Oil drain JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 15 of 2199

becomes contaminated, drain, flush, and replace with

fresh properly mixed coolant solution.

CAUTION: Do not use coolant additives that are

claimed to improve engine cooling.

ENGINE OIL

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied. MOPARtprovides engine oils that conform to

this service grade.

SAE VISCOSITY

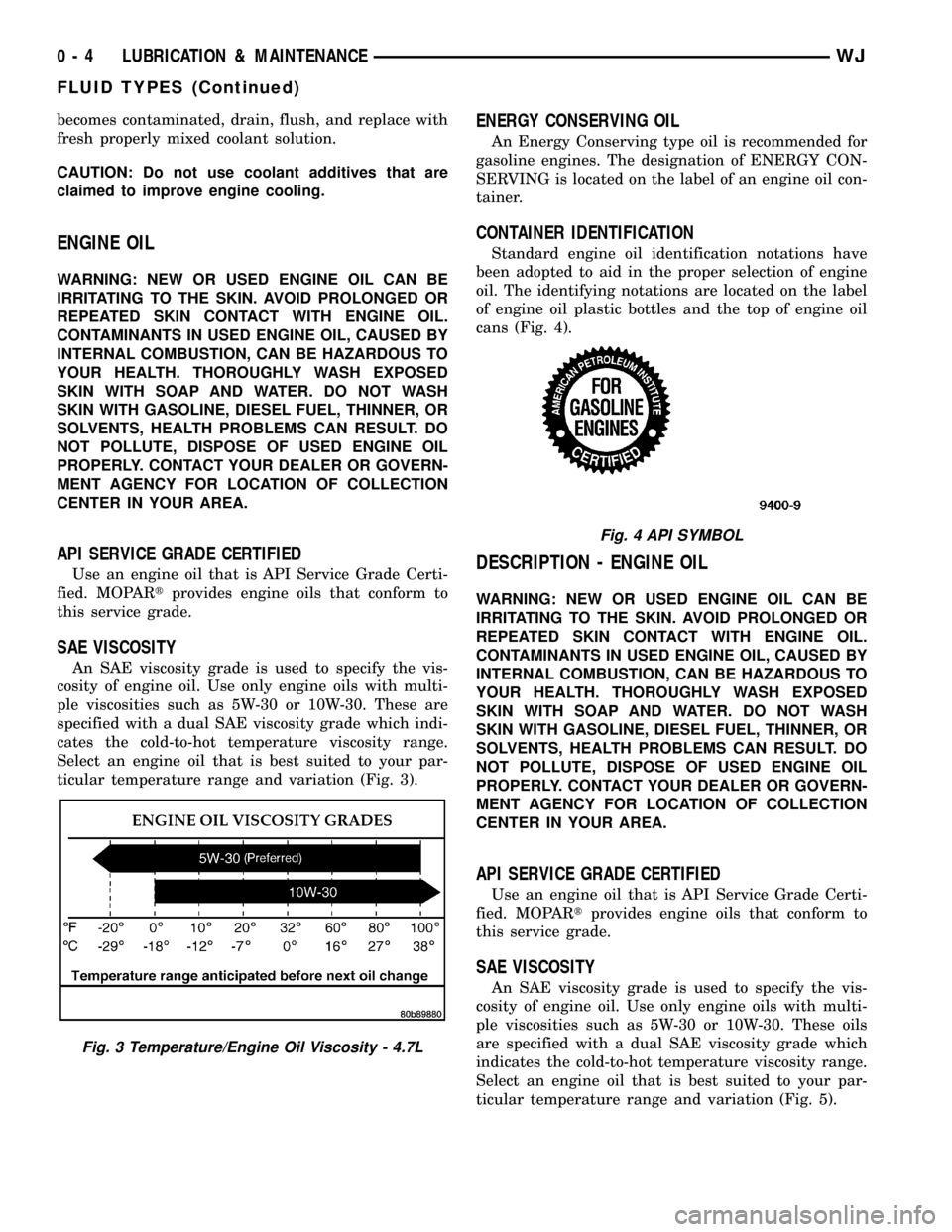

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only engine oils with multi-

ple viscosities such as 5W-30 or 10W-30. These are

specified with a dual SAE viscosity grade which indi-

cates the cold-to-hot temperature viscosity range.

Select an engine oil that is best suited to your par-

ticular temperature range and variation (Fig. 3).

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. The designation of ENERGY CON-

SERVING is located on the label of an engine oil con-

tainer.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 4).

DESCRIPTION - ENGINE OIL

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied. MOPARtprovides engine oils that conform to

this service grade.

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only engine oils with multi-

ple viscosities such as 5W-30 or 10W-30. These oils

are specified with a dual SAE viscosity grade which

indicates the cold-to-hot temperature viscosity range.

Select an engine oil that is best suited to your par-

ticular temperature range and variation (Fig. 5).

Fig. 3 Temperature/Engine Oil Viscosity - 4.7L

Fig. 4 API SYMBOL

0 - 4 LUBRICATION & MAINTENANCEWJ

FLUID TYPES (Continued)

Page 85 of 2199

²New Bearings: 1.7 to 3.4 N´m (15 to 30 in. lbs.).

(9) Install propeller shaft with reference marks

aligned.

(10) Install brake rotors and calipers.

(11) Add gear lubricant if necessary.

(12) Install wheel and tire assemblies.

(13) Lower vehicle.

DIFFERENTIAL

REMOVAL

(1) Raise and support the vehicle.

(2) Remove lubricant fill hole plug from the differ-

ential housing cover.

(3) Remove differential cover and drain lubricant.

(4) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.Never use water,

steam, kerosene or gasoline for cleaning.

(5) Remove hub bearings and axle shafts.

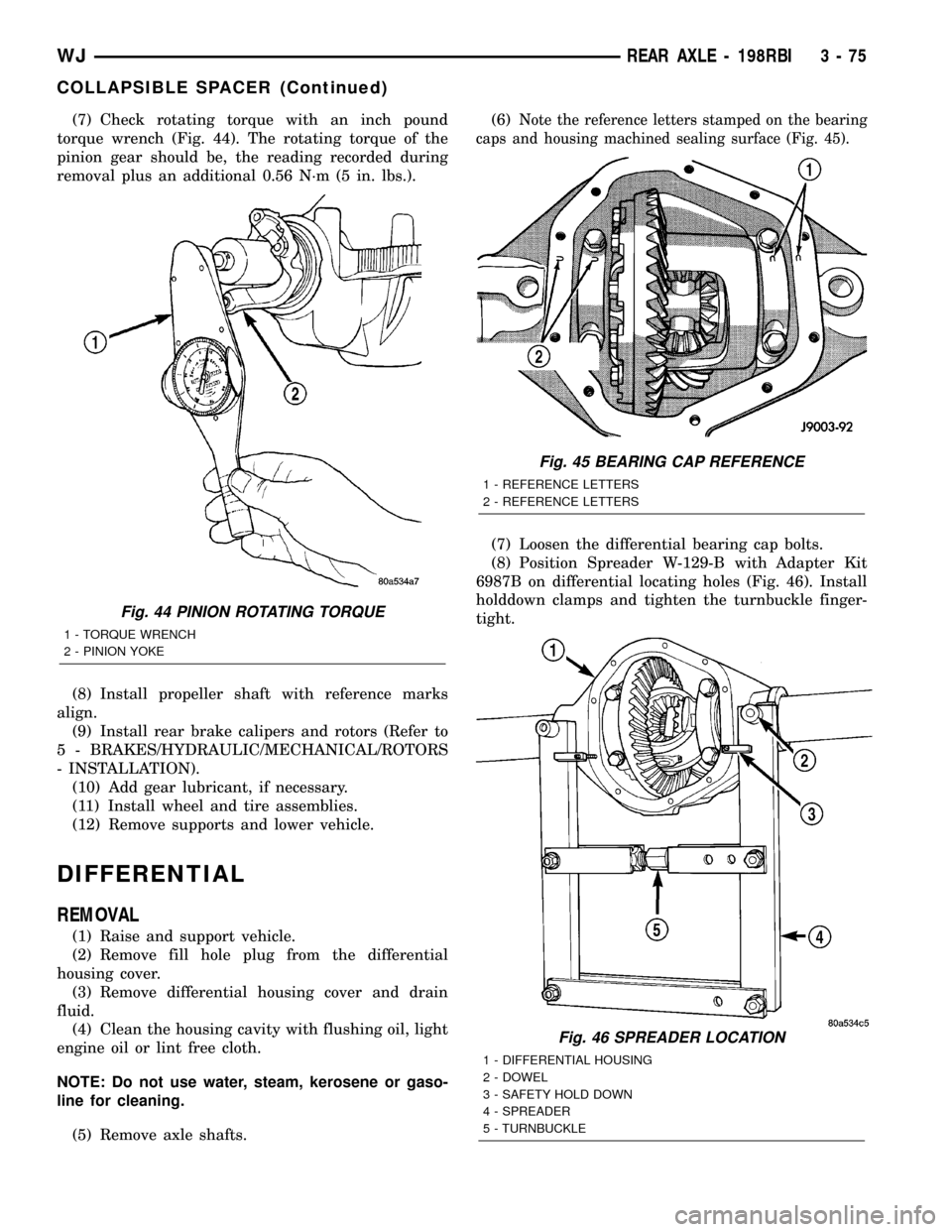

(6) Note installation reference letters stamped on

the bearing caps and housing machined sealing sur-

face (Fig. 38).

(7) Loosen the differential bearing cap bolts.

(8) Position Spreader W-129-B with Adapter Kit

6987B on differential locating holes (Fig. 39). Install

hold down clamps and tighten the tool turnbuckle

finger-tight.

Fig. 37 PINION COMPANION FLANGE

1 - COMPANION FLNAGE

2 - DIFFERENTIAL HOUSING

3 - SPANNER WRENCH

Fig. 38 BEARING CAP IDENTIFICATION

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

Fig. 39 DIFFERENTIAL SPREADER LOCATION

1 - DIFFERENTIAL HOUSING

2 - ADAPTER

3 - HOLD DOWN CLAMPS

4 - SPREADER

5 - TURNBUCKLE

3 - 40 FRONT AXLE - 186FBIWJ

COLLAPSIBLE SPACER (Continued)

Page 120 of 2199

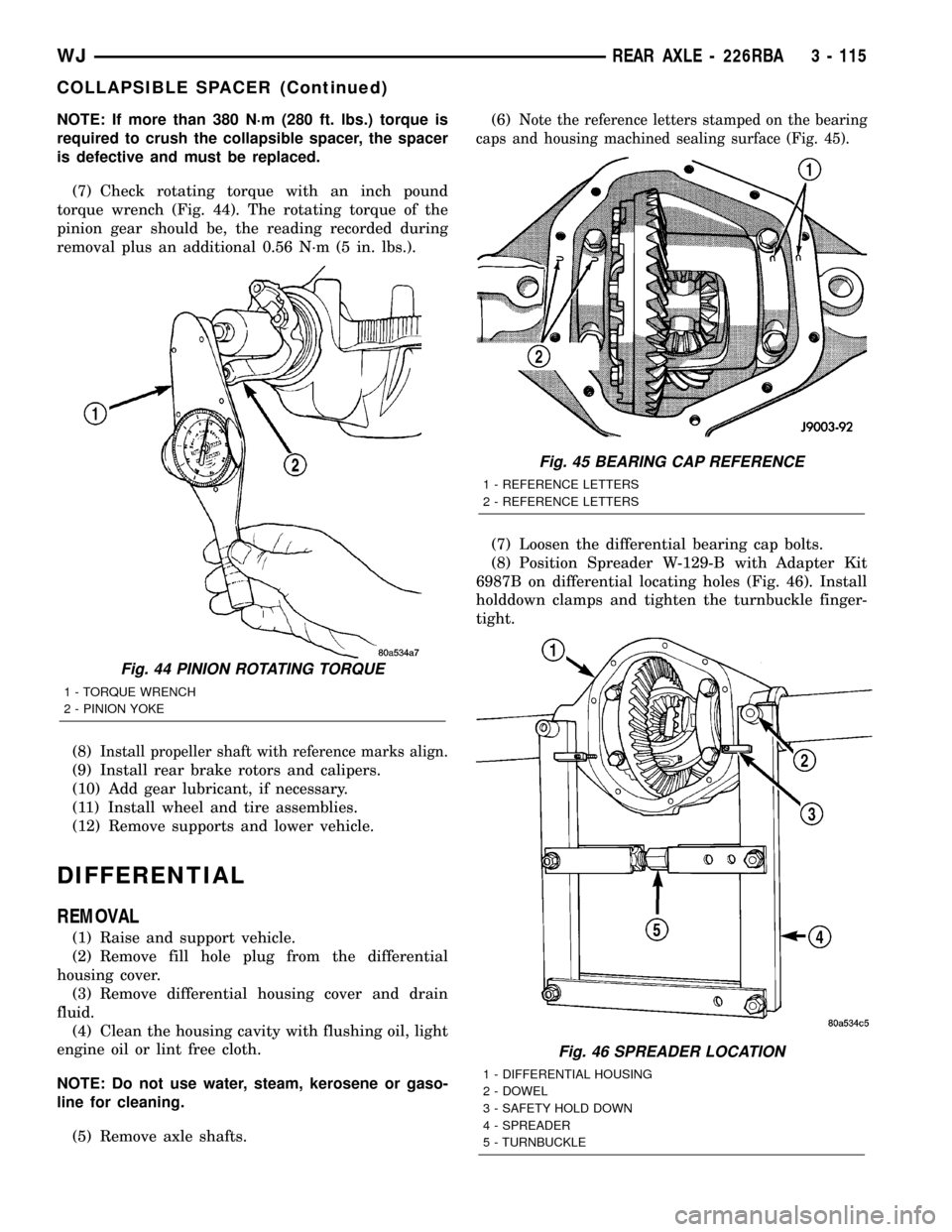

(7) Check rotating torque with an inch pound

torque wrench (Fig. 44). The rotating torque of the

pinion gear should be, the reading recorded during

removal plus an additional 0.56 N´m (5 in. lbs.).

(8) Install propeller shaft with reference marks

align.

(9) Install rear brake calipers and rotors (Refer to

5 - BRAKES/HYDRAULIC/MECHANICAL/ROTORS

- INSTALLATION).

(10) Add gear lubricant, if necessary.

(11) Install wheel and tire assemblies.

(12) Remove supports and lower vehicle.

DIFFERENTIAL

REMOVAL

(1) Raise and support vehicle.

(2) Remove fill hole plug from the differential

housing cover.

(3) Remove differential housing cover and drain

fluid.

(4) Clean the housing cavity with flushing oil, light

engine oil or lint free cloth.

NOTE: Do not use water, steam, kerosene or gaso-

line for cleaning.

(5) Remove axle shafts.(6)

Note the reference letters stamped on the bearing

caps and housing machined sealing surface (Fig. 45).

(7) Loosen the differential bearing cap bolts.

(8) Position Spreader W-129-B with Adapter Kit

6987B on differential locating holes (Fig. 46). Install

holddown clamps and tighten the turnbuckle finger-

tight.

Fig. 44 PINION ROTATING TORQUE

1 - TORQUE WRENCH

2 - PINION YOKE

Fig. 45 BEARING CAP REFERENCE

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

Fig. 46 SPREADER LOCATION

1 - DIFFERENTIAL HOUSING

2 - DOWEL

3 - SAFETY HOLD DOWN

4 - SPREADER

5 - TURNBUCKLE

WJREAR AXLE - 198RBI 3 - 75

COLLAPSIBLE SPACER (Continued)

Page 160 of 2199

NOTE: If more than 380 N´m (280 ft. lbs.) torque is

required to crush the collapsible spacer, the spacer

is defective and must be replaced.

(7) Check rotating torque with an inch pound

torque wrench (Fig. 44). The rotating torque of the

pinion gear should be, the reading recorded during

removal plus an additional 0.56 N´m (5 in. lbs.).

(8)

Install propeller shaft with reference marks align.

(9) Install rear brake rotors and calipers.

(10) Add gear lubricant, if necessary.

(11) Install wheel and tire assemblies.

(12) Remove supports and lower vehicle.

DIFFERENTIAL

REMOVAL

(1) Raise and support vehicle.

(2) Remove fill hole plug from the differential

housing cover.

(3) Remove differential housing cover and drain

fluid.

(4) Clean the housing cavity with flushing oil, light

engine oil or lint free cloth.

NOTE: Do not use water, steam, kerosene or gaso-

line for cleaning.

(5) Remove axle shafts.(6)

Note the reference letters stamped on the bearing

caps and housing machined sealing surface (Fig. 45).

(7) Loosen the differential bearing cap bolts.

(8) Position Spreader W-129-B with Adapter Kit

6987B on differential locating holes (Fig. 46). Install

holddown clamps and tighten the turnbuckle finger-

tight.

Fig. 44 PINION ROTATING TORQUE

1 - TORQUE WRENCH

2 - PINION YOKE

Fig. 45 BEARING CAP REFERENCE

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

Fig. 46 SPREADER LOCATION

1 - DIFFERENTIAL HOUSING

2 - DOWEL

3 - SAFETY HOLD DOWN

4 - SPREADER

5 - TURNBUCKLE

WJREAR AXLE - 226RBA 3 - 115

COLLAPSIBLE SPACER (Continued)

Page 198 of 2199

rates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If brake fluid is contaminated, drain and thor-

oughly flush system. Replace master cylinder with

reservoir, caliper seals, HCU and all hydraulic fluid

hoses.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications and SAE J1703 standards.

No other type of brake fluid is recommended or

approved for usage in the vehicle brake system. Use

only Mopar brake fluid or an equivalent from a

tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container of brake fluid will absorb moisture

from the air and contaminate the fluid.

CAUTION: Never use any type of a petroleum-based

fluid in the brake hydraulic system. Use of such

type fluids will result in seal damage of the vehicle

brake hydraulic system causing a failure of the

vehicle brake system. Petroleum based fluids would

be items such as engine oil, transmission fluid,

power steering fluid, etc.

FLUID RESERVOIR

REMOVAL

(1) Remove reservoir cap and remove fluid with a

cleansuction gun.

(2) Remove the wire connector from the brake fluid

level sensor.

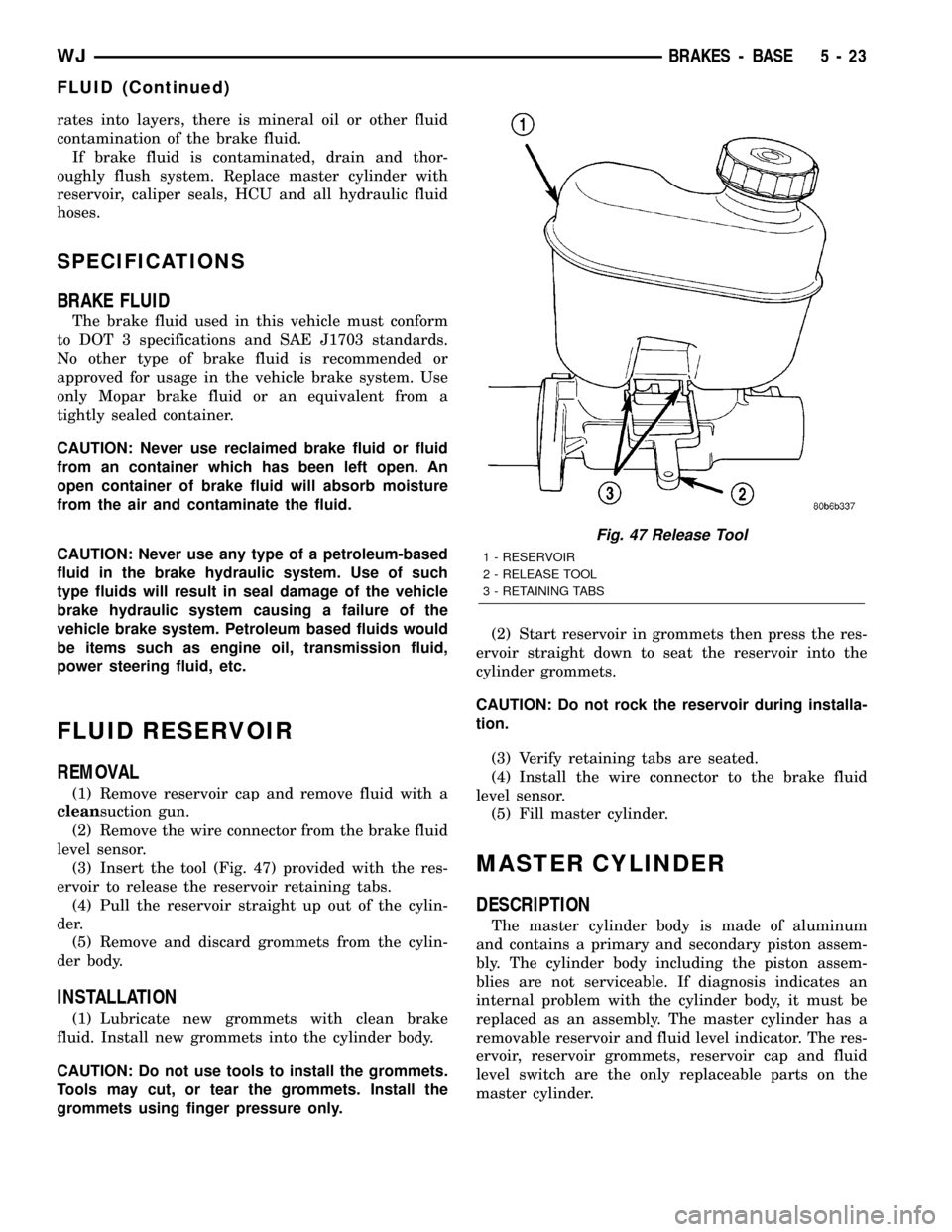

(3) Insert the tool (Fig. 47) provided with the res-

ervoir to release the reservoir retaining tabs.

(4) Pull the reservoir straight up out of the cylin-

der.

(5) Remove and discard grommets from the cylin-

der body.

INSTALLATION

(1) Lubricate new grommets with clean brake

fluid. Install new grommets into the cylinder body.

CAUTION: Do not use tools to install the grommets.

Tools may cut, or tear the grommets. Install the

grommets using finger pressure only.(2) Start reservoir in grommets then press the res-

ervoir straight down to seat the reservoir into the

cylinder grommets.

CAUTION: Do not rock the reservoir during installa-

tion.

(3) Verify retaining tabs are seated.

(4) Install the wire connector to the brake fluid

level sensor.

(5) Fill master cylinder.

MASTER CYLINDER

DESCRIPTION

The master cylinder body is made of aluminum

and contains a primary and secondary piston assem-

bly. The cylinder body including the piston assem-

blies are not serviceable. If diagnosis indicates an

internal problem with the cylinder body, it must be

replaced as an assembly. The master cylinder has a

removable reservoir and fluid level indicator. The res-

ervoir, reservoir grommets, reservoir cap and fluid

level switch are the only replaceable parts on the

master cylinder.

Fig. 47 Release Tool

1 - RESERVOIR

2 - RELEASE TOOL

3 - RETAINING TABS

WJBRAKES - BASE 5 - 23

FLUID (Continued)

Page 224 of 2199

COOLING

TABLE OF CONTENTS

page page

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM 4.7L

ENGINE..............................1

DESCRIPTION - COOLING SYSTEM

ROUTING 4.7L ENGINE..................1

DESCRIPTIONÐCOOLING SYSTEM 4.0L

ENGINE..............................1

DESCRIPTIONÐCOOLING SYSTEM

ROUTING 4.0L ENGINE..................1

DESCRIPTIONÐHOSE CLAMPS...........1

OPERATION

OPERATIONÐCOOLING SYSTEM.........2

OPERATIONÐHOSE CLAMPS............2

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTINGÐON-BOARD

DIAGNOSTICS (OBD)...................3

DIAGNOSIS AND TESTINGÐPRELIMINARY

CHECKS.............................3

DIAGNOSIS AND TESTING - COOLING

SYSTEM DIAGNOSIS CHART.............5

DIAGNOSIS AND TESTING - COOLING

SYSTEM LEAKS......................10DIAGNOSIS AND TESTING - COOLING

SYSTEM DEAERATION.................12

STANDARD PROCEDURE

STANDARD PROCEDUREÐDRAINING

COOLING SYSTEM 4.7L ENGINE.........12

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM 4.7L ENGINE.........12

STANDARD PROCEDURE - DRAINING

COOLING SYSTEM - 4.0L ENGINE........13

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM - 4.0L ENGINE........13

STANDARD PROCEDURE - ADDING

ADDITIONAL COOLANT.................13

STANDARD PROCEDURE - COOLING

SYSTEM - REVERSE FLUSHING..........14

SPECIFICATIONS

TORQUE............................14

SPECIAL TOOLS

COOLING...........................15

ACCESSORY DRIVE......................16

ENGINE...............................24

TRANSMISSION.........................55

COOLING

DESCRIPTION

DESCRIPTION - COOLING SYSTEM 4.7L

ENGINE

The cooling system consists of the following items:

²Hydraulic cooling fan and fan drive assembly

²Radiator

²Power steering oil cooler

²Radiator pressure cap

²Thermostat

²Coolant reserve/overflow system

²Transmission oil cooler (if equipped with an

automatic transmission)

²Coolant

²Water pump

²Hoses and hose clamps

DESCRIPTION - COOLING SYSTEM ROUTING

4.7L ENGINE

For cooling system routing refer to (Fig. 1).

DESCRIPTIONÐCOOLING SYSTEM 4.0L

ENGINE

The cooling system consists of:

²A radiator

²Mechanical Cooling Fan

²Thermal viscous fan drive-Low disengaged

²Fan shroud (Fig. 2)

²Radiator pressure cap

²Thermostat

²Coolant reserve/overflow system

²Transmission oil cooler (if equipped with an

automatic transmission)

²Coolant

²Water pump

²Hoses and hose clamps

²Accessory drive belt

DESCRIPTIONÐCOOLING SYSTEM ROUTING

4.0L ENGINE

For cooling system routing refer to (Fig. 3).

DESCRIPTIONÐHOSE CLAMPS

The cooling system utilizes both worm drive and

spring type hose clamps. If a spring type clamp

WJCOOLING 7 - 1

Page 234 of 2199

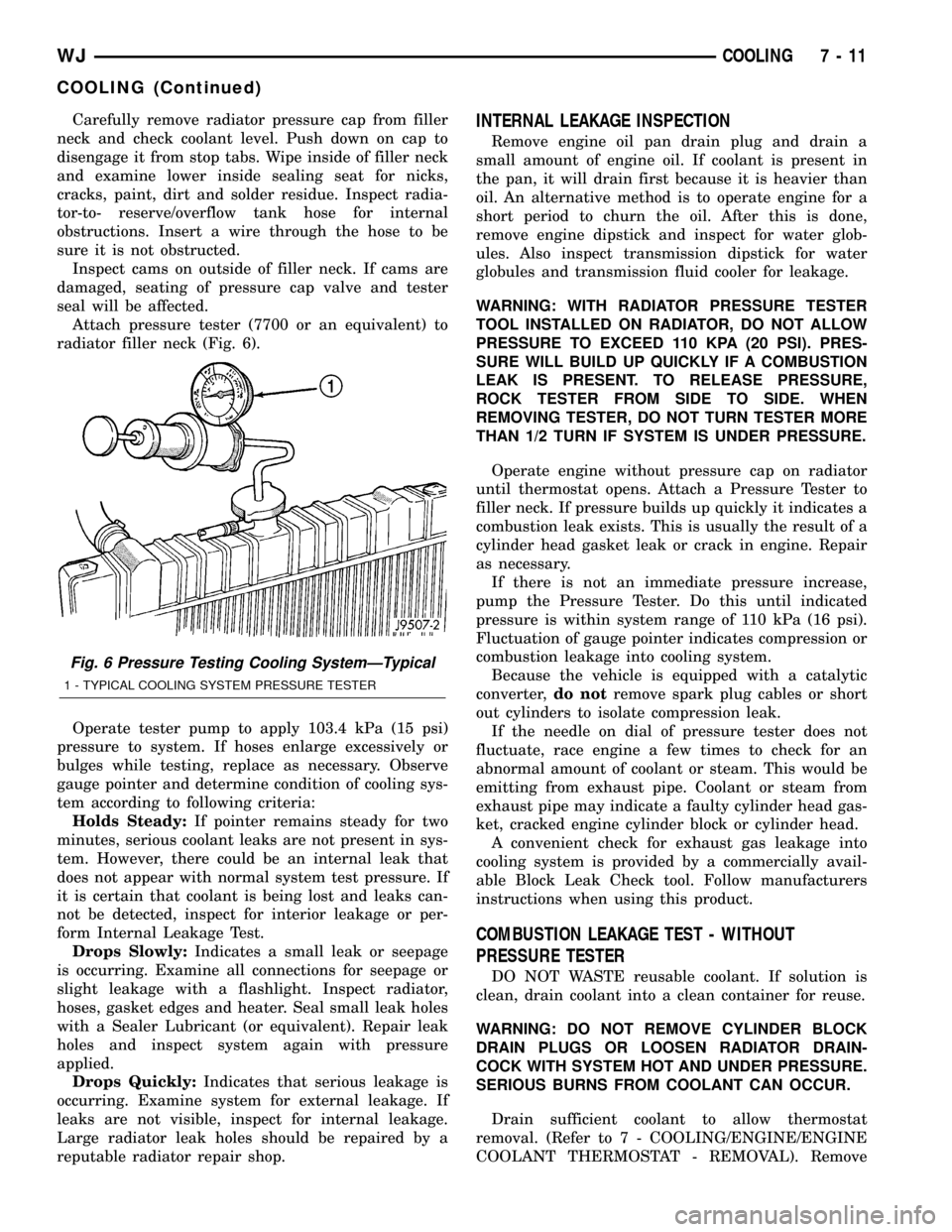

Carefully remove radiator pressure cap from filler

neck and check coolant level. Push down on cap to

disengage it from stop tabs. Wipe inside of filler neck

and examine lower inside sealing seat for nicks,

cracks, paint, dirt and solder residue. Inspect radia-

tor-to- reserve/overflow tank hose for internal

obstructions. Insert a wire through the hose to be

sure it is not obstructed.

Inspect cams on outside of filler neck. If cams are

damaged, seating of pressure cap valve and tester

seal will be affected.

Attach pressure tester (7700 or an equivalent) to

radiator filler neck (Fig. 6).

Operate tester pump to apply 103.4 kPa (15 psi)

pressure to system. If hoses enlarge excessively or

bulges while testing, replace as necessary. Observe

gauge pointer and determine condition of cooling sys-

tem according to following criteria:

Holds Steady:If pointer remains steady for two

minutes, serious coolant leaks are not present in sys-

tem. However, there could be an internal leak that

does not appear with normal system test pressure. If

it is certain that coolant is being lost and leaks can-

not be detected, inspect for interior leakage or per-

form Internal Leakage Test.

Drops Slowly:Indicates a small leak or seepage

is occurring. Examine all connections for seepage or

slight leakage with a flashlight. Inspect radiator,

hoses, gasket edges and heater. Seal small leak holes

with a Sealer Lubricant (or equivalent). Repair leak

holes and inspect system again with pressure

applied.

Drops Quickly:Indicates that serious leakage is

occurring. Examine system for external leakage. If

leaks are not visible, inspect for internal leakage.

Large radiator leak holes should be repaired by a

reputable radiator repair shop.INTERNAL LEAKAGE INSPECTION

Remove engine oil pan drain plug and drain a

small amount of engine oil. If coolant is present in

the pan, it will drain first because it is heavier than

oil. An alternative method is to operate engine for a

short period to churn the oil. After this is done,

remove engine dipstick and inspect for water glob-

ules. Also inspect transmission dipstick for water

globules and transmission fluid cooler for leakage.

WARNING: WITH RADIATOR PRESSURE TESTER

TOOL INSTALLED ON RADIATOR, DO NOT ALLOW

PRESSURE TO EXCEED 110 KPA (20 PSI). PRES-

SURE WILL BUILD UP QUICKLY IF A COMBUSTION

LEAK IS PRESENT. TO RELEASE PRESSURE,

ROCK TESTER FROM SIDE TO SIDE. WHEN

REMOVING TESTER, DO NOT TURN TESTER MORE

THAN 1/2 TURN IF SYSTEM IS UNDER PRESSURE.

Operate engine without pressure cap on radiator

until thermostat opens. Attach a Pressure Tester to

filler neck. If pressure builds up quickly it indicates a

combustion leak exists. This is usually the result of a

cylinder head gasket leak or crack in engine. Repair

as necessary.

If there is not an immediate pressure increase,

pump the Pressure Tester. Do this until indicated

pressure is within system range of 110 kPa (16 psi).

Fluctuation of gauge pointer indicates compression or

combustion leakage into cooling system.

Because the vehicle is equipped with a catalytic

converter,do notremove spark plug cables or short

out cylinders to isolate compression leak.

If the needle on dial of pressure tester does not

fluctuate, race engine a few times to check for an

abnormal amount of coolant or steam. This would be

emitting from exhaust pipe. Coolant or steam from

exhaust pipe may indicate a faulty cylinder head gas-

ket, cracked engine cylinder block or cylinder head.

A convenient check for exhaust gas leakage into

cooling system is provided by a commercially avail-

able Block Leak Check tool. Follow manufacturers

instructions when using this product.

COMBUSTION LEAKAGE TEST - WITHOUT

PRESSURE TESTER

DO NOT WASTE reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.

WARNING: DO NOT REMOVE CYLINDER BLOCK

DRAIN PLUGS OR LOOSEN RADIATOR DRAIN-

COCK WITH SYSTEM HOT AND UNDER PRESSURE.

SERIOUS BURNS FROM COOLANT CAN OCCUR.

Drain sufficient coolant to allow thermostat

removal. (Refer to 7 - COOLING/ENGINE/ENGINE

COOLANT THERMOSTAT - REMOVAL). Remove

Fig. 6 Pressure Testing Cooling SystemÐTypical

1 - TYPICAL COOLING SYSTEM PRESSURE TESTER

WJCOOLING 7 - 11

COOLING (Continued)

Page 235 of 2199

accessory drive belt (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - REMOVAL).

Add coolant to radiator to bring level to within 6.3

mm (1/4 in) of top of thermostat housing.

CAUTION: Avoid overheating. Do not operate

engine for an excessive period of time. Open drain-

cock immediately after test to eliminate boil over.

Start engine and accelerate rapidly three times, to

approximately 3000 rpm while observing coolant. If

internal engine combustion gases are leaking into

cooling system, bubbles will appear in coolant. If bub-

bles do not appear, internal combustion gas leakage

is not present.

DIAGNOSIS AND TESTING - COOLING SYSTEM

DEAERATION

As the engine operates, any air trapped in cooling

system gathers under the radiator cap. The next time

the engine is operated, thermal expansion of coolant

will push any trapped air past radiator cap into the

coolant reserve/overflow tank. Here it escapes to the

atmosphere into the tank. When the engine cools

down the coolant, it will be drawn from the reserve/

overflow tank into the radiator to replace any

removed air.

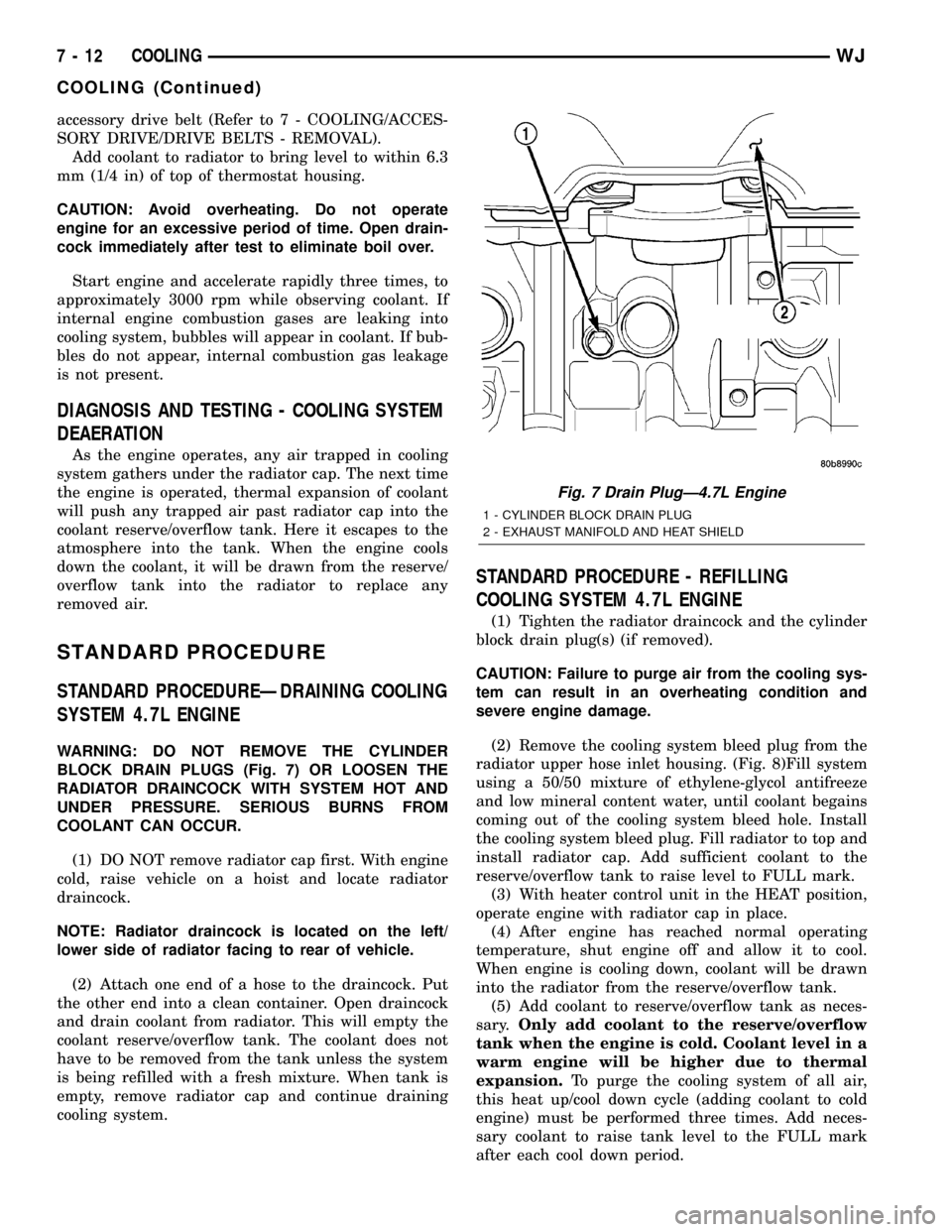

STANDARD PROCEDURE

STANDARD PROCEDUREÐDRAINING COOLING

SYSTEM 4.7L ENGINE

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS (Fig. 7) OR LOOSEN THE

RADIATOR DRAINCOCK WITH SYSTEM HOT AND

UNDER PRESSURE. SERIOUS BURNS FROM

COOLANT CAN OCCUR.

(1) DO NOT remove radiator cap first. With engine

cold, raise vehicle on a hoist and locate radiator

draincock.

NOTE: Radiator draincock is located on the left/

lower side of radiator facing to rear of vehicle.

(2) Attach one end of a hose to the draincock. Put

the other end into a clean container. Open draincock

and drain coolant from radiator. This will empty the

coolant reserve/overflow tank. The coolant does not

have to be removed from the tank unless the system

is being refilled with a fresh mixture. When tank is

empty, remove radiator cap and continue draining

cooling system.

STANDARD PROCEDURE - REFILLING

COOLING SYSTEM 4.7L ENGINE

(1) Tighten the radiator draincock and the cylinder

block drain plug(s) (if removed).

CAUTION: Failure to purge air from the cooling sys-

tem can result in an overheating condition and

severe engine damage.

(2) Remove the cooling system bleed plug from the

radiator upper hose inlet housing. (Fig. 8)Fill system

using a 50/50 mixture of ethylene-glycol antifreeze

and low mineral content water, until coolant begains

coming out of the cooling system bleed hole. Install

the cooling system bleed plug. Fill radiator to top and

install radiator cap. Add sufficient coolant to the

reserve/overflow tank to raise level to FULL mark.

(3) With heater control unit in the HEAT position,

operate engine with radiator cap in place.

(4) After engine has reached normal operating

temperature, shut engine off and allow it to cool.

When engine is cooling down, coolant will be drawn

into the radiator from the reserve/overflow tank.

(5) Add coolant to reserve/overflow tank as neces-

sary.Only add coolant to the reserve/overflow

tank when the engine is cold. Coolant level in a

warm engine will be higher due to thermal

expansion.To purge the cooling system of all air,

this heat up/cool down cycle (adding coolant to cold

engine) must be performed three times. Add neces-

sary coolant to raise tank level to the FULL mark

after each cool down period.

Fig. 7 Drain PlugÐ4.7L Engine

1 - CYLINDER BLOCK DRAIN PLUG

2 - EXHAUST MANIFOLD AND HEAT SHIELD

7 - 12 COOLINGWJ

COOLING (Continued)

Page 251 of 2199

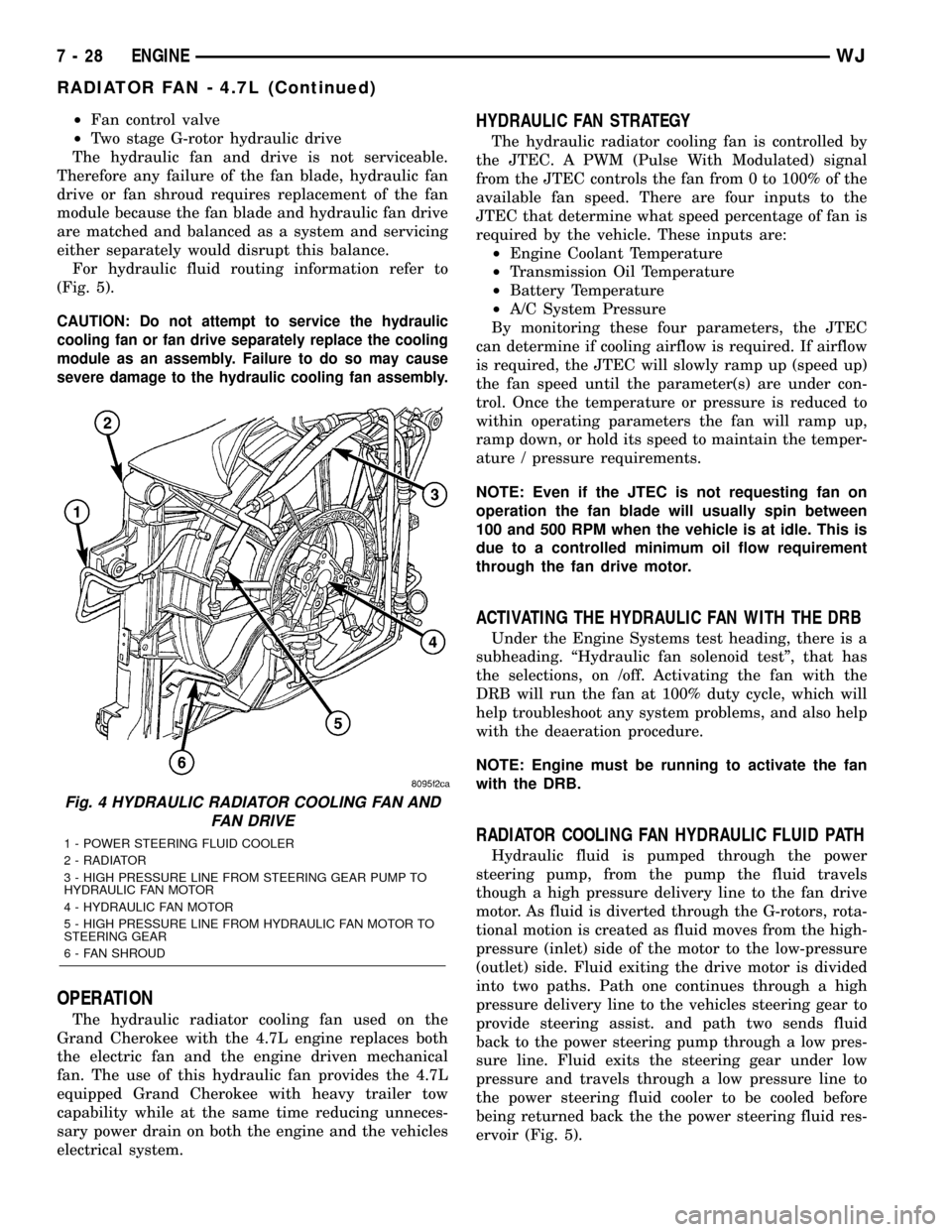

²Fan control valve

²Two stage G-rotor hydraulic drive

The hydraulic fan and drive is not serviceable.

Therefore any failure of the fan blade, hydraulic fan

drive or fan shroud requires replacement of the fan

module because the fan blade and hydraulic fan drive

are matched and balanced as a system and servicing

either separately would disrupt this balance.

For hydraulic fluid routing information refer to

(Fig. 5).

CAUTION: Do not attempt to service the hydraulic

cooling fan or fan drive separately replace the cooling

module as an assembly. Failure to do so may cause

severe damage to the hydraulic cooling fan assembly.

OPERATION

The hydraulic radiator cooling fan used on the

Grand Cherokee with the 4.7L engine replaces both

the electric fan and the engine driven mechanical

fan. The use of this hydraulic fan provides the 4.7L

equipped Grand Cherokee with heavy trailer tow

capability while at the same time reducing unneces-

sary power drain on both the engine and the vehicles

electrical system.

HYDRAULIC FAN STRATEGY

The hydraulic radiator cooling fan is controlled by

the JTEC. A PWM (Pulse With Modulated) signal

from the JTEC controls the fan from 0 to 100% of the

available fan speed. There are four inputs to the

JTEC that determine what speed percentage of fan is

required by the vehicle. These inputs are:

²Engine Coolant Temperature

²Transmission Oil Temperature

²Battery Temperature

²A/C System Pressure

By monitoring these four parameters, the JTEC

can determine if cooling airflow is required. If airflow

is required, the JTEC will slowly ramp up (speed up)

the fan speed until the parameter(s) are under con-

trol. Once the temperature or pressure is reduced to

within operating parameters the fan will ramp up,

ramp down, or hold its speed to maintain the temper-

ature / pressure requirements.

NOTE: Even if the JTEC is not requesting fan on

operation the fan blade will usually spin between

100 and 500 RPM when the vehicle is at idle. This is

due to a controlled minimum oil flow requirement

through the fan drive motor.

ACTIVATING THE HYDRAULIC FAN WITH THE DRB

Under the Engine Systems test heading, there is a

subheading. ªHydraulic fan solenoid testº, that has

the selections, on /off. Activating the fan with the

DRB will run the fan at 100% duty cycle, which will

help troubleshoot any system problems, and also help

with the deaeration procedure.

NOTE: Engine must be running to activate the fan

with the DRB.

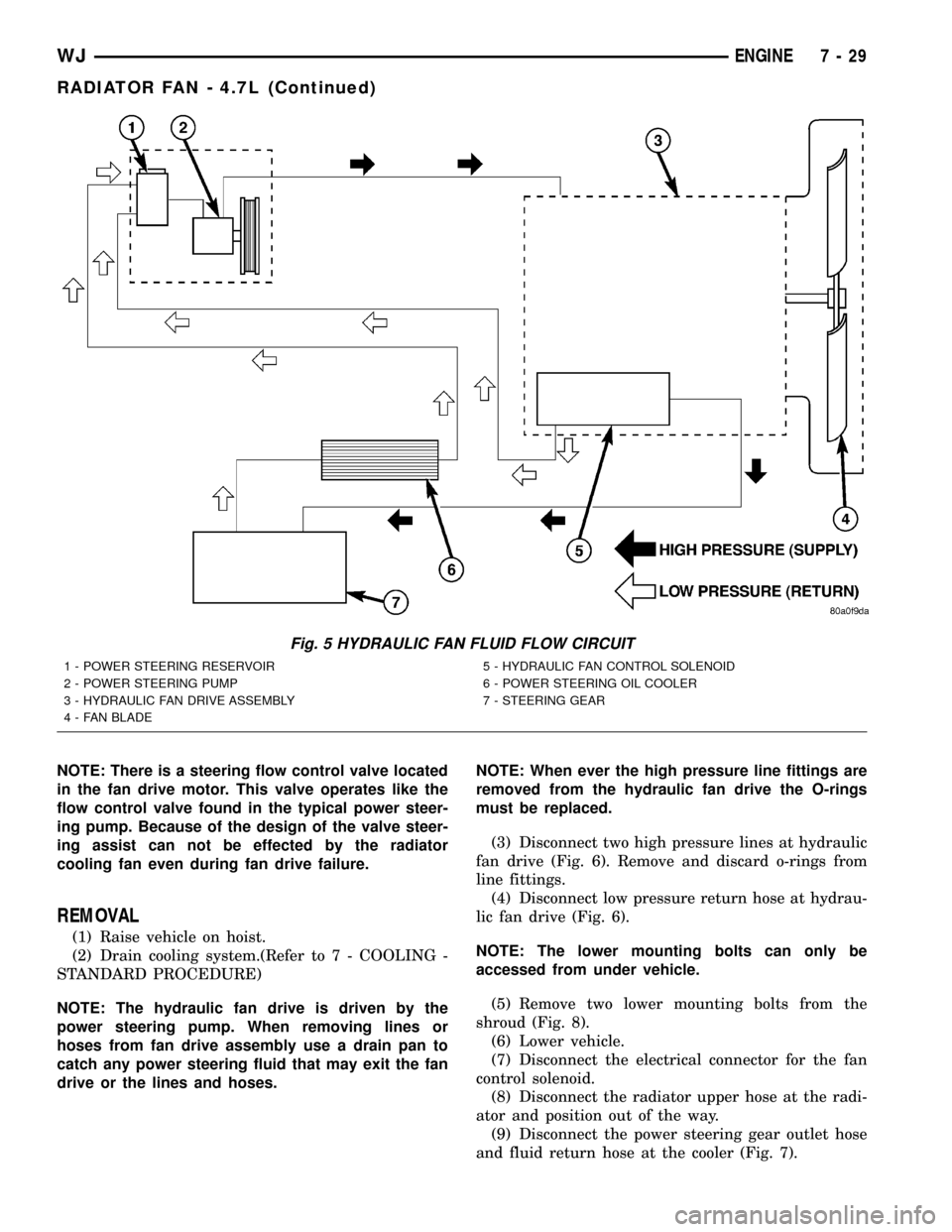

RADIATOR COOLING FAN HYDRAULIC FLUID PATH

Hydraulic fluid is pumped through the power

steering pump, from the pump the fluid travels

though a high pressure delivery line to the fan drive

motor. As fluid is diverted through the G-rotors, rota-

tional motion is created as fluid moves from the high-

pressure (inlet) side of the motor to the low-pressure

(outlet) side. Fluid exiting the drive motor is divided

into two paths. Path one continues through a high

pressure delivery line to the vehicles steering gear to

provide steering assist. and path two sends fluid

back to the power steering pump through a low pres-

sure line. Fluid exits the steering gear under low

pressure and travels through a low pressure line to

the power steering fluid cooler to be cooled before

being returned back the the power steering fluid res-

ervoir (Fig. 5).

Fig. 4 HYDRAULIC RADIATOR COOLING FAN AND

FAN DRIVE

1 - POWER STEERING FLUID COOLER

2 - RADIATOR

3 - HIGH PRESSURE LINE FROM STEERING GEAR PUMP TO

HYDRAULIC FAN MOTOR

4 - HYDRAULIC FAN MOTOR

5 - HIGH PRESSURE LINE FROM HYDRAULIC FAN MOTOR TO

STEERING GEAR

6 - FAN SHROUD

7 - 28 ENGINEWJ

RADIATOR FAN - 4.7L (Continued)

Page 252 of 2199

NOTE: There is a steering flow control valve located

in the fan drive motor. This valve operates like the

flow control valve found in the typical power steer-

ing pump. Because of the design of the valve steer-

ing assist can not be effected by the radiator

cooling fan even during fan drive failure.

REMOVAL

(1) Raise vehicle on hoist.

(2) Drain cooling system.(Refer to 7 - COOLING -

STANDARD PROCEDURE)

NOTE: The hydraulic fan drive is driven by the

power steering pump. When removing lines or

hoses from fan drive assembly use a drain pan to

catch any power steering fluid that may exit the fan

drive or the lines and hoses.NOTE: When ever the high pressure line fittings are

removed from the hydraulic fan drive the O-rings

must be replaced.

(3) Disconnect two high pressure lines at hydraulic

fan drive (Fig. 6). Remove and discard o-rings from

line fittings.

(4) Disconnect low pressure return hose at hydrau-

lic fan drive (Fig. 6).

NOTE: The lower mounting bolts can only be

accessed from under vehicle.

(5) Remove two lower mounting bolts from the

shroud (Fig. 8).

(6) Lower vehicle.

(7) Disconnect the electrical connector for the fan

control solenoid.

(8) Disconnect the radiator upper hose at the radi-

ator and position out of the way.

(9) Disconnect the power steering gear outlet hose

and fluid return hose at the cooler (Fig. 7).

Fig. 5 HYDRAULIC FAN FLUID FLOW CIRCUIT

1 - POWER STEERING RESERVOIR

2 - POWER STEERING PUMP

3 - HYDRAULIC FAN DRIVE ASSEMBLY

4 - FAN BLADE5 - HYDRAULIC FAN CONTROL SOLENOID

6 - POWER STEERING OIL COOLER

7 - STEERING GEAR

WJENGINE 7 - 29

RADIATOR FAN - 4.7L (Continued)