Engine JEEP GRAND CHEROKEE 2003 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 18 of 2199

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS IN GROUP 8A, BATTERY/START-

ING/CHARGING SYSTEMS DIAGNOSTICS. DO NOT

JUMP START A FROZEN BATTERY, PERSONAL

INJURY CAN RESULT. DO NOT JUMP START WHEN

MAINTENANCE FREE BATTERY INDICATOR DOT IS

YELLOW OR BRIGHT COLOR. DO NOT JUMP

START A VEHICLE WHEN THE BATTERY FLUID IS

BELOW THE TOP OF LEAD PLATES. DO NOT

ALLOW JUMPER CABLE CLAMPS TO TOUCH

EACH OTHER WHEN CONNECTED TO A BOOSTER

SOURCE. DO NOT USE OPEN FLAME NEAR BAT-

TERY. REMOVE METALLIC JEWELRY WORN ON

HANDS OR WRISTS TO AVOID INJURY BY ACCI-

DENTAL ARCING OF BATTERY CURRENT. WHEN

USING A HIGH OUTPUT BOOSTING DEVICE, DO

NOT ALLOW BATTERY VOLTAGE TO EXCEED 16

VOLTS. REFER TO INSTRUCTIONS PROVIDED

WITH DEVICE BEING USED.

CAUTION: When using another vehicle as a

booster, do not allow vehicles to touch. Electrical

systems can be damaged on either vehicle.

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3) On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accesso-

ries.

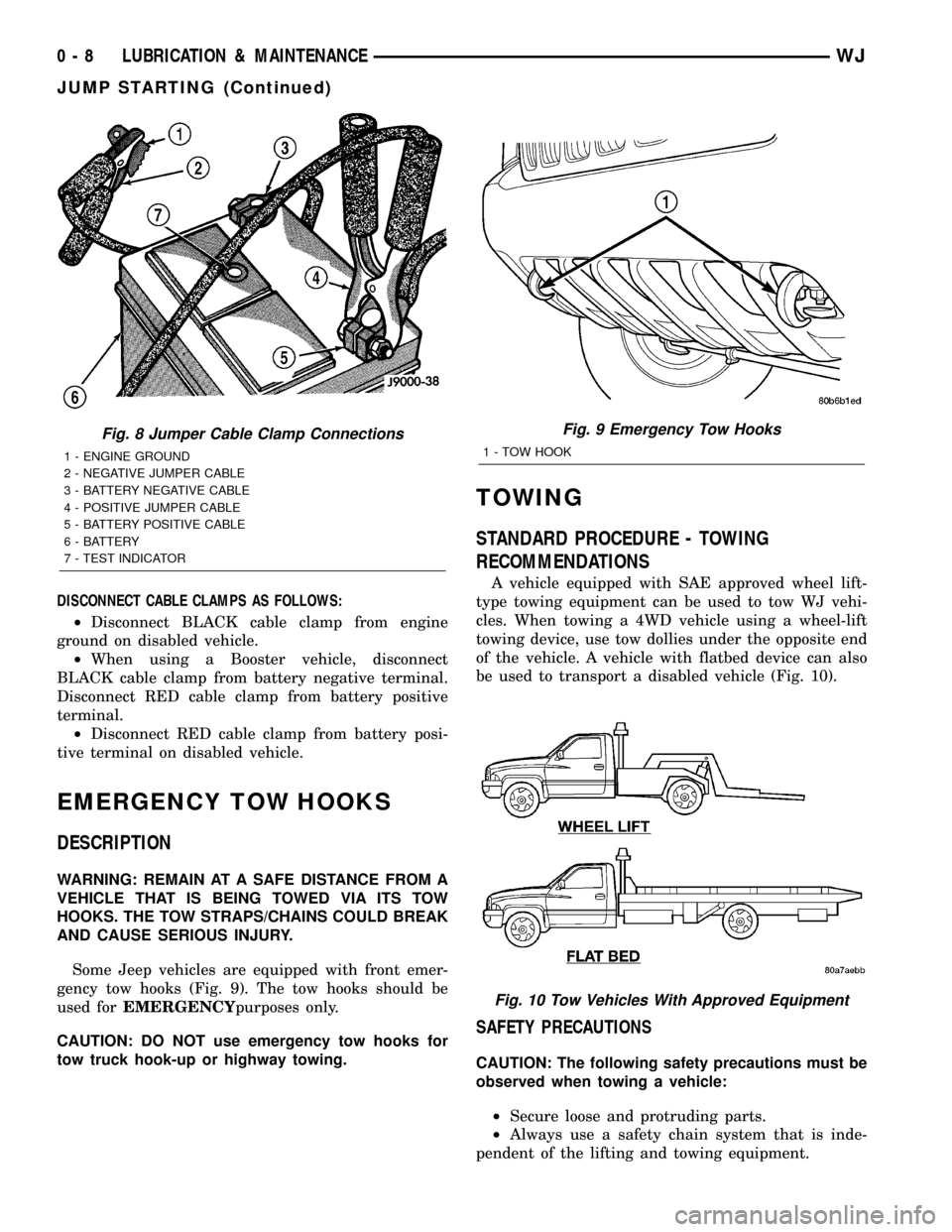

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 8).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 min.), before cranking again.

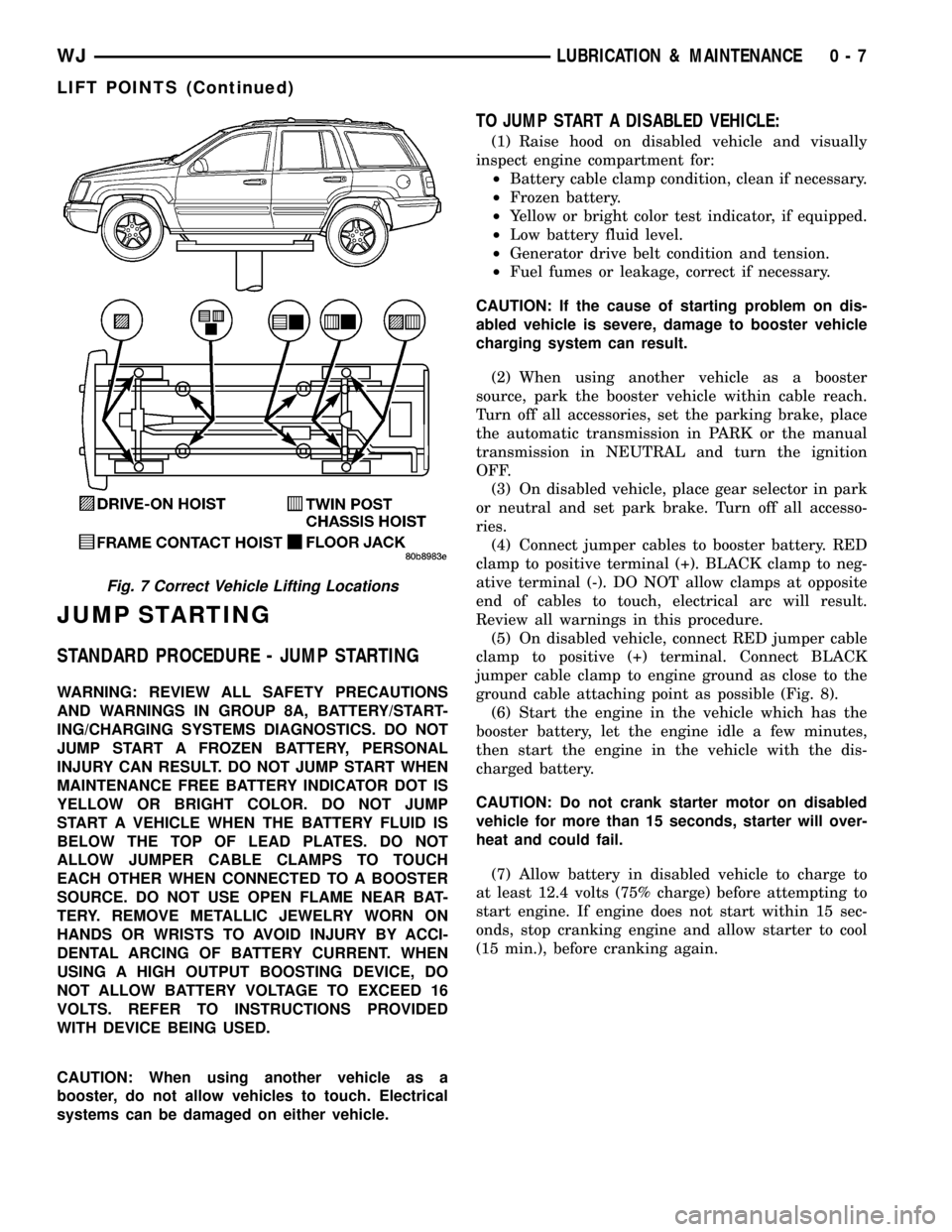

Fig. 7 Correct Vehicle Lifting Locations

WJLUBRICATION & MAINTENANCE 0 - 7

LIFT POINTS (Continued)

Page 19 of 2199

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

EMERGENCY TOW HOOKS

DESCRIPTION

WARNING: REMAIN AT A SAFE DISTANCE FROM A

VEHICLE THAT IS BEING TOWED VIA ITS TOW

HOOKS. THE TOW STRAPS/CHAINS COULD BREAK

AND CAUSE SERIOUS INJURY.

Some Jeep vehicles are equipped with front emer-

gency tow hooks (Fig. 9). The tow hooks should be

used forEMERGENCYpurposes only.

CAUTION: DO NOT use emergency tow hooks for

tow truck hook-up or highway towing.

TOWING

STANDARD PROCEDURE - TOWING

RECOMMENDATIONS

A vehicle equipped with SAE approved wheel lift-

type towing equipment can be used to tow WJ vehi-

cles. When towing a 4WD vehicle using a wheel-lift

towing device, use tow dollies under the opposite end

of the vehicle. A vehicle with flatbed device can also

be used to transport a disabled vehicle (Fig. 10).

SAFETY PRECAUTIONS

CAUTION: The following safety precautions must be

observed when towing a vehicle:

²Secure loose and protruding parts.

²Always use a safety chain system that is inde-

pendent of the lifting and towing equipment.

Fig. 8 Jumper Cable Clamp Connections

1 - ENGINE GROUND

2 - NEGATIVE JUMPER CABLE

3 - BATTERY NEGATIVE CABLE

4 - POSITIVE JUMPER CABLE

5 - BATTERY POSITIVE CABLE

6 - BATTERY

7 - TEST INDICATOR

Fig. 9 Emergency Tow Hooks

1 - TOW HOOK

Fig. 10 Tow Vehicles With Approved Equipment

0 - 8 LUBRICATION & MAINTENANCEWJ

JUMP STARTING (Continued)

Page 25 of 2199

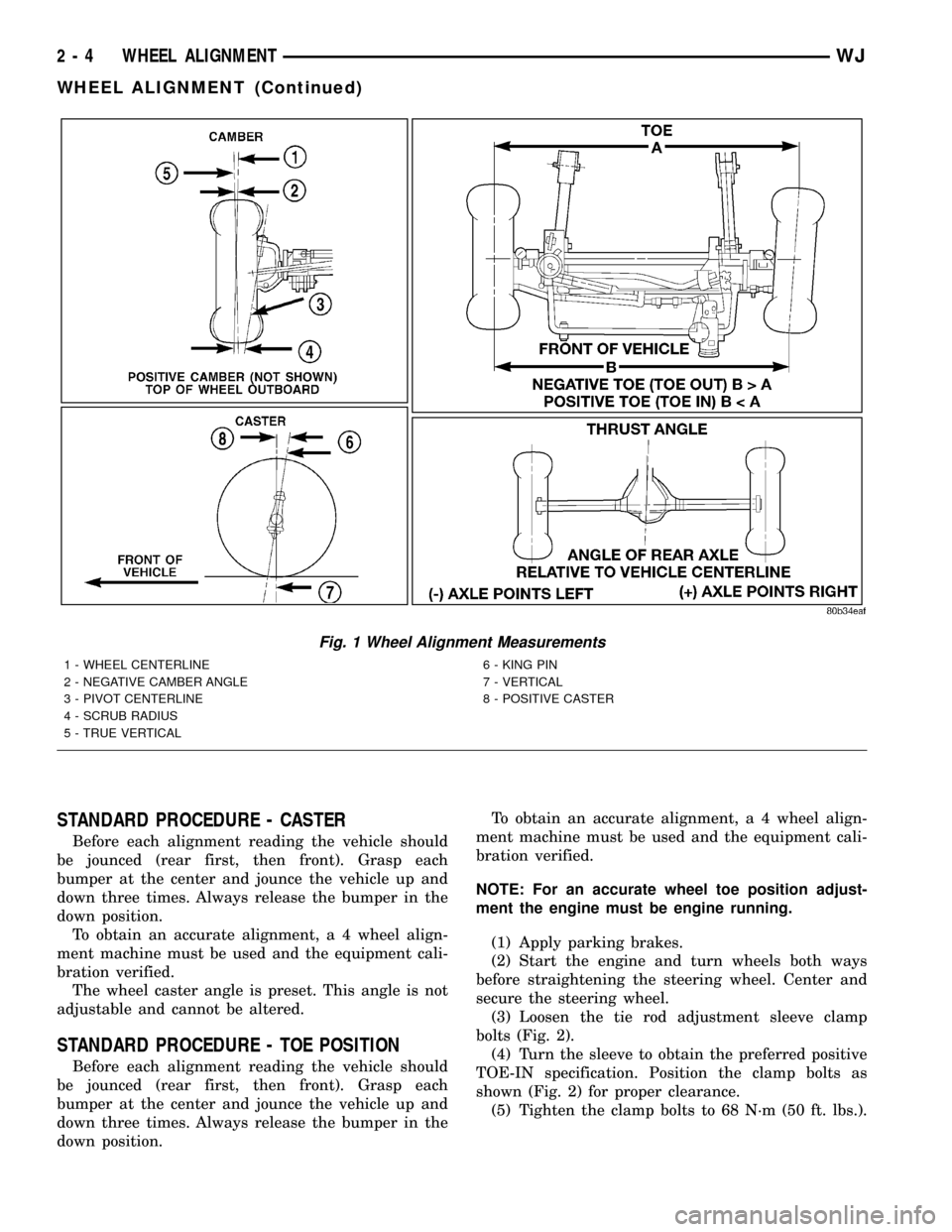

STANDARD PROCEDURE - CASTER

Before each alignment reading the vehicle should

be jounced (rear first, then front). Grasp each

bumper at the center and jounce the vehicle up and

down three times. Always release the bumper in the

down position.

To obtain an accurate alignment, a 4 wheel align-

ment machine must be used and the equipment cali-

bration verified.

The wheel caster angle is preset. This angle is not

adjustable and cannot be altered.

STANDARD PROCEDURE - TOE POSITION

Before each alignment reading the vehicle should

be jounced (rear first, then front). Grasp each

bumper at the center and jounce the vehicle up and

down three times. Always release the bumper in the

down position.To obtain an accurate alignment, a 4 wheel align-

ment machine must be used and the equipment cali-

bration verified.

NOTE: For an accurate wheel toe position adjust-

ment the engine must be engine running.

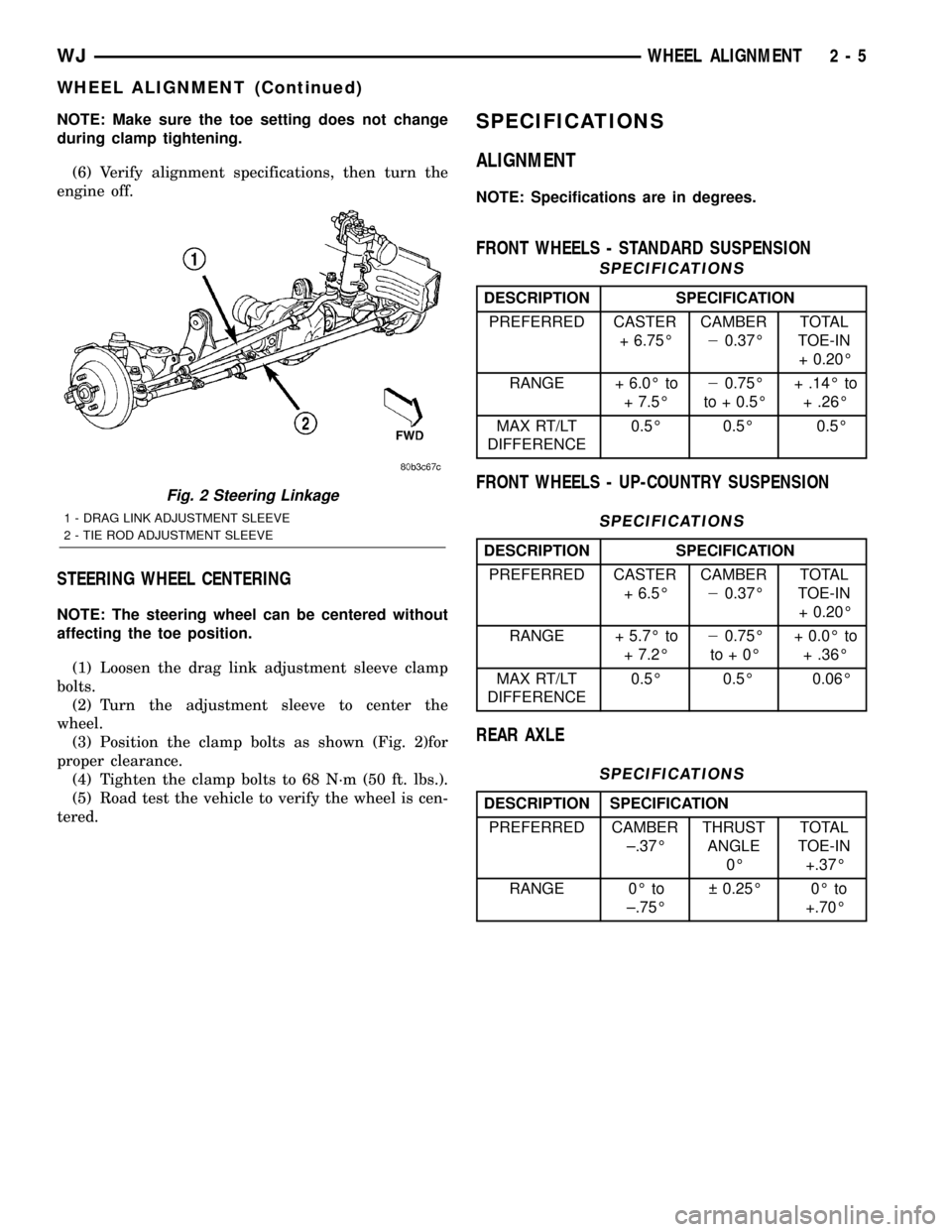

(1) Apply parking brakes.

(2) Start the engine and turn wheels both ways

before straightening the steering wheel. Center and

secure the steering wheel.

(3) Loosen the tie rod adjustment sleeve clamp

bolts (Fig. 2).

(4) Turn the sleeve to obtain the preferred positive

TOE-IN specification. Position the clamp bolts as

shown (Fig. 2) for proper clearance.

(5) Tighten the clamp bolts to 68 N´m (50 ft. lbs.).

Fig. 1 Wheel Alignment Measurements

1 - WHEEL CENTERLINE

2 - NEGATIVE CAMBER ANGLE

3 - PIVOT CENTERLINE

4 - SCRUB RADIUS

5 - TRUE VERTICAL6 - KING PIN

7 - VERTICAL

8 - POSITIVE CASTER

2 - 4 WHEEL ALIGNMENTWJ

WHEEL ALIGNMENT (Continued)

Page 26 of 2199

NOTE: Make sure the toe setting does not change

during clamp tightening.

(6) Verify alignment specifications, then turn the

engine off.

STEERING WHEEL CENTERING

NOTE: The steering wheel can be centered without

affecting the toe position.

(1) Loosen the drag link adjustment sleeve clamp

bolts.

(2) Turn the adjustment sleeve to center the

wheel.

(3) Position the clamp bolts as shown (Fig. 2)for

proper clearance.

(4) Tighten the clamp bolts to 68 N´m (50 ft. lbs.).

(5) Road test the vehicle to verify the wheel is cen-

tered.

SPECIFICATIONS

ALIGNMENT

NOTE: Specifications are in degrees.

FRONT WHEELS - STANDARD SUSPENSION

SPECIFICATIONS

DESCRIPTION SPECIFICATION

PREFERRED CASTER

+ 6.75ÉCAMBER

20.37ÉTOTAL

TOE-IN

+ 0.20É

RANGE + 6.0É to

+ 7.5É20.75É

to + 0.5É+ .14É to

+ .26É

MAX RT/LT

DIFFERENCE0.5É 0.5É 0.5É

FRONT WHEELS - UP-COUNTRY SUSPENSION

SPECIFICATIONS

DESCRIPTION SPECIFICATION

PREFERRED CASTER

+ 6.5ÉCAMBER

20.37ÉTOTAL

TOE-IN

+ 0.20É

RANGE + 5.7É to

+ 7.2É20.75É

to+0É+ 0.0É to

+ .36É

MAX RT/LT

DIFFERENCE0.5É 0.5É 0.06É

REAR AXLE

SPECIFICATIONS

DESCRIPTION SPECIFICATION

PREFERRED CAMBER

±.37ÉTHRUST

ANGLE

0ÉTOTAL

TOE-IN

+.37É

RANGE 0É to

±.75É 0.25É 0É to

+.70É

Fig. 2 Steering Linkage

1 - DRAG LINK ADJUSTMENT SLEEVE

2 - TIE ROD ADJUSTMENT SLEEVE

WJWHEEL ALIGNMENT 2 - 5

WHEEL ALIGNMENT (Continued)

Page 33 of 2199

SHOCK

DESCRIPTION

The top of the shock absorbers are bolted to the

body. The bottom of the shocks are bolted to the axle

brackets. The standard shocks have conventional

twin tube construction and are low pressure gas

charged. Gas charging prevents cavitation during

rough road operation. Up-Country shocks are mono

tube design and are high pressure gas charged.

OPERATION

The shock absorbers dampen jounce and rebound

motion of the vehicle over various road conditions

and limit suspension rebound travel.

REMOVAL

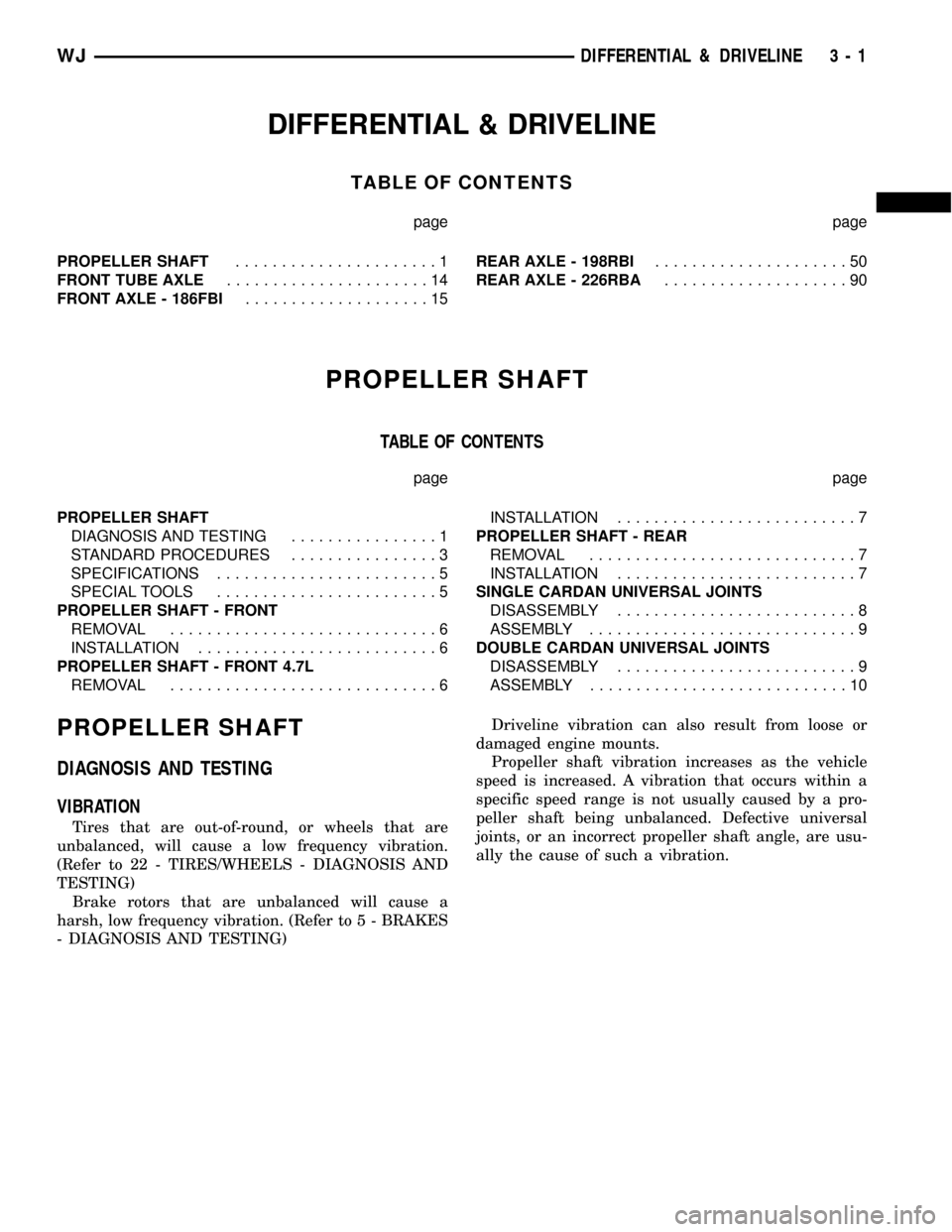

(1) Remove the nut, retainer and grommet from

the shock stud in the engine compartment (Fig. 8).

(2) Raise and support the front axle.

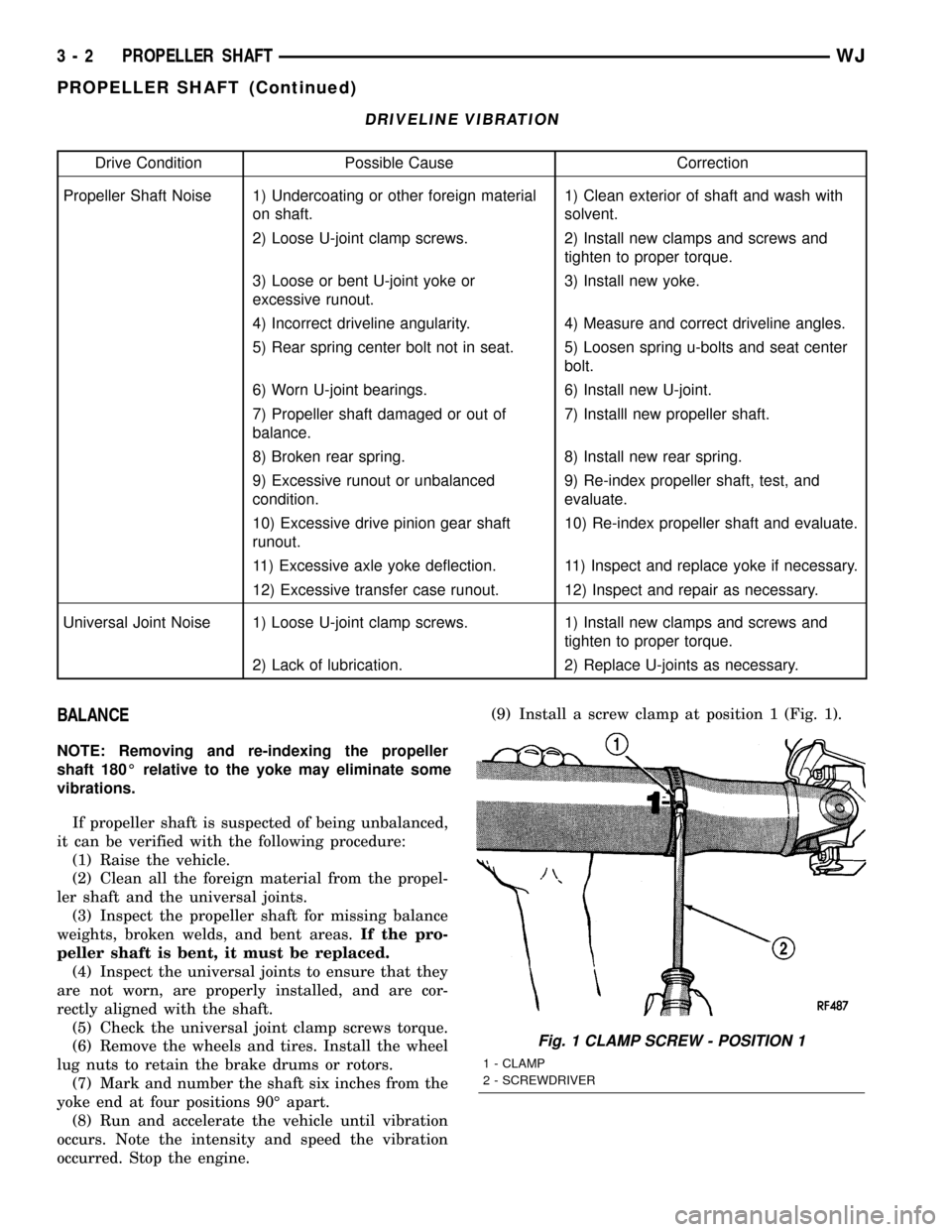

(3) Remove the lower mounting nuts from the axle

bracket (Fig. 9). Remove the shock absorber.

INSTALLATION

(1) Position the lower retainer and grommet on the

shock stud. Insert the shock absorber through the

shock tower hole.

(2) Install the lower shock studs into the axle

bracket.

(3) Install the mounting nuts and tighten to 28

N´m (250 in. lbs.).

(4) Remove support and lower the vehicle.(5) Install the upper grommet, retainer and nut on

the stud in the engine compartment. Hold the shock

stud witha8mmwrench and tighten the nut to 35

N´m (26 ft. lbs.).SPRING

DESCRIPTION

The coil springs mount up in the wheelhouse which

is part of the unitized body bracket. A rubber dough-

nut isolator is located between the top of the spring

and the body. The bottom of the spring seats on a

axle isolator made of rubber with a steel insert.

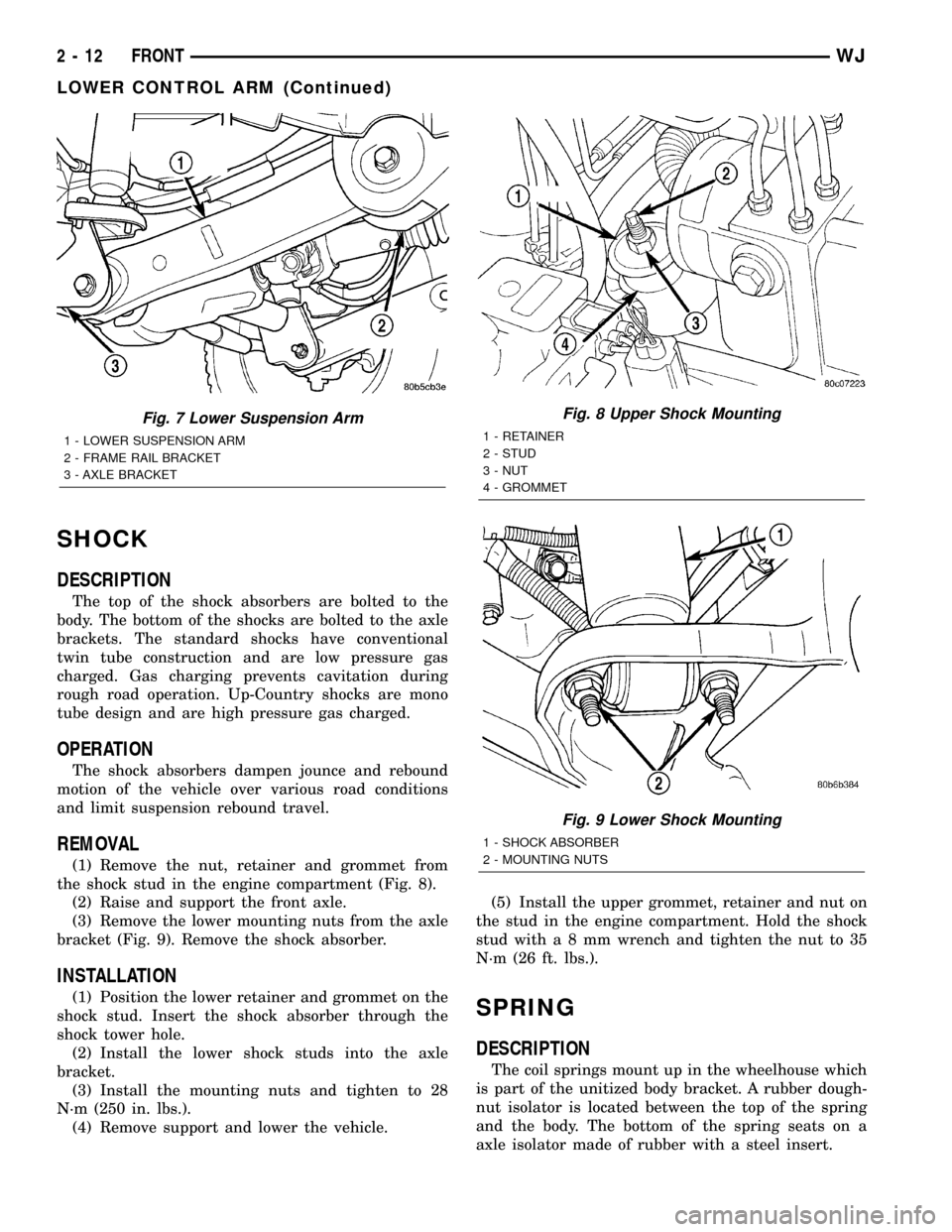

Fig. 7 Lower Suspension Arm

1 - LOWER SUSPENSION ARM

2 - FRAME RAIL BRACKET

3 - AXLE BRACKET

Fig. 8 Upper Shock Mounting

1 - RETAINER

2 - STUD

3 - NUT

4 - GROMMET

Fig. 9 Lower Shock Mounting

1 - SHOCK ABSORBER

2 - MOUNTING NUTS

2 - 12 FRONTWJ

LOWER CONTROL ARM (Continued)

Page 46 of 2199

DIFFERENTIAL & DRIVELINE

TABLE OF CONTENTS

page page

PROPELLER SHAFT......................1

FRONT TUBE AXLE......................14

FRONT AXLE - 186FBI....................15REAR AXLE - 198RBI.....................50

REAR AXLE - 226RBA....................90

PROPELLER SHAFT

TABLE OF CONTENTS

page page

PROPELLER SHAFT

DIAGNOSIS AND TESTING................1

STANDARD PROCEDURES................3

SPECIFICATIONS........................5

SPECIAL TOOLS........................5

PROPELLER SHAFT - FRONT

REMOVAL.............................6

INSTALLATION..........................6

PROPELLER SHAFT - FRONT 4.7L

REMOVAL.............................6INSTALLATION..........................7

PROPELLER SHAFT - REAR

REMOVAL.............................7

INSTALLATION..........................7

SINGLE CARDAN UNIVERSAL JOINTS

DISASSEMBLY..........................8

ASSEMBLY.............................9

DOUBLE CARDAN UNIVERSAL JOINTS

DISASSEMBLY..........................9

ASSEMBLY............................10

PROPELLER SHAFT

DIAGNOSIS AND TESTING

VIBRATION

Tires that are out-of-round, or wheels that are

unbalanced, will cause a low frequency vibration.

(Refer to 22 - TIRES/WHEELS - DIAGNOSIS AND

TESTING)

Brake rotors that are unbalanced will cause a

harsh, low frequency vibration. (Refer to 5 - BRAKES

- DIAGNOSIS AND TESTING)Driveline vibration can also result from loose or

damaged engine mounts.

Propeller shaft vibration increases as the vehicle

speed is increased. A vibration that occurs within a

specific speed range is not usually caused by a pro-

peller shaft being unbalanced. Defective universal

joints, or an incorrect propeller shaft angle, are usu-

ally the cause of such a vibration.

WJDIFFERENTIAL & DRIVELINE 3 - 1

Page 47 of 2199

DRIVELINE VIBRATION

Drive Condition Possible Cause Correction

Propeller Shaft Noise 1) Undercoating or other foreign material

on shaft.1) Clean exterior of shaft and wash with

solvent.

2) Loose U-joint clamp screws. 2) Install new clamps and screws and

tighten to proper torque.

3) Loose or bent U-joint yoke or

excessive runout.3) Install new yoke.

4) Incorrect driveline angularity. 4) Measure and correct driveline angles.

5) Rear spring center bolt not in seat. 5) Loosen spring u-bolts and seat center

bolt.

6) Worn U-joint bearings. 6) Install new U-joint.

7) Propeller shaft damaged or out of

balance.7) Installl new propeller shaft.

8) Broken rear spring. 8) Install new rear spring.

9) Excessive runout or unbalanced

condition.9) Re-index propeller shaft, test, and

evaluate.

10) Excessive drive pinion gear shaft

runout.10) Re-index propeller shaft and evaluate.

11) Excessive axle yoke deflection. 11) Inspect and replace yoke if necessary.

12) Excessive transfer case runout. 12) Inspect and repair as necessary.

Universal Joint Noise 1) Loose U-joint clamp screws. 1) Install new clamps and screws and

tighten to proper torque.

2) Lack of lubrication. 2) Replace U-joints as necessary.

BALANCE

NOTE: Removing and re-indexing the propeller

shaft 180É relative to the yoke may eliminate some

vibrations.

If propeller shaft is suspected of being unbalanced,

it can be verified with the following procedure:

(1) Raise the vehicle.

(2) Clean all the foreign material from the propel-

ler shaft and the universal joints.

(3) Inspect the propeller shaft for missing balance

weights, broken welds, and bent areas.If the pro-

peller shaft is bent, it must be replaced.

(4) Inspect the universal joints to ensure that they

are not worn, are properly installed, and are cor-

rectly aligned with the shaft.

(5) Check the universal joint clamp screws torque.

(6) Remove the wheels and tires. Install the wheel

lug nuts to retain the brake drums or rotors.

(7) Mark and number the shaft six inches from the

yoke end at four positions 90É apart.

(8) Run and accelerate the vehicle until vibration

occurs. Note the intensity and speed the vibration

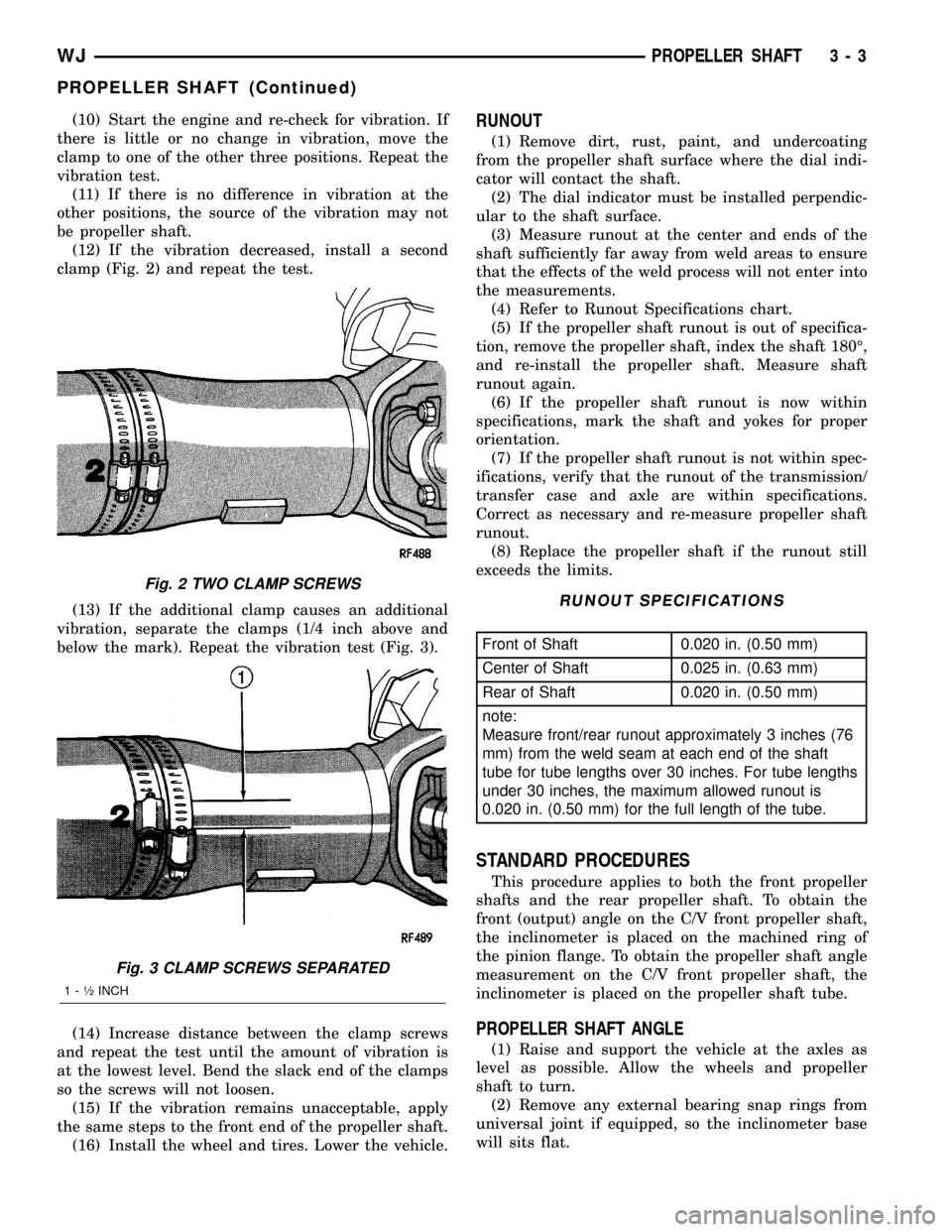

occurred. Stop the engine.(9) Install a screw clamp at position 1 (Fig. 1).

Fig. 1 CLAMP SCREW - POSITION 1

1 - CLAMP

2 - SCREWDRIVER

3 - 2 PROPELLER SHAFTWJ

PROPELLER SHAFT (Continued)

Page 48 of 2199

(10) Start the engine and re-check for vibration. If

there is little or no change in vibration, move the

clamp to one of the other three positions. Repeat the

vibration test.

(11) If there is no difference in vibration at the

other positions, the source of the vibration may not

be propeller shaft.

(12) If the vibration decreased, install a second

clamp (Fig. 2) and repeat the test.

(13) If the additional clamp causes an additional

vibration, separate the clamps (1/4 inch above and

below the mark). Repeat the vibration test (Fig. 3).

(14) Increase distance between the clamp screws

and repeat the test until the amount of vibration is

at the lowest level. Bend the slack end of the clamps

so the screws will not loosen.

(15) If the vibration remains unacceptable, apply

the same steps to the front end of the propeller shaft.

(16) Install the wheel and tires. Lower the vehicle.RUNOUT

(1) Remove dirt, rust, paint, and undercoating

from the propeller shaft surface where the dial indi-

cator will contact the shaft.

(2) The dial indicator must be installed perpendic-

ular to the shaft surface.

(3) Measure runout at the center and ends of the

shaft sufficiently far away from weld areas to ensure

that the effects of the weld process will not enter into

the measurements.

(4) Refer to Runout Specifications chart.

(5) If the propeller shaft runout is out of specifica-

tion, remove the propeller shaft, index the shaft 180É,

and re-install the propeller shaft. Measure shaft

runout again.

(6) If the propeller shaft runout is now within

specifications, mark the shaft and yokes for proper

orientation.

(7) If the propeller shaft runout is not within spec-

ifications, verify that the runout of the transmission/

transfer case and axle are within specifications.

Correct as necessary and re-measure propeller shaft

runout.

(8) Replace the propeller shaft if the runout still

exceeds the limits.

RUNOUT SPECIFICATIONS

Front of Shaft 0.020 in. (0.50 mm)

Center of Shaft 0.025 in. (0.63 mm)

Rear of Shaft 0.020 in. (0.50 mm)

note:

Measure front/rear runout approximately 3 inches (76

mm) from the weld seam at each end of the shaft

tube for tube lengths over 30 inches. For tube lengths

under 30 inches, the maximum allowed runout is

0.020 in. (0.50 mm) for the full length of the tube.

STANDARD PROCEDURES

This procedure applies to both the front propeller

shafts and the rear propeller shaft. To obtain the

front (output) angle on the C/V front propeller shaft,

the inclinometer is placed on the machined ring of

the pinion flange. To obtain the propeller shaft angle

measurement on the C/V front propeller shaft, the

inclinometer is placed on the propeller shaft tube.

PROPELLER SHAFT ANGLE

(1) Raise and support the vehicle at the axles as

level as possible. Allow the wheels and propeller

shaft to turn.

(2) Remove any external bearing snap rings from

universal joint if equipped, so the inclinometer base

will sits flat.

Fig. 2 TWO CLAMP SCREWS

Fig. 3 CLAMP SCREWS SEPARATED

1 - ó INCH

WJPROPELLER SHAFT 3 - 3

PROPELLER SHAFT (Continued)

Page 60 of 2199

FRONT AXLE - 186FBI

TABLE OF CONTENTS

page page

FRONT AXLE - 186FBI

DESCRIPTION.........................15

OPERATION...........................15

DIAGNOSIS AND TESTING................16

REMOVAL.............................20

INSTALLATION.........................21

ADJUSTMENTS........................21

SPECIFICATIONS.......................30

SPECIAL TOOLS.......................31

AXLE SHAFTS

REMOVAL.............................34

INSTALLATION.........................34

AXLE SHAFT SEALS

REMOVAL.............................35

INSTALLATION.........................35

AXLE - C/V JOINT

REMOVAL.............................35

INSTALLATION.........................35

AXLE - U-JOINT

REMOVAL.............................36INSTALLATION.........................37

PINION SEAL

REMOVAL.............................37

INSTALLATION.........................37

COLLAPSIBLE SPACER

REMOVAL.............................39

INSTALLATION.........................39

DIFFERENTIAL

REMOVAL.............................40

DISASSEMBLY.........................42

ASSEMBLY............................42

INSTALLATION.........................43

DIFFERENTIAL CASE BEARINGS

REMOVAL.............................44

INSTALLATION.........................44

PINION GEAR/RING GEAR

REMOVAL.............................45

INSTALLATION.........................46

FRONT AXLE - 186FBI

DESCRIPTION

The Front Beam-design Iron (FBI) axle consists of

a cast iron differential housing with axle shaft tubes

extending from either side. The tubes are pressed

into the differential housing and welded. The axles

are semi-floating axle shafts, meaning the loads are

supported by the hub bearings. The axle shafts are

retained by nuts at the hub bearings.

The differential case is a one-piece design. Differ-

ential bearing preload and ring gear backlash is

adjusted by the use of shims located between the dif-

ferential bearing cups and housing. Pinion bearing

preload is set and maintained by the use of a collaps-

ible spacer. A differential cover provides a means for

inspection and servicing.

An optional Vari-Loktdifferential has a one-piece

differential case which contains the gerotor pump

assembly and the clutch mechinism. This unit is ser-

viced as an assembly.

OPERATION

The axle receives power from the transfer case

through the front propeller shaft. The front propeller

shaft is connected to the pinion gear which rotatesthe differential through the gear mesh with the ring

gear bolted to the differential case. The engine power

is transmitted to the axle shafts through the pinion

mate and side gears. The side gears are splined to

the axle shafts.

STANDARD DIFFERENTIAL

During straight-ahead driving, the differential pinion

gears do not rotate on the pinion mate shaft. This

occurs because input torque applied to the gears is

divided and distributed equally between the two side

gears. As a result, the pinion gears revolve with the pin-

ion mate shaft but do not rotate around it (Fig. 1).

When turning corners, the outside wheel must

travel a greater distance than the inside wheel to

complete a turn. The difference must be compensated

for to prevent the tires from scuffing and skidding

through turns. To accomplish this, the differential

allows the axle shafts to turn at unequal speeds (Fig.

2). In this instance, the input torque applied to the

pinion gears is not divided equally. The pinion gears

now rotate around the pinion mate shaft in opposite

directions. This allows the side gear and axle shaft

attached to the outside wheel to rotate at a faster

speed.

WJFRONT AXLE - 186FBI 3 - 15

Page 62 of 2199

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining or a growling sound.

Pinion bearings have a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Worn or damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing noise. The pitch of differen-

tial bearing noise is also constant and varies only

with vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side-gear thrust washers. A worn

pinion shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).²Worn or out-of-balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front±end components

or engine/transmission mounts. These components

can contribute to what appears to be a rear-end

vibration. Do not overlook engine accessories, brack-

ets and drive belts.

All driveline components should be examined

before starting any repair.

(Refer to 22 - TIRES/WHEELS - DIAGNOSIS AND

TESTING)

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear. Listen

for the noise, a mechanics stethoscope is helpful in

isolating the source of a noise.

WJFRONT AXLE - 186FBI 3 - 17

FRONT AXLE - 186FBI (Continued)