Clamp JEEP GRAND CHEROKEE 2003 WJ / 2.G Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1458 of 2199

SPECIFICATIONS

TORQUE - FUEL INJECTION

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Air Cleaner Housing Mount. Nuts 10 93

Air Cleaner Air Duct Clamps 4 35

Air Cleaner Resonator Bolts 4 35

Engine Coolant Temperature SensorÐ4.0L Engine 11 96

Engine Coolant Temperature SensorÐ4.7L Engine 11 96

Fuel Hose Clamps 1 10

IAC Motor-To-Throttle Body BoltsÐ4.0L Engine 7860

IAC Motor-To-Throttle Body BoltsÐ4.7L Engine 7 60

Intake Manifold Air Temp. SensorÐ4.0L Engine 28 20

Intake Manifold Air Temp. SensorÐ4.7L Engine 28 20

MAP Sensor Mounting ScrewsÐ4.0L Engine 3 25

MAP Sensor Mounting ScrewsÐ4.7L Engine 3 25

Oxygen SensorÐAll Engines 30 22

PCM-to-Mounting Bracket Screws 3 25

PCM-to-Mounting Bracket Screws 9 80

Radiator Cooling Fan Relay Bolts 3 25

Throttle Body Mounting BoltsÐ4.0L Engine 11 100

Throttle Body Mounting BoltsÐ4.7L Engine 12 105

TPS Mounting ScrewsÐ4.0L Engine 7 60

TPS Mounting ScrewsÐ4.7L Engine 7 60

ACCELERATOR PEDAL

REMOVAL

The accelerator pedal is connected to the throttle

body linkage by the throttle cable. The cable is pro-

tected by a plastic sheathing and is connected to the

throttle body linkage by a ball socket. It is connected

to the accelerator pedal arm by a plastic retainer

(clip) (Fig. 16). This retainer (clip) snaps into the top

of the accelerator pedal arm. A retainer clip (Fig. 16)

is also used to fasten cable to dash panel.

CAUTION: Be careful not to damage or kink the

cable core wire (within the cable sheathing) while

servicing accelerator pedal or throttle cable.

(1) From inside vehicle, hold up accelerator pedal.

Remove plastic cable retainer (clip) and throttle cable

core wire from upper end of pedal arm. Plastic cable

retainer (clip) snaps into pedal arm.

(2) Remove accelerator pedal bracket nuts. Remove

accelerator pedal assembly.

INSTALLATION

The accelerator pedal is connected to the throttle

body linkage by the throttle cable. The cable is pro-

tected by a plastic sheathing and is connected to the

throttle body linkage by a ball socket. It is connected

to the accelerator pedal arm by a plastic retainer

(clip) (Fig. 16) . This retainer (clip) snaps into the top

of the accelerator pedal arm. A retainer clip (Fig. 16)

is also used to fasten cable to dash panel.

(1) Place accelerator pedal assembly over studs

protruding from floor pan. Tighten mounting nuts to

12 N´m 2 N´m (105 in. lbs. 20 in. lbs.) torque.

(2) Slide throttle cable into opening in top of pedal

arm. Push plastic cable retainer (clip) into pedal arm

opening until it snaps into place.

(3) Before starting engine, operate accelerator

pedal to check for any binding.

WJFUEL INJECTION 14 - 39

Page 1479 of 2199

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - POWER STEERING SYSTEM

STEERING NOISE

There is some noise in all power steering systems. One of the most common is a hissing sound evident at a

standstill parking. Or when the steering wheel is at the end of it's travel. Hiss is a high frequency noise similar

to that of a water tap being closed slowly. The noise is present in all valves that have a high velocity fluid passing

through an orifice. There is no relationship between this noise and steering performance.

CONDITION POSSIBLE CAUSES CORRECTION

OBJECTIONAL HISS OR

WHISTLE1. Steering intermediate shaft to dash panel

seal.1. Check and repair seal at dash

panel.

2. Noisy valve in power steering gear. 2. Replace steering gear.

RATTLE OR CLUNK 1. Gear mounting bolts loose. 1. Tighten bolts to specification.

2. Loose or damaged suspension

components/track bar.2. Inspect and repair suspension.

3. Loose or damaged steering linkage. 3. Inspect and repair steering

linkage.

4. Internal gear noise. 4. Replace gear.

5. Pressure hose in contact with other

components.5. Reposition hose.

CHIRP OR SQUEAL 1. Loose belt. 1. Adjust or replace.

2. Belt routing. 2. Verify belt routing is correct.

WHINE OR GROWL 1. Low fluid level. 1. Fill to proper level.

2. Pressure hose in contact with other

components.2. Reposition hose.

3. Internal pump noise. 3. Replace pump.

4. Air in the system. 4. Perform pump initial operation.

SUCKING AIR SOUND 1. Loose return line clamp. 1. Replace clamp.

2. O-ring missing or damaged on hose

fitting.2. Replace o-ring.

3. Low fluid level. 3. Fill to proper level.

4. Air leak between pump and reservoir. 4. Repair as necessary.

SCRUBBING OR

KNOCKING1. Wrong tire size. 1. Verify tire size.

2. Wrong gear. 2. Verify gear.

19 - 2 STEERINGWJ

STEERING (Continued)

Page 1505 of 2199

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Pitman Arm

Shaft Nut251 185 Ð

Drag Link

Pitman Arm Nut88 65 Ð

Drag Link

Knuckle Nut47 35 Ð

Drag Link

Clamp Nuts41 30 Ð

Tie Rod

Knuckle Nut47 35 Ð

Tie Rod

Clamp Nuts41 30 Ð

Steering Damper

Axle Bolt88 65 Ð

Steering Damper

Tie Rod Nut41 30 Ð

SPECIAL TOOLS

STEERING LINKAGEDAMPER

DESCRIPTION

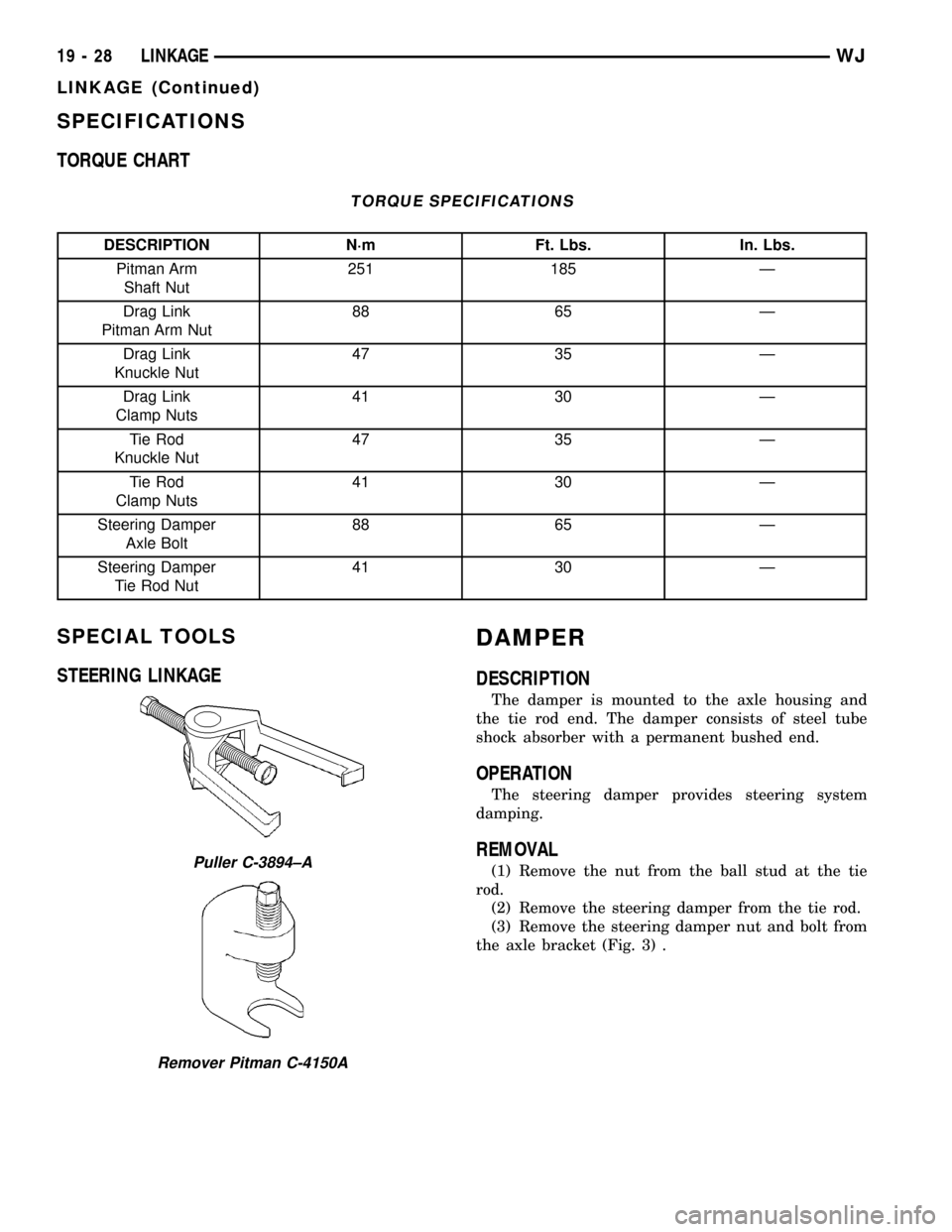

The damper is mounted to the axle housing and

the tie rod end. The damper consists of steel tube

shock absorber with a permanent bushed end.

OPERATION

The steering damper provides steering system

damping.

REMOVAL

(1) Remove the nut from the ball stud at the tie

rod.

(2) Remove the steering damper from the tie rod.

(3) Remove the steering damper nut and bolt from

the axle bracket (Fig. 3) .Puller C-3894±A

Remover Pitman C-4150A

19 - 28 LINKAGEWJ

LINKAGE (Continued)

Page 1506 of 2199

INSTALLATION

(1) Install the steering damper to the axle bracket

and tie rod.

(2) Install the steering damper bolt in the axle

bracket and tighten bolt to 88 N´m (65 ft. lbs.).

(3) Install the nut at the tie rod and tighten to 41

N´m (30 ft. lbs.).

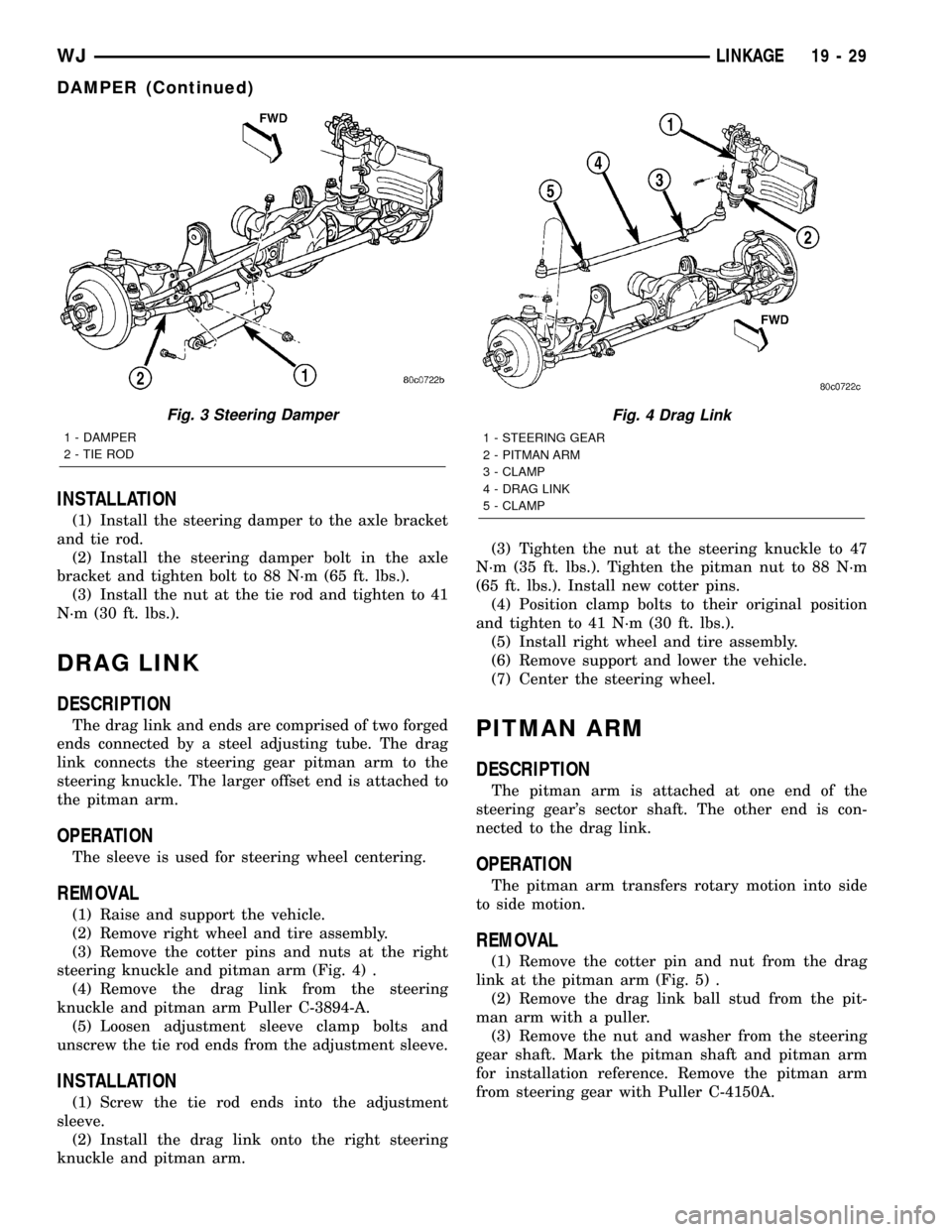

DRAG LINK

DESCRIPTION

The drag link and ends are comprised of two forged

ends connected by a steel adjusting tube. The drag

link connects the steering gear pitman arm to the

steering knuckle. The larger offset end is attached to

the pitman arm.

OPERATION

The sleeve is used for steering wheel centering.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove right wheel and tire assembly.

(3) Remove the cotter pins and nuts at the right

steering knuckle and pitman arm (Fig. 4) .

(4) Remove the drag link from the steering

knuckle and pitman arm Puller C-3894-A.

(5) Loosen adjustment sleeve clamp bolts and

unscrew the tie rod ends from the adjustment sleeve.

INSTALLATION

(1) Screw the tie rod ends into the adjustment

sleeve.

(2) Install the drag link onto the right steering

knuckle and pitman arm.(3) Tighten the nut at the steering knuckle to 47

N´m (35 ft. lbs.). Tighten the pitman nut to 88 N´m

(65 ft. lbs.). Install new cotter pins.

(4) Position clamp bolts to their original position

and tighten to 41 N´m (30 ft. lbs.).

(5) Install right wheel and tire assembly.

(6) Remove support and lower the vehicle.

(7) Center the steering wheel.

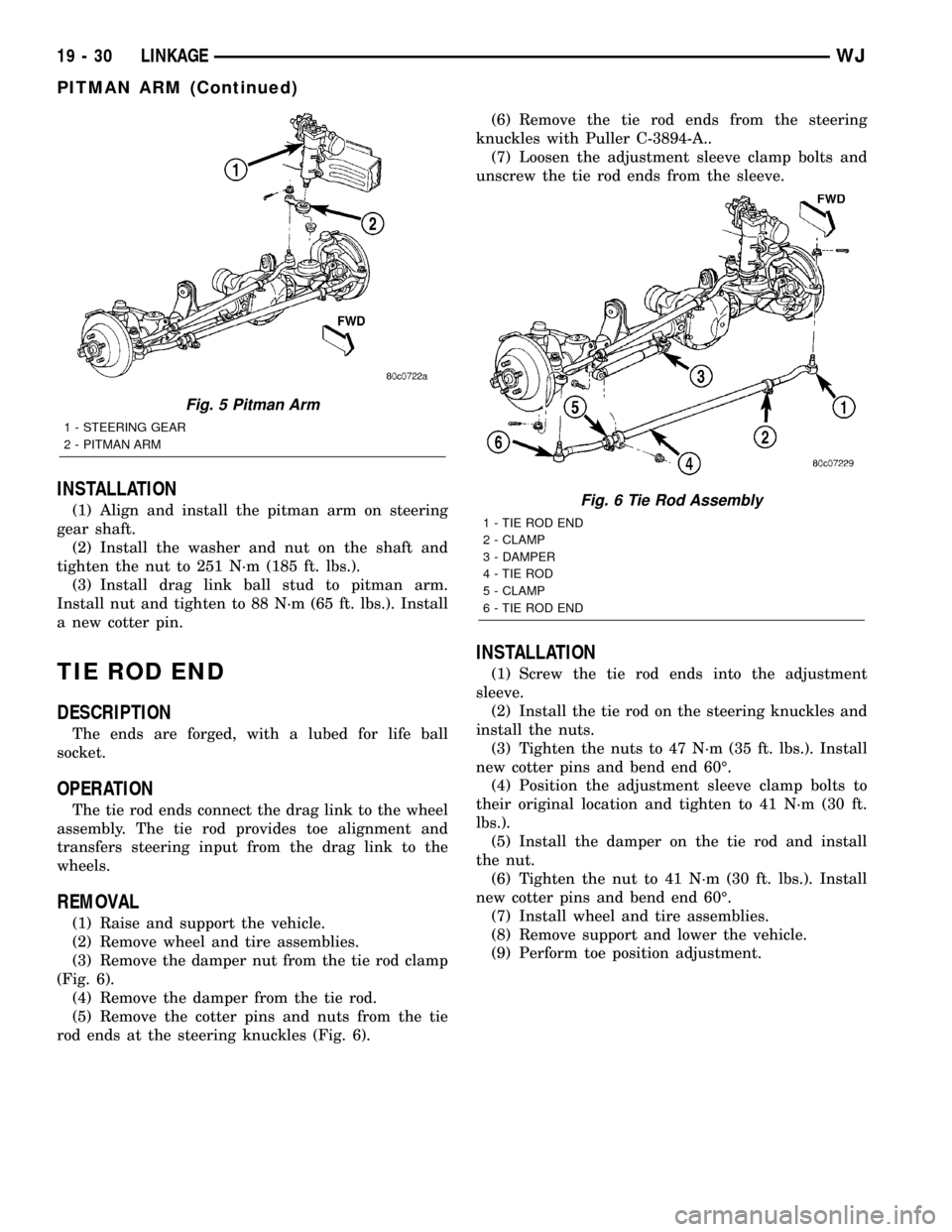

PITMAN ARM

DESCRIPTION

The pitman arm is attached at one end of the

steering gear's sector shaft. The other end is con-

nected to the drag link.

OPERATION

The pitman arm transfers rotary motion into side

to side motion.

REMOVAL

(1) Remove the cotter pin and nut from the drag

link at the pitman arm (Fig. 5) .

(2) Remove the drag link ball stud from the pit-

man arm with a puller.

(3) Remove the nut and washer from the steering

gear shaft. Mark the pitman shaft and pitman arm

for installation reference. Remove the pitman arm

from steering gear with Puller C-4150A.

Fig. 3 Steering Damper

1 - DAMPER

2 - TIE ROD

Fig. 4 Drag Link

1 - STEERING GEAR

2 - PITMAN ARM

3 - CLAMP

4 - DRAG LINK

5 - CLAMP

WJLINKAGE 19 - 29

DAMPER (Continued)

Page 1507 of 2199

INSTALLATION

(1) Align and install the pitman arm on steering

gear shaft.

(2) Install the washer and nut on the shaft and

tighten the nut to 251 N´m (185 ft. lbs.).

(3) Install drag link ball stud to pitman arm.

Install nut and tighten to 88 N´m (65 ft. lbs.). Install

a new cotter pin.

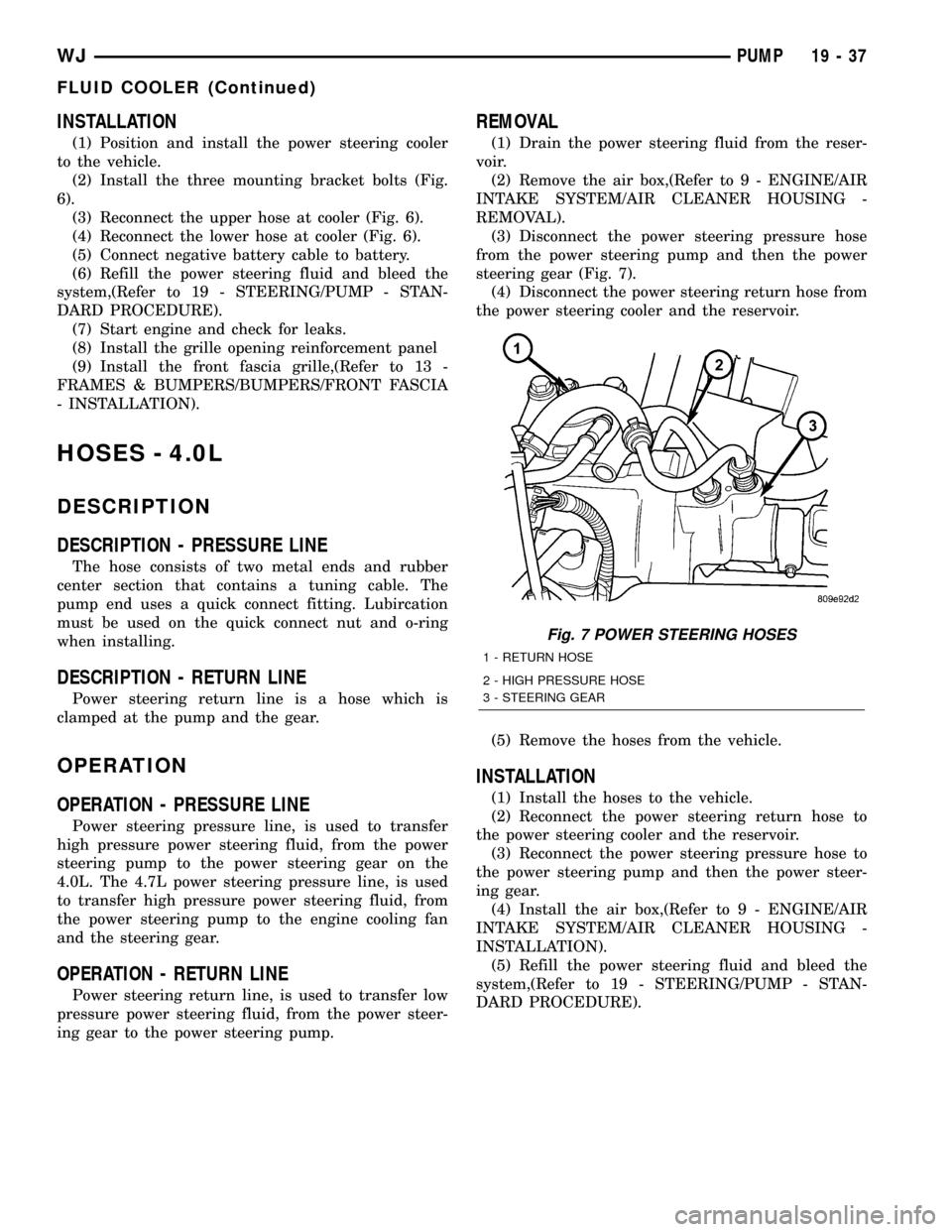

TIE ROD END

DESCRIPTION

The ends are forged, with a lubed for life ball

socket.

OPERATION

The tie rod ends connect the drag link to the wheel

assembly. The tie rod provides toe alignment and

transfers steering input from the drag link to the

wheels.

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Remove the damper nut from the tie rod clamp

(Fig. 6).

(4) Remove the damper from the tie rod.

(5) Remove the cotter pins and nuts from the tie

rod ends at the steering knuckles (Fig. 6).(6) Remove the tie rod ends from the steering

knuckles with Puller C-3894-A..

(7) Loosen the adjustment sleeve clamp bolts and

unscrew the tie rod ends from the sleeve.

INSTALLATION

(1) Screw the tie rod ends into the adjustment

sleeve.

(2) Install the tie rod on the steering knuckles and

install the nuts.

(3) Tighten the nuts to 47 N´m (35 ft. lbs.). Install

new cotter pins and bend end 60É.

(4) Position the adjustment sleeve clamp bolts to

their original location and tighten to 41 N´m (30 ft.

lbs.).

(5) Install the damper on the tie rod and install

the nut.

(6) Tighten the nut to 41 N´m (30 ft. lbs.). Install

new cotter pins and bend end 60É.

(7) Install wheel and tire assemblies.

(8) Remove support and lower the vehicle.

(9) Perform toe position adjustment.

Fig. 5 Pitman Arm

1 - STEERING GEAR

2 - PITMAN ARM

Fig. 6 Tie Rod Assembly

1 - TIE ROD END

2 - CLAMP

3 - DAMPER

4 - TIE ROD

5 - CLAMP

6 - TIE ROD END

19 - 30 LINKAGEWJ

PITMAN ARM (Continued)

Page 1514 of 2199

INSTALLATION

(1) Position and install the power steering cooler

to the vehicle.

(2) Install the three mounting bracket bolts (Fig.

6).

(3) Reconnect the upper hose at cooler (Fig. 6).

(4) Reconnect the lower hose at cooler (Fig. 6).

(5) Connect negative battery cable to battery.

(6) Refill the power steering fluid and bleed the

system,(Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

(7) Start engine and check for leaks.

(8) Install the grille opening reinforcement panel

(9) Install the front fascia grille,(Refer to 13 -

FRAMES & BUMPERS/BUMPERS/FRONT FASCIA

- INSTALLATION).

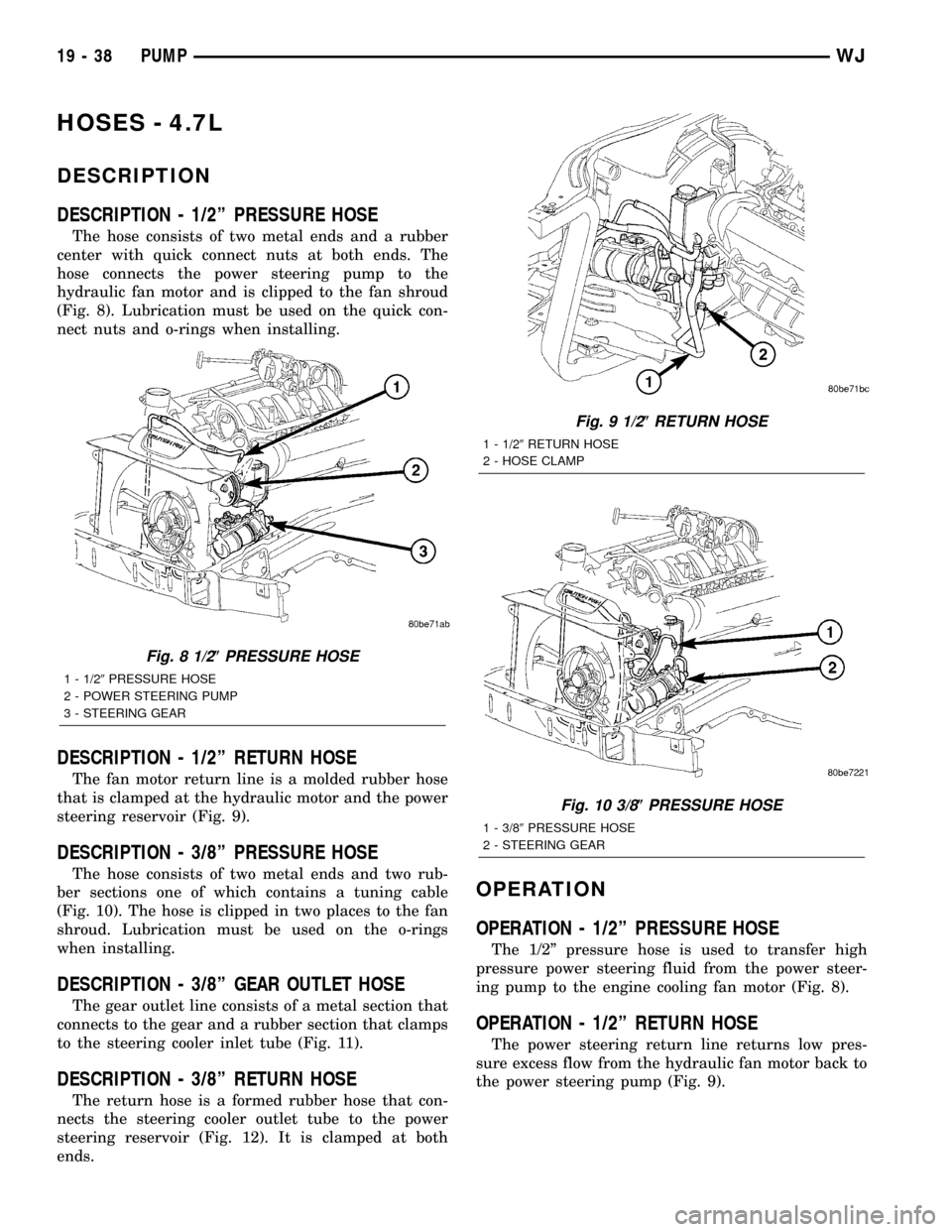

HOSES - 4.0L

DESCRIPTION

DESCRIPTION - PRESSURE LINE

The hose consists of two metal ends and rubber

center section that contains a tuning cable. The

pump end uses a quick connect fitting. Lubircation

must be used on the quick connect nut and o-ring

when installing.

DESCRIPTION - RETURN LINE

Power steering return line is a hose which is

clamped at the pump and the gear.

OPERATION

OPERATION - PRESSURE LINE

Power steering pressure line, is used to transfer

high pressure power steering fluid, from the power

steering pump to the power steering gear on the

4.0L. The 4.7L power steering pressure line, is used

to transfer high pressure power steering fluid, from

the power steering pump to the engine cooling fan

and the steering gear.

OPERATION - RETURN LINE

Power steering return line, is used to transfer low

pressure power steering fluid, from the power steer-

ing gear to the power steering pump.

REMOVAL

(1) Drain the power steering fluid from the reser-

voir.

(2) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Disconnect the power steering pressure hose

from the power steering pump and then the power

steering gear (Fig. 7).

(4) Disconnect the power steering return hose from

the power steering cooler and the reservoir.

(5) Remove the hoses from the vehicle.

INSTALLATION

(1) Install the hoses to the vehicle.

(2) Reconnect the power steering return hose to

the power steering cooler and the reservoir.

(3) Reconnect the power steering pressure hose to

the power steering pump and then the power steer-

ing gear.

(4) Install the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(5) Refill the power steering fluid and bleed the

system,(Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

Fig. 7 POWER STEERING HOSES

1 - RETURN HOSE

2 - HIGH PRESSURE HOSE

3 - STEERING GEAR

WJPUMP 19 - 37

FLUID COOLER (Continued)

Page 1515 of 2199

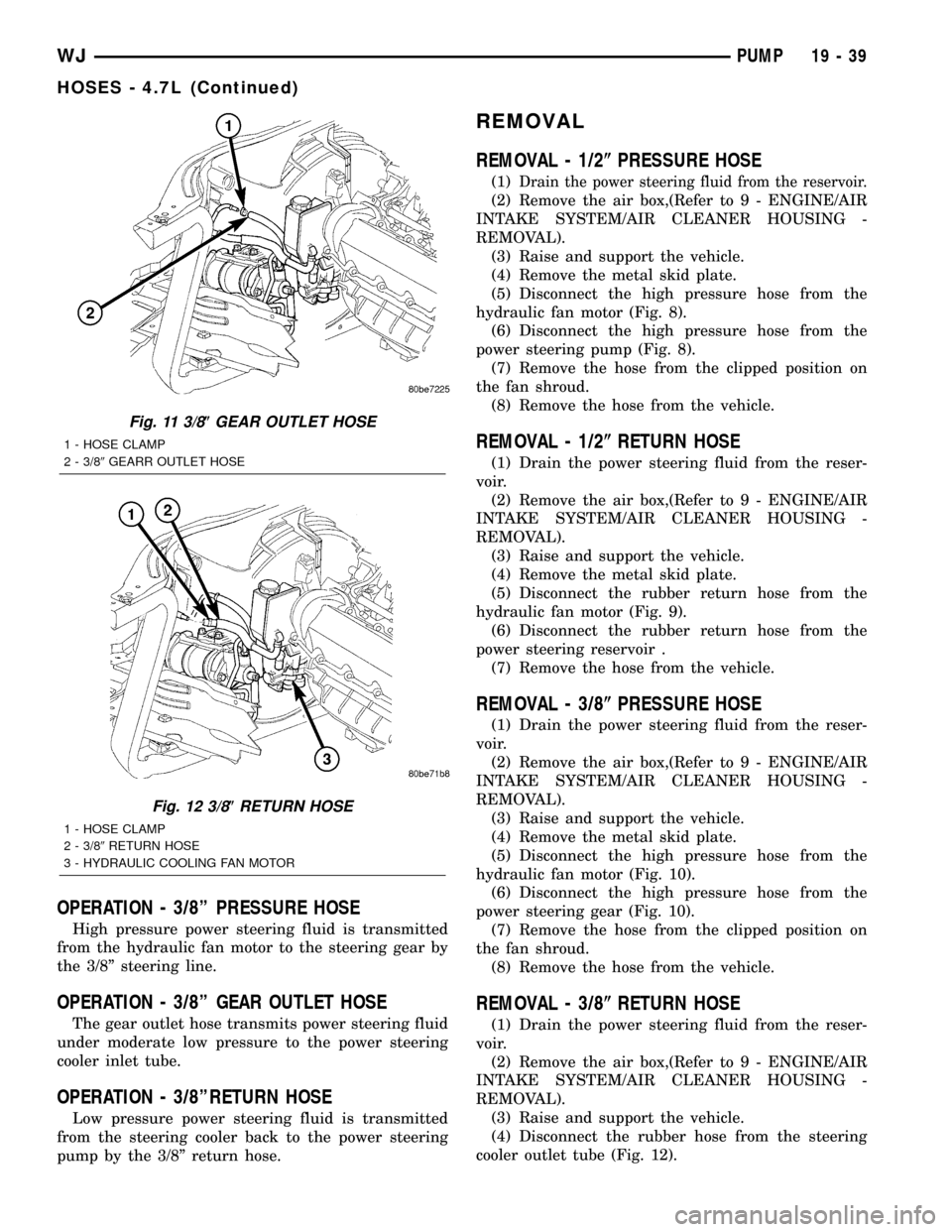

HOSES - 4.7L

DESCRIPTION

DESCRIPTION - 1/2º PRESSURE HOSE

The hose consists of two metal ends and a rubber

center with quick connect nuts at both ends. The

hose connects the power steering pump to the

hydraulic fan motor and is clipped to the fan shroud

(Fig. 8). Lubrication must be used on the quick con-

nect nuts and o-rings when installing.

DESCRIPTION - 1/2º RETURN HOSE

The fan motor return line is a molded rubber hose

that is clamped at the hydraulic motor and the power

steering reservoir (Fig. 9).

DESCRIPTION - 3/8º PRESSURE HOSE

The hose consists of two metal ends and two rub-

ber sections one of which contains a tuning cable

(Fig. 10). The hose is clipped in two places to the fan

shroud. Lubrication must be used on the o-rings

when installing.

DESCRIPTION - 3/8º GEAR OUTLET HOSE

The gear outlet line consists of a metal section that

connects to the gear and a rubber section that clamps

to the steering cooler inlet tube (Fig. 11).

DESCRIPTION - 3/8º RETURN HOSE

The return hose is a formed rubber hose that con-

nects the steering cooler outlet tube to the power

steering reservoir (Fig. 12). It is clamped at both

ends.

OPERATION

OPERATION - 1/2º PRESSURE HOSE

The 1/2º pressure hose is used to transfer high

pressure power steering fluid from the power steer-

ing pump to the engine cooling fan motor (Fig. 8).

OPERATION - 1/2º RETURN HOSE

The power steering return line returns low pres-

sure excess flow from the hydraulic fan motor back to

the power steering pump (Fig. 9).

Fig. 8 1/2(PRESSURE HOSE

1 - 1/29PRESSURE HOSE

2 - POWER STEERING PUMP

3 - STEERING GEAR

Fig. 9 1/2(RETURN HOSE

1 - 1/29RETURN HOSE

2 - HOSE CLAMP

Fig. 10 3/8(PRESSURE HOSE

1 - 3/89PRESSURE HOSE

2 - STEERING GEAR

19 - 38 PUMPWJ

Page 1516 of 2199

OPERATION - 3/8º PRESSURE HOSE

High pressure power steering fluid is transmitted

from the hydraulic fan motor to the steering gear by

the 3/8º steering line.

OPERATION - 3/8º GEAR OUTLET HOSE

The gear outlet hose transmits power steering fluid

under moderate low pressure to the power steering

cooler inlet tube.

OPERATION - 3/8ºRETURN HOSE

Low pressure power steering fluid is transmitted

from the steering cooler back to the power steering

pump by the 3/8º return hose.

REMOVAL

REMOVAL - 1/2(PRESSURE HOSE

(1)Drain the power steering fluid from the reservoir.

(2) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Raise and support the vehicle.

(4) Remove the metal skid plate.

(5) Disconnect the high pressure hose from the

hydraulic fan motor (Fig. 8).

(6) Disconnect the high pressure hose from the

power steering pump (Fig. 8).

(7) Remove the hose from the clipped position on

the fan shroud.

(8) Remove the hose from the vehicle.

REMOVAL - 1/2(RETURN HOSE

(1) Drain the power steering fluid from the reser-

voir.

(2) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Raise and support the vehicle.

(4) Remove the metal skid plate.

(5) Disconnect the rubber return hose from the

hydraulic fan motor (Fig. 9).

(6) Disconnect the rubber return hose from the

power steering reservoir .

(7) Remove the hose from the vehicle.

REMOVAL - 3/8(PRESSURE HOSE

(1) Drain the power steering fluid from the reser-

voir.

(2) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Raise and support the vehicle.

(4) Remove the metal skid plate.

(5) Disconnect the high pressure hose from the

hydraulic fan motor (Fig. 10).

(6) Disconnect the high pressure hose from the

power steering gear (Fig. 10).

(7) Remove the hose from the clipped position on

the fan shroud.

(8) Remove the hose from the vehicle.

REMOVAL - 3/8(RETURN HOSE

(1) Drain the power steering fluid from the reser-

voir.

(2) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Raise and support the vehicle.

(4) Disconnect the rubber hose from the steering

cooler outlet tube (Fig. 12).

Fig. 11 3/8(GEAR OUTLET HOSE

1 - HOSE CLAMP

2 - 3/89GEARR OUTLET HOSE

Fig. 12 3/8(RETURN HOSE

1 - HOSE CLAMP

2 - 3/89RETURN HOSE

3 - HYDRAULIC COOLING FAN MOTOR

WJPUMP 19 - 39

HOSES - 4.7L (Continued)

Page 1517 of 2199

(5) Disconnect the rubber hose from the power

steering reservoir (Fig. 12).

(6) Remove the hose from the vehicle.

REMOVAL - 3/8(GEAR OUTLET HOSE

(1) Drain the power steering fluid from the reser-

voir.

(2) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Raise and support the vehicle.

(4) Disconnect the rubber hose from the steering

cooler inlet tube (Fig. 11).

(5) Disconnect the metal tube from the power

steering gear (Fig. 11).

(6) Remove the hose from the vehicle.

REMOVAL - INLET COOLER HOSE

(1) Disconnect negative battery cable at battery.

(2) Drain the power steering fluid out of the reser-

voir.

(3) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(4) Remove the front fascia grille assembly,(Refer

to 13 - FRAMES & BUMPERS/BUMPERS/FRONT

FASCIA - REMOVAL).

(5) Remove the grille opening reinforcement panel

(6) Place a drain pan under the cooler.

(7) Disconnect the lower hose at cooler (Fig. 6).

(8) Disconnect the cooler hose at the gear.

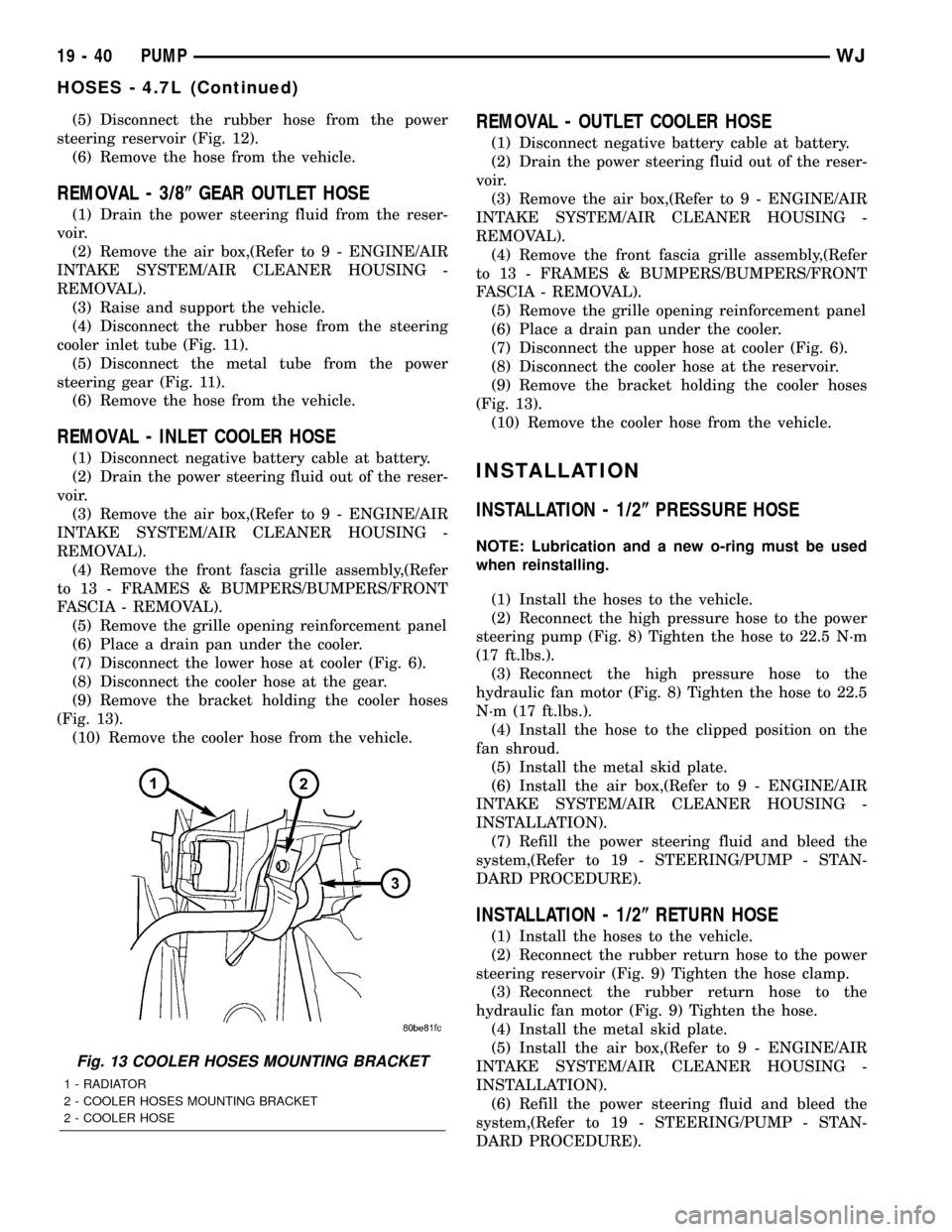

(9) Remove the bracket holding the cooler hoses

(Fig. 13).

(10) Remove the cooler hose from the vehicle.

REMOVAL - OUTLET COOLER HOSE

(1) Disconnect negative battery cable at battery.

(2) Drain the power steering fluid out of the reser-

voir.

(3) Remove the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(4) Remove the front fascia grille assembly,(Refer

to 13 - FRAMES & BUMPERS/BUMPERS/FRONT

FASCIA - REMOVAL).

(5) Remove the grille opening reinforcement panel

(6) Place a drain pan under the cooler.

(7) Disconnect the upper hose at cooler (Fig. 6).

(8) Disconnect the cooler hose at the reservoir.

(9) Remove the bracket holding the cooler hoses

(Fig. 13).

(10) Remove the cooler hose from the vehicle.

INSTALLATION

INSTALLATION - 1/2(PRESSURE HOSE

NOTE: Lubrication and a new o-ring must be used

when reinstalling.

(1) Install the hoses to the vehicle.

(2) Reconnect the high pressure hose to the power

steering pump (Fig. 8) Tighten the hose to 22.5 N´m

(17 ft.lbs.).

(3) Reconnect the high pressure hose to the

hydraulic fan motor (Fig. 8) Tighten the hose to 22.5

N´m (17 ft.lbs.).

(4) Install the hose to the clipped position on the

fan shroud.

(5) Install the metal skid plate.

(6) Install the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(7) Refill the power steering fluid and bleed the

system,(Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

INSTALLATION - 1/2(RETURN HOSE

(1) Install the hoses to the vehicle.

(2) Reconnect the rubber return hose to the power

steering reservoir (Fig. 9) Tighten the hose clamp.

(3) Reconnect the rubber return hose to the

hydraulic fan motor (Fig. 9) Tighten the hose.

(4) Install the metal skid plate.

(5) Install the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(6) Refill the power steering fluid and bleed the

system,(Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

Fig. 13 COOLER HOSES MOUNTING BRACKET

1 - RADIATOR

2 - COOLER HOSES MOUNTING BRACKET

2 - COOLER HOSE

19 - 40 PUMPWJ

HOSES - 4.7L (Continued)

Page 1518 of 2199

INSTALLATION - 3/8(PRESSURE HOSE

NOTE: Lubrication and a new o-ring must be used

when reinstalling.

(1) Install the hoses to the vehicle.

(2) Reconnect the high pressure hose to the

hydraulic fan motor (Fig. 10) Tighten the hose to

22.5 N´m (17 ft.lbs.).

(3) Reconnect the high pressure hose to the power

steering gear (Fig. 10) Tighten the hose to 22.5 N´m

(17 ft.lbs.).

(4) Install the hose to the clipped position on the

fan shroud.

(5) Install the metal skid plate.

(6) Install the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(7) Refill the power steering fluid and bleed the

system,(Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

INSTALLATION - 3/8(RETURN HOSE

(1) Install the hoses to the vehicle.

(2) Reconnect the rubber hose to the steering

cooler outlet tube (Fig. 12) Tighten the hose clamp.

(3) Reconnect the rubber hose to the power steer-

ing reservoir (Fig. 12) Tighten the hose clamp.

(4) Install the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(5) Refill the power steering fluid and bleed the

system,(Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

INSTALLATION - 3/8(GEAR OUTLET HOSE

NOTE: Lubrication and a new o-ring must be used

when reinstalling.

(1) Install the hoses to the vehicle.

(2) Reconnect the rubber hose to the steering

cooler inlet tube (Fig. 11) Tighten the hose clamp.

(3)

Reconnect the metal tube to the power steering

gear (Fig. 11) Tighten the hose to 22.5 N´m (17 ft.lbs.).

(4) Install the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(5) Refill the power steering fluid and bleed the

system,(Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

INSTALLATION - INLET COOLER HOSE

(1) Install the cooler hose to the vehicle.

(2) Reconnect the cooler hose at the gear.

(3) Reconnect the lower hose at cooler (Fig. 6).

Tighten the hose to 22.5 N´m (17 ft.lbs.)

(4) Install the bracket holding the cooler hoses

(Fig. 13).(5) Install the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(6) Install the grille opening reinforcement panel

(7) Install the front fascia grille assembly, (Refer to

13 - FRAMES & BUMPERS/BUMPERS/FRONT

FASCIA - INSTALLATION).

(8) Reconnect negative battery cable at battery.

(9) Refill the power steering fluid and bleed the

system,(Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

INSTALLATION - OUTLET COOLER HOSE

(1) Install the cooler hose to the vehicle.

(2) Reconnect the cooler hose at the reservoir.

(3) Reconnect the upper hose at the cooler (Fig. 6).

Tighten the hose to 22.5 N´m (17 ft. lbs.)

(4) Install the bracket holding the cooler hoses

(Fig. 13). Tighten the bracket to 22.5 N´m (17 ft. lbs.)

(5) Install the air box,(Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(6) Install the grille opening reinforcement panel

(7) Install the front fascia grille assembly, (Refer to

13 - FRAMES & BUMPERS/BUMPERS/FRONT

FASCIA - INSTALLATION).

(8) Reconnect negative battery cable at battery.

(9) Refill the power steering fluid and bleed the

system,(Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

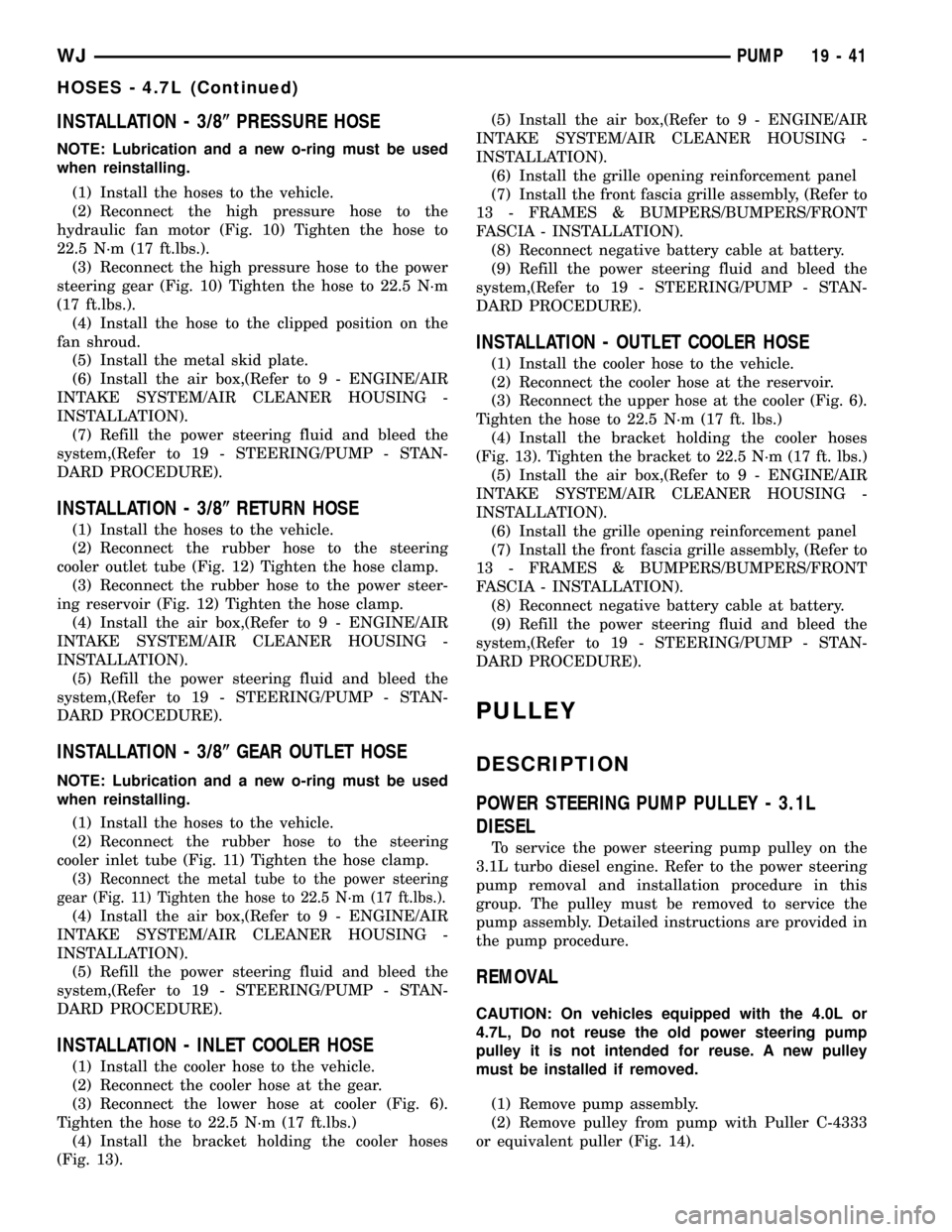

PULLEY

DESCRIPTION

POWER STEERING PUMP PULLEY - 3.1L

DIESEL

To service the power steering pump pulley on the

3.1L turbo diesel engine. Refer to the power steering

pump removal and installation procedure in this

group. The pulley must be removed to service the

pump assembly. Detailed instructions are provided in

the pump procedure.

REMOVAL

CAUTION: On vehicles equipped with the 4.0L or

4.7L, Do not reuse the old power steering pump

pulley it is not intended for reuse. A new pulley

must be installed if removed.

(1) Remove pump assembly.

(2) Remove pulley from pump with Puller C-4333

or equivalent puller (Fig. 14).

WJPUMP 19 - 41

HOSES - 4.7L (Continued)