Fill JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1985 of 2199

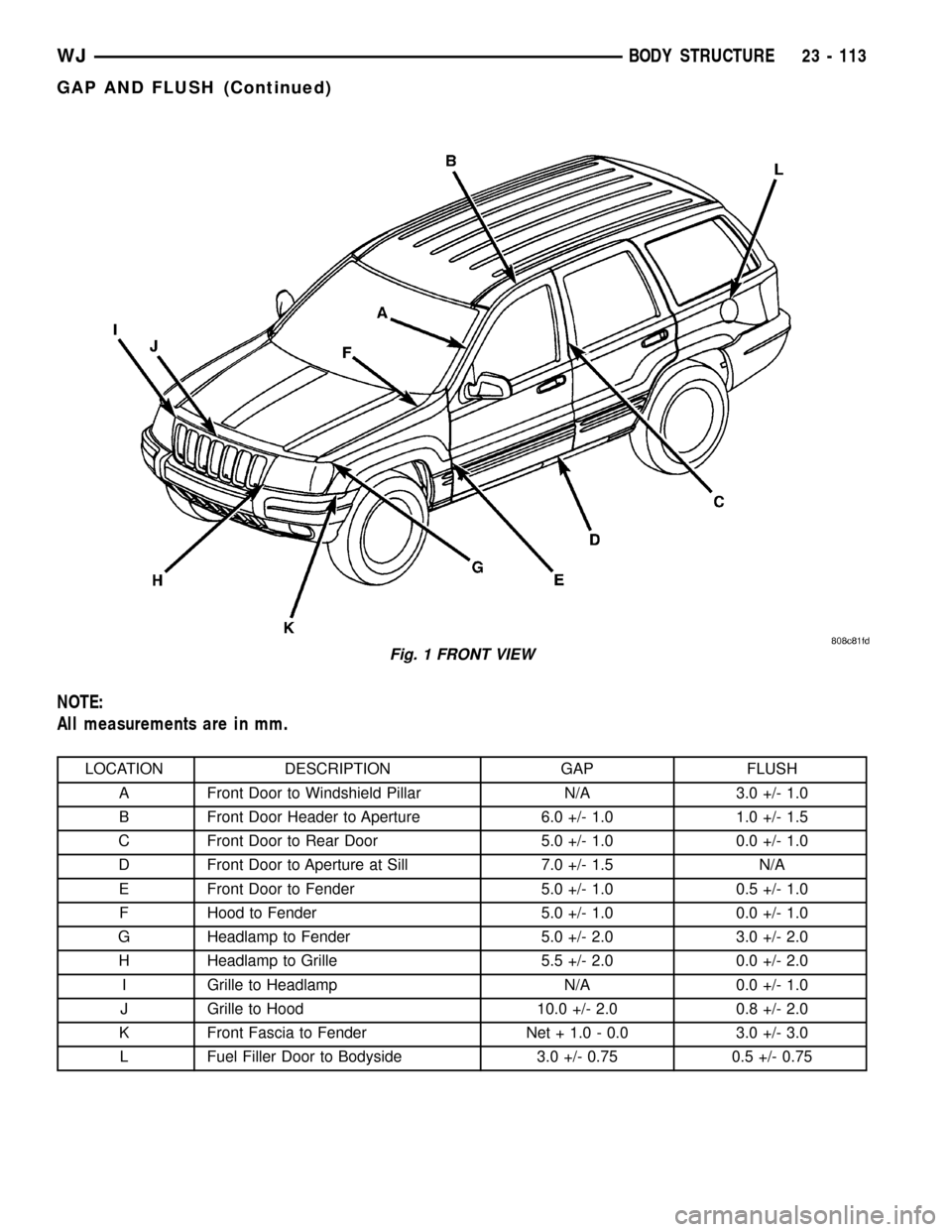

NOTE:

All measurements are in mm.

LOCATION DESCRIPTION GAP FLUSH

A Front Door to Windshield Pillar N/A 3.0 +/- 1.0

B Front Door Header to Aperture 6.0 +/- 1.0 1.0 +/- 1.5

C Front Door to Rear Door 5.0 +/- 1.0 0.0 +/- 1.0

D Front Door to Aperture at Sill 7.0 +/- 1.5 N/A

E Front Door to Fender 5.0 +/- 1.0 0.5 +/- 1.0

F Hood to Fender 5.0 +/- 1.0 0.0 +/- 1.0

G Headlamp to Fender 5.0 +/- 2.0 3.0 +/- 2.0

H Headlamp to Grille 5.5 +/- 2.0 0.0 +/- 2.0

I Grille to Headlamp N/A 0.0 +/- 1.0

J Grille to Hood 10.0 +/- 2.0 0.8 +/- 2.0

K Front Fascia to Fender Net + 1.0 - 0.0 3.0 +/- 3.0

L Fuel Filler Door to Bodyside 3.0 +/- 0.75 0.5 +/- 0.75

Fig. 1 FRONT VIEW

WJBODY STRUCTURE 23 - 113

GAP AND FLUSH (Continued)

Page 1991 of 2199

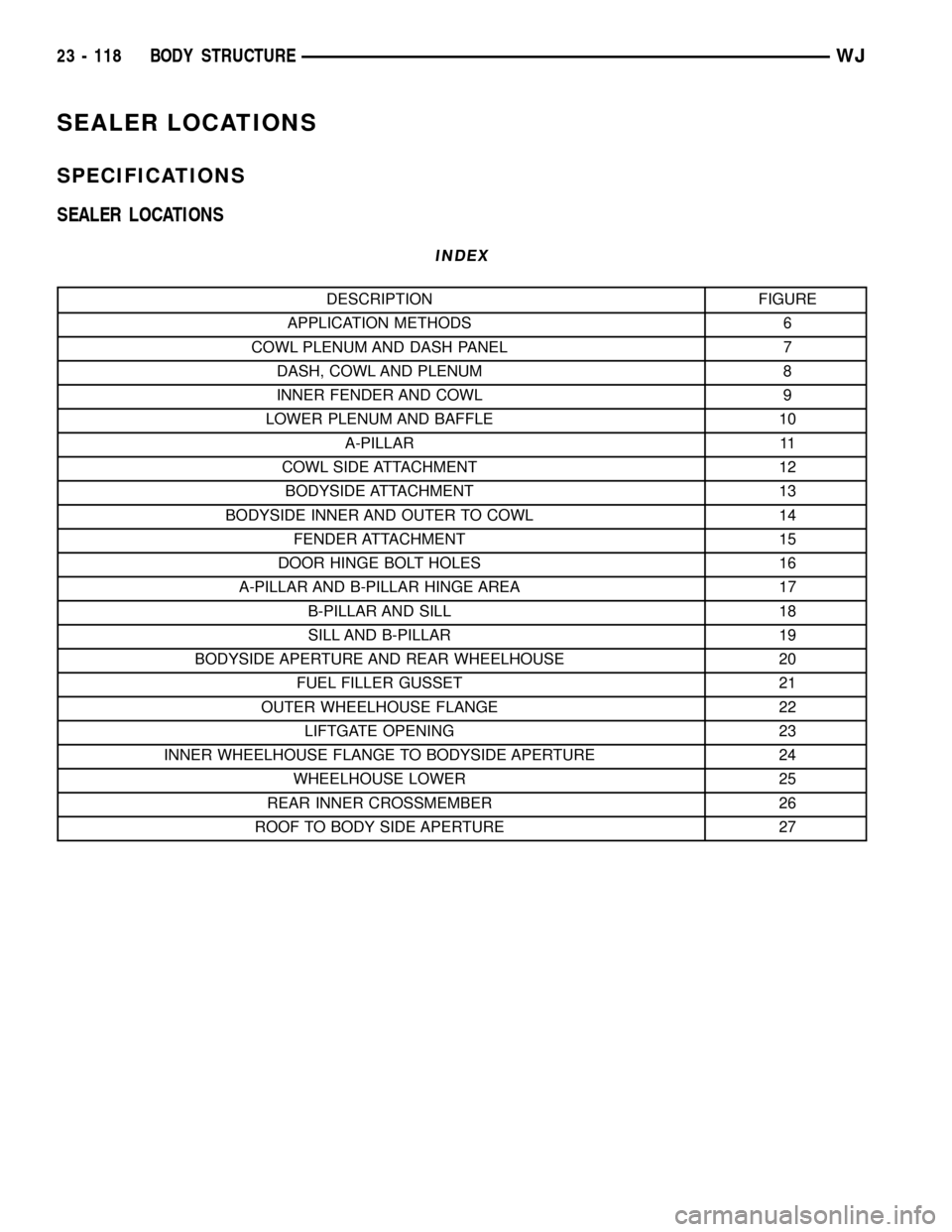

SEALER LOCATIONS

SPECIFICATIONS

SEALER LOCATIONS

INDEX

DESCRIPTION FIGURE

APPLICATION METHODS 6

COWL PLENUM AND DASH PANEL 7

DASH, COWL AND PLENUM 8

INNER FENDER AND COWL 9

LOWER PLENUM AND BAFFLE 10

A-PILLAR 11

COWL SIDE ATTACHMENT 12

BODYSIDE ATTACHMENT 13

BODYSIDE INNER AND OUTER TO COWL 14

FENDER ATTACHMENT 15

DOOR HINGE BOLT HOLES 16

A-PILLAR AND B-PILLAR HINGE AREA 17

B-PILLAR AND SILL 18

SILL AND B-PILLAR 19

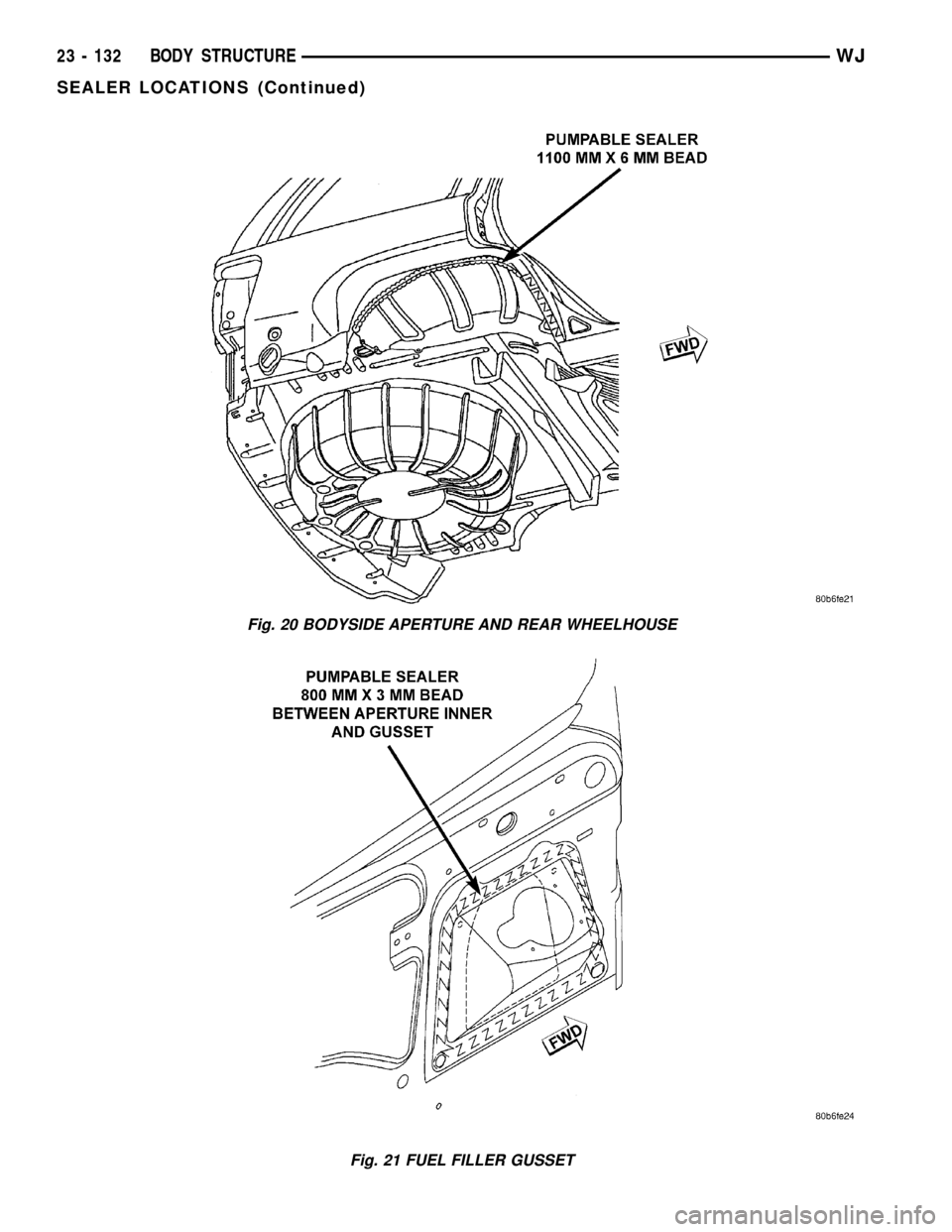

BODYSIDE APERTURE AND REAR WHEELHOUSE 20

FUEL FILLER GUSSET 21

OUTER WHEELHOUSE FLANGE 22

LIFTGATE OPENING 23

INNER WHEELHOUSE FLANGE TO BODYSIDE APERTURE 24

WHEELHOUSE LOWER 25

REAR INNER CROSSMEMBER 26

ROOF TO BODY SIDE APERTURE 27

23 - 118 BODY STRUCTUREWJ

Page 2005 of 2199

Fig. 20 BODYSIDE APERTURE AND REAR WHEELHOUSE

Fig. 21 FUEL FILLER GUSSET

23 - 132 BODY STRUCTUREWJ

SEALER LOCATIONS (Continued)

Page 2010 of 2199

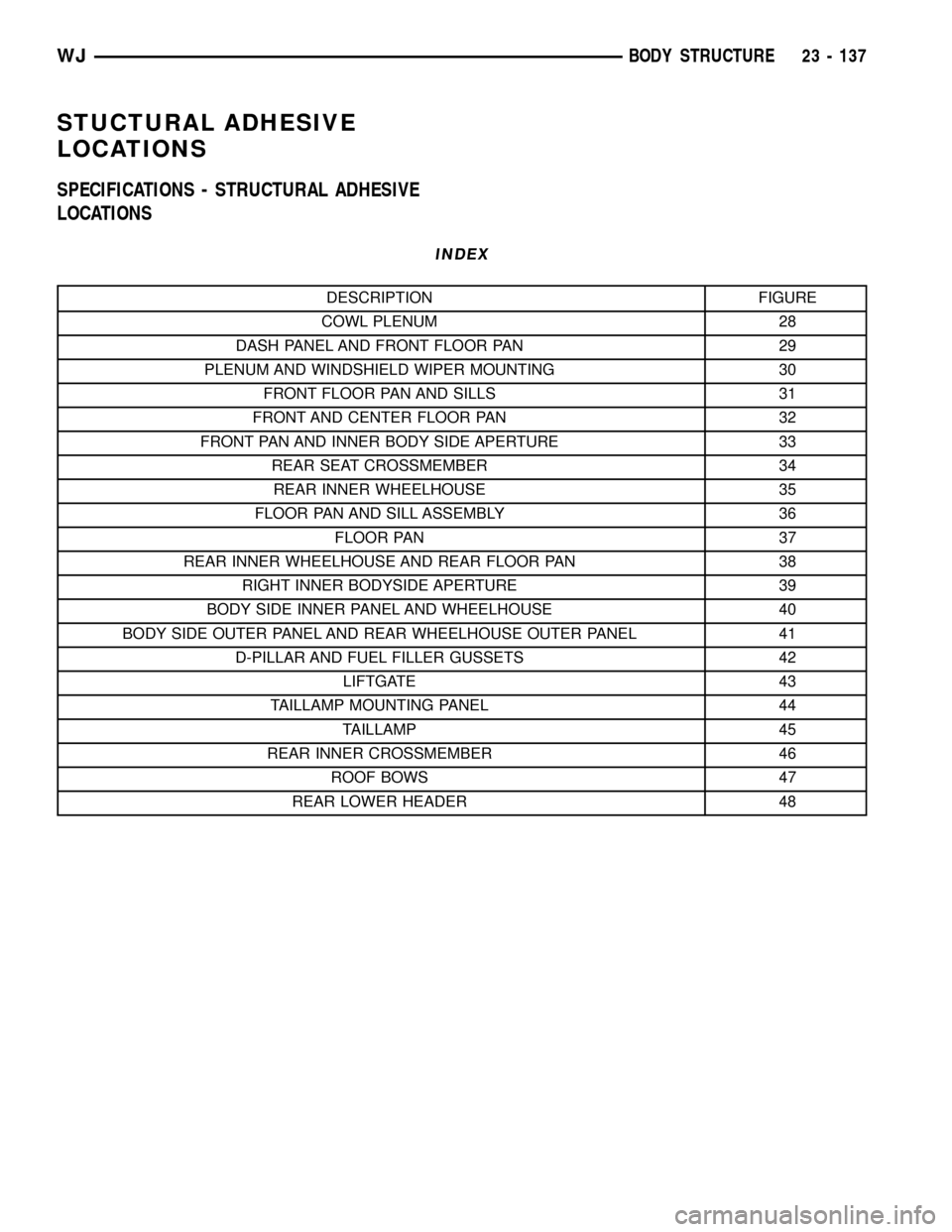

STUCTURAL ADHESIVE

LOCATIONS

SPECIFICATIONS - STRUCTURAL ADHESIVE

LOCATIONS

INDEX

DESCRIPTION FIGURE

COWL PLENUM 28

DASH PANEL AND FRONT FLOOR PAN 29

PLENUM AND WINDSHIELD WIPER MOUNTING 30

FRONT FLOOR PAN AND SILLS 31

FRONT AND CENTER FLOOR PAN 32

FRONT PAN AND INNER BODY SIDE APERTURE 33

REAR SEAT CROSSMEMBER 34

REAR INNER WHEELHOUSE 35

FLOOR PAN AND SILL ASSEMBLY 36

FLOOR PAN 37

REAR INNER WHEELHOUSE AND REAR FLOOR PAN 38

RIGHT INNER BODYSIDE APERTURE 39

BODY SIDE INNER PANEL AND WHEELHOUSE 40

BODY SIDE OUTER PANEL AND REAR WHEELHOUSE OUTER PANEL 41

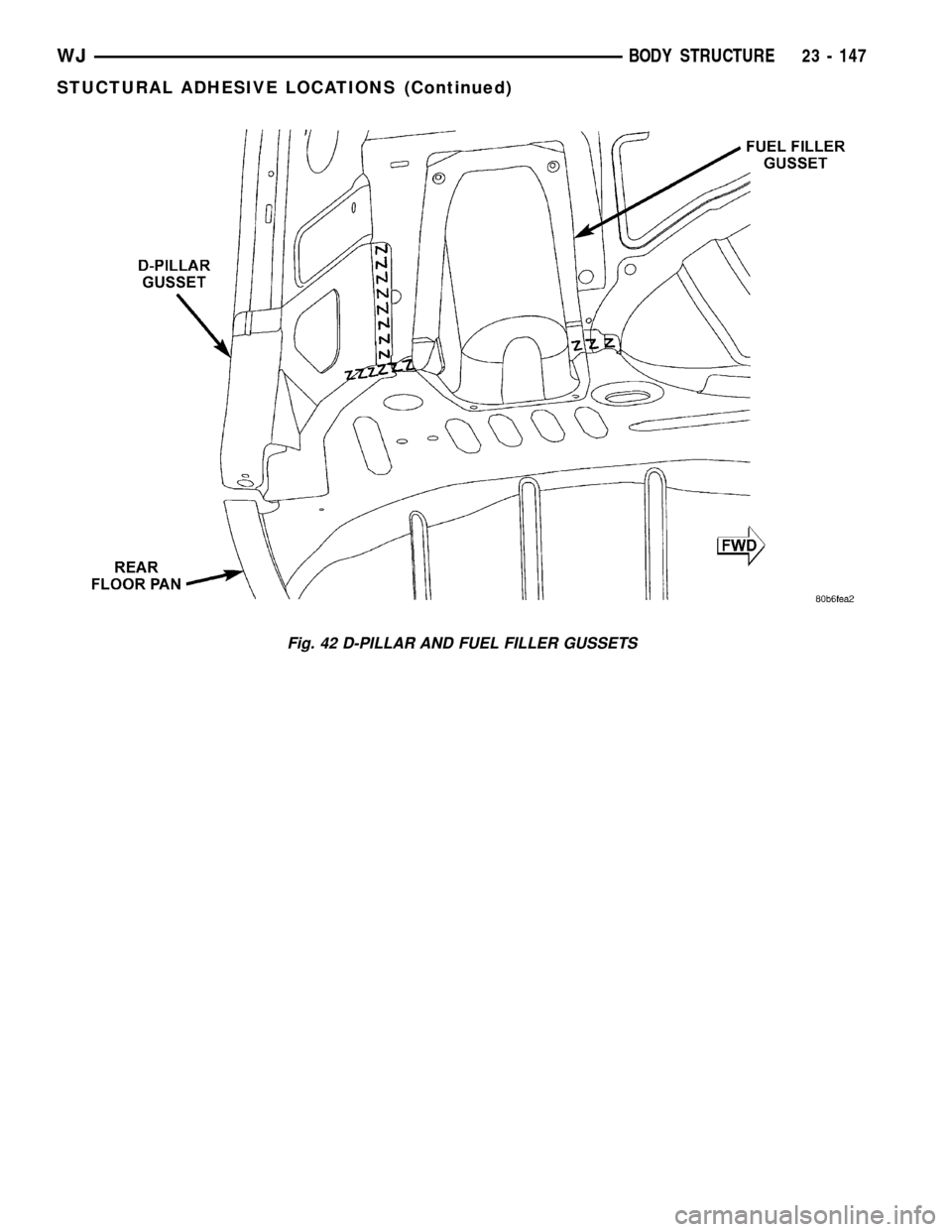

D-PILLAR AND FUEL FILLER GUSSETS 42

LIFTGATE 43

TAILLAMP MOUNTING PANEL 44

TAILLAMP 45

REAR INNER CROSSMEMBER 46

ROOF BOWS 47

REAR LOWER HEADER 48

WJBODY STRUCTURE 23 - 137

Page 2020 of 2199

Fig. 42 D-PILLAR AND FUEL FILLER GUSSETS

WJBODY STRUCTURE 23 - 147

STUCTURAL ADHESIVE LOCATIONS (Continued)

Page 2027 of 2199

DESCRIPTION FIGURE

REINFORCEMENT FOR FRONT ENGINE MOUNTING AND STEERING GEAR TO

FRONT INNER SILL81

LARGE AND SMALL SWAY BAR TAPPING PLATES TO FRONT INNER SILLS 82

FRONT AND REAR DOOR HINGE TAPPING PLATES 83

REAR DOOR STRIKER REINFORCEMENT 84

TAIL LAMP MOUNTING PANELS 85

ROOF PANEL TO BODYSIDE APERTURE 86

ROOF PANEL TO REAR HEADER 87

UPPER REAR HEADER TO LOWER HEADER 88

FRONT HEADER AND ROOF BOWS TO INNER PANEL 89

FRONT SEAT/SHOULDER BELT TO INNER PANEL REINFORCEMENT 90

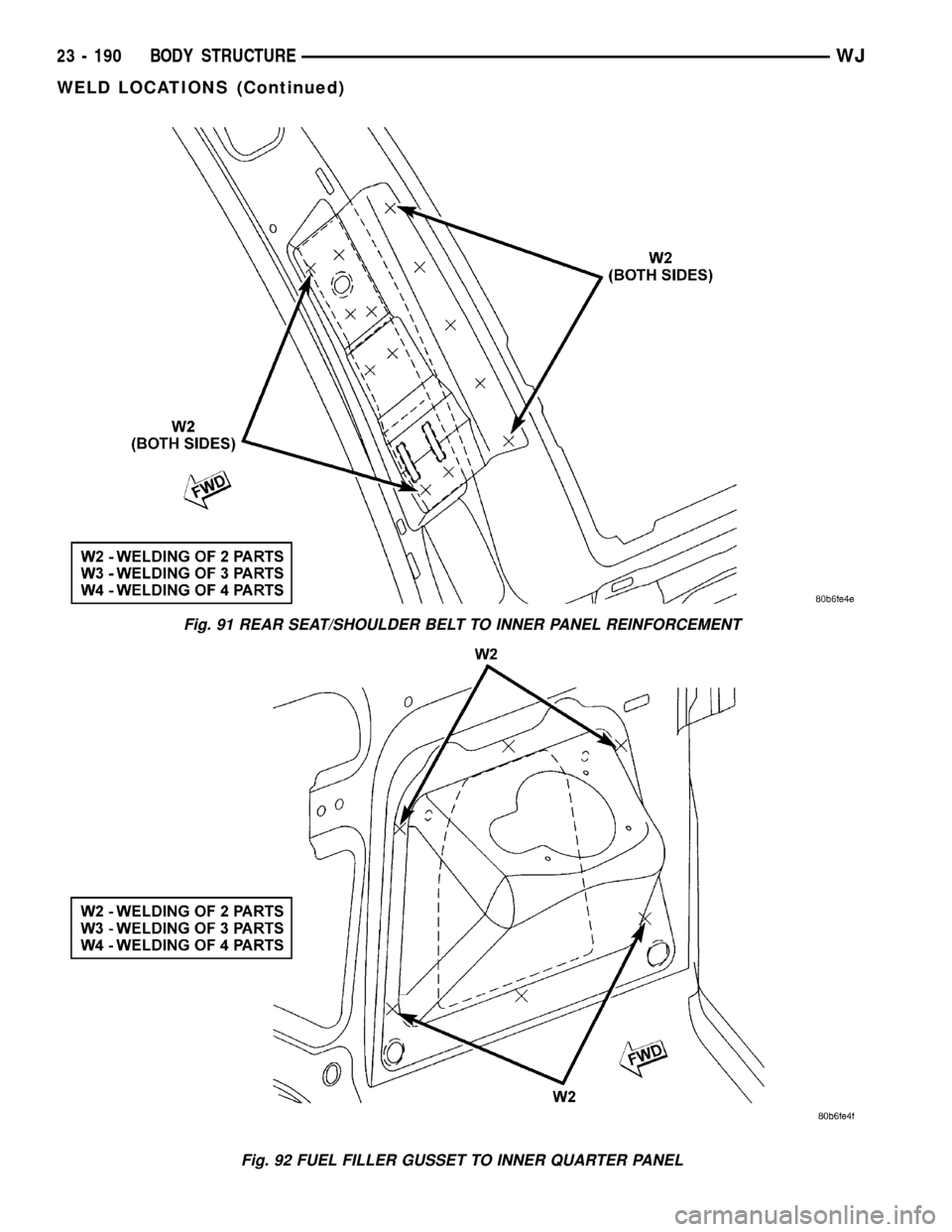

REAR SEAT/SHOULDER BELT TO INNER PANEL REINFORCEMENT 91

FUEL FILLER GUSSET TO INNER QUARTER PANEL 92

FRONT FLOOR PAN TO SILL REINFORCEMENT 93

CENTER FLOOR PAN TO REAR SEAT CROSSMEMBER 94

FRONT FLOOR PAN TO FRONT SEAT REINFORCEMENT AND RAILS 95

CENTER FLOOR PAN TO UPPER CONTROL ARM CROSSMEMBER AND RAILS 96

REAR FLOOR PAN TO RAILS AND SPRING GUIDE CROSSMEMBER 97

REAR RAILS 98

UPPER CONTROL ARM CROSSMEMBER TO REAR RAIL 99

REAR RAIL REINFORCEMENT TO REAR RAILS 100

UPPER CONTROL ARM REINFORCEMENTS TO REAR RAIL 101

OUTER TRANSMISSION CROSSMEMBER REINFORCEMENT TO RAIL AND

BODYSIDE SILL102

BODYSIDE SILL TO FLOOR PAN 103

REAR RAILS TO REAR CROSSMEMBER 104

INNER WHEELHOUSE TO FLOOR PAN 105

INNER WHEELHOUSE TO INNER BODYSIDE APERTURE AND FLOOR PAN 106

OUTER WHEELHOUSE TO OUTER BODYSIDE APERTURE 107

OUTER WHEELHOUSE TO INNER BODYSIDE APERTURE 108

INNER BODYSIDE APERTURE TO OUTER BODYSIDE APERTURE 109

REAR INBOARD SEAT BELT REINFORCEMENT TO FLOOR PAN 110

23 - 154 BODY STRUCTUREWJ

WELD LOCATIONS (Continued)

Page 2063 of 2199

Fig. 91 REAR SEAT/SHOULDER BELT TO INNER PANEL REINFORCEMENT

Fig. 92 FUEL FILLER GUSSET TO INNER QUARTER PANEL

23 - 190 BODY STRUCTUREWJ

WELD LOCATIONS (Continued)

Page 2122 of 2199

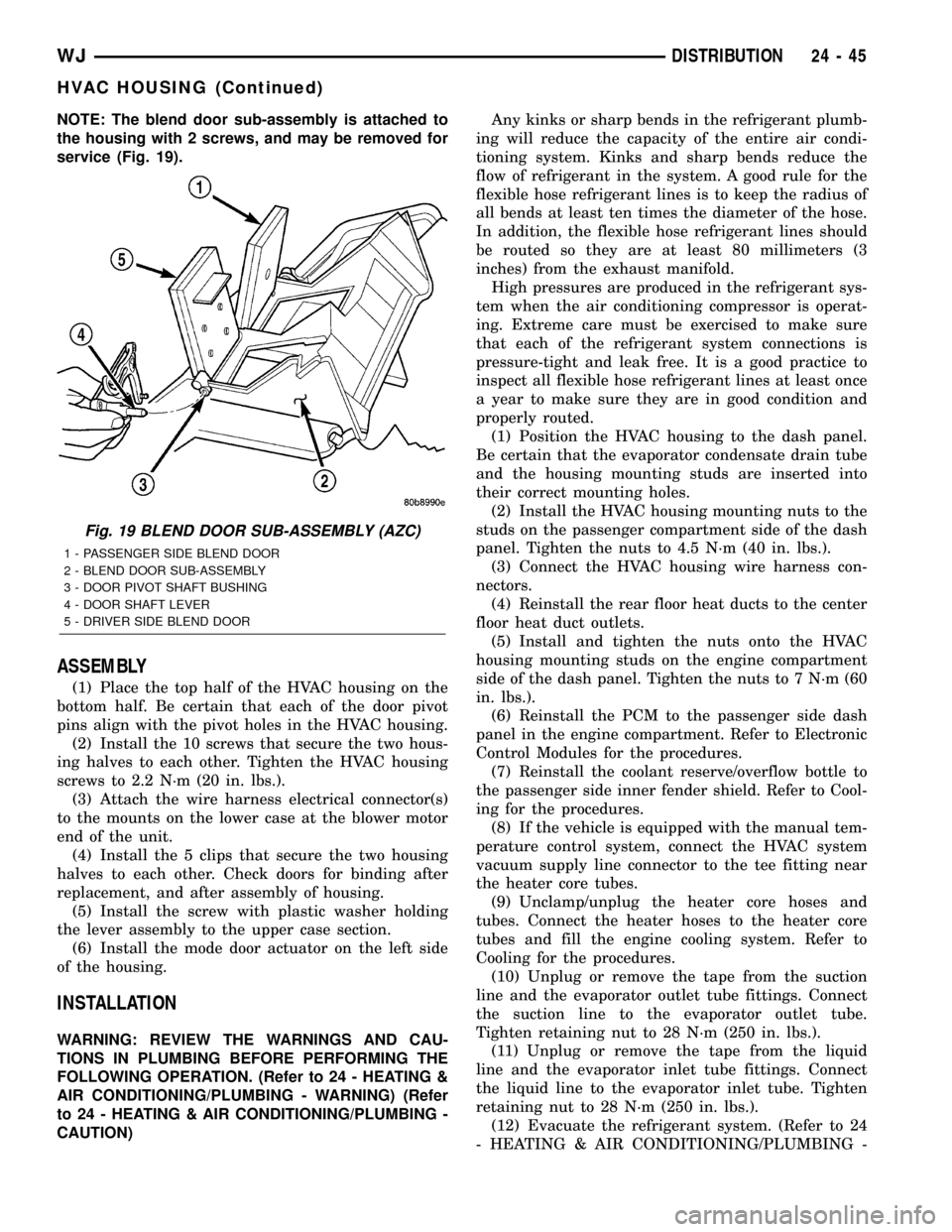

NOTE: The blend door sub-assembly is attached to

the housing with 2 screws, and may be removed for

service (Fig. 19).

ASSEMBLY

(1) Place the top half of the HVAC housing on the

bottom half. Be certain that each of the door pivot

pins align with the pivot holes in the HVAC housing.

(2) Install the 10 screws that secure the two hous-

ing halves to each other. Tighten the HVAC housing

screws to 2.2 N´m (20 in. lbs.).

(3) Attach the wire harness electrical connector(s)

to the mounts on the lower case at the blower motor

end of the unit.

(4) Install the 5 clips that secure the two housing

halves to each other. Check doors for binding after

replacement, and after assembly of housing.

(5) Install the screw with plastic washer holding

the lever assembly to the upper case section.

(6) Install the mode door actuator on the left side

of the housing.

INSTALLATION

WARNING: REVIEW THE WARNINGS AND CAU-

TIONS IN PLUMBING BEFORE PERFORMING THE

FOLLOWING OPERATION. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - WARNING) (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

CAUTION)Any kinks or sharp bends in the refrigerant plumb-

ing will reduce the capacity of the entire air condi-

tioning system. Kinks and sharp bends reduce the

flow of refrigerant in the system. A good rule for the

flexible hose refrigerant lines is to keep the radius of

all bends at least ten times the diameter of the hose.

In addition, the flexible hose refrigerant lines should

be routed so they are at least 80 millimeters (3

inches) from the exhaust manifold.

High pressures are produced in the refrigerant sys-

tem when the air conditioning compressor is operat-

ing. Extreme care must be exercised to make sure

that each of the refrigerant system connections is

pressure-tight and leak free. It is a good practice to

inspect all flexible hose refrigerant lines at least once

a year to make sure they are in good condition and

properly routed.

(1) Position the HVAC housing to the dash panel.

Be certain that the evaporator condensate drain tube

and the housing mounting studs are inserted into

their correct mounting holes.

(2) Install the HVAC housing mounting nuts to the

studs on the passenger compartment side of the dash

panel. Tighten the nuts to 4.5 N´m (40 in. lbs.).

(3) Connect the HVAC housing wire harness con-

nectors.

(4) Reinstall the rear floor heat ducts to the center

floor heat duct outlets.

(5) Install and tighten the nuts onto the HVAC

housing mounting studs on the engine compartment

side of the dash panel. Tighten the nuts to 7 N´m (60

in. lbs.).

(6) Reinstall the PCM to the passenger side dash

panel in the engine compartment. Refer to Electronic

Control Modules for the procedures.

(7) Reinstall the coolant reserve/overflow bottle to

the passenger side inner fender shield. Refer to Cool-

ing for the procedures.

(8) If the vehicle is equipped with the manual tem-

perature control system, connect the HVAC system

vacuum supply line connector to the tee fitting near

the heater core tubes.

(9) Unclamp/unplug the heater core hoses and

tubes. Connect the heater hoses to the heater core

tubes and fill the engine cooling system. Refer to

Cooling for the procedures.

(10) Unplug or remove the tape from the suction

line and the evaporator outlet tube fittings. Connect

the suction line to the evaporator outlet tube.

Tighten retaining nut to 28 N´m (250 in. lbs.).

(11) Unplug or remove the tape from the liquid

line and the evaporator inlet tube fittings. Connect

the liquid line to the evaporator inlet tube. Tighten

retaining nut to 28 N´m (250 in. lbs.).

(12) Evacuate the refrigerant system. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

Fig. 19 BLEND DOOR SUB-ASSEMBLY (AZC)

1 - PASSENGER SIDE BLEND DOOR

2 - BLEND DOOR SUB-ASSEMBLY

3 - DOOR PIVOT SHAFT BUSHING

4 - DOOR SHAFT LEVER

5 - DRIVER SIDE BLEND DOOR

WJDISTRIBUTION 24 - 45

HVAC HOUSING (Continued)

Page 2152 of 2199

REFRIGERANT

DESCRIPTION

The refrigerant used in this air conditioning sys-

tem is a HydroFluoroCarbon (HFC), type R-134a.

Unlike R-12, which is a ChloroFluoroCarbon (CFC),

R-134a refrigerant does not contain ozone-depleting

chlorine. R-134a refrigerant is a non-toxic, non-flam-

mable, clear, and colorless liquefied gas.

Even though R-134a does not contain chlorine, it

must be reclaimed and recycled just like CFC-type

refrigerants. This is because R-134a is a greenhouse

gas and can contribute to global warming.

OPERATION

R-134a refrigerant is not compatible with R-12

refrigerant in an air conditioning system. Even a

small amount of R-12 added to an R-134a refrigerant

system will cause compressor failure, refrigerant oil

sludge or poor air conditioning system performance.

In addition, the PolyAlkylene Glycol (PAG) synthetic

refrigerant oils used in an R-134a refrigerant system

are not compatible with the mineral-based refriger-

ant oils used in an R-12 refrigerant system.

R-134a refrigerant system service ports, service

tool couplers and refrigerant dispensing bottles have

all been designed with unique fittings to ensure that

an R-134a system is not accidentally contaminated

with the wrong refrigerant (R-12). There are also

labels posted in the engine compartment of the vehi-

cle and on the compressor identifying to service tech-

nicians that the air conditioning system is equipped

with R-134a.

REFRIGERANT OIL

DESCRIPTION

The refrigerant oil used in R-134a refrigerant sys-

tems is a synthetic-based, PolyAlkylene Glycol (PAG),

wax-free lubricant. Mineral-based R-12 refrigerant

oils are not compatible with PAG oils, and should

never be introduced to an R-134a refrigerant system.

There are different PAG oils available, and each

contains a different additive package. The 10PA17

compressor used in this vehicle is designed to use an

ND8 PAG refrigerant oil. Use only refrigerant oil of

this same type to service the refrigerant system.

OPERATION

After performing any refrigerant recovery or recy-

cling operation, always replenish the refrigerant sys-

tem with the same amount of the recommended

refrigerant oil as was removed. Too little refrigerant

oil can cause compressor damage, and too much can

reduce air conditioning system performance.PAG refrigerant oil is much more hygroscopic than

mineral oil, and will absorb any moisture it comes

into contact with, even moisture in the air. The PAG

oil container should always be kept tightly capped

until it is ready to be used. After use, recap the oil

container immediately to prevent moisture contami-

nation.

STANDARD PROCEDURE - REFRIGERANT OIL

LEVEL

When an air conditioning system is assembled at

the factory, all components except the compressor are

refrigerant oil free. After the refrigerant system has

been charged and operated, the refrigerant oil in the

compressor is dispersed throughout the refrigerant

system. The accumulator, evaporator, condenser, and

compressor will each retain a significant amount of

the needed refrigerant oil.

It is important to have the correct amount of oil in

the refrigerant system. This ensures proper lubrica-

tion of the compressor. Too little oil will result in

damage to the compressor. Too much oil will reduce

the cooling capacity of the air conditioning system.

It will not be necessary to check the oil level in the

compressor or to add oil, unless there has been an oil

loss. An oil loss may occur due to a rupture or leak

from a refrigerant line, a connector fitting, a compo-

nent, or a component seal. If a leak occurs, add 30

milliliters (1 fluid ounce) of refrigerant oil to the

refrigerant system after the repair has been made.

Refrigerant oil loss will be evident at the leak point

by the presence of a wet, shiny surface around the

leak.

Refrigerant oil must be added when a accumulator,

evaporator coil, or condenser are replaced. See the

Refrigerant Oil Capacities chart. When a compressor

is replaced, the refrigerant oil must be drained from

the old compressor and measured. Drain all of the

refrigerant oil from the new compressor, then fill the

new compressor with the same amount of refrigerant

oil that was drained out of the old compressor.

Refrigerant Oil Capacities

Component ml fl oz

A/C System 130 4.40

Receiver Drier 70 2.37

Condenser 10 0.34

Evaporator 50 1.69

Compressordrain and measure

the oil from the old

compressor - see

text.

WJPLUMBING 24 - 75

Page 2155 of 2199

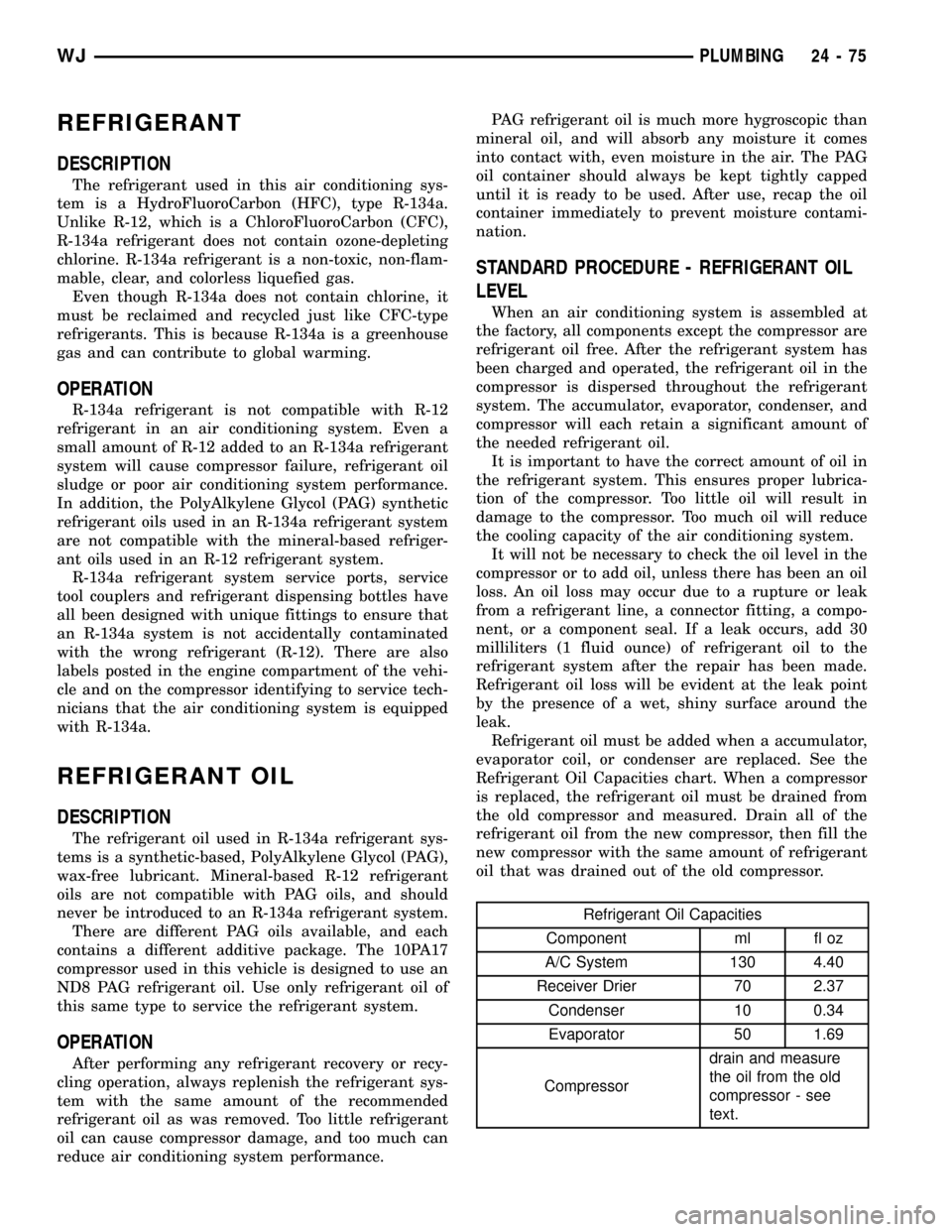

(14) Remove the snap ring from the hub and

remove the clutch field coil (Fig. 22). Slide the clutch

field coil off of the hub.

INSTALLATION

INSTALLATION

(1) Install Viscous Heater to engine mounting

bracket.

(2) Install the Viscous Heater mounting bolts and

tighten to 33 N´m ( 25 ft. lbs.).

(3) Plug the wiring harness electrical connector to

the Viscous Heater clutch.

(4) Install heater hoses to the Viscous Heater con-

nections.

(5) Install heater hose clamps to Viscous Heater

connections.

(6) Install the engine accessory drive belt(Refer to

7 - COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(7) Refill the engine cooling system(Refer to 7 -

COOLING/ENGINE - STANDARD PROCEDURE).

(8) Reconnect the battery negative cable.

(9) Operate vehicle and check for any coolant

leaks, repair as required.

INSTALLATION - VISCOUS HEATER CLUTCH

(1) Install the clutch field coil and snap ring.

(2) Install the screw and retainer on the clutch coil

lead wire harness on the viscous heater housing.

Tighten the screw to 2.2 N´m (20 in. lbs.)

(3) Align the rotor assembly squarely on the front

housing hub.

(4) Install the rotor bearing asembly with the

installer (Special Tool C-6871 or equalivent). Threadthe installer on the shaft, then turn the nut until the

rotor asembly is seated.

(5) Install the external front housing snap ring

with snap ring pliers. The bevel side of the snap ring

must be facing outward. Press the snap ring to make

sure it is properly seated in the groove.

CAUTION: If the snap ring is not fully seated in the

groove it will vibrate out, resulting in a clutch fail-

ure and severe damage to the front housing of the

compressor.

(6) Install the original clutch shims on the shaft.

(7) Install the clutch plate. Install the shaft hex

nut and tighten to 15±20 N´m (11±15 ft. lbs.).

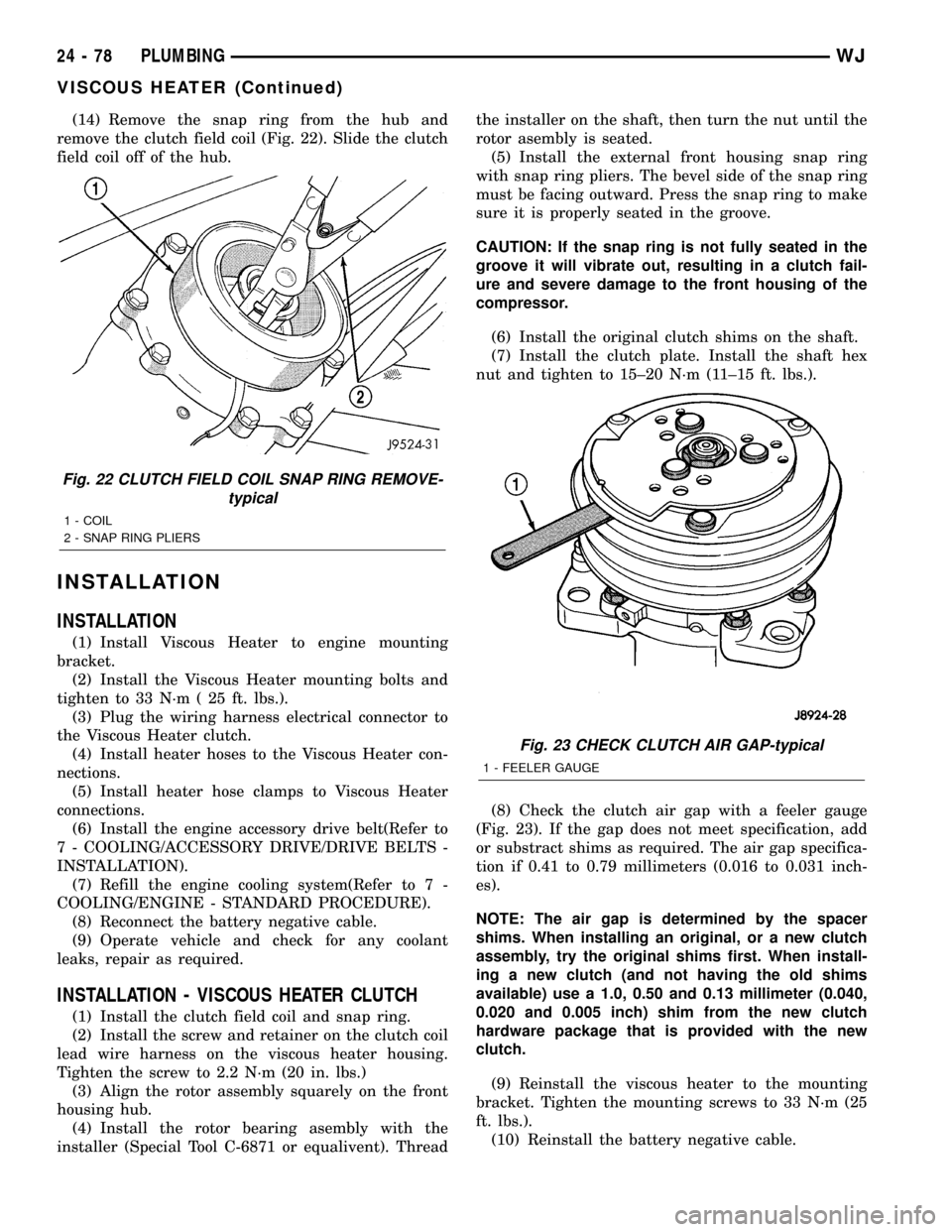

(8) Check the clutch air gap with a feeler gauge

(Fig. 23). If the gap does not meet specification, add

or substract shims as required. The air gap specifica-

tion if 0.41 to 0.79 millimeters (0.016 to 0.031 inch-

es).

NOTE: The air gap is determined by the spacer

shims. When installing an original, or a new clutch

assembly, try the original shims first. When install-

ing a new clutch (and not having the old shims

available) use a 1.0, 0.50 and 0.13 millimeter (0.040,

0.020 and 0.005 inch) shim from the new clutch

hardware package that is provided with the new

clutch.

(9) Reinstall the viscous heater to the mounting

bracket. Tighten the mounting screws to 33 N´m (25

ft. lbs.).

(10) Reinstall the battery negative cable.

Fig. 22 CLUTCH FIELD COIL SNAP RING REMOVE-

typical

1 - COIL

2 - SNAP RING PLIERS

Fig. 23 CHECK CLUTCH AIR GAP-typical

1 - FEELER GAUGE

24 - 78 PLUMBINGWJ

VISCOUS HEATER (Continued)