Brake JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1745 of 2199

BRAKE TRANSMISSION SHIFT

INTERLOCK MECHANISM

DESCRIPTION

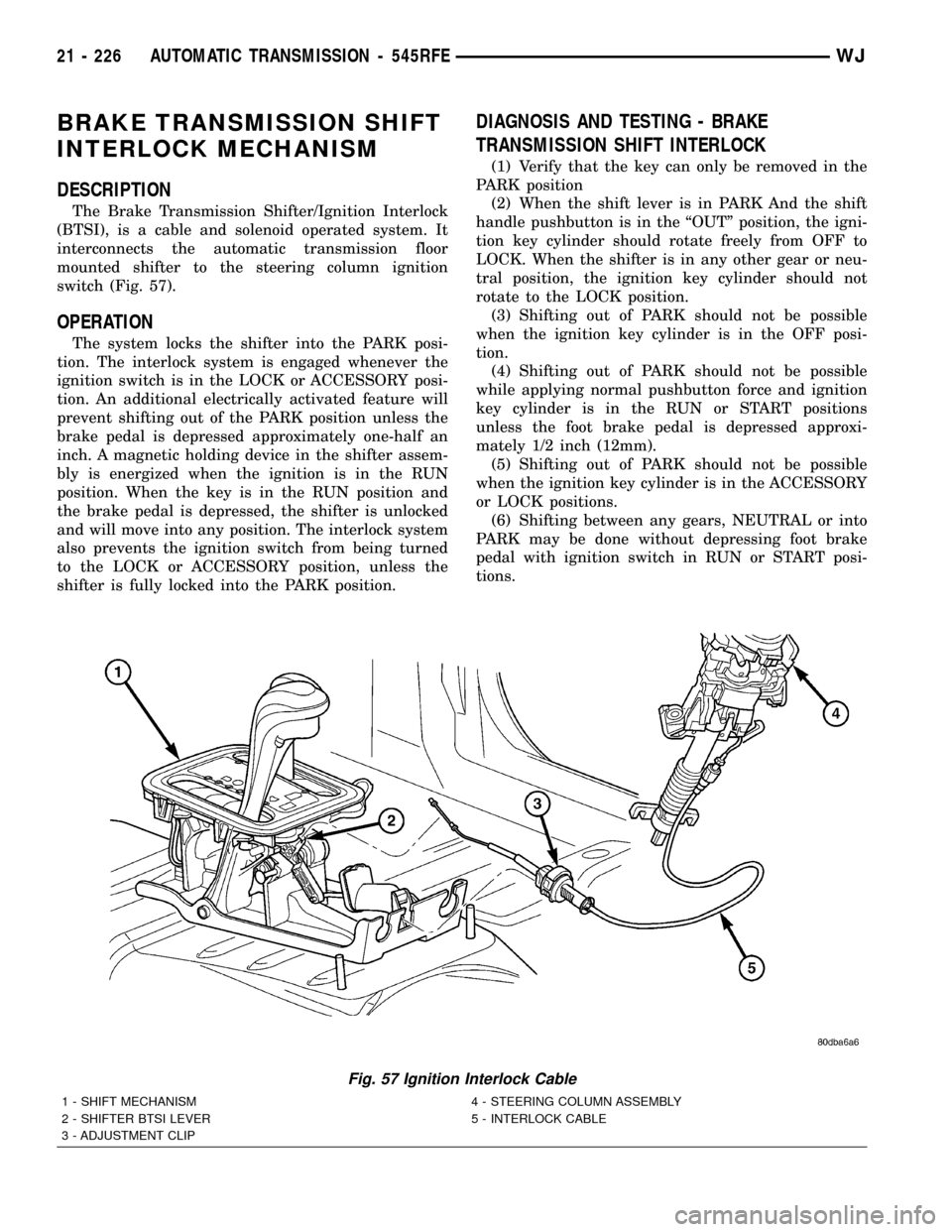

The Brake Transmission Shifter/Ignition Interlock

(BTSI), is a cable and solenoid operated system. It

interconnects the automatic transmission floor

mounted shifter to the steering column ignition

switch (Fig. 57).

OPERATION

The system locks the shifter into the PARK posi-

tion. The interlock system is engaged whenever the

ignition switch is in the LOCK or ACCESSORY posi-

tion. An additional electrically activated feature will

prevent shifting out of the PARK position unless the

brake pedal is depressed approximately one-half an

inch. A magnetic holding device in the shifter assem-

bly is energized when the ignition is in the RUN

position. When the key is in the RUN position and

the brake pedal is depressed, the shifter is unlocked

and will move into any position. The interlock system

also prevents the ignition switch from being turned

to the LOCK or ACCESSORY position, unless the

shifter is fully locked into the PARK position.

DIAGNOSIS AND TESTING - BRAKE

TRANSMISSION SHIFT INTERLOCK

(1) Verify that the key can only be removed in the

PARK position

(2) When the shift lever is in PARK And the shift

handle pushbutton is in the ªOUTº position, the igni-

tion key cylinder should rotate freely from OFF to

LOCK. When the shifter is in any other gear or neu-

tral position, the ignition key cylinder should not

rotate to the LOCK position.

(3) Shifting out of PARK should not be possible

when the ignition key cylinder is in the OFF posi-

tion.

(4) Shifting out of PARK should not be possible

while applying normal pushbutton force and ignition

key cylinder is in the RUN or START positions

unless the foot brake pedal is depressed approxi-

mately 1/2 inch (12mm).

(5) Shifting out of PARK should not be possible

when the ignition key cylinder is in the ACCESSORY

or LOCK positions.

(6) Shifting between any gears, NEUTRAL or into

PARK may be done without depressing foot brake

pedal with ignition switch in RUN or START posi-

tions.

Fig. 57 Ignition Interlock Cable

1 - SHIFT MECHANISM 4 - STEERING COLUMN ASSEMBLY

2 - SHIFTER BTSI LEVER 5 - INTERLOCK CABLE

3 - ADJUSTMENT CLIP

21 - 226 AUTOMATIC TRANSMISSION - 545RFEWJ

Page 1746 of 2199

ADJUSTMENTS - BRAKE TRANSMISSION

SHIFT INTERLOCK

The park interlock cable is part of the brake/shift

lever interlock system. Correct cable adjustment is

important to proper interlock operation. The gear

shift and park lock cables must both be correctly

adjusted in order to shift out of PARK.

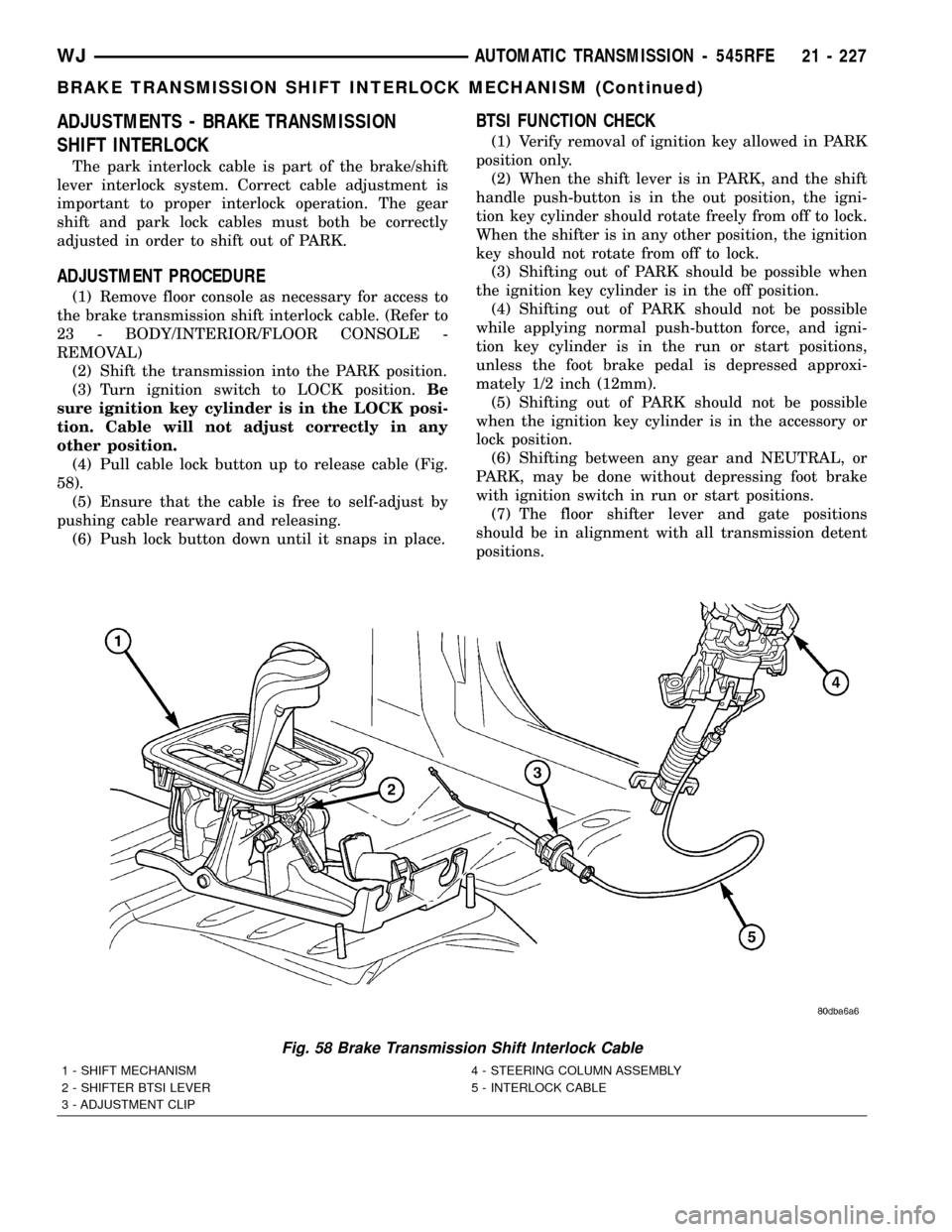

ADJUSTMENT PROCEDURE

(1) Remove floor console as necessary for access to

the brake transmission shift interlock cable. (Refer to

23 - BODY/INTERIOR/FLOOR CONSOLE -

REMOVAL)

(2) Shift the transmission into the PARK position.

(3) Turn ignition switch to LOCK position.Be

sure ignition key cylinder is in the LOCK posi-

tion. Cable will not adjust correctly in any

other position.

(4) Pull cable lock button up to release cable (Fig.

58).

(5) Ensure that the cable is free to self-adjust by

pushing cable rearward and releasing.

(6) Push lock button down until it snaps in place.

BTSI FUNCTION CHECK

(1) Verify removal of ignition key allowed in PARK

position only.

(2) When the shift lever is in PARK, and the shift

handle push-button is in the out position, the igni-

tion key cylinder should rotate freely from off to lock.

When the shifter is in any other position, the ignition

key should not rotate from off to lock.

(3) Shifting out of PARK should be possible when

the ignition key cylinder is in the off position.

(4) Shifting out of PARK should not be possible

while applying normal push-button force, and igni-

tion key cylinder is in the run or start positions,

unless the foot brake pedal is depressed approxi-

mately 1/2 inch (12mm).

(5) Shifting out of PARK should not be possible

when the ignition key cylinder is in the accessory or

lock position.

(6) Shifting between any gear and NEUTRAL, or

PARK, may be done without depressing foot brake

with ignition switch in run or start positions.

(7) The floor shifter lever and gate positions

should be in alignment with all transmission detent

positions.

Fig. 58 Brake Transmission Shift Interlock Cable

1 - SHIFT MECHANISM 4 - STEERING COLUMN ASSEMBLY

2 - SHIFTER BTSI LEVER 5 - INTERLOCK CABLE

3 - ADJUSTMENT CLIP

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 227

BRAKE TRANSMISSION SHIFT INTERLOCK MECHANISM (Continued)

Page 1747 of 2199

(8) Engine starts must be possible with shifter

lever in PARK or NEUTRAL gate positions only.

Engine starts must not be possible in any other gate

positions other than PARK or NEUTRAL.

(9) With shifter lever handle push-button not

depressed and lever detent in:

²PARK position- apply forward force on center of

handle and remove pressure. Engine start must be

possible.

²PARK position- apply rearward force on center

of handle and remove pressure. Engine start must be

possible.

²NEUTRAL position- engine start must be possi-

ble.

²NEUTRAL position, engine running and brakes

applied- Apply forward force on center of shift han-

dle. Transmission should not be able to shift into

REVERSE detent.

FLUID AND FILTER

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EFFECTS OF

INCORRECT FLUID LEVEL

A low fluid level allows the pump to take in air

along with the fluid. Air in the fluid will cause fluid

pressures to be low and develop slower than normal.

If the transmission is overfilled, the gears churn the

fluid into foam. This aerates the fluid and causing

the same conditions occurring with a low level. In

either case, air bubbles cause fluid overheating, oxi-

dation and varnish buildup which interferes with

valve and clutch operation. Foaming also causes fluid

expansion which can result in fluid overflow from the

transmission vent or fill tube. Fluid overflow can eas-

ily be mistaken for a leak if inspection is not careful.

DIAGNOSIS AND TESTING - CAUSES OF

BURNT FLUID

Burnt, discolored fluid is a result of overheating

which has three primary causes.

(1) Internal clutch slippage, usually caused by low

line pressure, inadequate clutch apply pressure, or

clutch seal failure.

(2) A result of restricted fluid flow through the

main and/or auxiliary cooler. This condition is usu-

ally the result of a faulty or improperly installed

drainback valve, a damaged main cooler, or severe

restrictions in the coolers and lines caused by debris

or kinked lines.(3) Heavy duty operation with a vehicle not prop-

erly equipped for this type of operation. Trailer tow-

ing or similar high load operation will overheat the

transmission fluid if the vehicle is improperly

equipped. Such vehicles should have an auxiliary

transmission fluid cooler, a heavy duty cooling sys-

tem, and the engine/axle ratio combination needed to

handle heavy loads.

DIAGNOSIS AND TESTING - FLUID

CONTAMINATION

Transmission fluid contamination is generally a

result of:

²adding incorrect fluid

²failure to clean dipstick and fill tube when

checking level

²engine coolant entering the fluid

²internal failure that generates debris

²overheat that generates sludge (fluid break-

down)

²failure to reverse flush cooler and lines after

repair

²failure to replace contaminated converter after

repair

The use of non-recommended fluids can result in

transmission failure. The usual results are erratic

shifts, slippage, abnormal wear and eventual failure

due to fluid breakdown and sludge formation. Avoid

this condition by using recommended fluids only.

The dipstick cap and fill tube should be wiped

clean before checking fluid level. Dirt, grease and

other foreign material on the cap and tube could fall

into the tube if not removed beforehand. Take the

time to wipe the cap and tube clean before withdraw-

ing the dipstick.

Engine coolant in the transmission fluid is gener-

ally caused by a cooler malfunction. The only remedy

is to replace the radiator as the cooler in the radiator

is not a serviceable part. If coolant has circulated

through the transmission, an overhaul is necessary.

The transmission cooler and lines should be

reverse flushed whenever a malfunction generates

sludge and/or debris. The torque converter should

also be replaced at the same time.

Failure to flush the cooler and lines will result in

recontamination. Flushing applies to auxiliary cool-

ers as well. The torque converter should also be

replaced whenever a failure generates sludge and

debris. This is necessary because normal converter

flushing procedures will not remove all contami-

nants.

21 - 228 AUTOMATIC TRANSMISSION - 545RFEWJ

BRAKE TRANSMISSION SHIFT INTERLOCK MECHANISM (Continued)

Page 1748 of 2199

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

CHECK

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transmssion has too much fluid, the

geartrain churns up foam and cause the same condi-

tions which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can inter-

fere with normal valve, clutch, and accumulator opera-

tion. Foaming can also result in fluid escaping from the

transmission vent where it may be mistaken for a leak.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

The transmission has a dipstick to check oil level.

It is located on the right side of the engine. Be sure

to wipe all dirt from dipstick handle before removing.

The torque converter fills in both the P (PARK)

and N (NEUTRAL) positions. Place the selector lever

in P (PARK) to be sure that the fluid level check is

accurate.The engine should be running at idle

speed for at least one minute, with the vehicle

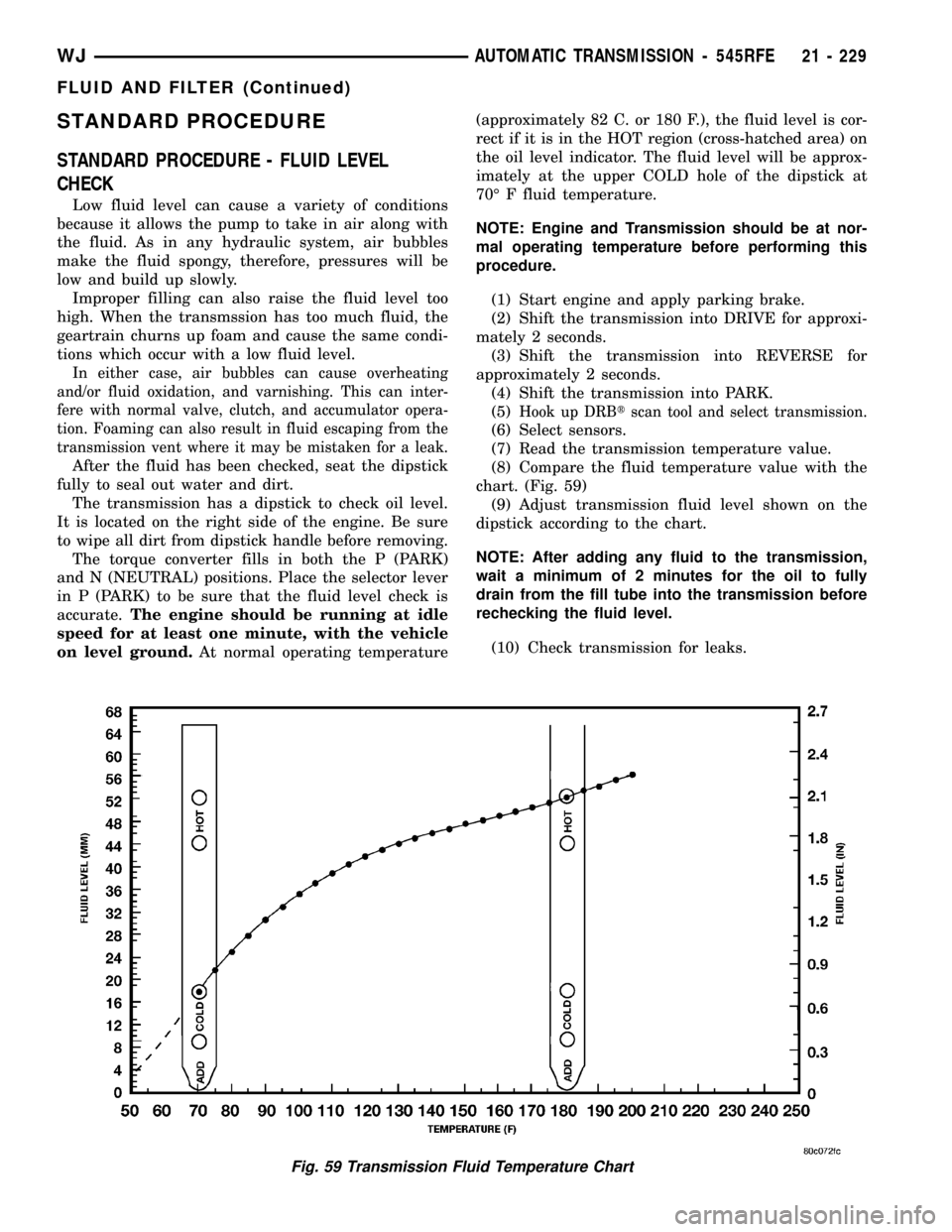

on level ground.At normal operating temperature(approximately 82 C. or 180 F.), the fluid level is cor-

rect if it is in the HOT region (cross-hatched area) on

the oil level indicator. The fluid level will be approx-

imately at the upper COLD hole of the dipstick at

70É F fluid temperature.

NOTE: Engine and Transmission should be at nor-

mal operating temperature before performing this

procedure.

(1) Start engine and apply parking brake.

(2) Shift the transmission into DRIVE for approxi-

mately 2 seconds.

(3) Shift the transmission into REVERSE for

approximately 2 seconds.

(4) Shift the transmission into PARK.

(5)

Hook up DRBtscan tool and select transmission.

(6) Select sensors.

(7) Read the transmission temperature value.

(8) Compare the fluid temperature value with the

chart. (Fig. 59)

(9) Adjust transmission fluid level shown on the

dipstick according to the chart.

NOTE: After adding any fluid to the transmission,

wait a minimum of 2 minutes for the oil to fully

drain from the fill tube into the transmission before

rechecking the fluid level.

(10) Check transmission for leaks.

Fig. 59 Transmission Fluid Temperature Chart

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 229

FLUID AND FILTER (Continued)

Page 1750 of 2199

GEARSHIFT CABLE

DIAGNOSIS AND TESTING - GEARSHIFT

CABLE

(1) The floor shifter lever and gate positions

should be in alignment with all transmission PARK,

NEUTRAL, and gear detent positions.

(2) Engine starts must be possible with floor shift

lever in PARK or NEUTRAL gate positions only.

Engine starts must not be possible in any other gear

position.

(3) With floor shift lever handle push-button not

depressed and lever in:

(a) PARK position - Apply forward force on cen-

ter of handle and remove pressure. Engine starts

must be possible.

(b) PARK position - Apply rearward force on cen-

ter of handle and remove pressure. Engine starts

must be possible.

(c) NEUTRAL position - Normal position. Engine

starts must be possible.

(d) NEUTRAL position - Engine running and

brakes applied, apply forward force on center of

shift handle. Transmission shall not be able to shift

from NEUTRAL to REVERSE.

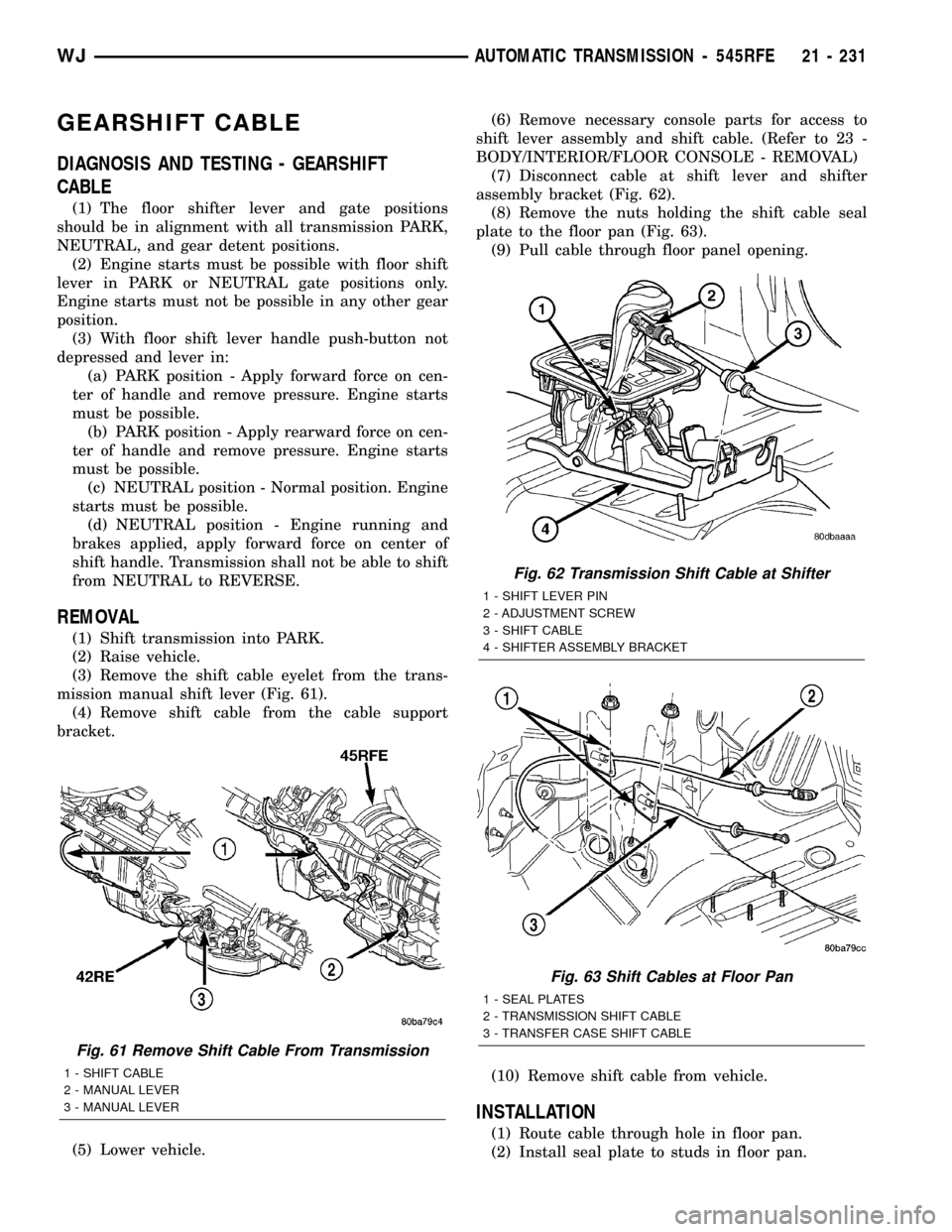

REMOVAL

(1) Shift transmission into PARK.

(2) Raise vehicle.

(3) Remove the shift cable eyelet from the trans-

mission manual shift lever (Fig. 61).

(4) Remove shift cable from the cable support

bracket.

(5) Lower vehicle.(6) Remove necessary console parts for access to

shift lever assembly and shift cable. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE - REMOVAL)

(7) Disconnect cable at shift lever and shifter

assembly bracket (Fig. 62).

(8) Remove the nuts holding the shift cable seal

plate to the floor pan (Fig. 63).

(9) Pull cable through floor panel opening.

(10) Remove shift cable from vehicle.

INSTALLATION

(1) Route cable through hole in floor pan.

(2) Install seal plate to studs in floor pan.

Fig. 61 Remove Shift Cable From Transmission

1 - SHIFT CABLE

2 - MANUAL LEVER

3 - MANUAL LEVER

Fig. 62 Transmission Shift Cable at Shifter

1 - SHIFT LEVER PIN

2 - ADJUSTMENT SCREW

3 - SHIFT CABLE

4 - SHIFTER ASSEMBLY BRACKET

Fig. 63 Shift Cables at Floor Pan

1 - SEAL PLATES

2 - TRANSMISSION SHIFT CABLE

3 - TRANSFER CASE SHIFT CABLE

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 231

Page 1774 of 2199

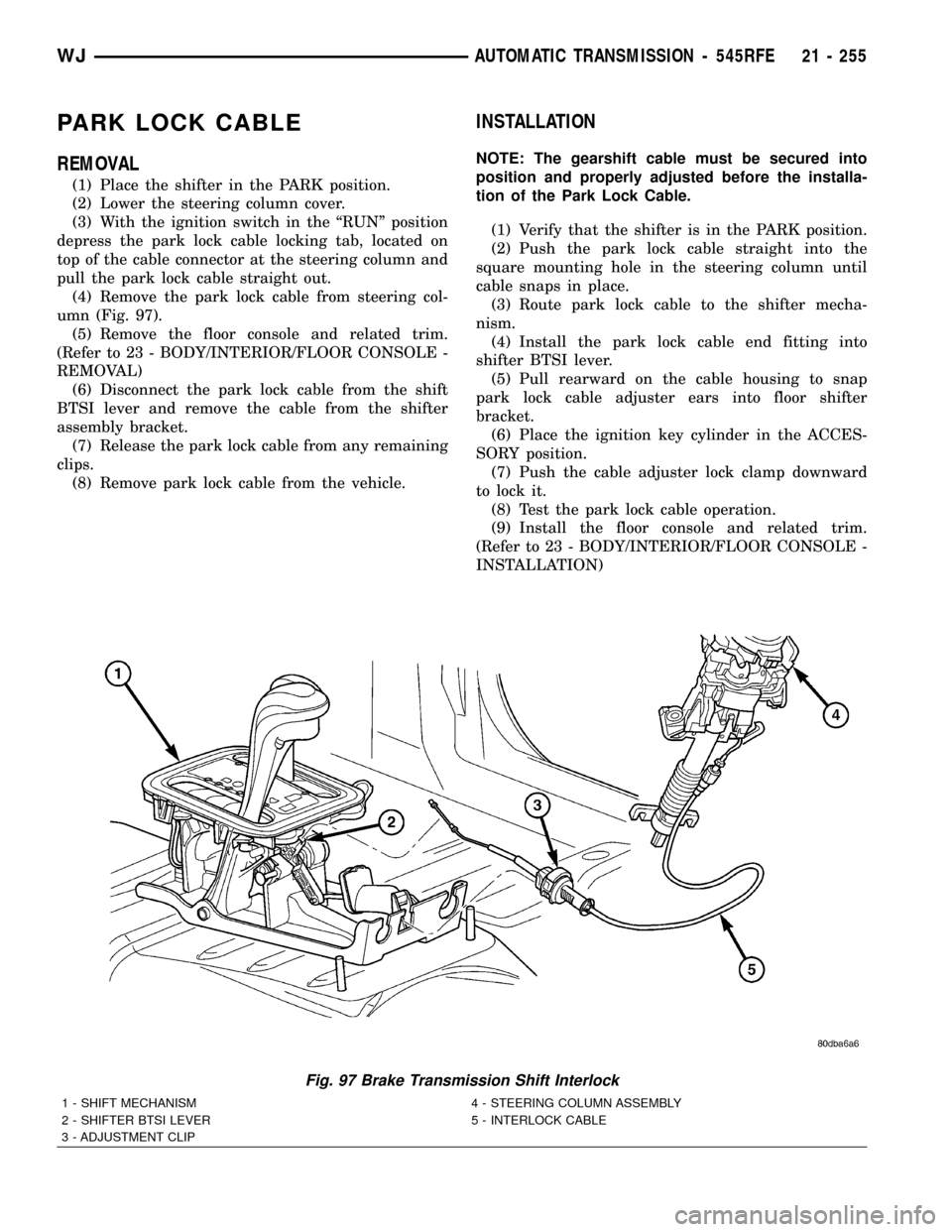

PARK LOCK CABLE

REMOVAL

(1) Place the shifter in the PARK position.

(2) Lower the steering column cover.

(3) With the ignition switch in the ªRUNº position

depress the park lock cable locking tab, located on

top of the cable connector at the steering column and

pull the park lock cable straight out.

(4) Remove the park lock cable from steering col-

umn (Fig. 97).

(5) Remove the floor console and related trim.

(Refer to 23 - BODY/INTERIOR/FLOOR CONSOLE -

REMOVAL)

(6) Disconnect the park lock cable from the shift

BTSI lever and remove the cable from the shifter

assembly bracket.

(7) Release the park lock cable from any remaining

clips.

(8) Remove park lock cable from the vehicle.

INSTALLATION

NOTE: The gearshift cable must be secured into

position and properly adjusted before the installa-

tion of the Park Lock Cable.

(1) Verify that the shifter is in the PARK position.

(2) Push the park lock cable straight into the

square mounting hole in the steering column until

cable snaps in place.

(3) Route park lock cable to the shifter mecha-

nism.

(4) Install the park lock cable end fitting into

shifter BTSI lever.

(5) Pull rearward on the cable housing to snap

park lock cable adjuster ears into floor shifter

bracket.

(6) Place the ignition key cylinder in the ACCES-

SORY position.

(7) Push the cable adjuster lock clamp downward

to lock it.

(8) Test the park lock cable operation.

(9) Install the floor console and related trim.

(Refer to 23 - BODY/INTERIOR/FLOOR CONSOLE -

INSTALLATION)

Fig. 97 Brake Transmission Shift Interlock

1 - SHIFT MECHANISM 4 - STEERING COLUMN ASSEMBLY

2 - SHIFTER BTSI LEVER 5 - INTERLOCK CABLE

3 - ADJUSTMENT CLIP

WJAUTOMATIC TRANSMISSION - 545RFE 21 - 255

Page 1781 of 2199

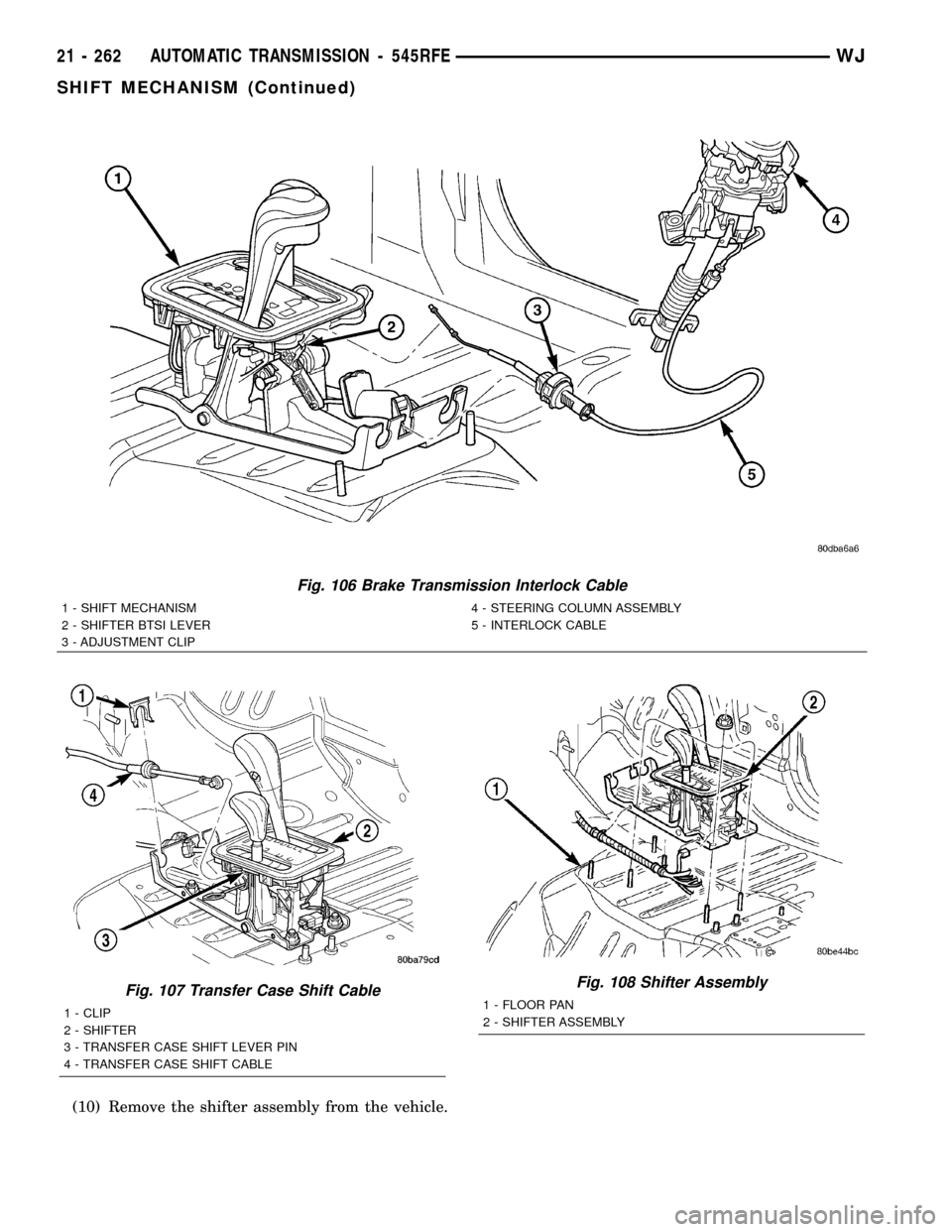

(10) Remove the shifter assembly from the vehicle.

Fig. 106 Brake Transmission Interlock Cable

1 - SHIFT MECHANISM 4 - STEERING COLUMN ASSEMBLY

2 - SHIFTER BTSI LEVER 5 - INTERLOCK CABLE

3 - ADJUSTMENT CLIP

Fig. 107 Transfer Case Shift Cable

1 - CLIP

2 - SHIFTER

3 - TRANSFER CASE SHIFT LEVER PIN

4 - TRANSFER CASE SHIFT CABLE

Fig. 108 Shifter Assembly

1 - FLOOR PAN

2 - SHIFTER ASSEMBLY

21 - 262 AUTOMATIC TRANSMISSION - 545RFEWJ

SHIFT MECHANISM (Continued)

Page 1860 of 2199

TIRES/WHEELS

TABLE OF CONTENTS

page page

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND

WHEEL RUNOUT......................1

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE AND

WHEEL BALANCE......................2

STANDARD PROCEDURE - MATCH

MOUNTING...........................4

STANDARD PROCEDURE - TIRE ROTATION . 5

STANDARD PROCEDURE - WHEEL

INSTALLATION........................5

TIRES

DESCRIPTION

DESCRIPTION - TIRES..................6

DESCRIPTION - RADIAL±PLY TIRES.......6

DESCRIPTION - TIRE INFLATION

PRESSURES..........................6

DESCRIPTION - TIRE PRESSURE FOR

HIGH SPEED..........................7

DESCRIPTION - REPLACEMENT TIRES.....7

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - PRESSURE

GAUGES.............................8

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS..........................8

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS...........................8

DIAGNOSIS AND TESTING - TIRE NOISE

OR VIBRATION........................8STANDARD PROCEDURE - REPAIRING

LEAKS...............................8

CLEANING.............................9

SPECIFICATIONS

TIRES...............................9

SPECIFICATIONS -.....................9

SPARE TIRE

DESCRIPTION - SPARE / TEMPORARY TIRE . . 10

WHEELS

DESCRIPTION.........................10

DIAGNOSIS AND TESTING - WHEEL

INSPECTION.........................10

STANDARD PROCEDURE - WHEEL

REPLACEMENT.......................10

SPECIFICATIONS

TORQUE CHART......................11

STUDS

REMOVAL.............................11

INSTALLATION.........................11

TIRE PRESSURE MONITORING

DESCRIPTION.........................12

OPERATION...........................12

DIAGNOSIS AND TESTING - TIRE PRESSURE

MONITORING SYSTEM.................12

SENSOR

REMOVAL - TIRE PRESSURE SENSOR/

TRANSMITTER.......................12

INSTALLATION - TIRE PRESSURE SENSOR/

TRANSMITTER.......................13

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND WHEEL

RUNOUT

Radial runout is the difference between the high

and low points on the tire or wheel (Fig. 1).

Lateral runout is thewobbleof the tire or wheel.

Radial runout of more than 1.5 mm (.060 inch)

measured at the center line of the tread may cause

the vehicle to shake.

Lateral runout of more than 2.0 mm (.080 inch)

measured near the shoulder of the tire may cause the

vehicle to shake.

Sometimes radial runout can be reduced. Relocate

the wheel and tire assembly on the mounting studs

(See Method 1). If this does not reduce runout to an

acceptable level, the tire can be rotated on the wheel.

(See Method 2).

METHOD 1 (RELOCATE WHEEL ON HUB)

(1) Drive vehicle a short distance to eliminate tire

flat spotting from a parked position.

(2) Check wheel bearings and adjust if adjustable

or replace if necessary.

(3) Check the wheel mounting surface.

(4) Relocate wheel on the mounting, two studs

over from the original position.

(5) Tighten wheel nuts until all are properly

torqued, to eliminate brake distortion.

(6) Check radial runout. If still excessive, mark

tire sidewall, wheel, and stud at point of maximum

runout and proceed to Method 2.

METHOD 2 (RELOCATE TIRE ON WHEEL)

NOTE: Rotating the tire on wheel is particularly

effective when there is runout in both tire and

wheel.

WJTIRES/WHEELS 22 - 1

Page 1865 of 2199

TIRES

DESCRIPTION

DESCRIPTION - TIRES

Tires are designed and engineered for each specific

vehicle. They provide the best overall performance

for normal operation. The ride and handling charac-

teristics match the vehicle's requirements. With

proper care they will give excellent reliability, trac-

tion, skid resistance, and tread life.

Driving habits have more effect on tire life than

any other factor. Careful drivers will obtain in most

cases, much greater mileage than severe use or care-

less drivers. A few of the driving habits which will

shorten the life of any tire are:

²Rapid acceleration

²Severe brake applications

²High speed driving

²Excessive speeds on turns

²Striking curbs and other obstacles

Radial-ply tires are more prone to irregular tread

wear. It is important to follow the tire rotation inter-

val shown in the section on Tire Rotation.(Refer to 22

- TIRES/WHEELS - STANDARD PROCEDURE),

This will help to achieve a greater tread life.

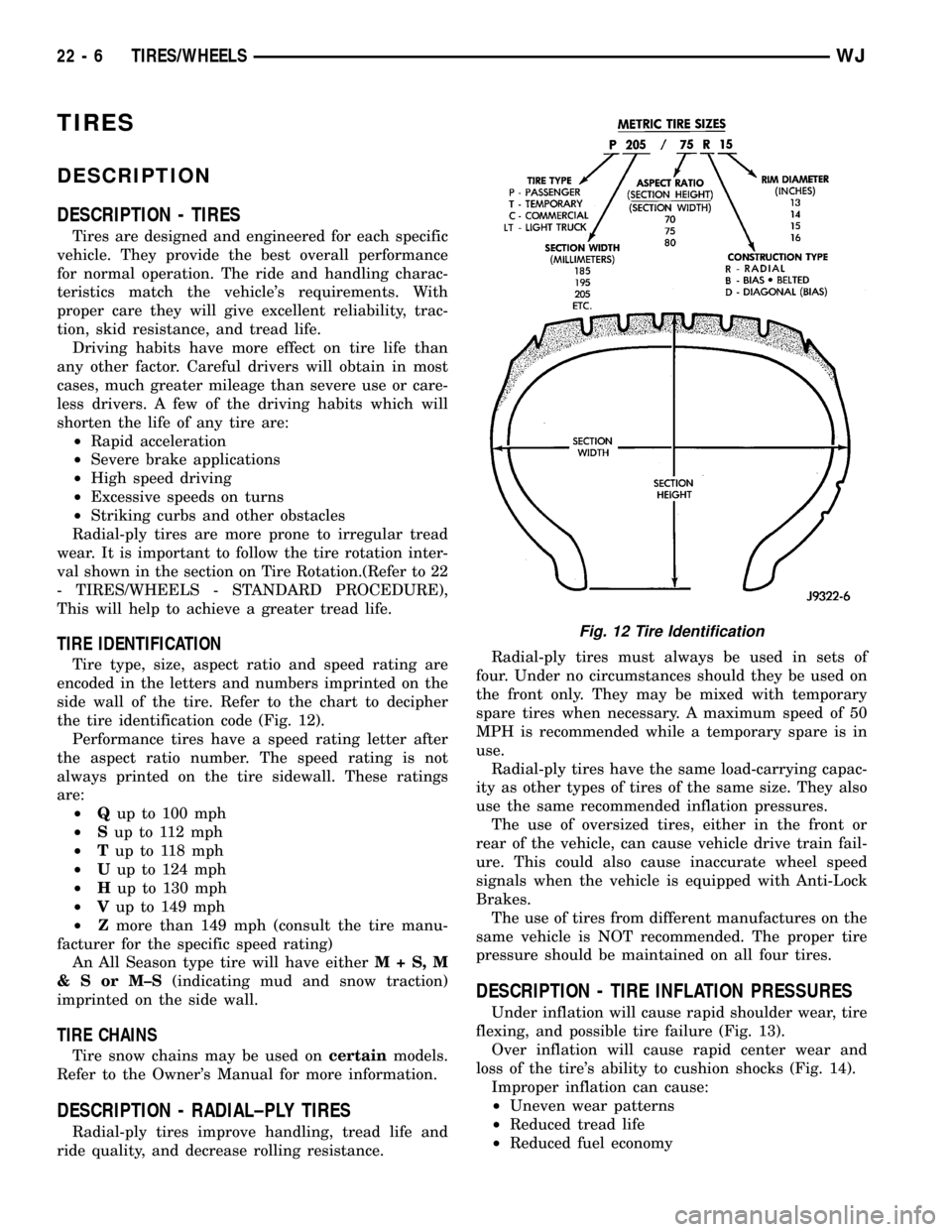

TIRE IDENTIFICATION

Tire type, size, aspect ratio and speed rating are

encoded in the letters and numbers imprinted on the

side wall of the tire. Refer to the chart to decipher

the tire identification code (Fig. 12).

Performance tires have a speed rating letter after

the aspect ratio number. The speed rating is not

always printed on the tire sidewall. These ratings

are:

²Qup to 100 mph

²Sup to 112 mph

²Tup to 118 mph

²Uup to 124 mph

²Hup to 130 mph

²Vup to 149 mph

²Zmore than 149 mph (consult the tire manu-

facturer for the specific speed rating)

An All Season type tire will have eitherM+S,M

&SorM±S(indicating mud and snow traction)

imprinted on the side wall.

TIRE CHAINS

Tire snow chains may be used oncertainmodels.

Refer to the Owner's Manual for more information.

DESCRIPTION - RADIAL±PLY TIRES

Radial-ply tires improve handling, tread life and

ride quality, and decrease rolling resistance.Radial-ply tires must always be used in sets of

four. Under no circumstances should they be used on

the front only. They may be mixed with temporary

spare tires when necessary. A maximum speed of 50

MPH is recommended while a temporary spare is in

use.

Radial-ply tires have the same load-carrying capac-

ity as other types of tires of the same size. They also

use the same recommended inflation pressures.

The use of oversized tires, either in the front or

rear of the vehicle, can cause vehicle drive train fail-

ure. This could also cause inaccurate wheel speed

signals when the vehicle is equipped with Anti-Lock

Brakes.

The use of tires from different manufactures on the

same vehicle is NOT recommended. The proper tire

pressure should be maintained on all four tires.

DESCRIPTION - TIRE INFLATION PRESSURES

Under inflation will cause rapid shoulder wear, tire

flexing, and possible tire failure (Fig. 13).

Over inflation will cause rapid center wear and

loss of the tire's ability to cushion shocks (Fig. 14).

Improper inflation can cause:

²Uneven wear patterns

²Reduced tread life

²Reduced fuel economy

Fig. 12 Tire Identification

22 - 6 TIRES/WHEELSWJ

Page 1870 of 2199

²Bent or dented

²Leak air through welds

²Have damaged bolt holes

Wheel repairs employing hammering, heating, or

welding are not allowed.

Original equipment wheels are available through

your dealer. Replacement wheels from any other

source should be equivalent in:

²Load carrying capacity

²Diameter

²Width²Offset

²Mounting configuration

Failure to use equivalent replacement wheels may

affect the safety and handling of your vehicle.

Replacement withusedwheels is not recommended.

Their service history may have included severe treat-

ment.

SPECIFICATIONS

TORQUE CHART

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Lug Nut

1/2 X 20 with 60É Cone115-150 85-115 Ð

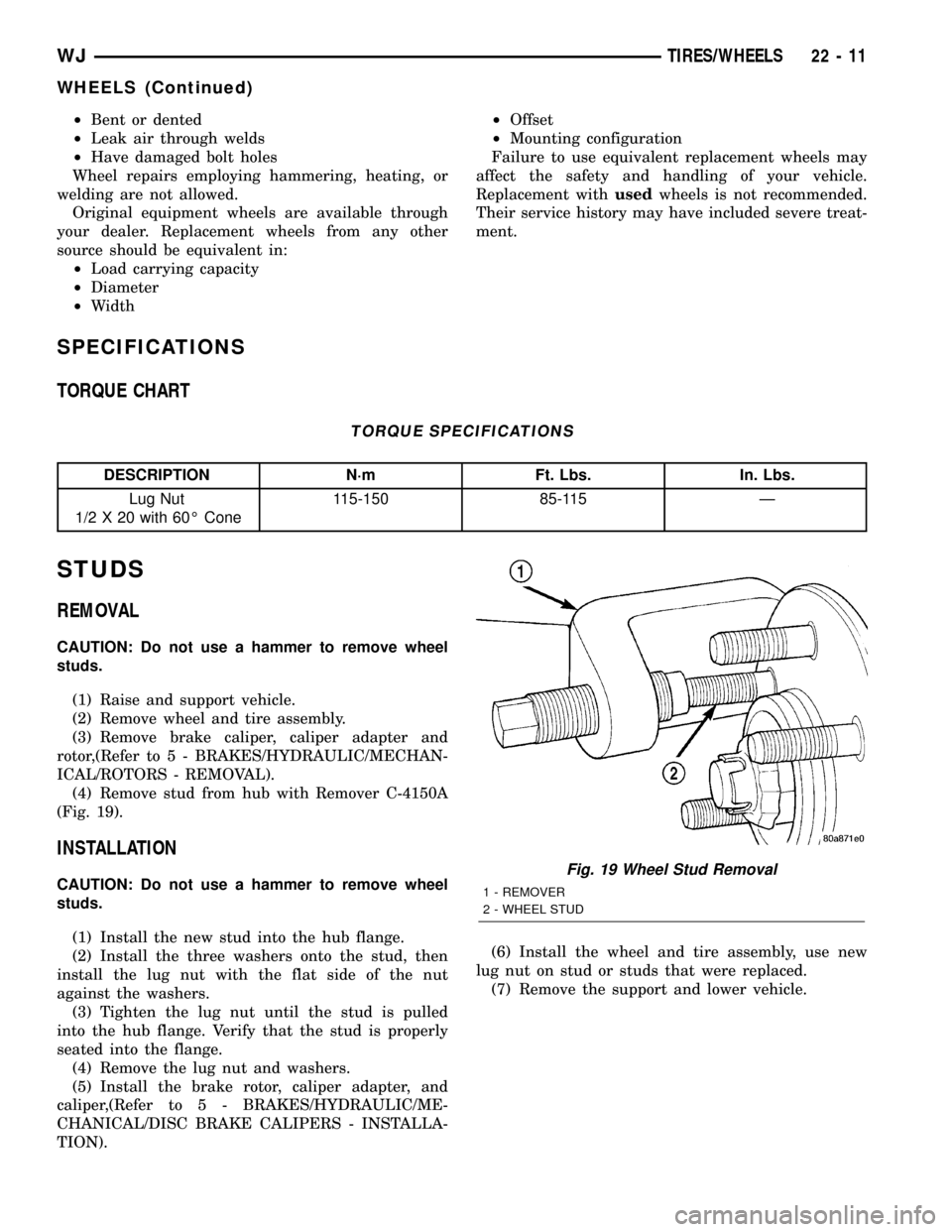

STUDS

REMOVAL

CAUTION: Do not use a hammer to remove wheel

studs.

(1) Raise and support vehicle.

(2) Remove wheel and tire assembly.

(3) Remove brake caliper, caliper adapter and

rotor,(Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/ROTORS - REMOVAL).

(4) Remove stud from hub with Remover C-4150A

(Fig. 19).

INSTALLATION

CAUTION: Do not use a hammer to remove wheel

studs.

(1) Install the new stud into the hub flange.

(2) Install the three washers onto the stud, then

install the lug nut with the flat side of the nut

against the washers.

(3) Tighten the lug nut until the stud is pulled

into the hub flange. Verify that the stud is properly

seated into the flange.

(4) Remove the lug nut and washers.

(5) Install the brake rotor, caliper adapter, and

caliper,(Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/DISC BRAKE CALIPERS - INSTALLA-

TION).(6) Install the wheel and tire assembly, use new

lug nut on stud or studs that were replaced.

(7) Remove the support and lower vehicle.Fig. 19 Wheel Stud Removal

1 - REMOVER

2 - WHEEL STUD

WJTIRES/WHEELS 22 - 11

WHEELS (Continued)