Clamp JEEP GRAND CHEROKEE 2003 WJ / 2.G Manual Online

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1410 of 2199

TAILPIPE

DESCRIPTION

The tailpipe is also made of stainless steel. (Fig.

18) .

OPERATION

The Tailpipe channels the exhaust out of the muf-

fler and out from under the vehicle to control noise

and prevent exhaust gas fumes from entering the

passenger compartment

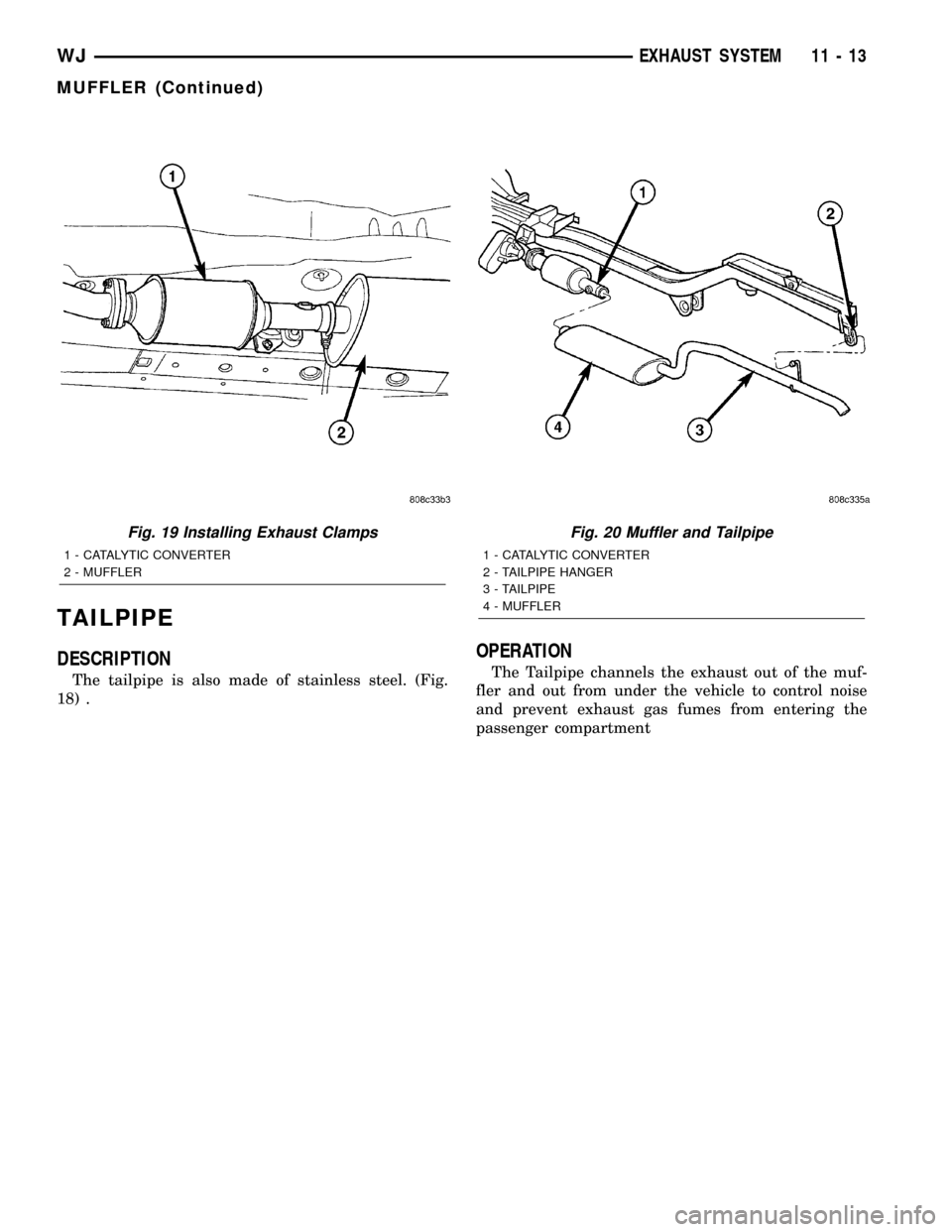

Fig. 19 Installing Exhaust Clamps

1 - CATALYTIC CONVERTER

2 - MUFFLER

Fig. 20 Muffler and Tailpipe

1 - CATALYTIC CONVERTER

2 - TAILPIPE HANGER

3 - TAILPIPE

4 - MUFFLER

WJEXHAUST SYSTEM 11 - 13

MUFFLER (Continued)

Page 1422 of 2199

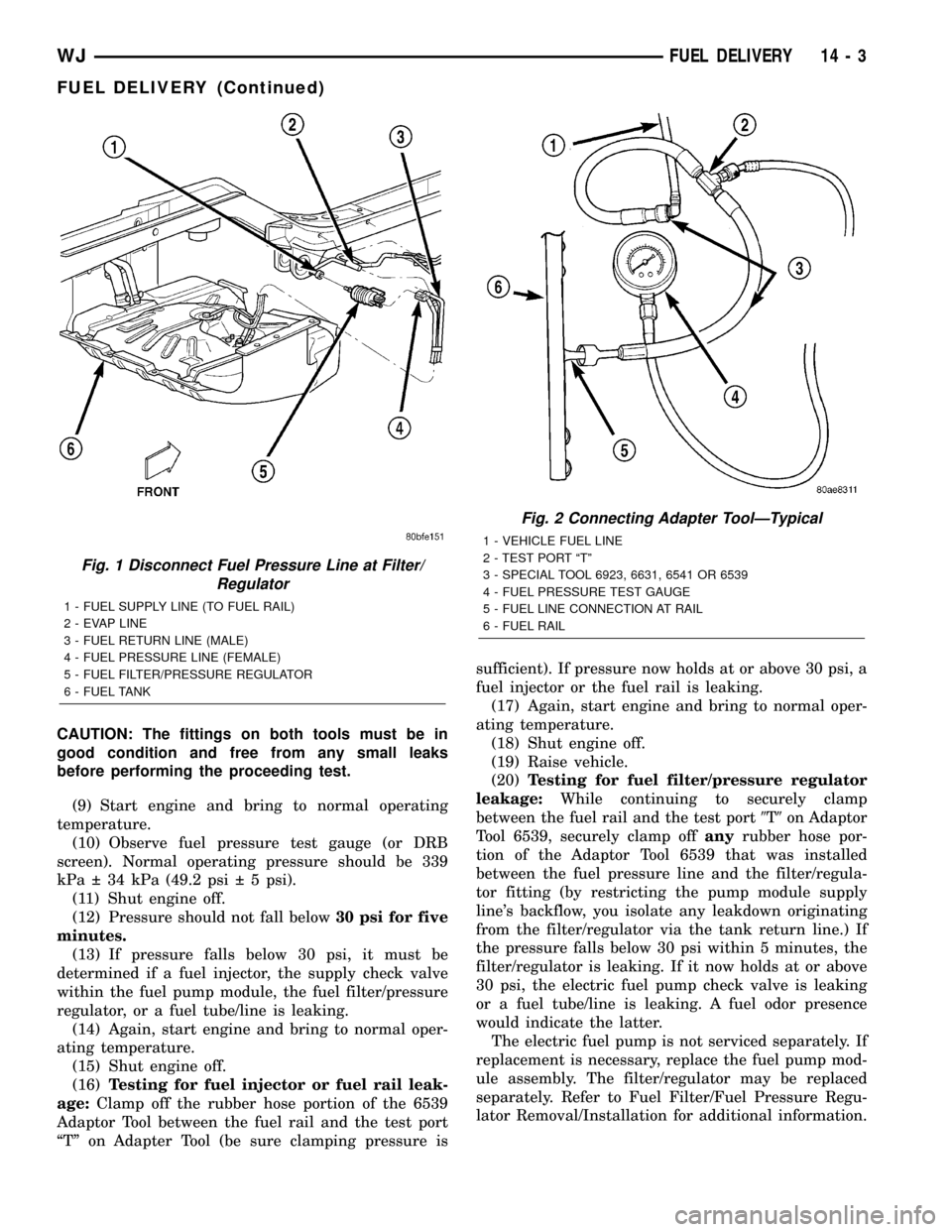

CAUTION: The fittings on both tools must be in

good condition and free from any small leaks

before performing the proceeding test.

(9) Start engine and bring to normal operating

temperature.

(10) Observe fuel pressure test gauge (or DRB

screen). Normal operating pressure should be 339

kPa 34 kPa (49.2 psi 5 psi).

(11) Shut engine off.

(12) Pressure should not fall below30 psi for five

minutes.

(13) If pressure falls below 30 psi, it must be

determined if a fuel injector, the supply check valve

within the fuel pump module, the fuel filter/pressure

regulator, or a fuel tube/line is leaking.

(14) Again, start engine and bring to normal oper-

ating temperature.

(15) Shut engine off.

(16)Testing for fuel injector or fuel rail leak-

age:Clamp off the rubber hose portion of the 6539

Adaptor Tool between the fuel rail and the test port

ªTº on Adapter Tool (be sure clamping pressure issufficient). If pressure now holds at or above 30 psi, a

fuel injector or the fuel rail is leaking.

(17) Again, start engine and bring to normal oper-

ating temperature.

(18) Shut engine off.

(19) Raise vehicle.

(20)Testing for fuel filter/pressure regulator

leakage:While continuing to securely clamp

between the fuel rail and the test port9T9on Adaptor

Tool 6539, securely clamp offanyrubber hose por-

tion of the Adaptor Tool 6539 that was installed

between the fuel pressure line and the filter/regula-

tor fitting (by restricting the pump module supply

line's backflow, you isolate any leakdown originating

from the filter/regulator via the tank return line.) If

the pressure falls below 30 psi within 5 minutes, the

filter/regulator is leaking. If it now holds at or above

30 psi, the electric fuel pump check valve is leaking

or a fuel tube/line is leaking. A fuel odor presence

would indicate the latter.

The electric fuel pump is not serviced separately. If

replacement is necessary, replace the fuel pump mod-

ule assembly. The filter/regulator may be replaced

separately. Refer to Fuel Filter/Fuel Pressure Regu-

lator Removal/Installation for additional information.

Fig. 1 Disconnect Fuel Pressure Line at Filter/

Regulator

1 - FUEL SUPPLY LINE (TO FUEL RAIL)

2 - EVAP LINE

3 - FUEL RETURN LINE (MALE)

4 - FUEL PRESSURE LINE (FEMALE)

5 - FUEL FILTER/PRESSURE REGULATOR

6 - FUEL TANK

Fig. 2 Connecting Adapter ToolÐTypical

1 - VEHICLE FUEL LINE

2 - TEST PORT ªTº

3 - SPECIAL TOOL 6923, 6631, 6541 OR 6539

4 - FUEL PRESSURE TEST GAUGE

5 - FUEL LINE CONNECTION AT RAIL

6 - FUEL RAIL

WJFUEL DELIVERY 14 - 3

FUEL DELIVERY (Continued)

Page 1423 of 2199

STANDARD PROCEDURE - FUEL SYSTEM

PRESSURE RELEASE

Use following procedure if the fuel injector

rail is, or is not equipped with a fuel pressure

test port.

(1) Remove fuel fill cap.

(2) Remove fuel pump relay from Power Distribu-

tion Center (PDC). For location of relay, refer to label

on underside of PDC cover.

(3) Start and run engine until it stalls.

(4) Attempt restarting engine until it will no

longer run.

(5) Turn ignition key to OFF position.

CAUTION: Steps 1, 2, 3 and 4 must be performed to

relieve high pressure fuel from within fuel rail. Do

not attempt to use following steps to relieve this

pressure as excessive fuel will be forced into a cyl-

inder chamber.

(6) Unplug connector from any fuel injector.

(7) Attach one end of a jumper wire with alligator

clips (18 gauge or smaller) to either injector terminal.(8) Connect other end of jumper wire to positive

side of battery.

(9) Connect one end of a second jumper wire to

remaining injector terminal.

CAUTION: Powering an injector for more than a few

seconds will permanently damage the injector.

(10) Momentarily touch other end of jumper wire

to negative terminal of battery for no more than a

few seconds.

(11) Place a rag or towel below fuel line quick-con-

nect fitting at fuel rail.

(12) Disconnect quick-connect fitting at fuel rail.

Refer to Quick-Connect Fittings.

(13) Return fuel pump relay to PDC.

(14) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in PCM memory due to fuel

pump relay removal. The DRBtscan tool must be

used to erase a DTC.

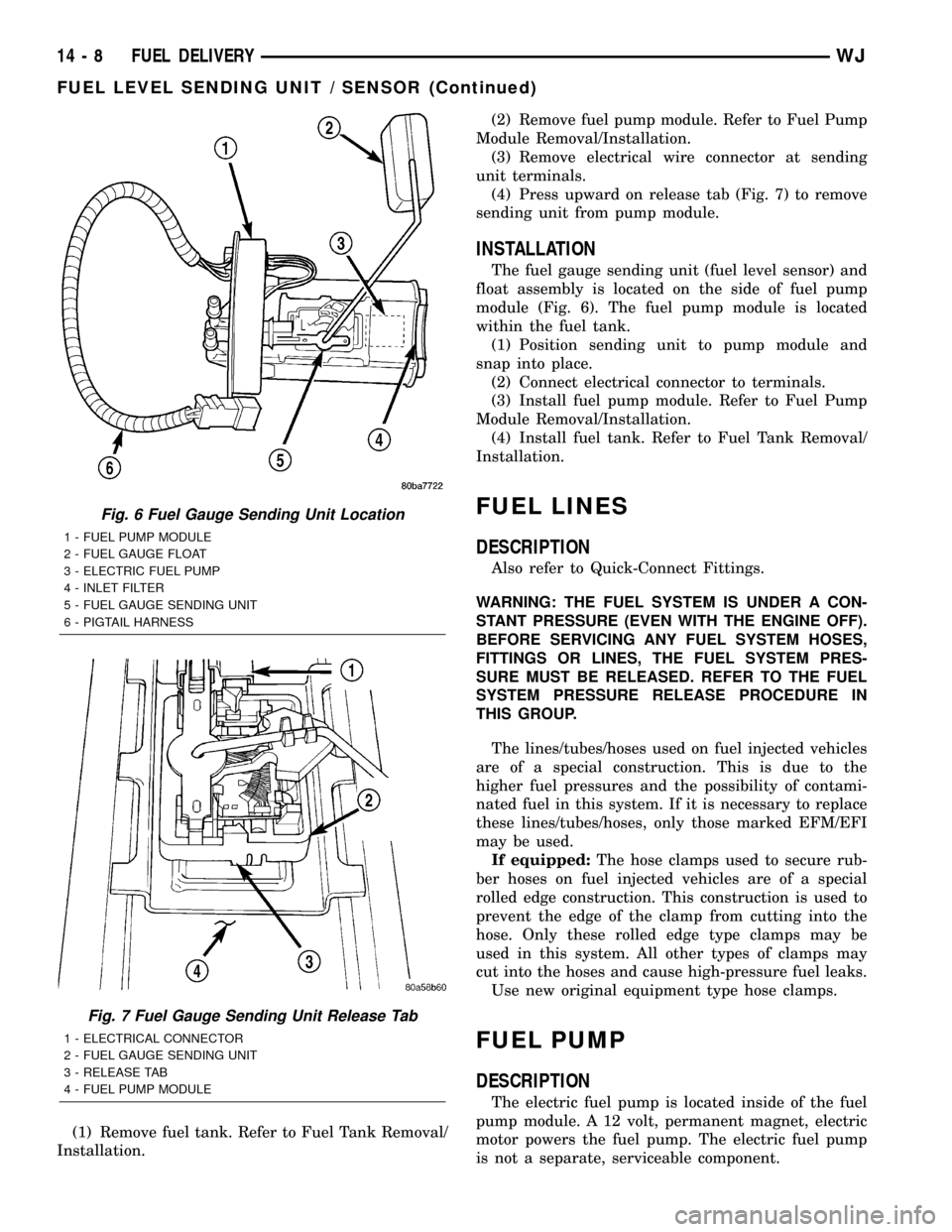

SPECIFICATIONS

FUEL SYSTEM PRESSURE

339 kPa 34 kPa (49.2 psi 5 psi).

TORQUE - FUEL DELIVERY

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Accelerator Pedal Bracket Mounting Nuts

(without adjustable pedals)12 2 - 105 20

Fuel Filter/Fuel Press. Reg. Bolts 3 - 26

Fuel Hose Clamps 3 - 26

Fuel Injector Rail Mounting Bolts -4.0L Engine 11 - 100

Fuel Injector Rail Mounting Bolts -4.7L V-8

Engine11 - 100

Fuel Pump Module Locknut 74 55 -

Fuel Tank Filler Tube-to-Body Mounting Bolts 2 - 15

Fuel Tank-to-Body Mounting Bolts 88 65 -

Fuel Tank Support Bracket Bolts (large brackets) 88 65 -

Fuel Tank Support Bracket Bolts (small bracket) 5 - 45

Fuel Tank Support Bracket Nuts (large brackets) 61 45 -

Fuel Tank Heat Shield Nuts (shield-to-tank) 9 - 85

Fuel Tank Heat Shield Nuts (shield-to-body) 3 - 25

14 - 4 FUEL DELIVERYWJ

FUEL DELIVERY (Continued)

Page 1427 of 2199

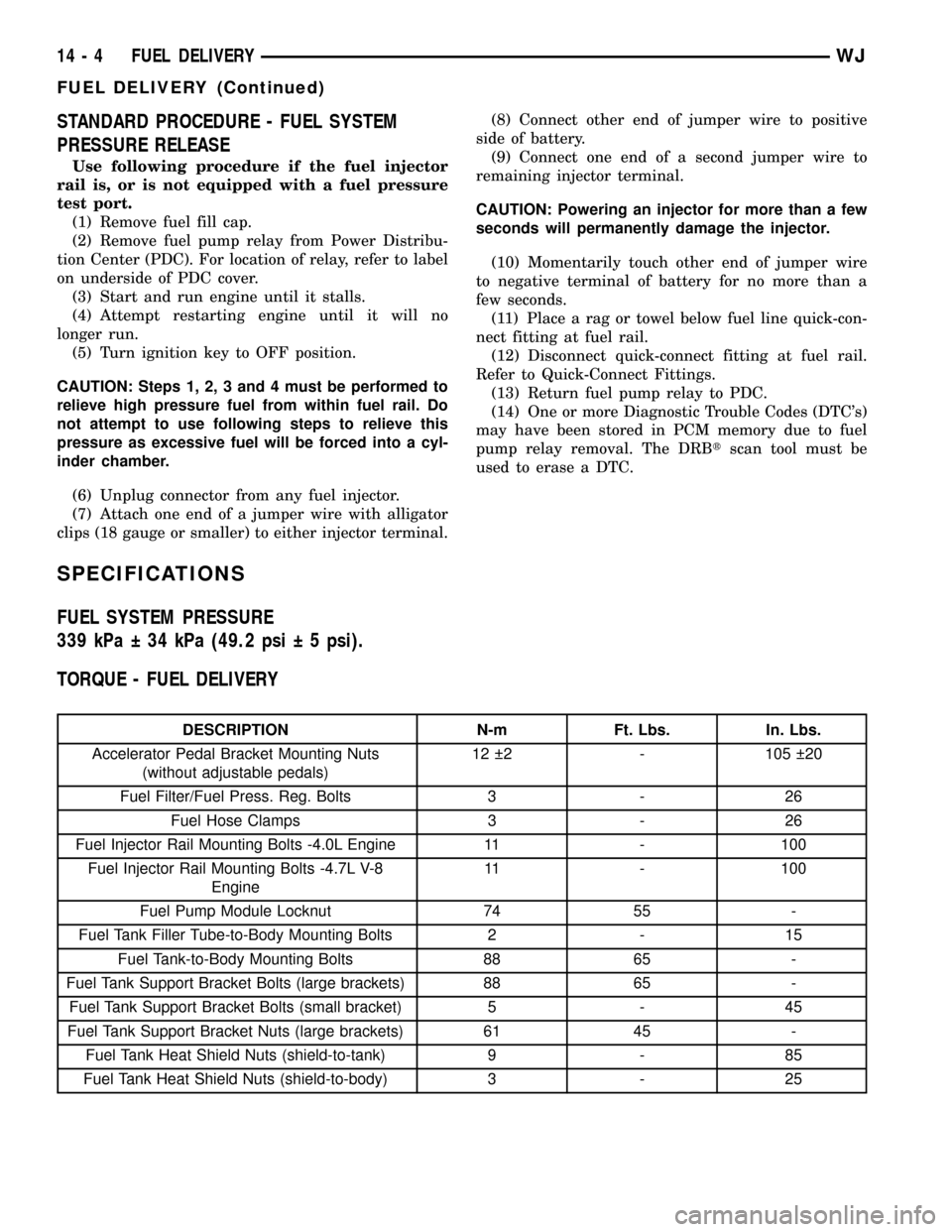

(1) Remove fuel tank. Refer to Fuel Tank Removal/

Installation.(2) Remove fuel pump module. Refer to Fuel Pump

Module Removal/Installation.

(3) Remove electrical wire connector at sending

unit terminals.

(4) Press upward on release tab (Fig. 7) to remove

sending unit from pump module.

INSTALLATION

The fuel gauge sending unit (fuel level sensor) and

float assembly is located on the side of fuel pump

module (Fig. 6). The fuel pump module is located

within the fuel tank.

(1) Position sending unit to pump module and

snap into place.

(2) Connect electrical connector to terminals.

(3) Install fuel pump module. Refer to Fuel Pump

Module Removal/Installation.

(4) Install fuel tank. Refer to Fuel Tank Removal/

Installation.

FUEL LINES

DESCRIPTION

Also refer to Quick-Connect Fittings.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

SYSTEM PRESSURE RELEASE PROCEDURE IN

THIS GROUP.

The lines/tubes/hoses used on fuel injected vehicles

are of a special construction. This is due to the

higher fuel pressures and the possibility of contami-

nated fuel in this system. If it is necessary to replace

these lines/tubes/hoses, only those marked EFM/EFI

may be used.

If equipped:The hose clamps used to secure rub-

ber hoses on fuel injected vehicles are of a special

rolled edge construction. This construction is used to

prevent the edge of the clamp from cutting into the

hose. Only these rolled edge type clamps may be

used in this system. All other types of clamps may

cut into the hoses and cause high-pressure fuel leaks.

Use new original equipment type hose clamps.

FUEL PUMP

DESCRIPTION

The electric fuel pump is located inside of the fuel

pump module. A 12 volt, permanent magnet, electric

motor powers the fuel pump. The electric fuel pump

is not a separate, serviceable component.

Fig. 6 Fuel Gauge Sending Unit Location

1 - FUEL PUMP MODULE

2 - FUEL GAUGE FLOAT

3 - ELECTRIC FUEL PUMP

4 - INLET FILTER

5 - FUEL GAUGE SENDING UNIT

6 - PIGTAIL HARNESS

Fig. 7 Fuel Gauge Sending Unit Release Tab

1 - ELECTRICAL CONNECTOR

2 - FUEL GAUGE SENDING UNIT

3 - RELEASE TAB

4 - FUEL PUMP MODULE

14 - 8 FUEL DELIVERYWJ

FUEL LEVEL SENDING UNIT / SENSOR (Continued)

Page 1435 of 2199

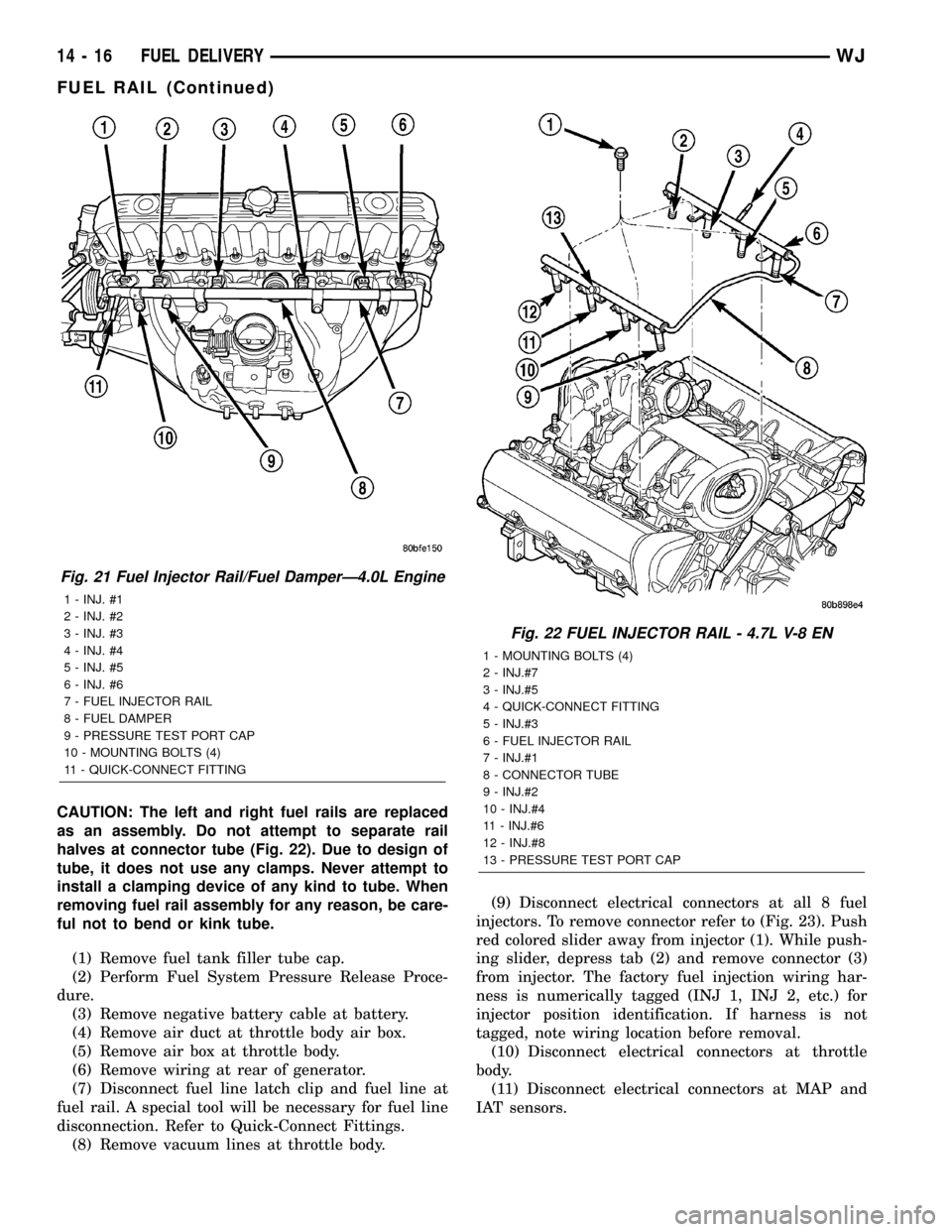

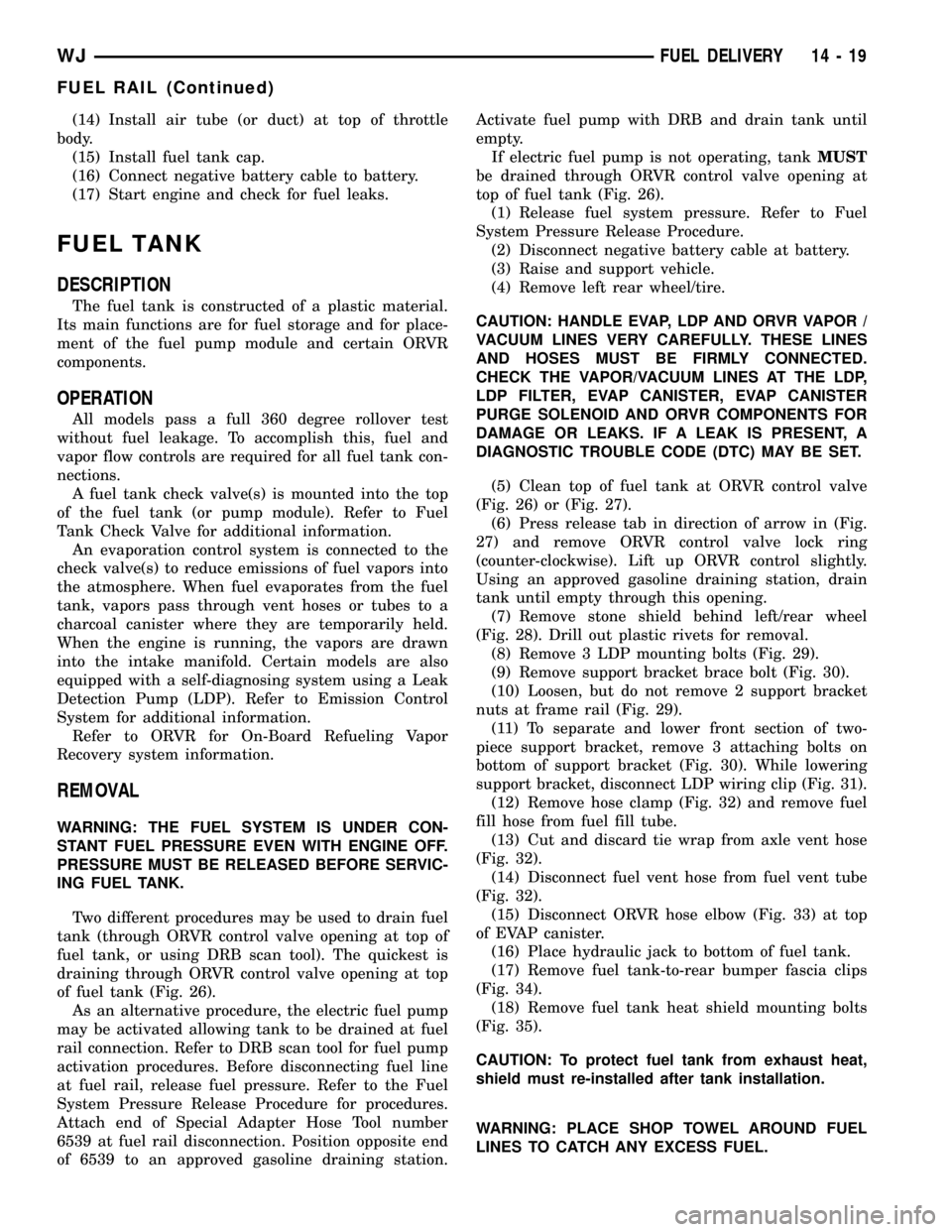

CAUTION: The left and right fuel rails are replaced

as an assembly. Do not attempt to separate rail

halves at connector tube (Fig. 22). Due to design of

tube, it does not use any clamps. Never attempt to

install a clamping device of any kind to tube. When

removing fuel rail assembly for any reason, be care-

ful not to bend or kink tube.

(1) Remove fuel tank filler tube cap.

(2) Perform Fuel System Pressure Release Proce-

dure.

(3) Remove negative battery cable at battery.

(4) Remove air duct at throttle body air box.

(5) Remove air box at throttle body.

(6) Remove wiring at rear of generator.

(7) Disconnect fuel line latch clip and fuel line at

fuel rail. A special tool will be necessary for fuel line

disconnection. Refer to Quick-Connect Fittings.

(8) Remove vacuum lines at throttle body.(9) Disconnect electrical connectors at all 8 fuel

injectors. To remove connector refer to (Fig. 23). Push

red colored slider away from injector (1). While push-

ing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring har-

ness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(10) Disconnect electrical connectors at throttle

body.

(11) Disconnect electrical connectors at MAP and

IAT sensors.

Fig. 21 Fuel Injector Rail/Fuel DamperÐ4.0L Engine

1 - INJ. #1

2 - INJ. #2

3 - INJ. #3

4 - INJ. #4

5 - INJ. #5

6 - INJ. #6

7 - FUEL INJECTOR RAIL

8 - FUEL DAMPER

9 - PRESSURE TEST PORT CAP

10 - MOUNTING BOLTS (4)

11 - QUICK-CONNECT FITTING

Fig. 22 FUEL INJECTOR RAIL - 4.7L V-8 EN

1 - MOUNTING BOLTS (4)

2 - INJ.#7

3 - INJ.#5

4 - QUICK-CONNECT FITTING

5 - INJ.#3

6 - FUEL INJECTOR RAIL

7 - INJ.#1

8 - CONNECTOR TUBE

9 - INJ.#2

10 - INJ.#4

11 - INJ.#6

12 - INJ.#8

13 - PRESSURE TEST PORT CAP

14 - 16 FUEL DELIVERYWJ

FUEL RAIL (Continued)

Page 1438 of 2199

(14) Install air tube (or duct) at top of throttle

body.

(15) Install fuel tank cap.

(16) Connect negative battery cable to battery.

(17) Start engine and check for fuel leaks.

FUEL TANK

DESCRIPTION

The fuel tank is constructed of a plastic material.

Its main functions are for fuel storage and for place-

ment of the fuel pump module and certain ORVR

components.

OPERATION

All models pass a full 360 degree rollover test

without fuel leakage. To accomplish this, fuel and

vapor flow controls are required for all fuel tank con-

nections.

A fuel tank check valve(s) is mounted into the top

of the fuel tank (or pump module). Refer to Fuel

Tank Check Valve for additional information.

An evaporation control system is connected to the

check valve(s) to reduce emissions of fuel vapors into

the atmosphere. When fuel evaporates from the fuel

tank, vapors pass through vent hoses or tubes to a

charcoal canister where they are temporarily held.

When the engine is running, the vapors are drawn

into the intake manifold. Certain models are also

equipped with a self-diagnosing system using a Leak

Detection Pump (LDP). Refer to Emission Control

System for additional information.

Refer to ORVR for On-Board Refueling Vapor

Recovery system information.

REMOVAL

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT FUEL PRESSURE EVEN WITH ENGINE OFF.

PRESSURE MUST BE RELEASED BEFORE SERVIC-

ING FUEL TANK.

Two different procedures may be used to drain fuel

tank (through ORVR control valve opening at top of

fuel tank, or using DRB scan tool). The quickest is

draining through ORVR control valve opening at top

of fuel tank (Fig. 26).

As an alternative procedure, the electric fuel pump

may be activated allowing tank to be drained at fuel

rail connection. Refer to DRB scan tool for fuel pump

activation procedures. Before disconnecting fuel line

at fuel rail, release fuel pressure. Refer to the Fuel

System Pressure Release Procedure for procedures.

Attach end of Special Adapter Hose Tool number

6539 at fuel rail disconnection. Position opposite end

of 6539 to an approved gasoline draining station.Activate fuel pump with DRB and drain tank until

empty.

If electric fuel pump is not operating, tankMUST

be drained through ORVR control valve opening at

top of fuel tank (Fig. 26).

(1) Release fuel system pressure. Refer to Fuel

System Pressure Release Procedure.

(2) Disconnect negative battery cable at battery.

(3) Raise and support vehicle.

(4) Remove left rear wheel/tire.

CAUTION: HANDLE EVAP, LDP AND ORVR VAPOR /

VACUUM LINES VERY CAREFULLY. THESE LINES

AND HOSES MUST BE FIRMLY CONNECTED.

CHECK THE VAPOR/VACUUM LINES AT THE LDP,

LDP FILTER, EVAP CANISTER, EVAP CANISTER

PURGE SOLENOID AND ORVR COMPONENTS FOR

DAMAGE OR LEAKS. IF A LEAK IS PRESENT, A

DIAGNOSTIC TROUBLE CODE (DTC) MAY BE SET.

(5) Clean top of fuel tank at ORVR control valve

(Fig. 26) or (Fig. 27).

(6) Press release tab in direction of arrow in (Fig.

27) and remove ORVR control valve lock ring

(counter-clockwise). Lift up ORVR control slightly.

Using an approved gasoline draining station, drain

tank until empty through this opening.

(7) Remove stone shield behind left/rear wheel

(Fig. 28). Drill out plastic rivets for removal.

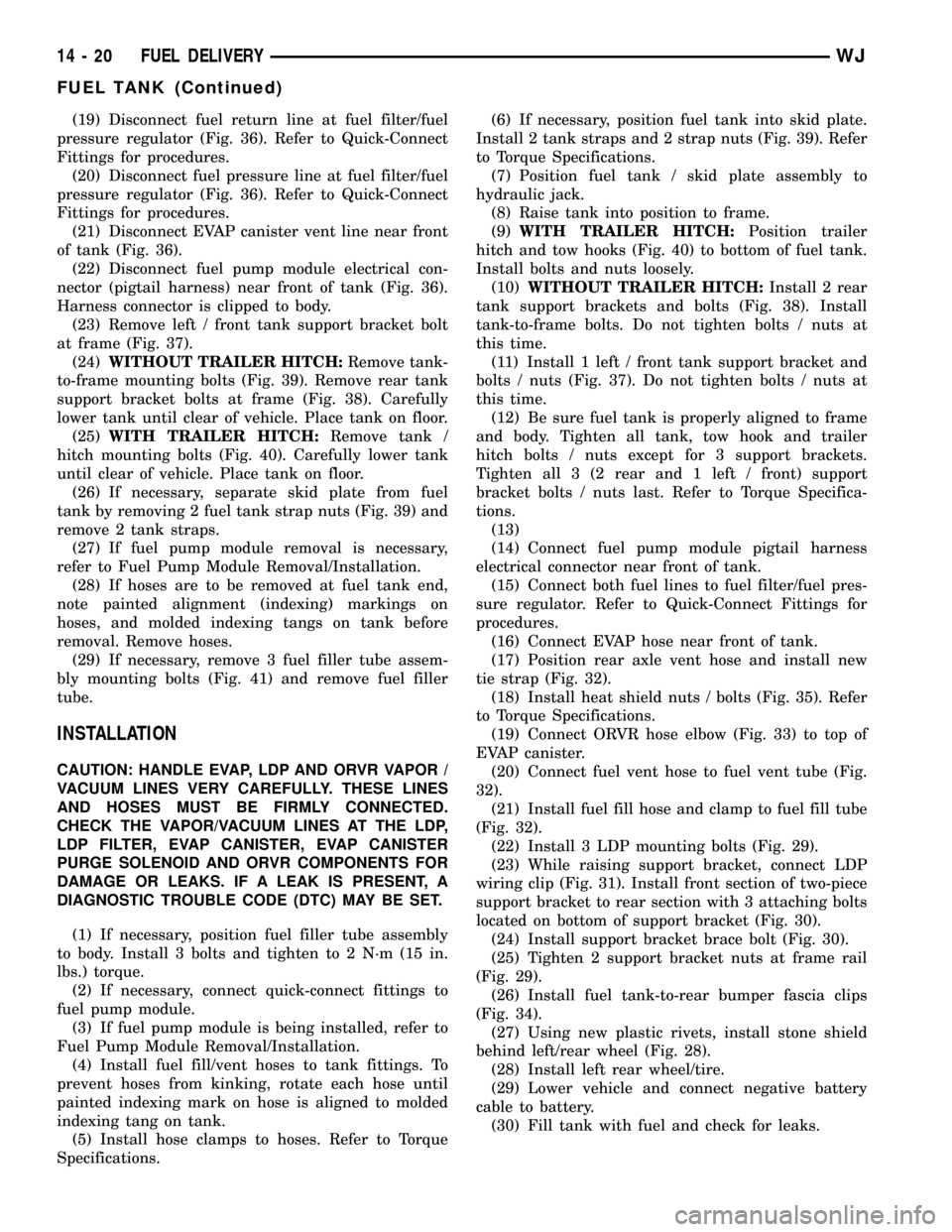

(8) Remove 3 LDP mounting bolts (Fig. 29).

(9) Remove support bracket brace bolt (Fig. 30).

(10) Loosen, but do not remove 2 support bracket

nuts at frame rail (Fig. 29).

(11) To separate and lower front section of two-

piece support bracket, remove 3 attaching bolts on

bottom of support bracket (Fig. 30). While lowering

support bracket, disconnect LDP wiring clip (Fig. 31).

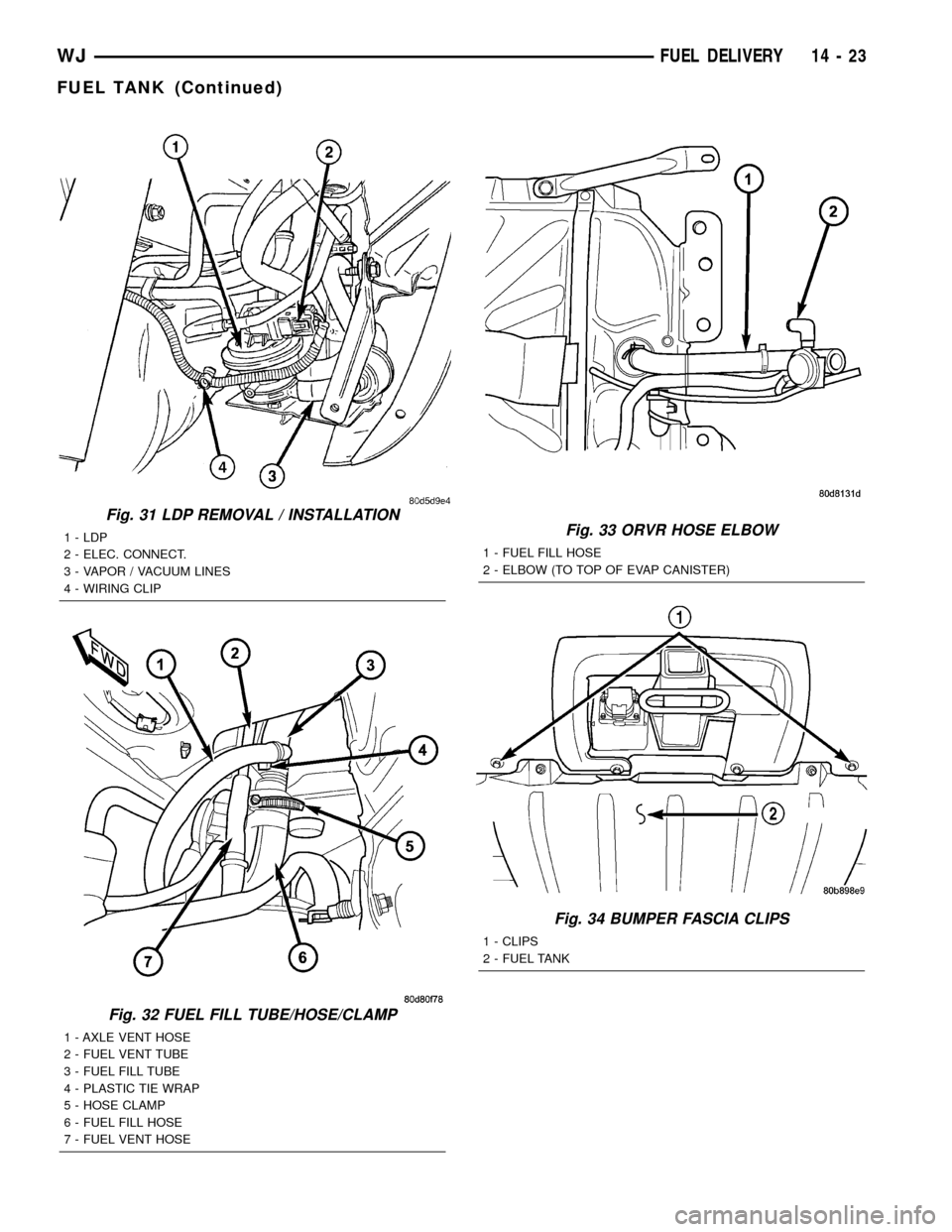

(12) Remove hose clamp (Fig. 32) and remove fuel

fill hose from fuel fill tube.

(13) Cut and discard tie wrap from axle vent hose

(Fig. 32).

(14) Disconnect fuel vent hose from fuel vent tube

(Fig. 32).

(15) Disconnect ORVR hose elbow (Fig. 33) at top

of EVAP canister.

(16) Place hydraulic jack to bottom of fuel tank.

(17) Remove fuel tank-to-rear bumper fascia clips

(Fig. 34).

(18) Remove fuel tank heat shield mounting bolts

(Fig. 35).

CAUTION: To protect fuel tank from exhaust heat,

shield must re-installed after tank installation.

WARNING: PLACE SHOP TOWEL AROUND FUEL

LINES TO CATCH ANY EXCESS FUEL.

WJFUEL DELIVERY 14 - 19

FUEL RAIL (Continued)

Page 1439 of 2199

(19) Disconnect fuel return line at fuel filter/fuel

pressure regulator (Fig. 36). Refer to Quick-Connect

Fittings for procedures.

(20) Disconnect fuel pressure line at fuel filter/fuel

pressure regulator (Fig. 36). Refer to Quick-Connect

Fittings for procedures.

(21) Disconnect EVAP canister vent line near front

of tank (Fig. 36).

(22) Disconnect fuel pump module electrical con-

nector (pigtail harness) near front of tank (Fig. 36).

Harness connector is clipped to body.

(23) Remove left / front tank support bracket bolt

at frame (Fig. 37).

(24)WITHOUT TRAILER HITCH:Remove tank-

to-frame mounting bolts (Fig. 39). Remove rear tank

support bracket bolts at frame (Fig. 38). Carefully

lower tank until clear of vehicle. Place tank on floor.

(25)WITH TRAILER HITCH:Remove tank /

hitch mounting bolts (Fig. 40). Carefully lower tank

until clear of vehicle. Place tank on floor.

(26) If necessary, separate skid plate from fuel

tank by removing 2 fuel tank strap nuts (Fig. 39) and

remove 2 tank straps.

(27) If fuel pump module removal is necessary,

refer to Fuel Pump Module Removal/Installation.

(28) If hoses are to be removed at fuel tank end,

note painted alignment (indexing) markings on

hoses, and molded indexing tangs on tank before

removal. Remove hoses.

(29) If necessary, remove 3 fuel filler tube assem-

bly mounting bolts (Fig. 41) and remove fuel filler

tube.

INSTALLATION

CAUTION: HANDLE EVAP, LDP AND ORVR VAPOR /

VACUUM LINES VERY CAREFULLY. THESE LINES

AND HOSES MUST BE FIRMLY CONNECTED.

CHECK THE VAPOR/VACUUM LINES AT THE LDP,

LDP FILTER, EVAP CANISTER, EVAP CANISTER

PURGE SOLENOID AND ORVR COMPONENTS FOR

DAMAGE OR LEAKS. IF A LEAK IS PRESENT, A

DIAGNOSTIC TROUBLE CODE (DTC) MAY BE SET.

(1) If necessary, position fuel filler tube assembly

to body. Install 3 bolts and tighten to 2 N´m (15 in.

lbs.) torque.

(2) If necessary, connect quick-connect fittings to

fuel pump module.

(3) If fuel pump module is being installed, refer to

Fuel Pump Module Removal/Installation.

(4) Install fuel fill/vent hoses to tank fittings. To

prevent hoses from kinking, rotate each hose until

painted indexing mark on hose is aligned to molded

indexing tang on tank.

(5) Install hose clamps to hoses. Refer to Torque

Specifications.(6) If necessary, position fuel tank into skid plate.

Install 2 tank straps and 2 strap nuts (Fig. 39). Refer

to Torque Specifications.

(7) Position fuel tank / skid plate assembly to

hydraulic jack.

(8) Raise tank into position to frame.

(9)WITH TRAILER HITCH:Position trailer

hitch and tow hooks (Fig. 40) to bottom of fuel tank.

Install bolts and nuts loosely.

(10)WITHOUT TRAILER HITCH:Install 2 rear

tank support brackets and bolts (Fig. 38). Install

tank-to-frame bolts. Do not tighten bolts / nuts at

this time.

(11) Install 1 left / front tank support bracket and

bolts / nuts (Fig. 37). Do not tighten bolts / nuts at

this time.

(12) Be sure fuel tank is properly aligned to frame

and body. Tighten all tank, tow hook and trailer

hitch bolts / nuts except for 3 support brackets.

Tighten all 3 (2 rear and 1 left / front) support

bracket bolts / nuts last. Refer to Torque Specifica-

tions.

(13)

(14) Connect fuel pump module pigtail harness

electrical connector near front of tank.

(15) Connect both fuel lines to fuel filter/fuel pres-

sure regulator. Refer to Quick-Connect Fittings for

procedures.

(16) Connect EVAP hose near front of tank.

(17) Position rear axle vent hose and install new

tie strap (Fig. 32).

(18) Install heat shield nuts / bolts (Fig. 35). Refer

to Torque Specifications.

(19) Connect ORVR hose elbow (Fig. 33) to top of

EVAP canister.

(20) Connect fuel vent hose to fuel vent tube (Fig.

32).

(21) Install fuel fill hose and clamp to fuel fill tube

(Fig. 32).

(22) Install 3 LDP mounting bolts (Fig. 29).

(23) While raising support bracket, connect LDP

wiring clip (Fig. 31). Install front section of two-piece

support bracket to rear section with 3 attaching bolts

located on bottom of support bracket (Fig. 30).

(24) Install support bracket brace bolt (Fig. 30).

(25) Tighten 2 support bracket nuts at frame rail

(Fig. 29).

(26) Install fuel tank-to-rear bumper fascia clips

(Fig. 34).

(27) Using new plastic rivets, install stone shield

behind left/rear wheel (Fig. 28).

(28) Install left rear wheel/tire.

(29) Lower vehicle and connect negative battery

cable to battery.

(30) Fill tank with fuel and check for leaks.

14 - 20 FUEL DELIVERYWJ

FUEL TANK (Continued)

Page 1442 of 2199

Fig. 31 LDP REMOVAL / INSTALLATION

1 - LDP

2 - ELEC. CONNECT.

3 - VAPOR / VACUUM LINES

4 - WIRING CLIP

Fig. 32 FUEL FILL TUBE/HOSE/CLAMP

1 - AXLE VENT HOSE

2 - FUEL VENT TUBE

3 - FUEL FILL TUBE

4 - PLASTIC TIE WRAP

5 - HOSE CLAMP

6 - FUEL FILL HOSE

7 - FUEL VENT HOSE

Fig. 33 ORVR HOSE ELBOW

1 - FUEL FILL HOSE

2 - ELBOW (TO TOP OF EVAP CANISTER)

Fig. 34 BUMPER FASCIA CLIPS

1 - CLIPS

2 - FUEL TANK

WJFUEL DELIVERY 14 - 23

FUEL TANK (Continued)

Page 1446 of 2199

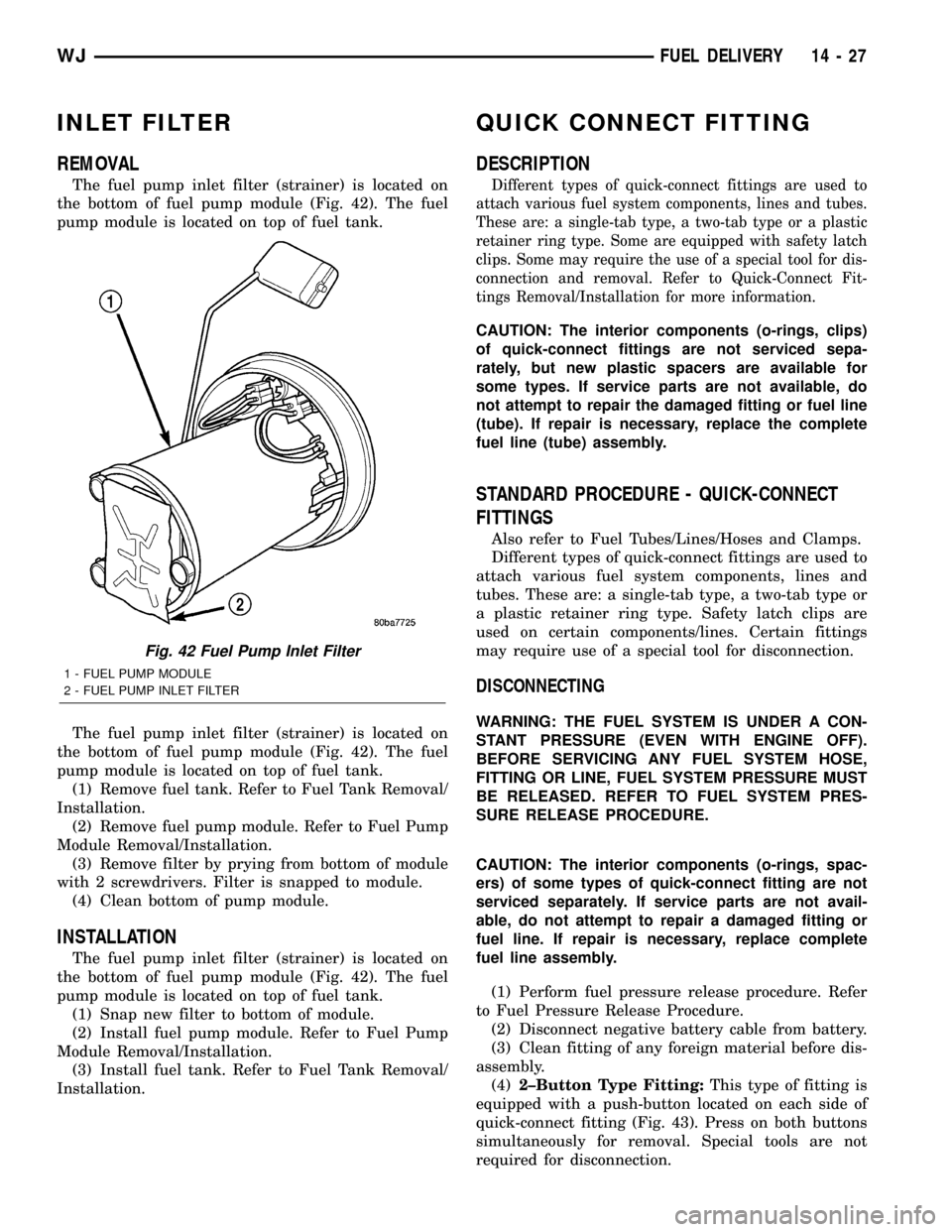

INLET FILTER

REMOVAL

The fuel pump inlet filter (strainer) is located on

the bottom of fuel pump module (Fig. 42). The fuel

pump module is located on top of fuel tank.

The fuel pump inlet filter (strainer) is located on

the bottom of fuel pump module (Fig. 42). The fuel

pump module is located on top of fuel tank.

(1) Remove fuel tank. Refer to Fuel Tank Removal/

Installation.

(2) Remove fuel pump module. Refer to Fuel Pump

Module Removal/Installation.

(3) Remove filter by prying from bottom of module

with 2 screwdrivers. Filter is snapped to module.

(4) Clean bottom of pump module.

INSTALLATION

The fuel pump inlet filter (strainer) is located on

the bottom of fuel pump module (Fig. 42). The fuel

pump module is located on top of fuel tank.

(1) Snap new filter to bottom of module.

(2) Install fuel pump module. Refer to Fuel Pump

Module Removal/Installation.

(3) Install fuel tank. Refer to Fuel Tank Removal/

Installation.

QUICK CONNECT FITTING

DESCRIPTION

Different types of quick-connect fittings are used to

attach various fuel system components, lines and tubes.

These are: a single-tab type, a two-tab type or a plastic

retainer ring type. Some are equipped with safety latch

clips. Some may require the use of a special tool for dis-

connection and removal. Refer to Quick-Connect Fit-

tings Removal/Installation for more information.

CAUTION: The interior components (o-rings, clips)

of quick-connect fittings are not serviced sepa-

rately, but new plastic spacers are available for

some types. If service parts are not available, do

not attempt to repair the damaged fitting or fuel line

(tube). If repair is necessary, replace the complete

fuel line (tube) assembly.

STANDARD PROCEDURE - QUICK-CONNECT

FITTINGS

Also refer to Fuel Tubes/Lines/Hoses and Clamps.

Different types of quick-connect fittings are used to

attach various fuel system components, lines and

tubes. These are: a single-tab type, a two-tab type or

a plastic retainer ring type. Safety latch clips are

used on certain components/lines. Certain fittings

may require use of a special tool for disconnection.

DISCONNECTING

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSE,

FITTING OR LINE, FUEL SYSTEM PRESSURE MUST

BE RELEASED. REFER TO FUEL SYSTEM PRES-

SURE RELEASE PROCEDURE.

CAUTION: The interior components (o-rings, spac-

ers) of some types of quick-connect fitting are not

serviced separately. If service parts are not avail-

able, do not attempt to repair a damaged fitting or

fuel line. If repair is necessary, replace complete

fuel line assembly.

(1) Perform fuel pressure release procedure. Refer

to Fuel Pressure Release Procedure.

(2) Disconnect negative battery cable from battery.

(3) Clean fitting of any foreign material before dis-

assembly.

(4)2±Button Type Fitting:This type of fitting is

equipped with a push-button located on each side of

quick-connect fitting (Fig. 43). Press on both buttons

simultaneously for removal. Special tools are not

required for disconnection.

Fig. 42 Fuel Pump Inlet Filter

1 - FUEL PUMP MODULE

2 - FUEL PUMP INLET FILTER

WJFUEL DELIVERY 14 - 27

Page 1452 of 2199

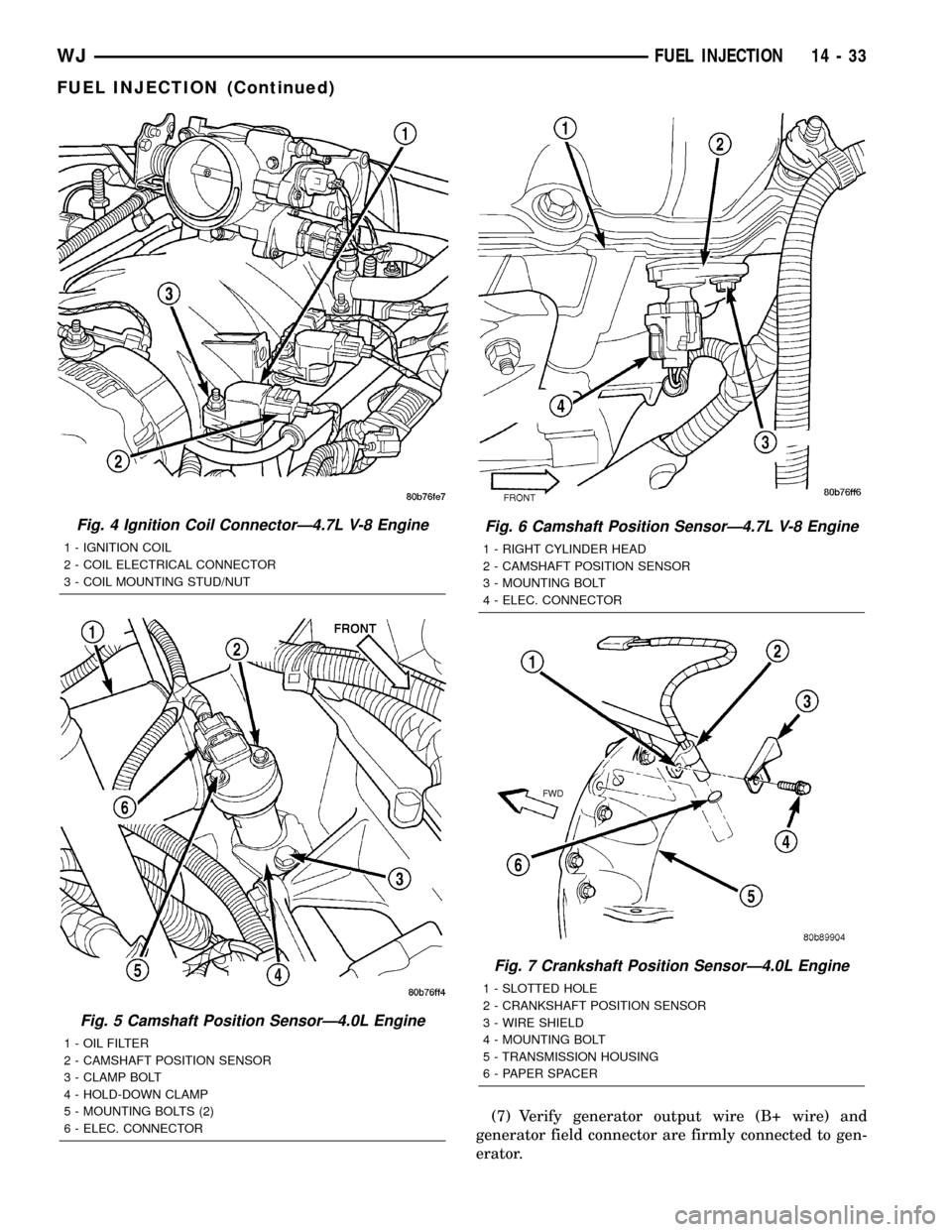

(7) Verify generator output wire (B+ wire) and

generator field connector are firmly connected to gen-

erator.

Fig. 4 Ignition Coil ConnectorÐ4.7L V-8 Engine

1 - IGNITION COIL

2 - COIL ELECTRICAL CONNECTOR

3 - COIL MOUNTING STUD/NUT

Fig. 5 Camshaft Position SensorÐ4.0L Engine

1 - OIL FILTER

2 - CAMSHAFT POSITION SENSOR

3 - CLAMP BOLT

4 - HOLD-DOWN CLAMP

5 - MOUNTING BOLTS (2)

6 - ELEC. CONNECTOR

Fig. 6 Camshaft Position SensorÐ4.7L V-8 Engine

1 - RIGHT CYLINDER HEAD

2 - CAMSHAFT POSITION SENSOR

3 - MOUNTING BOLT

4 - ELEC. CONNECTOR

Fig. 7 Crankshaft Position SensorÐ4.0L Engine

1 - SLOTTED HOLE

2 - CRANKSHAFT POSITION SENSOR

3 - WIRE SHIELD

4 - MOUNTING BOLT

5 - TRANSMISSION HOUSING

6 - PAPER SPACER

WJFUEL INJECTION 14 - 33

FUEL INJECTION (Continued)