spec JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 543 of 2199

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, FRONT IMPACT SENSOR,

SIDE IMPACT SENSOR, SIDE CURTAIN AIRBAG, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

STANDARD PROCEDURE

STANDARD PROCEDURE - HANDLING

NON-DEPLOYED SUPPLEMENTAL RESTRAINTS

At no time should any source of electricity be per-

mitted near the inflator on the back of a non-de-

ployed airbag. When carrying a non-deployed airbag,

the trim cover or airbag cushion side of the unit

should be pointed away from the body to minimize

injury in the event of an accidental deployment. If

the airbag unit is placed on a bench or any other sur-

face, the trim cover or airbag cushion side of the unit

should be face up to minimize movement in the event

of an accidental deployment. In addition, the supple-

mental restraint system should be disarmed when-

ever any steering wheel, steering column, driver

airbag, passenger airbag, front impact sensor, side

impact sensor, side curtain airbag, or instrument

panel components require diagnosis or service. Fail-

ure to observe this warning could result in accidental

airbag deployment and possible personal injury.

All damaged, faulty or non-deployed airbags which

are replaced on vehicles are to be handled and dis-

posed of properly. If an airbag unit is faulty or dam-

aged and non-deployed, refer to the Hazardous

Substance Control System for proper disposal. Dis-

pose of all non-deployed and deployed airbags in a

manner consistent with state, provincial, local and

federal regulations.

SUPPLEMENTAL RESTRAINT STORAGE

Airbags must be stored in their original, special

container until they are used for service. Also, they

must be stored in a clean, dry environment; away

from sources of extreme heat, sparks, and high elec-

trical energy. Always place or store any airbag on a

surface with its trim cover or airbag cushion side fac-ing up, to minimize movement in case of an acciden-

tal deployment.

STANDARD PROCEDURE - SERVICE AFTER A

SUPPLEMENTAL RESTRAINT DEPLOYMENT

Any vehicle which is to be returned to use follow-

ing a supplemental restraint deployment, must have

the deployed restraints replaced. In addition, if the

driver airbag has been deployed, the clockspring

must be replaced. If the passenger airbag is

deployed, the instrument panel top pad must be

replaced. If a side curtain airbag has been deployed,

the complete airbag unit, the headliner, as well as

the upper A, B, C and D-pillar trim must be replaced.

These components are not intended for reuse and

will be damaged or weakened as a result of a supple-

mental restraint deployment, which may or may not

be obvious during a visual inspection.

The passenger airbag mounting points on the

instrument panel structural duct must be closely

inspected for damage, and the instrument panel

assembly replaced if structural duct damage is evi-

dent. On vehicles with an optional sunroof, the sun-

roof drain tubes and hoses must be closely inspected

following a side curtain airbag deployment. It is also

critical that the mounting surfaces and/or mounting

brackets for the front and side impact sensors be

closely inspected and restored to their original condi-

tions following any vehicle impact damage. Because

the ACM and each impact sensor are used by the

supplemental restraint system to monitor or confirm

the direction and severity of a vehicle impact,

improper orientation or insecure fastening of these

components may cause airbags not to deploy when

required, or to deploy when not required.

All other vehicle components should be closely

inspected following any supplemental restraint

deployment, but are to be replaced only as required

by the extent of the visible damage incurred.

AIRBAG SQUIB STATUS

Multistage airbags with multiple initiators (squibs)

must be checked to determine that all squibs were

used during the deployment event. The driver and

passenger airbags in this model are deployed by elec-

trical signals generated by the Airbag Control Mod-

ule (ACM) through the driver or passenger squib 1

and squib 2 circuits to the two initiators in the air-

bag inflators. Typically, both initiators are used and

all potentially hazardous chemicals are burned dur-

ing an airbag deployment event. However, it is possi-

ble for only one initiator to be used due to an airbag

system fault; therefore, it is always necessary to con-

firm that both initiators have been used in order to

avoid the improper handling or disposal of poten-

tially live pyrotechnic or hazardous materials. The

8O - 6 RESTRAINTSWJ

RESTRAINTS (Continued)

Page 546 of 2199

(4) Check to be certain that nobody is in the vehi-

cle, then reconnect the battery negative cable.

(5) Using the DRBIIIt, read and record the active

(current) Diagnostic Trouble Code (DTC) data.

(6) Next, use the DRBIIItto read and record any

stored (historical) DTC data.

(7) If any DTC is found in Step 5 or Step 6, refer

to the appropriate diagnostic information.

(8) Use the DRBIIItto erase the stored DTC data.

If any problems remain, the stored DTC data will not

erase. Refer to the appropriate diagnostic informa-

tion to diagnose any stored DTC that will not erase.

If the stored DTC information is successfully erased,

go to Step 9.

(9) Turn the ignition switch to the Off position for

about fifteen seconds, and then back to the On posi-

tion. Observe the airbag indicator in the instrument

cluster. It should light for six to eight seconds, and

then go out. This indicates that the supplemental

restraint system is functioning normally and that the

repairs are complete. If the airbag indicator fails to

light, or lights and stays on, there is still an active

supplemental restraint system fault or malfunction.

Refer to the appropriate diagnostic information to

diagnose the problem.

AIRBAG CONTROL MODULE

DESCRIPTION

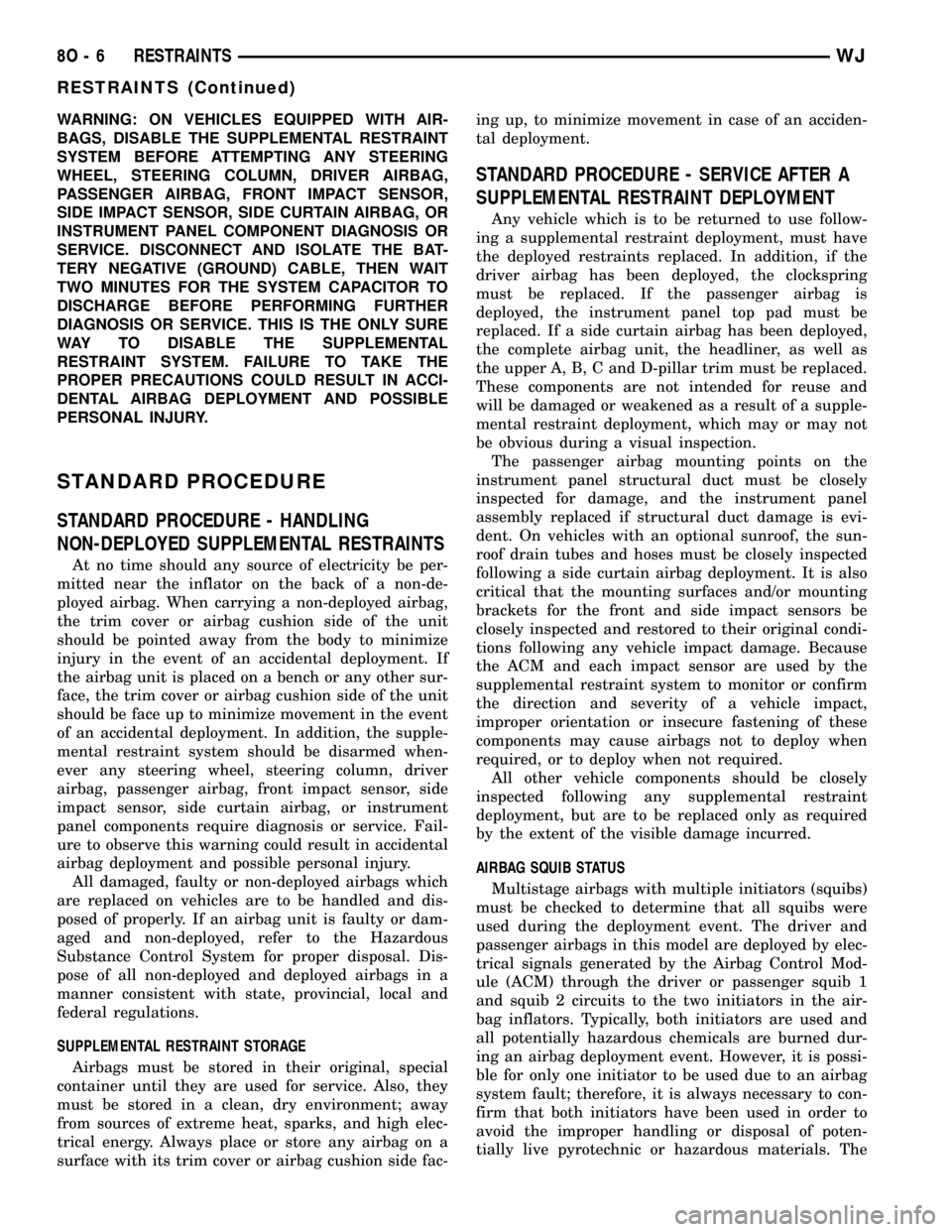

The Airbag Control Module (ACM) is also some-

times referred to as the Occupant Restraint Control-

ler (ORC) (Fig. 6). The ACM is concealed underneath

the center floor console, where it is secured by four

screws to a stamped steel mounting bracket welded

onto the top of the floor panel transmission tunnel

just forward of the park brake mechanism in the pas-

senger compartment of the vehicle.

Concealed within a hollow in the center of the die

cast aluminum ACM housing is the electronic cir-

cuitry of the ACM which includes a microprocessor,

an electronic impact sensor, an electronic safing sen-

sor, and an energy storage capacitor. A stamped

metal cover plate is secured to the bottom of the

ACM housing with four screws to enclose and protect

the internal electronic circuitry and components. A

printed label on the top of the ACM housing provides

a visual verification of the proper orientation of the

unit, and should always be pointed toward the front

of the vehicle.

Two molded plastic electrical connector receptacles

exit the forward side of the ACM housing. These two

receptacles connect the ACM to the vehicle electrical

system through a dedicated take out and connector of

the instrument panel wire harness, and a dedicated

take out and connector of the airbag overlay wire

harness. For vehicles equipped with the optional side

curtain airbags, both ACM connector receptacles are

black in color and the ACM contains a second bi-di-

rectional safing sensor for the side airbags. For vehi-

cles not equipped with the optional side curtain

airbags, the ACM connector receptacles are both

gray.

The impact sensor and safing sensor internal to

the ACM are calibrated for the specific vehicle, and

are only serviced as a unit with the ACM. The ACM

cannot be repaired or adjusted and, if damaged or

faulty, it must be replaced.

OPERATION

The microprocessor in the Airbag Control Module

(ACM) contains the supplemental restraint system

logic circuits and controls all of the supplemental

restraint system components. The ACM uses

On-Board Diagnostics (OBD) and can communicate

with other electronic modules in the vehicle as well

as with the DRBIIItscan tool using the Programma-

ble Communications Interface (PCI) data bus net-

work. This method of communication is used for

control of the airbag indicator in the ElectroMechani-

cal Instrument Cluster (EMIC) and for supplemental

restraint system diagnosis and testing through the

16-way data link connector located on the driver side

lower edge of the instrument panel. (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/COMMUNICATION - OPERATION).

Fig. 6 Airbag Control Module

1 - AIRBAG CONTROL MODULE

2 - ORIENTATION ARROW

3 - LABEL

4 - MOUNTING HOLES (4)

5 - CONNECTOR RECEPTACLE (2)

WJRESTRAINTS 8O - 9

RESTRAINTS (Continued)

Page 555 of 2199

(3) Align and seat the one pin and the two mount-

ing ears on the clockspring case to their respective

holes in the multi-function switch mounting housing.

(4) Install and tighten the two clockspring mount-

ing screws. Tighten the screws to 2.5 N´m (22 in.

lbs.).

(5) Reconnect the two instrument panel wire har-

ness connectors for the clockspring to the two connec-

tor receptacles below the steering column on the back

of the clockspring case.

(6) Position the lower tilting steering column

shroud onto the steering column (Fig. 16).

(7) Install and tighten the screw that secures the

lower tilting steering column shroud to the multi-

function switch mounting housing. Tighten the screw

to 2 N´m (17 in. lbs.).

(8) Position the upper tilting column shroud onto

the steering column with the hazard warning switch

button inserted through the hole in the upper surface

of the shroud. Align the upper tilting steering column

shroud to the lower shroud and snap the two shroud

halves together.

(9) Align the snap features on the upper and lower

shrouds and apply hand pressure to snap them

together.

(10) Reinstall the steering wheel onto the steering

column. (Refer to 19 - STEERING/COLUMN/STEER-

ING WHEEL - INSTALLATION).

(11)

Reconnect the steering wheel wire harness con-

nectors to the upper clockspring connector receptacles.

(12) Reinstall the driver airbag onto the steering

wheel. (Refer to 8 - ELECTRICAL/RESTRAINTS/

DRIVER AIRBAG - INSTALLATION).

DRIVER AIRBAG

DESCRIPTION

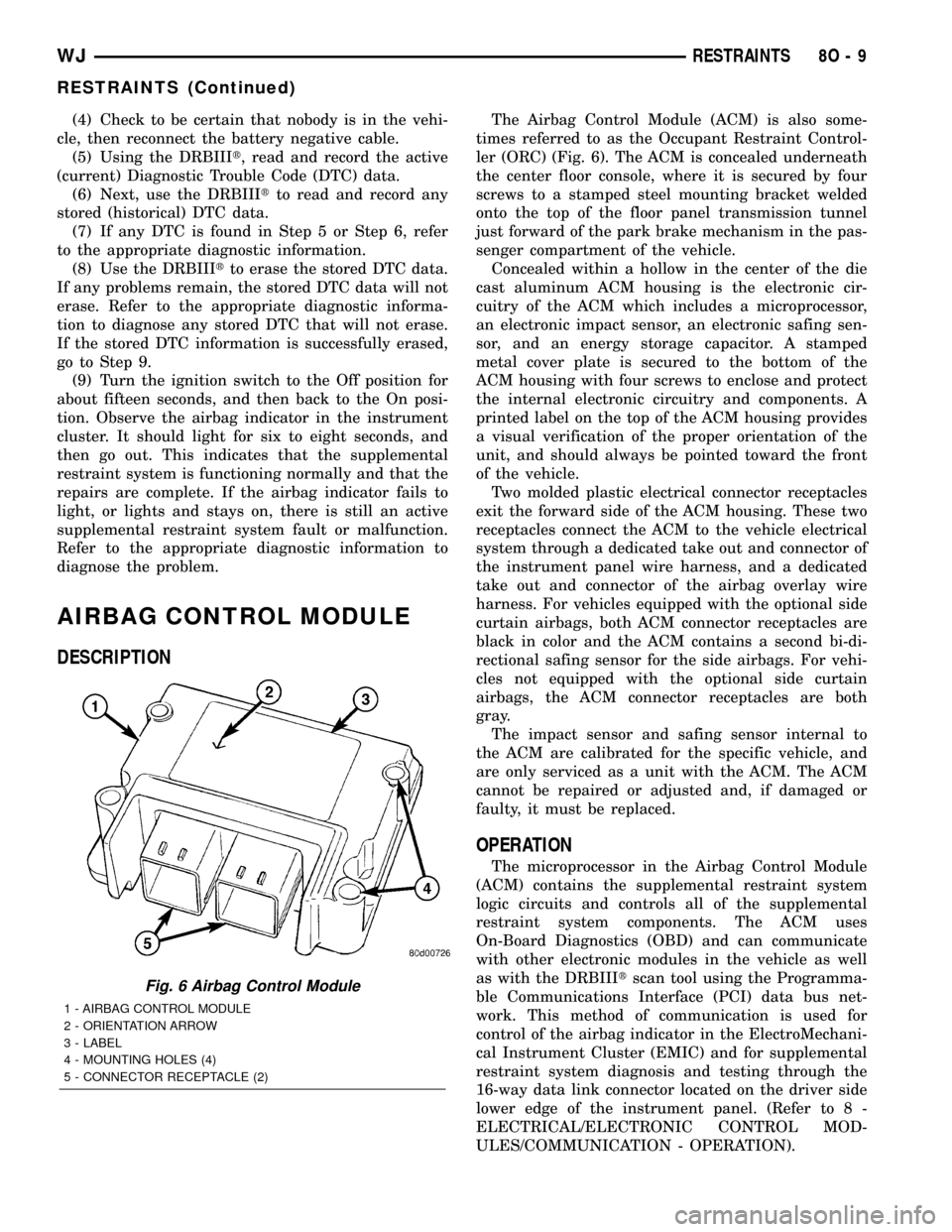

The injection molded, thermoplastic driver airbag

protective trim cover is the most visible part of the

driver airbag (Fig. 18). The driver airbag is located in

the center of the steering wheel, where it is secured

with two screws to the two horizontal spokes of the

four-spoke steering wheel armature. A stamped, satin

polished emblem with the Jeeptlogo is applied to the

center of the trim cover. Concealed beneath the

driver airbag trim cover are the horn switch, the

folded airbag cushion, the airbag retainer or housing,

the airbag inflator, and the retainers that secure the

inflator to the airbag housing.

The airbag cushion, housing, and inflator are

secured within an integral receptacle molded into the

back of the trim cover. The driver airbag trim cover

has locking blocks molded into the back side of it

that engage a lip formed around the perimeter of the

airbag housing. Two stamped metal retainers then fitover the inflator mounting studs on the back of the

airbag housing and are engaged in slots within the

upper and lower trim cover locking blocks, securely

locking the cover into place.

The resistive membrane-type horn switch is

secured within a plastic tray that is inserted in a

pocket or pouch sewn onto the airbag cushion

retainer strap, between the trim cover and the folded

airbag cushion. The horn switch ground pigtail wire

has an eyelet terminal connector that is captured on

the upper right inflator mounting stud between the

inflator and the upper trim cover retainer. The horn

switch feed pigtail wire has a white, molded plastic

insulator that is secured by an integral retainer to a

mounting hole located in the upper trim cover

retainer near the upper left corner on the back of the

airbag housing, and is connected to the vehicle elec-

trical system through a take out and connector of the

steering wheel wire harness.

The airbag used in this model is a multistage, Next

Generation-type that complies with revised federal air-

bag standards to deploy with less force than those used

in some prior models. A radial deploying fabric airbag

cushion with tethers is used. The airbag inflator is a

dual-initiator, non-azide, pyrotechnic-type unit with

four mounting studs and is secured to the stamped

metal airbag housing using four hex nuts with washers.

Two keyed and color-coded connector receptacles on the

driver airbag inflator connect the two inflator initiators

to the vehicle electrical system through two yellow-

jacketed, two-wire pigtail harnesses of the clockspring.

The driver airbag cannot be repaired, and must be

replaced if deployed or in any way damaged. The driver

airbag trim cover and the horn switch are available

individually, and may be disassembled from the driver

airbag for service replacement.

Fig. 18 Driver Airbag Trim Cover

1 - STEERING WHEEL

2 - TRIM COVER

8O - 18 RESTRAINTSWJ

CLOCKSPRING (Continued)

Page 564 of 2199

(4) For the right impact sensor and bracket unit,

the tightening sequence for the three screws that

secure it to the right radiator support vertical mem-

ber is from top to bottom. For the left impact sensor

and bracket unit, the tightening sequence for the

three screws that secure it to the left radiator sup-

port vertical member is from bottom to top. Tighten

the screws to 12 N´m (105 in. lbs.).

(5) Reconnect the right or left headlamp and dash

wire harness connector for the front impact sensor to

the sensor connector receptacle.

(6) Reinstall the headlamp mounting module to

the front of the vehicle. (Refer to 23 - BODY/EXTE-

RIOR/HEADLAMP MOUNTING MODULE -

INSTALLATION).

(7) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

FRONT SEAT BELT &

RETRACTOR

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

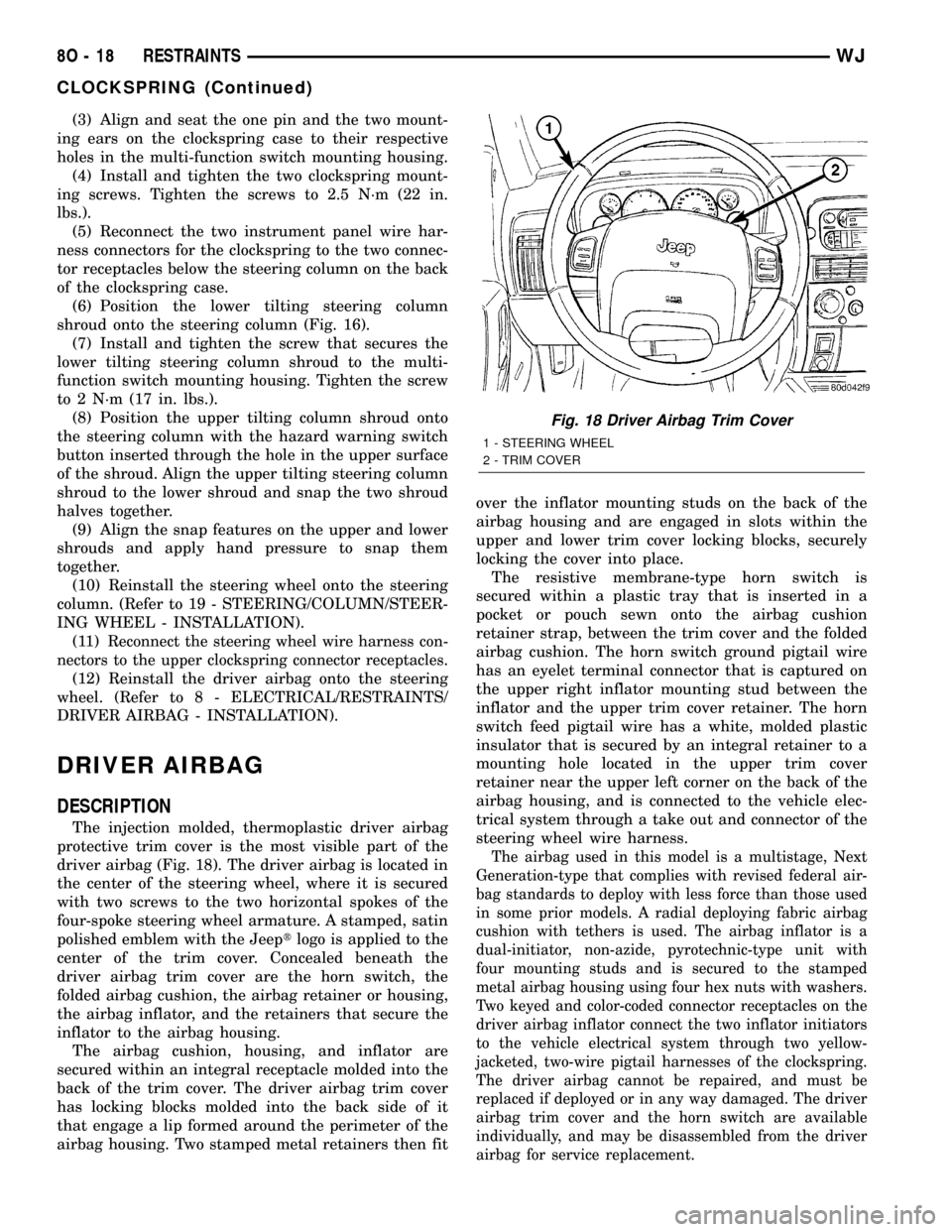

(1) Adjust the front seat to its most forward posi-

tion for easiest access to the front seat belt lower

anchor and the B-pillar trim.

(2) Disconnect and isolate the battery negative

cable.

(3) Lift the front seat belt lower anchor cover far

enough to access the screw that secures it to the

lower B-pillar (Fig. 27).

(4) Remove the screw that secures the lower

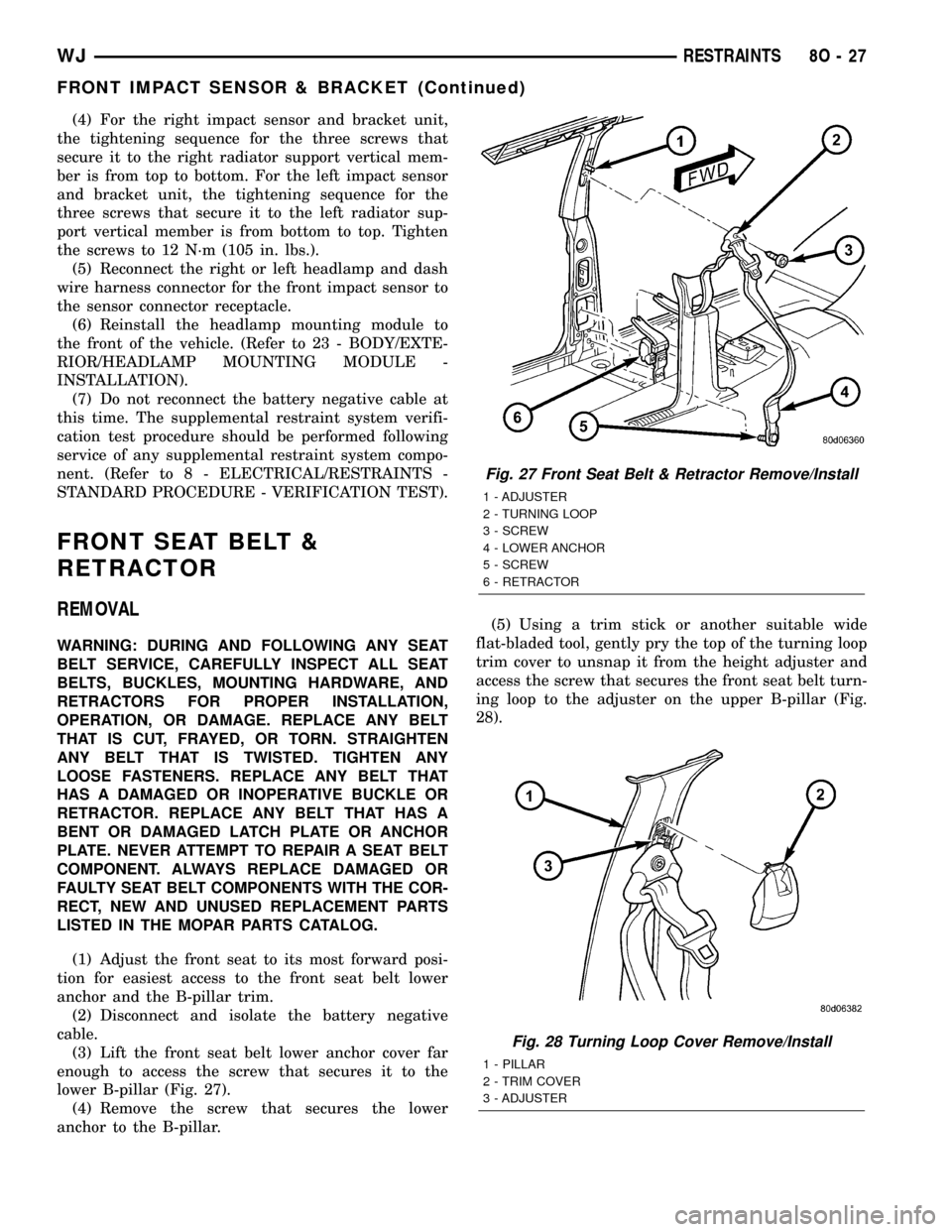

anchor to the B-pillar.(5) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the top of the turning loop

trim cover to unsnap it from the height adjuster and

access the screw that secures the front seat belt turn-

ing loop to the adjuster on the upper B-pillar (Fig.

28).

Fig. 27 Front Seat Belt & Retractor Remove/Install

1 - ADJUSTER

2 - TURNING LOOP

3 - SCREW

4 - LOWER ANCHOR

5 - SCREW

6 - RETRACTOR

Fig. 28 Turning Loop Cover Remove/Install

1 - PILLAR

2 - TRIM COVER

3 - ADJUSTER

WJRESTRAINTS 8O - 27

FRONT IMPACT SENSOR & BRACKET (Continued)

Page 565 of 2199

(6) Remove the screw that secures the seat belt

turning loop to the height adjuster on the upper

B-pillar.

(7) Remove the seat belt turning loop from the

height adjuster.

(8) Remove the trim from the lower B-pillar. (Refer

to 23 - BODY/INTERIOR/B-PILLAR LOWER TRIM -

REMOVAL).

(9) Pull the front seat belt turning loop and lower

anchor through the access hole in the lower B-pillar

trim.

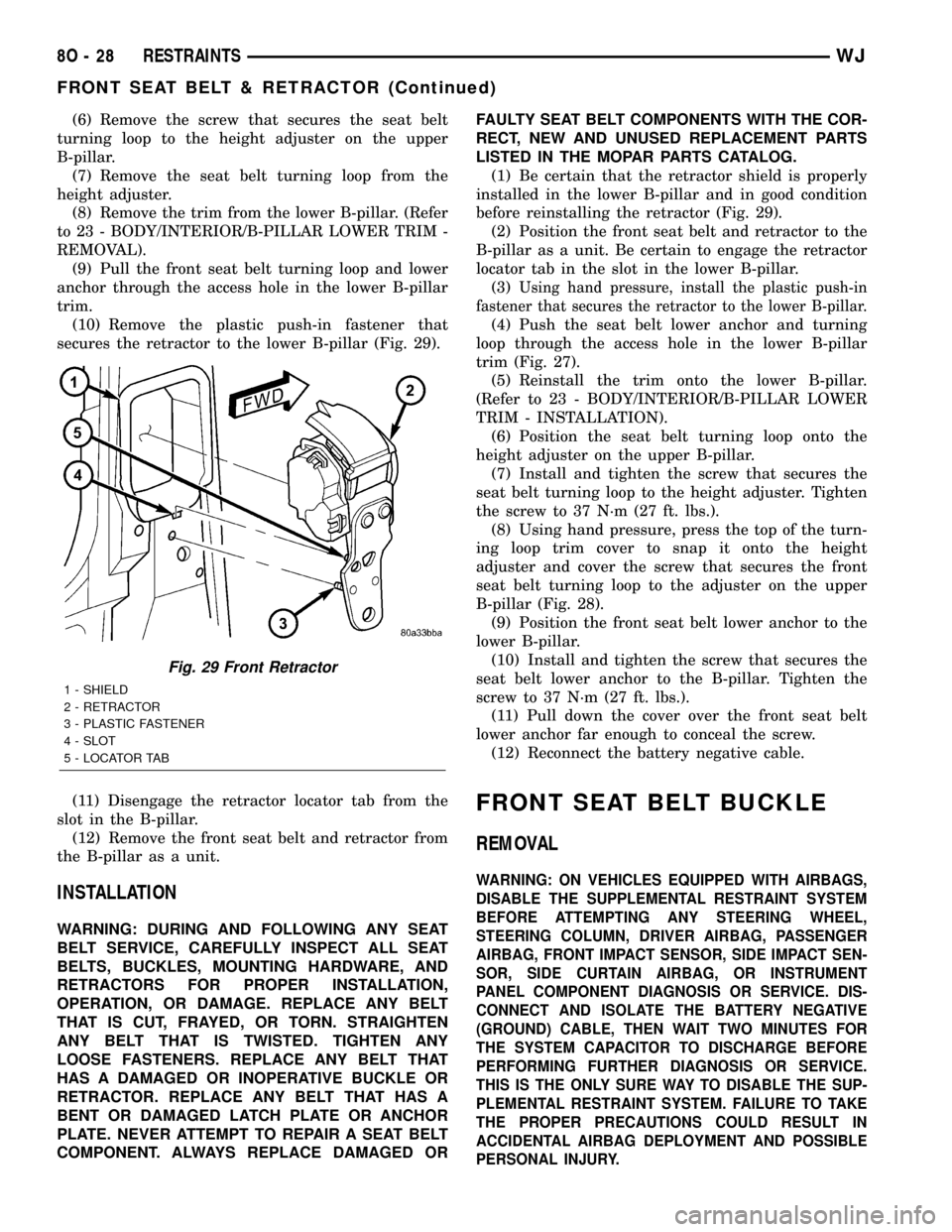

(10) Remove the plastic push-in fastener that

secures the retractor to the lower B-pillar (Fig. 29).

(11) Disengage the retractor locator tab from the

slot in the B-pillar.

(12) Remove the front seat belt and retractor from

the B-pillar as a unit.

INSTALLATION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED ORFAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Be certain that the retractor shield is properly

installed in the lower B-pillar and in good condition

before reinstalling the retractor (Fig. 29).

(2) Position the front seat belt and retractor to the

B-pillar as a unit. Be certain to engage the retractor

locator tab in the slot in the lower B-pillar.

(3)

Using hand pressure, install the plastic push-in

fastener that secures the retractor to the lower B-pillar.

(4) Push the seat belt lower anchor and turning

loop through the access hole in the lower B-pillar

trim (Fig. 27).

(5) Reinstall the trim onto the lower B-pillar.

(Refer to 23 - BODY/INTERIOR/B-PILLAR LOWER

TRIM - INSTALLATION).

(6) Position the seat belt turning loop onto the

height adjuster on the upper B-pillar.

(7) Install and tighten the screw that secures the

seat belt turning loop to the height adjuster. Tighten

the screw to 37 N´m (27 ft. lbs.).

(8) Using hand pressure, press the top of the turn-

ing loop trim cover to snap it onto the height

adjuster and cover the screw that secures the front

seat belt turning loop to the adjuster on the upper

B-pillar (Fig. 28).

(9) Position the front seat belt lower anchor to the

lower B-pillar.

(10) Install and tighten the screw that secures the

seat belt lower anchor to the B-pillar. Tighten the

screw to 37 N´m (27 ft. lbs.).

(11) Pull down the cover over the front seat belt

lower anchor far enough to conceal the screw.

(12) Reconnect the battery negative cable.

FRONT SEAT BELT BUCKLE

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYSTEM

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, DRIVER AIRBAG, PASSENGER

AIRBAG, FRONT IMPACT SENSOR, SIDE IMPACT SEN-

SOR, SIDE CURTAIN AIRBAG, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE. DIS-

CONNECT AND ISOLATE THE BATTERY NEGATIVE

(GROUND) CABLE, THEN WAIT TWO MINUTES FOR

THE SYSTEM CAPACITOR TO DISCHARGE BEFORE

PERFORMING FURTHER DIAGNOSIS OR SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE SUP-

PLEMENTAL RESTRAINT SYSTEM. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

Fig. 29 Front Retractor

1 - SHIELD

2 - RETRACTOR

3 - PLASTIC FASTENER

4 - SLOT

5 - LOCATOR TAB

8O - 28 RESTRAINTSWJ

FRONT SEAT BELT & RETRACTOR (Continued)

Page 566 of 2199

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Move the front seat to its most forward position

for easiest access to the front seat belt buckle lower

anchor screw.

(2) Disconnect and isolate the battery negative

cable. Wait two minutes for the system capacitor to

discharge before further service.

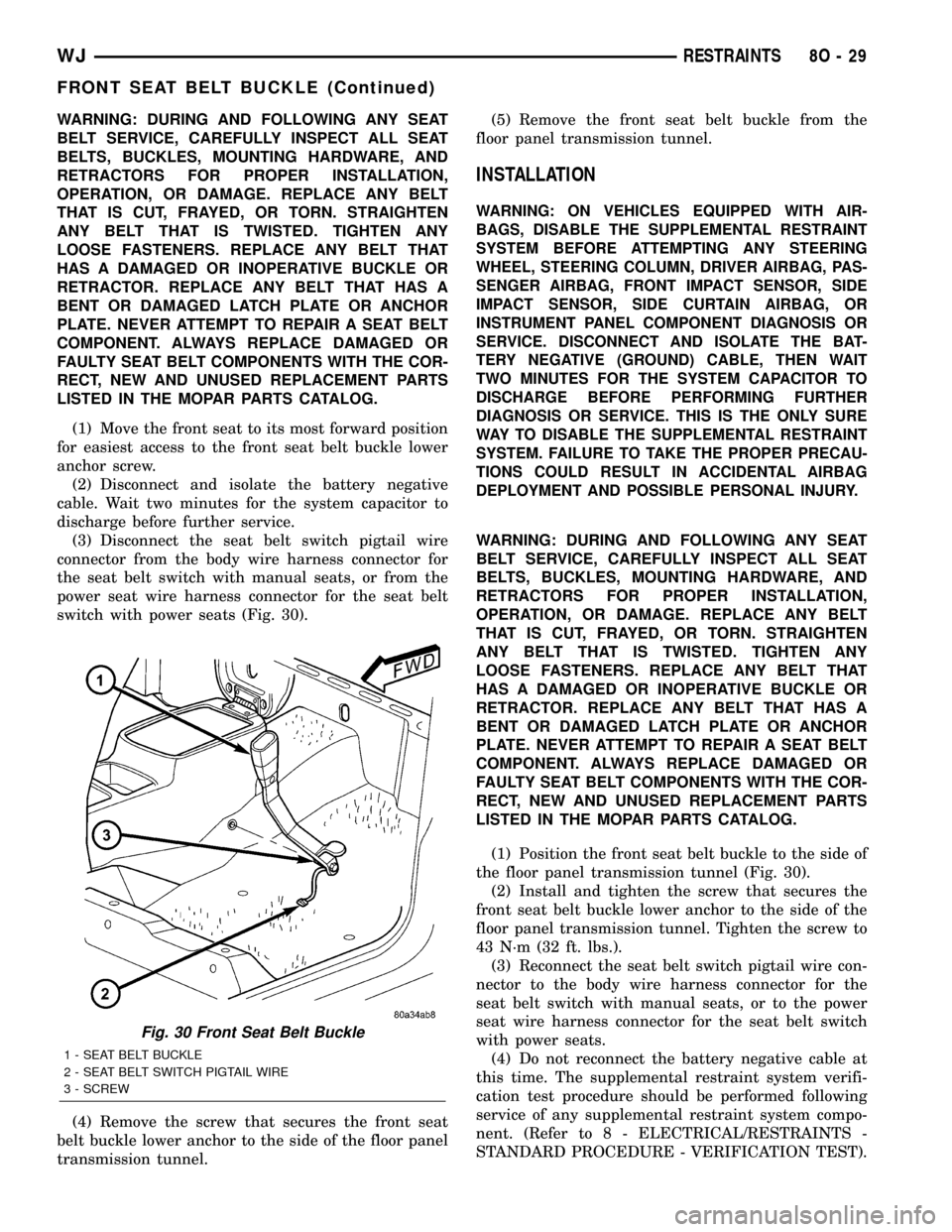

(3) Disconnect the seat belt switch pigtail wire

connector from the body wire harness connector for

the seat belt switch with manual seats, or from the

power seat wire harness connector for the seat belt

switch with power seats (Fig. 30).

(4) Remove the screw that secures the front seat

belt buckle lower anchor to the side of the floor panel

transmission tunnel.(5) Remove the front seat belt buckle from the

floor panel transmission tunnel.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG, PAS-

SENGER AIRBAG, FRONT IMPACT SENSOR, SIDE

IMPACT SENSOR, SIDE CURTAIN AIRBAG, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM. FAILURE TO TAKE THE PROPER PRECAU-

TIONS COULD RESULT IN ACCIDENTAL AIRBAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY.

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the front seat belt buckle to the side of

the floor panel transmission tunnel (Fig. 30).

(2) Install and tighten the screw that secures the

front seat belt buckle lower anchor to the side of the

floor panel transmission tunnel. Tighten the screw to

43 N´m (32 ft. lbs.).

(3) Reconnect the seat belt switch pigtail wire con-

nector to the body wire harness connector for the

seat belt switch with manual seats, or to the power

seat wire harness connector for the seat belt switch

with power seats.

(4) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

Fig. 30 Front Seat Belt Buckle

1 - SEAT BELT BUCKLE

2 - SEAT BELT SWITCH PIGTAIL WIRE

3 - SCREW

WJRESTRAINTS 8O - 29

FRONT SEAT BELT BUCKLE (Continued)

Page 567 of 2199

PASSENGER AIRBAG

DESCRIPTION

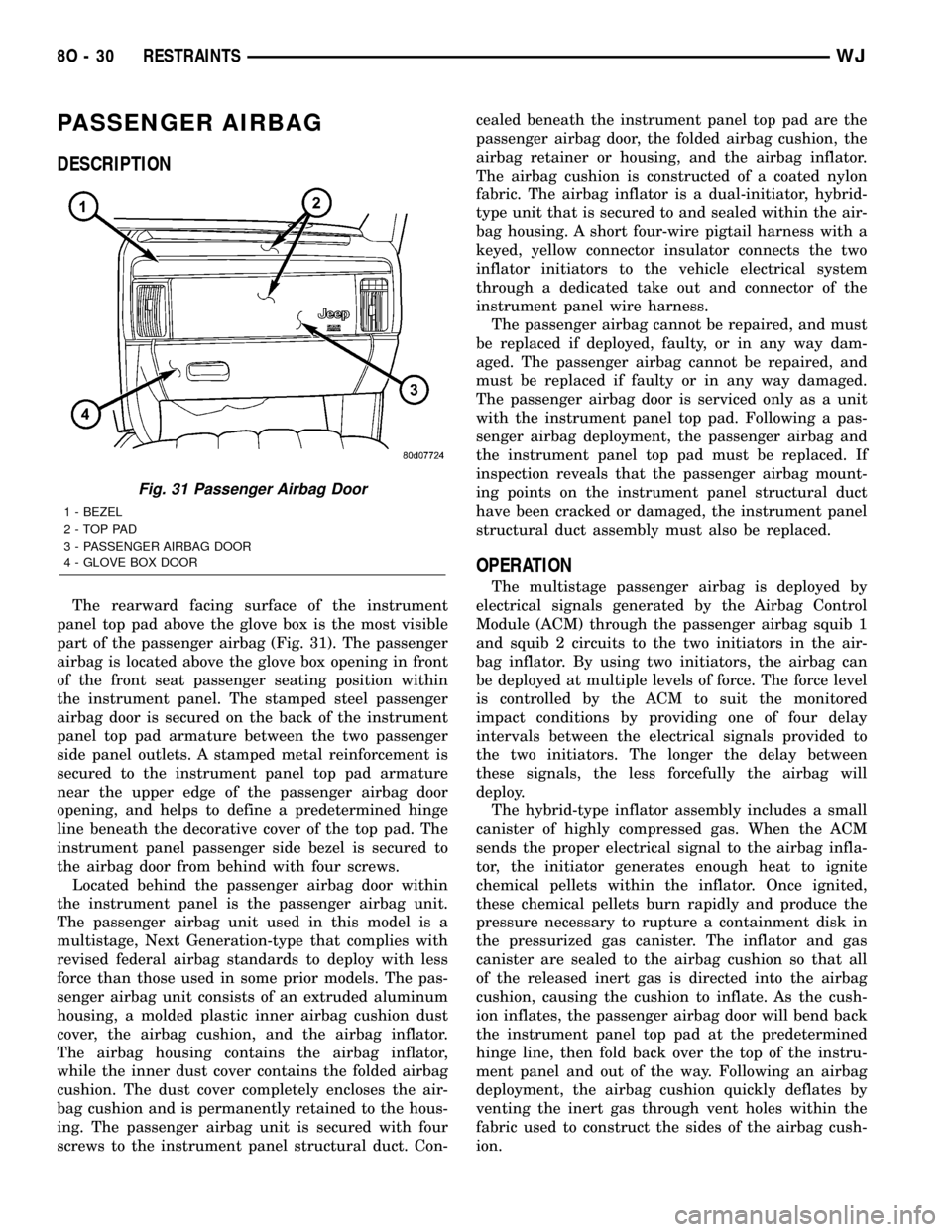

The rearward facing surface of the instrument

panel top pad above the glove box is the most visible

part of the passenger airbag (Fig. 31). The passenger

airbag is located above the glove box opening in front

of the front seat passenger seating position within

the instrument panel. The stamped steel passenger

airbag door is secured on the back of the instrument

panel top pad armature between the two passenger

side panel outlets. A stamped metal reinforcement is

secured to the instrument panel top pad armature

near the upper edge of the passenger airbag door

opening, and helps to define a predetermined hinge

line beneath the decorative cover of the top pad. The

instrument panel passenger side bezel is secured to

the airbag door from behind with four screws.

Located behind the passenger airbag door within

the instrument panel is the passenger airbag unit.

The passenger airbag unit used in this model is a

multistage, Next Generation-type that complies with

revised federal airbag standards to deploy with less

force than those used in some prior models. The pas-

senger airbag unit consists of an extruded aluminum

housing, a molded plastic inner airbag cushion dust

cover, the airbag cushion, and the airbag inflator.

The airbag housing contains the airbag inflator,

while the inner dust cover contains the folded airbag

cushion. The dust cover completely encloses the air-

bag cushion and is permanently retained to the hous-

ing. The passenger airbag unit is secured with four

screws to the instrument panel structural duct. Con-cealed beneath the instrument panel top pad are the

passenger airbag door, the folded airbag cushion, the

airbag retainer or housing, and the airbag inflator.

The airbag cushion is constructed of a coated nylon

fabric. The airbag inflator is a dual-initiator, hybrid-

type unit that is secured to and sealed within the air-

bag housing. A short four-wire pigtail harness with a

keyed, yellow connector insulator connects the two

inflator initiators to the vehicle electrical system

through a dedicated take out and connector of the

instrument panel wire harness.

The passenger airbag cannot be repaired, and must

be replaced if deployed, faulty, or in any way dam-

aged. The passenger airbag cannot be repaired, and

must be replaced if faulty or in any way damaged.

The passenger airbag door is serviced only as a unit

with the instrument panel top pad. Following a pas-

senger airbag deployment, the passenger airbag and

the instrument panel top pad must be replaced. If

inspection reveals that the passenger airbag mount-

ing points on the instrument panel structural duct

have been cracked or damaged, the instrument panel

structural duct assembly must also be replaced.

OPERATION

The multistage passenger airbag is deployed by

electrical signals generated by the Airbag Control

Module (ACM) through the passenger airbag squib 1

and squib 2 circuits to the two initiators in the air-

bag inflator. By using two initiators, the airbag can

be deployed at multiple levels of force. The force level

is controlled by the ACM to suit the monitored

impact conditions by providing one of four delay

intervals between the electrical signals provided to

the two initiators. The longer the delay between

these signals, the less forcefully the airbag will

deploy.

The hybrid-type inflator assembly includes a small

canister of highly compressed gas. When the ACM

sends the proper electrical signal to the airbag infla-

tor, the initiator generates enough heat to ignite

chemical pellets within the inflator. Once ignited,

these chemical pellets burn rapidly and produce the

pressure necessary to rupture a containment disk in

the pressurized gas canister. The inflator and gas

canister are sealed to the airbag cushion so that all

of the released inert gas is directed into the airbag

cushion, causing the cushion to inflate. As the cush-

ion inflates, the passenger airbag door will bend back

the instrument panel top pad at the predetermined

hinge line, then fold back over the top of the instru-

ment panel and out of the way. Following an airbag

deployment, the airbag cushion quickly deflates by

venting the inert gas through vent holes within the

fabric used to construct the sides of the airbag cush-

ion.

Fig. 31 Passenger Airbag Door

1 - BEZEL

2-TOPPAD

3 - PASSENGER AIRBAG DOOR

4 - GLOVE BOX DOOR

8O - 30 RESTRAINTSWJ

Page 569 of 2199

INSTALLATION

The following procedure is for replacement of a

faulty or damaged passenger airbag. If the airbag is

faulty or damaged, but not deployed, review the rec-

ommended procedures for handling non-deployed

supplemental restraints. (Refer to 8 - ELECTRICAL/

RESTRAINTS - STANDARD PROCEDURE - HAN-

DLING NON-DEPLOYED SUPPLEMENTAL

RESTRAINTS). If the passenger airbag has been

deployed, review the recommended procedures for

service after a supplemental restraint deployment

before removing the airbag from the vehicle. (Refer to

8 - ELECTRICAL/RESTRAINTS - STANDARD PRO-

CEDURE - SERVICE AFTER A SUPPLEMENTAL

RESTRAINT DEPLOYMENT).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE SUPPLEMENTAL RESTRAINT

SYSTEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, DRIVER AIRBAG,

PASSENGER AIRBAG, FRONT IMPACT SENSOR,

SIDE IMPACT SENSOR, SIDE CURTAIN AIRBAG, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER

DIAGNOSIS OR SERVICE. THIS IS THE ONLY SURE

WAY TO DISABLE THE SUPPLEMENTAL

RESTRAINT SYSTEM. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

WARNING: WHEN REMOVING A DEPLOYED AIR-

BAG, RUBBER GLOVES, EYE PROTECTION, AND A

LONG-SLEEVED SHIRT SHOULD BE WORN. THERE

MAY BE DEPOSITS ON THE AIRBAG UNIT AND

OTHER INTERIOR SURFACES. IN LARGE DOSES,

THESE DEPOSITS MAY CAUSE IRRITATION TO THE

SKIN AND EYES.

WARNING: USE EXTREME CARE TO PREVENT ANY

FOREIGN MATERIAL FROM ENTERING THE PAS-

SENGER AIRBAG, OR BECOMING ENTRAPPED

BETWEEN THE PASSENGER AIRBAG CUSHION

AND THE INSTRUMENT PANEL TOP PAD. FAILURE

TO OBSERVE THIS WARNING COULD RESULT IN

OCCUPANT INJURIES UPON AIRBAG DEPLOY-

MENT.WARNING: THE INSTRUMENT PANEL TOP PAD

MUST NEVER BE PAINTED. REPLACEMENT TOP

PADS ARE SERVICED IN THE ORIGINAL COLORS.

PAINT MAY CHANGE THE WAY IN WHICH THE

MATERIAL OF THE TOP PAD RESPONDS TO AN

AIRBAG DEPLOYMENT. FAILURE TO OBSERVE

THIS WARNING COULD RESULT IN OCCUPANT

INJURIES UPON AIRBAG DEPLOYMENT.

(1) Carefully position the passenger airbag onto

the instrument panel structural duct (Fig. 32).

(2) Install and tighten the four screws that secure

the passenger airbag to the instrument panel struc-

tural duct. Tighten the screws to 11.8 N´m (105 in.

lbs.).

(3) Reconnect the instrument panel wire harness

connector for the passenger airbag to the passenger

airbag pigtail wire connector. This connector is

secured to the outside of the outboard airbag unit

end bracket. Be certain that the latch on the connec-

tor and the red Connector Position Assurance (CPA)

lock are each fully engaged.

(4) Reinstall the top pad onto the instrument

panel. (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL TOP PAD - INSTALLA-

TION).

(5) Do not reconnect the battery negative cable at

this time. The supplemental restraint system verifi-

cation test procedure should be performed following

service of any supplemental restraint system compo-

nent. (Refer to 8 - ELECTRICAL/RESTRAINTS -

STANDARD PROCEDURE - VERIFICATION TEST).

REAR CENTER SEAT BELT &

RETRACTOR

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

8O - 32 RESTRAINTSWJ

PASSENGER AIRBAG (Continued)

Page 571 of 2199

INSTALLATION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Position the rear center seat belt and retractor

unit onto the seat back panel.

(2) Install and tighten the screw that secures the

retractor to the rear seat back panel (Fig. 35).

Tighten the screw to 43 N´m (32 ft. lbs.).

(3) Position the seat back latch cable plunger

against the retractor latch lever, then engage the

cable fitting into the cable support on the retractor,

which is a light snap fit (Fig. 34).

(4) Route the rear seat belt lower anchor and belt

web guide through the top of the seat back panel.

(5) Reinstall the trim onto the right rear seat

back. (Refer to 23 - BODY/SEATS/SEAT BACK

COVER - REAR - INSTALLATION).

(6) Install and tighten the two screws that secure

the belt web guide to the top of the right rear seat

back panel. Tighten the screws to 2 N´m (20 in. lbs.).

(7) Reinstall the right rear seat back panel into

the vehicle. (Refer to 23 - BODY/SEATS/SEAT BACK

- REAR - INSTALLATION).

(8) Restore the cargo area carpet to the base of the

seat back panel and unfold the right rear seat back

to its upright position.

(9) Position the rear center seat belt lower anchor

to the right rear seat belt buckle unit bracket on the

rear floor panel (Fig. 33).

(10) Install and tighten the screw that secures the

rear center seat belt lower anchor to the right rear

seat belt buckle unit bracket on the rear floor panel.

Tighten the screw to 43 N´m (32 ft. lbs.).

(11) Fold and latch the right rear seat cushion in

its normal seating position.

REAR OUTBOARD SEAT BELT

& RETRACTOR

REMOVAL

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

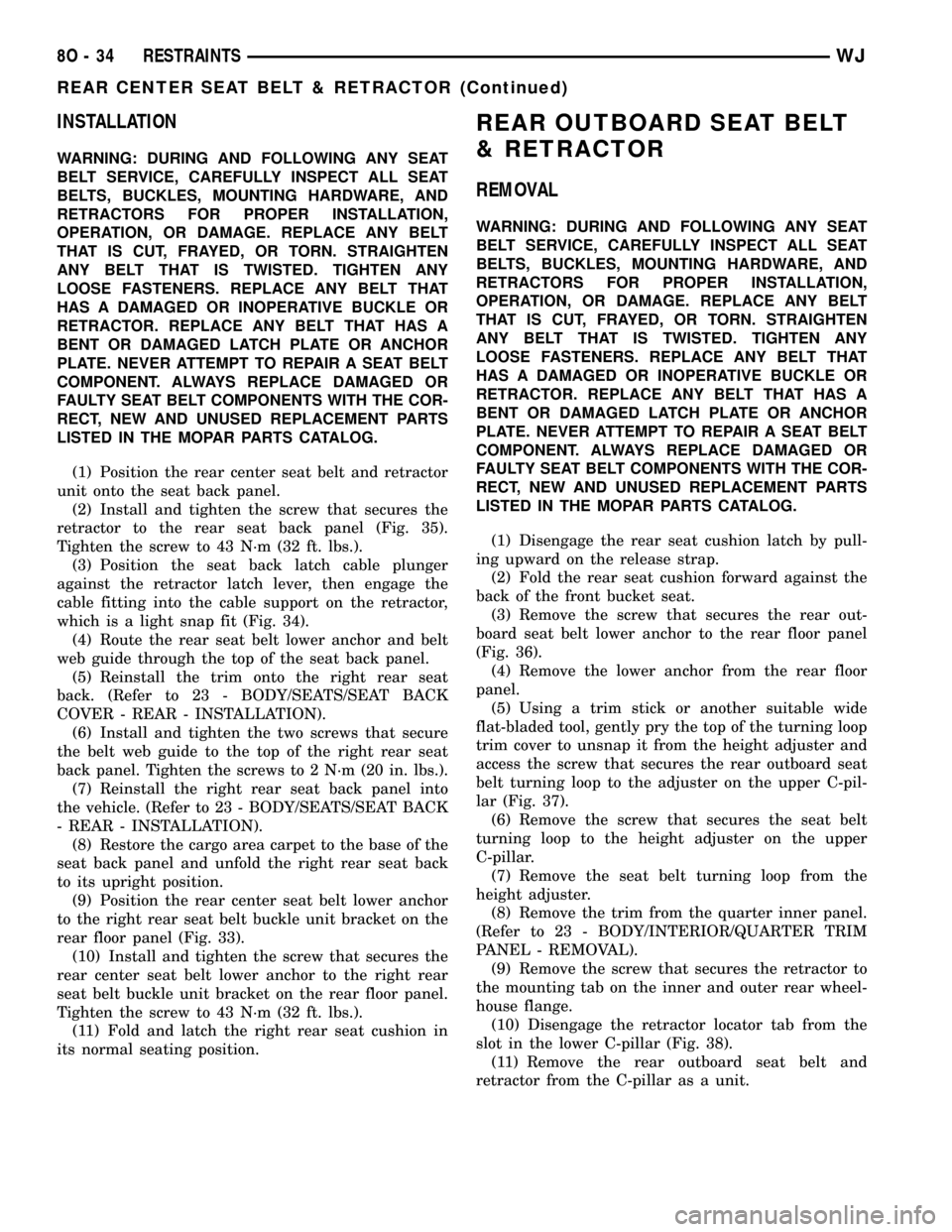

(1) Disengage the rear seat cushion latch by pull-

ing upward on the release strap.

(2) Fold the rear seat cushion forward against the

back of the front bucket seat.

(3) Remove the screw that secures the rear out-

board seat belt lower anchor to the rear floor panel

(Fig. 36).

(4) Remove the lower anchor from the rear floor

panel.

(5) Using a trim stick or another suitable wide

flat-bladed tool, gently pry the top of the turning loop

trim cover to unsnap it from the height adjuster and

access the screw that secures the rear outboard seat

belt turning loop to the adjuster on the upper C-pil-

lar (Fig. 37).

(6) Remove the screw that secures the seat belt

turning loop to the height adjuster on the upper

C-pillar.

(7) Remove the seat belt turning loop from the

height adjuster.

(8) Remove the trim from the quarter inner panel.

(Refer to 23 - BODY/INTERIOR/QUARTER TRIM

PANEL - REMOVAL).

(9) Remove the screw that secures the retractor to

the mounting tab on the inner and outer rear wheel-

house flange.

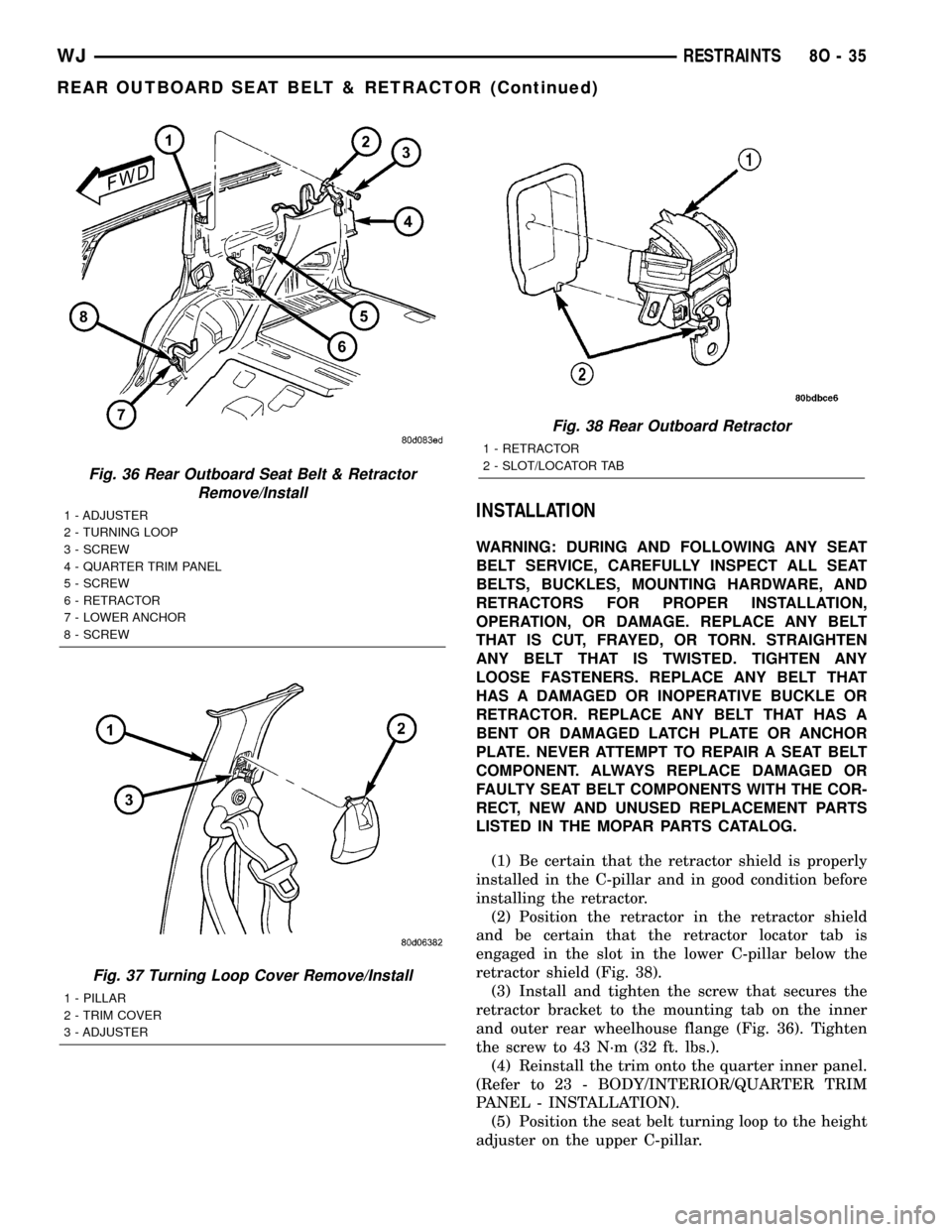

(10) Disengage the retractor locator tab from the

slot in the lower C-pillar (Fig. 38).

(11) Remove the rear outboard seat belt and

retractor from the C-pillar as a unit.

8O - 34 RESTRAINTSWJ

REAR CENTER SEAT BELT & RETRACTOR (Continued)

Page 572 of 2199

INSTALLATION

WARNING: DURING AND FOLLOWING ANY SEAT

BELT SERVICE, CAREFULLY INSPECT ALL SEAT

BELTS, BUCKLES, MOUNTING HARDWARE, AND

RETRACTORS FOR PROPER INSTALLATION,

OPERATION, OR DAMAGE. REPLACE ANY BELT

THAT IS CUT, FRAYED, OR TORN. STRAIGHTEN

ANY BELT THAT IS TWISTED. TIGHTEN ANY

LOOSE FASTENERS. REPLACE ANY BELT THAT

HAS A DAMAGED OR INOPERATIVE BUCKLE OR

RETRACTOR. REPLACE ANY BELT THAT HAS A

BENT OR DAMAGED LATCH PLATE OR ANCHOR

PLATE. NEVER ATTEMPT TO REPAIR A SEAT BELT

COMPONENT. ALWAYS REPLACE DAMAGED OR

FAULTY SEAT BELT COMPONENTS WITH THE COR-

RECT, NEW AND UNUSED REPLACEMENT PARTS

LISTED IN THE MOPAR PARTS CATALOG.

(1) Be certain that the retractor shield is properly

installed in the C-pillar and in good condition before

installing the retractor.

(2) Position the retractor in the retractor shield

and be certain that the retractor locator tab is

engaged in the slot in the lower C-pillar below the

retractor shield (Fig. 38).

(3) Install and tighten the screw that secures the

retractor bracket to the mounting tab on the inner

and outer rear wheelhouse flange (Fig. 36). Tighten

the screw to 43 N´m (32 ft. lbs.).

(4) Reinstall the trim onto the quarter inner panel.

(Refer to 23 - BODY/INTERIOR/QUARTER TRIM

PANEL - INSTALLATION).

(5) Position the seat belt turning loop to the height

adjuster on the upper C-pillar.

Fig. 36 Rear Outboard Seat Belt & Retractor

Remove/Install

1 - ADJUSTER

2 - TURNING LOOP

3 - SCREW

4 - QUARTER TRIM PANEL

5 - SCREW

6 - RETRACTOR

7 - LOWER ANCHOR

8 - SCREW

Fig. 37 Turning Loop Cover Remove/Install

1 - PILLAR

2 - TRIM COVER

3 - ADJUSTER

Fig. 38 Rear Outboard Retractor

1 - RETRACTOR

2 - SLOT/LOCATOR TAB

WJRESTRAINTS 8O - 35

REAR OUTBOARD SEAT BELT & RETRACTOR (Continued)