Power steering JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 2118 of 2199

HVAC HOUSING

REMOVAL

The HVAC housing assembly must be removed

from the vehicle and the two halves of the housing

separated for service access of the heater core, evap-

orator coil, blend door(s), and each of the various

mode doors.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN PLUMBING BEFORE PERFORMING THE

FOLLOWING OPERATION. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - WARNING) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION)

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel from the vehi-

cle(Refer to 23 - BODY/INSTRUMENT PANEL -

REMOVAL).

(3) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - STANDARD PROCEDURE -

REFRIGERANT RECOVERY)

(4) Disconnect the liquid line refrigerant line from

the evaporator inlet tube(Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING/LIQUID LINE -

REMOVAL) or (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING/LIQUID LINE - REMOV-

AL). Install plugs in, or tape over all of the opened

refrigerant line fittings.

(5) Disconnect the suction line refrigerant line

from the evaporator outlet tube(Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING/SUCTION

LINE - REMOVAL), (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING/SUCTION LINE -

REMOVAL) or (Refer to 24 - HEATING & AIR CON-

DITIONING/PLUMBING/SUCTION LINE - REMOV-

AL). Install plugs in, or tape over all of the opened

refrigerant line fittings.(6) Disconnect the heater hoses from the heater

core tubes. Clamp off the heater hoses to prevent loss

of coolant. Refer to Cooling for the procedures. Install

plugs in, or tape over the opened heater core tubes.

(7) If the vehicle is equipped with the manual tem-

perature control system, unplug the HVAC system

vacuum supply line connector from the tee fitting

near the heater core tubes.

(8) Remove the coolant reserve/overflow bottle

from the passenger side inner fender shield. Refer to

Cooling for the procedures.

(9) Remove the Powertrain Control Module (PCM)

from the passenger side dash panel in the engine

compartment and set it aside. Do not unplug the

PCM wire harness connectors. Refer to Electronic

Control Modules for the procedures.

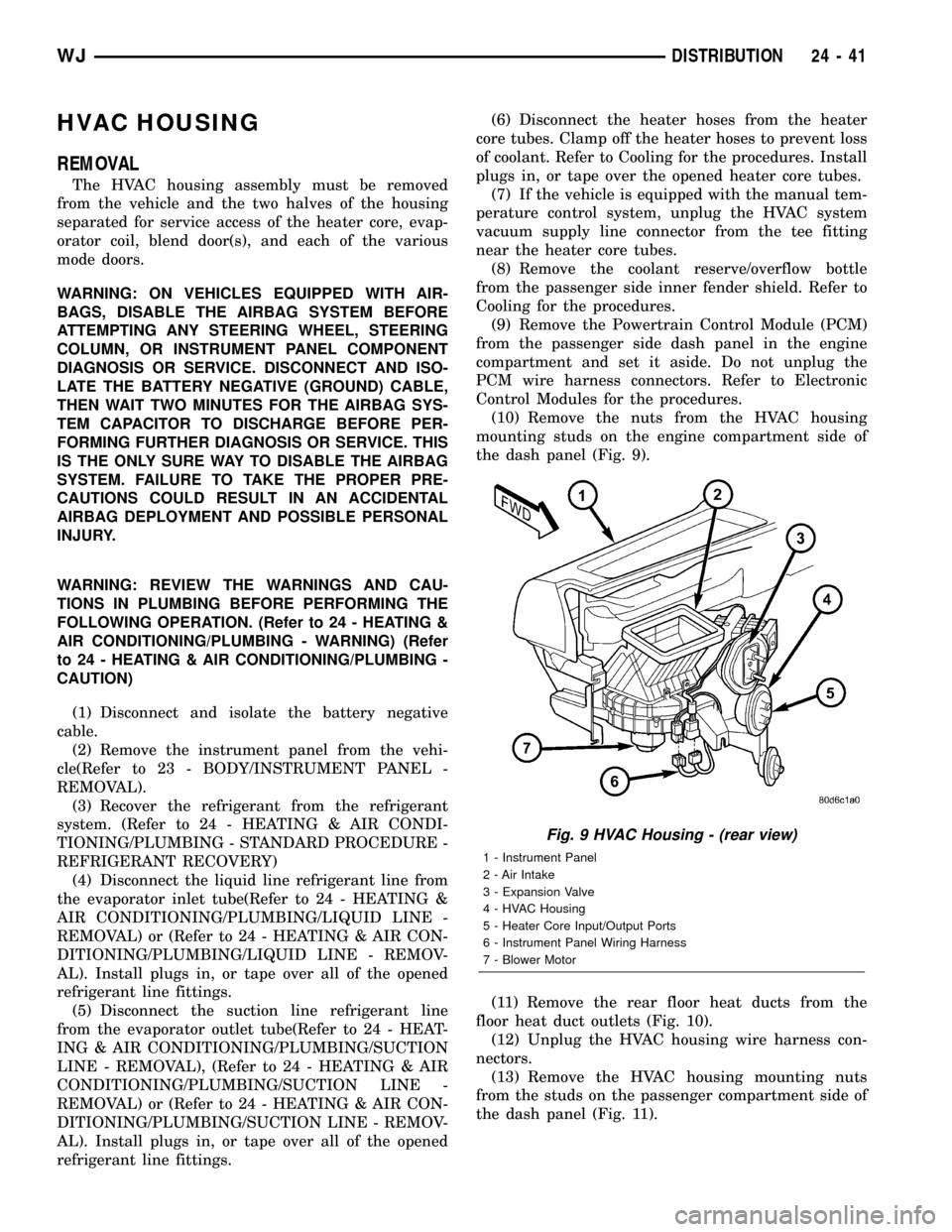

(10) Remove the nuts from the HVAC housing

mounting studs on the engine compartment side of

the dash panel (Fig. 9).

(11) Remove the rear floor heat ducts from the

floor heat duct outlets (Fig. 10).

(12) Unplug the HVAC housing wire harness con-

nectors.

(13) Remove the HVAC housing mounting nuts

from the studs on the passenger compartment side of

the dash panel (Fig. 11).

Fig. 9 HVAC Housing - (rear view)

1 - Instrument Panel

2 - Air Intake

3 - Expansion Valve

4 - HVAC Housing

5 - Heater Core Input/Output Ports

6 - Instrument Panel Wiring Harness

7 - Blower Motor

WJDISTRIBUTION 24 - 41

Page 2136 of 2199

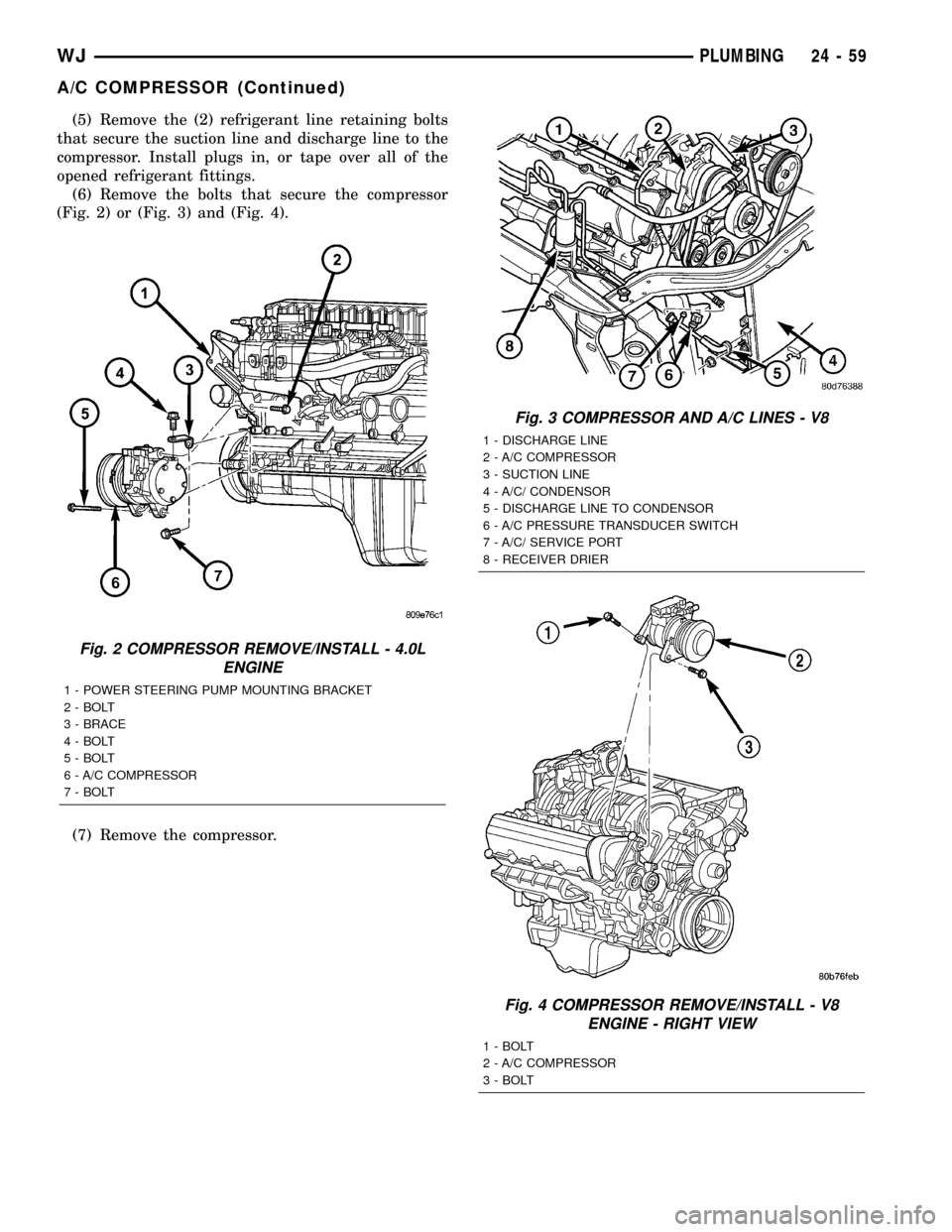

(5) Remove the (2) refrigerant line retaining bolts

that secure the suction line and discharge line to the

compressor. Install plugs in, or tape over all of the

opened refrigerant fittings.

(6) Remove the bolts that secure the compressor

(Fig. 2) or (Fig. 3) and (Fig. 4).

(7) Remove the compressor.

Fig. 2 COMPRESSOR REMOVE/INSTALL - 4.0L

ENGINE

1 - POWER STEERING PUMP MOUNTING BRACKET

2 - BOLT

3 - BRACE

4 - BOLT

5 - BOLT

6 - A/C COMPRESSOR

7 - BOLT

Fig. 3 COMPRESSOR AND A/C LINES - V8

1 - DISCHARGE LINE

2 - A/C COMPRESSOR

3 - SUCTION LINE

4 - A/C/ CONDENSOR

5 - DISCHARGE LINE TO CONDENSOR

6 - A/C PRESSURE TRANSDUCER SWITCH

7 - A/C/ SERVICE PORT

8 - RECEIVER DRIER

Fig. 4 COMPRESSOR REMOVE/INSTALL - V8

ENGINE - RIGHT VIEW

1 - BOLT

2 - A/C COMPRESSOR

3 - BOLT

WJPLUMBING 24 - 59

A/C COMPRESSOR (Continued)

Page 2157 of 2199

DESCRIPTION - STATE DISPLAY TEST MODE

The switch inputs to the Powertrain Control Mod-

ule (PCM) have two recognized states; HIGH and

LOW. For this reason, the PCM cannot recognize the

difference between a selected switch position versus

an open circuit, a short circuit, or a defective switch.

If the State Display screen shows the change from

HIGH to LOW or LOW to HIGH, assume the entire

switch circuit to the PCM functions properly. Connect

the DRB scan tool to the data link connector and

access the state display screen. Then access either

State Display Inputs and Outputs or State Display

Sensors.

DESCRIPTION - CIRCUIT ACTUATION TEST

MODE

The Circuit Actuation Test Mode checks for proper

operation of output circuits or devices the Powertrain

Control Module (PCM) may not internally recognize.

The PCM attempts to activate these outputs and

allow an observer to verify proper operation. Most of

the tests provide an audible or visual indication of

device operation (click of relay contacts, fuel spray,

etc.). Except for intermittent conditions, if a device

functions properly during testing, assume the device,

its associated wiring, and driver circuit work cor-

rectly. Connect the DRB scan tool to the data link

connector and access the Actuators screen.

DESCRIPTION - DIAGNOSTIC TROUBLE CODES

A Diagnostic Trouble Code (DTC) indicates the

PCM has recognized an abnormal condition in the

system.Remember that DTC's are the results of a sys-

tem or circuit failure, but do not directly iden-

tify the failed component or components.

NOTE: For a list of DTC's, refer to the charts in this

section.

BULB CHECK

Each time the ignition key is turned to the ON

position, the malfunction indicator (check engine)

lamp on the instrument panel should illuminate for

approximately 2 seconds then go out. This is done for

a bulb check.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

(2) Turn the ignition switch on and access the

ªRead Faultº screen.

(3) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(4) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

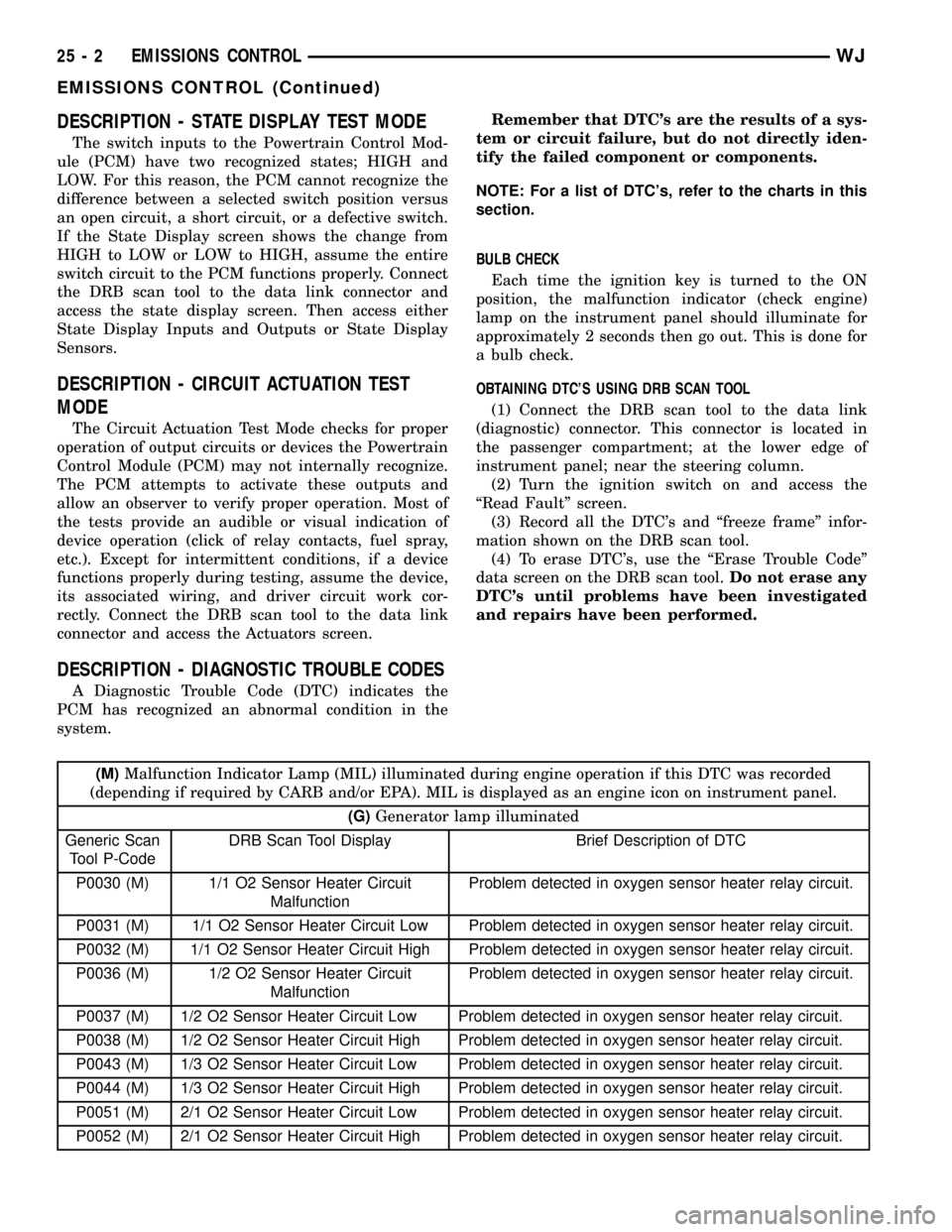

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P0030 (M) 1/1 O2 Sensor Heater Circuit

MalfunctionProblem detected in oxygen sensor heater relay circuit.

P0031 (M) 1/1 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0032 (M) 1/1 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0036 (M) 1/2 O2 Sensor Heater Circuit

MalfunctionProblem detected in oxygen sensor heater relay circuit.

P0037 (M) 1/2 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0038 (M) 1/2 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0043 (M) 1/3 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0044 (M) 1/3 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

P0051 (M) 2/1 O2 Sensor Heater Circuit Low Problem detected in oxygen sensor heater relay circuit.

P0052 (M) 2/1 O2 Sensor Heater Circuit High Problem detected in oxygen sensor heater relay circuit.

25 - 2 EMISSIONS CONTROLWJ

EMISSIONS CONTROL (Continued)

Page 2164 of 2199

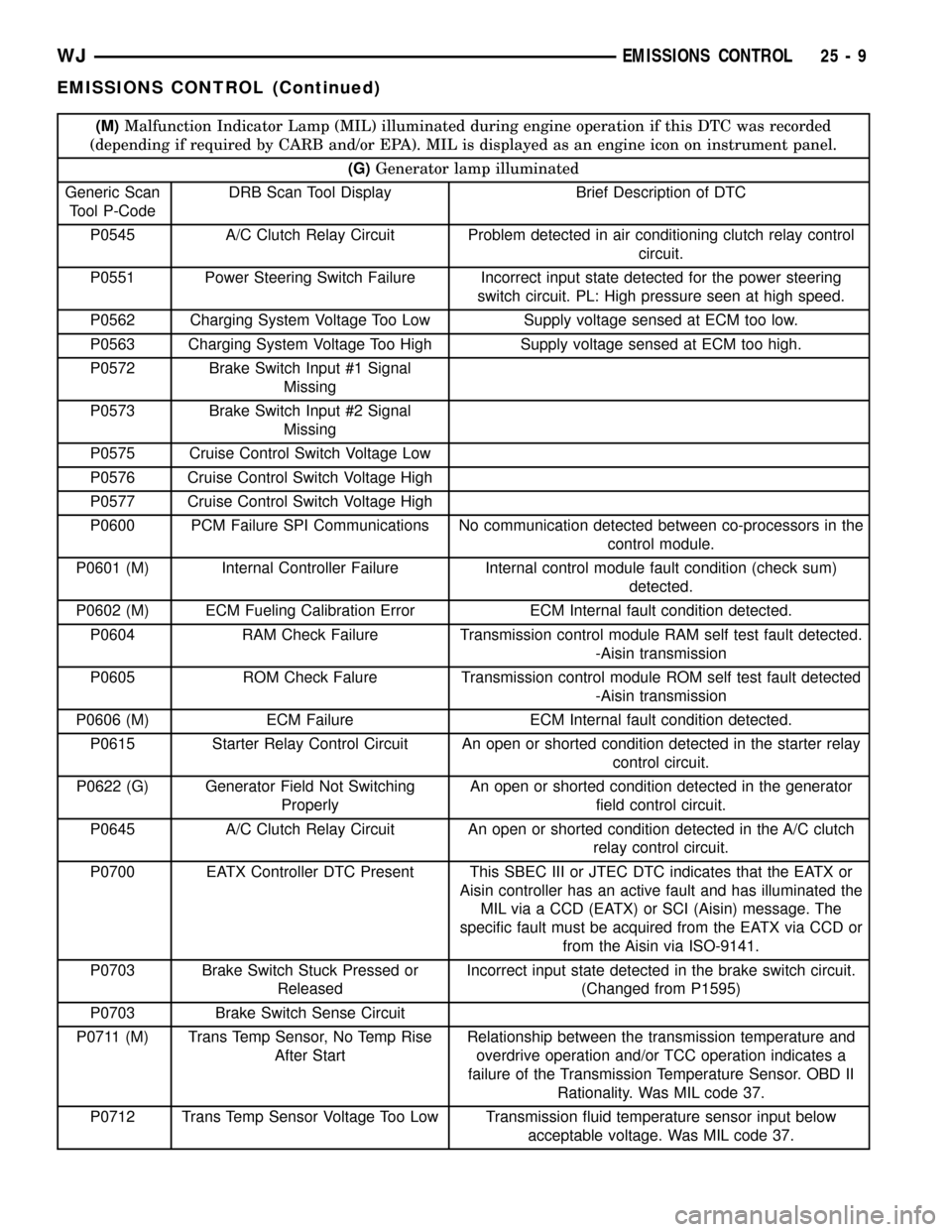

(M)Malfunction Indicator Lamp (MIL) illuminated during engine operation if this DTC was recorded

(depending if required by CARB and/or EPA). MIL is displayed as an engine icon on instrument panel.

(G)Generator lamp illuminated

Generic Scan

Tool P-CodeDRB Scan Tool Display Brief Description of DTC

P0545 A/C Clutch Relay Circuit Problem detected in air conditioning clutch relay control

circuit.

P0551 Power Steering Switch Failure Incorrect input state detected for the power steering

switch circuit. PL: High pressure seen at high speed.

P0562 Charging System Voltage Too Low Supply voltage sensed at ECM too low.

P0563 Charging System Voltage Too High Supply voltage sensed at ECM too high.

P0572 Brake Switch Input #1 Signal

Missing

P0573 Brake Switch Input #2 Signal

Missing

P0575 Cruise Control Switch Voltage Low

P0576 Cruise Control Switch Voltage High

P0577 Cruise Control Switch Voltage High

P0600 PCM Failure SPI Communications No communication detected between co-processors in the

control module.

P0601 (M) Internal Controller Failure Internal control module fault condition (check sum)

detected.

P0602 (M) ECM Fueling Calibration Error ECM Internal fault condition detected.

P0604 RAM Check Failure Transmission control module RAM self test fault detected.

-Aisin transmission

P0605 ROM Check Falure Transmission control module ROM self test fault detected

-Aisin transmission

P0606 (M) ECM Failure ECM Internal fault condition detected.

P0615 Starter Relay Control Circuit An open or shorted condition detected in the starter relay

control circuit.

P0622 (G) Generator Field Not Switching

ProperlyAn open or shorted condition detected in the generator

field control circuit.

P0645 A/C Clutch Relay Circuit An open or shorted condition detected in the A/C clutch

relay control circuit.

P0700 EATX Controller DTC Present This SBEC III or JTEC DTC indicates that the EATX or

Aisin controller has an active fault and has illuminated the

MIL via a CCD (EATX) or SCI (Aisin) message. The

specific fault must be acquired from the EATX via CCD or

from the Aisin via ISO-9141.

P0703 Brake Switch Stuck Pressed or

ReleasedIncorrect input state detected in the brake switch circuit.

(Changed from P1595)

P0703 Brake Switch Sense Circuit

P0711 (M) Trans Temp Sensor, No Temp Rise

After StartRelationship between the transmission temperature and

overdrive operation and/or TCC operation indicates a

failure of the Transmission Temperature Sensor. OBD II

Rationality. Was MIL code 37.

P0712 Trans Temp Sensor Voltage Too Low Transmission fluid temperature sensor input below

acceptable voltage. Was MIL code 37.

WJEMISSIONS CONTROL 25 - 9

EMISSIONS CONTROL (Continued)