Wheel remove JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 629 of 2199

function switch provides a resistor multiplexed out-

put to the Body Control Module (BCM) on a

windshield wiper switch mux circuit, and the BCM

responds by energizing the wiper on/off relay in the

Power Distribution Center (PDC) to operate the front

wiper motor momentarily at low speed to provide the

front wiper mist mode.

²Intermittent Front Wipe Mode- On models

not equipped with the optional automatic wiper sys-

tem, the control knob on the end of the right (wiper)

multi-function switch control stalk is rotated to one

of five minor intermediate detents to select the

desired intermittent front wipe delay interval. The

control knob is rotated rearward (counterclockwise)

to increase the delay, or forward (clockwise) to

decrease the delay. The right (wiper) multi-function

switch provides a resistor multiplexed output to the

Body Control Module (BCM) on a windshield wiper

switch mux circuit. The BCM responds by monitoring

electronic vehicle speed messages received from the

Powertrain Control Module (PCM) over the Program-

mable Communications Interface (PCI) data bus,

then energizing the wiper on/off relay in the Power

Distribution Center (PDC) to operate the front wiper

motor at the proper delay intervals.

²Intermittent Rear Wipe Mode- The control

ring on the right (wiper) multi-function switch con-

trol stalk is rotated to the center detent to select the

intermittent rear wiper mode. The right (wiper)

multi-function switch provides a battery current out-

put to the rear wiper motor on a rear wiper motor

delay control circuit to signal the rear wiper module

to operate the rear wiper in the intermittent wipe

mode.

²Rear Washer Mode- The right (wiper) multi-

function switch control stalk is pushed forward

toward the instrument panel to a momentary posi-

tions to activate the rear washer pump/motor in the

rear washer mode. The rear washer pump will con-

tinue to operate in the rear washer mode until the

control stalk is released. The right (wiper) multi-

function switch provides battery current on a rear

washer pump motor control circuit to energize the

rear washer pump in the rear washer mode.DIAGNOSIS AND TESTING - RIGHT MULTI-

FUNCTION SWITCH

Be certain to perform the diagnosis for the front

wiper system, front washer system, rear wiper sys-

tem, and/or rear washer system before testing the

right multi-function switch. (Refer to 8 - ELECTRI-

CAL/FRONT WIPERS/WASHERS - DIAGNOSIS

AND TESTING) or (Refer to 8 - ELECTRICAL/REAR

WIPERS/WASHERS - DIAGNOSIS AND TESTING).

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE PASSIVE RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG. SIDE CURTAIN AIRBAG,

FRONT IMPACT SENSOR, SIDE IMPACT SENSOR,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE (GROUND) CABLE, THEN

WAIT TWO MINUTES FOR THE SYSTEM CAPACI-

TOR TO DISCHARGE BEFORE PERFORMING FUR-

THER DIAGNOSIS OR SERVICE. THIS IS THE ONLY

SURE WAY TO DISABLE THE PASSIVE RESTRAINT

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the right multi-function switch from

the steering column and disconnect the instrument

panel wire harness connector for the switch from the

switch connector receptacle.

(3) Using an ohmmeter, check the right multi-func-

tion switch continuity and resistances at the switch

terminals as shown in the Right Multi-Function

Switch test chart (Fig. 17).

8R - 22 FRONT WIPERS/WASHERSWJ

RIGHT MULTI-FUNCTION SWITCH (Continued)

Page 631 of 2199

(4) If the right multi-function switch fails any of

the continuity or resistance tests, replace the faulty

right multi-function switch as required.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

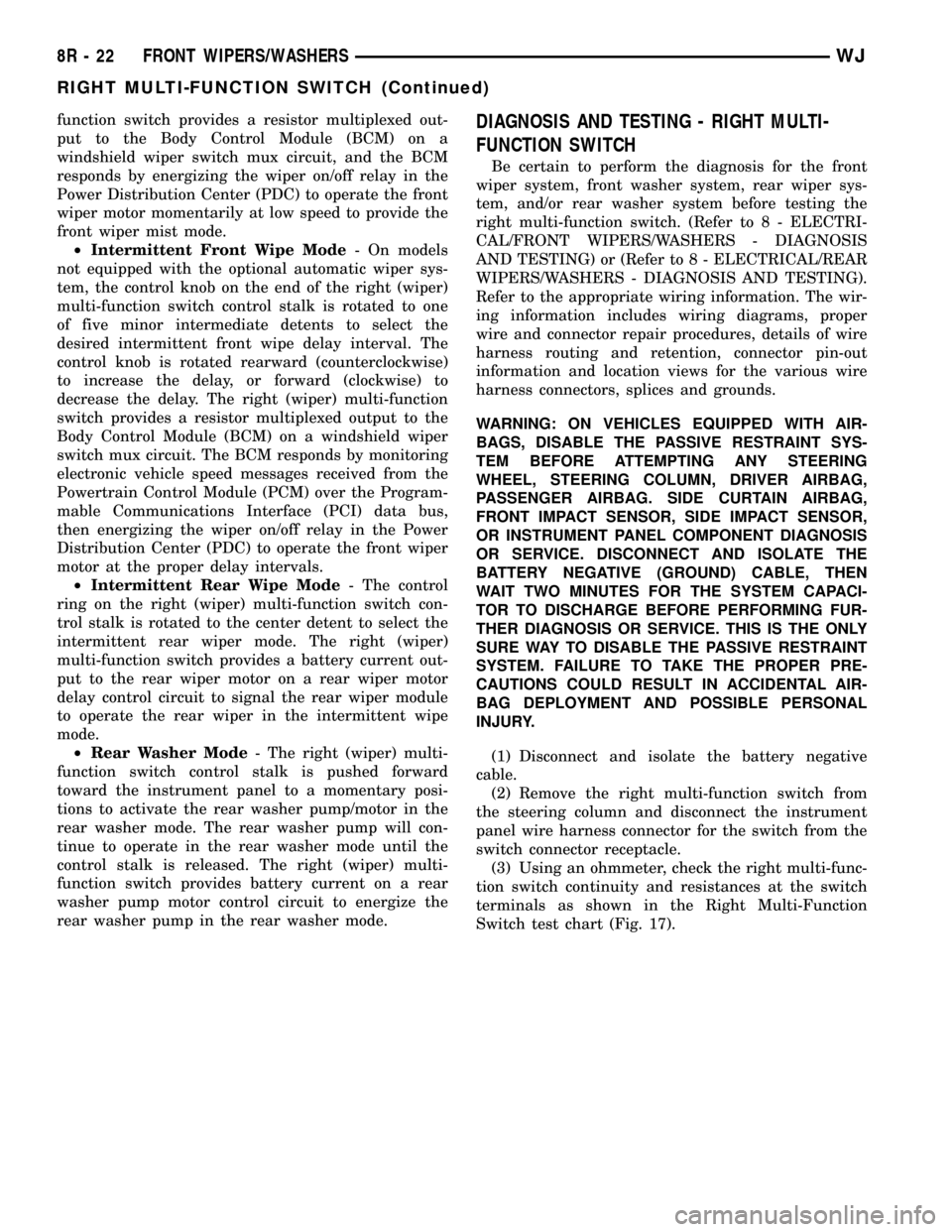

(2) Remove the screw that secures the lower tilting

steering column shroud to the steering column multi-

function switch mounting housing (Fig. 18).(3) Unsnap the two halves of the tilting steering

column shroud from each other and remove both

halves from the steering column.

(4) Disconnect the instrument panel wire harness

connector for the right multi-function switch from the

switch connector receptacle.

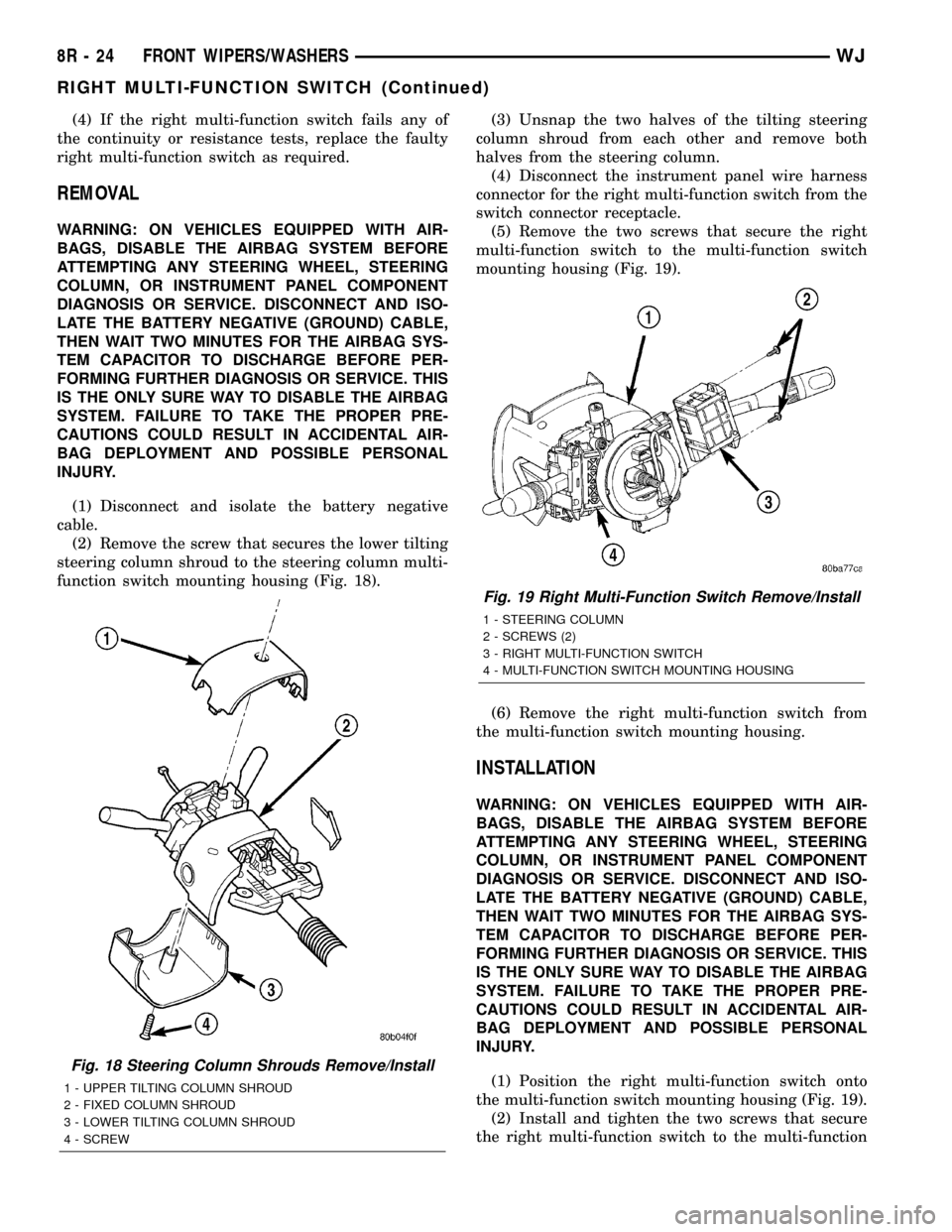

(5) Remove the two screws that secure the right

multi-function switch to the multi-function switch

mounting housing (Fig. 19).

(6) Remove the right multi-function switch from

the multi-function switch mounting housing.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the right multi-function switch onto

the multi-function switch mounting housing (Fig. 19).

(2) Install and tighten the two screws that secure

the right multi-function switch to the multi-function

Fig. 18 Steering Column Shrouds Remove/Install

1 - UPPER TILTING COLUMN SHROUD

2 - FIXED COLUMN SHROUD

3 - LOWER TILTING COLUMN SHROUD

4 - SCREW

Fig. 19 Right Multi-Function Switch Remove/Install

1 - STEERING COLUMN

2 - SCREWS (2)

3 - RIGHT MULTI-FUNCTION SWITCH

4 - MULTI-FUNCTION SWITCH MOUNTING HOUSING

8R - 24 FRONT WIPERS/WASHERSWJ

RIGHT MULTI-FUNCTION SWITCH (Continued)

Page 633 of 2199

REMOVAL

The washer fluid level switch can be removed from

the washer reservoir without removing the reservoir

from the vehicle.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the one screw that secures the washer

reservoir filler neck to the left inner fender shield.

(3) Raise and support the vehicle.

(4) Remove the liner from the left front fender

wheel house.

(5) Disconnect the washer hose from the barbed

outlet nipple of the rearmost (front) washer pump/

motor unit and allow the washer fluid to drain into a

clean container for reuse.

(6) Remove the two screws that secure the inboard

mounting flange of the washer reservoir to the left

inner wheel house.

(7) Pull the bottom of the washer reservoir rear-

ward far enough to access the left headlamp and

dash wire harness connector for the washer fluid

level switch on the front of the reservoir.

(8) Disconnect the left headlamp and dash wire

harness connector for the washer fluid level switch

from the switch connector receptacle.

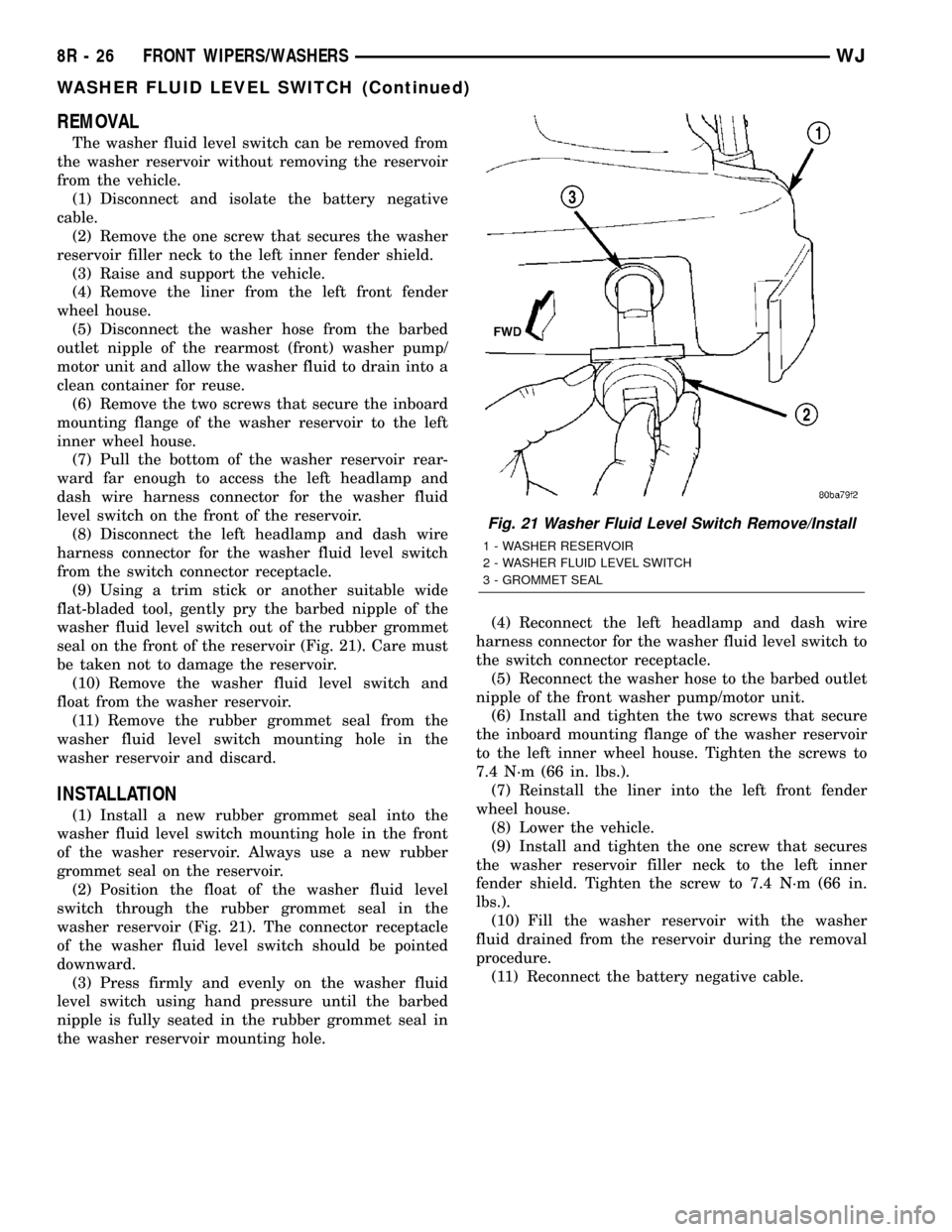

(9) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the barbed nipple of the

washer fluid level switch out of the rubber grommet

seal on the front of the reservoir (Fig. 21). Care must

be taken not to damage the reservoir.

(10) Remove the washer fluid level switch and

float from the washer reservoir.

(11) Remove the rubber grommet seal from the

washer fluid level switch mounting hole in the

washer reservoir and discard.

INSTALLATION

(1) Install a new rubber grommet seal into the

washer fluid level switch mounting hole in the front

of the washer reservoir. Always use a new rubber

grommet seal on the reservoir.

(2) Position the float of the washer fluid level

switch through the rubber grommet seal in the

washer reservoir (Fig. 21). The connector receptacle

of the washer fluid level switch should be pointed

downward.

(3) Press firmly and evenly on the washer fluid

level switch using hand pressure until the barbed

nipple is fully seated in the rubber grommet seal in

the washer reservoir mounting hole.(4) Reconnect the left headlamp and dash wire

harness connector for the washer fluid level switch to

the switch connector receptacle.

(5) Reconnect the washer hose to the barbed outlet

nipple of the front washer pump/motor unit.

(6) Install and tighten the two screws that secure

the inboard mounting flange of the washer reservoir

to the left inner wheel house. Tighten the screws to

7.4 N´m (66 in. lbs.).

(7) Reinstall the liner into the left front fender

wheel house.

(8) Lower the vehicle.

(9) Install and tighten the one screw that secures

the washer reservoir filler neck to the left inner

fender shield. Tighten the screw to 7.4 N´m (66 in.

lbs.).

(10) Fill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(11) Reconnect the battery negative cable.

Fig. 21 Washer Fluid Level Switch Remove/Install

1 - WASHER RESERVOIR

2 - WASHER FLUID LEVEL SWITCH

3 - GROMMET SEAL

8R - 26 FRONT WIPERS/WASHERSWJ

WASHER FLUID LEVEL SWITCH (Continued)

Page 634 of 2199

WASHER RESERVOIR

DESCRIPTION

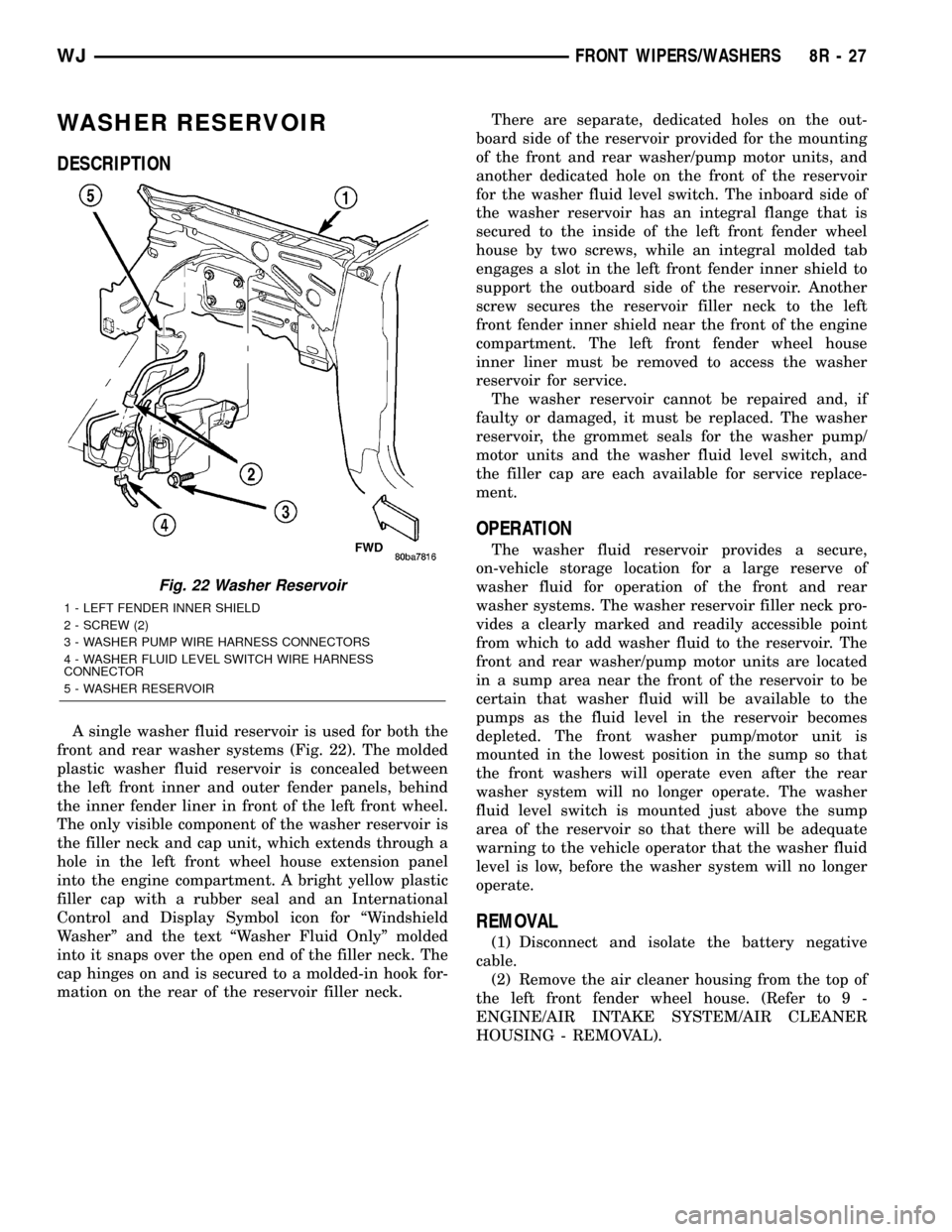

A single washer fluid reservoir is used for both the

front and rear washer systems (Fig. 22). The molded

plastic washer fluid reservoir is concealed between

the left front inner and outer fender panels, behind

the inner fender liner in front of the left front wheel.

The only visible component of the washer reservoir is

the filler neck and cap unit, which extends through a

hole in the left front wheel house extension panel

into the engine compartment. A bright yellow plastic

filler cap with a rubber seal and an International

Control and Display Symbol icon for ªWindshield

Washerº and the text ªWasher Fluid Onlyº molded

into it snaps over the open end of the filler neck. The

cap hinges on and is secured to a molded-in hook for-

mation on the rear of the reservoir filler neck.There are separate, dedicated holes on the out-

board side of the reservoir provided for the mounting

of the front and rear washer/pump motor units, and

another dedicated hole on the front of the reservoir

for the washer fluid level switch. The inboard side of

the washer reservoir has an integral flange that is

secured to the inside of the left front fender wheel

house by two screws, while an integral molded tab

engages a slot in the left front fender inner shield to

support the outboard side of the reservoir. Another

screw secures the reservoir filler neck to the left

front fender inner shield near the front of the engine

compartment. The left front fender wheel house

inner liner must be removed to access the washer

reservoir for service.

The washer reservoir cannot be repaired and, if

faulty or damaged, it must be replaced. The washer

reservoir, the grommet seals for the washer pump/

motor units and the washer fluid level switch, and

the filler cap are each available for service replace-

ment.

OPERATION

The washer fluid reservoir provides a secure,

on-vehicle storage location for a large reserve of

washer fluid for operation of the front and rear

washer systems. The washer reservoir filler neck pro-

vides a clearly marked and readily accessible point

from which to add washer fluid to the reservoir. The

front and rear washer/pump motor units are located

in a sump area near the front of the reservoir to be

certain that washer fluid will be available to the

pumps as the fluid level in the reservoir becomes

depleted. The front washer pump/motor unit is

mounted in the lowest position in the sump so that

the front washers will operate even after the rear

washer system will no longer operate. The washer

fluid level switch is mounted just above the sump

area of the reservoir so that there will be adequate

warning to the vehicle operator that the washer fluid

level is low, before the washer system will no longer

operate.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the air cleaner housing from the top of

the left front fender wheel house. (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - REMOVAL).

Fig. 22 Washer Reservoir

1 - LEFT FENDER INNER SHIELD

2 - SCREW (2)

3 - WASHER PUMP WIRE HARNESS CONNECTORS

4 - WASHER FLUID LEVEL SWITCH WIRE HARNESS

CONNECTOR

5 - WASHER RESERVOIR

WJFRONT WIPERS/WASHERS 8R - 27

Page 635 of 2199

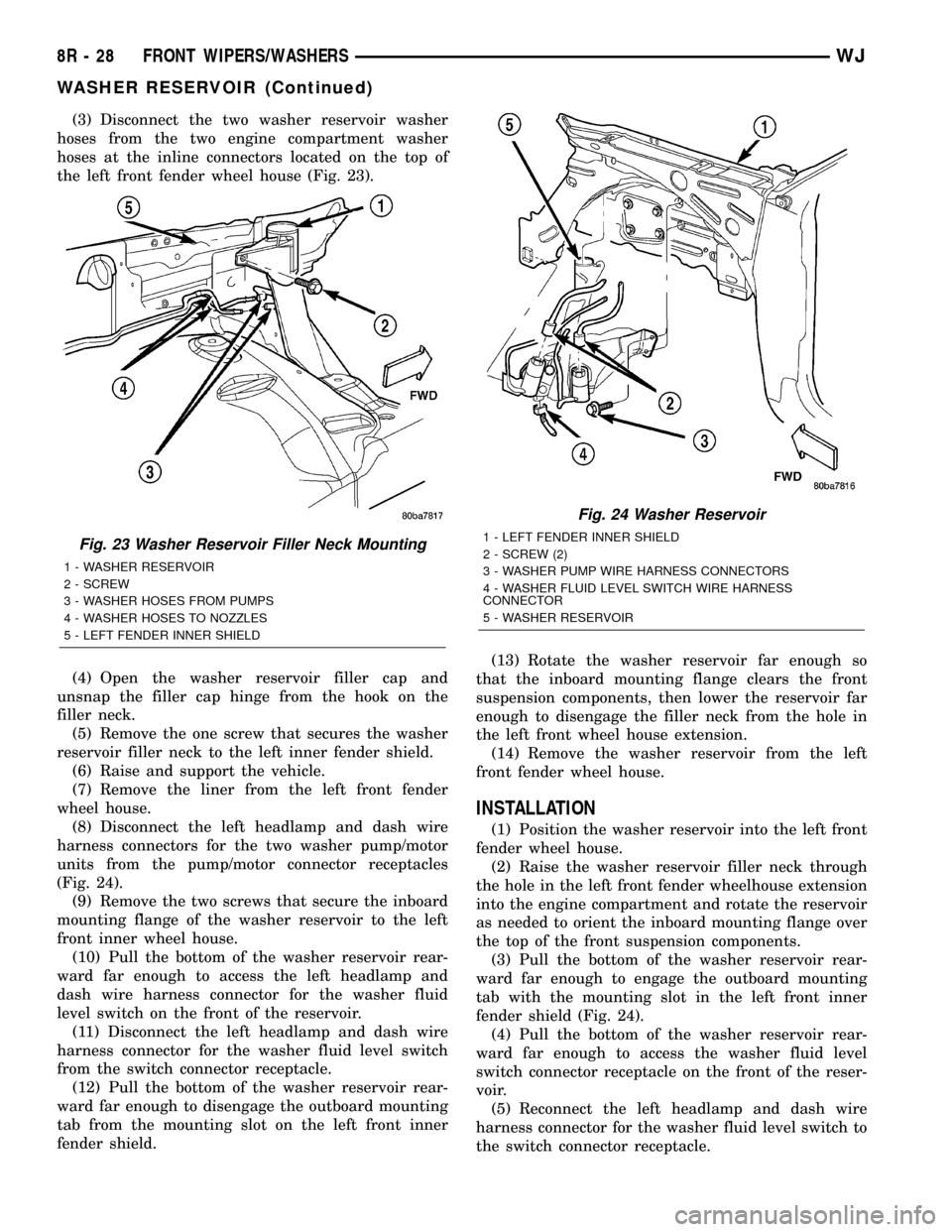

(3) Disconnect the two washer reservoir washer

hoses from the two engine compartment washer

hoses at the inline connectors located on the top of

the left front fender wheel house (Fig. 23).

(4) Open the washer reservoir filler cap and

unsnap the filler cap hinge from the hook on the

filler neck.

(5) Remove the one screw that secures the washer

reservoir filler neck to the left inner fender shield.

(6) Raise and support the vehicle.

(7) Remove the liner from the left front fender

wheel house.

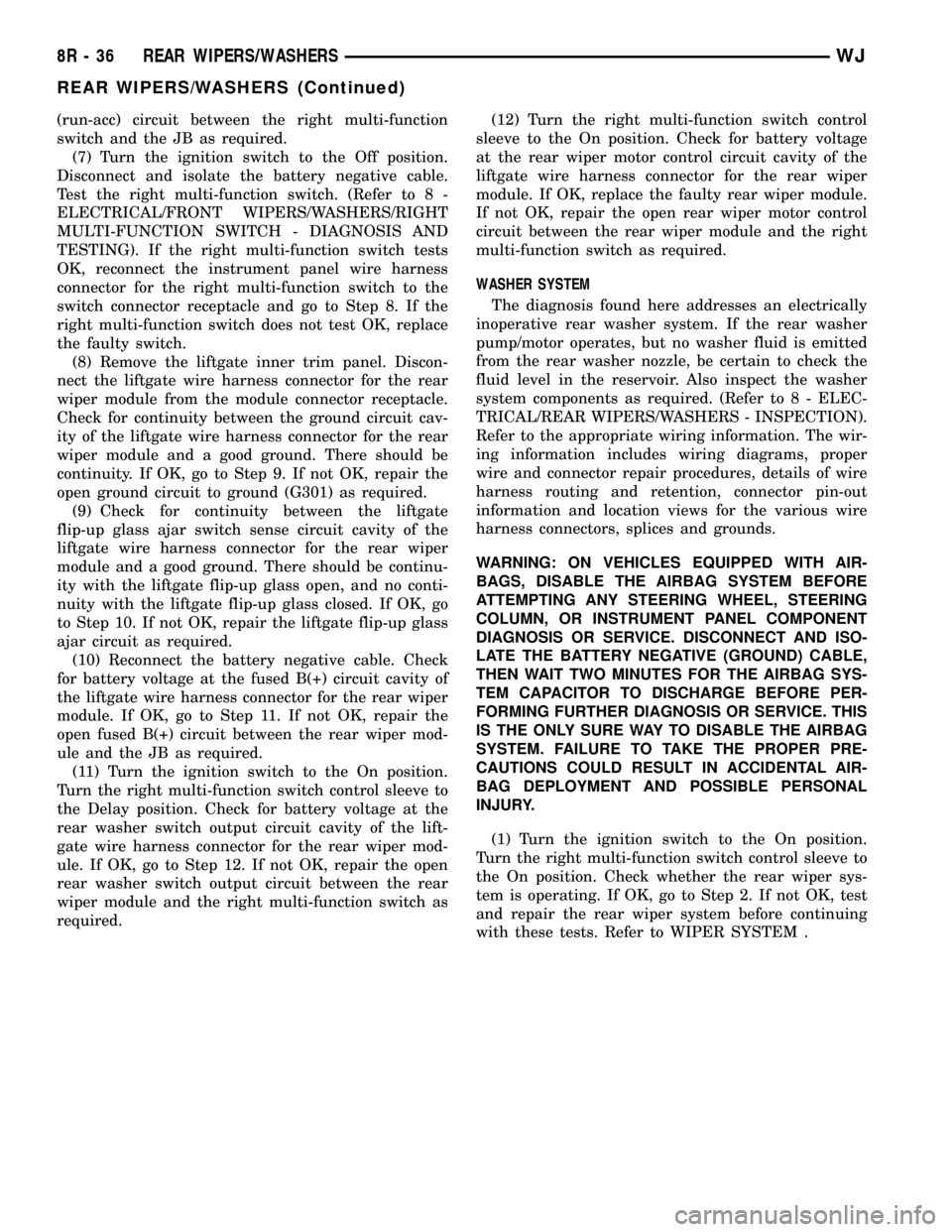

(8) Disconnect the left headlamp and dash wire

harness connectors for the two washer pump/motor

units from the pump/motor connector receptacles

(Fig. 24).

(9) Remove the two screws that secure the inboard

mounting flange of the washer reservoir to the left

front inner wheel house.

(10) Pull the bottom of the washer reservoir rear-

ward far enough to access the left headlamp and

dash wire harness connector for the washer fluid

level switch on the front of the reservoir.

(11) Disconnect the left headlamp and dash wire

harness connector for the washer fluid level switch

from the switch connector receptacle.

(12) Pull the bottom of the washer reservoir rear-

ward far enough to disengage the outboard mounting

tab from the mounting slot on the left front inner

fender shield.(13) Rotate the washer reservoir far enough so

that the inboard mounting flange clears the front

suspension components, then lower the reservoir far

enough to disengage the filler neck from the hole in

the left front wheel house extension.

(14) Remove the washer reservoir from the left

front fender wheel house.

INSTALLATION

(1) Position the washer reservoir into the left front

fender wheel house.

(2) Raise the washer reservoir filler neck through

the hole in the left front fender wheelhouse extension

into the engine compartment and rotate the reservoir

as needed to orient the inboard mounting flange over

the top of the front suspension components.

(3) Pull the bottom of the washer reservoir rear-

ward far enough to engage the outboard mounting

tab with the mounting slot in the left front inner

fender shield (Fig. 24).

(4) Pull the bottom of the washer reservoir rear-

ward far enough to access the washer fluid level

switch connector receptacle on the front of the reser-

voir.

(5) Reconnect the left headlamp and dash wire

harness connector for the washer fluid level switch to

the switch connector receptacle.

Fig. 23 Washer Reservoir Filler Neck Mounting

1 - WASHER RESERVOIR

2 - SCREW

3 - WASHER HOSES FROM PUMPS

4 - WASHER HOSES TO NOZZLES

5 - LEFT FENDER INNER SHIELD

Fig. 24 Washer Reservoir

1 - LEFT FENDER INNER SHIELD

2 - SCREW (2)

3 - WASHER PUMP WIRE HARNESS CONNECTORS

4 - WASHER FLUID LEVEL SWITCH WIRE HARNESS

CONNECTOR

5 - WASHER RESERVOIR

8R - 28 FRONT WIPERS/WASHERSWJ

WASHER RESERVOIR (Continued)

Page 643 of 2199

(run-acc) circuit between the right multi-function

switch and the JB as required.

(7) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Test the right multi-function switch. (Refer to 8 -

ELECTRICAL/FRONT WIPERS/WASHERS/RIGHT

MULTI-FUNCTION SWITCH - DIAGNOSIS AND

TESTING). If the right multi-function switch tests

OK, reconnect the instrument panel wire harness

connector for the right multi-function switch to the

switch connector receptacle and go to Step 8. If the

right multi-function switch does not test OK, replace

the faulty switch.

(8) Remove the liftgate inner trim panel. Discon-

nect the liftgate wire harness connector for the rear

wiper module from the module connector receptacle.

Check for continuity between the ground circuit cav-

ity of the liftgate wire harness connector for the rear

wiper module and a good ground. There should be

continuity. If OK, go to Step 9. If not OK, repair the

open ground circuit to ground (G301) as required.

(9) Check for continuity between the liftgate

flip-up glass ajar switch sense circuit cavity of the

liftgate wire harness connector for the rear wiper

module and a good ground. There should be continu-

ity with the liftgate flip-up glass open, and no conti-

nuity with the liftgate flip-up glass closed. If OK, go

to Step 10. If not OK, repair the liftgate flip-up glass

ajar circuit as required.

(10) Reconnect the battery negative cable. Check

for battery voltage at the fused B(+) circuit cavity of

the liftgate wire harness connector for the rear wiper

module. If OK, go to Step 11. If not OK, repair the

open fused B(+) circuit between the rear wiper mod-

ule and the JB as required.

(11) Turn the ignition switch to the On position.

Turn the right multi-function switch control sleeve to

the Delay position. Check for battery voltage at the

rear washer switch output circuit cavity of the lift-

gate wire harness connector for the rear wiper mod-

ule. If OK, go to Step 12. If not OK, repair the open

rear washer switch output circuit between the rear

wiper module and the right multi-function switch as

required.(12) Turn the right multi-function switch control

sleeve to the On position. Check for battery voltage

at the rear wiper motor control circuit cavity of the

liftgate wire harness connector for the rear wiper

module. If OK, replace the faulty rear wiper module.

If not OK, repair the open rear wiper motor control

circuit between the rear wiper module and the right

multi-function switch as required.

WASHER SYSTEM

The diagnosis found here addresses an electrically

inoperative rear washer system. If the rear washer

pump/motor operates, but no washer fluid is emitted

from the rear washer nozzle, be certain to check the

fluid level in the reservoir. Also inspect the washer

system components as required. (Refer to 8 - ELEC-

TRICAL/REAR WIPERS/WASHERS - INSPECTION).

Refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Turn the ignition switch to the On position.

Turn the right multi-function switch control sleeve to

the On position. Check whether the rear wiper sys-

tem is operating. If OK, go to Step 2. If not OK, test

and repair the rear wiper system before continuing

with these tests. Refer to WIPER SYSTEM .

8R - 36 REAR WIPERS/WASHERSWJ

REAR WIPERS/WASHERS (Continued)

Page 648 of 2199

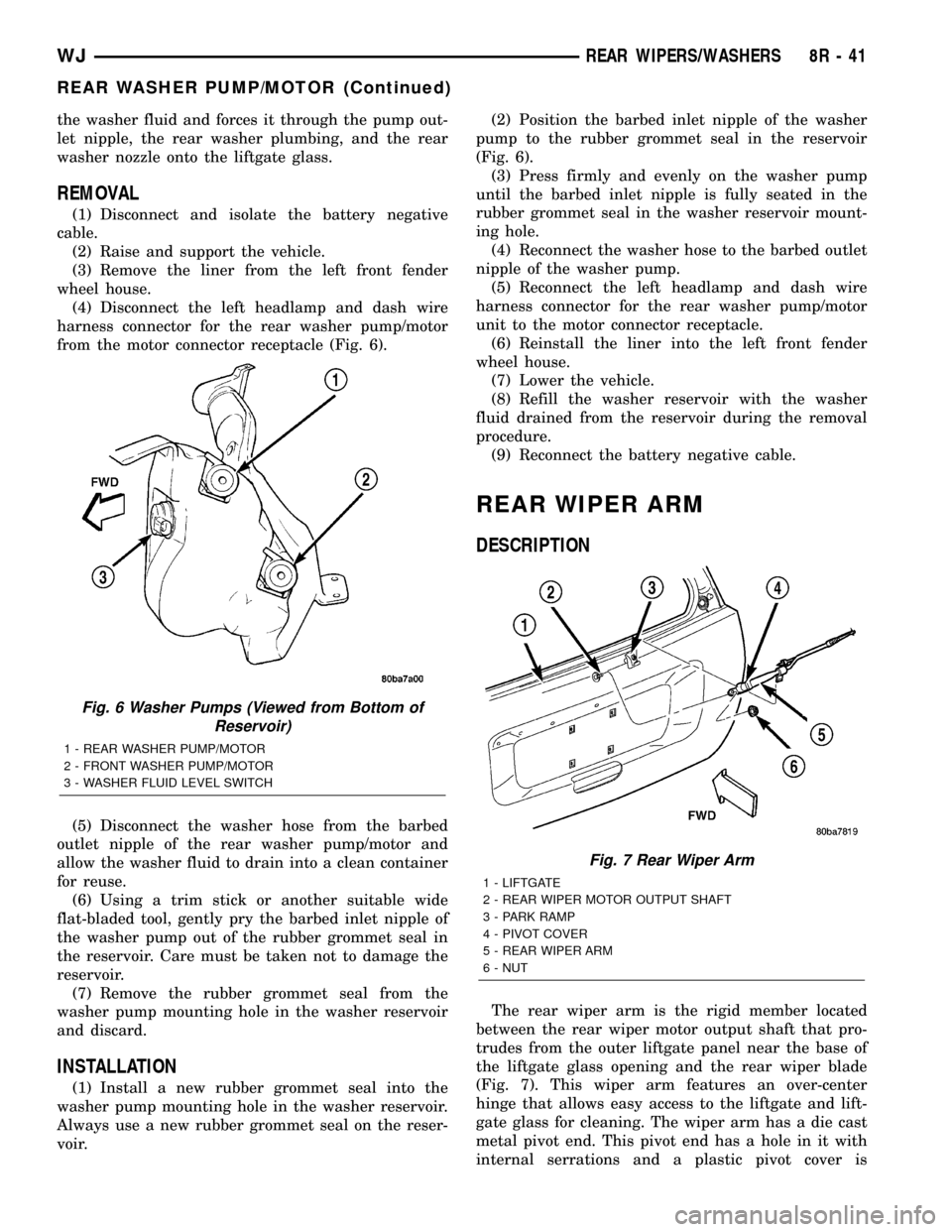

the washer fluid and forces it through the pump out-

let nipple, the rear washer plumbing, and the rear

washer nozzle onto the liftgate glass.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Raise and support the vehicle.

(3) Remove the liner from the left front fender

wheel house.

(4) Disconnect the left headlamp and dash wire

harness connector for the rear washer pump/motor

from the motor connector receptacle (Fig. 6).

(5) Disconnect the washer hose from the barbed

outlet nipple of the rear washer pump/motor and

allow the washer fluid to drain into a clean container

for reuse.

(6) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the barbed inlet nipple of

the washer pump out of the rubber grommet seal in

the reservoir. Care must be taken not to damage the

reservoir.

(7) Remove the rubber grommet seal from the

washer pump mounting hole in the washer reservoir

and discard.

INSTALLATION

(1) Install a new rubber grommet seal into the

washer pump mounting hole in the washer reservoir.

Always use a new rubber grommet seal on the reser-

voir.(2) Position the barbed inlet nipple of the washer

pump to the rubber grommet seal in the reservoir

(Fig. 6).

(3) Press firmly and evenly on the washer pump

until the barbed inlet nipple is fully seated in the

rubber grommet seal in the washer reservoir mount-

ing hole.

(4) Reconnect the washer hose to the barbed outlet

nipple of the washer pump.

(5) Reconnect the left headlamp and dash wire

harness connector for the rear washer pump/motor

unit to the motor connector receptacle.

(6) Reinstall the liner into the left front fender

wheel house.

(7) Lower the vehicle.

(8) Refill the washer reservoir with the washer

fluid drained from the reservoir during the removal

procedure.

(9) Reconnect the battery negative cable.

REAR WIPER ARM

DESCRIPTION

The rear wiper arm is the rigid member located

between the rear wiper motor output shaft that pro-

trudes from the outer liftgate panel near the base of

the liftgate glass opening and the rear wiper blade

(Fig. 7). This wiper arm features an over-center

hinge that allows easy access to the liftgate and lift-

gate glass for cleaning. The wiper arm has a die cast

metal pivot end. This pivot end has a hole in it with

internal serrations and a plastic pivot cover is

Fig. 6 Washer Pumps (Viewed from Bottom of

Reservoir)

1 - REAR WASHER PUMP/MOTOR

2 - FRONT WASHER PUMP/MOTOR

3 - WASHER FLUID LEVEL SWITCH

Fig. 7 Rear Wiper Arm

1 - LIFTGATE

2 - REAR WIPER MOTOR OUTPUT SHAFT

3 - PARK RAMP

4 - PIVOT COVER

5 - REAR WIPER ARM

6 - NUT

WJREAR WIPERS/WASHERS 8R - 41

REAR WASHER PUMP/MOTOR (Continued)

Page 1230 of 2199

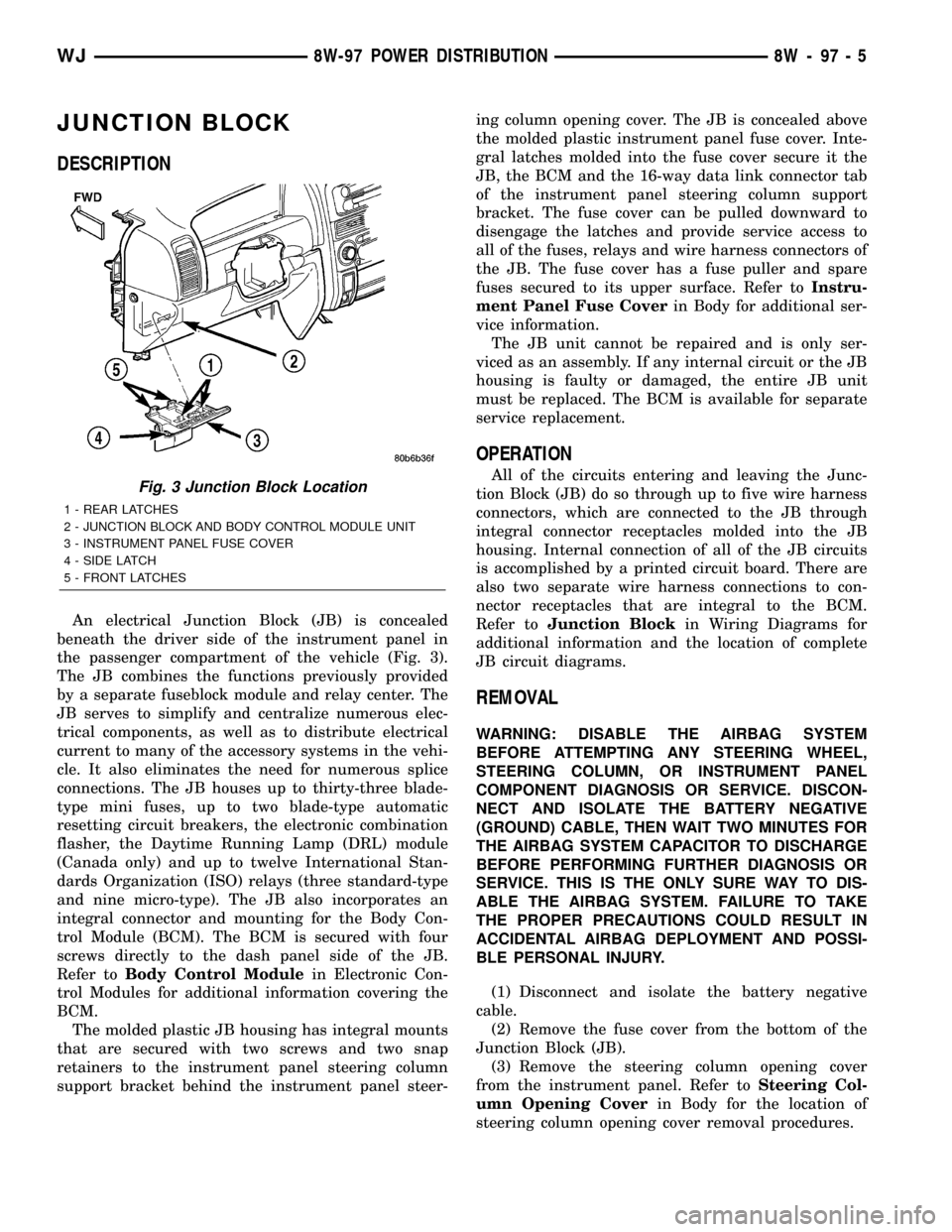

JUNCTION BLOCK

DESCRIPTION

An electrical Junction Block (JB) is concealed

beneath the driver side of the instrument panel in

the passenger compartment of the vehicle (Fig. 3).

The JB combines the functions previously provided

by a separate fuseblock module and relay center. The

JB serves to simplify and centralize numerous elec-

trical components, as well as to distribute electrical

current to many of the accessory systems in the vehi-

cle. It also eliminates the need for numerous splice

connections. The JB houses up to thirty-three blade-

type mini fuses, up to two blade-type automatic

resetting circuit breakers, the electronic combination

flasher, the Daytime Running Lamp (DRL) module

(Canada only) and up to twelve International Stan-

dards Organization (ISO) relays (three standard-type

and nine micro-type). The JB also incorporates an

integral connector and mounting for the Body Con-

trol Module (BCM). The BCM is secured with four

screws directly to the dash panel side of the JB.

Refer toBody Control Modulein Electronic Con-

trol Modules for additional information covering the

BCM.

The molded plastic JB housing has integral mounts

that are secured with two screws and two snap

retainers to the instrument panel steering column

support bracket behind the instrument panel steer-ing column opening cover. The JB is concealed above

the molded plastic instrument panel fuse cover. Inte-

gral latches molded into the fuse cover secure it the

JB, the BCM and the 16-way data link connector tab

of the instrument panel steering column support

bracket. The fuse cover can be pulled downward to

disengage the latches and provide service access to

all of the fuses, relays and wire harness connectors of

the JB. The fuse cover has a fuse puller and spare

fuses secured to its upper surface. Refer toInstru-

ment Panel Fuse Coverin Body for additional ser-

vice information.

The JB unit cannot be repaired and is only ser-

viced as an assembly. If any internal circuit or the JB

housing is faulty or damaged, the entire JB unit

must be replaced. The BCM is available for separate

service replacement.

OPERATION

All of the circuits entering and leaving the Junc-

tion Block (JB) do so through up to five wire harness

connectors, which are connected to the JB through

integral connector receptacles molded into the JB

housing. Internal connection of all of the JB circuits

is accomplished by a printed circuit board. There are

also two separate wire harness connections to con-

nector receptacles that are integral to the BCM.

Refer toJunction Blockin Wiring Diagrams for

additional information and the location of complete

JB circuit diagrams.

REMOVAL

WARNING: DISABLE THE AIRBAG SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. DISCON-

NECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE AIRBAG SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE AIRBAG SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSI-

BLE PERSONAL INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the fuse cover from the bottom of the

Junction Block (JB).

(3) Remove the steering column opening cover

from the instrument panel. Refer toSteering Col-

umn Opening Coverin Body for the location of

steering column opening cover removal procedures.

Fig. 3 Junction Block Location

1 - REAR LATCHES

2 - JUNCTION BLOCK AND BODY CONTROL MODULE UNIT

3 - INSTRUMENT PANEL FUSE COVER

4 - SIDE LATCH

5 - FRONT LATCHES

WJ8W-97 POWER DISTRIBUTION 8W - 97 - 5

Page 1239 of 2199

The cigar lighter relay cannot be repaired or

adjusted and, if faulty or damaged, it must be

replaced.

OPERATION

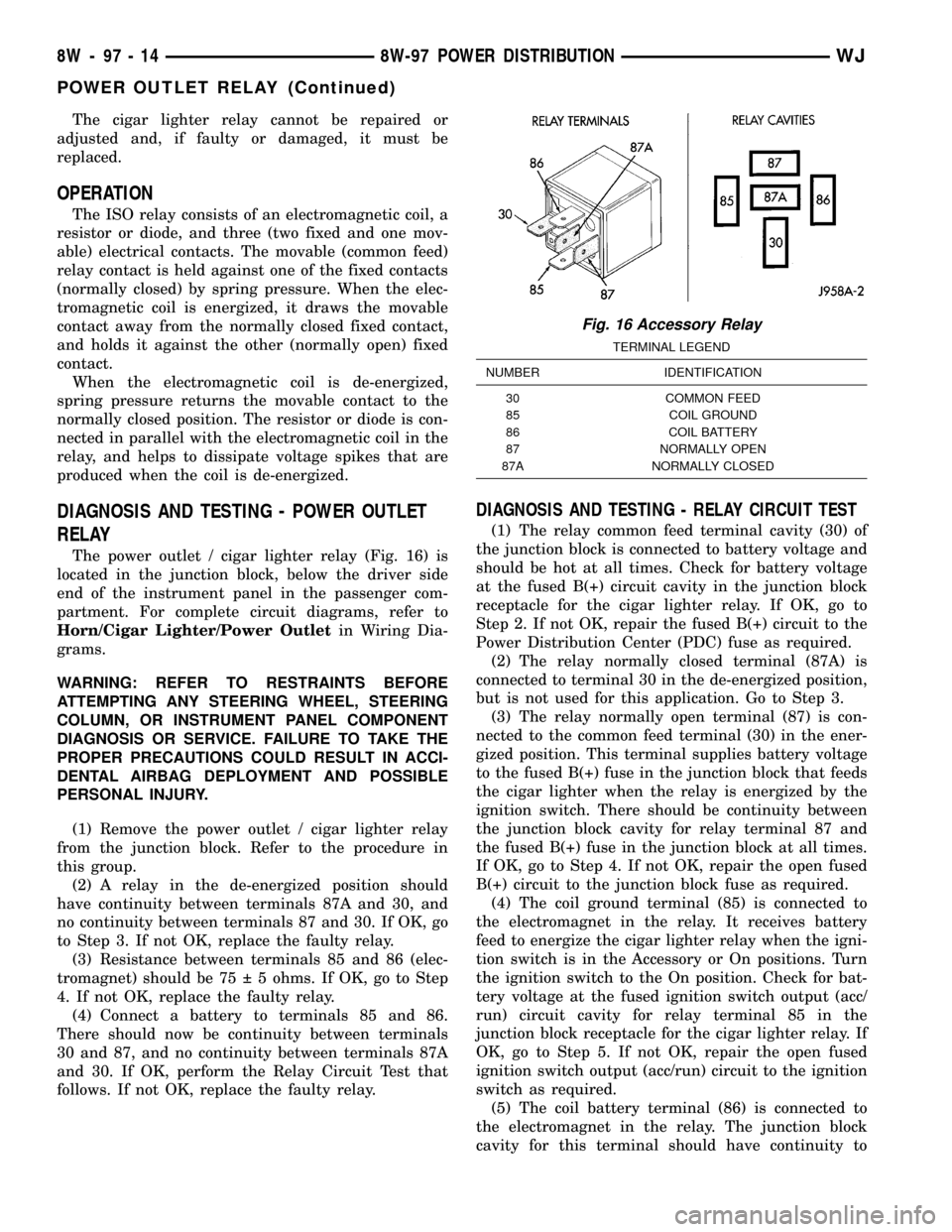

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one mov-

able) electrical contacts. The movable (common feed)

relay contact is held against one of the fixed contacts

(normally closed) by spring pressure. When the elec-

tromagnetic coil is energized, it draws the movable

contact away from the normally closed fixed contact,

and holds it against the other (normally open) fixed

contact.

When the electromagnetic coil is de-energized,

spring pressure returns the movable contact to the

normally closed position. The resistor or diode is con-

nected in parallel with the electromagnetic coil in the

relay, and helps to dissipate voltage spikes that are

produced when the coil is de-energized.

DIAGNOSIS AND TESTING - POWER OUTLET

RELAY

The power outlet / cigar lighter relay (Fig. 16) is

located in the junction block, below the driver side

end of the instrument panel in the passenger com-

partment. For complete circuit diagrams, refer to

Horn/Cigar Lighter/Power Outletin Wiring Dia-

grams.

WARNING: REFER TO RESTRAINTS BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Remove the power outlet / cigar lighter relay

from the junction block. Refer to the procedure in

this group.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform the Relay Circuit Test that

follows. If not OK, replace the faulty relay.

DIAGNOSIS AND TESTING - RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) of

the junction block is connected to battery voltage and

should be hot at all times. Check for battery voltage

at the fused B(+) circuit cavity in the junction block

receptacle for the cigar lighter relay. If OK, go to

Step 2. If not OK, repair the fused B(+) circuit to the

Power Distribution Center (PDC) fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the fused B(+) fuse in the junction block that feeds

the cigar lighter when the relay is energized by the

ignition switch. There should be continuity between

the junction block cavity for relay terminal 87 and

the fused B(+) fuse in the junction block at all times.

If OK, go to Step 4. If not OK, repair the open fused

B(+) circuit to the junction block fuse as required.

(4) The coil ground terminal (85) is connected to

the electromagnet in the relay. It receives battery

feed to energize the cigar lighter relay when the igni-

tion switch is in the Accessory or On positions. Turn

the ignition switch to the On position. Check for bat-

tery voltage at the fused ignition switch output (acc/

run) circuit cavity for relay terminal 85 in the

junction block receptacle for the cigar lighter relay. If

OK, go to Step 5. If not OK, repair the open fused

ignition switch output (acc/run) circuit to the ignition

switch as required.

(5) The coil battery terminal (86) is connected to

the electromagnet in the relay. The junction block

cavity for this terminal should have continuity to

Fig. 16 Accessory Relay

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

8W - 97 - 14 8W-97 POWER DISTRIBUTIONWJ

POWER OUTLET RELAY (Continued)

Page 1250 of 2199

CONDITION POSSIBLE CAUSES CORRECTION

3. Thin or diluted oil 3. Change oil to correct viscosity.

4. Excessive main bearing clearance 4. Measure bearings for correct

clearance. Repair as necessary

5. Excessive end play 5. Check crankshaft thrust bearing for

excessive wear on flanges

6. Crankshaft main journal out of

round or worn6. Grind journals or replace

crankshaft

7. Loose flywheel or torque converter 7. Inspect crankshaft, flexplate/

flywheel and bolts for damage.

Tighten to correct torque

LOW OIL PRESSURE 1. Low oil level 1. Check oil level and fill if necessary

2. Faulty oil pressure sending unit 2. Install new sending unit

3. Clogged oil filter 3. Install new oil filter

4. Worn oil pump 4. Replace oil pump assembly.

5. Thin or diluted oil 5. Change oil to correct viscosity.

6. Excessive bearing clearance 6. Measure bearings for correct

clearance

7. Oil pump relief valve stuck 7. Remove valve to inspect, clean

and reinstall

8. Oil pump suction tube loose,

broken, bent or clogged8. Inspect suction tube and clean or

replace if necessary

9. Oil pump cover warped or cracked 9. Install new oil pump

OIL LEAKS 1. Misaligned or deteriorated gaskets 1. Replace gasket

2. Loose fastener, broken or porous

metal part2. Tighten, repair or replace the part

3. Front or rear crankshaft oil seal

leaking3. Replace seal

4. Leaking oil gallery plug or cup

plug4. Remove and reseal threaded plug.

Replace cup style plug

EXCESSIVE OIL

CONSUMPTION OR SPARK

PLUGS OIL FOULED1. CCV System malfunction 1. (Refer to 25 - EMISSIONS

CONTROL/EVAPORATIVE

EMISSIONS - DESCRIPTION) for

correct operation

2. Defective valve stem seal(s) 2. Repair or replace seal(s)

3. Worn or broken piston rings 3. Hone cylinder bores. Install new

rings

4. Scuffed pistons/cylinder walls 4. Hone cylinder bores and replace

pistons as required

5. Carbon in oil control ring groove 5. Remove rings and de-carbon

piston

6. Worn valve guides 6. Inspect/replace valve guides as

necessary

7. Piston rings fitted too tightly in

grooves7. Remove rings and check ring end

gap and side clearance. Replace if

necessary

WJENGINE - 4.0L 9 - 7

ENGINE - 4.0L (Continued)