spot JEEP GRAND CHEROKEE 2002 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2002, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2002 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 64 of 2199

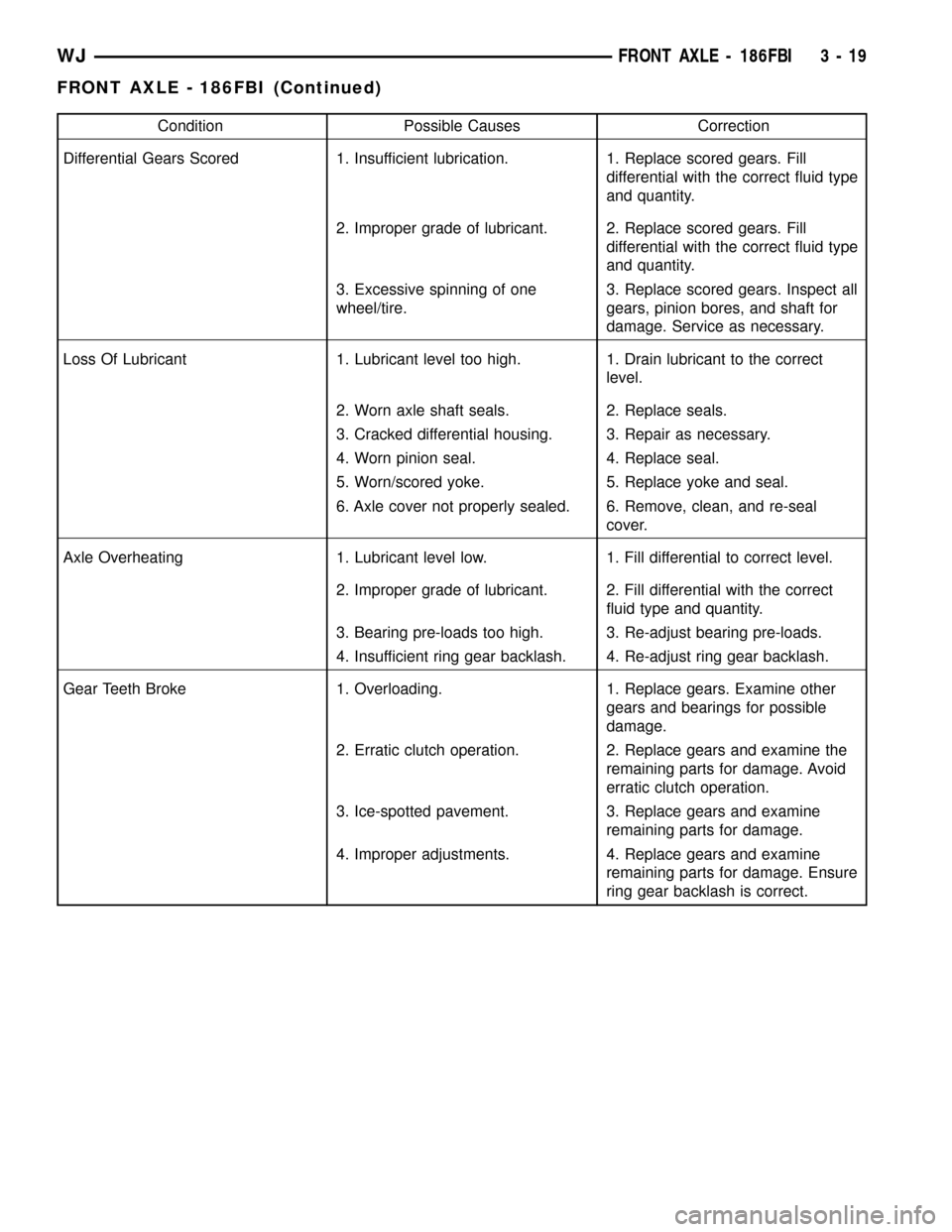

Condition Possible Causes Correction

Differential Gears Scored 1. Insufficient lubrication. 1. Replace scored gears. Fill

differential with the correct fluid type

and quantity.

2. Improper grade of lubricant. 2. Replace scored gears. Fill

differential with the correct fluid type

and quantity.

3. Excessive spinning of one

wheel/tire.3. Replace scored gears. Inspect all

gears, pinion bores, and shaft for

damage. Service as necessary.

Loss Of Lubricant 1. Lubricant level too high. 1. Drain lubricant to the correct

level.

2. Worn axle shaft seals. 2. Replace seals.

3. Cracked differential housing. 3. Repair as necessary.

4. Worn pinion seal. 4. Replace seal.

5. Worn/scored yoke. 5. Replace yoke and seal.

6. Axle cover not properly sealed. 6. Remove, clean, and re-seal

cover.

Axle Overheating 1. Lubricant level low. 1. Fill differential to correct level.

2. Improper grade of lubricant. 2. Fill differential with the correct

fluid type and quantity.

3. Bearing pre-loads too high. 3. Re-adjust bearing pre-loads.

4. Insufficient ring gear backlash. 4. Re-adjust ring gear backlash.

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

WJFRONT AXLE - 186FBI 3 - 19

FRONT AXLE - 186FBI (Continued)

Page 99 of 2199

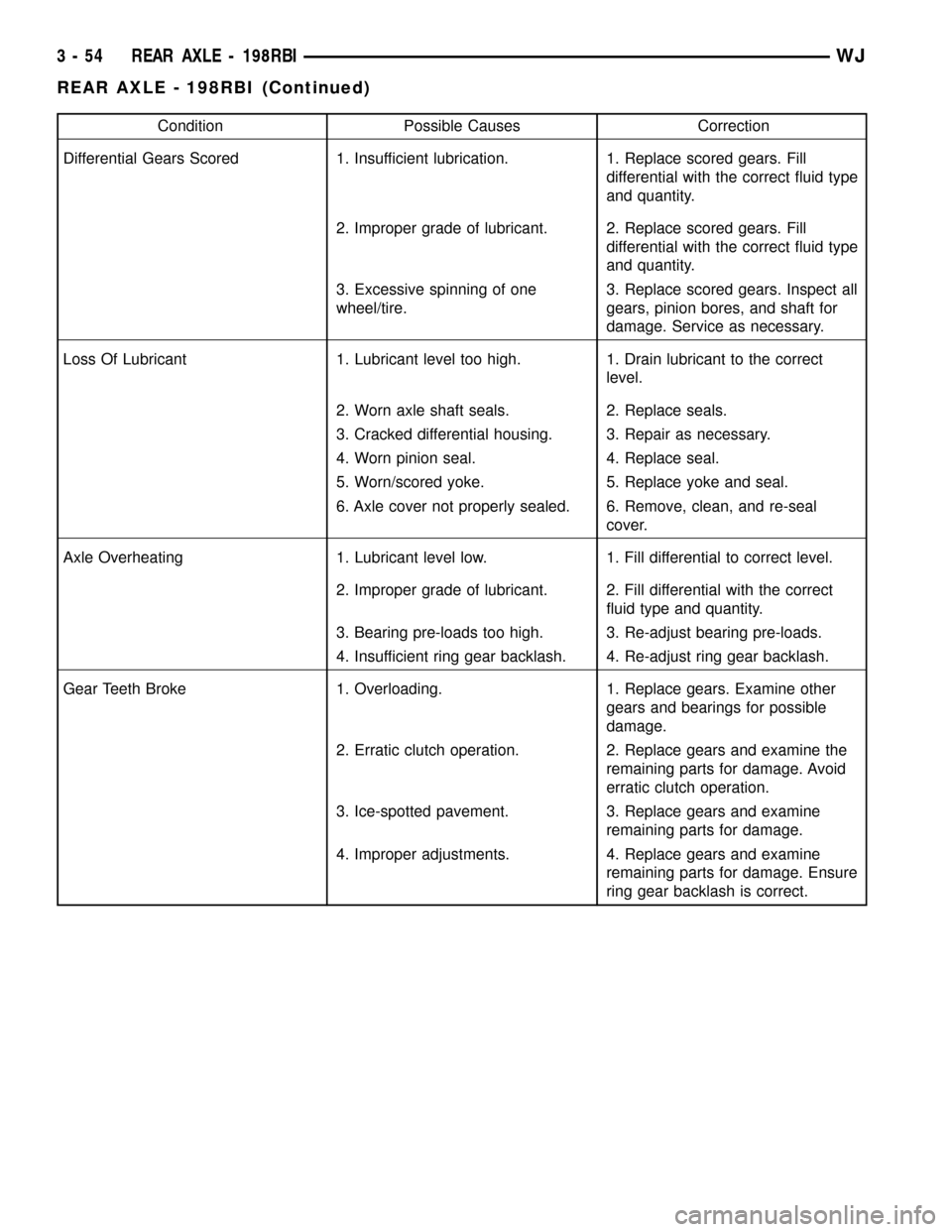

Condition Possible Causes Correction

Differential Gears Scored 1. Insufficient lubrication. 1. Replace scored gears. Fill

differential with the correct fluid type

and quantity.

2. Improper grade of lubricant. 2. Replace scored gears. Fill

differential with the correct fluid type

and quantity.

3. Excessive spinning of one

wheel/tire.3. Replace scored gears. Inspect all

gears, pinion bores, and shaft for

damage. Service as necessary.

Loss Of Lubricant 1. Lubricant level too high. 1. Drain lubricant to the correct

level.

2. Worn axle shaft seals. 2. Replace seals.

3. Cracked differential housing. 3. Repair as necessary.

4. Worn pinion seal. 4. Replace seal.

5. Worn/scored yoke. 5. Replace yoke and seal.

6. Axle cover not properly sealed. 6. Remove, clean, and re-seal

cover.

Axle Overheating 1. Lubricant level low. 1. Fill differential to correct level.

2. Improper grade of lubricant. 2. Fill differential with the correct

fluid type and quantity.

3. Bearing pre-loads too high. 3. Re-adjust bearing pre-loads.

4. Insufficient ring gear backlash. 4. Re-adjust ring gear backlash.

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

3 - 54 REAR AXLE - 198RBIWJ

REAR AXLE - 198RBI (Continued)

Page 140 of 2199

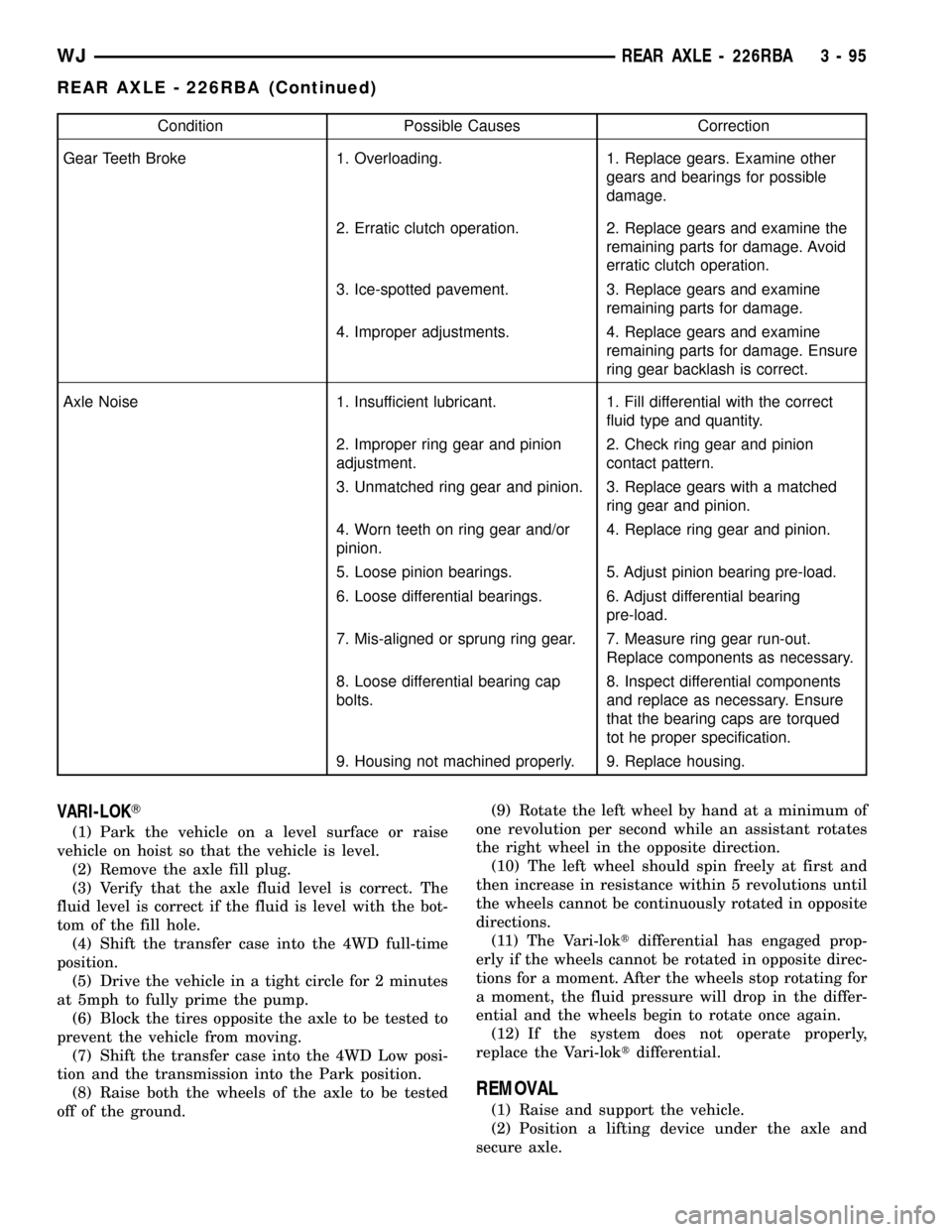

Condition Possible Causes Correction

Gear Teeth Broke 1. Overloading. 1. Replace gears. Examine other

gears and bearings for possible

damage.

2. Erratic clutch operation. 2. Replace gears and examine the

remaining parts for damage. Avoid

erratic clutch operation.

3. Ice-spotted pavement. 3. Replace gears and examine

remaining parts for damage.

4. Improper adjustments. 4. Replace gears and examine

remaining parts for damage. Ensure

ring gear backlash is correct.

Axle Noise 1. Insufficient lubricant. 1. Fill differential with the correct

fluid type and quantity.

2. Improper ring gear and pinion

adjustment.2. Check ring gear and pinion

contact pattern.

3. Unmatched ring gear and pinion. 3. Replace gears with a matched

ring gear and pinion.

4. Worn teeth on ring gear and/or

pinion.4. Replace ring gear and pinion.

5. Loose pinion bearings. 5. Adjust pinion bearing pre-load.

6. Loose differential bearings. 6. Adjust differential bearing

pre-load.

7. Mis-aligned or sprung ring gear. 7. Measure ring gear run-out.

Replace components as necessary.

8. Loose differential bearing cap

bolts.8. Inspect differential components

and replace as necessary. Ensure

that the bearing caps are torqued

tot he proper specification.

9. Housing not machined properly. 9. Replace housing.

VARI-LOKT

(1) Park the vehicle on a level surface or raise

vehicle on hoist so that the vehicle is level.

(2) Remove the axle fill plug.

(3) Verify that the axle fluid level is correct. The

fluid level is correct if the fluid is level with the bot-

tom of the fill hole.

(4) Shift the transfer case into the 4WD full-time

position.

(5) Drive the vehicle in a tight circle for 2 minutes

at 5mph to fully prime the pump.

(6) Block the tires opposite the axle to be tested to

prevent the vehicle from moving.

(7) Shift the transfer case into the 4WD Low posi-

tion and the transmission into the Park position.

(8) Raise both the wheels of the axle to be tested

off of the ground.(9) Rotate the left wheel by hand at a minimum of

one revolution per second while an assistant rotates

the right wheel in the opposite direction.

(10) The left wheel should spin freely at first and

then increase in resistance within 5 revolutions until

the wheels cannot be continuously rotated in opposite

directions.

(11) The Vari-loktdifferential has engaged prop-

erly if the wheels cannot be rotated in opposite direc-

tions for a moment. After the wheels stop rotating for

a moment, the fluid pressure will drop in the differ-

ential and the wheels begin to rotate once again.

(12) If the system does not operate properly,

replace the Vari-loktdifferential.

REMOVAL

(1) Raise and support the vehicle.

(2) Position a lifting device under the axle and

secure axle.

WJREAR AXLE - 226RBA 3 - 95

REAR AXLE - 226RBA (Continued)

Page 178 of 2199

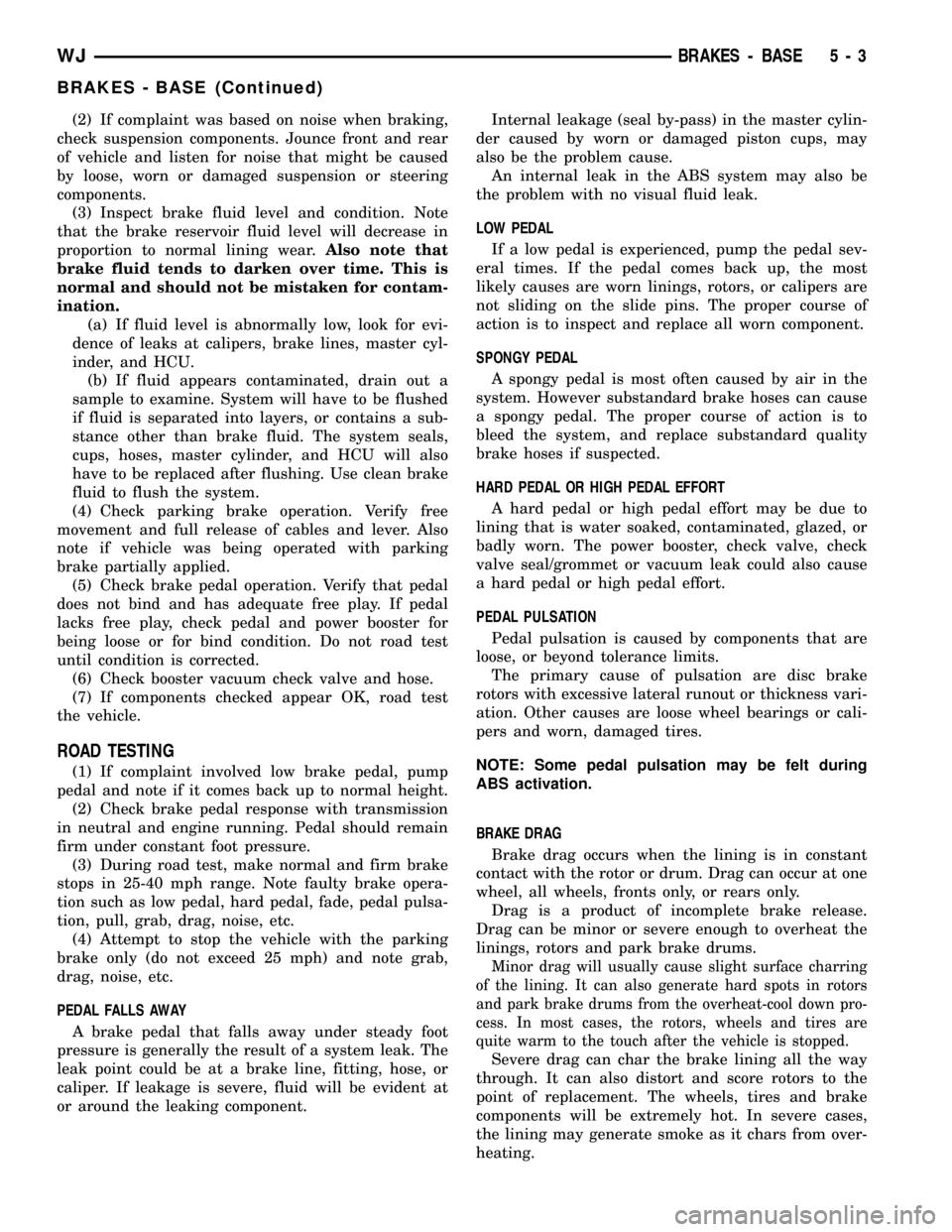

(2) If complaint was based on noise when braking,

check suspension components. Jounce front and rear

of vehicle and listen for noise that might be caused

by loose, worn or damaged suspension or steering

components.

(3) Inspect brake fluid level and condition. Note

that the brake reservoir fluid level will decrease in

proportion to normal lining wear.Also note that

brake fluid tends to darken over time. This is

normal and should not be mistaken for contam-

ination.

(a) If fluid level is abnormally low, look for evi-

dence of leaks at calipers, brake lines, master cyl-

inder, and HCU.

(b) If fluid appears contaminated, drain out a

sample to examine. System will have to be flushed

if fluid is separated into layers, or contains a sub-

stance other than brake fluid. The system seals,

cups, hoses, master cylinder, and HCU will also

have to be replaced after flushing. Use clean brake

fluid to flush the system.

(4) Check parking brake operation. Verify free

movement and full release of cables and lever. Also

note if vehicle was being operated with parking

brake partially applied.

(5) Check brake pedal operation. Verify that pedal

does not bind and has adequate free play. If pedal

lacks free play, check pedal and power booster for

being loose or for bind condition. Do not road test

until condition is corrected.

(6) Check booster vacuum check valve and hose.

(7) If components checked appear OK, road test

the vehicle.

ROAD TESTING

(1) If complaint involved low brake pedal, pump

pedal and note if it comes back up to normal height.

(2) Check brake pedal response with transmission

in neutral and engine running. Pedal should remain

firm under constant foot pressure.

(3) During road test, make normal and firm brake

stops in 25-40 mph range. Note faulty brake opera-

tion such as low pedal, hard pedal, fade, pedal pulsa-

tion, pull, grab, drag, noise, etc.

(4) Attempt to stop the vehicle with the parking

brake only (do not exceed 25 mph) and note grab,

drag, noise, etc.

PEDAL FALLS AWAY

A brake pedal that falls away under steady foot

pressure is generally the result of a system leak. The

leak point could be at a brake line, fitting, hose, or

caliper. If leakage is severe, fluid will be evident at

or around the leaking component.Internal leakage (seal by-pass) in the master cylin-

der caused by worn or damaged piston cups, may

also be the problem cause.

An internal leak in the ABS system may also be

the problem with no visual fluid leak.

LOW PEDAL

If a low pedal is experienced, pump the pedal sev-

eral times. If the pedal comes back up, the most

likely causes are worn linings, rotors, or calipers are

not sliding on the slide pins. The proper course of

action is to inspect and replace all worn component.

SPONGY PEDAL

A spongy pedal is most often caused by air in the

system. However substandard brake hoses can cause

a spongy pedal. The proper course of action is to

bleed the system, and replace substandard quality

brake hoses if suspected.

HARD PEDAL OR HIGH PEDAL EFFORT

A hard pedal or high pedal effort may be due to

lining that is water soaked, contaminated, glazed, or

badly worn. The power booster, check valve, check

valve seal/grommet or vacuum leak could also cause

a hard pedal or high pedal effort.

PEDAL PULSATION

Pedal pulsation is caused by components that are

loose, or beyond tolerance limits.

The primary cause of pulsation are disc brake

rotors with excessive lateral runout or thickness vari-

ation. Other causes are loose wheel bearings or cali-

pers and worn, damaged tires.

NOTE: Some pedal pulsation may be felt during

ABS activation.

BRAKE DRAG

Brake drag occurs when the lining is in constant

contact with the rotor or drum. Drag can occur at one

wheel, all wheels, fronts only, or rears only.

Drag is a product of incomplete brake release.

Drag can be minor or severe enough to overheat the

linings, rotors and park brake drums.

Minor drag will usually cause slight surface charring

of the lining. It can also generate hard spots in rotors

and park brake drums from the overheat-cool down pro-

cess. In most cases, the rotors, wheels and tires are

quite warm to the touch after the vehicle is stopped.

Severe drag can char the brake lining all the way

through. It can also distort and score rotors to the

point of replacement. The wheels, tires and brake

components will be extremely hot. In severe cases,

the lining may generate smoke as it chars from over-

heating.

WJBRAKES - BASE 5 - 3

BRAKES - BASE (Continued)

Page 179 of 2199

Common causes of brake drag are:

²Parking brake partially applied.

²Loose/worn wheel bearing.

²Seized caliper.

²Caliper binding.

²Loose caliper mounting.

²Mis-assembled components.

²Damaged brake lines.

If brake drag occurs at the front, rear or all

wheels, the problem may be related to a blocked mas-

ter cylinder return port, faulty power booster (binds-

does not release) or the ABS system.

BRAKE FADE

Brake fade is usually a product of overheating

caused by brake drag. However, brake overheating

and resulting fade can also be caused by riding the

brake pedal, making repeated high deceleration stops

in a short time span, or constant braking on steep

mountain roads. Refer to the Brake Drag information

in this section for causes.

BRAKE PULL

Front brake pull condition could result from:

²Contaminated lining in one caliper

²Seized caliper piston

²Binding caliper

²Loose caliper

²Rusty caliper slide surfaces

²Improper brake shoes

²Damaged rotor

²Wheel alignment.

²Tire pressure.

A worn, damaged wheel bearing or suspension compo-

nent are further causes of pull. A damaged front tire

(bruised, ply separation) can also cause pull.

A common and frequently misdiagnosed pull condi-

tion is where direction of pull changes after a few

stops. The cause is a combination of brake drag fol-

lowed by fade at one of the brake units.

As the dragging brake overheats, efficiency is so

reduced that fade occurs. Since the opposite brake

unit is still functioning normally, its braking effect is

magnified. This causes pull to switch direction in

favor of the normally functioning brake unit.

An additional point when diagnosing a change in

pull condition concerns brake cool down. Remember

that pull will return to the original direction, if the

dragging brake unit is allowed to cool down (and is

not seriously damaged).

REAR BRAKE DRAG OR PULL

Rear drag or pull may be caused by improperly

adjusted park brake shoes or seized parking brake

cables, contaminated lining, bent or binding shoes or

improperly assembled components. This is particu-

larly true when only one rear wheel is involved.However, when both rear wheels are affected, the

master cylinder or ABS system could be at fault.

BRAKES DO NOT HOLD AFTER DRIVING THROUGH DEEP

WATER PUDDLES

This condition is generally caused by water soaked

lining. If the lining is only wet, it can be dried by

driving with the brakes very lightly applied for a

mile or two. However, if the lining is both soaked and

dirt contaminated, cleaning and or replacement will

be necessary.

BRAKE LINING CONTAMINATION

Brake lining contamination is mostly a product of

leaking calipers or worn seals, driving through deep

water puddles, or lining that has become covered with

grease and grit during repair. Contaminated lining

should be replaced to avoid further brake problems.

WHEEL AND TIRE PROBLEMS

Some conditions attributed to brake components

may actually be caused by a wheel or tire problem.

A damaged wheel can cause shudder, vibration and

pull. A worn or damaged tire can also cause pull.

NOTE: Propshaft angle can also cause vibration/

shudder.

Severely worn tires with very little tread left can

produce a grab-like condition as the tire loses and

recovers traction. Flat-spotted tires can cause vibra-

tion and generate shudder during brake operation.

Tire damage such as a severe bruise, cut, ply separa-

tion, low air pressure can cause pull and vibration.

BRAKE NOISES

Some brake noise is common on some disc brakes

during the first few stops after a vehicle has been

parked overnight or stored. This is primarily due to

the formation of trace corrosion (light rust) on metal

surfaces. This light corrosion is typically cleared from

the metal surfaces after a few brake applications

causing the noise to subside.

BRAKE SQUEAK/SQUEAL

Brake squeak or squeal may be due to linings that

are wet or contaminated with brake fluid, grease, or oil.

Glazed linings and rotors with hard spots can also con-

tribute to squeak. Dirt and foreign material embedded

in the brake lining will also cause squeak/squeal.

A very loud squeak or squeal is frequently a sign of

severely worn brake lining. If the lining has worn

through to the brake shoes in spots, metal-to-metal

contact occurs. If the condition is allowed to continue,

rotors may become so scored that replacement is nec-

essary.

5 - 4 BRAKES - BASEWJ

BRAKES - BASE (Continued)

Page 180 of 2199

NOTE: The front outer brake shoes are equipped

with a wear indicator. The indicator will produce an

audible noise when it contacts the rotor surface.

BRAKE CHATTER

Brake chatter is usually caused by loose or worn

components, or glazed/burnt lining. Rotors with hard

spots can also contribute to chatter. Additional causes

of chatter are out-of-tolerance rotors, brake lining not

securely attached to the shoes, loose wheel bearings

and contaminated brake lining.

THUMP/CLUNK NOISE

Thumping or clunk noises during braking are fre-

quentlynotcaused by brake components. In many

cases, such noises are caused by loose or damaged

steering, suspension, or engine components.

STANDARD PROCEDURE

STANDARD PROCEDURE - MANUAL BLEEDING

Use Mopar brake fluid, or an equivalent quality

fluid meeting SAE J1703-F and DOT 3 standards

only. Use fresh, clean fluid from a sealed container at

all times.

Do not pump the brake pedal at any time while

bleeding. Air in the system will be compressed into

small bubbles that are distributed throughout the

hydraulic system. This will make additional bleeding

operations necessary.

Do not allow the master cylinder to run out of fluid

during bleed operations. An empty cylinder will allow

additional air to be drawn into the system. Check the

cylinder fluid level frequently and add fluid as

needed.

Bleed only one brake component at a time in the

following sequence:

(1) Fill the master cylinder reservoir with brake

fluid.

(2) If calipers are overhauled, open all caliper

bleed screws. Then close each bleed screw as fluid

starts to drip from it. Top off master cylinder reser-

voir once more before proceeding.

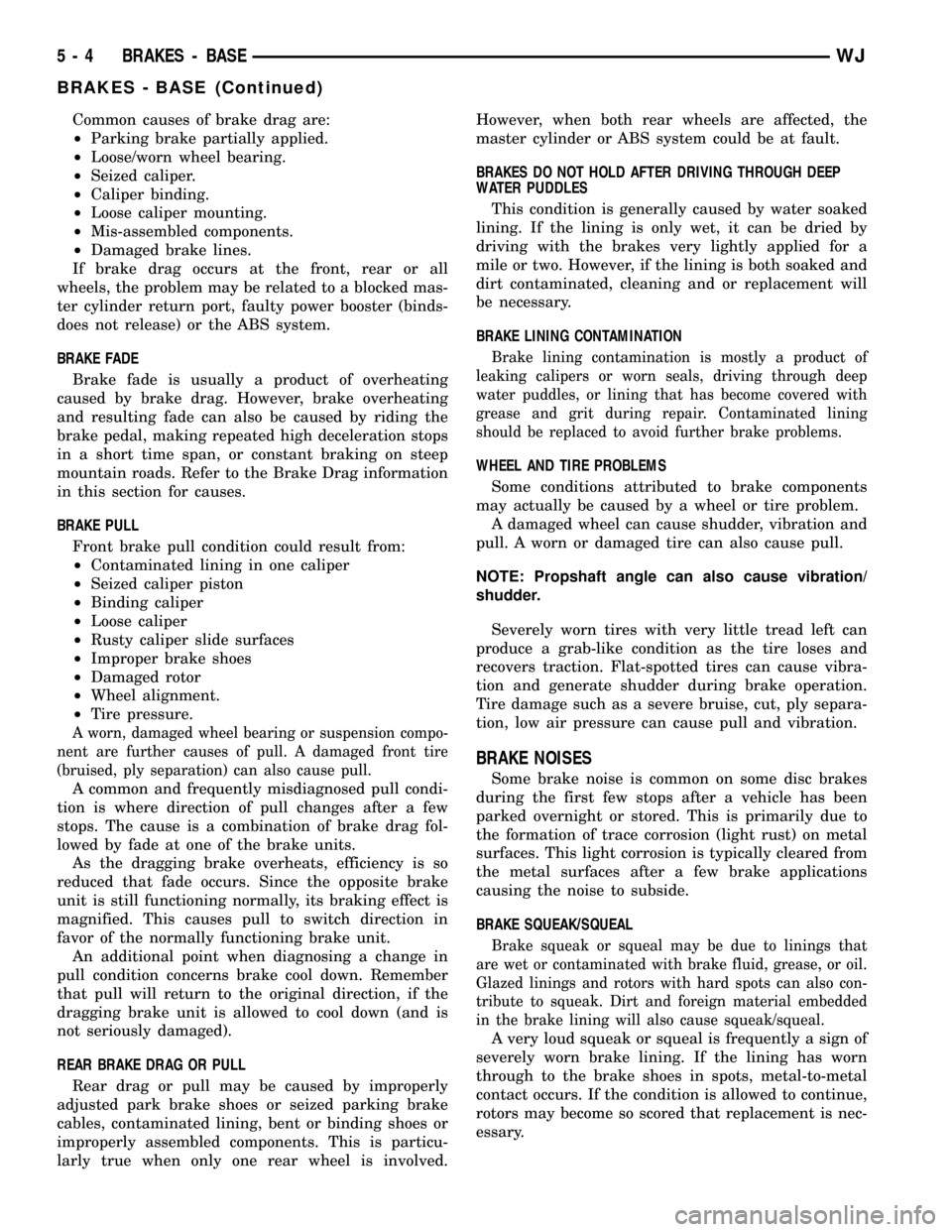

(3) Attach one end of bleed hose to bleed screw

and insert opposite end in glass container partially

filled with brake fluid (Fig. 1). Be sure end of bleed

hose is immersed in fluid.

(4) Open up bleeder, then have a helper press

down the brake pedal. Once the pedal is down close

the bleeder. Repeat bleeding until fluid stream is

clear and free of bubbles. Then move to the next

wheel.

STANDARD PROCEDURE - PRESSURE

BLEEDING

Use Mopar brake fluid, or an equivalent quality

fluid meeting SAE J1703-F and DOT 3 standards

only. Use fresh, clean fluid from a sealed container at

all times.

Do not pump the brake pedal at any time while

bleeding. Air in the system will be compressed into

small bubbles that are distributed throughout the

hydraulic system. This will make additional bleeding

operations necessary.

Do not allow the master cylinder to run out of fluid

during bleed operations. An empty cylinder will allow

additional air to be drawn into the system. Check the

cylinder fluid level frequently and add fluid as

needed.

Bleed only one brake component at a time in the

following sequence:

Follow the manufacturers instructions carefully

when using pressure equipment. Do not exceed the

tank manufacturers pressure recommendations. Gen-

erally, a tank pressure of 51-67 kPa (15-20 psi) is suf-

ficient for bleeding.

Fill the bleeder tank with recommended fluid and

purge air from the tank lines before bleeding.

Do not pressure bleed without a proper master cyl-

inder adapter. The wrong adapter can lead to leak-

age, or drawing air back into the system. Use

adapter provided with the equipment or Adapter

6921.

Fig. 1 Bleed Hose Setup

1 - BLEED HOSE

2 - FLUID CONTAINER PARTIALLY FILLED WITH FLUID

WJBRAKES - BASE 5 - 5

BRAKES - BASE (Continued)

Page 183 of 2199

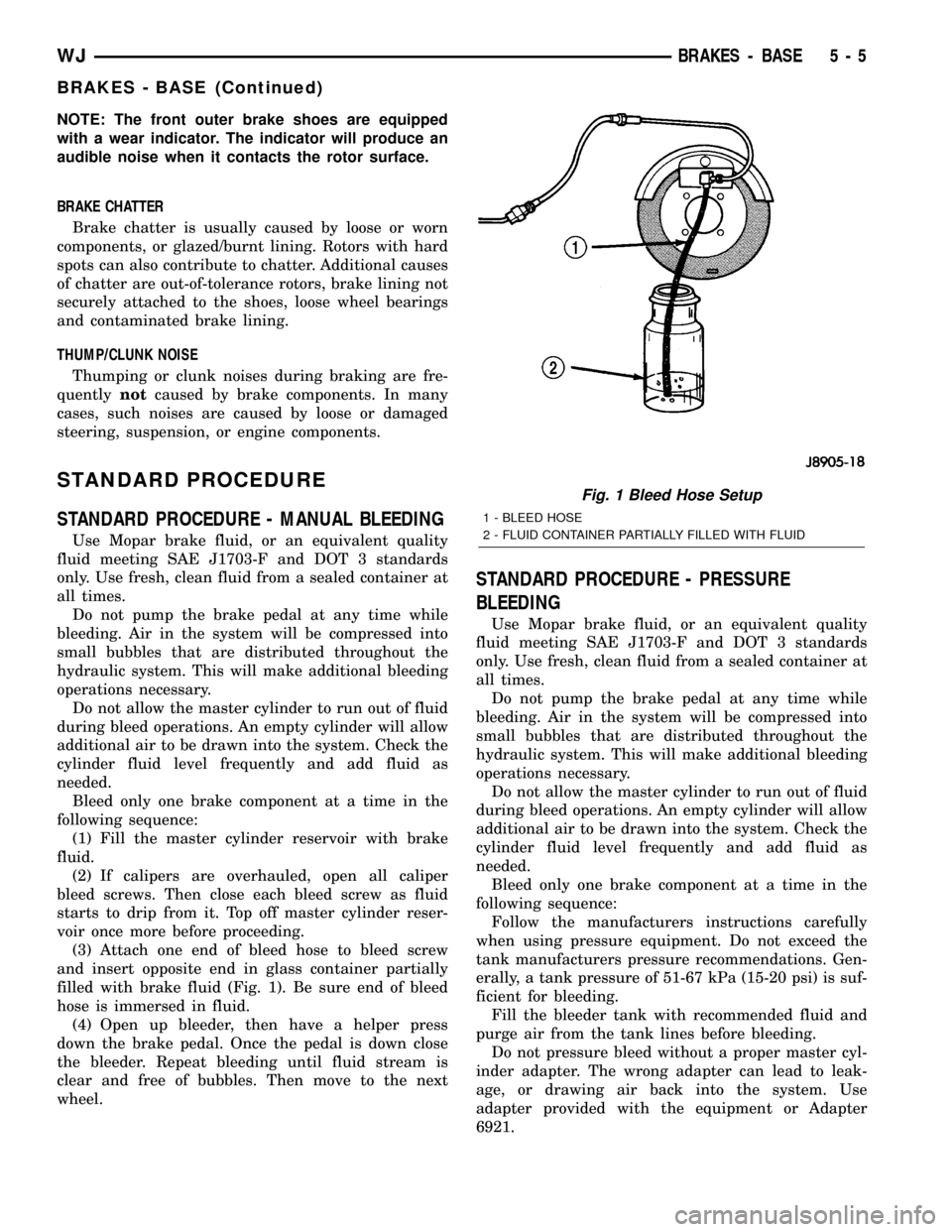

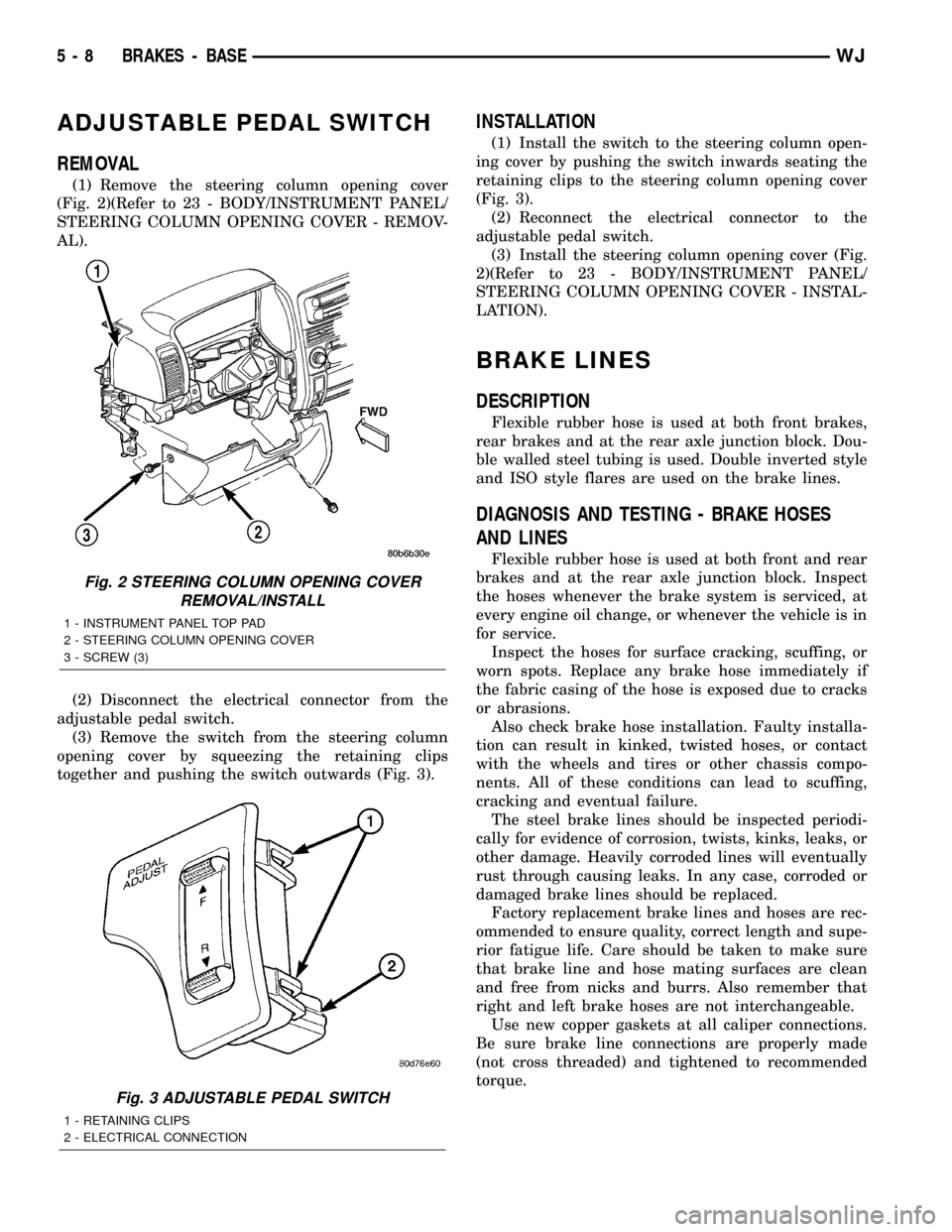

ADJUSTABLE PEDAL SWITCH

REMOVAL

(1) Remove the steering column opening cover

(Fig. 2)(Refer to 23 - BODY/INSTRUMENT PANEL/

STEERING COLUMN OPENING COVER - REMOV-

AL).

(2) Disconnect the electrical connector from the

adjustable pedal switch.

(3) Remove the switch from the steering column

opening cover by squeezing the retaining clips

together and pushing the switch outwards (Fig. 3).

INSTALLATION

(1) Install the switch to the steering column open-

ing cover by pushing the switch inwards seating the

retaining clips to the steering column opening cover

(Fig. 3).

(2) Reconnect the electrical connector to the

adjustable pedal switch.

(3) Install the steering column opening cover (Fig.

2)(Refer to 23 - BODY/INSTRUMENT PANEL/

STEERING COLUMN OPENING COVER - INSTAL-

LATION).

BRAKE LINES

DESCRIPTION

Flexible rubber hose is used at both front brakes,

rear brakes and at the rear axle junction block. Dou-

ble walled steel tubing is used. Double inverted style

and ISO style flares are used on the brake lines.

DIAGNOSIS AND TESTING - BRAKE HOSES

AND LINES

Flexible rubber hose is used at both front and rear

brakes and at the rear axle junction block. Inspect

the hoses whenever the brake system is serviced, at

every engine oil change, or whenever the vehicle is in

for service.

Inspect the hoses for surface cracking, scuffing, or

worn spots. Replace any brake hose immediately if

the fabric casing of the hose is exposed due to cracks

or abrasions.

Also check brake hose installation. Faulty installa-

tion can result in kinked, twisted hoses, or contact

with the wheels and tires or other chassis compo-

nents. All of these conditions can lead to scuffing,

cracking and eventual failure.

The steel brake lines should be inspected periodi-

cally for evidence of corrosion, twists, kinks, leaks, or

other damage. Heavily corroded lines will eventually

rust through causing leaks. In any case, corroded or

damaged brake lines should be replaced.

Factory replacement brake lines and hoses are rec-

ommended to ensure quality, correct length and supe-

rior fatigue life. Care should be taken to make sure

that brake line and hose mating surfaces are clean

and free from nicks and burrs. Also remember that

right and left brake hoses are not interchangeable.

Use new copper gaskets at all caliper connections.

Be sure brake line connections are properly made

(not cross threaded) and tightened to recommended

torque.

Fig. 2 STEERING COLUMN OPENING COVER

REMOVAL/INSTALL

1 - INSTRUMENT PANEL TOP PAD

2 - STEERING COLUMN OPENING COVER

3 - SCREW (3)

Fig. 3 ADJUSTABLE PEDAL SWITCH

1 - RETAINING CLIPS

2 - ELECTRICAL CONNECTION

5 - 8 BRAKES - BASEWJ

Page 218 of 2199

ELECTRIC BRAKE

DESCRIPTION

The electronic brake distribution (EBD) functions

like a rear proportioning valve. The EBD system uses

the ABS system to control the slip of the rear wheels

in partial braking range. The braking force of the

rear wheels is controlled electronically by using the

inlet and outlet valves located in the HCU.

OPERATION

Upon entry into EBD the inlet valve for the rear

brake circuit is switched on so that the fluid supply

from the master cylinder is shut off. In order to

decrease the rear brake pressure the outlet valve for

the rear brake circuit is pulsed. This allows fluid to

enter the low pressure accumulator (LPA) in the

HCU resulting in a drop in fluid pressure to the rear

brakes. In order to increase the rear brake pressure

the outlet valve is switched off and the inlet valve is

pulsed. This increases the pressure to the rear

brakes. This will continue until the required slip dif-

ference is obtained. At the end of EBD braking (no

brake application) the fluid in the LPA drains back to

the master cylinder by switching on the outlet valve

and draining through the inlet valve check valve. At

the same time the inlet valve is switched on to pre-

vent a hydraulic short circiut in case of another

brake application.

The EBD will remain functional during many ABS

fault modes. If the red and amber warning lamps are

illuminated the EBD may have a fault.

FRONT WHEEL SPEED

SENSOR

DESCRIPTION

A wheel speed sensor is used at each wheel. The

front sensors are mounted to the steering knuckles.

The rear sensors are mounted at the outboard end of

the axle. Tone wheels are mounted to the outboard

ends of the front and rear axle shafts. The gear type

tone wheel serves as the trigger mechanism for each

sensor.

OPERATION

The sensors convert wheel speed into a small digi-

tal signal. The CAB sends 12 volts to the sensors.

The sensor has an internal magneto resistance

bridge that alters the voltage and amperage of the

signal circuit. This voltage and amperage is changed

by magnetic induction when the toothed tone wheel

passes the wheel speed sensor. This digital signal issent to the CAB. The CAB measures the voltage and

amperage of the digital signal for each wheel.

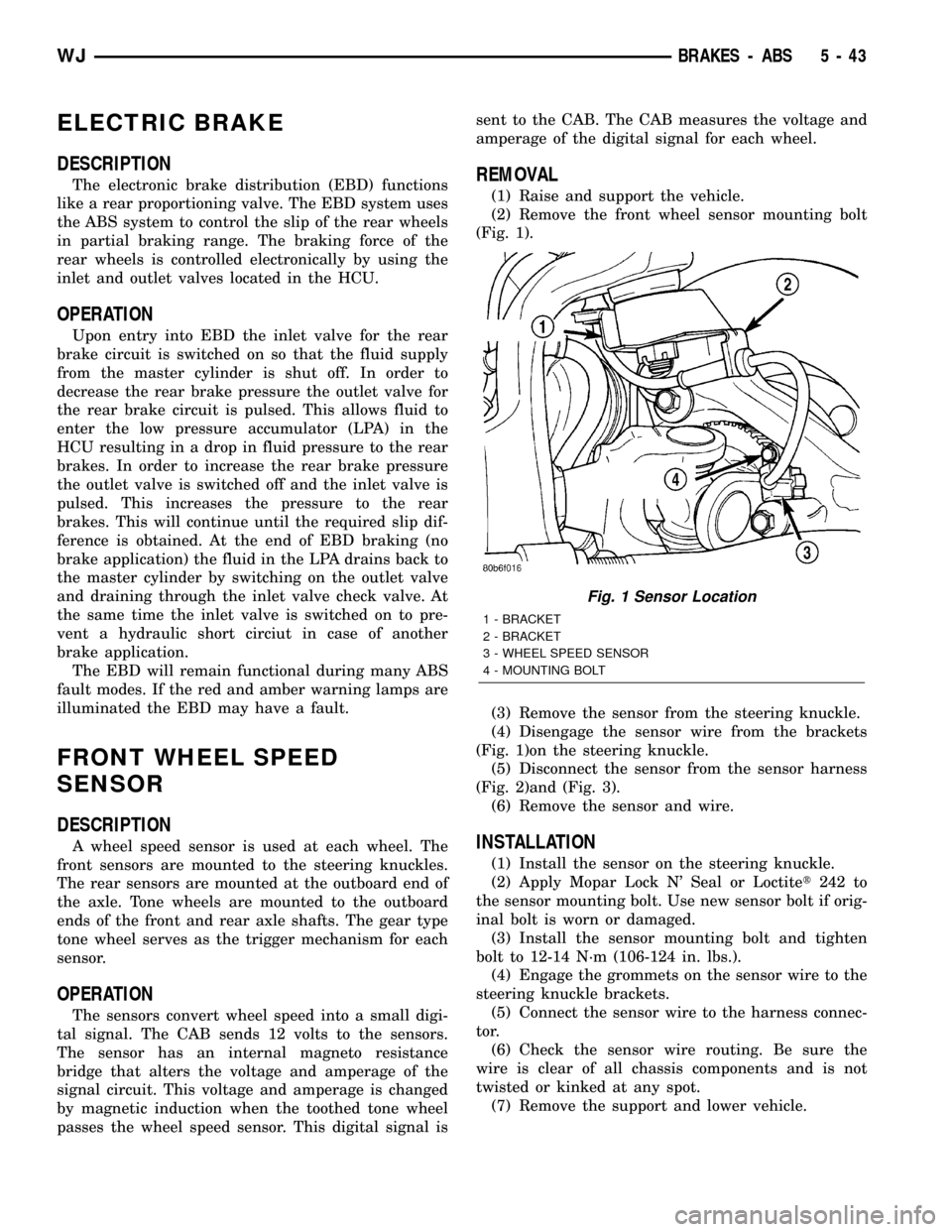

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the front wheel sensor mounting bolt

(Fig. 1).

(3) Remove the sensor from the steering knuckle.

(4) Disengage the sensor wire from the brackets

(Fig. 1)on the steering knuckle.

(5) Disconnect the sensor from the sensor harness

(Fig. 2)and (Fig. 3).

(6) Remove the sensor and wire.

INSTALLATION

(1) Install the sensor on the steering knuckle.

(2) Apply Mopar Lock N' Seal or Loctitet242 to

the sensor mounting bolt. Use new sensor bolt if orig-

inal bolt is worn or damaged.

(3) Install the sensor mounting bolt and tighten

bolt to 12-14 N´m (106-124 in. lbs.).

(4) Engage the grommets on the sensor wire to the

steering knuckle brackets.

(5) Connect the sensor wire to the harness connec-

tor.

(6) Check the sensor wire routing. Be sure the

wire is clear of all chassis components and is not

twisted or kinked at any spot.

(7) Remove the support and lower vehicle.

Fig. 1 Sensor Location

1 - BRACKET

2 - BRACKET

3 - WHEEL SPEED SENSOR

4 - MOUNTING BOLT

WJBRAKES - ABS 5 - 43

Page 1271 of 2199

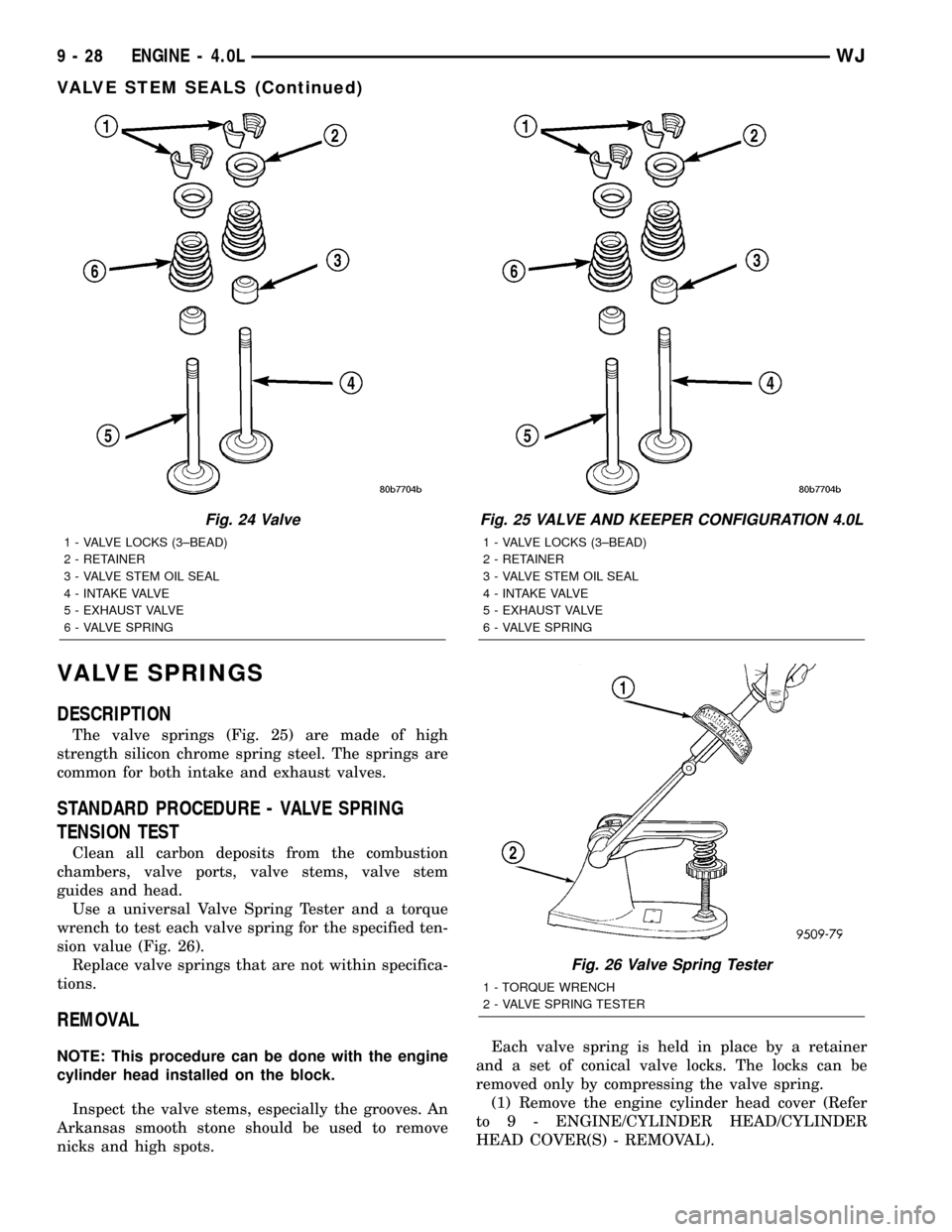

VALVE SPRINGS

DESCRIPTION

The valve springs (Fig. 25) are made of high

strength silicon chrome spring steel. The springs are

common for both intake and exhaust valves.

STANDARD PROCEDURE - VALVE SPRING

TENSION TEST

Clean all carbon deposits from the combustion

chambers, valve ports, valve stems, valve stem

guides and head.

Use a universal Valve Spring Tester and a torque

wrench to test each valve spring for the specified ten-

sion value (Fig. 26).

Replace valve springs that are not within specifica-

tions.

REMOVAL

NOTE: This procedure can be done with the engine

cylinder head installed on the block.

Inspect the valve stems, especially the grooves. An

Arkansas smooth stone should be used to remove

nicks and high spots.Each valve spring is held in place by a retainer

and a set of conical valve locks. The locks can be

removed only by compressing the valve spring.

(1) Remove the engine cylinder head cover (Refer

to 9 - ENGINE/CYLINDER HEAD/CYLINDER

HEAD COVER(S) - REMOVAL).

Fig. 24 Valve

1 - VALVE LOCKS (3±BEAD)

2 - RETAINER

3 - VALVE STEM OIL SEAL

4 - INTAKE VALVE

5 - EXHAUST VALVE

6 - VALVE SPRING

Fig. 25 VALVE AND KEEPER CONFIGURATION 4.0L

1 - VALVE LOCKS (3±BEAD)

2 - RETAINER

3 - VALVE STEM OIL SEAL

4 - INTAKE VALVE

5 - EXHAUST VALVE

6 - VALVE SPRING

Fig. 26 Valve Spring Tester

1 - TORQUE WRENCH

2 - VALVE SPRING TESTER

9 - 28 ENGINE - 4.0LWJ

VALVE STEM SEALS (Continued)

Page 1451 of 2199

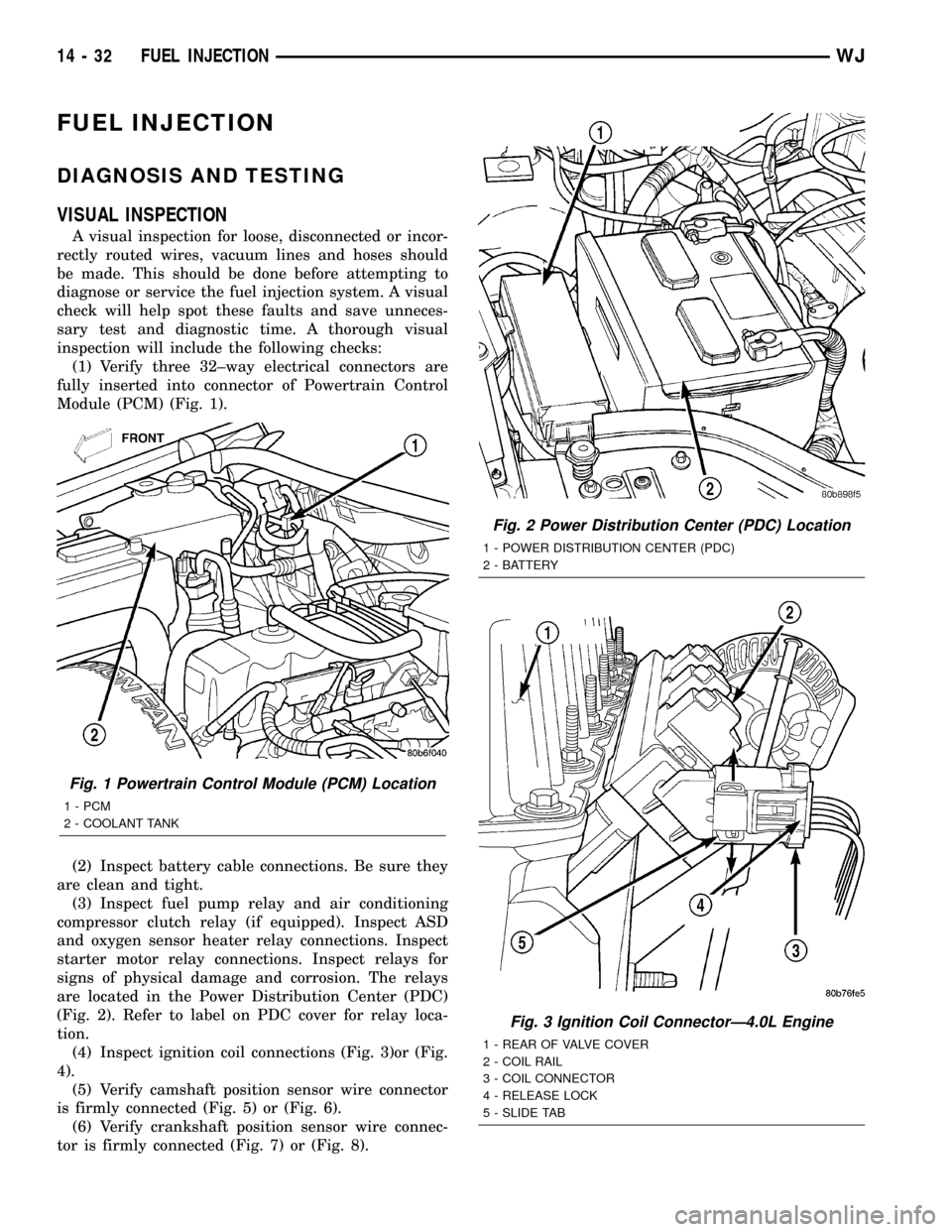

FUEL INJECTION

DIAGNOSIS AND TESTING

VISUAL INSPECTION

A visual inspection for loose, disconnected or incor-

rectly routed wires, vacuum lines and hoses should

be made. This should be done before attempting to

diagnose or service the fuel injection system. A visual

check will help spot these faults and save unneces-

sary test and diagnostic time. A thorough visual

inspection will include the following checks:

(1) Verify three 32±way electrical connectors are

fully inserted into connector of Powertrain Control

Module (PCM) (Fig. 1).

(2) Inspect battery cable connections. Be sure they

are clean and tight.

(3) Inspect fuel pump relay and air conditioning

compressor clutch relay (if equipped). Inspect ASD

and oxygen sensor heater relay connections. Inspect

starter motor relay connections. Inspect relays for

signs of physical damage and corrosion. The relays

are located in the Power Distribution Center (PDC)

(Fig. 2). Refer to label on PDC cover for relay loca-

tion.

(4) Inspect ignition coil connections (Fig. 3)or (Fig.

4).

(5) Verify camshaft position sensor wire connector

is firmly connected (Fig. 5) or (Fig. 6).

(6) Verify crankshaft position sensor wire connec-

tor is firmly connected (Fig. 7) or (Fig. 8).

Fig. 1 Powertrain Control Module (PCM) Location

1 - PCM

2 - COOLANT TANK

Fig. 2 Power Distribution Center (PDC) Location

1 - POWER DISTRIBUTION CENTER (PDC)

2 - BATTERY

Fig. 3 Ignition Coil ConnectorÐ4.0L Engine

1 - REAR OF VALVE COVER

2 - COIL RAIL

3 - COIL CONNECTOR

4 - RELEASE LOCK

5 - SLIDE TAB

14 - 32 FUEL INJECTIONWJ