compress JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1882 of 2199

LIFTGATE

REMOVAL

CAUTION: DO NOT DISCONNECT THE SUPPORT ROD

CYLINDERS WITH THE LIFTGATE CLOSED. THE SUP-

PORT ROD PISTONS ARE OPERATED BY HIGH PRES-

SURE GAS. THIS PRESSURE COULD CAUSE DAMAGE

AND /OR PERSONAL INJURY IF THEY ARE REMOVED

WHILE THE PISTONS ARE COMPRESSED.

(1) Open the liftgate. Support the liftgate for ease

of repair.

(2) Remove the liftgate trim panel.

(3) Remove the prop rods from the liftgate.

(4) Unplug the wire harnesses and disconnect the

washer hose.

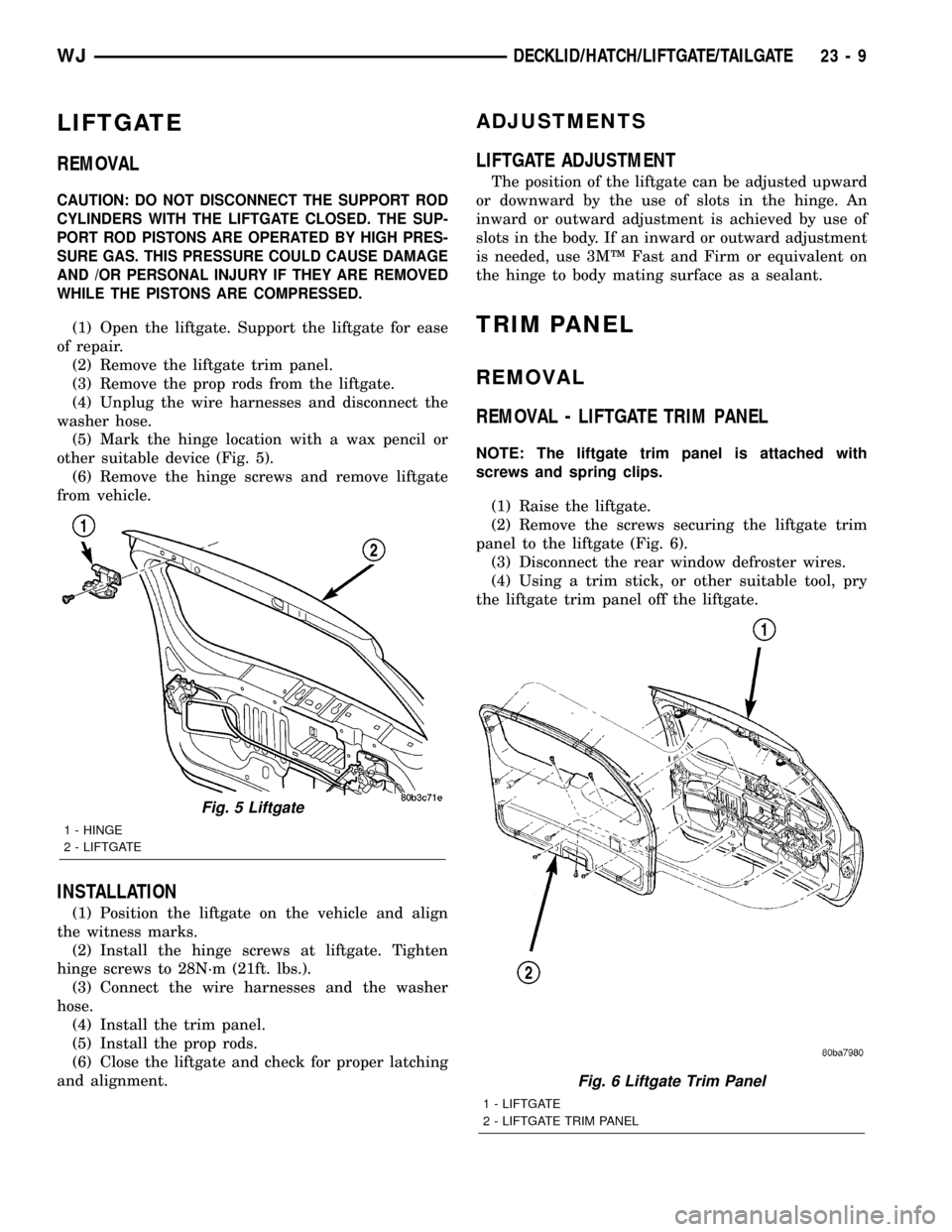

(5) Mark the hinge location with a wax pencil or

other suitable device (Fig. 5).

(6) Remove the hinge screws and remove liftgate

from vehicle.

INSTALLATION

(1) Position the liftgate on the vehicle and align

the witness marks.

(2) Install the hinge screws at liftgate. Tighten

hinge screws to 28N´m (21ft. lbs.).

(3) Connect the wire harnesses and the washer

hose.

(4) Install the trim panel.

(5) Install the prop rods.

(6) Close the liftgate and check for proper latching

and alignment.

ADJUSTMENTS

LIFTGATE ADJUSTMENT

The position of the liftgate can be adjusted upward

or downward by the use of slots in the hinge. An

inward or outward adjustment is achieved by use of

slots in the body. If an inward or outward adjustment

is needed, use 3MŸ Fast and Firm or equivalent on

the hinge to body mating surface as a sealant.

TRIM PANEL

REMOVAL

REMOVAL - LIFTGATE TRIM PANEL

NOTE: The liftgate trim panel is attached with

screws and spring clips.

(1) Raise the liftgate.

(2) Remove the screws securing the liftgate trim

panel to the liftgate (Fig. 6).

(3) Disconnect the rear window defroster wires.

(4) Using a trim stick, or other suitable tool, pry

the liftgate trim panel off the liftgate.

Fig. 5 Liftgate

1 - HINGE

2 - LIFTGATE

Fig. 6 Liftgate Trim Panel

1 - LIFTGATE

2 - LIFTGATE TRIM PANEL

WJDECKLID/HATCH/LIFTGATE/TAILGATE 23 - 9

Page 1970 of 2199

releasing the control switch before the sunroof was

fully closed. The sunroof module has a water-man-

agement system. During washing high-pressure

water may be forced between the glass panel seal

and the roof opening. Normally this water will drain.

However, when some type of drying blower system is

used, like those found in automatic car washes, thewater may not have a chance to drain before the

blower forces air between the seal and the roof open-

ing. This causes the water to blow over the edge of

the module and onto the headlining.

Refer to (Fig. 1) Sunroof Assembly for exploded

view of the sunroof.

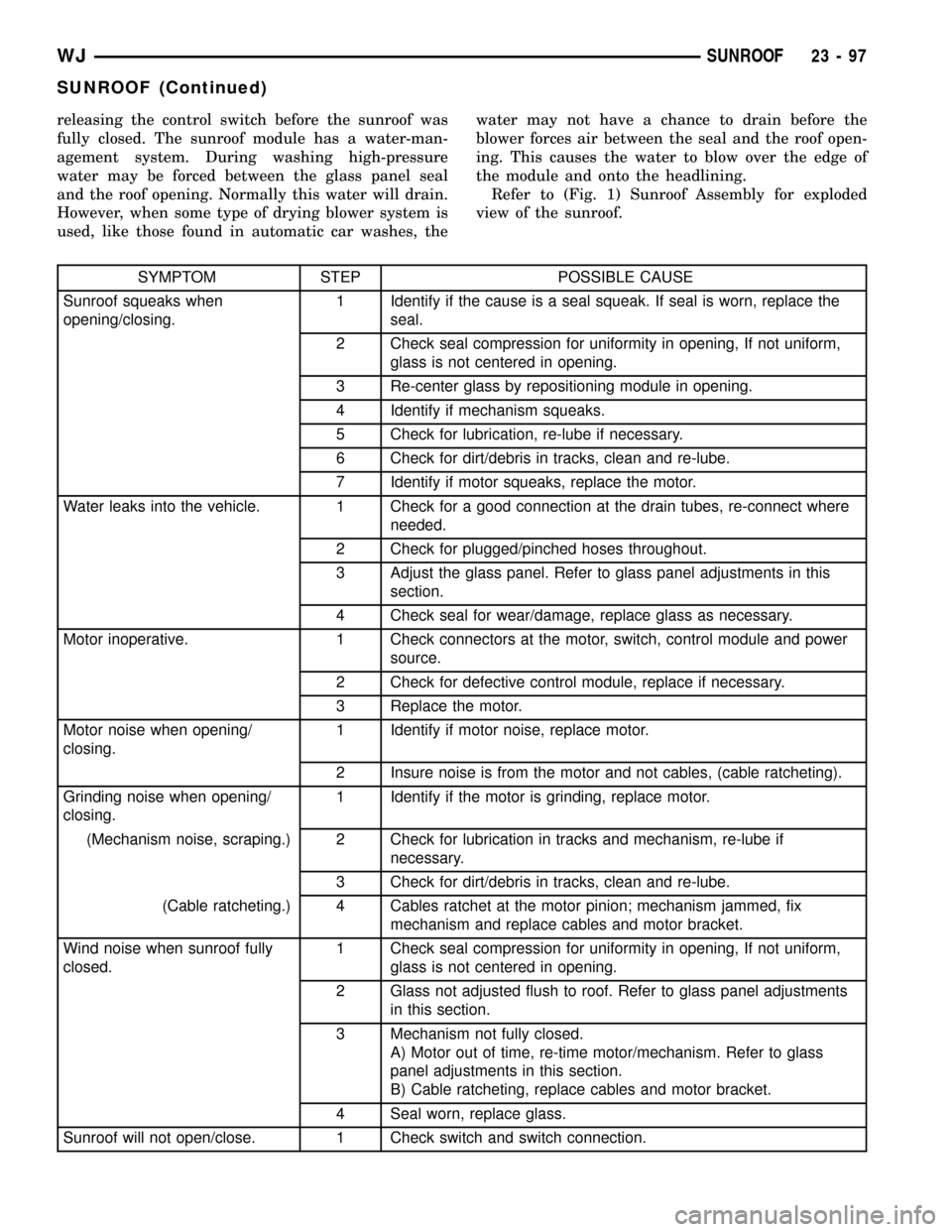

SYMPTOM STEP POSSIBLE CAUSE

Sunroof squeaks when

opening/closing.1 Identify if the cause is a seal squeak. If seal is worn, replace the

seal.

2 Check seal compression for uniformity in opening, If not uniform,

glass is not centered in opening.

3 Re-center glass by repositioning module in opening.

4 Identify if mechanism squeaks.

5 Check for lubrication, re-lube if necessary.

6 Check for dirt/debris in tracks, clean and re-lube.

7 Identify if motor squeaks, replace the motor.

Water leaks into the vehicle. 1 Check for a good connection at the drain tubes, re-connect where

needed.

2 Check for plugged/pinched hoses throughout.

3 Adjust the glass panel. Refer to glass panel adjustments in this

section.

4 Check seal for wear/damage, replace glass as necessary.

Motor inoperative. 1 Check connectors at the motor, switch, control module and power

source.

2 Check for defective control module, replace if necessary.

3 Replace the motor.

Motor noise when opening/

closing.1 Identify if motor noise, replace motor.

2 Insure noise is from the motor and not cables, (cable ratcheting).

Grinding noise when opening/

closing.1 Identify if the motor is grinding, replace motor.

(Mechanism noise, scraping.) 2 Check for lubrication in tracks and mechanism, re-lube if

necessary.

3 Check for dirt/debris in tracks, clean and re-lube.

(Cable ratcheting.) 4 Cables ratchet at the motor pinion; mechanism jammed, fix

mechanism and replace cables and motor bracket.

Wind noise when sunroof fully

closed.1 Check seal compression for uniformity in opening, If not uniform,

glass is not centered in opening.

2 Glass not adjusted flush to roof. Refer to glass panel adjustments

in this section.

3 Mechanism not fully closed.

A) Motor out of time, re-time motor/mechanism. Refer to glass

panel adjustments in this section.

B) Cable ratcheting, replace cables and motor bracket.

4 Seal worn, replace glass.

Sunroof will not open/close. 1 Check switch and switch connection.

WJSUNROOF 23 - 97

SUNROOF (Continued)

Page 1976 of 2199

INSTALLATION

NOTE: Sunroof glass must be set in place and

attached as close as possible to flush with the roof

surface. For wind noise reasons, care must be

taken to ensure that the glass is not remounted

either a) Overflush to the roof surface at the front

edge of the glass, or b) Underflush to the roof sur-

face at the rear edge of the glass.

(1) Position glass panel in to opening.

(2) Start the four attaching screws.

(3) Tighten screws.

(4) Verify sunroof operation and alignment. Check

fit and adjust as necessary. (Refer to 23 - BODY/

SUNROOF/GLASS PANEL - ADJUSTMENTS - FIT)

ADJUSTMENTS

ADJUSTMENTS - FIT

(1) Move the sunshade rearward to the open posi-

tion.

(2) Move the sunroof glass panel to the fully closed

position.

(3) Loosen the forward screws on each side enough

to make the front adjustment.

(4) Adjust the front of the sunroof glass panel 1

mm (1/32 inch) below the top surface of the roof

panel.

(5) Tighten the front two screws.

(6) Loosen the rear screws on each side enough to

make the rear adjustment.

(7) Adjust the rear of the sunroof glass panel 1

mm (1/32 inch) above the top surface of the roof

panel.

(8) Tighten the rear two screws.

(9) Check for proper fit. If not OK, repeat glass

panel adjustment.

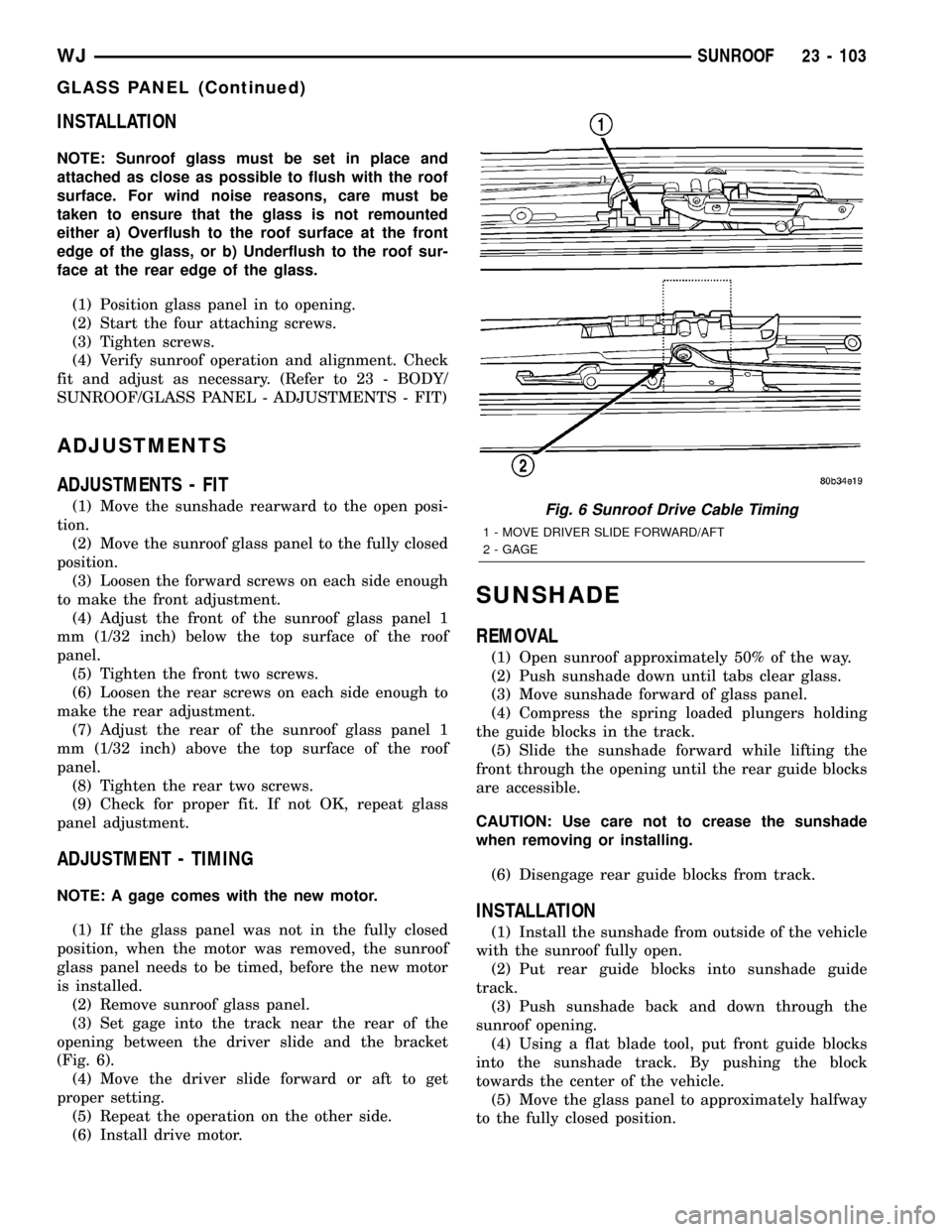

ADJUSTMENT - TIMING

NOTE: A gage comes with the new motor.

(1) If the glass panel was not in the fully closed

position, when the motor was removed, the sunroof

glass panel needs to be timed, before the new motor

is installed.

(2) Remove sunroof glass panel.

(3) Set gage into the track near the rear of the

opening between the driver slide and the bracket

(Fig. 6).

(4) Move the driver slide forward or aft to get

proper setting.

(5) Repeat the operation on the other side.

(6) Install drive motor.

SUNSHADE

REMOVAL

(1) Open sunroof approximately 50% of the way.

(2) Push sunshade down until tabs clear glass.

(3) Move sunshade forward of glass panel.

(4) Compress the spring loaded plungers holding

the guide blocks in the track.

(5) Slide the sunshade forward while lifting the

front through the opening until the rear guide blocks

are accessible.

CAUTION: Use care not to crease the sunshade

when removing or installing.

(6) Disengage rear guide blocks from track.

INSTALLATION

(1) Install the sunshade from outside of the vehicle

with the sunroof fully open.

(2) Put rear guide blocks into sunshade guide

track.

(3) Push sunshade back and down through the

sunroof opening.

(4) Using a flat blade tool, put front guide blocks

into the sunshade track. By pushing the block

towards the center of the vehicle.

(5) Move the glass panel to approximately halfway

to the fully closed position.

Fig. 6 Sunroof Drive Cable Timing

1 - MOVE DRIVER SLIDE FORWARD/AFT

2 - GAGE

WJSUNROOF 23 - 103

GLASS PANEL (Continued)

Page 2080 of 2199

However, evaporator capacity used to reduce the

amount of moisture in the air is not wasted. Wring-

ing some of the moisture out of the air entering the

vehicle adds to the comfort of the passengers.

Although, an owner may expect too much from their

air conditioning system on humid days. A perfor-

mance test is the best way to determine whether the

system is performing up to standard. This test also

provides valuable clues as to the possible cause of

trouble with the air conditioning system.

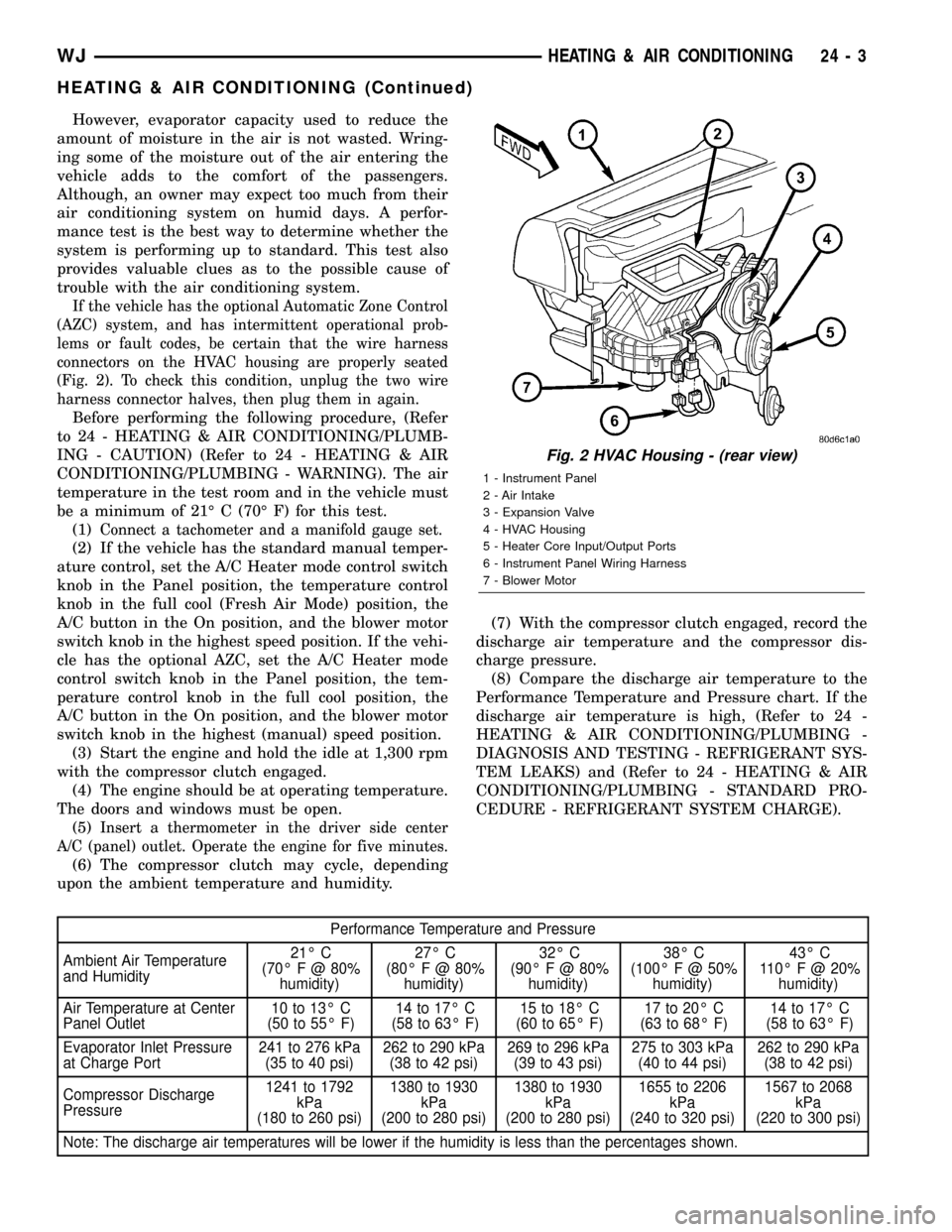

If the vehicle has the optional Automatic Zone Control

(AZC) system, and has intermittent operational prob-

lems or fault codes, be certain that the wire harness

connectors on the HVAC housing are properly seated

(Fig. 2). To check this condition, unplug the two wire

harness connector halves, then plug them in again.

Before performing the following procedure, (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING - CAUTION) (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - WARNING). The air

temperature in the test room and in the vehicle must

be a minimum of 21É C (70É F) for this test.

(1)

Connect a tachometer and a manifold gauge set.

(2) If the vehicle has the standard manual temper-

ature control, set the A/C Heater mode control switch

knob in the Panel position, the temperature control

knob in the full cool (Fresh Air Mode) position, the

A/C button in the On position, and the blower motor

switch knob in the highest speed position. If the vehi-

cle has the optional AZC, set the A/C Heater mode

control switch knob in the Panel position, the tem-

perature control knob in the full cool position, the

A/C button in the On position, and the blower motor

switch knob in the highest (manual) speed position.

(3) Start the engine and hold the idle at 1,300 rpm

with the compressor clutch engaged.

(4) The engine should be at operating temperature.

The doors and windows must be open.

(5)

Insert a thermometer in the driver side center

A/C (panel) outlet. Operate the engine for five minutes.

(6) The compressor clutch may cycle, depending

upon the ambient temperature and humidity.(7) With the compressor clutch engaged, record the

discharge air temperature and the compressor dis-

charge pressure.

(8) Compare the discharge air temperature to the

Performance Temperature and Pressure chart. If the

discharge air temperature is high, (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

DIAGNOSIS AND TESTING - REFRIGERANT SYS-

TEM LEAKS) and (Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING - STANDARD PRO-

CEDURE - REFRIGERANT SYSTEM CHARGE).

Performance Temperature and Pressure

Ambient Air Temperature

and Humidity21É C

(70É F @ 80%

humidity)27É C

(80É F @ 80%

humidity)32É C

(90É F @ 80%

humidity)38É C

(100ÉF@50%

humidity)43É C

110É F @ 20%

humidity)

Air Temperature at Center

Panel Outlet10 to 13É C

(50 to 55É F)14 to 17É C

(58 to 63É F)15 to 18É C

(60 to 65É F)17 to 20É C

(63 to 68É F)14 to 17É C

(58 to 63É F)

Evaporator Inlet Pressure

at Charge Port241 to 276 kPa

(35 to 40 psi)262 to 290 kPa

(38 to 42 psi)269 to 296 kPa

(39 to 43 psi)275 to 303 kPa

(40 to 44 psi)262 to 290 kPa

(38 to 42 psi)

Compressor Discharge

Pressure1241 to 1792

kPa

(180 to 260 psi)1380 to 1930

kPa

(200 to 280 psi)1380 to 1930

kPa

(200 to 280 psi)1655 to 2206

kPa

(240 to 320 psi)1567 to 2068

kPa

(220 to 300 psi)

Note: The discharge air temperatures will be lower if the humidity is less than the percentages shown.

Fig. 2 HVAC Housing - (rear view)

1 - Instrument Panel

2 - Air Intake

3 - Expansion Valve

4 - HVAC Housing

5 - Heater Core Input/Output Ports

6 - Instrument Panel Wiring Harness

7 - Blower Motor

WJHEATING & AIR CONDITIONING 24 - 3

HEATING & AIR CONDITIONING (Continued)

Page 2081 of 2199

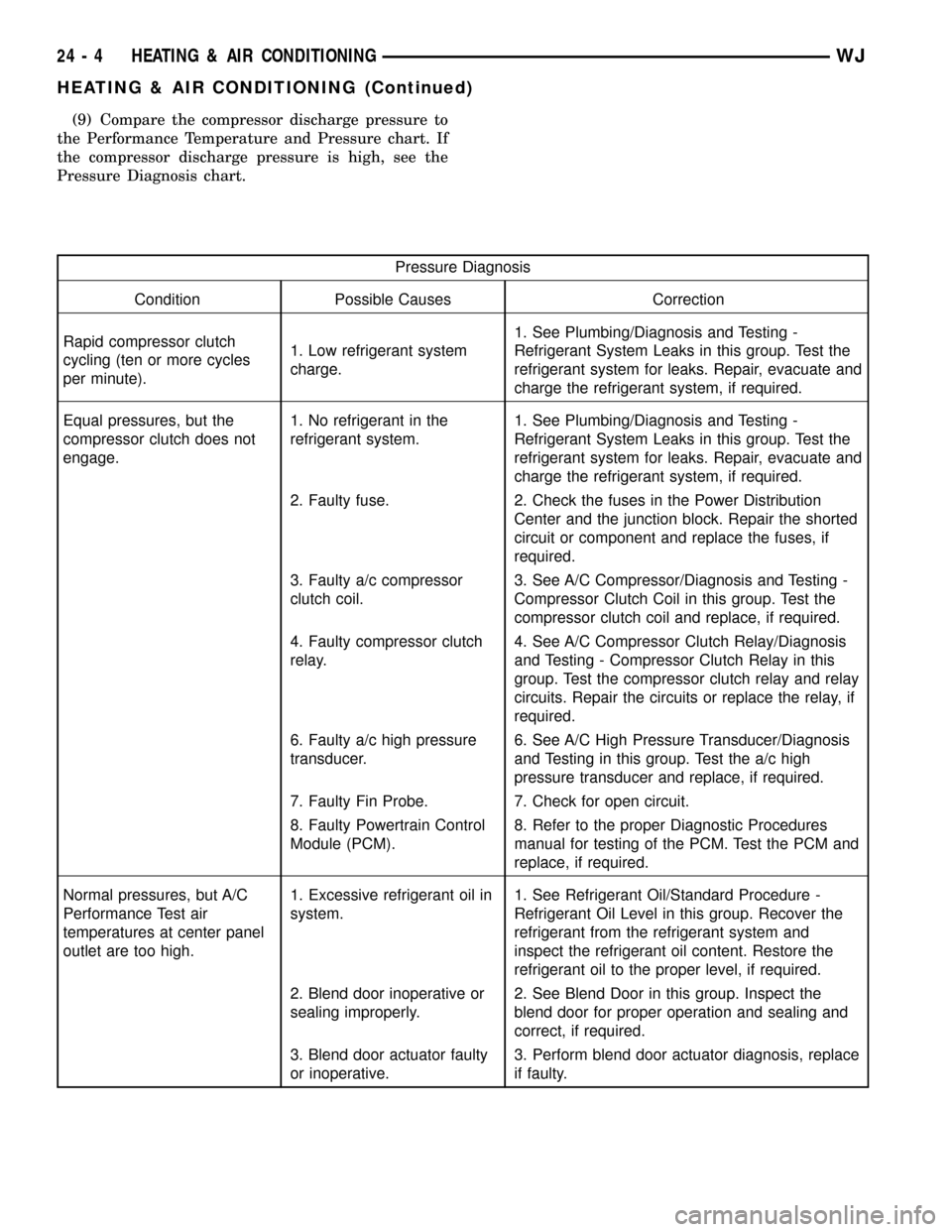

(9) Compare the compressor discharge pressure to

the Performance Temperature and Pressure chart. If

the compressor discharge pressure is high, see the

Pressure Diagnosis chart.

Pressure Diagnosis

Condition Possible Causes Correction

Rapid compressor clutch

cycling (ten or more cycles

per minute).1. Low refrigerant system

charge.1. See Plumbing/Diagnosis and Testing -

Refrigerant System Leaks in this group. Test the

refrigerant system for leaks. Repair, evacuate and

charge the refrigerant system, if required.

Equal pressures, but the

compressor clutch does not

engage.1. No refrigerant in the

refrigerant system.1. See Plumbing/Diagnosis and Testing -

Refrigerant System Leaks in this group. Test the

refrigerant system for leaks. Repair, evacuate and

charge the refrigerant system, if required.

2. Faulty fuse. 2. Check the fuses in the Power Distribution

Center and the junction block. Repair the shorted

circuit or component and replace the fuses, if

required.

3. Faulty a/c compressor

clutch coil.3. See A/C Compressor/Diagnosis and Testing -

Compressor Clutch Coil in this group. Test the

compressor clutch coil and replace, if required.

4. Faulty compressor clutch

relay.4. See A/C Compressor Clutch Relay/Diagnosis

and Testing - Compressor Clutch Relay in this

group. Test the compressor clutch relay and relay

circuits. Repair the circuits or replace the relay, if

required.

6. Faulty a/c high pressure

transducer.6. See A/C High Pressure Transducer/Diagnosis

and Testing in this group. Test the a/c high

pressure transducer and replace, if required.

7. Faulty Fin Probe. 7. Check for open circuit.

8. Faulty Powertrain Control

Module (PCM).8. Refer to the proper Diagnostic Procedures

manual for testing of the PCM. Test the PCM and

replace, if required.

Normal pressures, but A/C

Performance Test air

temperatures at center panel

outlet are too high.1. Excessive refrigerant oil in

system.1. See Refrigerant Oil/Standard Procedure -

Refrigerant Oil Level in this group. Recover the

refrigerant from the refrigerant system and

inspect the refrigerant oil content. Restore the

refrigerant oil to the proper level, if required.

2. Blend door inoperative or

sealing improperly.2. See Blend Door in this group. Inspect the

blend door for proper operation and sealing and

correct, if required.

3. Blend door actuator faulty

or inoperative.3. Perform blend door actuator diagnosis, replace

if faulty.

24 - 4 HEATING & AIR CONDITIONINGWJ

HEATING & AIR CONDITIONING (Continued)

Page 2082 of 2199

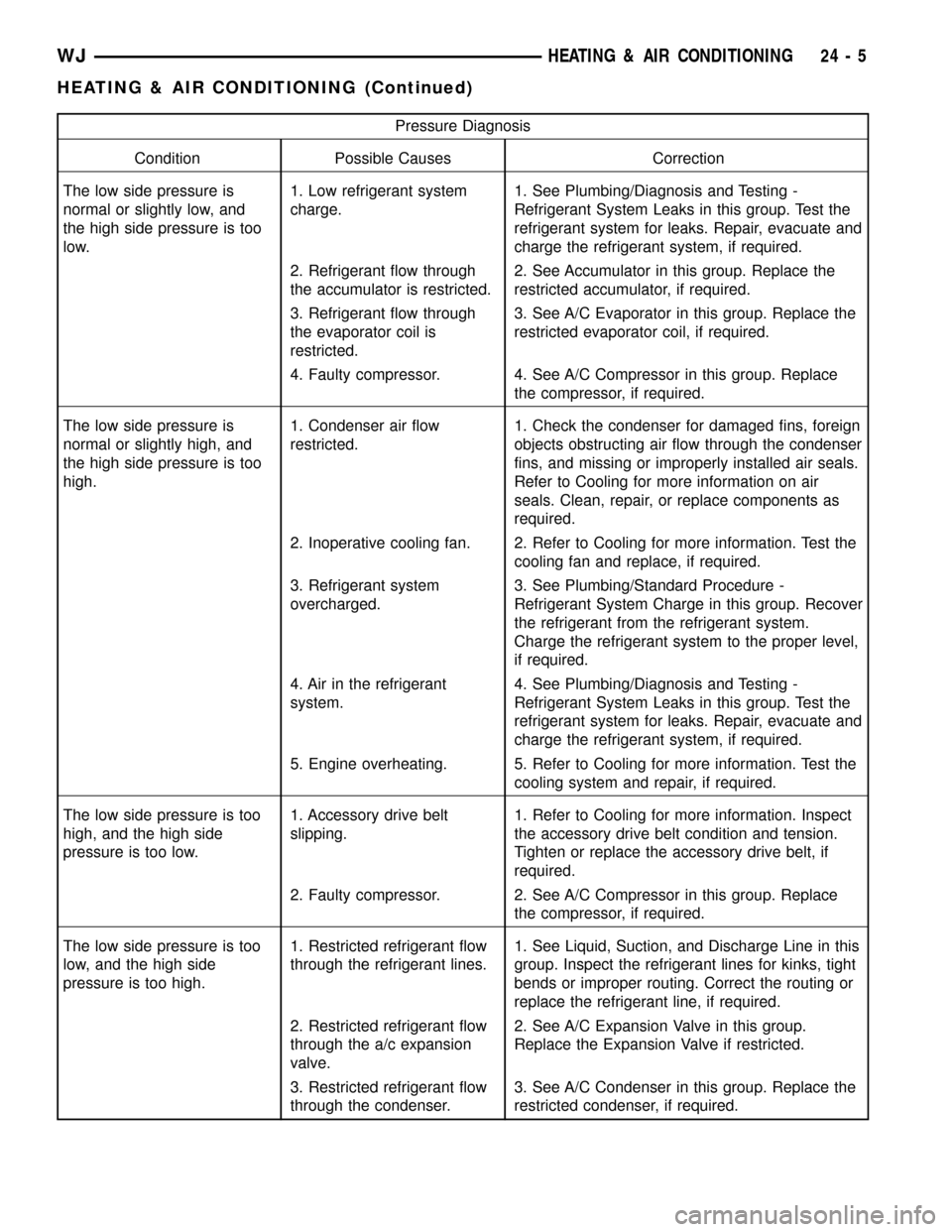

Pressure Diagnosis

Condition Possible Causes Correction

The low side pressure is

normal or slightly low, and

the high side pressure is too

low.1. Low refrigerant system

charge.1. See Plumbing/Diagnosis and Testing -

Refrigerant System Leaks in this group. Test the

refrigerant system for leaks. Repair, evacuate and

charge the refrigerant system, if required.

2. Refrigerant flow through

the accumulator is restricted.2. See Accumulator in this group. Replace the

restricted accumulator, if required.

3. Refrigerant flow through

the evaporator coil is

restricted.3. See A/C Evaporator in this group. Replace the

restricted evaporator coil, if required.

4. Faulty compressor. 4. See A/C Compressor in this group. Replace

the compressor, if required.

The low side pressure is

normal or slightly high, and

the high side pressure is too

high.1. Condenser air flow

restricted.1. Check the condenser for damaged fins, foreign

objects obstructing air flow through the condenser

fins, and missing or improperly installed air seals.

Refer to Cooling for more information on air

seals. Clean, repair, or replace components as

required.

2. Inoperative cooling fan. 2. Refer to Cooling for more information. Test the

cooling fan and replace, if required.

3. Refrigerant system

overcharged.3. See Plumbing/Standard Procedure -

Refrigerant System Charge in this group. Recover

the refrigerant from the refrigerant system.

Charge the refrigerant system to the proper level,

if required.

4. Air in the refrigerant

system.4. See Plumbing/Diagnosis and Testing -

Refrigerant System Leaks in this group. Test the

refrigerant system for leaks. Repair, evacuate and

charge the refrigerant system, if required.

5. Engine overheating. 5. Refer to Cooling for more information. Test the

cooling system and repair, if required.

The low side pressure is too

high, and the high side

pressure is too low.1. Accessory drive belt

slipping.1. Refer to Cooling for more information. Inspect

the accessory drive belt condition and tension.

Tighten or replace the accessory drive belt, if

required.

2. Faulty compressor. 2. See A/C Compressor in this group. Replace

the compressor, if required.

The low side pressure is too

low, and the high side

pressure is too high.1. Restricted refrigerant flow

through the refrigerant lines.1. See Liquid, Suction, and Discharge Line in this

group. Inspect the refrigerant lines for kinks, tight

bends or improper routing. Correct the routing or

replace the refrigerant line, if required.

2. Restricted refrigerant flow

through the a/c expansion

valve.2. See A/C Expansion Valve in this group.

Replace the Expansion Valve if restricted.

3. Restricted refrigerant flow

through the condenser.3. See A/C Condenser in this group. Replace the

restricted condenser, if required.

WJHEATING & AIR CONDITIONING 24 - 5

HEATING & AIR CONDITIONING (Continued)

Page 2084 of 2199

(5) Install the new diode in the harness, making

sure current flow is correct. If necessary refer to the

appropriate wiring diagram for current flow.

(6) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(7) Tape the diode to the harness using electrical

tape making, sure the diode is completely sealed

from the elements.

(8) Re-connect the battery, and test affected sys-

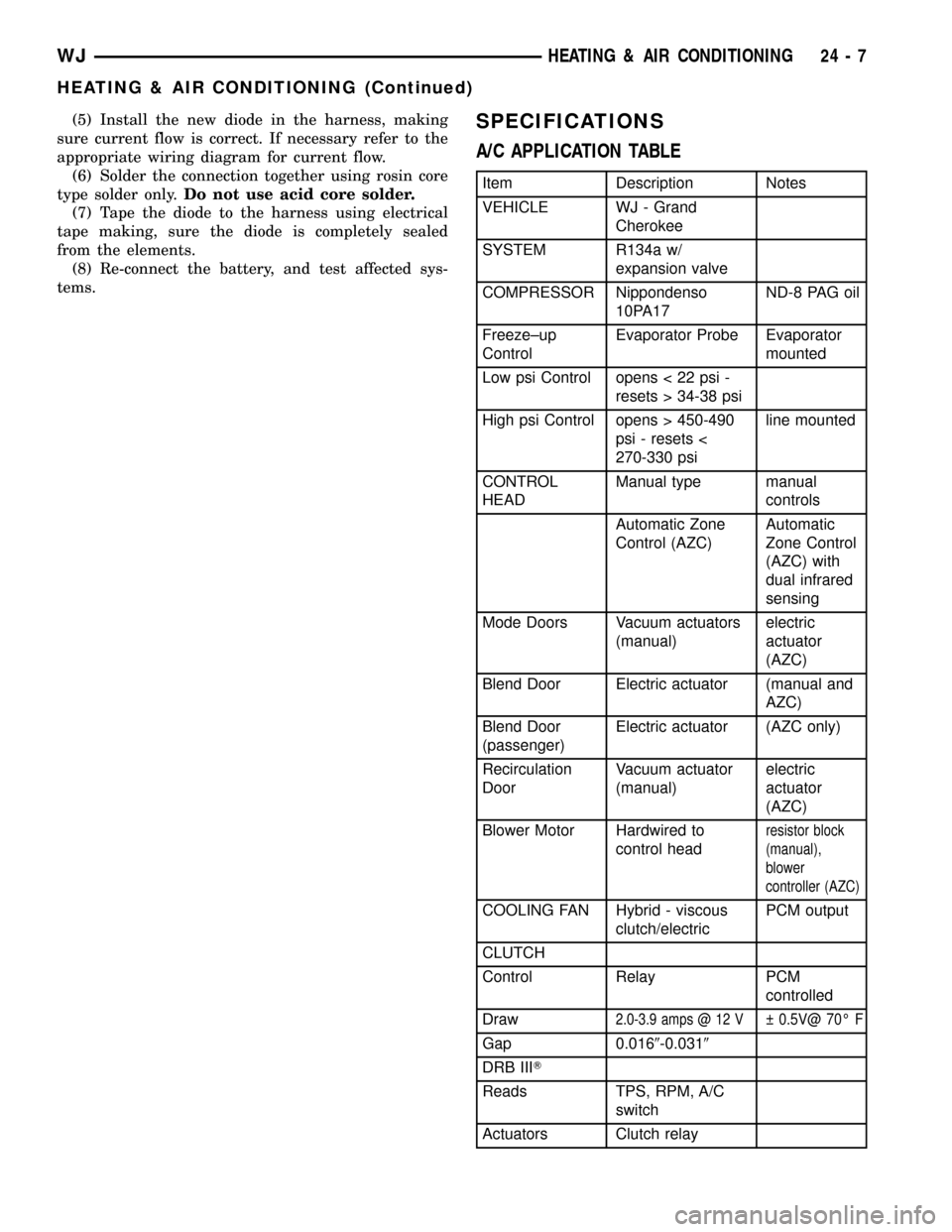

tems.SPECIFICATIONS

A/C APPLICATION TABLE

Item Description Notes

VEHICLE WJ - Grand

Cherokee

SYSTEM R134a w/

expansion valve

COMPRESSOR Nippondenso

10PA17ND-8 PAG oil

Freeze±up

ControlEvaporator Probe Evaporator

mounted

Low psi Control opens < 22 psi -

resets > 34-38 psi

High psi Control opens > 450-490

psi - resets <

270-330 psiline mounted

CONTROL

HEADManual type manual

controls

Automatic Zone

Control (AZC)Automatic

Zone Control

(AZC) with

dual infrared

sensing

Mode Doors Vacuum actuators

(manual)electric

actuator

(AZC)

Blend Door Electric actuator (manual and

AZC)

Blend Door

(passenger)Electric actuator (AZC only)

Recirculation

DoorVacuum actuator

(manual)electric

actuator

(AZC)

Blower Motor Hardwired to

control head

resistor block

(manual),

blower

controller (AZC)

COOLING FAN Hybrid - viscous

clutch/electricPCM output

CLUTCH

Control Relay PCM

controlled

Draw

2.0-3.9 amps @ 12 V 0.5V@ 70É F

Gap 0.0169-0.0319

DRB IIIT

Reads TPS, RPM, A/C

switch

Actuators Clutch relay

WJHEATING & AIR CONDITIONING 24 - 7

HEATING & AIR CONDITIONING (Continued)

Page 2085 of 2199

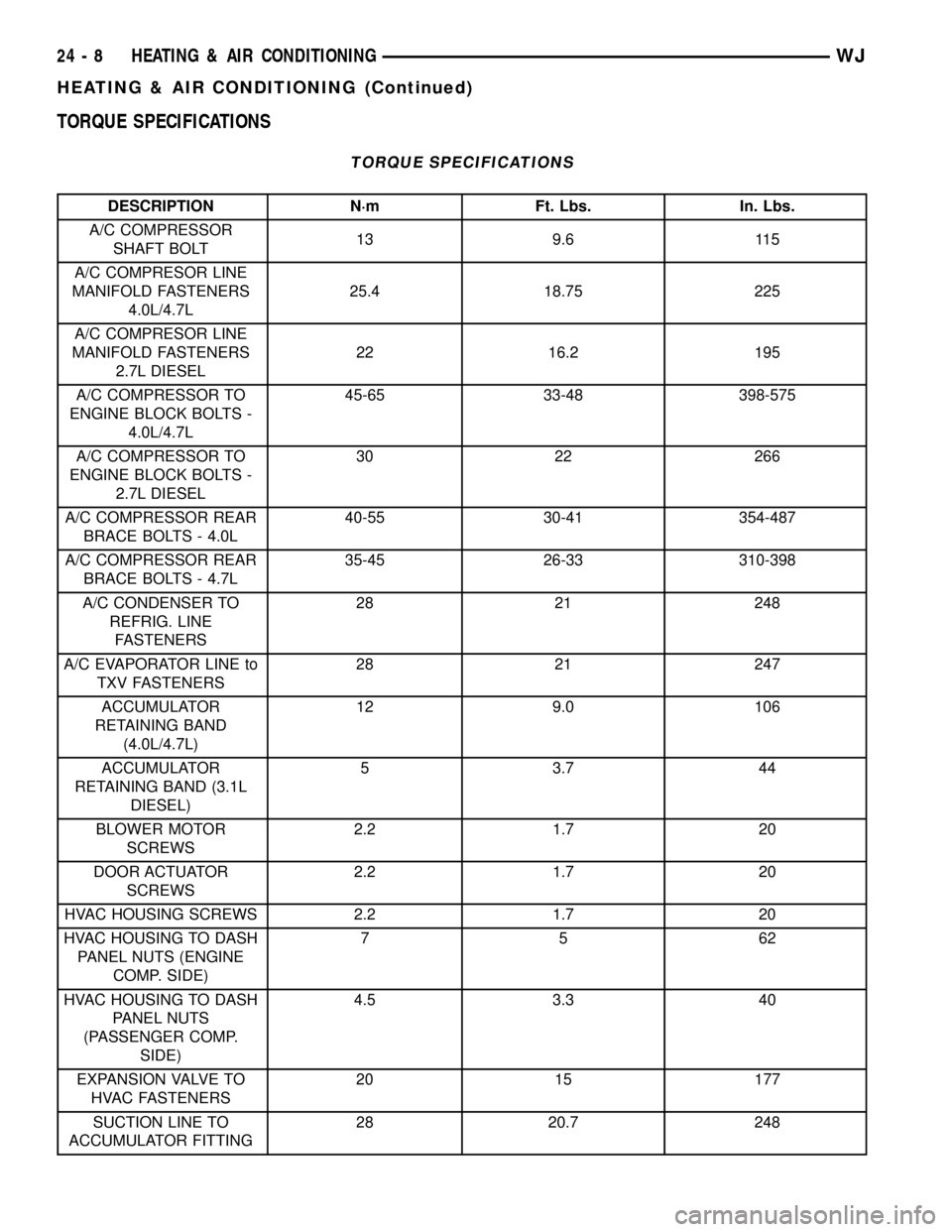

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

A/C COMPRESSOR

SHAFT BOLT13 9.6 115

A/C COMPRESOR LINE

MANIFOLD FASTENERS

4.0L/4.7L25.4 18.75 225

A/C COMPRESOR LINE

MANIFOLD FASTENERS

2.7L DIESEL22 16.2 195

A/C COMPRESSOR TO

ENGINE BLOCK BOLTS -

4.0L/4.7L45-65 33-48 398-575

A/C COMPRESSOR TO

ENGINE BLOCK BOLTS -

2.7L DIESEL30 22 266

A/C COMPRESSOR REAR

BRACE BOLTS - 4.0L40-55 30-41 354-487

A/C COMPRESSOR REAR

BRACE BOLTS - 4.7L35-45 26-33 310-398

A/C CONDENSER TO

REFRIG. LINE

FASTENERS28 21 248

A/C EVAPORATOR LINE to

TXV FASTENERS28 21 247

ACCUMULATOR

RETAINING BAND

(4.0L/4.7L)12 9.0 106

ACCUMULATOR

RETAINING BAND (3.1L

DIESEL)5 3.7 44

BLOWER MOTOR

SCREWS2.2 1.7 20

DOOR ACTUATOR

SCREWS2.2 1.7 20

HVAC HOUSING SCREWS 2.2 1.7 20

HVAC HOUSING TO DASH

PANEL NUTS (ENGINE

COMP. SIDE)75 62

HVAC HOUSING TO DASH

PANEL NUTS

(PASSENGER COMP.

SIDE)4.5 3.3 40

EXPANSION VALVE TO

HVAC FASTENERS20 15 177

SUCTION LINE TO

ACCUMULATOR FITTING28 20.7 248

24 - 8 HEATING & AIR CONDITIONINGWJ

HEATING & AIR CONDITIONING (Continued)

Page 2086 of 2199

CONTROLS

TABLE OF CONTENTS

page page

CONTROLS

DIAGNOSIS AND TESTING - VACUUM

SYSTEM............................10

A/C COMPRESSOR CLUTCH

DESCRIPTION.........................13

OPERATION...........................13

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH COIL........................13

STANDARD PROCEDURE - COMPRESSOR

CLUTCH BREAK-IN....................14

REMOVAL.............................14

INSPECTION..........................15

INSTALLATION.........................15

A/C COMPRESSOR CLUTCH RELAY

DESCRIPTION.........................16

OPERATION...........................16

DIAGNOSIS AND TESTING - A/C

COMPRESSOR CLUTCH RELAY..........16

REMOVAL.............................17

INSTALLATION.........................17

A/C HEATER CONTROL

DESCRIPTION.........................17

OPERATION...........................17

DIAGNOSIS AND TESTING - AUTOMATIC

ZONE CONTROL SYSTEM..............18

REMOVAL.............................24

INSTALLATION.........................25

A/C PRESSURE TRANSDUCER

DESCRIPTION.........................25

OPERATION...........................25

DIAGNOSIS AND TESTING - A/C PRESSURE

TRANSDUCER.......................26

REMOVAL.............................26

INSTALLATION.........................26

BLOWER MOTOR CONTROLLER

DESCRIPTION.........................26

OPERATION...........................26

REMOVAL.............................27

INSTALLATION.........................27

BLOWER MOTOR RESISTOR BLOCK

DESCRIPTION.........................27

OPERATION...........................27

DIAGNOSIS AND TESTING - BLOWER

MOTOR RESISTOR BLOCK..............27

REMOVAL.............................28

INSTALLATION.........................28BLOWER MOTOR SWITCH

DESCRIPTION.........................28

OPERATION...........................28

DIAGNOSIS AND TESTING - BLOWER

MOTOR SWITCH-MANUAL TEMPERATURE

CONTROL SYSTEM....................28

REMOVAL.............................29

IN-CAR TEMPERATURE SENSOR

DESCRIPTION.........................29

OPERATION...........................29

REMOVAL.............................29

BLEND DOOR ACTUATOR

DESCRIPTION.........................30

REMOVAL.............................30

INSTALLATION.........................30

MODE DOOR ACTUATOR

DESCRIPTION.........................30

REMOVAL

REMOVAL - HEAT/DEFROST - PANEL/

DEFROST DOOR ELECTRIC ACTUATOR . . . 31

REMOVAL - HEAT/DEFROST DOOR

VACUUM ACTUATOR..................31

REMOVAL - PANEL/DEFROST DOOR

VACUUM ACTUATOR..................32

INSTALLATION

INSTALLATION - HEAT/DEFROST -

PANEL/DEFROST DOOR ELECTRIC

ACTUATOR..........................32

INSTALLATION - HEAT/DEFROST DOOR

VACUUM ACTUATOR..................33

INSTALLATION - PANEL/DEFROST DOOR

VACUUM ACTUATOR..................33

RECIRCULATION DOOR ACTUATOR

DESCRIPTION.........................33

REMOVAL

REMOVAL - RECIRCULATION DOOR

VACUUM ACTUATOR..................33

REMOVAL - RECIRCULATION DOOR

ELECTRIC ACTUATOR.................33

INSTALLATION

INSTALLATION - RECIRCULATION DOOR

VACUUM ACTUATOR..................34

INSTALLATION - RECIRCULATION DOOR

ELECTRIC ACTUATOR.................34

VACUUM CHECK VALVE

DESCRIPTION.........................34

OPERATION...........................34

REMOVAL.............................34

INSTALLATION.........................34

WJCONTROLS 24 - 9

Page 2090 of 2199

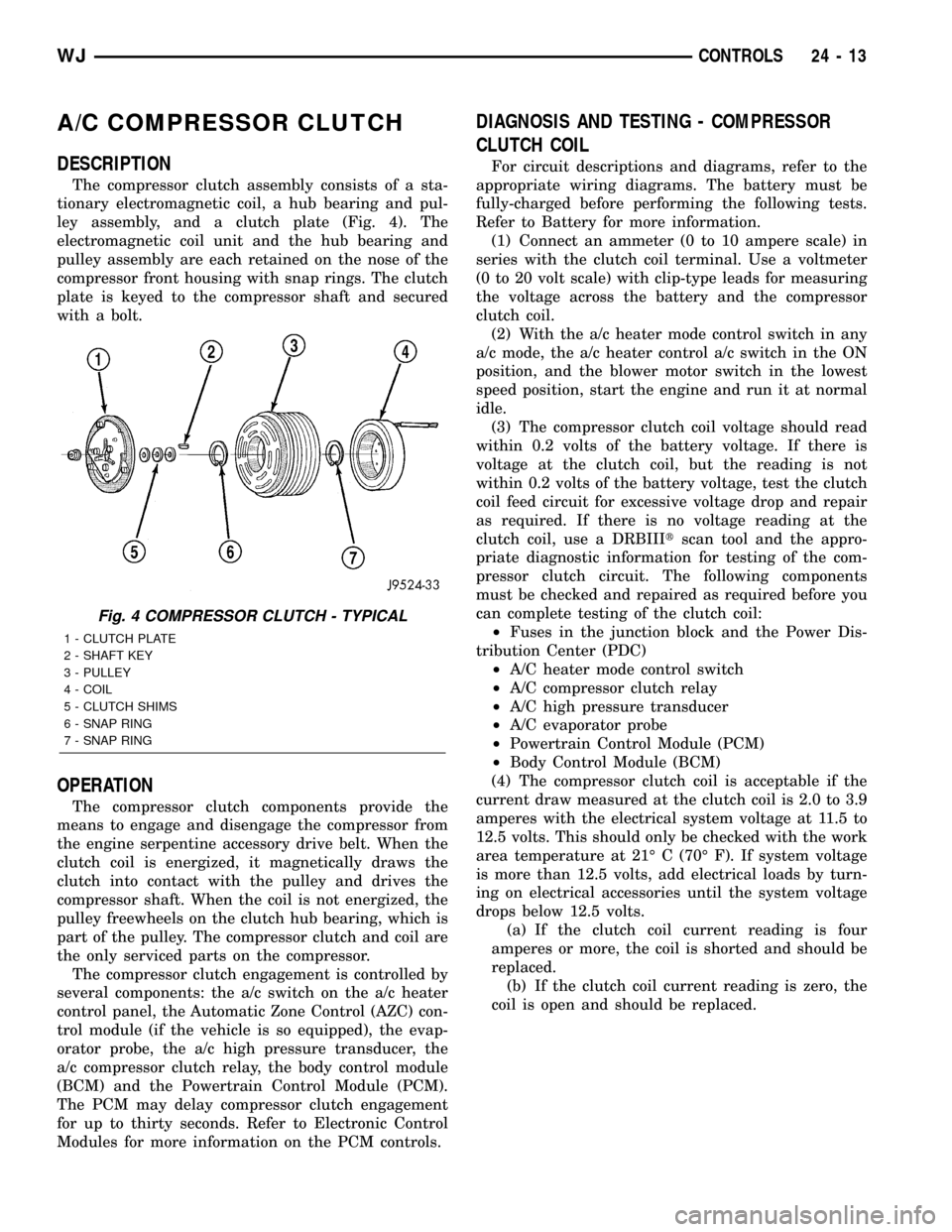

A/C COMPRESSOR CLUTCH

DESCRIPTION

The compressor clutch assembly consists of a sta-

tionary electromagnetic coil, a hub bearing and pul-

ley assembly, and a clutch plate (Fig. 4). The

electromagnetic coil unit and the hub bearing and

pulley assembly are each retained on the nose of the

compressor front housing with snap rings. The clutch

plate is keyed to the compressor shaft and secured

with a bolt.

OPERATION

The compressor clutch components provide the

means to engage and disengage the compressor from

the engine serpentine accessory drive belt. When the

clutch coil is energized, it magnetically draws the

clutch into contact with the pulley and drives the

compressor shaft. When the coil is not energized, the

pulley freewheels on the clutch hub bearing, which is

part of the pulley. The compressor clutch and coil are

the only serviced parts on the compressor.

The compressor clutch engagement is controlled by

several components: the a/c switch on the a/c heater

control panel, the Automatic Zone Control (AZC) con-

trol module (if the vehicle is so equipped), the evap-

orator probe, the a/c high pressure transducer, the

a/c compressor clutch relay, the body control module

(BCM) and the Powertrain Control Module (PCM).

The PCM may delay compressor clutch engagement

for up to thirty seconds. Refer to Electronic Control

Modules for more information on the PCM controls.

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH COIL

For circuit descriptions and diagrams, refer to the

appropriate wiring diagrams. The battery must be

fully-charged before performing the following tests.

Refer to Battery for more information.

(1) Connect an ammeter (0 to 10 ampere scale) in

series with the clutch coil terminal. Use a voltmeter

(0 to 20 volt scale) with clip-type leads for measuring

the voltage across the battery and the compressor

clutch coil.

(2) With the a/c heater mode control switch in any

a/c mode, the a/c heater control a/c switch in the ON

position, and the blower motor switch in the lowest

speed position, start the engine and run it at normal

idle.

(3) The compressor clutch coil voltage should read

within 0.2 volts of the battery voltage. If there is

voltage at the clutch coil, but the reading is not

within 0.2 volts of the battery voltage, test the clutch

coil feed circuit for excessive voltage drop and repair

as required. If there is no voltage reading at the

clutch coil, use a DRBIIItscan tool and the appro-

priate diagnostic information for testing of the com-

pressor clutch circuit. The following components

must be checked and repaired as required before you

can complete testing of the clutch coil:

²Fuses in the junction block and the Power Dis-

tribution Center (PDC)

²A/C heater mode control switch

²A/C compressor clutch relay

²A/C high pressure transducer

²A/C evaporator probe

²Powertrain Control Module (PCM)

²Body Control Module (BCM)

(4) The compressor clutch coil is acceptable if the

current draw measured at the clutch coil is 2.0 to 3.9

amperes with the electrical system voltage at 11.5 to

12.5 volts. This should only be checked with the work

area temperature at 21É C (70É F). If system voltage

is more than 12.5 volts, add electrical loads by turn-

ing on electrical accessories until the system voltage

drops below 12.5 volts.

(a) If the clutch coil current reading is four

amperes or more, the coil is shorted and should be

replaced.

(b) If the clutch coil current reading is zero, the

coil is open and should be replaced.

Fig. 4 COMPRESSOR CLUTCH - TYPICAL

1 - CLUTCH PLATE

2 - SHAFT KEY

3 - PULLEY

4 - COIL

5 - CLUTCH SHIMS

6 - SNAP RING

7 - SNAP RING

WJCONTROLS 24 - 13