light JEEP GRAND CHEROKEE 2003 WJ / 2.G Workshop Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 5 of 2199

FASTENER USAGE

DESCRIPTION - FASTENER USAGE

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Fasteners and torque specifications references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

THREADED HOLE REPAIR

DESCRIPTION - THREADED HOLE REPAIR

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

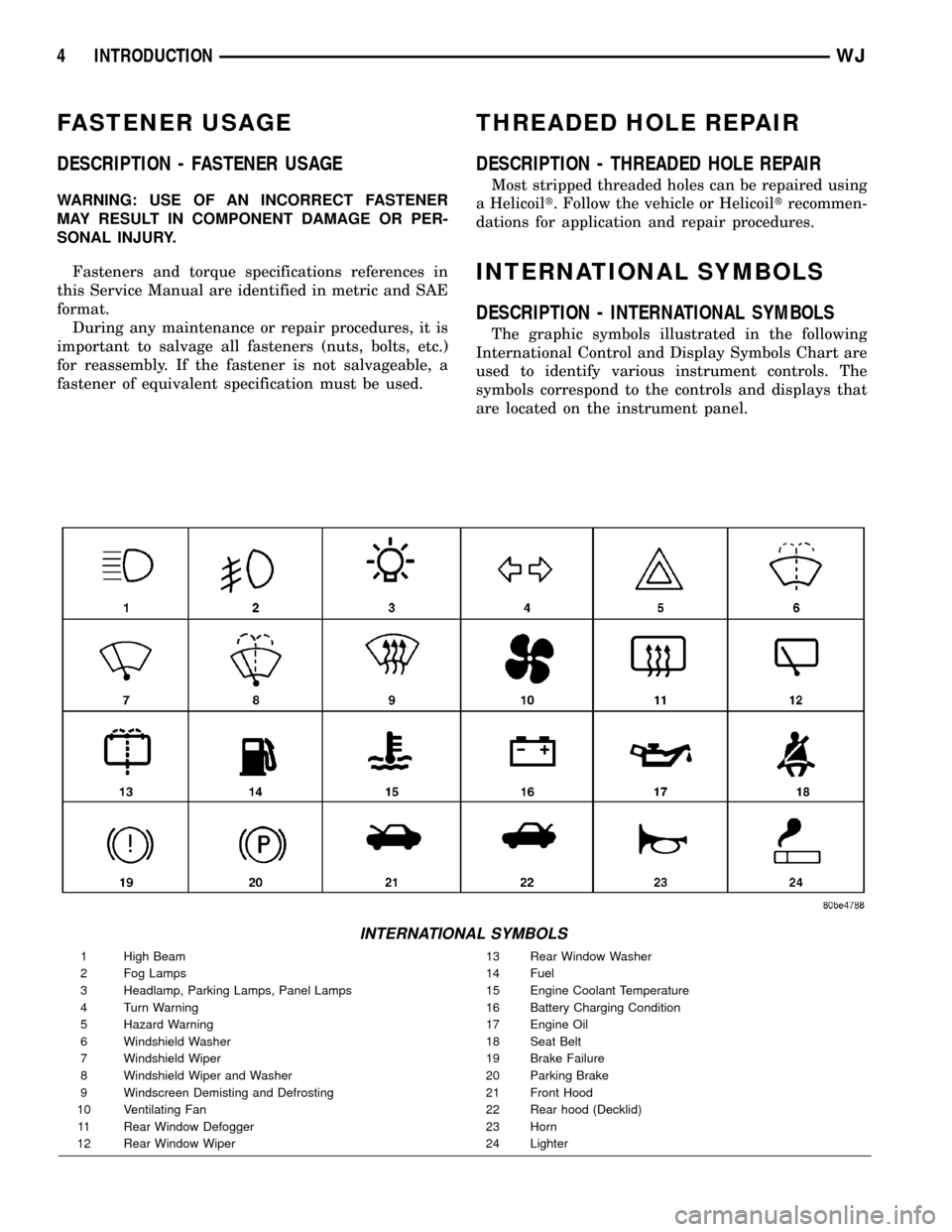

INTERNATIONAL SYMBOLS

DESCRIPTION - INTERNATIONAL SYMBOLS

The graphic symbols illustrated in the following

International Control and Display Symbols Chart are

used to identify various instrument controls. The

symbols correspond to the controls and displays that

are located on the instrument panel.

INTERNATIONAL SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

4 INTRODUCTIONWJ

Page 61 of 2199

VARI-LOKTDIFFERENTIAL

In a standard differential if one wheel spins, the

opposite wheel will generate only as much torque as

the spinning wheel.

A gerotor pump and clutch pack are used to pro-

vide the torque transfer capability. One axle shaft is

splined to the gerotor pump and one of the differen-

tial side gears, which provides the input to the pump.

As a wheel begins to lose traction, the speed differ-

ential is transmitted from one side of the differential

to the other through the side gears. The motion of

one side gear relative to the other turns the inner

rotor of the pump. Since the outer rotor of the pump

is grounded to the differential case, the inner and

outer rotors are now moving relative to each other

and therefore creates pressure in the pump. The tun-ing of the front and rear axle orifices and valves

inside the gerotor pump is unique and each system

includes a torque-limiting pressure relief valve to

protect the clutch pack, which also facilitates vehicle

control under extreme side-to-side traction varia-

tions. The resulting pressure is applied to the clutch

pack and the transfer of torque is completed.

Under conditions in which opposite wheels are on

surfaces with widely different friction characteristics,

Vari-loktdelivers far more torque to the wheel on

the higher traction surface than do conventional

Trac-loktsystems. Because conventional Trac-lokt

differentials are initially pre-loaded to assure torque

transfer, normal driving (where inner and outer

wheel speeds differ during cornering, etc.) produces

torque transfer during even slight side-to-side speed

variations. Since these devices rely on friction from

this preload to transfer torque, normal use tends to

cause wear that reduces the ability of the differential

to transfer torque over time. By design, the Vari-lokt

system is less subject to wear, remaining more con-

sistent over time in its ability to transfer torque. The

coupling assembly is serviced as a unit. From a ser-

vice standpoint the coupling also benefits from using

the same lubricant supply as the ring and pinion

gears.

DIAGNOSIS AND TESTING

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant, incorrect backlash, tooth contact, worn/damaged

gears or the carrier housing not having the proper

offset and squareness.

Gear noise usually happens at a specific speed

range. The noise can also occur during a specific type

of driving condition. These conditions are accelera-

tion, deceleration, coast or constant load.

When road testing, first warm-up the axle fluid by

driving the vehicle at least 5 miles and then acceler-

ate the vehicle to the speed range where the noise is

the greatest. Shift out-of-gear and coast through the

peak-noise range. If the noise stops or changes

greatly:

²Check for insufficient lubricant.

²Incorrect ring gear backlash.

²Gear damage.

Differential side gears and pinions can be checked

by turning the vehicle. They usually do not cause

noise during straight-ahead driving when the gears

are unloaded. The side gears are loaded during vehi-

cle turns. A worn pinion mate shaft can also cause a

snapping or a knocking noise.

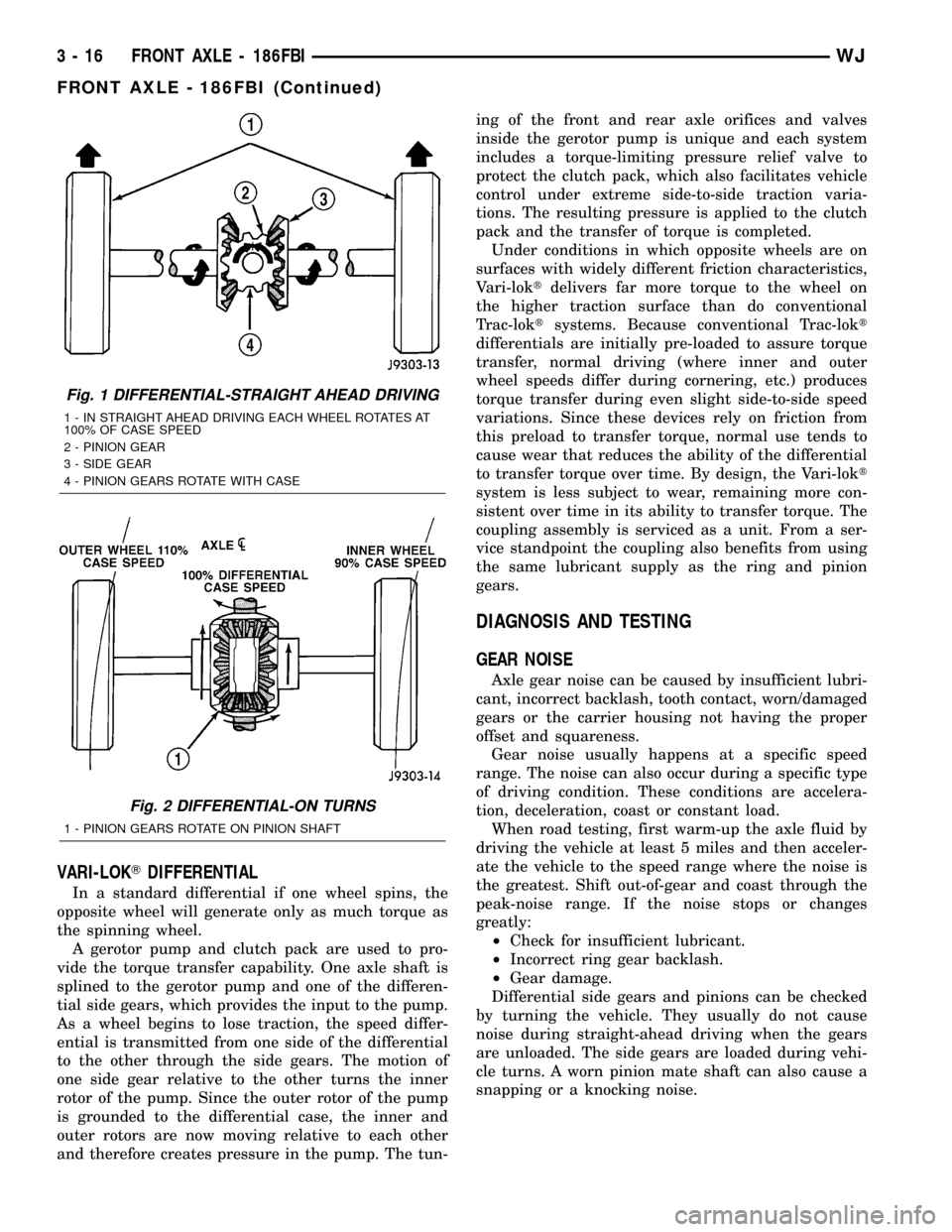

Fig. 1 DIFFERENTIAL-STRAIGHT AHEAD DRIVING

1 - IN STRAIGHT AHEAD DRIVING EACH WHEEL ROTATES AT

100% OF CASE SPEED

2 - PINION GEAR

3 - SIDE GEAR

4 - PINION GEARS ROTATE WITH CASE

Fig. 2 DIFFERENTIAL-ON TURNS

1 - PINION GEARS ROTATE ON PINION SHAFT

3 - 16 FRONT AXLE - 186FBIWJ

FRONT AXLE - 186FBI (Continued)

Page 62 of 2199

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining or a growling sound.

Pinion bearings have a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Worn or damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing noise. The pitch of differen-

tial bearing noise is also constant and varies only

with vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side-gear thrust washers. A worn

pinion shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).²Worn or out-of-balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front±end components

or engine/transmission mounts. These components

can contribute to what appears to be a rear-end

vibration. Do not overlook engine accessories, brack-

ets and drive belts.

All driveline components should be examined

before starting any repair.

(Refer to 22 - TIRES/WHEELS - DIAGNOSIS AND

TESTING)

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear. Listen

for the noise, a mechanics stethoscope is helpful in

isolating the source of a noise.

WJFRONT AXLE - 186FBI 3 - 17

FRONT AXLE - 186FBI (Continued)

Page 82 of 2199

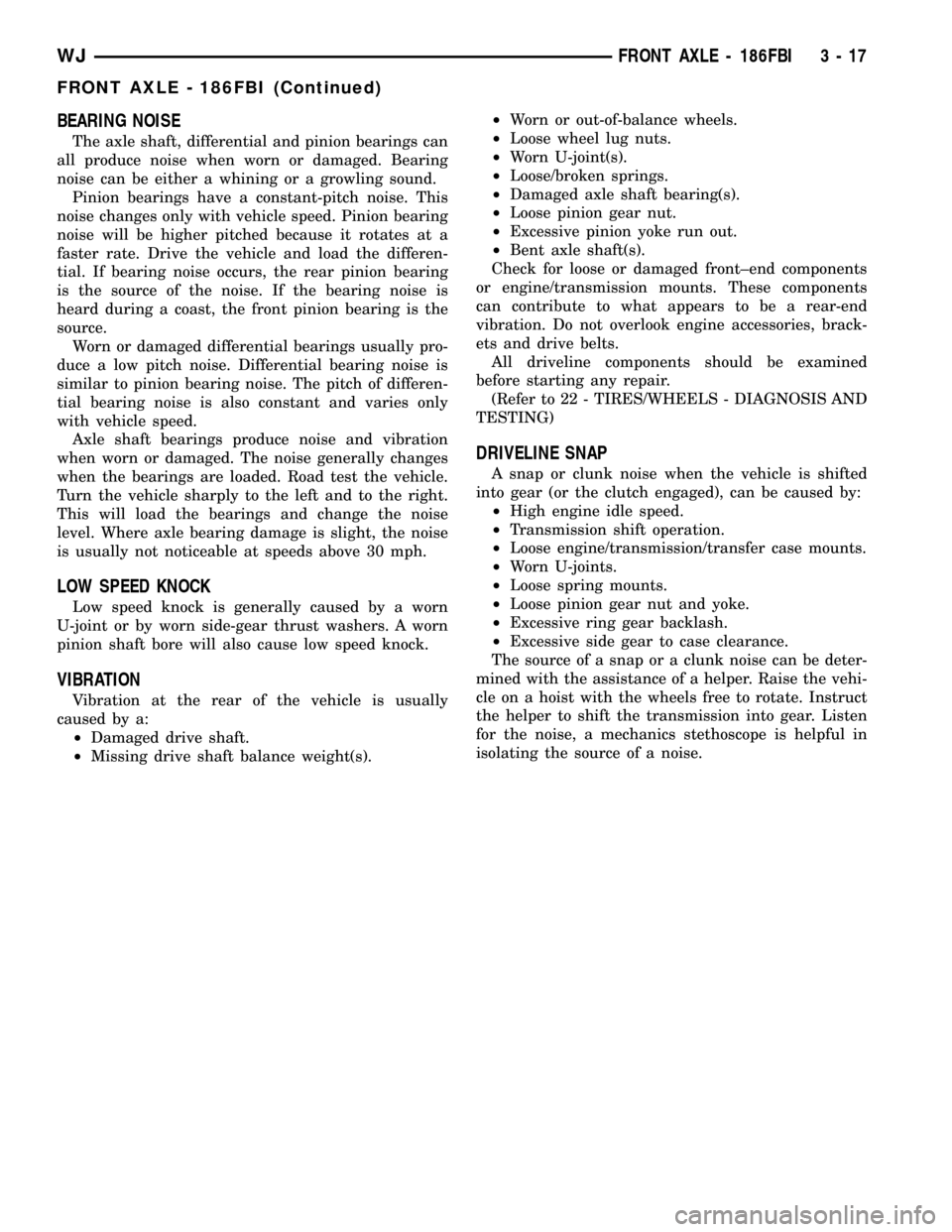

INSTALLATION

(1) Pack the bearing caps 1/3 full of wheel bearing

lubricant. Apply extreme pressure (EP), lithium-base

lubricant to aid in installation.

(2) Position the spider in the yoke. Insert the seals

and bearings, then tap bearing caps into the yoke

bores far enough to hold the spider in position.

(3) Place the socket (driver) against one bearing

cap. Position the yoke with the socket in a vise.

(4) Tighten the vise to force the bearing caps into

the yoke. Force the caps enough to install the retain-

ing clips.

(5) Install the bearing cap retaining clips.

(6) Install axle shaft.

PINION SEAL

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Remove brake rotors and calipers, refer to 5

Brakes for procedures.

(4) Mark propeller shaft and pinion companion

flange for installation reference.

(5) Remove the propeller shaft from the pinion

companion flange.

(6) Rotate the pinion gear a minimum of ten times

and verify the pinion rotates smoothly.

(7) Record torque necessary to rotate the pinion

gear with a inch pound torque wrench.

(8) Using a short piece of pipe and Spanner

Wrench 6958 to hold the pinion companion flange

and remove the pinion nut and washer.

(9) Remove pinion companion flange with Remover

C-452 and Flange Wrench C-3281.

(10) Remove pinion seal with Remover 7794-A and

a slide hammer (Fig. 31).

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal. Install seal with an appropriate

installer (Fig. 32).

(2) Install pinion companion flange on the pinion

gear with Installer W-162-D, Cup 8109 and Wrench

6958.

CAUTION: Never exceed the minimum tightening

torque 298 N´m (220 ft. lbs.) while installing pinion

nut at this point. Damage to collapsible spacer or

bearings may result.

(3) Install the pinion washer and anewnut on

the pinion gear.Tighten the nut only enough to

remove the shaft end play.

Fig. 29 AXLE SHAFT OUTER U-JOINT

1 - SHAFT YOKE

2 - BEARING CAP

3 - SNAP RINGS

4 - BEARING CAP

5 - SPINDLE YOKE

6 - BEARING

7 - BEARING CAP

8 - SNAP RINGS

9 - BEARING CAP

Fig. 30 YOKE BEARING CAP

1 - LARGE-DIAMETER SOCKET

2 - VISE

3 - SMALL-DIAMETER SOCKET

WJFRONT AXLE - 186FBI 3 - 37

AXLE - U-JOINT (Continued)

Page 84 of 2199

(6) Install propeller shaft with installation refer-

ence marks aligned.

(7) Fill differential with gear lubricant.

(8) Install brake rotors and calipers.

(9) Install wheel and tire assemblies.

(10) Lower the vehicle.

COLLAPSIBLE SPACER

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Remove brake rotors and calipers. Refer to 5

Brakes for procedures.

(4) Mark the propeller shaft and pinion companion

flange for installation reference.

(5) Remove propeller shaft from the pinion com-

panion flange.

(6) Rotate pinion gear a minimum of ten times and

verify pinion rotates smoothly.

(7) Record pinion gear rotating torque with a

torque wrench for installation reference.

(8) Remove pinion nut and washer. Using a short

piece of pipe and Spanner Wrench 6958 to hold the

pinion companion flange.

(9) Remove pinion companion flange with Remover

C-452 and Flange Wrench C-3281.

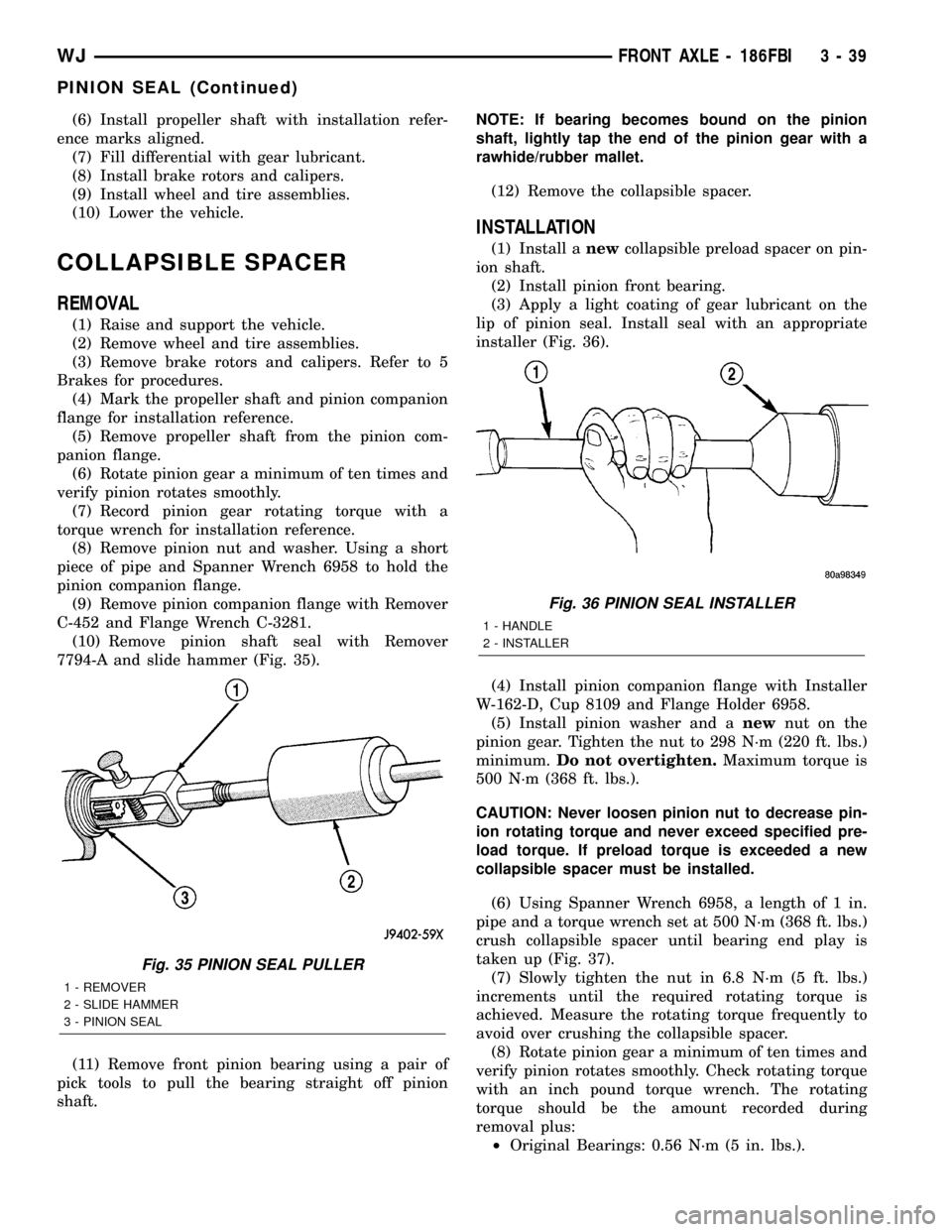

(10) Remove pinion shaft seal with Remover

7794-A and slide hammer (Fig. 35).

(11) Remove front pinion bearing using a pair of

pick tools to pull the bearing straight off pinion

shaft.NOTE: If bearing becomes bound on the pinion

shaft, lightly tap the end of the pinion gear with a

rawhide/rubber mallet.

(12) Remove the collapsible spacer.

INSTALLATION

(1) Install anewcollapsible preload spacer on pin-

ion shaft.

(2) Install pinion front bearing.

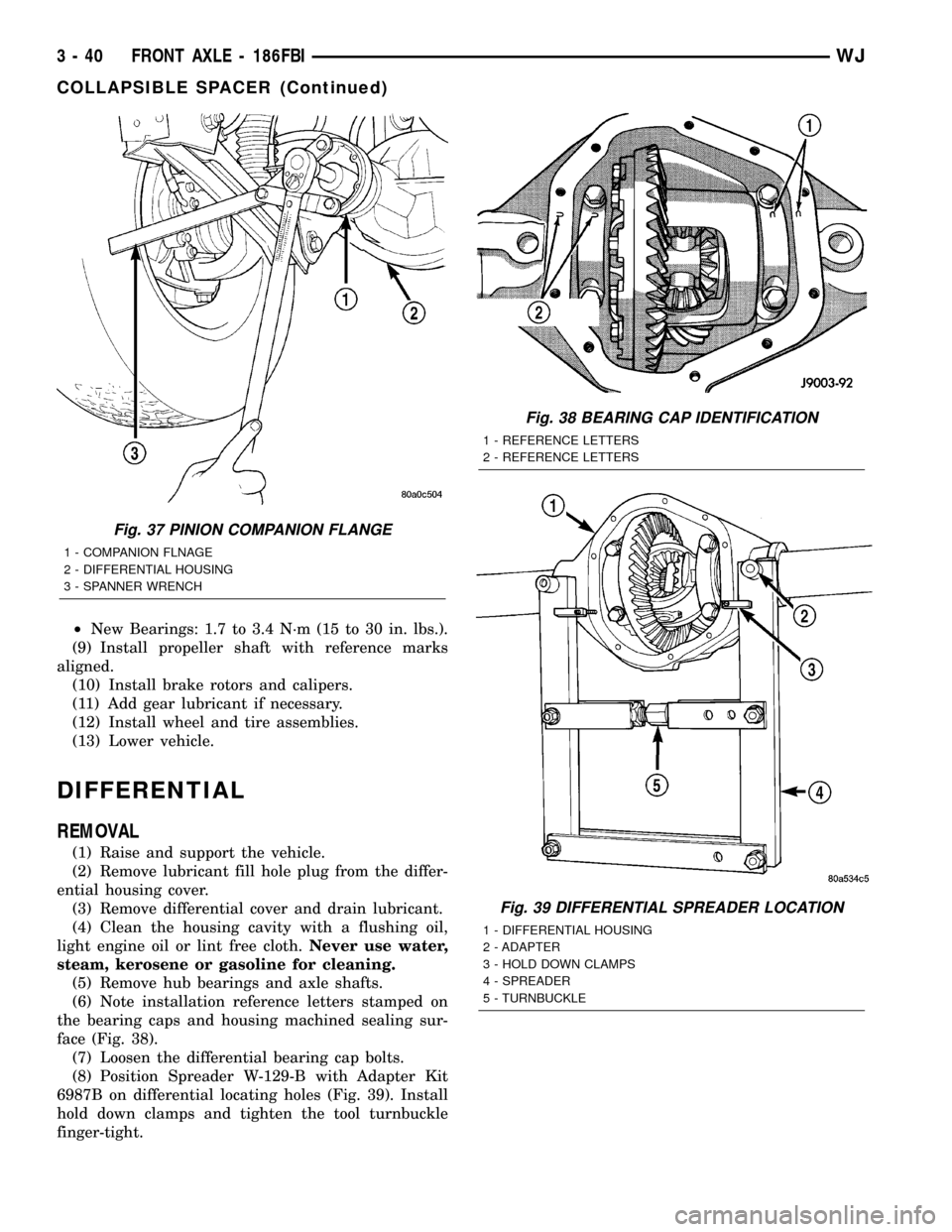

(3) Apply a light coating of gear lubricant on the

lip of pinion seal. Install seal with an appropriate

installer (Fig. 36).

(4) Install pinion companion flange with Installer

W-162-D, Cup 8109 and Flange Holder 6958.

(5) Install pinion washer and anewnut on the

pinion gear. Tighten the nut to 298 N´m (220 ft. lbs.)

minimum.Do not overtighten.Maximum torque is

500 N´m (368 ft. lbs.).

CAUTION: Never loosen pinion nut to decrease pin-

ion rotating torque and never exceed specified pre-

load torque. If preload torque is exceeded a new

collapsible spacer must be installed.

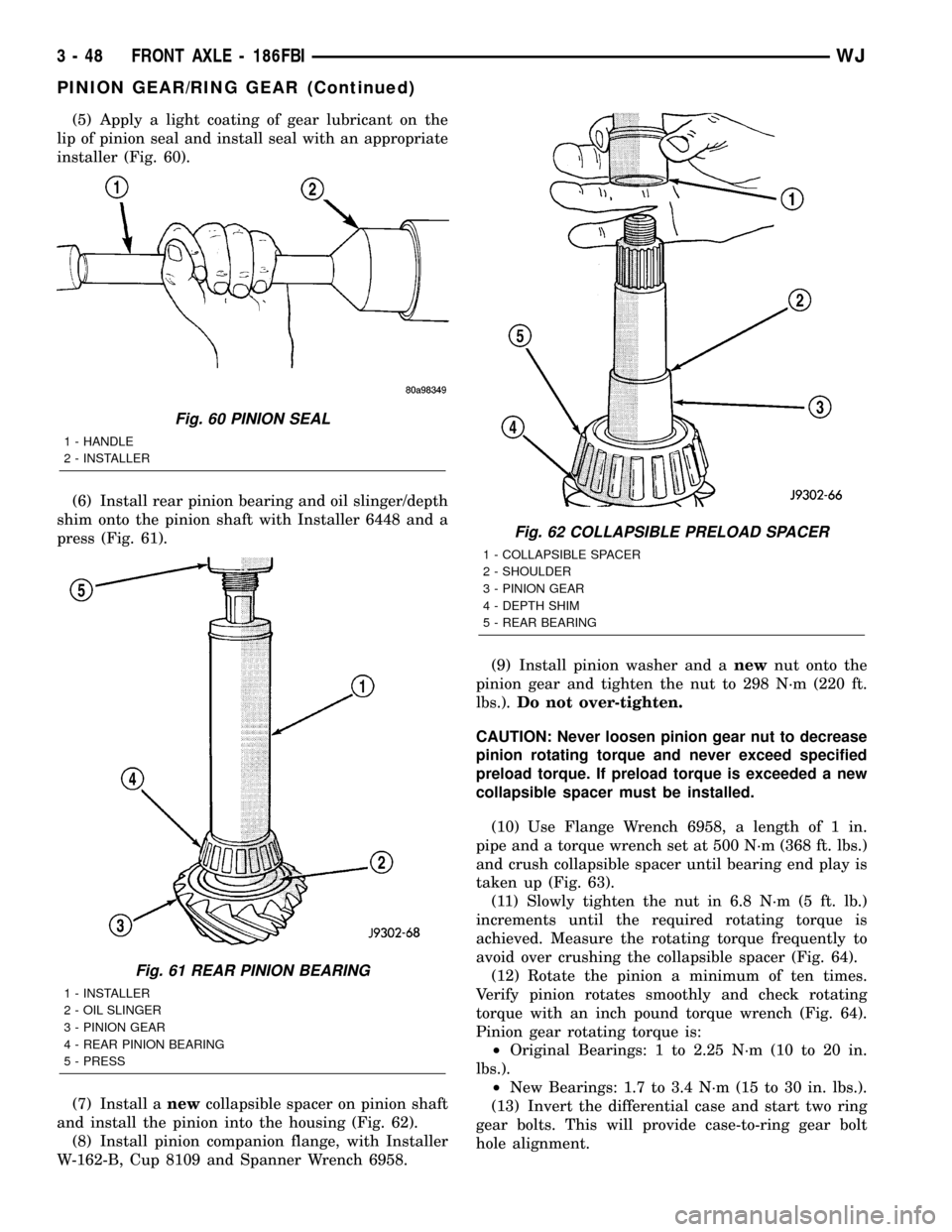

(6) Using Spanner Wrench 6958, a length of 1 in.

pipe and a torque wrench set at 500 N´m (368 ft. lbs.)

crush collapsible spacer until bearing end play is

taken up (Fig. 37).

(7) Slowly tighten the nut in 6.8 N´m (5 ft. lbs.)

increments until the required rotating torque is

achieved. Measure the rotating torque frequently to

avoid over crushing the collapsible spacer.

(8) Rotate pinion gear a minimum of ten times and

verify pinion rotates smoothly. Check rotating torque

with an inch pound torque wrench. The rotating

torque should be the amount recorded during

removal plus:

²Original Bearings: 0.56 N´m (5 in. lbs.).

Fig. 35 PINION SEAL PULLER

1 - REMOVER

2 - SLIDE HAMMER

3 - PINION SEAL

Fig. 36 PINION SEAL INSTALLER

1 - HANDLE

2 - INSTALLER

WJFRONT AXLE - 186FBI 3 - 39

PINION SEAL (Continued)

Page 85 of 2199

²New Bearings: 1.7 to 3.4 N´m (15 to 30 in. lbs.).

(9) Install propeller shaft with reference marks

aligned.

(10) Install brake rotors and calipers.

(11) Add gear lubricant if necessary.

(12) Install wheel and tire assemblies.

(13) Lower vehicle.

DIFFERENTIAL

REMOVAL

(1) Raise and support the vehicle.

(2) Remove lubricant fill hole plug from the differ-

ential housing cover.

(3) Remove differential cover and drain lubricant.

(4) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.Never use water,

steam, kerosene or gasoline for cleaning.

(5) Remove hub bearings and axle shafts.

(6) Note installation reference letters stamped on

the bearing caps and housing machined sealing sur-

face (Fig. 38).

(7) Loosen the differential bearing cap bolts.

(8) Position Spreader W-129-B with Adapter Kit

6987B on differential locating holes (Fig. 39). Install

hold down clamps and tighten the tool turnbuckle

finger-tight.

Fig. 37 PINION COMPANION FLANGE

1 - COMPANION FLNAGE

2 - DIFFERENTIAL HOUSING

3 - SPANNER WRENCH

Fig. 38 BEARING CAP IDENTIFICATION

1 - REFERENCE LETTERS

2 - REFERENCE LETTERS

Fig. 39 DIFFERENTIAL SPREADER LOCATION

1 - DIFFERENTIAL HOUSING

2 - ADAPTER

3 - HOLD DOWN CLAMPS

4 - SPREADER

5 - TURNBUCKLE

3 - 40 FRONT AXLE - 186FBIWJ

COLLAPSIBLE SPACER (Continued)

Page 93 of 2199

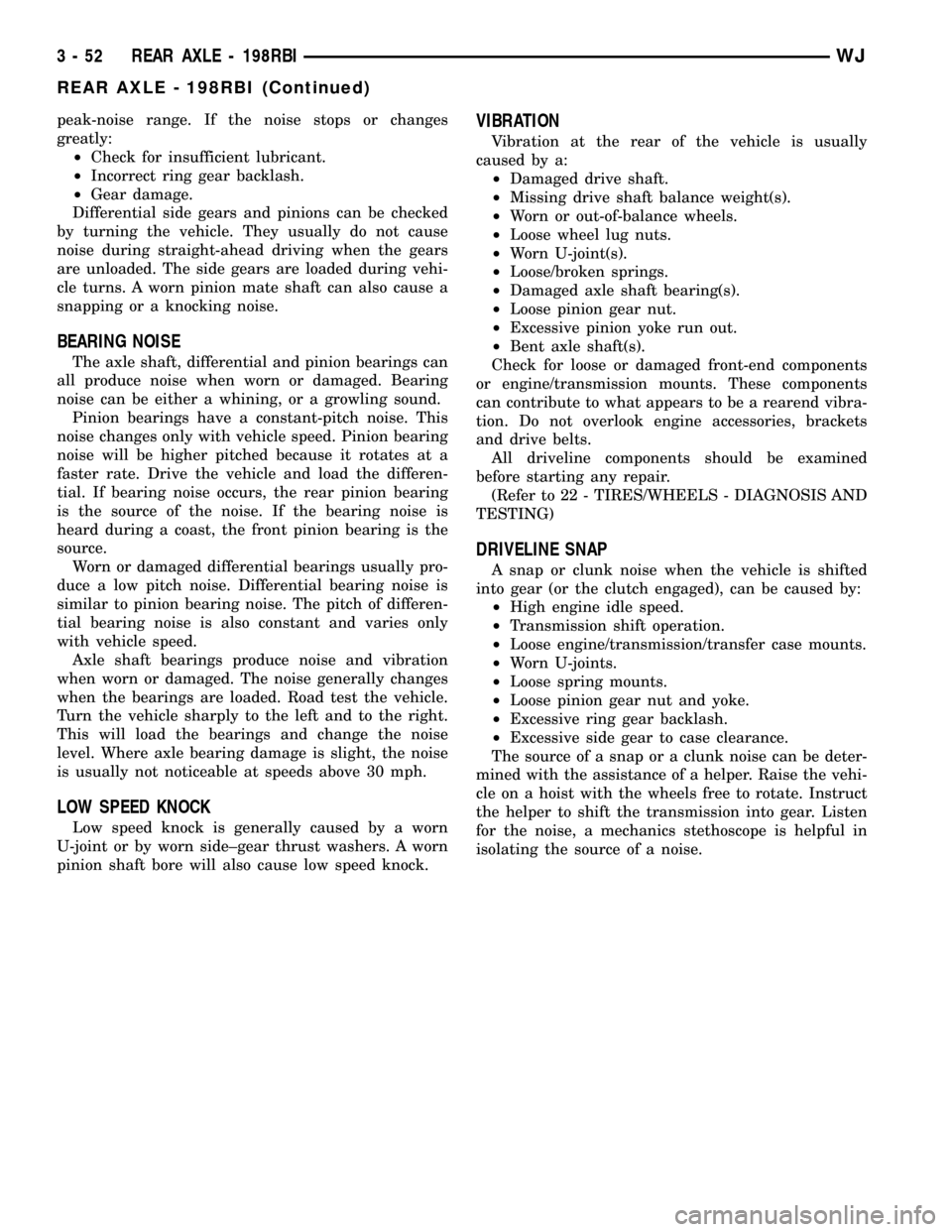

(5) Apply a light coating of gear lubricant on the

lip of pinion seal and install seal with an appropriate

installer (Fig. 60).

(6) Install rear pinion bearing and oil slinger/depth

shim onto the pinion shaft with Installer 6448 and a

press (Fig. 61).

(7) Install anewcollapsible spacer on pinion shaft

and install the pinion into the housing (Fig. 62).

(8) Install pinion companion flange, with Installer

W-162-B, Cup 8109 and Spanner Wrench 6958.(9) Install pinion washer and anewnut onto the

pinion gear and tighten the nut to 298 N´m (220 ft.

lbs.).Do not over-tighten.

CAUTION: Never loosen pinion gear nut to decrease

pinion rotating torque and never exceed specified

preload torque. If preload torque is exceeded a new

collapsible spacer must be installed.

(10) Use Flange Wrench 6958, a length of 1 in.

pipe and a torque wrench set at 500 N´m (368 ft. lbs.)

and crush collapsible spacer until bearing end play is

taken up (Fig. 63).

(11) Slowly tighten the nut in 6.8 N´m (5 ft. lb.)

increments until the required rotating torque is

achieved. Measure the rotating torque frequently to

avoid over crushing the collapsible spacer (Fig. 64).

(12) Rotate the pinion a minimum of ten times.

Verify pinion rotates smoothly and check rotating

torque with an inch pound torque wrench (Fig. 64).

Pinion gear rotating torque is:

²Original Bearings: 1 to 2.25 N´m (10 to 20 in.

lbs.).

²New Bearings: 1.7 to 3.4 N´m (15 to 30 in. lbs.).

(13) Invert the differential case and start two ring

gear bolts. This will provide case-to-ring gear bolt

hole alignment.

Fig. 60 PINION SEAL

1 - HANDLE

2 - INSTALLER

Fig. 61 REAR PINION BEARING

1 - INSTALLER

2 - OIL SLINGER

3 - PINION GEAR

4 - REAR PINION BEARING

5 - PRESS

Fig. 62 COLLAPSIBLE PRELOAD SPACER

1 - COLLAPSIBLE SPACER

2 - SHOULDER

3 - PINION GEAR

4 - DEPTH SHIM

5 - REAR BEARING

3 - 48 FRONT AXLE - 186FBIWJ

PINION GEAR/RING GEAR (Continued)

Page 97 of 2199

peak-noise range. If the noise stops or changes

greatly:

²Check for insufficient lubricant.

²Incorrect ring gear backlash.

²Gear damage.

Differential side gears and pinions can be checked

by turning the vehicle. They usually do not cause

noise during straight-ahead driving when the gears

are unloaded. The side gears are loaded during vehi-

cle turns. A worn pinion mate shaft can also cause a

snapping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion bearings can

all produce noise when worn or damaged. Bearing

noise can be either a whining, or a growling sound.

Pinion bearings have a constant-pitch noise. This

noise changes only with vehicle speed. Pinion bearing

noise will be higher pitched because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs, the rear pinion bearing

is the source of the noise. If the bearing noise is

heard during a coast, the front pinion bearing is the

source.

Worn or damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing noise. The pitch of differen-

tial bearing noise is also constant and varies only

with vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

This will load the bearings and change the noise

level. Where axle bearing damage is slight, the noise

is usually not noticeable at speeds above 30 mph.

LOW SPEED KNOCK

Low speed knock is generally caused by a worn

U-joint or by worn side±gear thrust washers. A worn

pinion shaft bore will also cause low speed knock.

VIBRATION

Vibration at the rear of the vehicle is usually

caused by a:

²Damaged drive shaft.

²Missing drive shaft balance weight(s).

²Worn or out-of-balance wheels.

²Loose wheel lug nuts.

²Worn U-joint(s).

²Loose/broken springs.

²Damaged axle shaft bearing(s).

²Loose pinion gear nut.

²Excessive pinion yoke run out.

²Bent axle shaft(s).

Check for loose or damaged front-end components

or engine/transmission mounts. These components

can contribute to what appears to be a rearend vibra-

tion. Do not overlook engine accessories, brackets

and drive belts.

All driveline components should be examined

before starting any repair.

(Refer to 22 - TIRES/WHEELS - DIAGNOSIS AND

TESTING)

DRIVELINE SNAP

A snap or clunk noise when the vehicle is shifted

into gear (or the clutch engaged), can be caused by:

²High engine idle speed.

²Transmission shift operation.

²Loose engine/transmission/transfer case mounts.

²Worn U-joints.

²Loose spring mounts.

²Loose pinion gear nut and yoke.

²Excessive ring gear backlash.

²Excessive side gear to case clearance.

The source of a snap or a clunk noise can be deter-

mined with the assistance of a helper. Raise the vehi-

cle on a hoist with the wheels free to rotate. Instruct

the helper to shift the transmission into gear. Listen

for the noise, a mechanics stethoscope is helpful in

isolating the source of a noise.

3 - 52 REAR AXLE - 198RBIWJ

REAR AXLE - 198RBI (Continued)

Page 116 of 2199

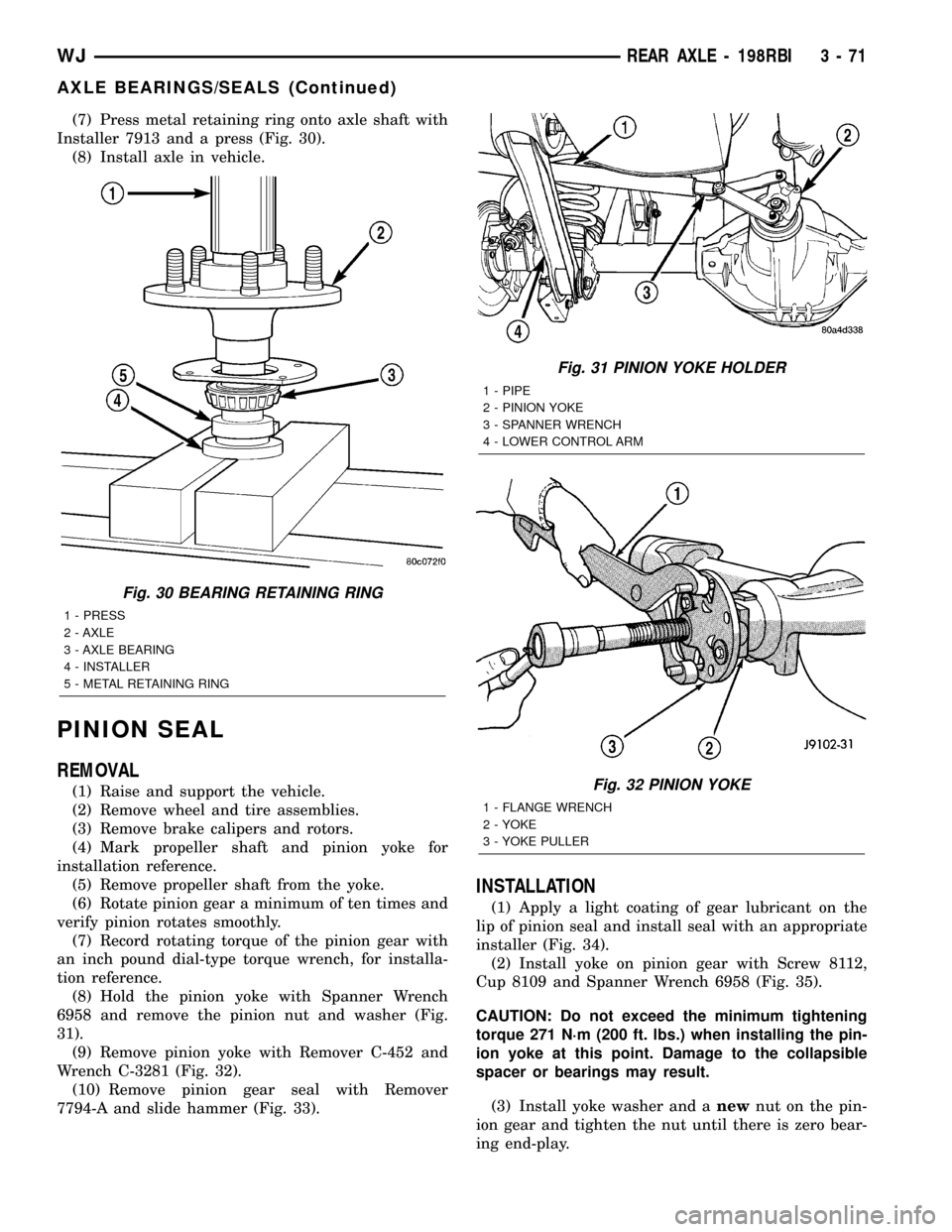

(7) Press metal retaining ring onto axle shaft with

Installer 7913 and a press (Fig. 30).

(8) Install axle in vehicle.

PINION SEAL

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Remove brake calipers and rotors.

(4) Mark propeller shaft and pinion yoke for

installation reference.

(5) Remove propeller shaft from the yoke.

(6) Rotate pinion gear a minimum of ten times and

verify pinion rotates smoothly.

(7) Record rotating torque of the pinion gear with

an inch pound dial-type torque wrench, for installa-

tion reference.

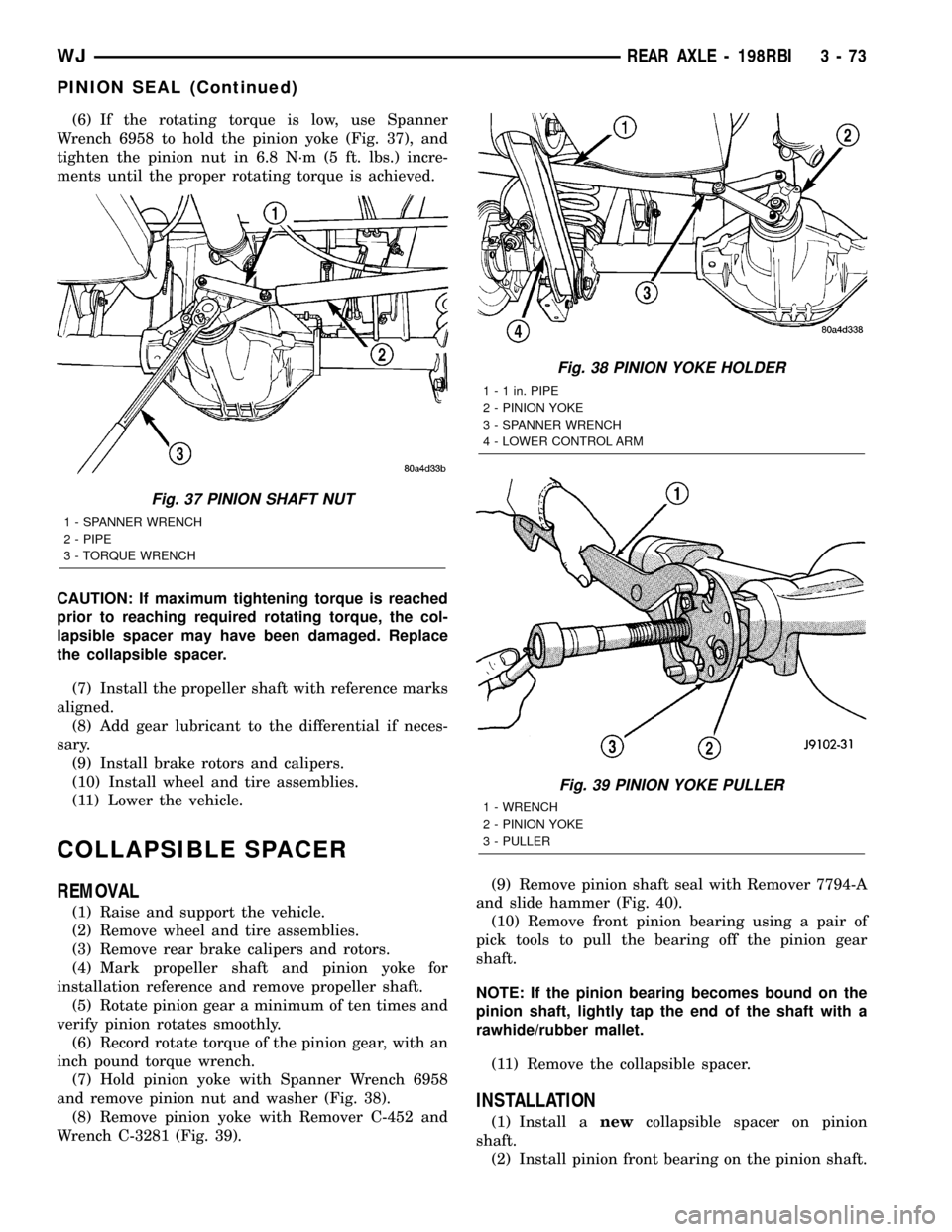

(8) Hold the pinion yoke with Spanner Wrench

6958 and remove the pinion nut and washer (Fig.

31).

(9) Remove pinion yoke with Remover C-452 and

Wrench C-3281 (Fig. 32).

(10) Remove pinion gear seal with Remover

7794-A and slide hammer (Fig. 33).

INSTALLATION

(1) Apply a light coating of gear lubricant on the

lip of pinion seal and install seal with an appropriate

installer (Fig. 34).

(2) Install yoke on pinion gear with Screw 8112,

Cup 8109 and Spanner Wrench 6958 (Fig. 35).

CAUTION: Do not exceed the minimum tightening

torque 271 N´m (200 ft. lbs.) when installing the pin-

ion yoke at this point. Damage to the collapsible

spacer or bearings may result.

(3) Install yoke washer and anewnut on the pin-

ion gear and tighten the nut until there is zero bear-

ing end-play.

Fig. 30 BEARING RETAINING RING

1 - PRESS

2 - AXLE

3 - AXLE BEARING

4 - INSTALLER

5 - METAL RETAINING RING

Fig. 31 PINION YOKE HOLDER

1 - PIPE

2 - PINION YOKE

3 - SPANNER WRENCH

4 - LOWER CONTROL ARM

Fig. 32 PINION YOKE

1 - FLANGE WRENCH

2 - YOKE

3 - YOKE PULLER

WJREAR AXLE - 198RBI 3 - 71

AXLE BEARINGS/SEALS (Continued)

Page 118 of 2199

(6) If the rotating torque is low, use Spanner

Wrench 6958 to hold the pinion yoke (Fig. 37), and

tighten the pinion nut in 6.8 N´m (5 ft. lbs.) incre-

ments until the proper rotating torque is achieved.

CAUTION: If maximum tightening torque is reached

prior to reaching required rotating torque, the col-

lapsible spacer may have been damaged. Replace

the collapsible spacer.

(7) Install the propeller shaft with reference marks

aligned.

(8) Add gear lubricant to the differential if neces-

sary.

(9) Install brake rotors and calipers.

(10) Install wheel and tire assemblies.

(11) Lower the vehicle.

COLLAPSIBLE SPACER

REMOVAL

(1) Raise and support the vehicle.

(2) Remove wheel and tire assemblies.

(3) Remove rear brake calipers and rotors.

(4) Mark propeller shaft and pinion yoke for

installation reference and remove propeller shaft.

(5) Rotate pinion gear a minimum of ten times and

verify pinion rotates smoothly.

(6) Record rotate torque of the pinion gear, with an

inch pound torque wrench.

(7) Hold pinion yoke with Spanner Wrench 6958

and remove pinion nut and washer (Fig. 38).

(8) Remove pinion yoke with Remover C-452 and

Wrench C-3281 (Fig. 39).(9) Remove pinion shaft seal with Remover 7794-A

and slide hammer (Fig. 40).

(10) Remove front pinion bearing using a pair of

pick tools to pull the bearing off the pinion gear

shaft.

NOTE: If the pinion bearing becomes bound on the

pinion shaft, lightly tap the end of the shaft with a

rawhide/rubber mallet.

(11) Remove the collapsible spacer.

INSTALLATION

(1) Install anewcollapsible spacer on pinion

shaft.

(2) Install pinion front bearing on the pinion shaft.

Fig. 37 PINION SHAFT NUT

1 - SPANNER WRENCH

2 - PIPE

3 - TORQUE WRENCH

Fig. 38 PINION YOKE HOLDER

1 - 1 in. PIPE

2 - PINION YOKE

3 - SPANNER WRENCH

4 - LOWER CONTROL ARM

Fig. 39 PINION YOKE PULLER

1 - WRENCH

2 - PINION YOKE

3 - PULLER

WJREAR AXLE - 198RBI 3 - 73

PINION SEAL (Continued)