load capacity JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 276 of 2199

CAUTION: When installing the serpentine engine

accessory drive belt, the belt MUST be routed cor-

rectly. If not, the engine may overheat due to the

water pump rotating in the wrong direction. Refer to

the Belt Removal and Installtion in this group for

appropriate belt routing. You may also refer to the

Belt Routing Label in the vehicle engine compart-

ment.

Install accessory drive belt (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - INSTALLA-

TION).

(6) Install fan blade and viscous fan drive onto

water pump.

(7) Fill cooling system with coolant and check for

leaks. (Refer to 7 - COOLING - STANDARD PROCE-

DURE).

(8) Connect battery cable to battery.

(9) Start and warm the engine. Check for leaks.

RADIATOR PRESSURE CAP

DESCRIPTION

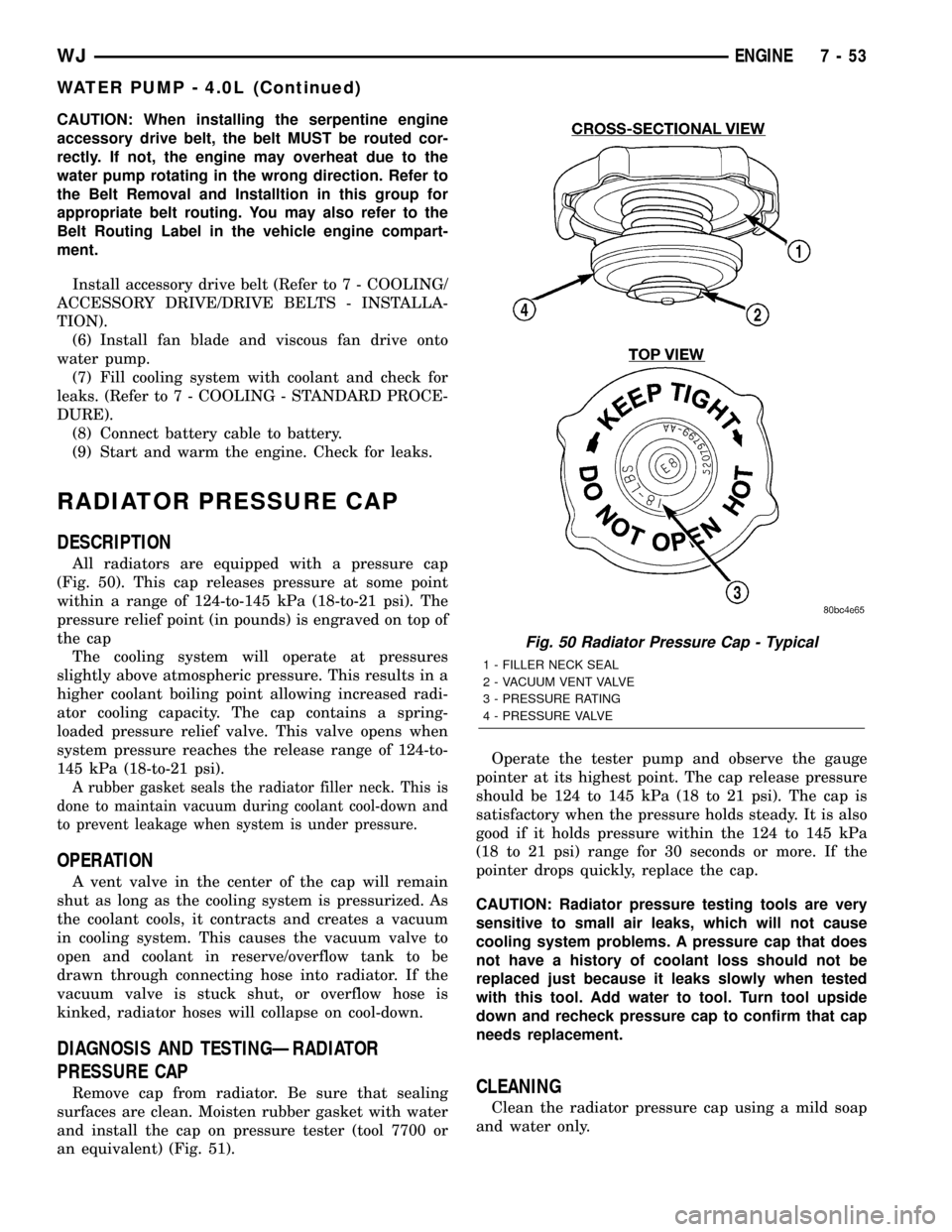

All radiators are equipped with a pressure cap

(Fig. 50). This cap releases pressure at some point

within a range of 124-to-145 kPa (18-to-21 psi). The

pressure relief point (in pounds) is engraved on top of

the cap

The cooling system will operate at pressures

slightly above atmospheric pressure. This results in a

higher coolant boiling point allowing increased radi-

ator cooling capacity. The cap contains a spring-

loaded pressure relief valve. This valve opens when

system pressure reaches the release range of 124-to-

145 kPa (18-to-21 psi).

A rubber gasket seals the radiator filler neck. This is

done to maintain vacuum during coolant cool-down and

to prevent leakage when system is under pressure.

OPERATION

A vent valve in the center of the cap will remain

shut as long as the cooling system is pressurized. As

the coolant cools, it contracts and creates a vacuum

in cooling system. This causes the vacuum valve to

open and coolant in reserve/overflow tank to be

drawn through connecting hose into radiator. If the

vacuum valve is stuck shut, or overflow hose is

kinked, radiator hoses will collapse on cool-down.

DIAGNOSIS AND TESTINGÐRADIATOR

PRESSURE CAP

Remove cap from radiator. Be sure that sealing

surfaces are clean. Moisten rubber gasket with water

and install the cap on pressure tester (tool 7700 or

an equivalent) (Fig. 51).Operate the tester pump and observe the gauge

pointer at its highest point. The cap release pressure

should be 124 to 145 kPa (18 to 21 psi). The cap is

satisfactory when the pressure holds steady. It is also

good if it holds pressure within the 124 to 145 kPa

(18 to 21 psi) range for 30 seconds or more. If the

pointer drops quickly, replace the cap.

CAUTION: Radiator pressure testing tools are very

sensitive to small air leaks, which will not cause

cooling system problems. A pressure cap that does

not have a history of coolant loss should not be

replaced just because it leaks slowly when tested

with this tool. Add water to tool. Turn tool upside

down and recheck pressure cap to confirm that cap

needs replacement.CLEANING

Clean the radiator pressure cap using a mild soap

and water only.

Fig. 50 Radiator Pressure Cap - Typical

1 - FILLER NECK SEAL

2 - VACUUM VENT VALVE

3 - PRESSURE RATING

4 - PRESSURE VALVE

WJENGINE 7 - 53

WATER PUMP - 4.0L (Continued)

Page 337 of 2199

INSPECTION

The following information details the recommended

inspection procedures for the battery and related

components. In addition to the maintenance sched-

ules found in this service manual and the owner's

manual, it is recommended that these procedures be

performed any time the battery or related compo-

nents must be removed for vehicle service.

(1) Inspect the battery cable terminal clamps for

damage. Replace any battery cable that has a dam-

aged or deformed terminal clamp.

(2) Inspect the battery tray and battery holddown

hardware for damage. Replace any damaged parts.

(3) Slide the thermal guard off of the battery case.

Inspect the battery case for cracks or other damage

that could result in electrolyte leaks. Also, check the

battery terminal posts for looseness. Batteries with

damaged cases or loose terminal posts must be

replaced.

(4) Inspect the battery built-in test indicator sight

glass for an indication of the battery condition. If the

battery is discharged, charge as required. Refer to

Standard Procedures for the proper battery built-in

indicator test procedures. Also refer to Standard Pro-

cedures for the proper battery charging procedures.

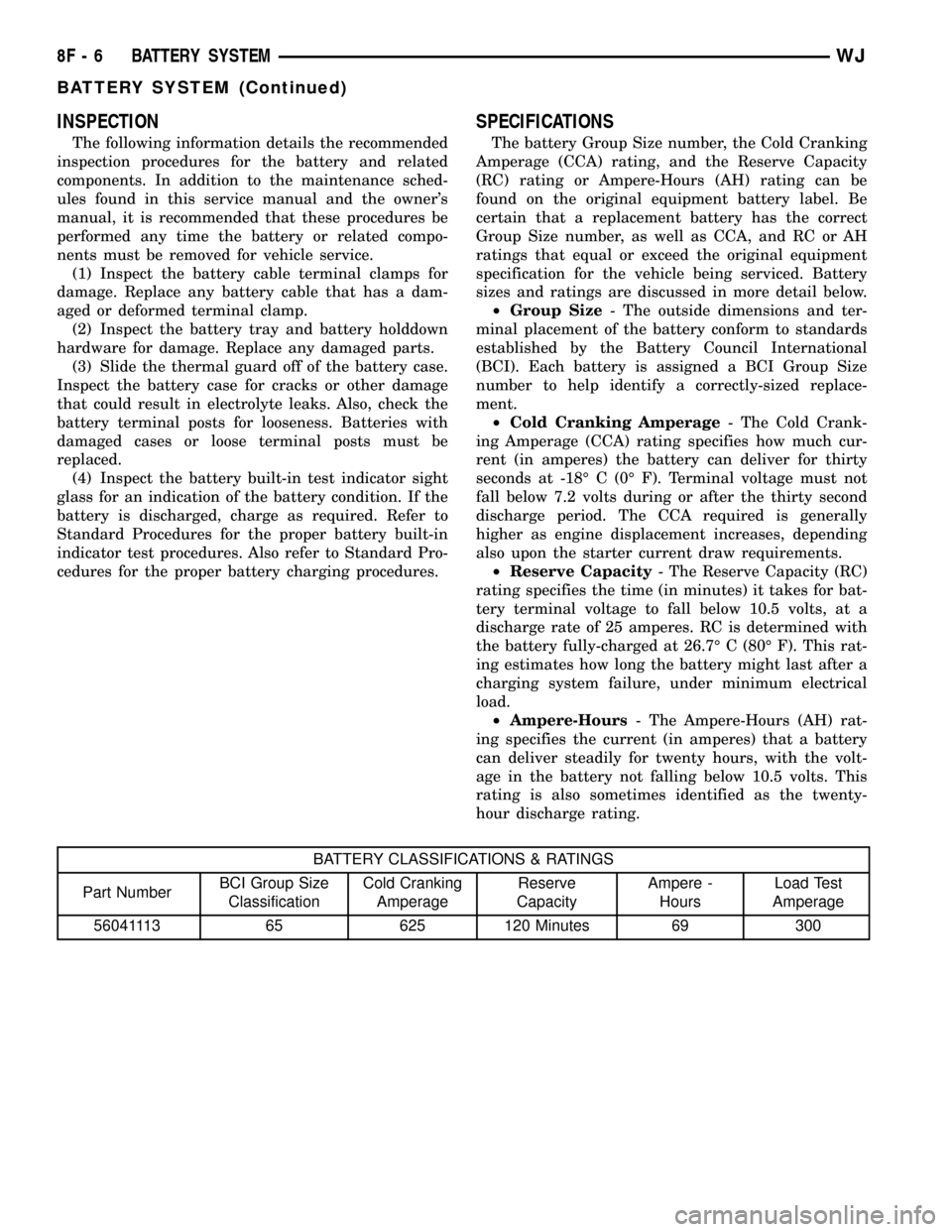

SPECIFICATIONS

The battery Group Size number, the Cold Cranking

Amperage (CCA) rating, and the Reserve Capacity

(RC) rating or Ampere-Hours (AH) rating can be

found on the original equipment battery label. Be

certain that a replacement battery has the correct

Group Size number, as well as CCA, and RC or AH

ratings that equal or exceed the original equipment

specification for the vehicle being serviced. Battery

sizes and ratings are discussed in more detail below.

²Group Size- The outside dimensions and ter-

minal placement of the battery conform to standards

established by the Battery Council International

(BCI). Each battery is assigned a BCI Group Size

number to help identify a correctly-sized replace-

ment.

²Cold Cranking Amperage- The Cold Crank-

ing Amperage (CCA) rating specifies how much cur-

rent (in amperes) the battery can deliver for thirty

seconds at -18É C (0É F). Terminal voltage must not

fall below 7.2 volts during or after the thirty second

discharge period. The CCA required is generally

higher as engine displacement increases, depending

also upon the starter current draw requirements.

²Reserve Capacity- The Reserve Capacity (RC)

rating specifies the time (in minutes) it takes for bat-

tery terminal voltage to fall below 10.5 volts, at a

discharge rate of 25 amperes. RC is determined with

the battery fully-charged at 26.7É C (80É F). This rat-

ing estimates how long the battery might last after a

charging system failure, under minimum electrical

load.

²Ampere-Hours- The Ampere-Hours (AH) rat-

ing specifies the current (in amperes) that a battery

can deliver steadily for twenty hours, with the volt-

age in the battery not falling below 10.5 volts. This

rating is also sometimes identified as the twenty-

hour discharge rating.

BATTERY CLASSIFICATIONS & RATINGS

Part NumberBCI Group Size

ClassificationCold Cranking

AmperageReserve

CapacityAmpere -

HoursLoad Test

Amperage

56041113 65 625 120 Minutes 69 300

8F - 6 BATTERY SYSTEMWJ

BATTERY SYSTEM (Continued)

Page 340 of 2199

to determine its cranking capacity. A battery that is

fully-charged, but does not pass the load test, is

faulty and must be replaced.

NOTE: Completely discharged batteries may take

several hours to accept a charge. Refer to Standard

Procedures for the proper battery charging proce-

dures.

STANDARD PROCEDURE

STANDARD PROCEDURE - BATTERY

CHARGING

Battery charging is the means by which the bat-

tery can be restored to its full voltage potential. A

battery is fully-charged when:

²Micro 420 electrical system tester indicates bat-

tery is OK.

²All of the battery cells are gassing freely during

battery charging.

²Three hydrometer tests, taken at one-hour inter-

vals, indicate no increase in the temperature-cor-

rected specific gravity of the battery electrolyte.

²Open-circuit voltage of the battery is 12.4 volts

or above.

WARNING: NEVER EXCEED TWENTY AMPERES

WHEN CHARGING A COLD (-1É C [30É F] OR

LOWER) BATTERY. THE BATTERY MAY ARC INTER-

NALLY AND EXPLODE. PERSONAL INJURY AND/OR

VEHICLE DAMAGE MAY RESULT.

WARNING: IF THE BATTERY SHOWS SIGNS OF

FREEZING, LEAKING, LOOSE POSTS, DO NOT

TEST, ASSIST-BOOST, OR CHARGE. THE BATTERY

MAY ARC INTERNALLY AND EXPLODE. PERSONAL

INJURY AND/OR VEHICLE DAMAGE MAY RESULT.

WARNING: EXPLOSIVE HYDROGEN GAS FORMS IN

AND AROUND THE BATTERY. DO NOT SMOKE,

USE FLAME, OR CREATE SPARKS NEAR THE BAT-

TERY. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT.

WARNING: THE BATTERY CONTAINS SULFURIC

ACID, WHICH IS POISONOUS AND CAUSTIC. AVOID

CONTACT WITH THE SKIN, EYES, OR CLOTHING.

IN THE EVENT OF CONTACT, FLUSH WITH WATER

AND CALL A PHYSICIAN IMMEDIATELY. KEEP OUT

OF THE REACH OF CHILDREN.WARNING: IF THE BATTERY IS EQUIPPED WITH

REMOVABLE CELL CAPS, BE CERTAIN THAT EACH

OF THE CELL CAPS IS IN PLACE AND TIGHT

BEFORE THE BATTERY IS RETURNED TO SER-

VICE. PERSONAL INJURY AND/OR VEHICLE DAM-

AGE MAY RESULT FROM LOOSE OR MISSING

CELL CAPS.

CAUTION: Always disconnect and isolate the bat-

tery negative cable before charging a battery. Do

not exceed sixteen volts while charging a battery.

Damage to the vehicle electrical system compo-

nents may result.

CAUTION: Battery electrolyte will bubble inside the

battery case during normal battery charging. Elec-

trolyte boiling or being discharged from the battery

vents indicates a battery overcharging condition.

Immediately reduce the charging rate or turn off the

charger to evaluate the battery condition. Damage

to the battery may result from overcharging.

CAUTION: The battery should not be hot to the

touch. If the battery feels hot to the touch, turn off

the charger and let the battery cool before continu-

ing the charging operation. Damage to the battery

may result.

After the battery has been charged to 12.4 volts or

greater, perform a load test to determine the battery

cranking capacity. Refer to Standard Procedures for

the proper battery load test procedures. If the battery

will endure a load test, return the battery to service.

If the battery will not endure a load test, it is faulty

and must be replaced.

Clean and inspect the battery hold downs, tray,

terminals, posts, and top before completing battery

service. Refer to Battery System Cleaning for the

proper battery system cleaning procedures, and Bat-

tery System Inspection for the proper battery system

inspection procedures.

CHARGING A COMPLETELY DISCHARGED

BATTERY

The following procedure should be used to recharge

a completely discharged battery. Unless this proce-

dure is properly followed, a good battery may be

needlessly replaced.

(1) Measure the voltage at the battery posts with a

voltmeter, accurate to 1/10 (0.10) volt (Fig. 5). If the

reading is below ten volts, the battery charging cur-

rent will be low. It could take some time before the

battery accepts a current greater than a few milliam-

peres. Such low current may not be detectable on the

ammeters built into many battery chargers.

WJBATTERY SYSTEM 8F - 9

BATTERY (Continued)

Page 342 of 2199

(2) If testing the battery IN-THE-VEHICLE, make

certain all of the vehicle accessory loads are OFF,

including the ignition.The preferred test position

is at the battery terminal. If the battery is not

accessible, you may test using both the positive and

negative jumper posts. Select TESTING AT JUMPER

POST when connecting to that location.

(3) Connect the tester (Fig. 6) to the battery or

jumper posts, the red clamp to positive (+) and the

black clamp to negative (±).

NOTE: Multiple batteries connected in parallel must

have the ground cable disconnected to perform a

battery test. Failure to disconnect may result in

false battery test readings.

(4) Using the ARROW key selectinoroutof vehi-

cle testing and press ENTER to make a selection.

(5) If not selected, choose the Cold Cranking Amp

(CCA) battery rating. Or select the appropriate bat-

tery rating for your area (see menu). The tester will

then run its self programmed test of the battery and

display the results. Refer to the test result table

noted below.

CAUTION: If REPLACE BATTERY is the result of the

test, this may mean a poor connection between the

vehicle's cables and battery exists. After discon-

necting the vehicle's battery cables from the bat-

tery, retest the battery using the OUT-OF-VEHICLE

test before replacing.(6) While viewing the battery test result, press the

CODE button and the tester will prompt you for the

last 4 digits of the VIN. Use the UP/DOWN arrow

buttons to scroll to the correct character; then press

ENTER to select and move to the next digit. Then

press the ENTER button to view the SERVICE

CODE. Pressing the CODE button a second time will

return you to the test results.

BATTERY TEST RESULTS

GOOD BATTERY Return to service

GOOD - RECHARGE Fully charge battery and

return to service

CHARGE & RETEST Fully charge battery and

retest battery

REPLACE BATTERY Replace the battery and

retest complete system

BAD-CELL REPLACE Replace the battery and

retest complete system

NOTE: The SERVICE CODE is required on every

warranty claim submitted for battery replacement.

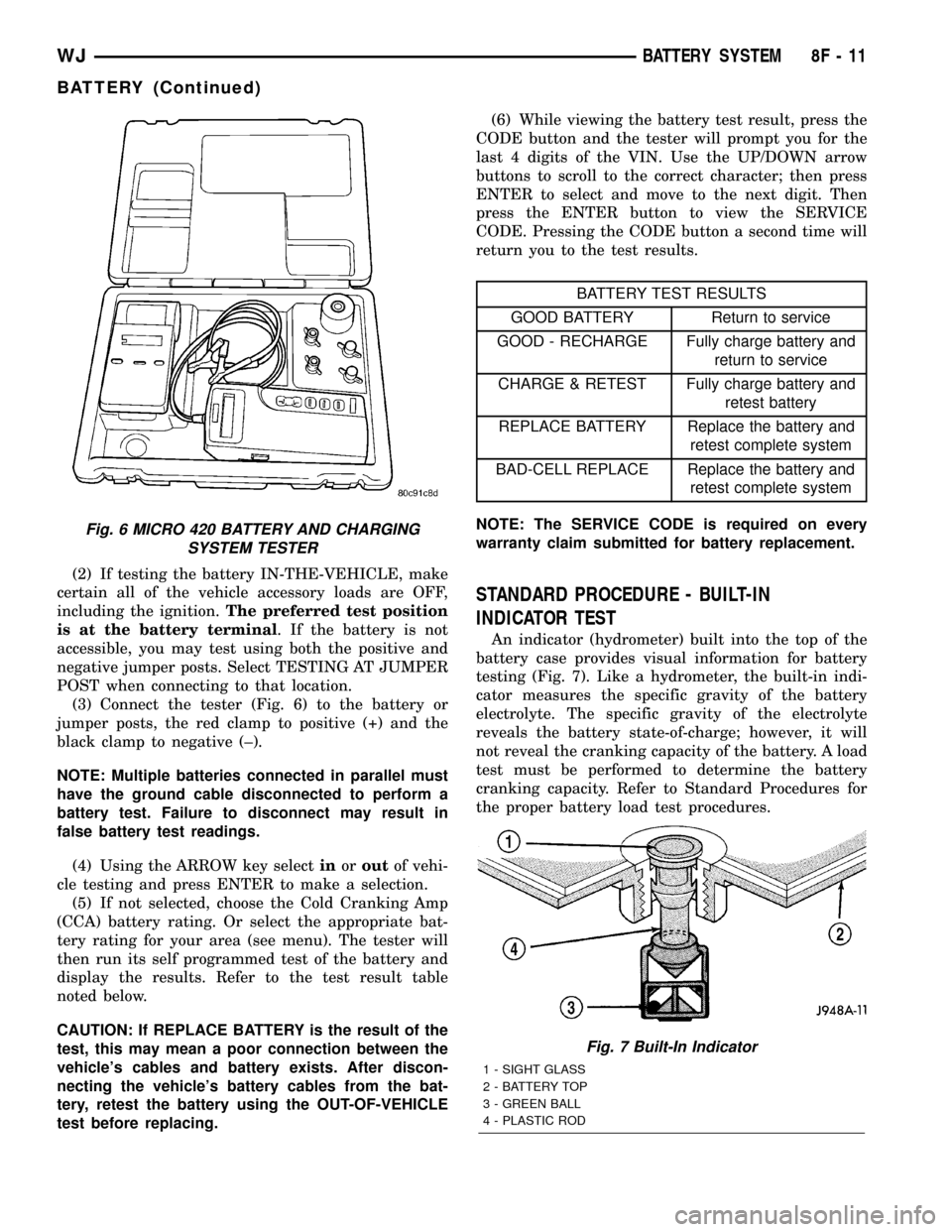

STANDARD PROCEDURE - BUILT-IN

INDICATOR TEST

An indicator (hydrometer) built into the top of the

battery case provides visual information for battery

testing (Fig. 7). Like a hydrometer, the built-in indi-

cator measures the specific gravity of the battery

electrolyte. The specific gravity of the electrolyte

reveals the battery state-of-charge; however, it will

not reveal the cranking capacity of the battery. A load

test must be performed to determine the battery

cranking capacity. Refer to Standard Procedures for

the proper battery load test procedures.

Fig. 6 MICRO 420 BATTERY AND CHARGING

SYSTEM TESTER

Fig. 7 Built-In Indicator

1 - SIGHT GLASS

2 - BATTERY TOP

3 - GREEN BALL

4 - PLASTIC ROD

WJBATTERY SYSTEM 8F - 11

BATTERY (Continued)

Page 343 of 2199

Before testing, visually inspect the battery for any

damage (a cracked case or cover, loose posts, etc.)

that would cause the battery to be faulty. In order to

obtain correct indications from the built-in indicator,

it is important that the battery be level and have a

clean sight glass. Additional light may be required to

view the indicator.Do not use open flame as a

source of additional light.

To read the built-in indicator, look into the sight

glass and note the color of the indication (Fig. 8). The

battery condition that each color indicates is

described in the following list:

²Green- Indicates 75% to 100% battery state-of-

charge. The battery is adequately charged for further

testing or return to service. If the starter will not

crank for a minimum of fifteen seconds with a fully-

charged battery, the battery must be load tested.

Refer to Standard Procedures for the proper battery

load test procedures.

²Black or Dark- Indicates 0% to 75% battery

state-of-charge. The battery is inadequately charged

and must be charged until a green indication is visi-

ble in the sight glass (12.4 volts or more), before the

battery is tested further or returned to service. Refer

to Standard Procedures for the proper battery charg-

ing procedures. Also refer to Diagnosis and Testing

for more information on the possible causes of the

discharged battery condition.

²Clear or Bright- Indicates a low battery elec-

trolyte level. The electrolyte level in the battery is

below the built-in indicator. A maintenance-free bat-

tery with non-removable cell caps must be replaced if

the electrolyte level is low. Water must be added to a

low-maintenance battery with removable cell caps

before it is charged. Refer to Standard Procedures for

the proper battery filling procedures. A low electro-

lyte level may be caused by an overcharging condi-

tion. Refer to Charging System for the proper

charging system diagnosis and testing procedures.STANDARD PROCEDURE - OPEN-CIRCUIT

VOLTAGE TEST

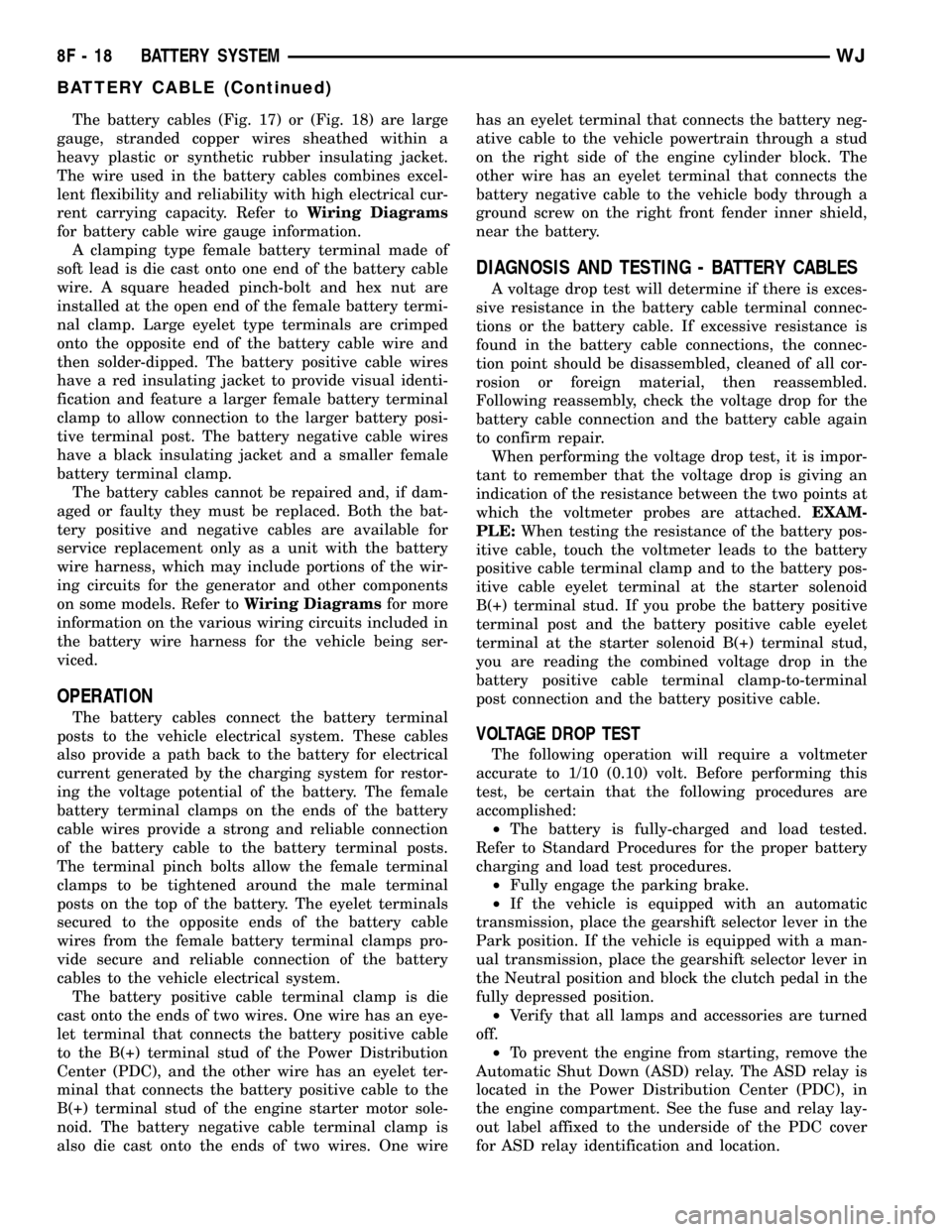

A battery open-circuit voltage (no load) test will

show the approximate state-of-charge of a battery.

This test can be used in place of the hydrometer test

when a hydrometer is not available, or for mainte-

nance-free batteries with non-removable cell caps.

Before proceeding with this test, completely charge

the battery (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM/BATTERY - STANDARD PROCEDURE).

(1) Before measuring the open-circuit voltage, the

surface charge must be removed from the battery.

Turn on the headlamps for fifteen seconds, then

allow up to five minutes for the battery voltage to

stabilize.

(2) Disconnect and isolate both battery cables, neg-

ative cable first.

(3) Using a voltmeter connected to the battery

posts (see the instructions provided by the manufac-

turer of the voltmeter), measure the open-circuit volt-

age (Fig. 9).

See the Open-Circuit Voltage Table. This voltage

reading will indicate the battery state-of-charge, but

will not reveal its cranking capacity. If a battery has

an open-circuit voltage reading of 12.4 volts or

greater, it may be load tested to reveal its cranking

capacity (Refer to 8 - ELECTRICAL/BATTERY SYS-

TEM/BATTERY - STANDARD PROCEDURE).

OPEN CIRCUIT VOLTAGE TABLE

Open Circuit Voltage Charge Percentage

11.7 volts or less 0%

12.0 volts 25%

12.2 volts 50%

12.4 volts 75%

12.6 volts or more 100%

Fig. 8 Built-In Indicator Sight Glass Chart

Fig. 9 Testing Open-Circuit Voltage - Typical

8F - 12 BATTERY SYSTEMWJ

BATTERY (Continued)

Page 349 of 2199

The battery cables (Fig. 17) or (Fig. 18) are large

gauge, stranded copper wires sheathed within a

heavy plastic or synthetic rubber insulating jacket.

The wire used in the battery cables combines excel-

lent flexibility and reliability with high electrical cur-

rent carrying capacity. Refer toWiring Diagrams

for battery cable wire gauge information.

A clamping type female battery terminal made of

soft lead is die cast onto one end of the battery cable

wire. A square headed pinch-bolt and hex nut are

installed at the open end of the female battery termi-

nal clamp. Large eyelet type terminals are crimped

onto the opposite end of the battery cable wire and

then solder-dipped. The battery positive cable wires

have a red insulating jacket to provide visual identi-

fication and feature a larger female battery terminal

clamp to allow connection to the larger battery posi-

tive terminal post. The battery negative cable wires

have a black insulating jacket and a smaller female

battery terminal clamp.

The battery cables cannot be repaired and, if dam-

aged or faulty they must be replaced. Both the bat-

tery positive and negative cables are available for

service replacement only as a unit with the battery

wire harness, which may include portions of the wir-

ing circuits for the generator and other components

on some models. Refer toWiring Diagramsfor more

information on the various wiring circuits included in

the battery wire harness for the vehicle being ser-

viced.

OPERATION

The battery cables connect the battery terminal

posts to the vehicle electrical system. These cables

also provide a path back to the battery for electrical

current generated by the charging system for restor-

ing the voltage potential of the battery. The female

battery terminal clamps on the ends of the battery

cable wires provide a strong and reliable connection

of the battery cable to the battery terminal posts.

The terminal pinch bolts allow the female terminal

clamps to be tightened around the male terminal

posts on the top of the battery. The eyelet terminals

secured to the opposite ends of the battery cable

wires from the female battery terminal clamps pro-

vide secure and reliable connection of the battery

cables to the vehicle electrical system.

The battery positive cable terminal clamp is die

cast onto the ends of two wires. One wire has an eye-

let terminal that connects the battery positive cable

to the B(+) terminal stud of the Power Distribution

Center (PDC), and the other wire has an eyelet ter-

minal that connects the battery positive cable to the

B(+) terminal stud of the engine starter motor sole-

noid. The battery negative cable terminal clamp is

also die cast onto the ends of two wires. One wirehas an eyelet terminal that connects the battery neg-

ative cable to the vehicle powertrain through a stud

on the right side of the engine cylinder block. The

other wire has an eyelet terminal that connects the

battery negative cable to the vehicle body through a

ground screw on the right front fender inner shield,

near the battery.

DIAGNOSIS AND TESTING - BATTERY CABLES

A voltage drop test will determine if there is exces-

sive resistance in the battery cable terminal connec-

tions or the battery cable. If excessive resistance is

found in the battery cable connections, the connec-

tion point should be disassembled, cleaned of all cor-

rosion or foreign material, then reassembled.

Following reassembly, check the voltage drop for the

battery cable connection and the battery cable again

to confirm repair.

When performing the voltage drop test, it is impor-

tant to remember that the voltage drop is giving an

indication of the resistance between the two points at

which the voltmeter probes are attached.EXAM-

PLE:When testing the resistance of the battery pos-

itive cable, touch the voltmeter leads to the battery

positive cable terminal clamp and to the battery pos-

itive cable eyelet terminal at the starter solenoid

B(+) terminal stud. If you probe the battery positive

terminal post and the battery positive cable eyelet

terminal at the starter solenoid B(+) terminal stud,

you are reading the combined voltage drop in the

battery positive cable terminal clamp-to-terminal

post connection and the battery positive cable.

VOLTAGE DROP TEST

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing this

test, be certain that the following procedures are

accomplished:

²The battery is fully-charged and load tested.

Refer to Standard Procedures for the proper battery

charging and load test procedures.

²Fully engage the parking brake.

²If the vehicle is equipped with an automatic

transmission, place the gearshift selector lever in the

Park position. If the vehicle is equipped with a man-

ual transmission, place the gearshift selector lever in

the Neutral position and block the clutch pedal in the

fully depressed position.

²Verify that all lamps and accessories are turned

off.

²To prevent the engine from starting, remove the

Automatic Shut Down (ASD) relay. The ASD relay is

located in the Power Distribution Center (PDC), in

the engine compartment. See the fuse and relay lay-

out label affixed to the underside of the PDC cover

for ASD relay identification and location.

8F - 18 BATTERY SYSTEMWJ

BATTERY CABLE (Continued)

Page 363 of 2199

INSPECTION

For complete circuit diagrams, refer toStarting

Systemin the Contents of Group 8W - Wiring Dia-

grams. Before removing any unit from the starting

system for repair or diagnosis, perform the following

inspections:

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

²Battery- Visually inspect the battery for indi-

cations of physical damage and loose or corroded

cable connections. Determine the state-of-charge and

cranking capacity of the battery. Charge or replace

the battery, if required. Refer toBatteryin the

proper section of Group 8A - Battery for complete ser-

vice information for the battery.

²Ignition Switch- Visually inspect the ignition

switch for indications of physical damage and loose

or corroded wire harness connections. Refer toIgni-

tion Switch and Key Lock Cylinderin the proper

section of Group 8D - Ignition System for complete

service information for the ignition switch.

²Park/Neutral Position Switch- Visually

inspect the park/neutral position switch for indica-

tions of physical damage and loose or corroded wire

harness connections. Refer toPark/Neutral Posi-

tion Switchin the proper section of Group 21 -

Transmission for complete service information for the

park/neutral position switch.

²Starter Relay- Visually inspect the starter

relay for indications of physical damage and loose or

corroded wire harness connections.

²Starter Motor- Visually inspect the starter

motor for indications of physical damage and loose or

corroded wire harness connections.

²Starter Solenoid- Visually inspect the starter

solenoid for indications of physical damage and loose

or corroded wire harness connections.

²Wiring- Visually inspect the wire harnesses for

damage. Repair or replace any faulty wiring, as

required. Refer to the proper section ofGroup 8W -

Wiring Diagramsfor complete service information

and circuit diagrams for the starting system wiring

components.TESTING

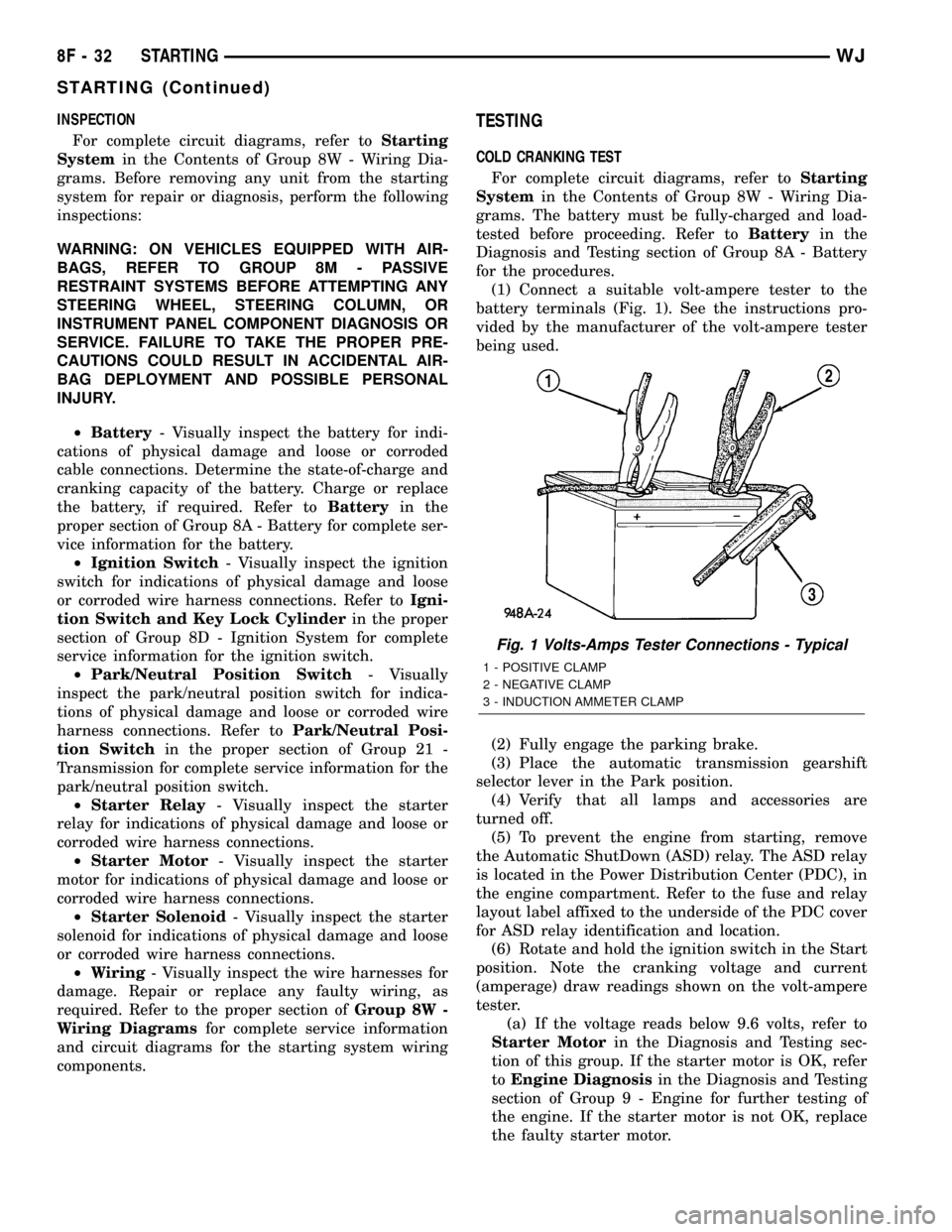

COLD CRANKING TEST

For complete circuit diagrams, refer toStarting

Systemin the Contents of Group 8W - Wiring Dia-

grams. The battery must be fully-charged and load-

tested before proceeding. Refer toBatteryin the

Diagnosis and Testing section of Group 8A - Battery

for the procedures.

(1) Connect a suitable volt-ampere tester to the

battery terminals (Fig. 1). See the instructions pro-

vided by the manufacturer of the volt-ampere tester

being used.

(2) Fully engage the parking brake.

(3) Place the automatic transmission gearshift

selector lever in the Park position.

(4) Verify that all lamps and accessories are

turned off.

(5) To prevent the engine from starting, remove

the Automatic ShutDown (ASD) relay. The ASD relay

is located in the Power Distribution Center (PDC), in

the engine compartment. Refer to the fuse and relay

layout label affixed to the underside of the PDC cover

for ASD relay identification and location.

(6) Rotate and hold the ignition switch in the Start

position. Note the cranking voltage and current

(amperage) draw readings shown on the volt-ampere

tester.

(a) If the voltage reads below 9.6 volts, refer to

Starter Motorin the Diagnosis and Testing sec-

tion of this group. If the starter motor is OK, refer

toEngine Diagnosisin the Diagnosis and Testing

section of Group 9 - Engine for further testing of

the engine. If the starter motor is not OK, replace

the faulty starter motor.

Fig. 1 Volts-Amps Tester Connections - Typical

1 - POSITIVE CLAMP

2 - NEGATIVE CLAMP

3 - INDUCTION AMMETER CLAMP

8F - 32 STARTINGWJ

STARTING (Continued)

Page 1866 of 2199

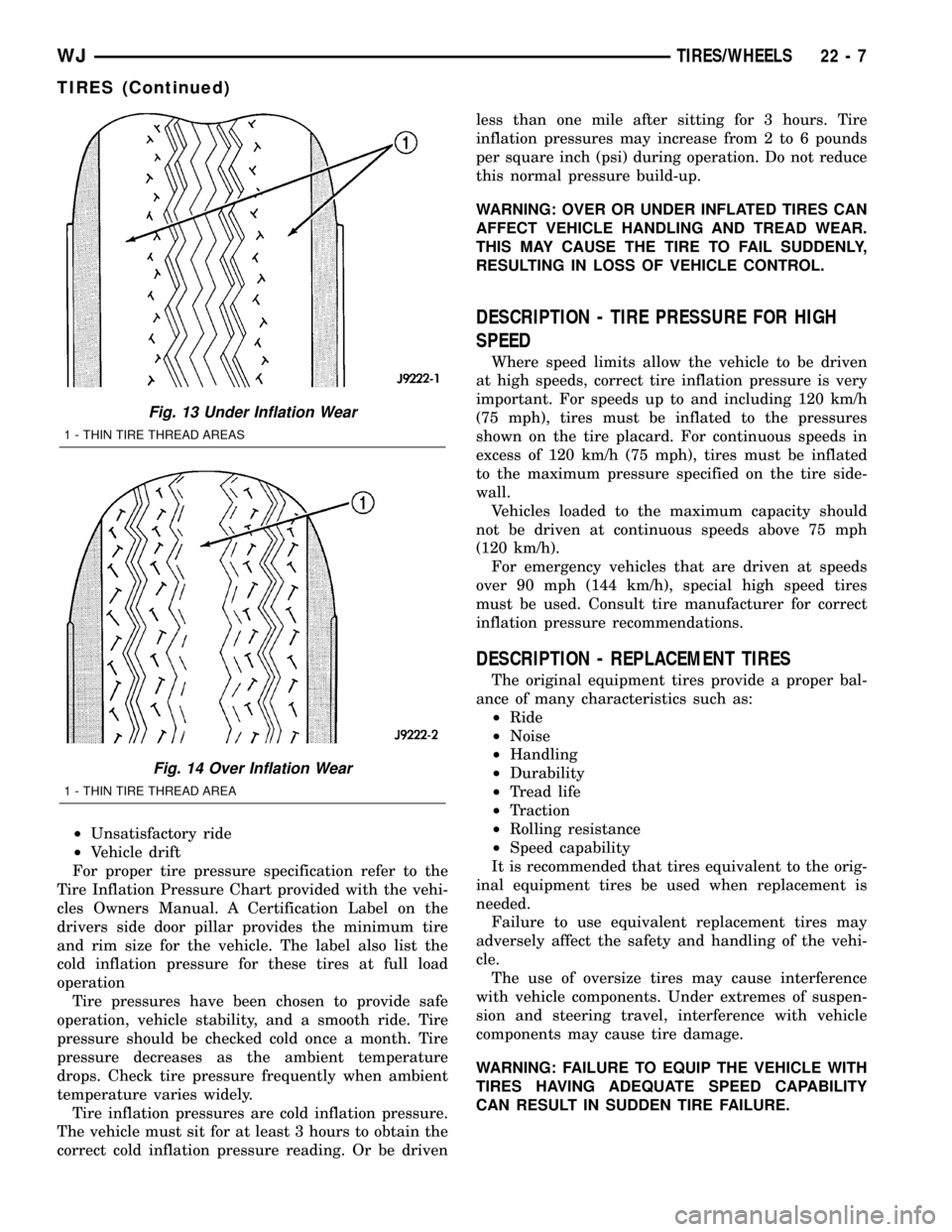

²Unsatisfactory ride

²Vehicle drift

For proper tire pressure specification refer to the

Tire Inflation Pressure Chart provided with the vehi-

cles Owners Manual. A Certification Label on the

drivers side door pillar provides the minimum tire

and rim size for the vehicle. The label also list the

cold inflation pressure for these tires at full load

operation

Tire pressures have been chosen to provide safe

operation, vehicle stability, and a smooth ride. Tire

pressure should be checked cold once a month. Tire

pressure decreases as the ambient temperature

drops. Check tire pressure frequently when ambient

temperature varies widely.

Tire inflation pressures are cold inflation pressure.

The vehicle must sit for at least 3 hours to obtain the

correct cold inflation pressure reading. Or be drivenless than one mile after sitting for 3 hours. Tire

inflation pressures may increase from 2 to 6 pounds

per square inch (psi) during operation. Do not reduce

this normal pressure build-up.

WARNING: OVER OR UNDER INFLATED TIRES CAN

AFFECT VEHICLE HANDLING AND TREAD WEAR.

THIS MAY CAUSE THE TIRE TO FAIL SUDDENLY,

RESULTING IN LOSS OF VEHICLE CONTROL.

DESCRIPTION - TIRE PRESSURE FOR HIGH

SPEED

Where speed limits allow the vehicle to be driven

at high speeds, correct tire inflation pressure is very

important. For speeds up to and including 120 km/h

(75 mph), tires must be inflated to the pressures

shown on the tire placard. For continuous speeds in

excess of 120 km/h (75 mph), tires must be inflated

to the maximum pressure specified on the tire side-

wall.

Vehicles loaded to the maximum capacity should

not be driven at continuous speeds above 75 mph

(120 km/h).

For emergency vehicles that are driven at speeds

over 90 mph (144 km/h), special high speed tires

must be used. Consult tire manufacturer for correct

inflation pressure recommendations.

DESCRIPTION - REPLACEMENT TIRES

The original equipment tires provide a proper bal-

ance of many characteristics such as:

²Ride

²Noise

²Handling

²Durability

²Tread life

²Traction

²Rolling resistance

²Speed capability

It is recommended that tires equivalent to the orig-

inal equipment tires be used when replacement is

needed.

Failure to use equivalent replacement tires may

adversely affect the safety and handling of the vehi-

cle.

The use of oversize tires may cause interference

with vehicle components. Under extremes of suspen-

sion and steering travel, interference with vehicle

components may cause tire damage.

WARNING: FAILURE TO EQUIP THE VEHICLE WITH

TIRES HAVING ADEQUATE SPEED CAPABILITY

CAN RESULT IN SUDDEN TIRE FAILURE.

Fig. 13 Under Inflation Wear

1 - THIN TIRE THREAD AREAS

Fig. 14 Over Inflation Wear

1 - THIN TIRE THREAD AREA

WJTIRES/WHEELS 22 - 7

TIRES (Continued)

Page 1869 of 2199

SPARE TIRE

DESCRIPTION - SPARE / TEMPORARY TIRE

The temporary spare tire is designed for emer-

gency use only. The original tire should be repaired

or replaced at the first opportunity, then reinstalled.

Do not exceed speeds of 50 M.P.H. when using the

temporary spare tire. Refer to Owner's Manual for

complete details.

WHEELS

DESCRIPTION

The rim size is on the vehicle safety certification

label located on the drivers door shut face. The size

of the rim is determined by the drivetrain package.

Original equipment wheels/rims are designed for

operation up to the specified maximum vehicle capac-

ity.

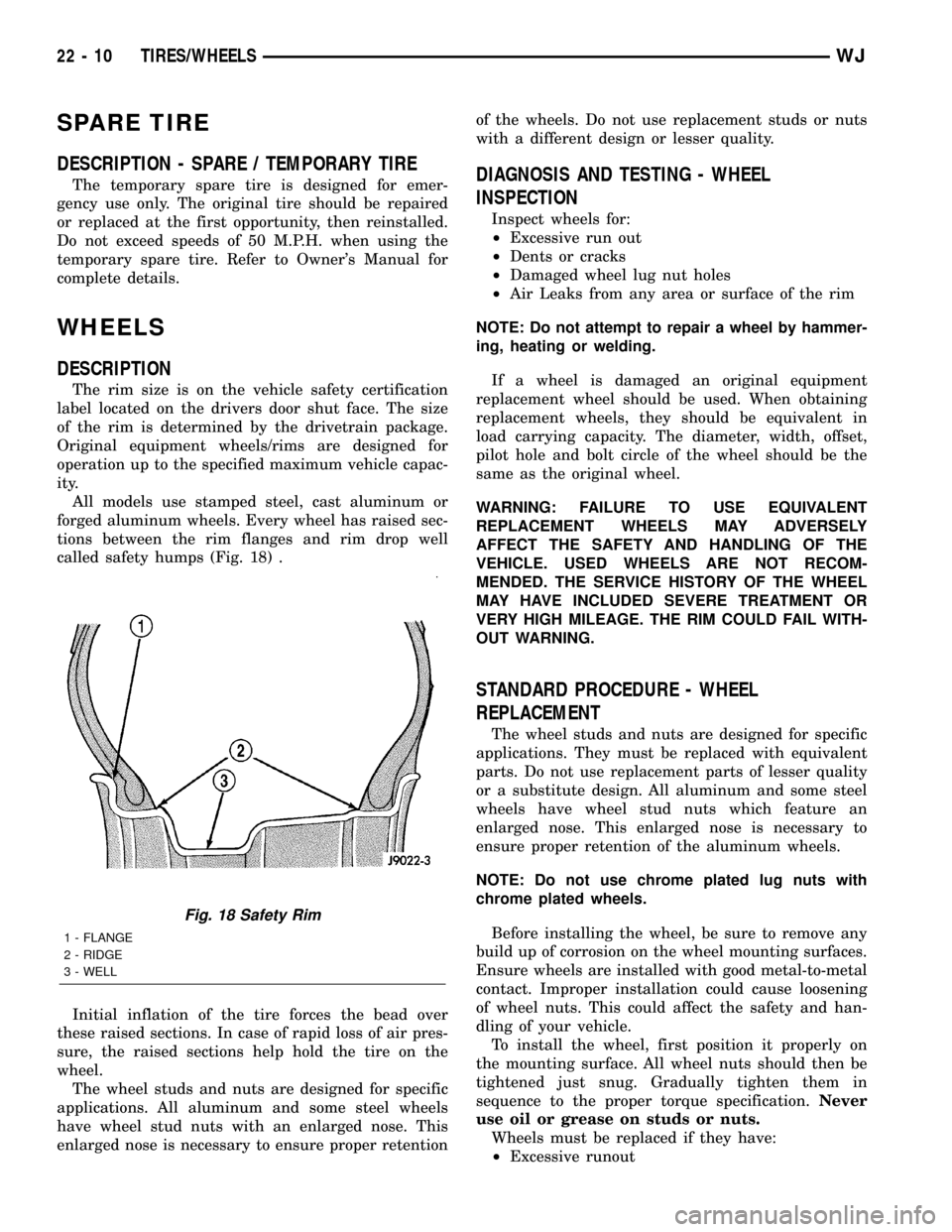

All models use stamped steel, cast aluminum or

forged aluminum wheels. Every wheel has raised sec-

tions between the rim flanges and rim drop well

called safety humps (Fig. 18) .

Initial inflation of the tire forces the bead over

these raised sections. In case of rapid loss of air pres-

sure, the raised sections help hold the tire on the

wheel.

The wheel studs and nuts are designed for specific

applications. All aluminum and some steel wheels

have wheel stud nuts with an enlarged nose. This

enlarged nose is necessary to ensure proper retentionof the wheels. Do not use replacement studs or nuts

with a different design or lesser quality.

DIAGNOSIS AND TESTING - WHEEL

INSPECTION

Inspect wheels for:

²Excessive run out

²Dents or cracks

²Damaged wheel lug nut holes

²Air Leaks from any area or surface of the rim

NOTE: Do not attempt to repair a wheel by hammer-

ing, heating or welding.

If a wheel is damaged an original equipment

replacement wheel should be used. When obtaining

replacement wheels, they should be equivalent in

load carrying capacity. The diameter, width, offset,

pilot hole and bolt circle of the wheel should be the

same as the original wheel.

WARNING: FAILURE TO USE EQUIVALENT

REPLACEMENT WHEELS MAY ADVERSELY

AFFECT THE SAFETY AND HANDLING OF THE

VEHICLE. USED WHEELS ARE NOT RECOM-

MENDED. THE SERVICE HISTORY OF THE WHEEL

MAY HAVE INCLUDED SEVERE TREATMENT OR

VERY HIGH MILEAGE. THE RIM COULD FAIL WITH-

OUT WARNING.

STANDARD PROCEDURE - WHEEL

REPLACEMENT

The wheel studs and nuts are designed for specific

applications. They must be replaced with equivalent

parts. Do not use replacement parts of lesser quality

or a substitute design. All aluminum and some steel

wheels have wheel stud nuts which feature an

enlarged nose. This enlarged nose is necessary to

ensure proper retention of the aluminum wheels.

NOTE: Do not use chrome plated lug nuts with

chrome plated wheels.

Before installing the wheel, be sure to remove any

build up of corrosion on the wheel mounting surfaces.

Ensure wheels are installed with good metal-to-metal

contact. Improper installation could cause loosening

of wheel nuts. This could affect the safety and han-

dling of your vehicle.

To install the wheel, first position it properly on

the mounting surface. All wheel nuts should then be

tightened just snug. Gradually tighten them in

sequence to the proper torque specification.Never

use oil or grease on studs or nuts.

Wheels must be replaced if they have:

²Excessive runout

Fig. 18 Safety Rim

1 - FLANGE

2 - RIDGE

3 - WELL

22 - 10 TIRES/WHEELSWJ

Page 1870 of 2199

²Bent or dented

²Leak air through welds

²Have damaged bolt holes

Wheel repairs employing hammering, heating, or

welding are not allowed.

Original equipment wheels are available through

your dealer. Replacement wheels from any other

source should be equivalent in:

²Load carrying capacity

²Diameter

²Width²Offset

²Mounting configuration

Failure to use equivalent replacement wheels may

affect the safety and handling of your vehicle.

Replacement withusedwheels is not recommended.

Their service history may have included severe treat-

ment.

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Lug Nut

1/2 X 20 with 60É Cone115-150 85-115 Ð

STUDS

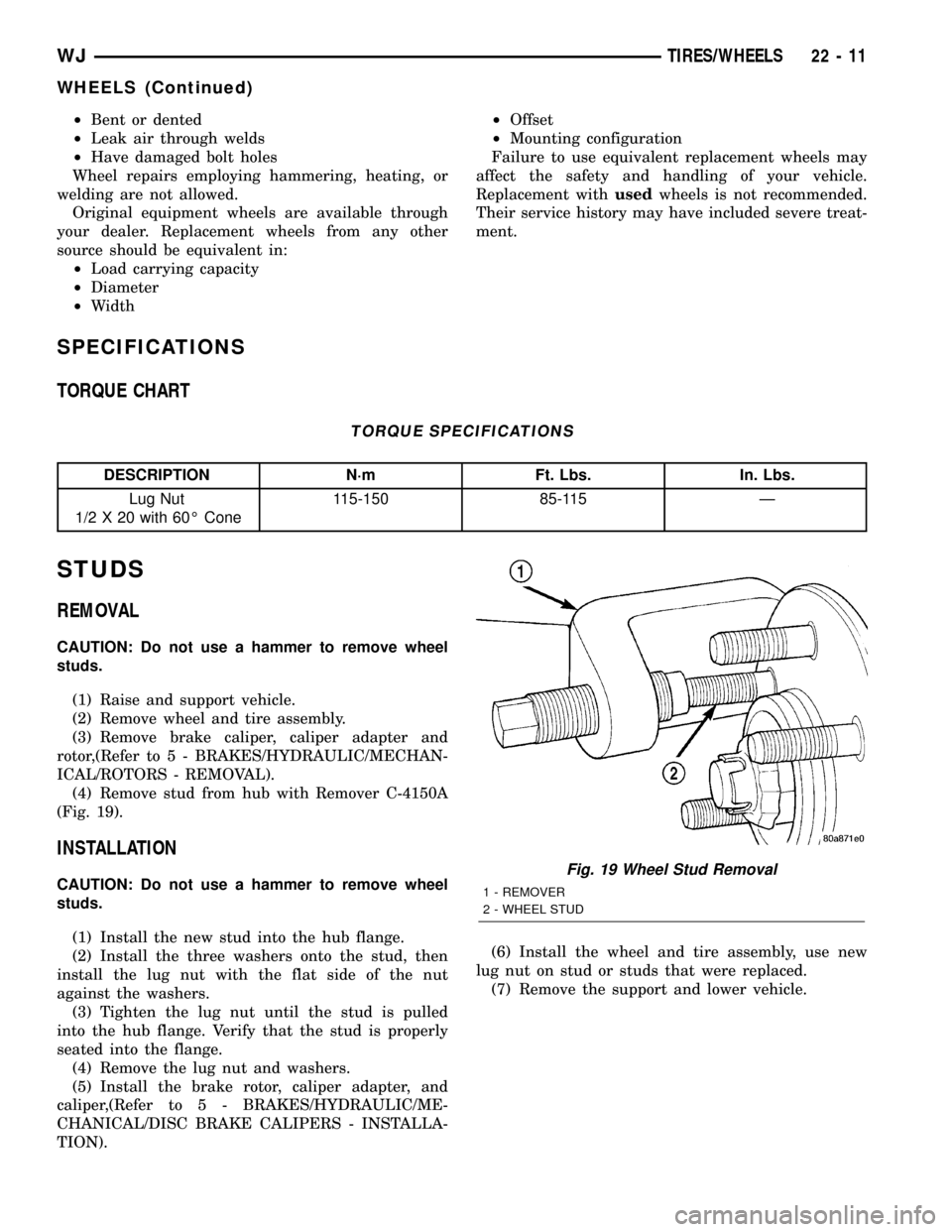

REMOVAL

CAUTION: Do not use a hammer to remove wheel

studs.

(1) Raise and support vehicle.

(2) Remove wheel and tire assembly.

(3) Remove brake caliper, caliper adapter and

rotor,(Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/ROTORS - REMOVAL).

(4) Remove stud from hub with Remover C-4150A

(Fig. 19).

INSTALLATION

CAUTION: Do not use a hammer to remove wheel

studs.

(1) Install the new stud into the hub flange.

(2) Install the three washers onto the stud, then

install the lug nut with the flat side of the nut

against the washers.

(3) Tighten the lug nut until the stud is pulled

into the hub flange. Verify that the stud is properly

seated into the flange.

(4) Remove the lug nut and washers.

(5) Install the brake rotor, caliper adapter, and

caliper,(Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/DISC BRAKE CALIPERS - INSTALLA-

TION).(6) Install the wheel and tire assembly, use new

lug nut on stud or studs that were replaced.

(7) Remove the support and lower vehicle.Fig. 19 Wheel Stud Removal

1 - REMOVER

2 - WHEEL STUD

WJTIRES/WHEELS 22 - 11

WHEELS (Continued)