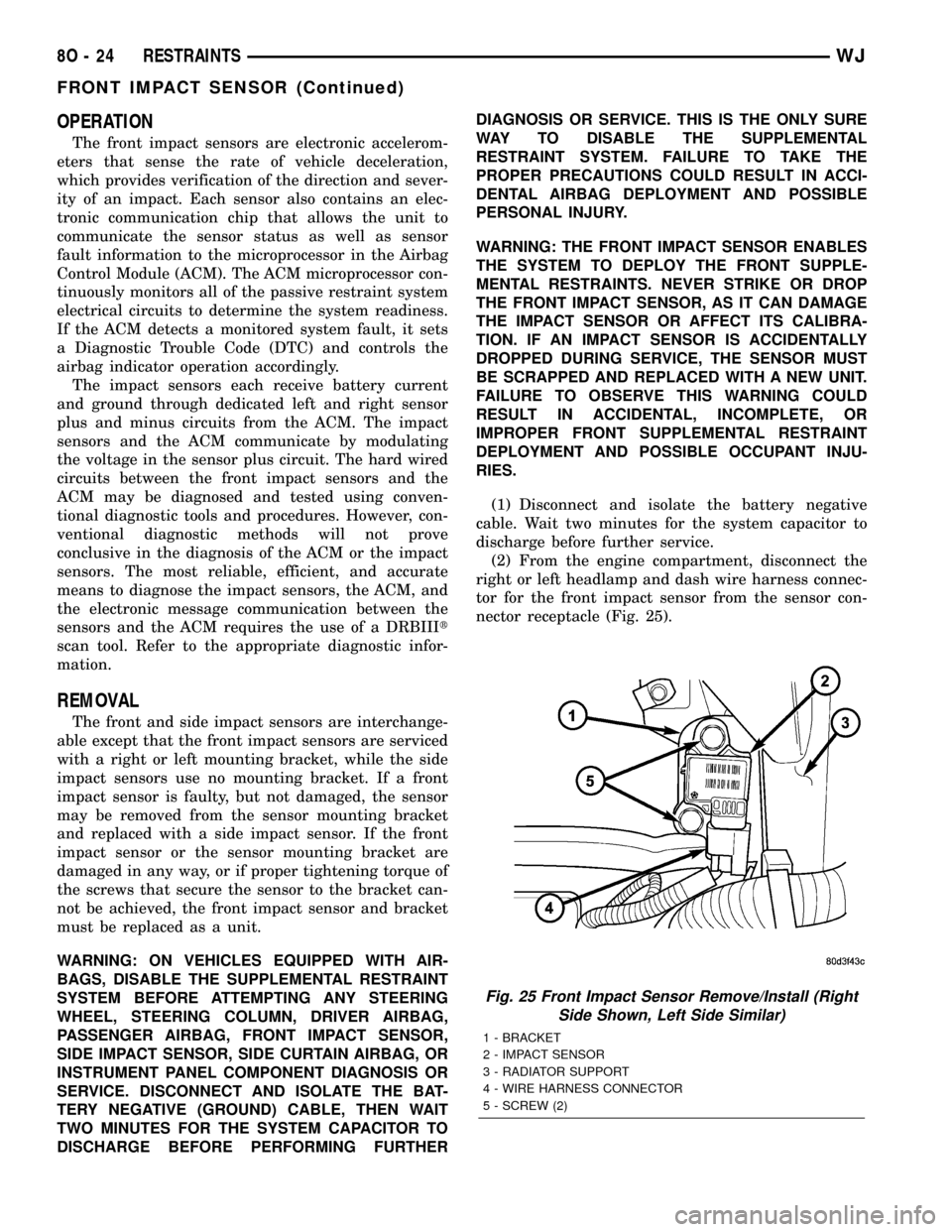

(2) From the engine compartment, disconnect the

right or left headlamp and dash wire harness connec-

tor for the front impact sensor from the sensor con-

nector receptacle (Fig. 25).

Fig. 25 Front Impact Sensor Remove/Install (Right

Side Shown, Left Side Similar)

1 - BRACKET

2 - IMPACT SENSOR

3 - RADIATOR SUPPORT

4 - WIRE HARNESS CONNECTOR

5 - SCREW (2)

8O - 24 RESTRAINTSWJ

FRONT IMPACT SENSOR (Continued)

Page 562 of 2199

(3) From the engine compartment, remove the two

screws that secure the right or left front impact sen-

sor to the sensor mounting bracket on the right or

left radiator support vertical member.

(4) Remove the front impact sensor from the sen-

sor mounting bracket.

INSTALLATION

The front and side impact sensors are interchange-

able except that the front impact sensors are serviced

with a right or left mounting bracket, while the side

impact sensors use no mounting bracket. If a front

impact sensor is faulty, but not damaged, the sensor

may be removed from the sensor mounting bracket

and replaced with a side impact sensor. If the front

impact sensor or the sensor mounting bracket are

damaged in any way, or if proper tightening torque of

the screws that secure the sensor to the bracket can-

not be achieved, the front impact sensor and bracket

must be replaced as a unit.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, FRONT IMPACT SENSOR,

SIDE IMPACT SENSOR, SIDE CURTAIN AIRBAG, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

WARNING: THE FRONT IMPACT SENSOR ENABLES

THE SYSTEM TO DEPLOY THE FRONT SUPPLE-

MENTAL RESTRAINTS. NEVER STRIKE OR DROP

THE FRONT IMPACT SENSOR, AS IT CAN DAMAGE

THE IMPACT SENSOR OR AFFECT ITS CALIBRA-

TION. IF AN IMPACT SENSOR IS ACCIDENTALLY

DROPPED DURING SERVICE, THE SENSOR MUST

BE SCRAPPED AND REPLACED WITH A NEW UNIT.

FAILURE TO OBSERVE THIS WARNING COULD

RESULT IN ACCIDENTAL, INCOMPLETE, OR

IMPROPER FRONT SUPPLEMENTAL RESTRAINT

DEPLOYMENT AND POSSIBLE OCCUPANT INJU-

RIES.(1) Position the right or left front impact sensor to

the sensor mounting bracket on the right or left radi-

ator support vertical member in the engine compart-

ment (Fig. 25).

(2) Install and tighten the two screws that secure

the right or left front impact sensor to the sensor

mounting bracket. Tighten the screws to 10 N´m (85

in. lbs.).

(3) Reconnect the right or left headlamp and dash

wire harness connector for the front impact sensor to

the sensor connector receptacle.

(4) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

FRONT IMPACT SENSOR &

BRACKET

REMOVAL

The front and side impact sensors are interchange-

able except that the front impact sensors are serviced

with a right or left mounting bracket, while the side

impact sensors use no mounting bracket. If a front

impact sensor is faulty, but not damaged, the sensor

may be removed from the sensor mounting bracket

and replaced with a side impact sensor. If the front

impact sensor or the sensor mounting bracket are

damaged in any way, or if proper tightening torque of

the screws that secure the sensor to the bracket can-

not be achieved, the front impact sensor and bracket

must be replaced as a unit.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, FRONT IMPACT SENSOR,

SIDE IMPACT SENSOR, SIDE CURTAIN AIRBAG, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

WJRESTRAINTS 8O - 25

FRONT IMPACT SENSOR (Continued)

Page 563 of 2199

WARNING: THE FRONT IMPACT SENSOR ENABLES

THE SYSTEM TO DEPLOY THE FRONT SUPPLE-

MENTAL RESTRAINTS. NEVER STRIKE OR DROP

THE FRONT IMPACT SENSOR, AS IT CAN DAMAGE

THE IMPACT SENSOR OR AFFECT ITS CALIBRA-

TION. IF AN IMPACT SENSOR IS ACCIDENTALLY

DROPPED DURING SERVICE, THE SENSOR MUST

BE SCRAPPED AND REPLACED WITH A NEW UNIT.

FAILURE TO OBSERVE THIS WARNING COULD

RESULT IN ACCIDENTAL, INCOMPLETE, OR

IMPROPER FRONT SUPPLEMENTAL RESTRAINT

DEPLOYMENT AND POSSIBLE OCCUPANT INJU-

RIES.

(1) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

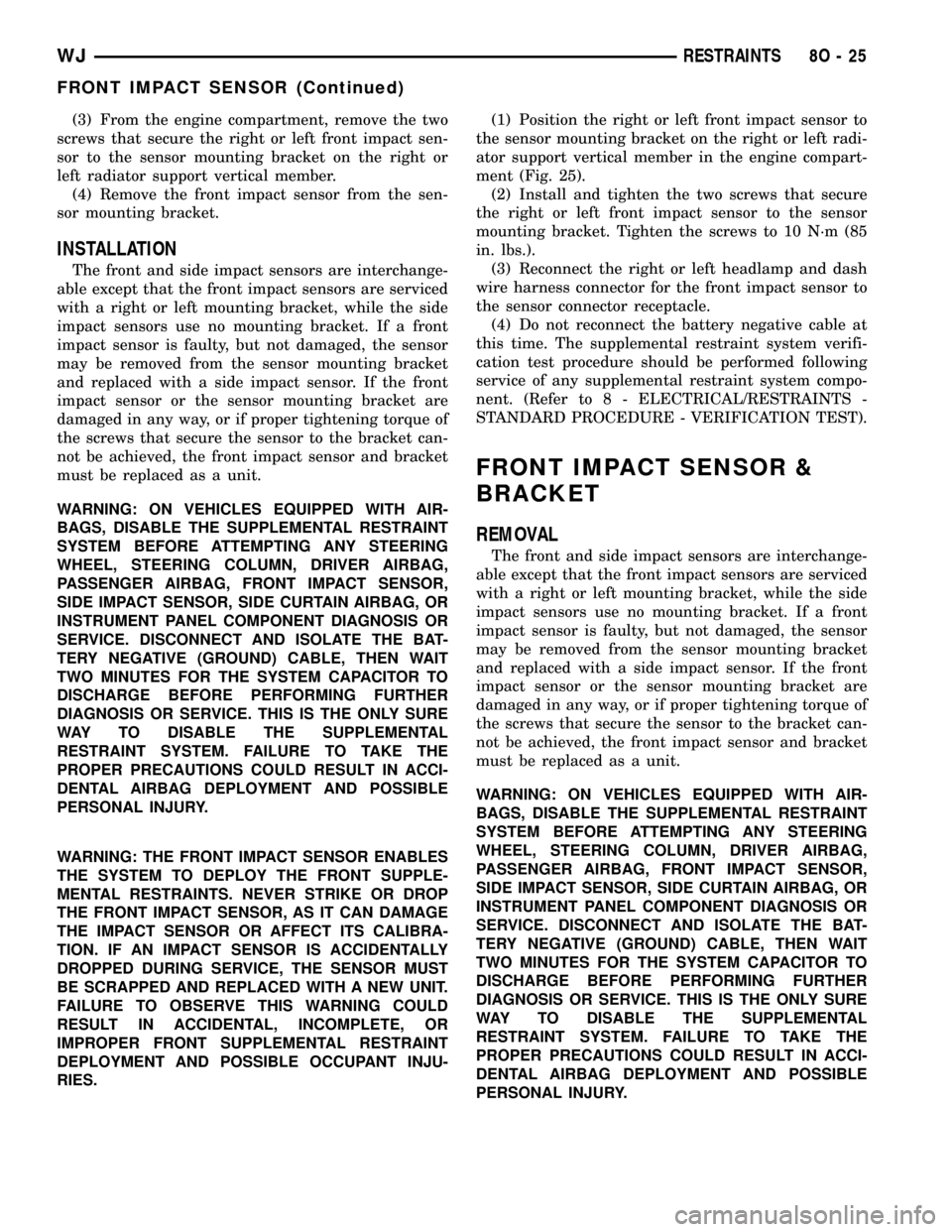

(2) Remove the headlamp mounting module from

the front of the vehicle. (Refer to 23 - BODY/EXTE-

RIOR/HEADLAMP MOUNTING MODULE -

REMOVAL).

(3) Disconnect the right or left headlamp and dash

wire harness connector for the front impact sensor

from the sensor connector receptacle.

(4) Remove the three screws that secure the right

or left front impact sensor and bracket unit to the

right or left radiator support vertical member (Fig.

26).

(5) Remove the right or left front impact sensor

and bracket unit from the front of the vehicle.INSTALLATION

The front and side impact sensors are interchange-

able except that the front impact sensors are serviced

with a right or left mounting bracket, while the side

impact sensors use no mounting bracket. If a front

impact sensor is faulty, but not damaged, the sensor

may be removed from the sensor mounting bracket

and replaced with a side impact sensor. If the front

impact sensor or the sensor mounting bracket are

damaged in any way, or if proper tightening torque of

the screws that secure the sensor to the bracket can-

not be achieved, the front impact sensor and bracket

must be replaced as a unit.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, FRONT IMPACT SENSOR,

SIDE IMPACT SENSOR, SIDE CURTAIN AIRBAG, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

WARNING: THE FRONT IMPACT SENSOR ENABLES

THE SYSTEM TO DEPLOY THE FRONT SUPPLE-

MENTAL RESTRAINTS. NEVER STRIKE OR DROP

THE FRONT IMPACT SENSOR, AS IT CAN DAMAGE

THE IMPACT SENSOR OR AFFECT ITS CALIBRA-

TION. IF AN IMPACT SENSOR IS ACCIDENTALLY

DROPPED DURING SERVICE, THE SENSOR MUST

BE SCRAPPED AND REPLACED WITH A NEW UNIT.

FAILURE TO OBSERVE THIS WARNING COULD

RESULT IN ACCIDENTAL, INCOMPLETE, OR

IMPROPER FRONT SUPPLEMENTAL RESTRAINT

DEPLOYMENT AND POSSIBLE OCCUPANT INJU-

RIES.

(1) Position the right or left front impact sensor

and bracket unit to the front of the vehicle (Fig. 26).

(2) Position the right or left front impact sensor

and bracket unit to the right or left radiator support

vertical member.

(3) Loosely install the three screws that secure the

right or left front impact sensor and bracket unit

right or left radiator support vertical member.

Fig. 26 Front Impact Sensor & B Remove/Install

1 - RADIATOR SUPPORT

2 - SCREW (3)

3 - BRACKET

4 - WIRE HARNESS CONNECTOR

5 - IMPACT SENSOR

8O - 26 RESTRAINTSWJ

FRONT IMPACT SENSOR & BRACKET (Continued)

Page 564 of 2199

(4) For the right impact sensor and bracket unit,

the tightening sequence for the three screws that

secure it to the right radiator support vertical mem-

ber is from top to bottom. For the left impact sensor

and bracket unit, the tightening sequence for the

three screws that secure it to the left radiator sup-

port vertical member is from bottom to top. Tighten

the screws to 12 N´m (105 in. lbs.).

(5) Reconnect the right or left headlamp and dash

wire harness connector for the front impact sensor to

the sensor connector receptacle.

(6) Reinstall the headlamp mounting module to

the front of the vehicle. (Refer to 23 - BODY/EXTE-

RIOR/HEADLAMP MOUNTING MODULE -

INSTALLATION).

(7) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

FRONT SEAT BELT &

RETRACTOR

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

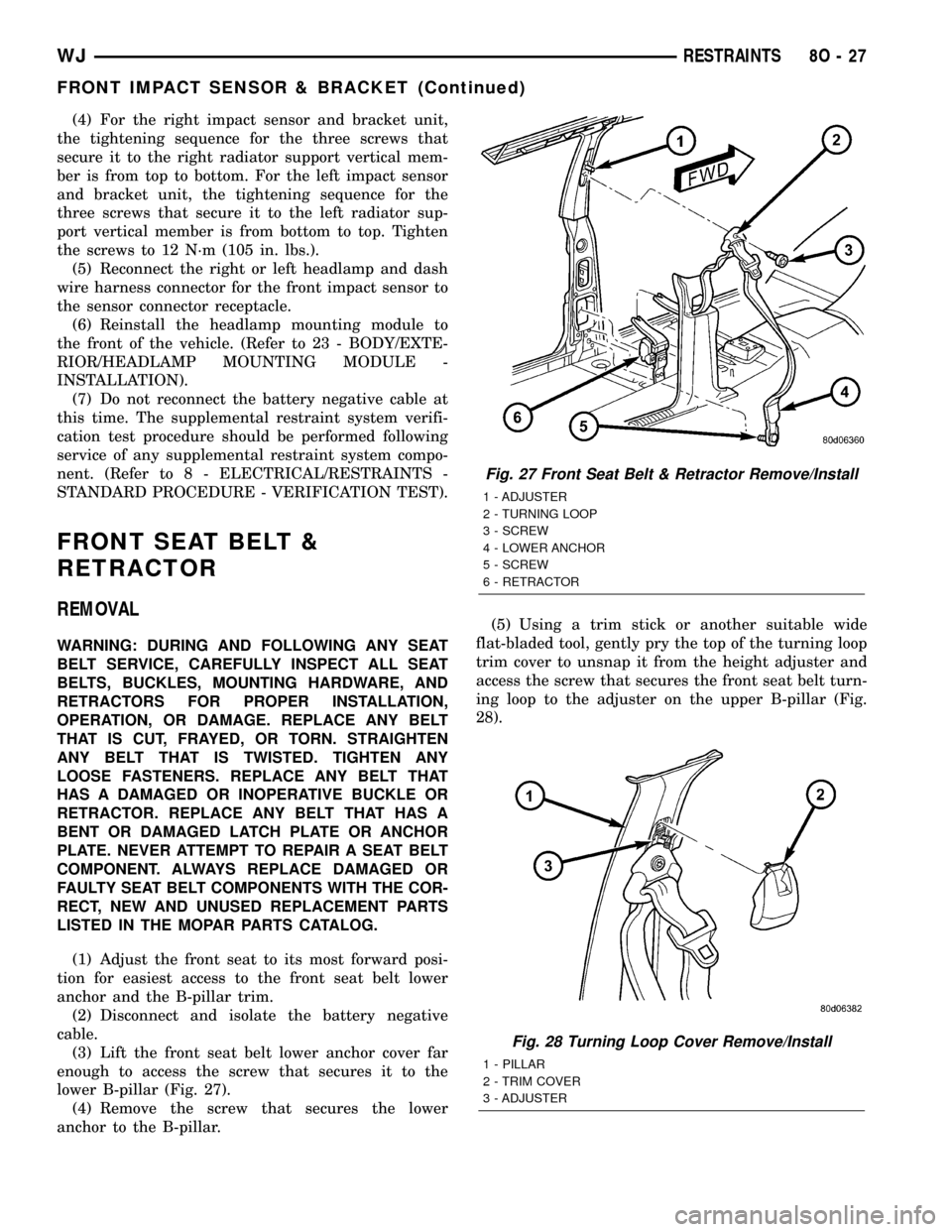

(1) Adjust the front seat to its most forward posi-

tion for easiest access to the front seat belt lower

anchor and the B-pillar trim.

(2) Disconnect and isolate the battery negative

cable.

(3) Lift the front seat belt lower anchor cover far

enough to access the screw that secures it to the

lower B-pillar (Fig. 27).

(4) Remove the screw that secures the lower

anchor to the B-pillar.(5) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the top of the turning loop

trim cover to unsnap it from the height adjuster and

access the screw that secures the front seat belt turn-

ing loop to the adjuster on the upper B-pillar (Fig.

28).

Fig. 27 Front Seat Belt & Retractor Remove/Install

1 - ADJUSTER

2 - TURNING LOOP

3 - SCREW

4 - LOWER ANCHOR

5 - SCREW

6 - RETRACTOR

Fig. 28 Turning Loop Cover Remove/Install

1 - PILLAR

2 - TRIM COVER

3 - ADJUSTER

WJRESTRAINTS 8O - 27

FRONT IMPACT SENSOR & BRACKET (Continued)

Page 619 of 2199

(4) Reinstall the washer hoses for the front washer

nozzle(s) into their routing clips on the underside of

the cowl grille cover.

(5) Position the cowl grille cover onto the cowl ple-

num and cowl top panels through the opening

between the hood and the base of the windshield

(Fig. 4).

(6) Lift the left end of the cowl grille cover off of

the cowl plenum panel far enough to access the front

washer plumbing.

(7) Reconnect the cowl grille cover washer hose to

the engine compartment washer hose at the elbow

connector.

(8) Install the six plastic nuts that secure the cowl

grille cover to the studs on the cowl top panel near

the base of the windshield. These nuts are to be

installed by pushing them onto the studs in the fol-

lowing sequence:

(a) First, install the short nuts to the third stud

from the right, then the second stud from the left.

(b) Next, install the long nuts to the right out-

board stud, then the left outboard stud.

(c) Finally, install the two remaining long nuts

to the third stud from the left, then the second

stud from the right.

(9) Starting at the ends and working toward the

center, push the hood to plenum seal onto the for-

ward flanges of the cowl grille cover and the plenum

panel.

(10) Close and latch the hood.

(11) Reinstall the wiper arms onto the wiper piv-

ots. (Refer to 8 - ELECTRICAL/FRONT WIPERS/

WASHERS/FRONT WIPER ARMS -

INSTALLATION).

(12) Reconnect the battery negative cable.

FRONT WASHER PUMP/

MOTOR

DESCRIPTION

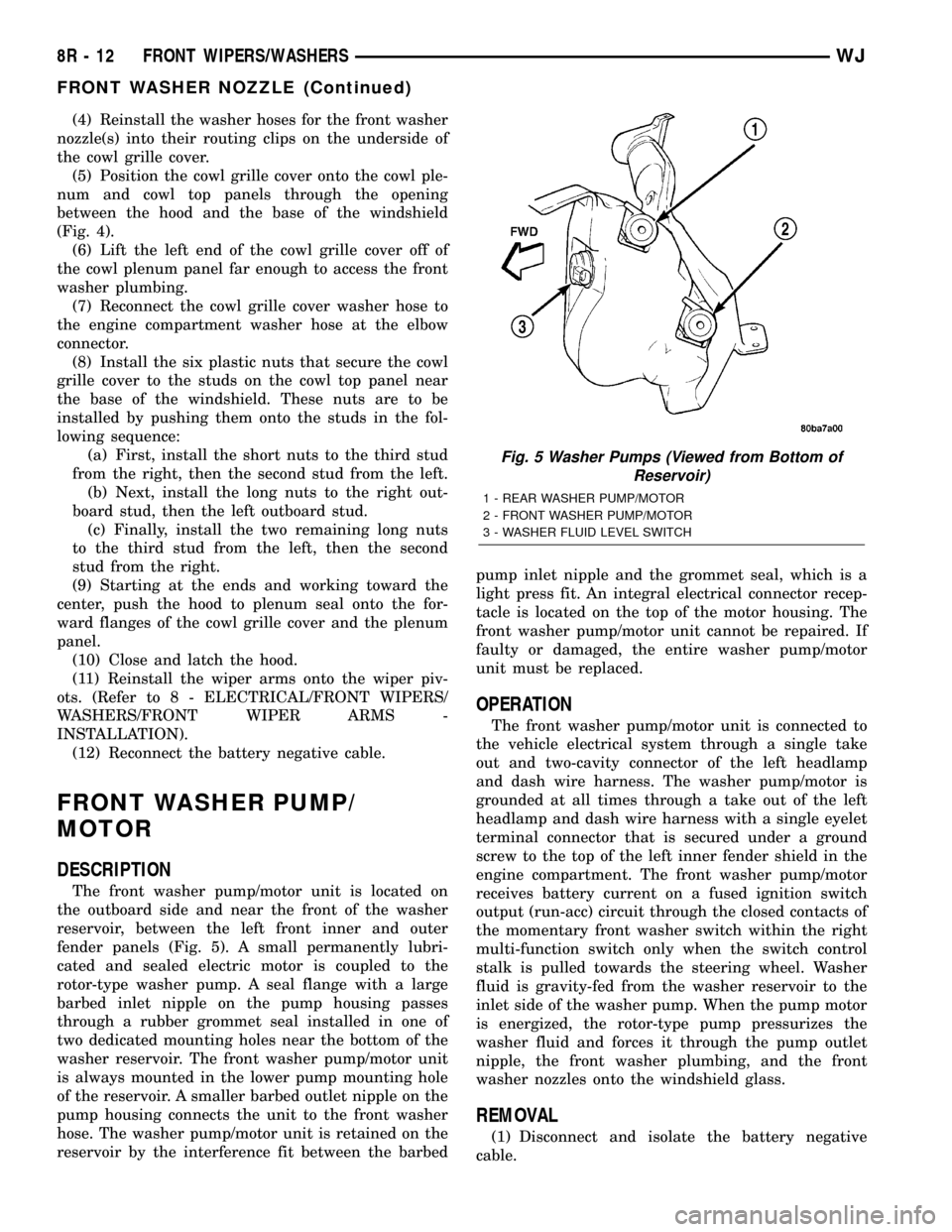

The front washer pump/motor unit is located on

the outboard side and near the front of the washer

reservoir, between the left front inner and outer

fender panels (Fig. 5). A small permanently lubri-

cated and sealed electric motor is coupled to the

rotor-type washer pump. A seal flange with a large

barbed inlet nipple on the pump housing passes

through a rubber grommet seal installed in one of

two dedicated mounting holes near the bottom of the

washer reservoir. The front washer pump/motor unit

is always mounted in the lower pump mounting hole

of the reservoir. A smaller barbed outlet nipple on the

pump housing connects the unit to the front washer

hose. The washer pump/motor unit is retained on the

reservoir by the interference fit between the barbedpump inlet nipple and the grommet seal, which is a

light press fit. An integral electrical connector recep-

tacle is located on the top of the motor housing. The

front washer pump/motor unit cannot be repaired. If

faulty or damaged, the entire washer pump/motor

unit must be replaced.

OPERATION

The front washer pump/motor unit is connected to

the vehicle electrical system through a single take

out and two-cavity connector of the left headlamp

and dash wire harness. The washer pump/motor is

grounded at all times through a take out of the left

headlamp and dash wire harness with a single eyelet

terminal connector that is secured under a ground

screw to the top of the left inner fender shield in the

engine compartment. The front washer pump/motor

receives battery current on a fused ignition switch

output (run-acc) circuit through the closed contacts of

the momentary front washer switch within the right

multi-function switch only when the switch control

stalk is pulled towards the steering wheel. Washer

fluid is gravity-fed from the washer reservoir to the

inlet side of the washer pump. When the pump motor

is energized, the rotor-type pump pressurizes the

washer fluid and forces it through the pump outlet

nipple, the front washer plumbing, and the front

washer nozzles onto the windshield glass.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

Fig. 5 Washer Pumps (Viewed from Bottom of

Reservoir)

1 - REAR WASHER PUMP/MOTOR

2 - FRONT WASHER PUMP/MOTOR

3 - WASHER FLUID LEVEL SWITCH

8R - 12 FRONT WIPERS/WASHERSWJ

FRONT WASHER NOZZLE (Continued)