Fill JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1829 of 2199

FLUID

STANDARD PROCEDURE - FLUID DRAIN/

REFILL

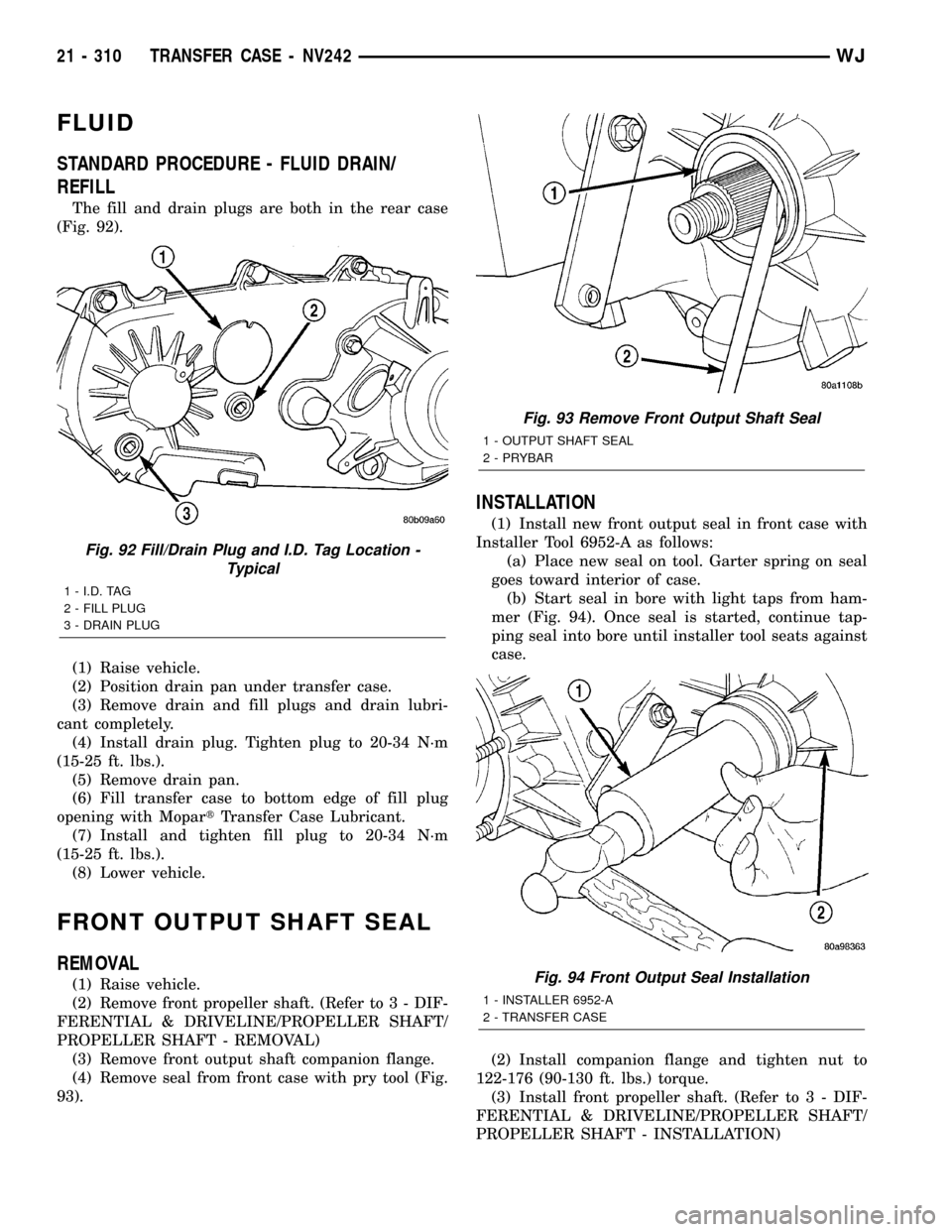

The fill and drain plugs are both in the rear case

(Fig. 92).

(1) Raise vehicle.

(2) Position drain pan under transfer case.

(3) Remove drain and fill plugs and drain lubri-

cant completely.

(4) Install drain plug. Tighten plug to 20-34 N´m

(15-25 ft. lbs.).

(5) Remove drain pan.

(6) Fill transfer case to bottom edge of fill plug

opening with MopartTransfer Case Lubricant.

(7) Install and tighten fill plug to 20-34 N´m

(15-25 ft. lbs.).

(8) Lower vehicle.

FRONT OUTPUT SHAFT SEAL

REMOVAL

(1) Raise vehicle.

(2) Remove front propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

(3) Remove front output shaft companion flange.

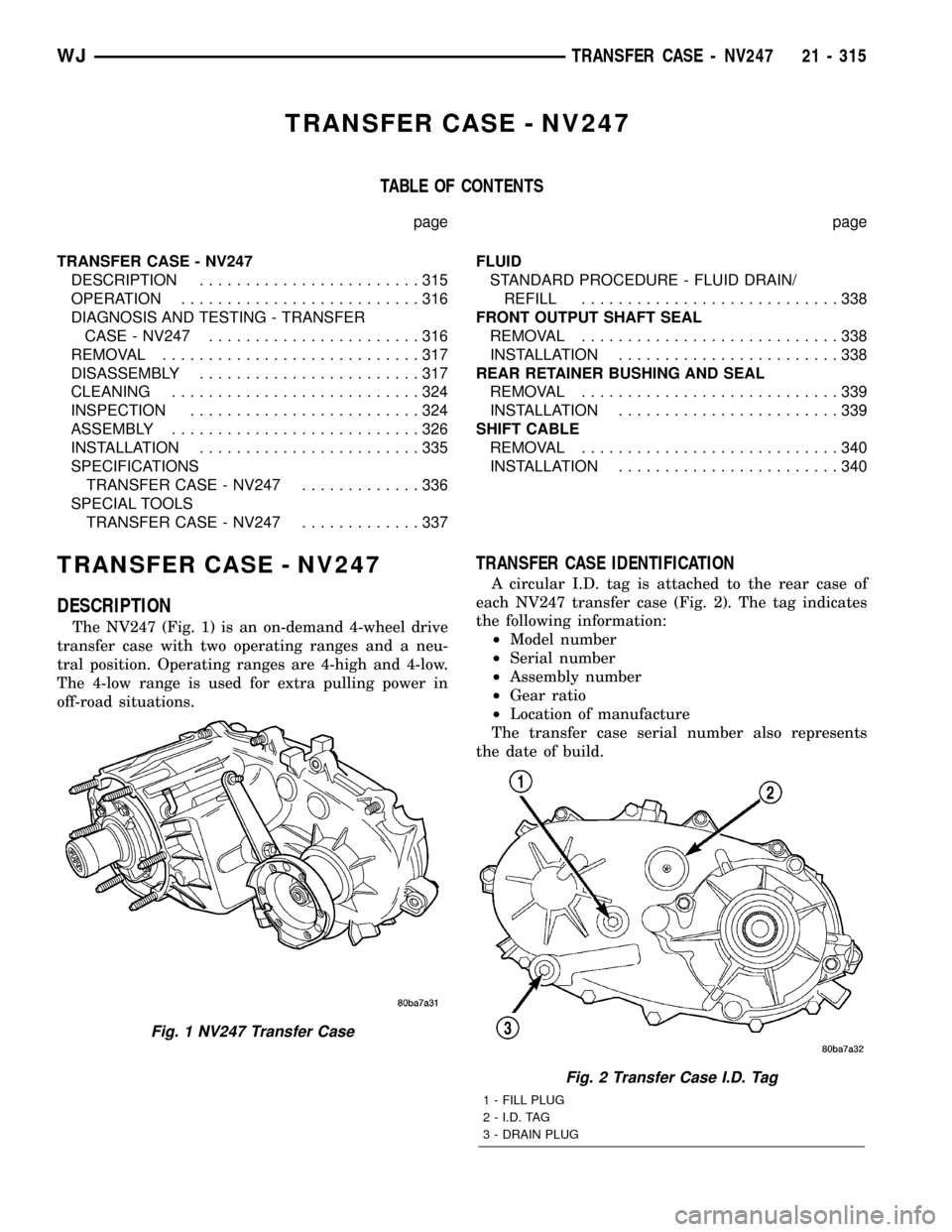

(4) Remove seal from front case with pry tool (Fig.

93).

INSTALLATION

(1) Install new front output seal in front case with

Installer Tool 6952-A as follows:

(a) Place new seal on tool. Garter spring on seal

goes toward interior of case.

(b) Start seal in bore with light taps from ham-

mer (Fig. 94). Once seal is started, continue tap-

ping seal into bore until installer tool seats against

case.

(2) Install companion flange and tighten nut to

122-176 (90-130 ft. lbs.) torque.

(3) Install front propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - INSTALLATION)

Fig. 92 Fill/Drain Plug and I.D. Tag Location -

Typical

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

Fig. 93 Remove Front Output Shaft Seal

1 - OUTPUT SHAFT SEAL

2 - PRYBAR

Fig. 94 Front Output Seal Installation

1 - INSTALLER 6952-A

2 - TRANSFER CASE

21 - 310 TRANSFER CASE - NV242WJ

Page 1834 of 2199

TRANSFER CASE - NV247

TABLE OF CONTENTS

page page

TRANSFER CASE - NV247

DESCRIPTION........................315

OPERATION..........................316

DIAGNOSIS AND TESTING - TRANSFER

CASE - NV247.......................316

REMOVAL............................317

DISASSEMBLY........................317

CLEANING...........................324

INSPECTION.........................324

ASSEMBLY...........................326

INSTALLATION........................335

SPECIFICATIONS

TRANSFER CASE - NV247.............336

SPECIAL TOOLS

TRANSFER CASE - NV247.............337FLUID

STANDARD PROCEDURE - FLUID DRAIN/

REFILL............................338

FRONT OUTPUT SHAFT SEAL

REMOVAL............................338

INSTALLATION........................338

REAR RETAINER BUSHING AND SEAL

REMOVAL............................339

INSTALLATION........................339

SHIFT CABLE

REMOVAL............................340

INSTALLATION........................340

TRANSFER CASE - NV247

DESCRIPTION

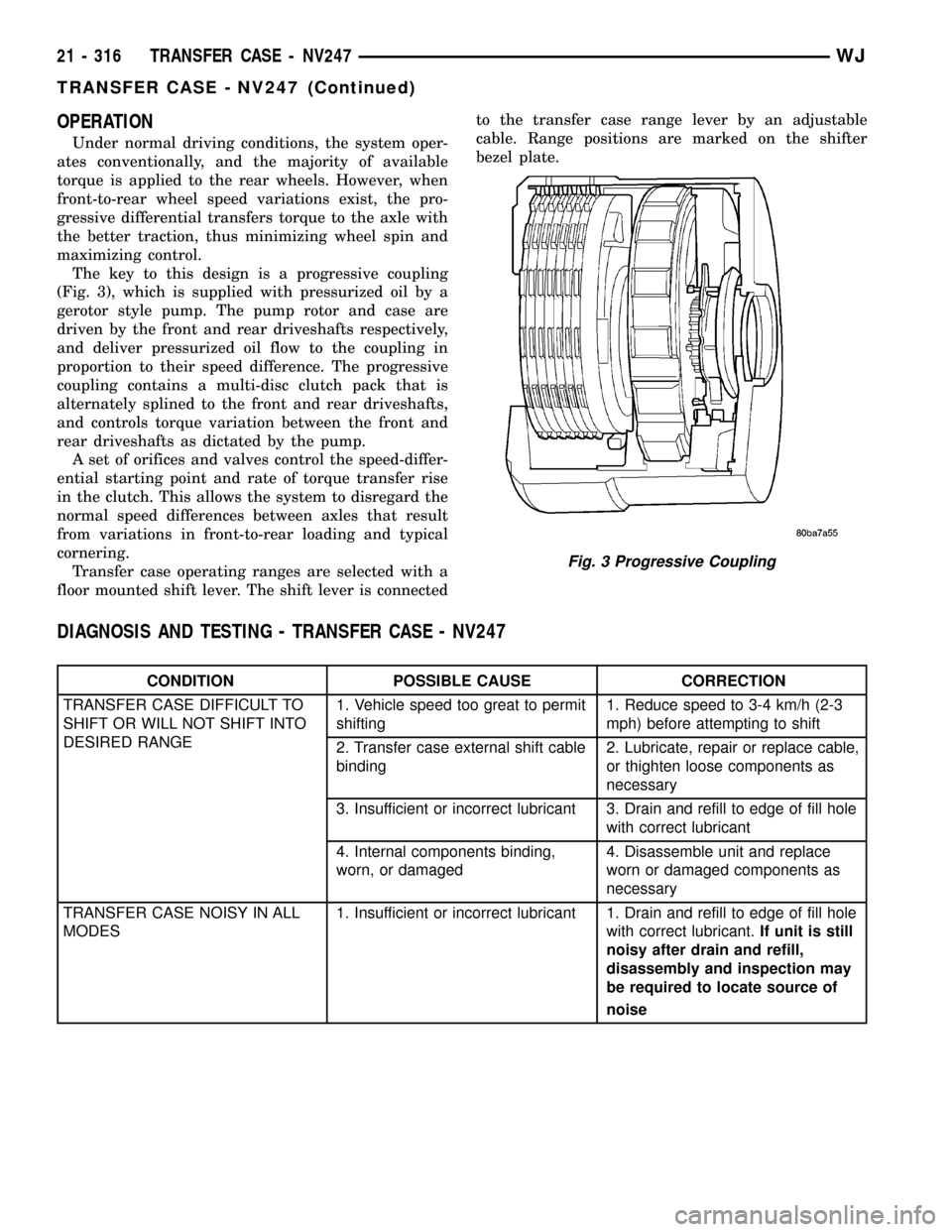

The NV247 (Fig. 1) is an on-demand 4-wheel drive

transfer case with two operating ranges and a neu-

tral position. Operating ranges are 4-high and 4-low.

The 4-low range is used for extra pulling power in

off-road situations.

TRANSFER CASE IDENTIFICATION

A circular I.D. tag is attached to the rear case of

each NV247 transfer case (Fig. 2). The tag indicates

the following information:

²Model number

²Serial number

²Assembly number

²Gear ratio

²Location of manufacture

The transfer case serial number also represents

the date of build.

Fig. 1 NV247 Transfer Case

Fig. 2 Transfer Case I.D. Tag

1 - FILL PLUG

2 - I.D. TAG

3 - DRAIN PLUG

WJTRANSFER CASE - NV247 21 - 315

Page 1835 of 2199

OPERATION

Under normal driving conditions, the system oper-

ates conventionally, and the majority of available

torque is applied to the rear wheels. However, when

front-to-rear wheel speed variations exist, the pro-

gressive differential transfers torque to the axle with

the better traction, thus minimizing wheel spin and

maximizing control.

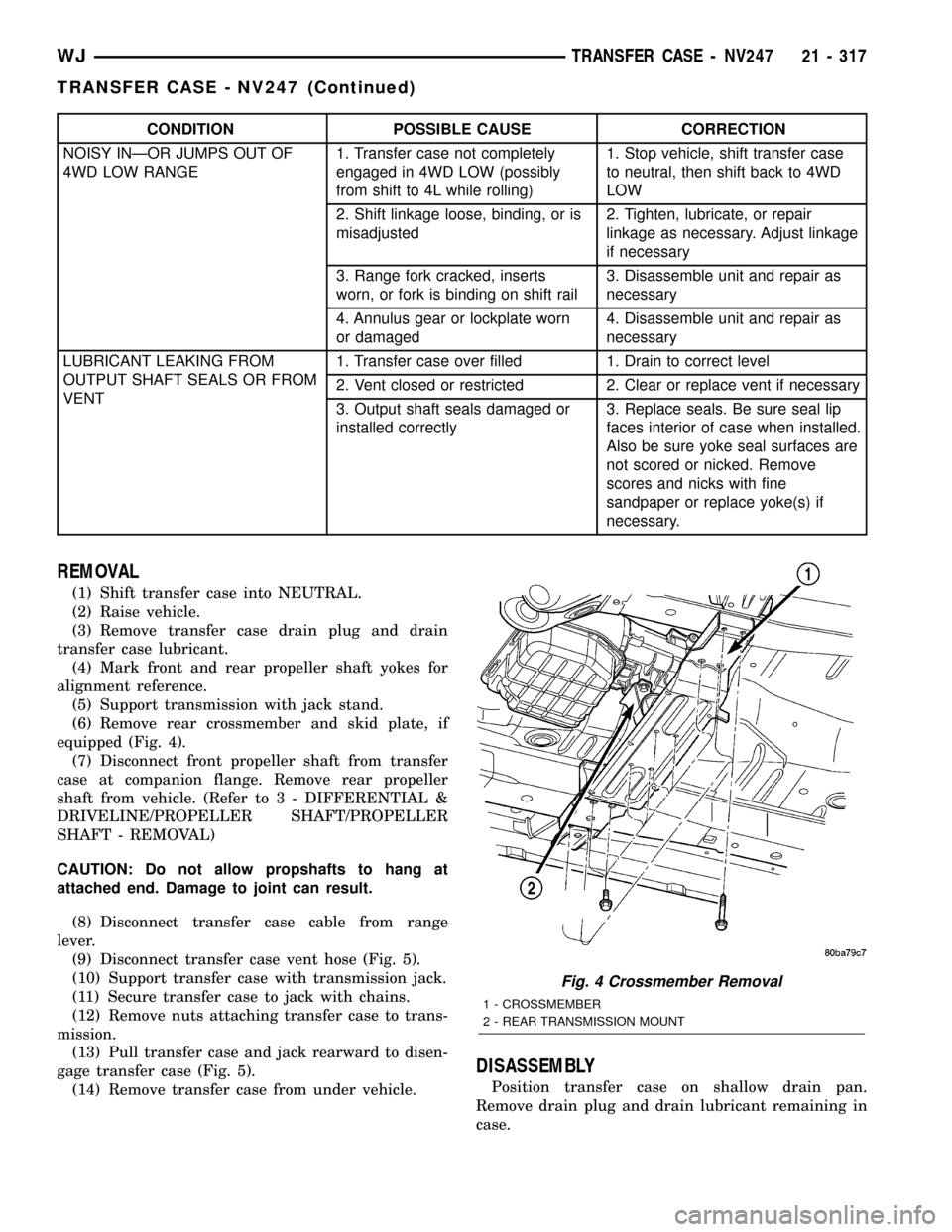

The key to this design is a progressive coupling

(Fig. 3), which is supplied with pressurized oil by a

gerotor style pump. The pump rotor and case are

driven by the front and rear driveshafts respectively,

and deliver pressurized oil flow to the coupling in

proportion to their speed difference. The progressive

coupling contains a multi-disc clutch pack that is

alternately splined to the front and rear driveshafts,

and controls torque variation between the front and

rear driveshafts as dictated by the pump.

A set of orifices and valves control the speed-differ-

ential starting point and rate of torque transfer rise

in the clutch. This allows the system to disregard the

normal speed differences between axles that result

from variations in front-to-rear loading and typical

cornering.

Transfer case operating ranges are selected with a

floor mounted shift lever. The shift lever is connectedto the transfer case range lever by an adjustable

cable. Range positions are marked on the shifter

bezel plate.

DIAGNOSIS AND TESTING - TRANSFER CASE - NV247

CONDITION POSSIBLE CAUSE CORRECTION

TRANSFER CASE DIFFICULT TO

SHIFT OR WILL NOT SHIFT INTO

DESIRED RANGE1. Vehicle speed too great to permit

shifting1. Reduce speed to 3-4 km/h (2-3

mph) before attempting to shift

2. Transfer case external shift cable

binding2. Lubricate, repair or replace cable,

or thighten loose components as

necessary

3. Insufficient or incorrect lubricant 3. Drain and refill to edge of fill hole

with correct lubricant

4. Internal components binding,

worn, or damaged4. Disassemble unit and replace

worn or damaged components as

necessary

TRANSFER CASE NOISY IN ALL

MODES1. Insufficient or incorrect lubricant 1. Drain and refill to edge of fill hole

with correct lubricant.If unit is still

noisy after drain and refill,

disassembly and inspection may

be required to locate source of

noise

Fig. 3 Progressive Coupling

21 - 316 TRANSFER CASE - NV247WJ

TRANSFER CASE - NV247 (Continued)

Page 1836 of 2199

CONDITION POSSIBLE CAUSE CORRECTION

NOISY INÐOR JUMPS OUT OF

4WD LOW RANGE1. Transfer case not completely

engaged in 4WD LOW (possibly

from shift to 4L while rolling)1. Stop vehicle, shift transfer case

to neutral, then shift back to 4WD

LOW

2. Shift linkage loose, binding, or is

misadjusted2. Tighten, lubricate, or repair

linkage as necessary. Adjust linkage

if necessary

3. Range fork cracked, inserts

worn, or fork is binding on shift rail3. Disassemble unit and repair as

necessary

4. Annulus gear or lockplate worn

or damaged4. Disassemble unit and repair as

necessary

LUBRICANT LEAKING FROM

OUTPUT SHAFT SEALS OR FROM

VENT1. Transfer case over filled 1. Drain to correct level

2. Vent closed or restricted 2. Clear or replace vent if necessary

3. Output shaft seals damaged or

installed correctly3. Replace seals. Be sure seal lip

faces interior of case when installed.

Also be sure yoke seal surfaces are

not scored or nicked. Remove

scores and nicks with fine

sandpaper or replace yoke(s) if

necessary.

REMOVAL

(1) Shift transfer case into NEUTRAL.

(2) Raise vehicle.

(3) Remove transfer case drain plug and drain

transfer case lubricant.

(4) Mark front and rear propeller shaft yokes for

alignment reference.

(5) Support transmission with jack stand.

(6) Remove rear crossmember and skid plate, if

equipped (Fig. 4).

(7) Disconnect front propeller shaft from transfer

case at companion flange. Remove rear propeller

shaft from vehicle. (Refer to 3 - DIFFERENTIAL &

DRIVELINE/PROPELLER SHAFT/PROPELLER

SHAFT - REMOVAL)

CAUTION: Do not allow propshafts to hang at

attached end. Damage to joint can result.

(8) Disconnect transfer case cable from range

lever.

(9) Disconnect transfer case vent hose (Fig. 5).

(10) Support transfer case with transmission jack.

(11) Secure transfer case to jack with chains.

(12) Remove nuts attaching transfer case to trans-

mission.

(13) Pull transfer case and jack rearward to disen-

gage transfer case (Fig. 5).

(14) Remove transfer case from under vehicle.

DISASSEMBLY

Position transfer case on shallow drain pan.

Remove drain plug and drain lubricant remaining in

case.

Fig. 4 Crossmember Removal

1 - CROSSMEMBER

2 - REAR TRANSMISSION MOUNT

WJTRANSFER CASE - NV247 21 - 317

TRANSFER CASE - NV247 (Continued)

Page 1854 of 2199

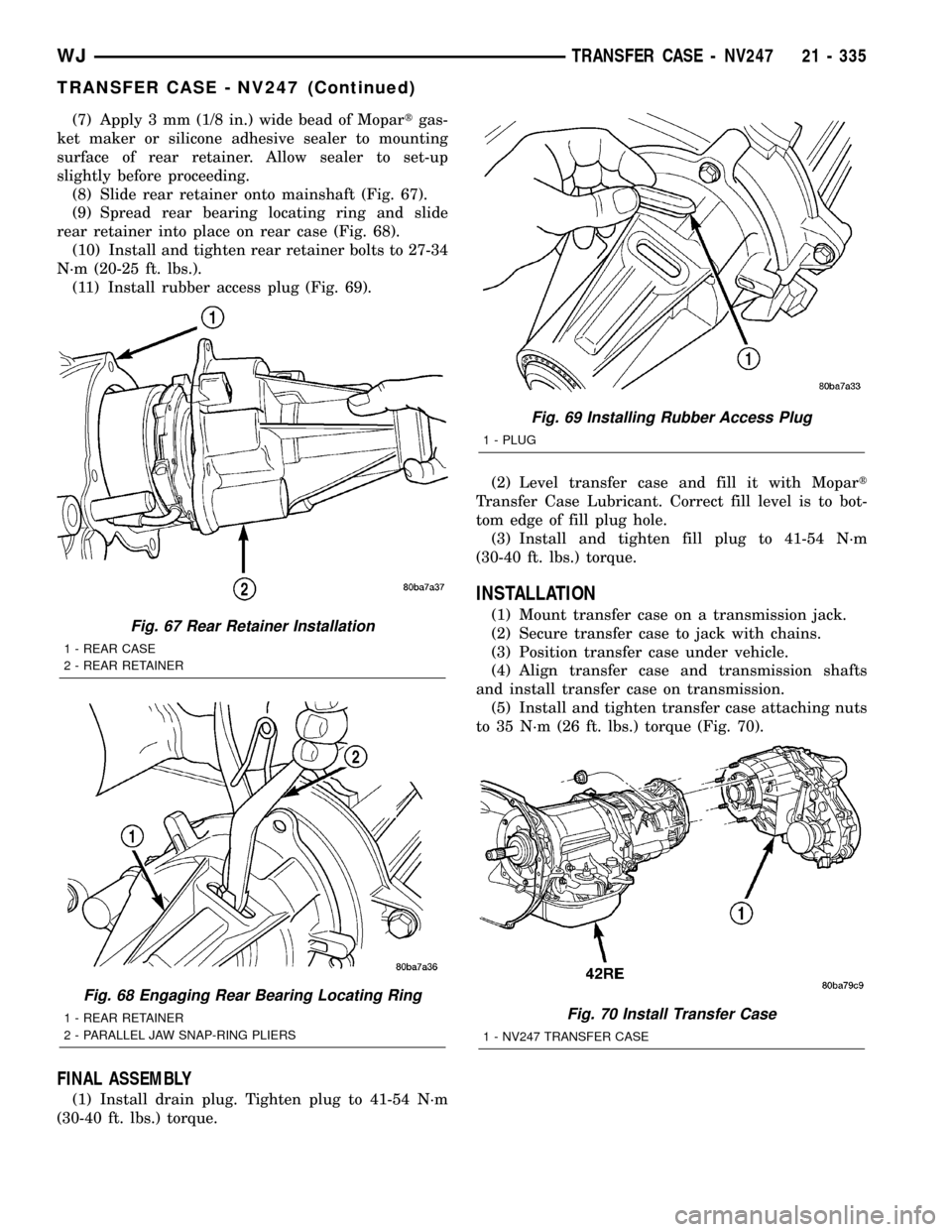

(7) Apply 3 mm (1/8 in.) wide bead of Mopartgas-

ket maker or silicone adhesive sealer to mounting

surface of rear retainer. Allow sealer to set-up

slightly before proceeding.

(8) Slide rear retainer onto mainshaft (Fig. 67).

(9) Spread rear bearing locating ring and slide

rear retainer into place on rear case (Fig. 68).

(10) Install and tighten rear retainer bolts to 27-34

N´m (20-25 ft. lbs.).

(11) Install rubber access plug (Fig. 69).

FINAL ASSEMBLY

(1) Install drain plug. Tighten plug to 41-54 N´m

(30-40 ft. lbs.) torque.(2) Level transfer case and fill it with Mopart

Transfer Case Lubricant. Correct fill level is to bot-

tom edge of fill plug hole.

(3) Install and tighten fill plug to 41-54 N´m

(30-40 ft. lbs.) torque.

INSTALLATION

(1) Mount transfer case on a transmission jack.

(2) Secure transfer case to jack with chains.

(3) Position transfer case under vehicle.

(4) Align transfer case and transmission shafts

and install transfer case on transmission.

(5) Install and tighten transfer case attaching nuts

to 35 N´m (26 ft. lbs.) torque (Fig. 70).Fig. 67 Rear Retainer Installation

1 - REAR CASE

2 - REAR RETAINER

Fig. 68 Engaging Rear Bearing Locating Ring

1 - REAR RETAINER

2 - PARALLEL JAW SNAP-RING PLIERS

Fig. 69 Installing Rubber Access Plug

1 - PLUG

Fig. 70 Install Transfer Case

1 - NV247 TRANSFER CASE

WJTRANSFER CASE - NV247 21 - 335

TRANSFER CASE - NV247 (Continued)

Page 1855 of 2199

(6) Connect front propeller shaft and install rear

propeller shaft. (Refer to 3 - DIFFERENTIAL &

DRIVELINE/PROPELLER SHAFT/PROPELLER

SHAFT - INSTALLATION)

(7) Fill transfer case with correct fluid. Check

transmission fluid level. Correct as necessary.

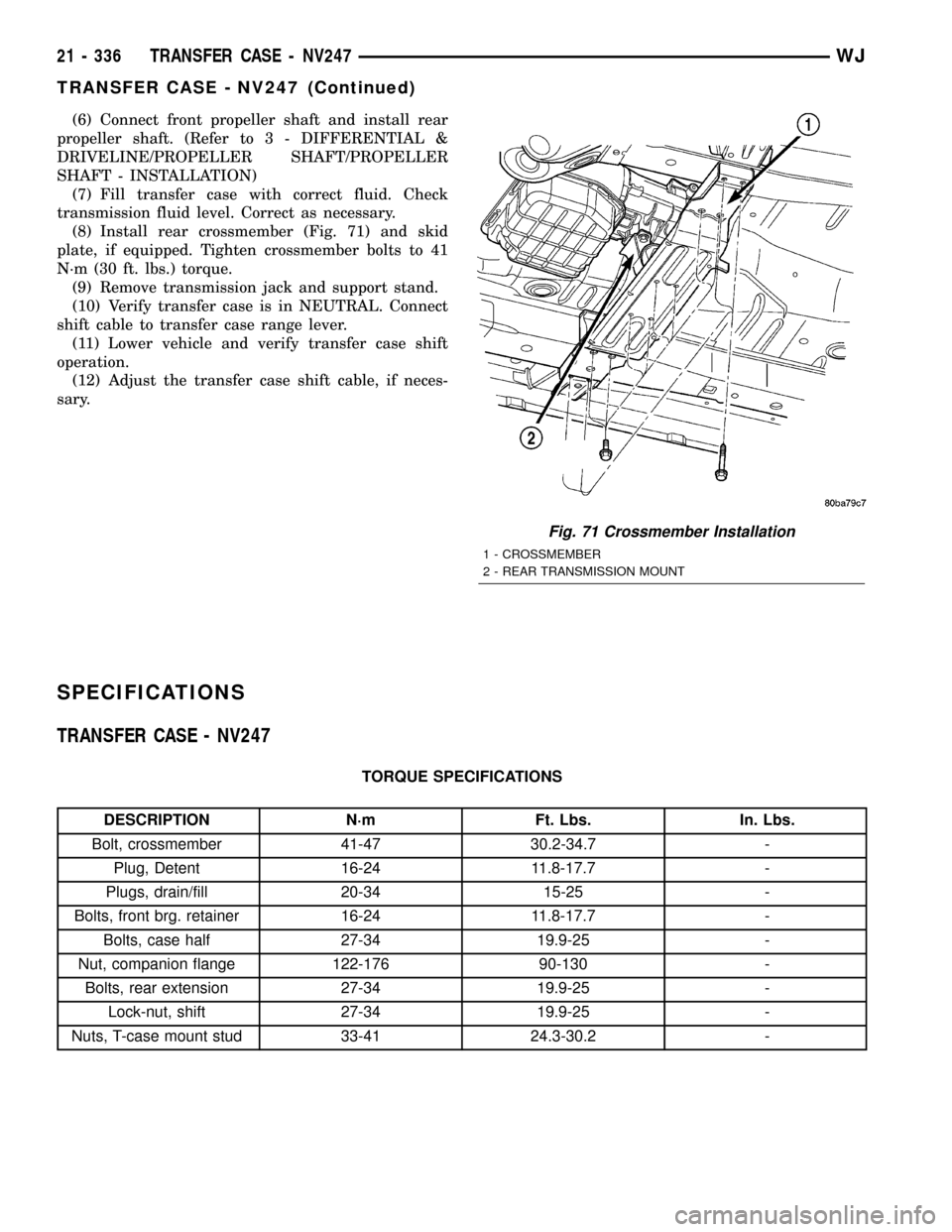

(8) Install rear crossmember (Fig. 71) and skid

plate, if equipped. Tighten crossmember bolts to 41

N´m (30 ft. lbs.) torque.

(9) Remove transmission jack and support stand.

(10) Verify transfer case is in NEUTRAL. Connect

shift cable to transfer case range lever.

(11) Lower vehicle and verify transfer case shift

operation.

(12) Adjust the transfer case shift cable, if neces-

sary.

SPECIFICATIONS

TRANSFER CASE - NV247

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Bolt, crossmember 41-47 30.2-34.7 -

Plug, Detent 16-24 11.8-17.7 -

Plugs, drain/fill 20-34 15-25 -

Bolts, front brg. retainer 16-24 11.8-17.7 -

Bolts, case half 27-34 19.9-25 -

Nut, companion flange 122-176 90-130 -

Bolts, rear extension 27-34 19.9-25 -

Lock-nut, shift 27-34 19.9-25 -

Nuts, T-case mount stud 33-41 24.3-30.2 -

Fig. 71 Crossmember Installation

1 - CROSSMEMBER

2 - REAR TRANSMISSION MOUNT

21 - 336 TRANSFER CASE - NV247WJ

TRANSFER CASE - NV247 (Continued)

Page 1857 of 2199

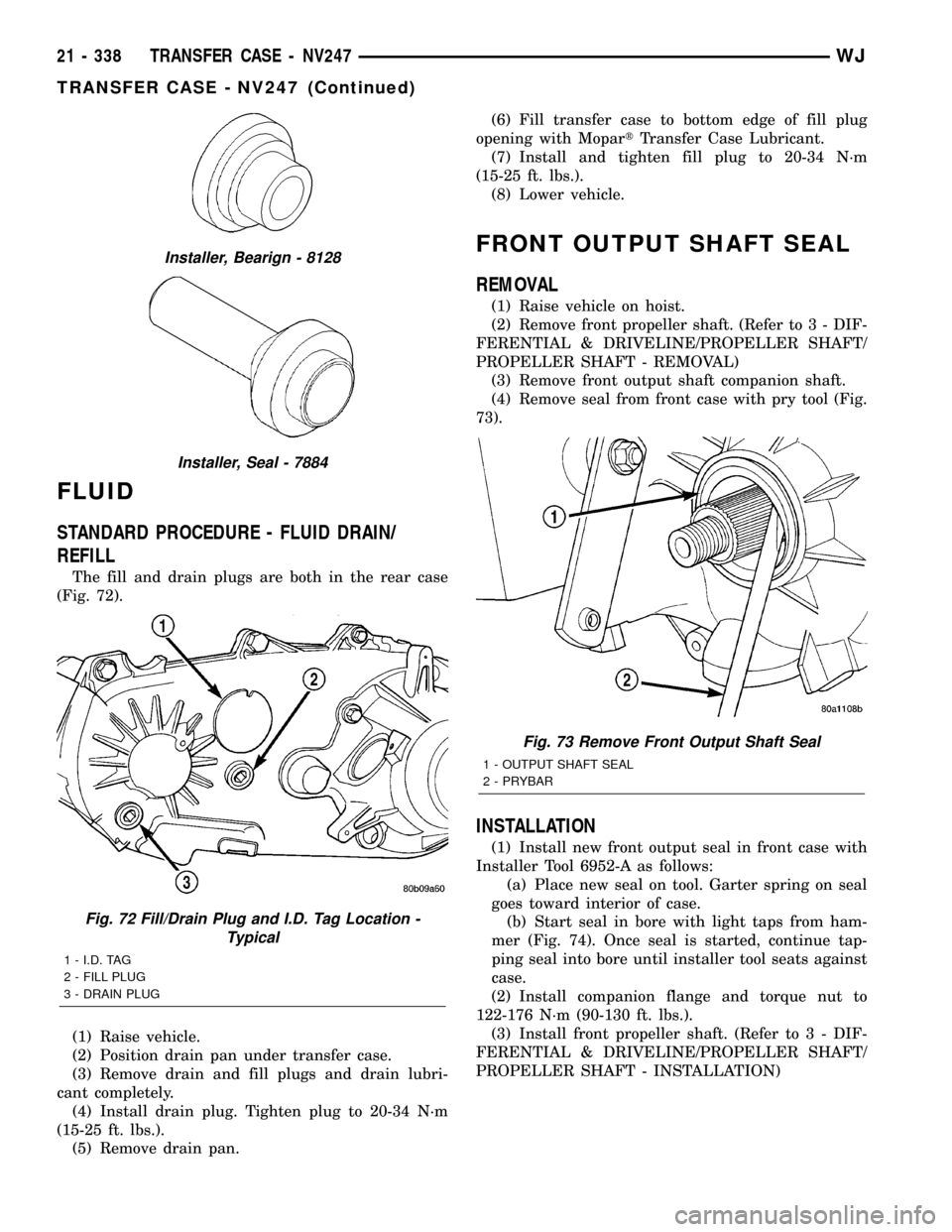

FLUID

STANDARD PROCEDURE - FLUID DRAIN/

REFILL

The fill and drain plugs are both in the rear case

(Fig. 72).

(1) Raise vehicle.

(2) Position drain pan under transfer case.

(3) Remove drain and fill plugs and drain lubri-

cant completely.

(4) Install drain plug. Tighten plug to 20-34 N´m

(15-25 ft. lbs.).

(5) Remove drain pan.(6) Fill transfer case to bottom edge of fill plug

opening with MopartTransfer Case Lubricant.

(7) Install and tighten fill plug to 20-34 N´m

(15-25 ft. lbs.).

(8) Lower vehicle.

FRONT OUTPUT SHAFT SEAL

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove front propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

(3) Remove front output shaft companion shaft.

(4) Remove seal from front case with pry tool (Fig.

73).

INSTALLATION

(1) Install new front output seal in front case with

Installer Tool 6952-A as follows:

(a) Place new seal on tool. Garter spring on seal

goes toward interior of case.

(b) Start seal in bore with light taps from ham-

mer (Fig. 74). Once seal is started, continue tap-

ping seal into bore until installer tool seats against

case.

(2) Install companion flange and torque nut to

122-176 N´m (90-130 ft. lbs.).

(3) Install front propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - INSTALLATION)

Installer, Bearign - 8128

Installer, Seal - 7884

Fig. 72 Fill/Drain Plug and I.D. Tag Location -

Typical

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

Fig. 73 Remove Front Output Shaft Seal

1 - OUTPUT SHAFT SEAL

2 - PRYBAR

21 - 338 TRANSFER CASE - NV247WJ

TRANSFER CASE - NV247 (Continued)

Page 1898 of 2199

EXTERIOR

TABLE OF CONTENTS

page page

BODY SIDE MOLDINGS

REMOVAL

REMOVAL±FRONT DOOR...............25

REMOVAL±REAR DOOR................26

REMOVAL±FENDER/QUARTER PANEL.....26

INSTALLATION

INSTALLATION±FRONT DOOR...........26

INSTALLATION±REAR DOOR............26

INSTALLATION±FENDER/QUARTER PANEL . 26

COWL GRILLE

REMOVAL.............................27

INSTALLATION.........................27

D-PILLAR APPLIQUE

REMOVAL.............................27

INSTALLATION.........................27

D-PILLAR AIR EXHAUSTER

REMOVAL.............................27

INSTALLATION.........................27

AIR EXHAUSTER

REMOVAL.............................27

INSTALLATION.........................27

EXTERIOR NAME PLATES

REMOVAL.............................28

INSTALLATION.........................28FRONT FENDER

REMOVAL.............................28

INSTALLATION.........................29

FUEL FILL DOOR

REMOVAL.............................29

INSTALLATION.........................29

GRILLE

REMOVAL.............................29

INSTALLATION.........................29

HEADLAMP MOUNTING MODULE

REMOVAL.............................30

INSTALLATION.........................30

LUGGAGE RACK

REMOVAL.............................30

INSTALLATION.........................31

SIDE VIEW MIRROR GLASS

REMOVAL.............................31

INSTALLATION.........................31

SIDE VIEW MIRROR

REMOVAL.............................31

INSTALLATION.........................31

ROCK RAIL

REMOVAL.............................32

INSTALLATION.........................32

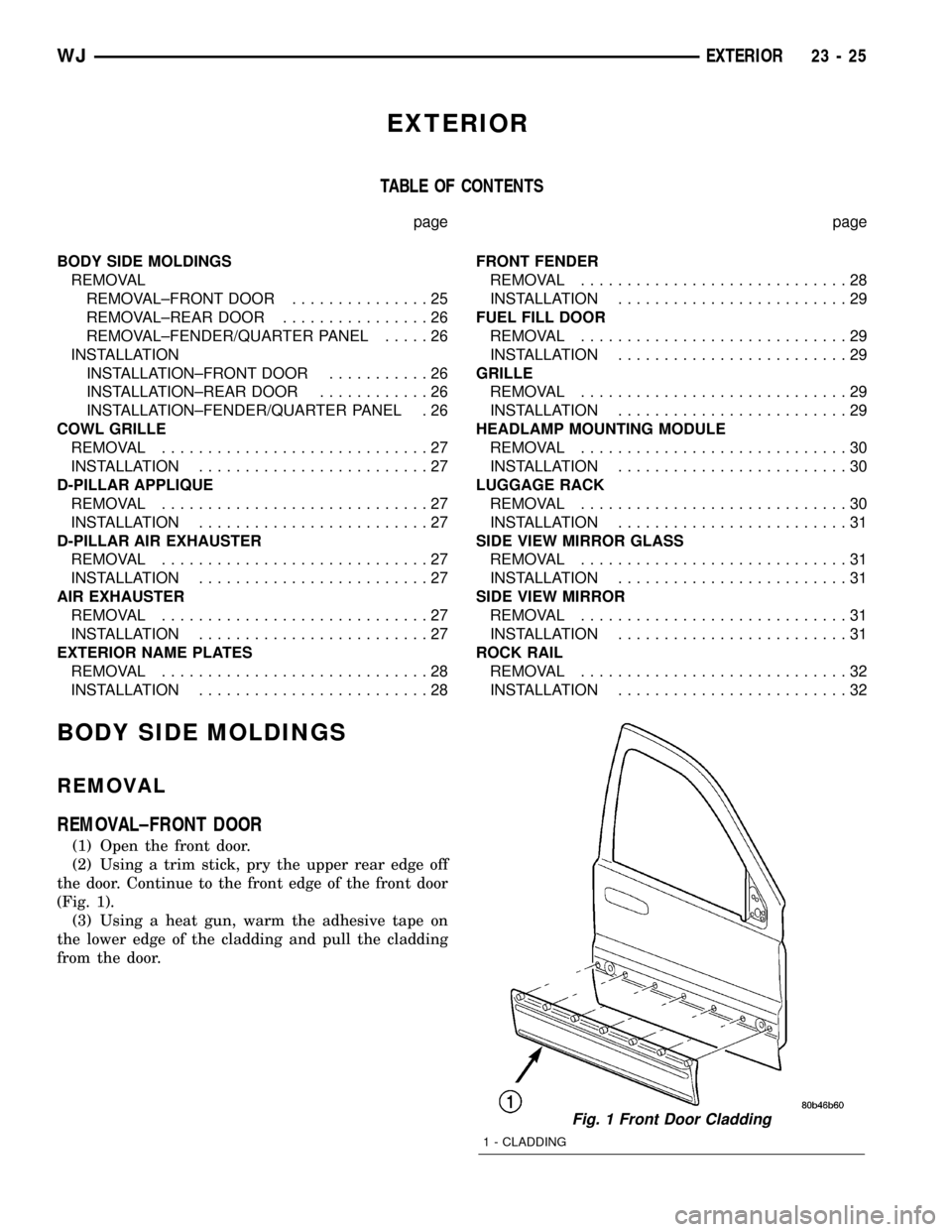

BODY SIDE MOLDINGS

REMOVAL

REMOVAL±FRONT DOOR

(1) Open the front door.

(2) Using a trim stick, pry the upper rear edge off

the door. Continue to the front edge of the front door

(Fig. 1).

(3) Using a heat gun, warm the adhesive tape on

the lower edge of the cladding and pull the cladding

from the door.

Fig. 1 Front Door Cladding

1 - CLADDING

WJEXTERIOR 23 - 25

Page 1902 of 2199

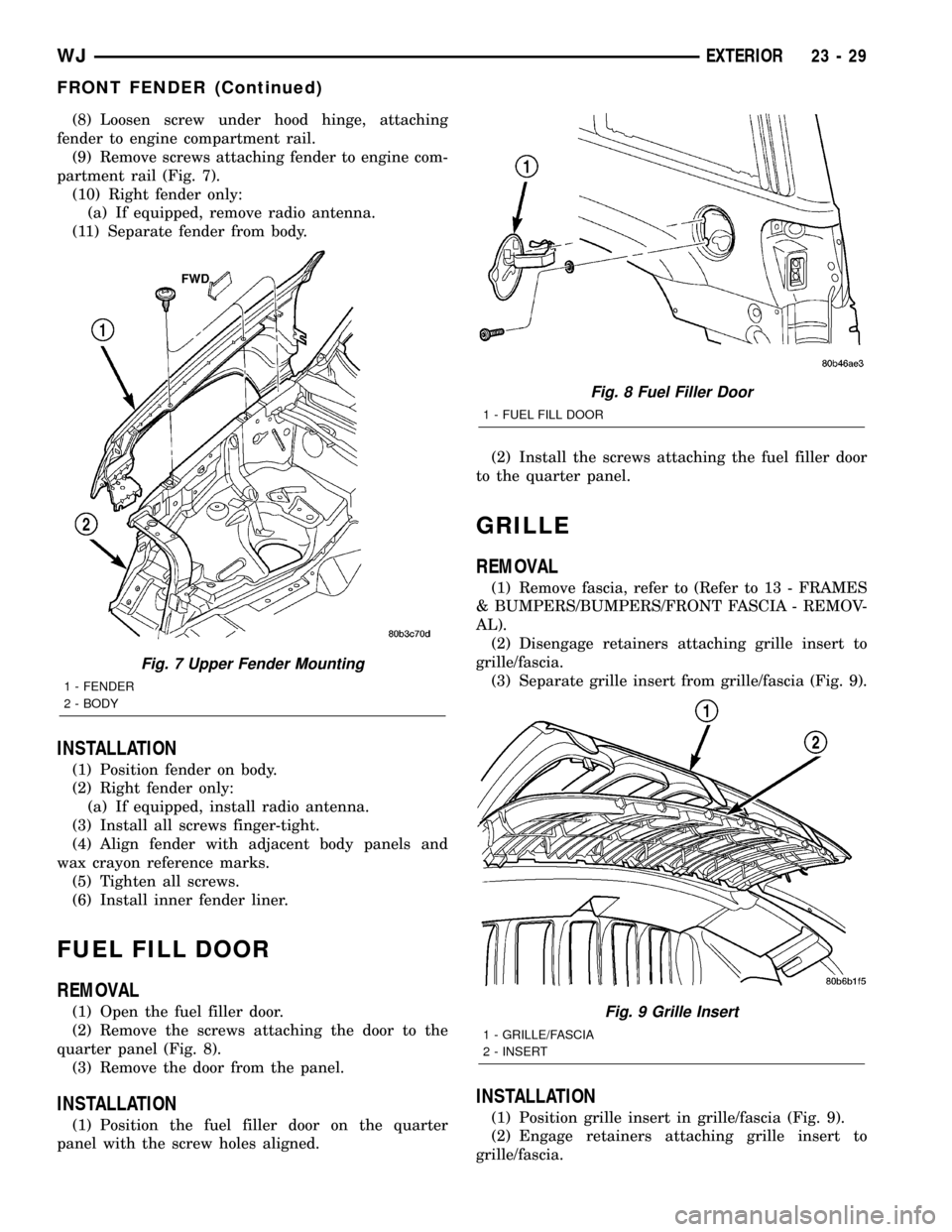

(8) Loosen screw under hood hinge, attaching

fender to engine compartment rail.

(9) Remove screws attaching fender to engine com-

partment rail (Fig. 7).

(10) Right fender only:

(a) If equipped, remove radio antenna.

(11) Separate fender from body.

INSTALLATION

(1) Position fender on body.

(2) Right fender only:

(a) If equipped, install radio antenna.

(3) Install all screws finger-tight.

(4) Align fender with adjacent body panels and

wax crayon reference marks.

(5) Tighten all screws.

(6) Install inner fender liner.

FUEL FILL DOOR

REMOVAL

(1) Open the fuel filler door.

(2) Remove the screws attaching the door to the

quarter panel (Fig. 8).

(3) Remove the door from the panel.

INSTALLATION

(1) Position the fuel filler door on the quarter

panel with the screw holes aligned.(2) Install the screws attaching the fuel filler door

to the quarter panel.

GRILLE

REMOVAL

(1) Remove fascia, refer to (Refer to 13 - FRAMES

& BUMPERS/BUMPERS/FRONT FASCIA - REMOV-

AL).

(2) Disengage retainers attaching grille insert to

grille/fascia.

(3) Separate grille insert from grille/fascia (Fig. 9).

INSTALLATION

(1) Position grille insert in grille/fascia (Fig. 9).

(2) Engage retainers attaching grille insert to

grille/fascia.

Fig. 7 Upper Fender Mounting

1 - FENDER

2 - BODY

Fig. 8 Fuel Filler Door

1 - FUEL FILL DOOR

Fig. 9 Grille Insert

1 - GRILLE/FASCIA

2 - INSERT

WJEXTERIOR 23 - 29

FRONT FENDER (Continued)

Page 1955 of 2199

PAINT TOUCH-UP

DESCRIPTION

When a painted metal surface has been scratched

or chipped, it should be touched-up as soon as possi-

ble to avoid corrosion. For best results, use Mopart

Scratch Filler/Primer, Touch-Up Paints and Clear Top

Coat. Refer to Introduction group of this manual for

Body Code Plate information.

WARNING: USE AN OSHA APPROVED BREATHING

FILTER WHEN SPRAYING PAINT OR SOLVENTS IN

A CONFINED AREA. PERSONAL INJURY CAN

RESULT.

OPERATION

(1) Scrape loose paint and corrosion from inside

scratch or chip.

(2) Clean affected area with MopartTar/Road Oil

Remover, and allow to dry.

(3) Fill the inside of the scratch or chip with a coat

of filler/primer. Do not overlap primer onto good sur-

face finish. The applicator brush should be wet

enough to puddle-fill the defect without running. Do

not stroke brush applicator on body surface. Allow

the filler/primer to dry hard.

(4) Cover the filler/primer with color touch-up

paint. Do not overlap touch-up color onto the original

color coat around the scratch or chip. Butt the new

color to the original color, if possible. Do not stroke

applicator brush on body surface. Allow touch-up

paint to dry hard.

(5) On vehicles without clear coat, the touch-up

color can be lightly finesse sanded (1500 grit) and

polished with rubbing compound.

(6) On vehicles with clear coat, apply clear top coat

to touch-up paint with the same technique as

described in Step 4. Allow clear top coat to dry hard.

If desired, Step 5 can be performed on clear top coat.

WARNING: AVOID PROLONGED SKIN CONTACT

WITH PETROLEUM OR ALCOHOL ± BASED CLEAN-

ING SOLVENTS. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH PETRO-

LEUM OR ALCOHOL ± BASED CLEANING SOL-

VENTS. PERSONAL INJURY CAN RESULT.

FINESSE SANDING/BUFFING &

POLISHING

DESCRIPTION

CAUTION: Do not remove more than .5 mils of

clearcoat finish, if equipped. Base coat paint must

retain clear coat for durability.

Use a Paint Thickness Gauge #PR-ETG-2X or equiv-

alent to determine film thickness before and after

the repair.

Minor acid etching, orange peel, or smudging in

clearcoat or single-stage finishes can be reduced with

light finesse sanding, hand buffing, and polishing.If

the finish has been finesse sanded in the past,

it cannot be repeated. Finesse sanding opera-

tion should be performed by a trained automo-

tive paint technician.

23 - 82 PAINTWJ