manual neutral JEEP GRAND CHEROKEE 2003 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 511 of 2199

(4) Turn the ignition switch to the Off position.

Check for continuity between the ground circuit cav-

ity of the overhead wire harness connector for the

automatic day/night mirror and a good ground. There

should be continuity. If OK, go to Step 5. If not OK,

repair the open ground circuit to ground as required.

(5) Turn the ignition switch to the On position. Set

the parking brake. Place the transmission gear selec-

tor lever in the Reverse position. Check for battery

voltage at the backup lamp switch output circuit cav-

ity of the overhead wire harness connector for the

automatic day/night mirror. If OK, reconnect the

overhead wire harness connector to the automatic

day/night mirror connector receptacle and go to Step

6. If not OK, repair the open backup lamp switch

output circuit as required.

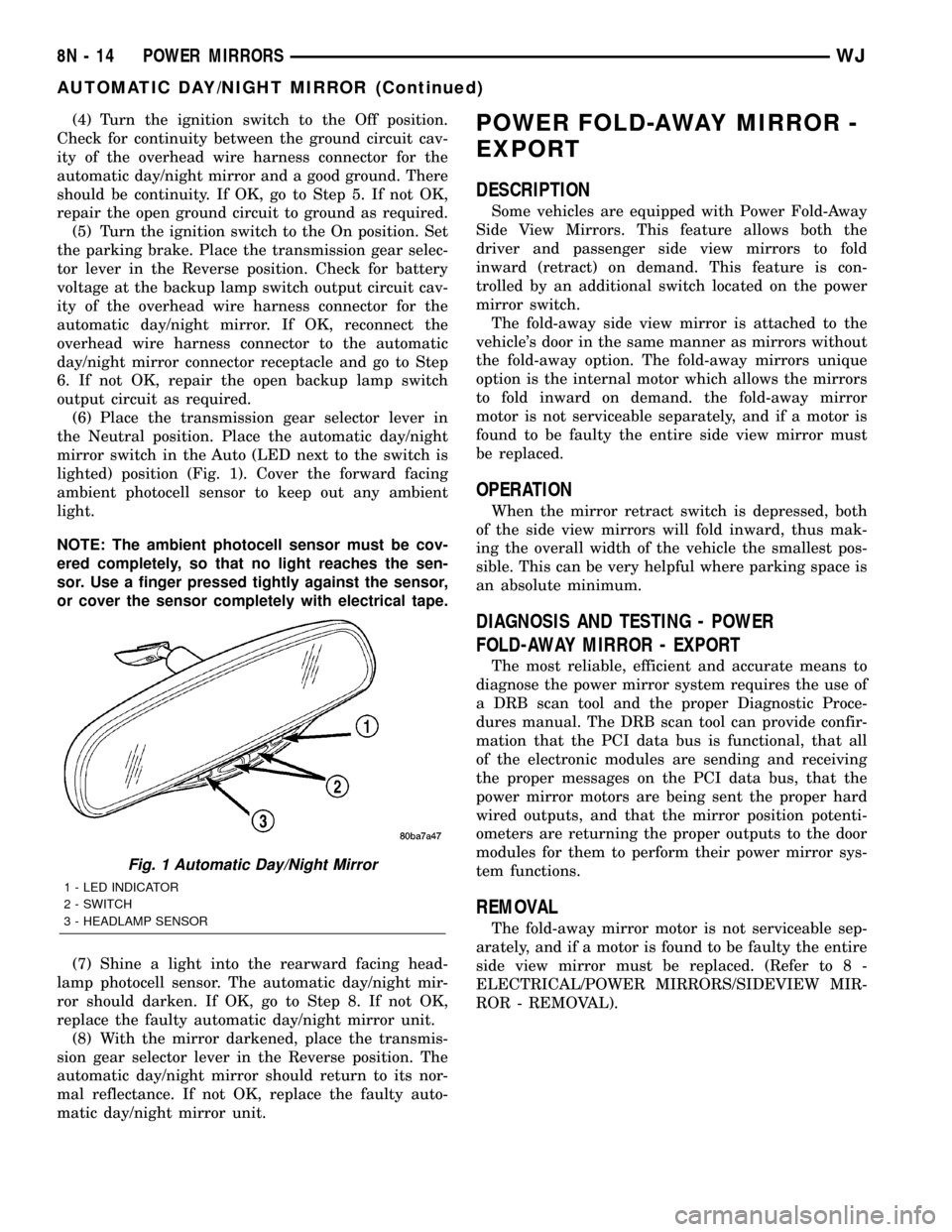

(6) Place the transmission gear selector lever in

the Neutral position. Place the automatic day/night

mirror switch in the Auto (LED next to the switch is

lighted) position (Fig. 1). Cover the forward facing

ambient photocell sensor to keep out any ambient

light.

NOTE: The ambient photocell sensor must be cov-

ered completely, so that no light reaches the sen-

sor. Use a finger pressed tightly against the sensor,

or cover the sensor completely with electrical tape.

(7) Shine a light into the rearward facing head-

lamp photocell sensor. The automatic day/night mir-

ror should darken. If OK, go to Step 8. If not OK,

replace the faulty automatic day/night mirror unit.

(8) With the mirror darkened, place the transmis-

sion gear selector lever in the Reverse position. The

automatic day/night mirror should return to its nor-

mal reflectance. If not OK, replace the faulty auto-

matic day/night mirror unit.POWER FOLD-AWAY MIRROR -

EXPORT

DESCRIPTION

Some vehicles are equipped with Power Fold-Away

Side View Mirrors. This feature allows both the

driver and passenger side view mirrors to fold

inward (retract) on demand. This feature is con-

trolled by an additional switch located on the power

mirror switch.

The fold-away side view mirror is attached to the

vehicle's door in the same manner as mirrors without

the fold-away option. The fold-away mirrors unique

option is the internal motor which allows the mirrors

to fold inward on demand. the fold-away mirror

motor is not serviceable separately, and if a motor is

found to be faulty the entire side view mirror must

be replaced.

OPERATION

When the mirror retract switch is depressed, both

of the side view mirrors will fold inward, thus mak-

ing the overall width of the vehicle the smallest pos-

sible. This can be very helpful where parking space is

an absolute minimum.

DIAGNOSIS AND TESTING - POWER

FOLD-AWAY MIRROR - EXPORT

The most reliable, efficient and accurate means to

diagnose the power mirror system requires the use of

a DRB scan tool and the proper Diagnostic Proce-

dures manual. The DRB scan tool can provide confir-

mation that the PCI data bus is functional, that all

of the electronic modules are sending and receiving

the proper messages on the PCI data bus, that the

power mirror motors are being sent the proper hard

wired outputs, and that the mirror position potenti-

ometers are returning the proper outputs to the door

modules for them to perform their power mirror sys-

tem functions.

REMOVAL

The fold-away mirror motor is not serviceable sep-

arately, and if a motor is found to be faulty the entire

side view mirror must be replaced. (Refer to 8 -

ELECTRICAL/POWER MIRRORS/SIDEVIEW MIR-

ROR - REMOVAL).

Fig. 1 Automatic Day/Night Mirror

1 - LED INDICATOR

2 - SWITCH

3 - HEADLAMP SENSOR

8N - 14 POWER MIRRORSWJ

AUTOMATIC DAY/NIGHT MIRROR (Continued)

Page 524 of 2199

(LED) for visibility, and are also color-coded to coin-

cide with the color-coded Driver 1 and Driver 2

Remote Keyless Entry (RKE) transmitters. The

Driver 1 memory switch button and RKE transmitter

are black, and the Driver 2 memory switch button

and RKE transmitter are gray. The memory switch

Set button also has an LED that will illuminate and

flash to indicate that the memory system is in the set

mode. This LED will automatically be extinguished

when a set request has been successfully completed.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the memory switch. For diagnosis of the memory

switch, the DDM or the PCI data bus, the use of a

DRB scan tool and the proper Diagnostic Procedures

manual are recommended.

DIAGNOSIS AND TESTING - MEMORY SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver side front door trim panel.

Refer to the Body section for the procedure.

(3) Disconnect the memory switch wire harness

connector from the driver door module connector

receptacle.

(4) Use an ohmmeter to test the resistances of the

memory switch in each switch position. See the Mem-

ory Switch Test chart MEMORY SWITCH TEST . If

OK, refer toMemory System Diagnosis and Test-

ingin this group. If not OK, replace the faulty mem-

ory switch.

MEMORY SWITCH TEST

MEMORY

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

RANGE

(OHMS)

NEUTRAL A&D 14000 1%

MEMORY 1 A&B 4600 1%

MEMORY 2 A&B 1700 1%

SET A&B 300 1%

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the trim panel from the driver side

front door. Refer toFront Door Trim Panelin Body

for the procedure.

(3) Disconnect the memory switch wire harness

connector from the driver door module connector

receptacle.

(4) Remove the two screws that secure the memory

switch to the back of the driver side front door trim

panel.(5) Remove the memory switch from the back of

the driver side front door trim panel.

INSTALLATION

(1) Position the memory switch onto the back of

the driver side front door trim panel.

(2) Install and tighten the two screws that secure

the memory switch to the back of the driver side

front door trim panel. Tighten the screws to 2.2 N´m

(20 in. lbs.).

(3) Reconnect the memory switch wire harness

connector to the driver door module connector recep-

tacle.

(4) Install the trim panel onto the driver side front

door. Refer toFront Door Trim Panelin Body for

the procedure.

(5) Reconnect the battery negative cable.

PASSENGER SEAT SWITCH

DESCRIPTION

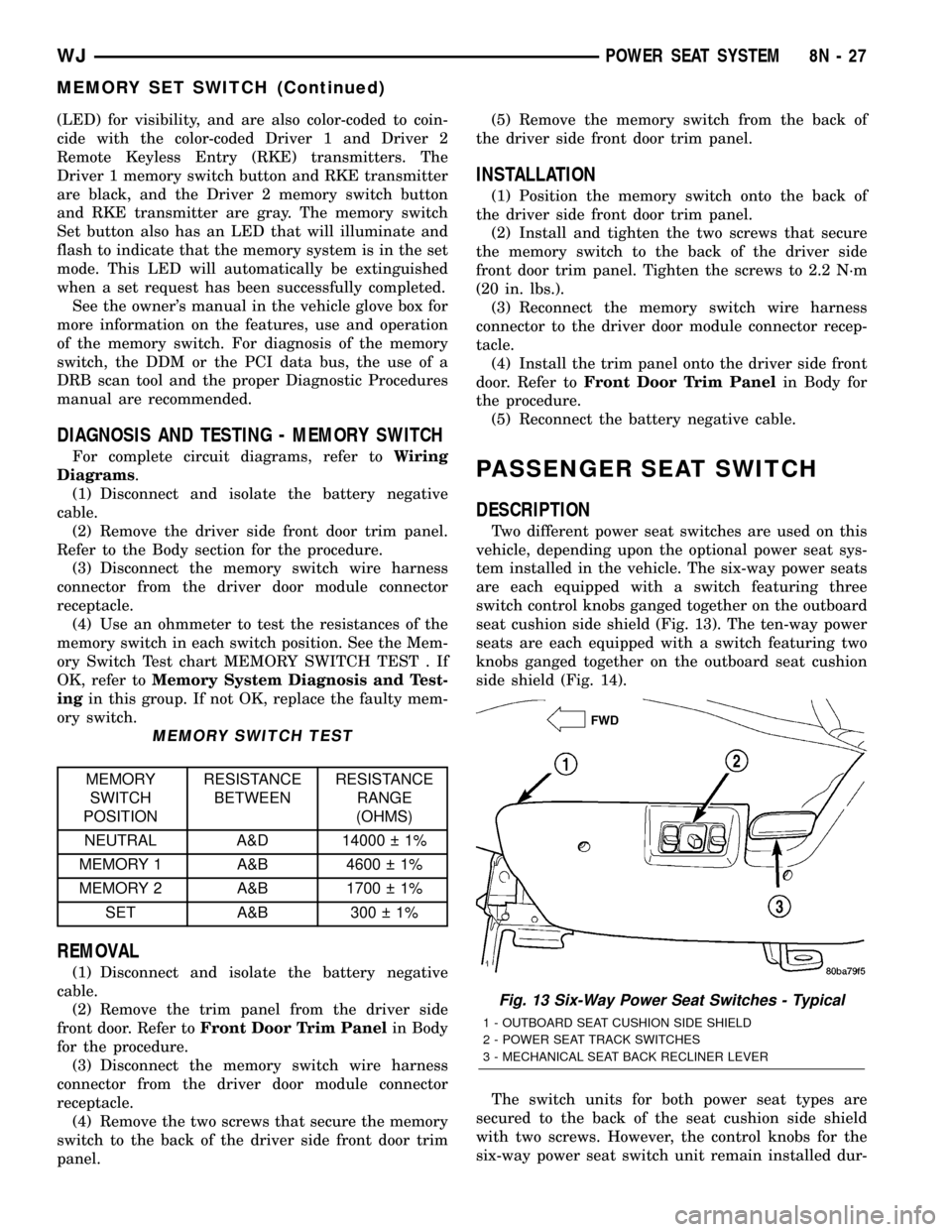

Two different power seat switches are used on this

vehicle, depending upon the optional power seat sys-

tem installed in the vehicle. The six-way power seats

are each equipped with a switch featuring three

switch control knobs ganged together on the outboard

seat cushion side shield (Fig. 13). The ten-way power

seats are each equipped with a switch featuring two

knobs ganged together on the outboard seat cushion

side shield (Fig. 14).

The switch units for both power seat types are

secured to the back of the seat cushion side shield

with two screws. However, the control knobs for the

six-way power seat switch unit remain installed dur-

Fig. 13 Six-Way Power Seat Switches - Typical

1 - OUTBOARD SEAT CUSHION SIDE SHIELD

2 - POWER SEAT TRACK SWITCHES

3 - MECHANICAL SEAT BACK RECLINER LEVER

WJPOWER SEAT SYSTEM 8N - 27

MEMORY SET SWITCH (Continued)

Page 582 of 2199

SPEED CONTROL

TABLE OF CONTENTS

page page

SPEED CONTROL

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING - ROAD TEST.....2

SPECIFICATIONS

TORQUE - SPEED CONTROL.............3

CABLE

DESCRIPTION..........................3

OPERATION............................3

REMOVAL

REMOVAL - 4.0L.......................3

REMOVAL - 4.7L.......................3

INSTALLATION

INSTALLATION - 4.0L...................4

INSTALLATION - 4.7L...................4

SERVO

DESCRIPTION..........................5OPERATION............................5

REMOVAL.............................5

INSTALLATION..........................6

SWITCH

DESCRIPTION..........................7

OPERATION............................7

REMOVAL.............................7

INSTALLATION..........................7

VACUUM RESERVOIR

DESCRIPTION..........................8

OPERATION............................8

DIAGNOSIS AND TESTING - VACUUM

RESERVOIR..........................8

REMOVAL.............................8

INSTALLATION..........................9

SPEED CONTROL

DESCRIPTION

The speed control system is electronically con-

trolled and vacuum operated. Electronic control of

the speed control system is integrated into the Pow-

ertrain Control Module (PCM). The controls consist

of two steering wheel mounted switches. The

switches are labeled: ON/OFF, RES/ACCEL, SET,

COAST, and CANCEL.

The system is designed to operate at speeds above

30 mph (50 km/h).

WARNING: THE USE OF SPEED CONTROL IS NOT

RECOMMENDED WHEN DRIVING CONDITIONS DO

NOT PERMIT MAINTAINING A CONSTANT SPEED,

SUCH AS IN HEAVY TRAFFIC OR ON ROADS THAT

ARE WINDING, ICY, SNOW COVERED, OR SLIP-

PERY.

OPERATION

When speed control is selected by depressing the

ON switch, the PCM allows a set speed to be stored

in PCM RAM for speed control. To store a set speed,

depress the SET switch while the vehicle is moving

at a speed between 35 and 85 mph. In order for the

speed control to engage, the brakes cannot be

applied, nor can the gear selector be indicating the

transmission is in Park or Neutral.

The speed control can be disengaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

²Depressing the clutch pedal (if equipped).

NOTE: Depressing the OFF switch or turning off the

ignition switch will erase the set speed stored in

the PCM.

For added safety, the speed control system is pro-

grammed to disengage for any of the following condi-

tions:

²An indication of Park or Neutral

²A rapid increase rpm (indicates that the clutch

has been disengaged)

²Excessive engine rpm (indicates that the trans-

mission may be in a low gear)

²The speed signal increases at a rate of 10 mph

per second (indicates that the coefficient of friction

between the road surface and tires is extremely low)

WJSPEED CONTROL 8P - 1

Page 588 of 2199

SWITCH

DESCRIPTION

There are two separate switch pods that operate

the speed control system. The steering-wheel-

mounted switches use multiplexed circuits to provide

inputs to the PCM for ON, OFF, RESUME, ACCEL-

ERATE, SET, DECEL and CANCEL modes. Refer to

the owner's manual for more information on speed

control switch functions and setting procedures.

The individual switches cannot be repaired. If one

switch fails, the entire switch module must be

replaced.

OPERATION

When speed control is selected by depressing the

ON, OFF switch, the PCM allows a set speed to be

stored in its RAM for speed control. To store a set

speed, depress the SET switch while the vehicle is

moving at a speed between approximately 35 and 85

mph. In order for the speed control to engage, the

brakes cannot be applied, nor can the gear selector

be indicating the transmission is in Park or Neutral.

The speed control can be disengaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

The speed control can be disengaged also by any of

the following conditions:

²An indication of Park or Neutral

²The VSS signal increases at a rate of 10 mph

per second (indicates that the co-efficient of friction

between the road surface and tires is extremely low)

²Depressing the clutch pedal.

²Excessive engine rpm (indicates that the trans-

mission may be in a low gear)

²The VSS signal decreases at a rate of 10 mph

per second (indicates that the vehicle may have

decelerated at an extremely high rate)

²If the actual speed is not within 20 mph of the

set speed

The previous disengagement conditions are pro-

grammed for added safety.

Once the speed control has been disengaged,

depressing the ACCEL switch restores the vehicle to

the target speed that was stored in the PCM's RAM.

NOTE: Depressing the OFF switch will erase the set

speed stored in the PCM's RAM.

If, while the speed control is engaged, the driver

wishes to increase vehicle speed, the PCM is pro-

grammed for an acceleration feature. With the

ACCEL switch held closed, the vehicle accelerates

slowly to the desired speed. The new target speed is

stored in the PCM's RAM when the ACCEL switch isreleased. The PCM also has a9tap-up9feature in

which vehicle speed increases at a rate of approxi-

mately 2 mph for each momentary switch activation

of the ACCEL switch.

The PCM also provides a means to decelerate with-

out disengaging speed control. To decelerate from an

existing recorded target speed, depress and hold the

COAST switch until the desired speed is reached.

Then release the switch. The ON, OFF switch oper-

ates two components: the PCM's ON, OFF input, and

the battery voltage to the brake switch, which powers

the speed control servo.

Multiplexing

The PCM sends out 5 volts through a fixed resistor

and monitors the voltage change between the fixed

resistor and the switches. If none of the switches are

depressed, the PCM will measure 5 volts at the sen-

sor point (open circuit). If a switch with no resistor is

closed, the PCM will measure 0 volts (grounded cir-

cuit). Now, if a resistor is added to a switch, then the

PCM will measure some voltage proportional to the

size of the resistor. By adding a different resistor to

each switch, the PCM will see a different voltage

depending on which switch is pushed.

Another resistor has been added to the 'at rest cir-

cuit' causing the PCM to never see 5 volts. This was

done for diagnostic purposes. If the switch circuit

should open (bad connection), then the PCM will see

the 5 volts and know the circuit is bad. The PCM will

then set an open circuit fault.

REMOVAL

WARNING: BEFORE BEGINNING ANY AIRBAG SYS-

TEM COMPONENT REMOVAL OR INSTALLATION,

REMOVE AND ISOLATE THE NEGATIVE (-) CABLE

FROM THE BATTERY. THIS IS THE ONLY SURE

WAY TO DISABLE THE AIRBAG SYSTEM. THEN

WAIT TWO MINUTES FOR SYSTEM CAPACITOR TO

DISCHARGE BEFORE FURTHER SYSTEM SERVICE.

FAILURE TO DO THIS COULD RESULT IN ACCIDEN-

TAL AIRBAG DEPLOYMENT AND POSSIBLE

INJURY.

(1) Disconnect and isolate negative battery cable.

(2) Remove airbag module. Refer to Group 8M,

Passive Restraint Systems.

(3) Remove electrical connector at switch.

(4) Remove switch-to-steering wheel mounting

screw (Fig. 7) .

(5) Remove switch.

INSTALLATION

(1) Install switch and mounting screw.

(2) Tighten screw to 1.5 N´m (15 in. lbs.) torque.

(3) Install electrical connector to switch.

WJSPEED CONTROL 8P - 7

Page 662 of 2199

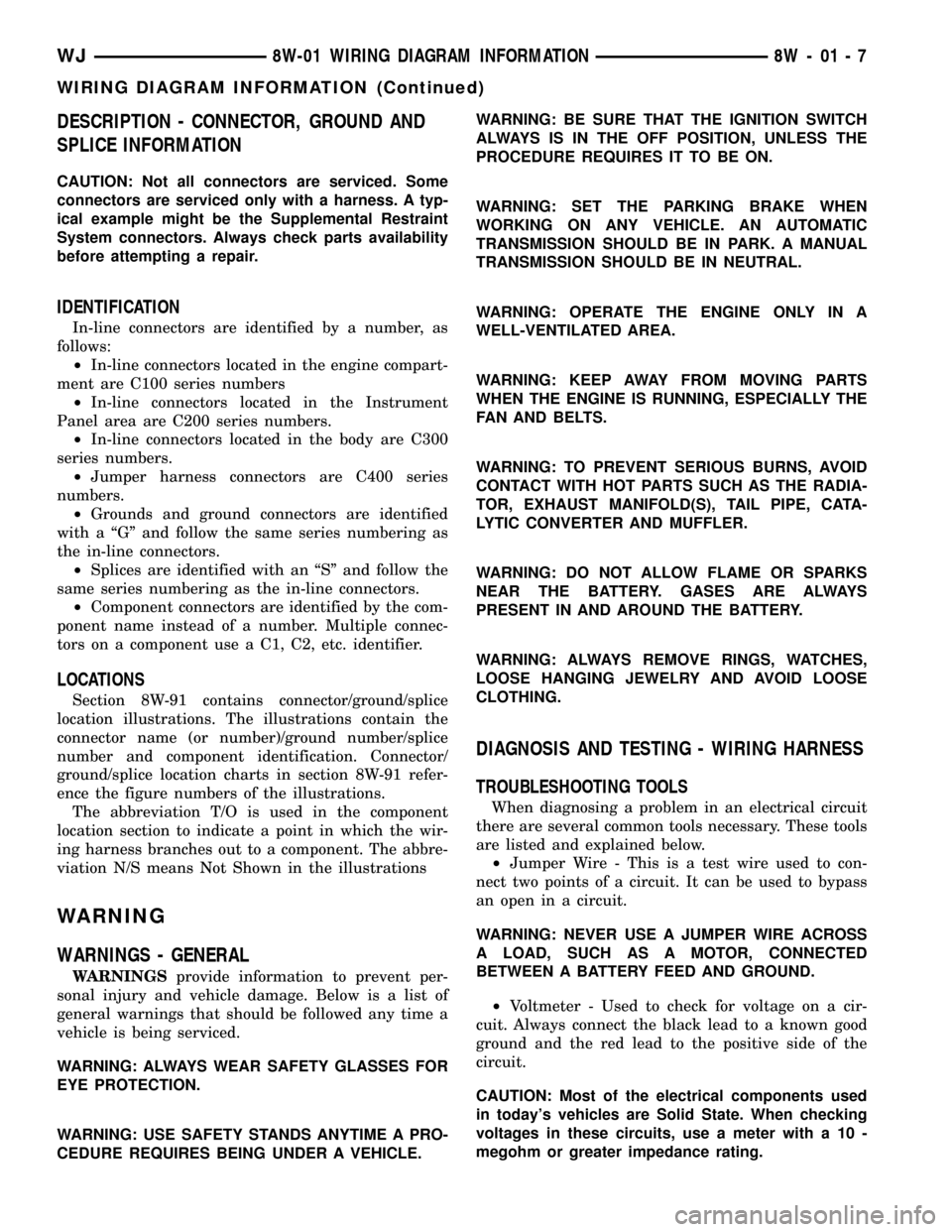

DESCRIPTION - CONNECTOR, GROUND AND

SPLICE INFORMATION

CAUTION: Not all connectors are serviced. Some

connectors are serviced only with a harness. A typ-

ical example might be the Supplemental Restraint

System connectors. Always check parts availability

before attempting a repair.

IDENTIFICATION

In-line connectors are identified by a number, as

follows:

²In-line connectors located in the engine compart-

ment are C100 series numbers

²In-line connectors located in the Instrument

Panel area are C200 series numbers.

²In-line connectors located in the body are C300

series numbers.

²Jumper harness connectors are C400 series

numbers.

²Grounds and ground connectors are identified

with a ªGº and follow the same series numbering as

the in-line connectors.

²Splices are identified with an ªSº and follow the

same series numbering as the in-line connectors.

²Component connectors are identified by the com-

ponent name instead of a number. Multiple connec-

tors on a component use a C1, C2, etc. identifier.

LOCATIONS

Section 8W-91 contains connector/ground/splice

location illustrations. The illustrations contain the

connector name (or number)/ground number/splice

number and component identification. Connector/

ground/splice location charts in section 8W-91 refer-

ence the figure numbers of the illustrations.

The abbreviation T/O is used in the component

location section to indicate a point in which the wir-

ing harness branches out to a component. The abbre-

viation N/S means Not Shown in the illustrations

WARNING

WARNINGS - GENERAL

WARNINGSprovide information to prevent per-

sonal injury and vehicle damage. Below is a list of

general warnings that should be followed any time a

vehicle is being serviced.

WARNING: ALWAYS WEAR SAFETY GLASSES FOR

EYE PROTECTION.

WARNING: USE SAFETY STANDS ANYTIME A PRO-

CEDURE REQUIRES BEING UNDER A VEHICLE.WARNING: BE SURE THAT THE IGNITION SWITCH

ALWAYS IS IN THE OFF POSITION, UNLESS THE

PROCEDURE REQUIRES IT TO BE ON.

WARNING: SET THE PARKING BRAKE WHEN

WORKING ON ANY VEHICLE. AN AUTOMATIC

TRANSMISSION SHOULD BE IN PARK. A MANUAL

TRANSMISSION SHOULD BE IN NEUTRAL.

WARNING: OPERATE THE ENGINE ONLY IN A

WELL-VENTILATED AREA.

WARNING: KEEP AWAY FROM MOVING PARTS

WHEN THE ENGINE IS RUNNING, ESPECIALLY THE

FAN AND BELTS.

WARNING: TO PREVENT SERIOUS BURNS, AVOID

CONTACT WITH HOT PARTS SUCH AS THE RADIA-

TOR, EXHAUST MANIFOLD(S), TAIL PIPE, CATA-

LYTIC CONVERTER AND MUFFLER.

WARNING: DO NOT ALLOW FLAME OR SPARKS

NEAR THE BATTERY. GASES ARE ALWAYS

PRESENT IN AND AROUND THE BATTERY.

WARNING: ALWAYS REMOVE RINGS, WATCHES,

LOOSE HANGING JEWELRY AND AVOID LOOSE

CLOTHING.

DIAGNOSIS AND TESTING - WIRING HARNESS

TROUBLESHOOTING TOOLS

When diagnosing a problem in an electrical circuit

there are several common tools necessary. These tools

are listed and explained below.

²Jumper Wire - This is a test wire used to con-

nect two points of a circuit. It can be used to bypass

an open in a circuit.

WARNING: NEVER USE A JUMPER WIRE ACROSS

A LOAD, SUCH AS A MOTOR, CONNECTED

BETWEEN A BATTERY FEED AND GROUND.

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicles are Solid State. When checking

voltages in these circuits, use a meter with a 10 -

megohm or greater impedance rating.

WJ8W-01 WIRING DIAGRAM INFORMATION 8W - 01 - 7

WIRING DIAGRAM INFORMATION (Continued)

Page 672 of 2199

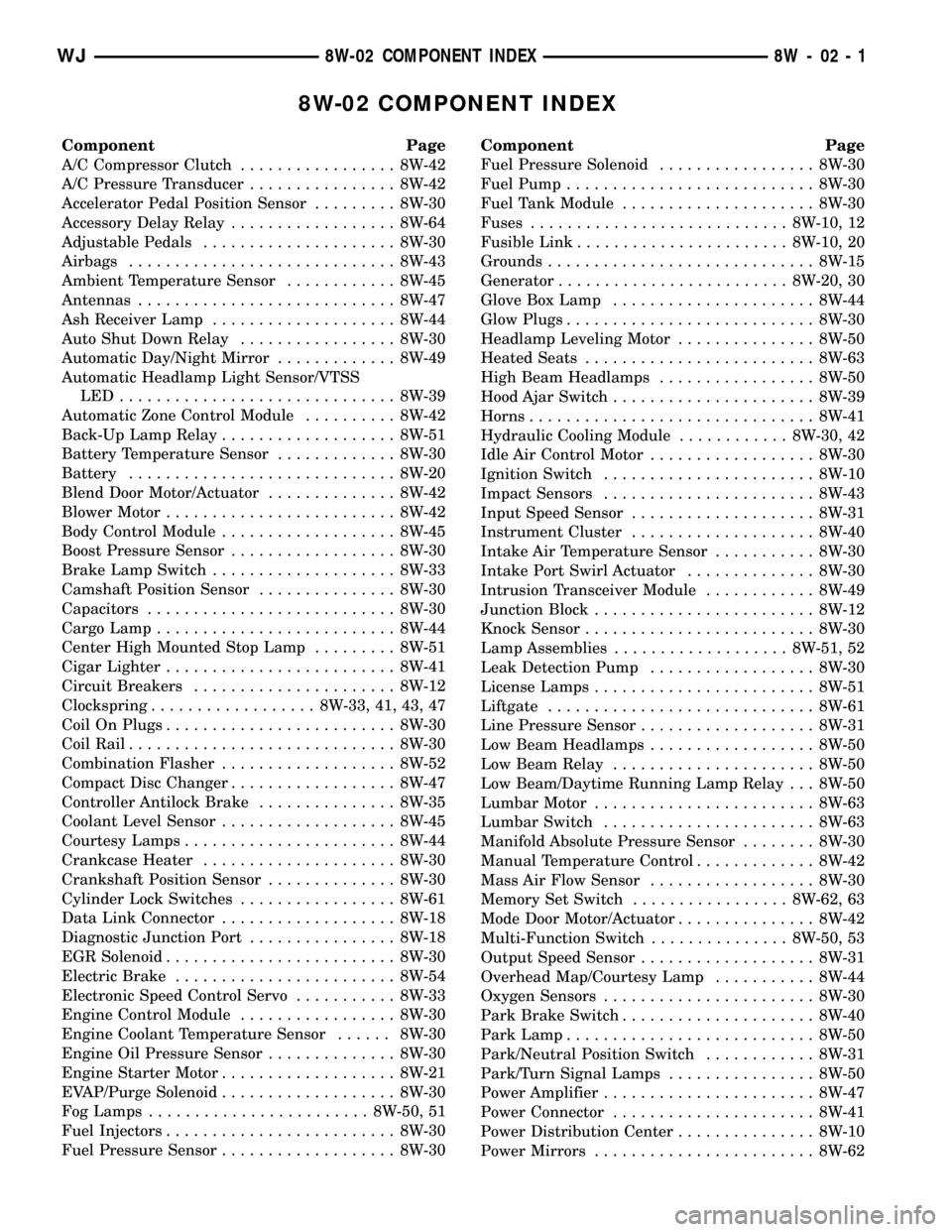

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch................. 8W-42

A/C Pressure Transducer................ 8W-42

Accelerator Pedal Position Sensor......... 8W-30

Accessory Delay Relay.................. 8W-64

Adjustable Pedals..................... 8W-30

Airbags............................. 8W-43

Ambient Temperature Sensor............ 8W-45

Antennas............................ 8W-47

Ash Receiver Lamp.................... 8W-44

Auto Shut Down Relay................. 8W-30

Automatic Day/Night Mirror............. 8W-49

Automatic Headlamp Light Sensor/VTSS

LED.............................. 8W-39

Automatic Zone Control Module.......... 8W-42

Back-Up Lamp Relay................... 8W-51

Battery Temperature Sensor............. 8W-30

Battery............................. 8W-20

Blend Door Motor/Actuator.............. 8W-42

Blower Motor......................... 8W-42

Body Control Module................... 8W-45

Boost Pressure Sensor.................. 8W-30

Brake Lamp Switch.................... 8W-33

Camshaft Position Sensor............... 8W-30

Capacitors........................... 8W-30

Cargo Lamp.......................... 8W-44

Center High Mounted Stop Lamp......... 8W-51

Cigar Lighter......................... 8W-41

Circuit Breakers...................... 8W-12

Clockspring.................. 8W-33, 41, 43, 47

Coil On Plugs......................... 8W-30

Coil Rail............................. 8W-30

Combination Flasher................... 8W-52

Compact Disc Changer.................. 8W-47

Controller Antilock Brake............... 8W-35

Coolant Level Sensor................... 8W-45

Courtesy Lamps....................... 8W-44

Crankcase Heater..................... 8W-30

Crankshaft Position Sensor.............. 8W-30

Cylinder Lock Switches................. 8W-61

Data Link Connector................... 8W-18

Diagnostic Junction Port................ 8W-18

EGR Solenoid......................... 8W-30

Electric Brake........................ 8W-54

Electronic Speed Control Servo........... 8W-33

Engine Control Module................. 8W-30

Engine Coolant Temperature Sensor...... 8W-30

Engine Oil Pressure Sensor.............. 8W-30

Engine Starter Motor................... 8W-21

EVAP/Purge Solenoid................... 8W-30

Fog Lamps........................ 8W-50, 51

Fuel Injectors......................... 8W-30

Fuel Pressure Sensor................... 8W-30Component Page

Fuel Pressure Solenoid................. 8W-30

Fuel Pump........................... 8W-30

Fuel Tank Module..................... 8W-30

Fuses............................ 8W-10, 12

Fusible Link....................... 8W-10, 20

Grounds............................. 8W-15

Generator......................... 8W-20, 30

Glove Box Lamp...................... 8W-44

Glow Plugs........................... 8W-30

Headlamp Leveling Motor............... 8W-50

Heated Seats......................... 8W-63

High Beam Headlamps................. 8W-50

Hood Ajar Switch...................... 8W-39

Horns............................... 8W-41

Hydraulic Cooling Module............ 8W-30, 42

Idle Air Control Motor.................. 8W-30

Ignition Switch....................... 8W-10

Impact Sensors....................... 8W-43

Input Speed Sensor.................... 8W-31

Instrument Cluster.................... 8W-40

Intake Air Temperature Sensor........... 8W-30

Intake Port Swirl Actuator.............. 8W-30

Intrusion Transceiver Module............ 8W-49

Junction Block........................ 8W-12

Knock Sensor......................... 8W-30

Lamp Assemblies................... 8W-51, 52

Leak Detection Pump.................. 8W-30

License Lamps........................ 8W-51

Liftgate............................. 8W-61

Line Pressure Sensor................... 8W-31

Low Beam Headlamps.................. 8W-50

Low Beam Relay...................... 8W-50

Low Beam/Daytime Running Lamp Relay . . . 8W-50

Lumbar Motor........................ 8W-63

Lumbar Switch....................... 8W-63

Manifold Absolute Pressure Sensor........ 8W-30

Manual Temperature Control............. 8W-42

Mass Air Flow Sensor.................. 8W-30

Memory Set Switch................. 8W-62, 63

Mode Door Motor/Actuator............... 8W-42

Multi-Function Switch............... 8W-50, 53

Output Speed Sensor................... 8W-31

Overhead Map/Courtesy Lamp........... 8W-44

Oxygen Sensors....................... 8W-30

Park Brake Switch..................... 8W-40

Park Lamp........................... 8W-50

Park/Neutral Position Switch............ 8W-31

Park/Turn Signal Lamps................ 8W-50

Power Amplifier....................... 8W-47

Power Connector...................... 8W-41

Power Distribution Center............... 8W-10

Power Mirrors........................ 8W-62

WJ8W-02 COMPONENT INDEX 8W - 02 - 1

Page 706 of 2199

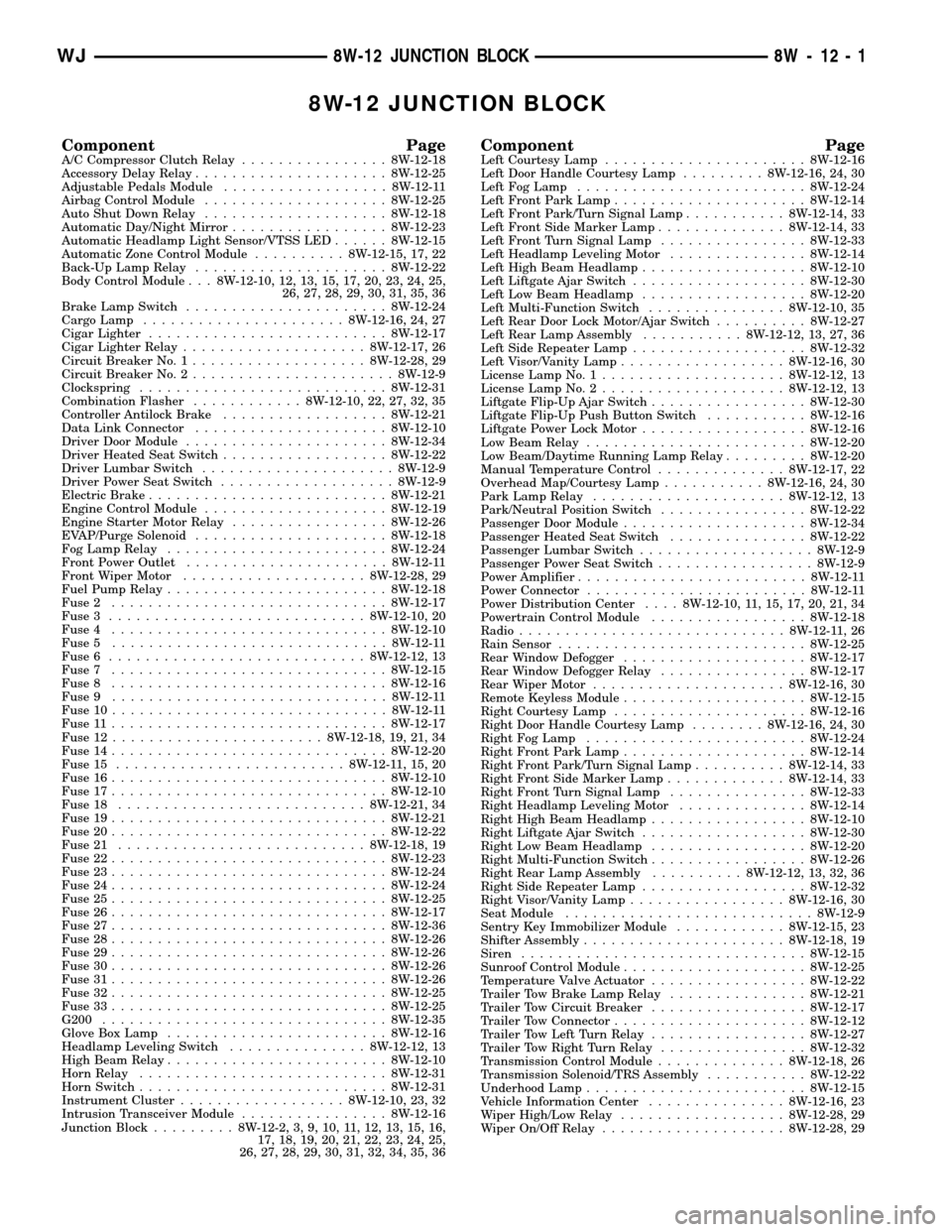

8W-12 JUNCTION BLOCK

Component PageA/C Compressor Clutch Relay................8W-12-18

Accessory Delay Relay.....................8W-12-25

Adjustable Pedals Module..................8W-12-11

Airbag Control Module....................8W-12-25

Auto Shut Down Relay....................8W-12-18

Automatic Day/Night Mirror.................8W-12-23

Automatic Headlamp Light Sensor/VTSS LED......8W-12-15

Automatic Zone Control Module..........8W-12-15, 17, 22

Back-Up Lamp Relay.....................8W-12-22

Body Control Module . . . 8W-12-10, 12, 13, 15, 17, 20, 23, 24, 25,

26, 27, 28, 29, 30, 31, 35, 36

Brake Lamp Switch......................8W-12-24

Cargo Lamp......................8W-12-16, 24, 27

Cigar Lighter..........................8W-12-17

Cigar Lighter Relay....................8W-12-17, 26

Circuit Breaker No. 1...................8W-12-28, 29

Circuit Breaker No. 2......................8W-12-9

Clockspring...........................8W-12-31

Combination Flasher............8W-12-10, 22, 27, 32, 35

Controller Antilock Brake..................8W-12-21

Data Link Connector.....................8W-12-10

Driver Door Module......................8W-12-34

Driver Heated Seat Switch..................8W-12-22

Driver Lumbar Switch.....................8W-12-9

Driver Power Seat Switch...................8W-12-9

Electric Brake..........................8W-12-21

Engine Control Module....................8W-12-19

Engine Starter Motor Relay.................8W-12-26

EVAP/Purge Solenoid.....................8W-12-18

Fog Lamp Relay........................8W-12-24

Front Power Outlet......................8W-12-11

Front Wiper Motor....................8W-12-28, 29

Fuel Pump Relay........................8W-12-18

Fuse 2..............................8W-12-17

Fuse 3............................8W-12-10, 20

Fuse 4..............................8W-12-10

Fuse 5..............................8W-12-11

Fuse 6............................8W-12-12, 13

Fuse 7..............................8W-12-15

Fuse 8..............................8W-12-16

Fuse 9..............................8W-12-11

Fuse 10..............................8W-12-11

Fuse 11..............................8W-12-17

Fuse 12.......................8W-12-18, 19, 21, 34

Fuse 14..............................8W-12-20

Fuse 15.........................8W-12-11, 15, 20

Fuse 16..............................8W-12-10

Fuse 17..............................8W-12-10

Fuse 18...........................8W-12-21, 34

Fuse 19..............................8W-12-21

Fuse 20..............................8W-12-22

Fuse 21...........................8W-12-18, 19

Fuse 22..............................8W-12-23

Fuse 23..............................8W-12-24

Fuse 24..............................8W-12-24

Fuse 25..............................8W-12-25

Fuse 26..............................8W-12-17

Fuse 27..............................8W-12-36

Fuse 28..............................8W-12-26

Fuse 29..............................8W-12-26

Fuse 30..............................8W-12-26

Fuse 31..............................8W-12-26

Fuse 32..............................8W-12-25

Fuse 33..............................8W-12-25

G200...............................8W-12-35

Glove Box Lamp........................8W-12-16

Headlamp Leveling Switch...............8W-12-12, 13

High Beam Relay........................8W-12-10

Horn Relay...........................8W-12-31

Horn Switch...........................8W-12-31

Instrument Cluster..................8W-12-10, 23, 32

Intrusion Transceiver Module................8W-12-16

Junction Block.........8W-12-2, 3, 9, 10, 11, 12, 13, 15, 16,

17, 18, 19, 20, 21, 22, 23, 24, 25,

26, 27, 28, 29, 30, 31, 32, 34, 35, 36Component PageLeft Courtesy Lamp......................8W-12-16

Left Door Handle Courtesy Lamp.........8W-12-16, 24, 30

Left Fog Lamp.........................8W-12-24

Left Front Park Lamp.....................8W-12-14

Left Front Park/Turn Signal Lamp...........8W-12-14, 33

Left Front Side Marker Lamp..............8W-12-14, 33

Left Front Turn Signal Lamp................8W-12-33

Left Headlamp Leveling Motor...............8W-12-14

Left High Beam Headlamp..................8W-12-10

Left Liftgate Ajar Switch...................8W-12-30

Left Low Beam Headlamp..................8W-12-20

Left Multi-Function Switch...............8W-12-10, 35

Left Rear Door Lock Motor/Ajar Switch..........8W-12-27

Left Rear Lamp Assembly...........8W-12-12, 13, 27, 36

Left Side Repeater Lamp...................8W-12-32

Left Visor/Vanity Lamp..................8W-12-16, 30

License Lamp No. 1....................8W-12-12, 13

License Lamp No. 2....................8W-12-12, 13

Liftgate Flip-Up Ajar Switch.................8W-12-30

Liftgate Flip-Up Push Button Switch...........8W-12-16

Liftgate Power Lock Motor..................8W-12-16

Low Beam Relay........................8W-12-20

Low Beam/Daytime Running Lamp Relay.........8W-12-20

Manual Temperature Control..............8W-12-17, 22

Overhead Map/Courtesy Lamp...........8W-12-16, 24, 30

Park Lamp Relay.....................8W-12-12, 13

Park/Neutral Position Switch................8W-12-22

Passenger Door Module....................8W-12-34

Passenger Heated Seat Switch...............8W-12-22

Passenger Lumbar Switch...................8W-12-9

Passenger Power Seat Switch.................8W-12-9

Power Amplifier.........................8W-12-11

Power Connector........................8W-12-11

Power Distribution Center....8W-12-10, 11, 15, 17, 20, 21, 34

Powertrain Control Module.................8W-12-18

Radio.............................8W-12-11, 26

Rain Sensor...........................8W-12-25

Rear Window Defogger....................8W-12-17

Rear Window Defogger Relay................8W-12-17

Rear Wiper Motor.....................8W-12-16, 30

Remote Keyless Module....................8W-12-15

Right Courtesy Lamp.....................8W-12-16

Right Door Handle Courtesy Lamp........8W-12-16, 24, 30

Right Fog Lamp........................8W-12-24

Right Front Park Lamp....................8W-12-14

Right Front Park/Turn Signal Lamp..........8W-12-14, 33

Right Front Side Marker Lamp.............8W-12-14, 33

Right Front Turn Signal Lamp...............8W-12-33

Right Headlamp Leveling Motor..............8W-12-14

Right High Beam Headlamp.................8W-12-10

Right Liftgate Ajar Switch..................8W-12-30

Right Low Beam Headlamp.................8W-12-20

Right Multi-Function Switch.................8W-12-26

Right Rear Lamp Assembly..........8W-12-12, 13, 32, 36

Right Side Repeater Lamp..................8W-12-32

Right Visor/Vanity Lamp.................8W-12-16, 30

Seat Module...........................8W-12-9

Sentry Key Immobilizer Module............8W-12-15, 23

Shifter Assembly......................8W-12-18, 19

Siren...............................8W-12-15

Sunroof Control Module....................8W-12-25

Temperature Valve Actuator.................8W-12-22

Trailer Tow Brake Lamp Relay...............8W-12-21

Trailer Tow Circuit Breaker.................8W-12-17

Trailer Tow Connector.....................8W-12-12

Trailer Tow Left Turn Relay.................8W-12-27

Trailer Tow Right Turn Relay................8W-12-32

Transmission Control Module..............8W-12-18, 26

Transmission Solenoid/TRS Assembly...........8W-12-22

Underhood Lamp........................8W-12-15

Vehicle Information Center...............8W-12-16, 23

Wiper High/Low Relay..................8W-12-28, 29

Wiper On/Off Relay....................8W-12-28, 29

WJ8W-12 JUNCTION BLOCK 8W - 12 - 1

Page 1051 of 2199

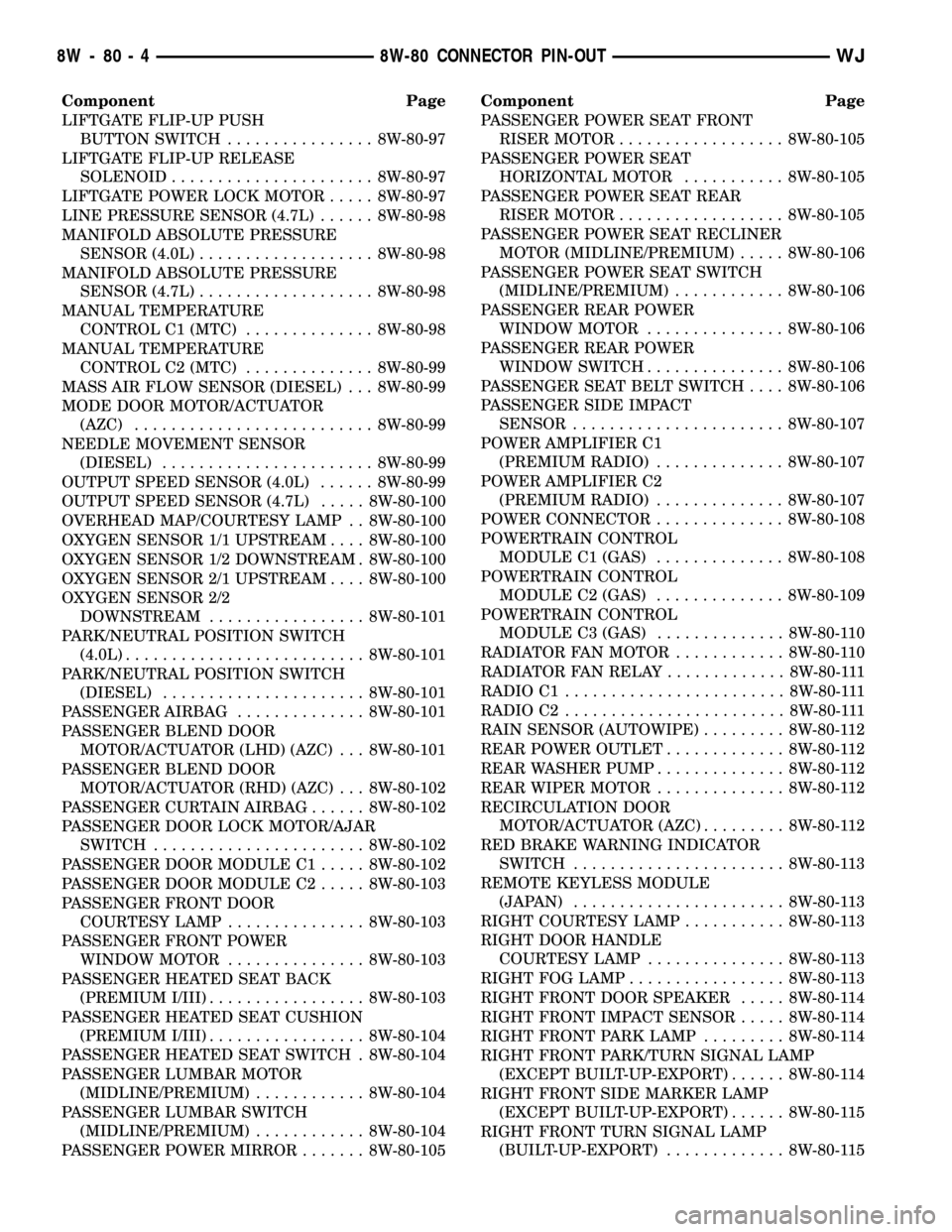

Component Page

LIFTGATE FLIP-UP PUSH

BUTTON SWITCH................ 8W-80-97

LIFTGATE FLIP-UP RELEASE

SOLENOID...................... 8W-80-97

LIFTGATE POWER LOCK MOTOR..... 8W-80-97

LINE PRESSURE SENSOR (4.7L)...... 8W-80-98

MANIFOLD ABSOLUTE PRESSURE

SENSOR (4.0L)................... 8W-80-98

MANIFOLD ABSOLUTE PRESSURE

SENSOR (4.7L)................... 8W-80-98

MANUAL TEMPERATURE

CONTROL C1 (MTC).............. 8W-80-98

MANUAL TEMPERATURE

CONTROL C2 (MTC).............. 8W-80-99

MASS AIR FLOW SENSOR (DIESEL) . . . 8W-80-99

MODE DOOR MOTOR/ACTUATOR

(AZC).......................... 8W-80-99

NEEDLE MOVEMENT SENSOR

(DIESEL)....................... 8W-80-99

OUTPUT SPEED SENSOR (4.0L)...... 8W-80-99

OUTPUT SPEED SENSOR (4.7L)..... 8W-80-100

OVERHEAD MAP/COURTESY LAMP . . 8W-80-100

OXYGEN SENSOR 1/1 UPSTREAM.... 8W-80-100

OXYGEN SENSOR 1/2 DOWNSTREAM . 8W-80-100

OXYGEN SENSOR 2/1 UPSTREAM.... 8W-80-100

OXYGEN SENSOR 2/2

DOWNSTREAM................. 8W-80-101

PARK/NEUTRAL POSITION SWITCH

(4.0L).......................... 8W-80-101

PARK/NEUTRAL POSITION SWITCH

(DIESEL)...................... 8W-80-101

PASSENGER AIRBAG.............. 8W-80-101

PASSENGER BLEND DOOR

MOTOR/ACTUATOR (LHD) (AZC) . . . 8W-80-101

PASSENGER BLEND DOOR

MOTOR/ACTUATOR (RHD) (AZC) . . . 8W-80-102

PASSENGER CURTAIN AIRBAG...... 8W-80-102

PASSENGER DOOR LOCK MOTOR/AJAR

SWITCH....................... 8W-80-102

PASSENGER DOOR MODULE C1..... 8W-80-102

PASSENGER DOOR MODULE C2..... 8W-80-103

PASSENGER FRONT DOOR

COURTESY LAMP............... 8W-80-103

PASSENGER FRONT POWER

WINDOW MOTOR............... 8W-80-103

PASSENGER HEATED SEAT BACK

(PREMIUM I/III)................. 8W-80-103

PASSENGER HEATED SEAT CUSHION

(PREMIUM I/III)................. 8W-80-104

PASSENGER HEATED SEAT SWITCH . 8W-80-104

PASSENGER LUMBAR MOTOR

(MIDLINE/PREMIUM)............ 8W-80-104

PASSENGER LUMBAR SWITCH

(MIDLINE/PREMIUM)............ 8W-80-104

PASSENGER POWER MIRROR....... 8W-80-105Component Page

PASSENGER POWER SEAT FRONT

RISER MOTOR.................. 8W-80-105

PASSENGER POWER SEAT

HORIZONTAL MOTOR........... 8W-80-105

PASSENGER POWER SEAT REAR

RISER MOTOR.................. 8W-80-105

PASSENGER POWER SEAT RECLINER

MOTOR (MIDLINE/PREMIUM)..... 8W-80-106

PASSENGER POWER SEAT SWITCH

(MIDLINE/PREMIUM)............ 8W-80-106

PASSENGER REAR POWER

WINDOW MOTOR............... 8W-80-106

PASSENGER REAR POWER

WINDOW SWITCH............... 8W-80-106

PASSENGER SEAT BELT SWITCH.... 8W-80-106

PASSENGER SIDE IMPACT

SENSOR....................... 8W-80-107

POWER AMPLIFIER C1

(PREMIUM RADIO).............. 8W-80-107

POWER AMPLIFIER C2

(PREMIUM RADIO).............. 8W-80-107

POWER CONNECTOR.............. 8W-80-108

POWERTRAIN CONTROL

MODULE C1 (GAS).............. 8W-80-108

POWERTRAIN CONTROL

MODULE C2 (GAS).............. 8W-80-109

POWERTRAIN CONTROL

MODULE C3 (GAS).............. 8W-80-110

RADIATOR FAN MOTOR............ 8W-80-110

RADIATOR FAN RELAY............. 8W-80-111

RADIO C1........................ 8W-80-111

RADIO C2........................ 8W-80-111

RAIN SENSOR (AUTOWIPE)......... 8W-80-112

REAR POWER OUTLET............. 8W-80-112

REAR WASHER PUMP.............. 8W-80-112

REAR WIPER MOTOR.............. 8W-80-112

RECIRCULATION DOOR

MOTOR/ACTUATOR (AZC)......... 8W-80-112

RED BRAKE WARNING INDICATOR

SWITCH....................... 8W-80-113

REMOTE KEYLESS MODULE

(JAPAN)....................... 8W-80-113

RIGHT COURTESY LAMP........... 8W-80-113

RIGHT DOOR HANDLE

COURTESY LAMP............... 8W-80-113

RIGHT FOG LAMP................. 8W-80-113

RIGHT FRONT DOOR SPEAKER..... 8W-80-114

RIGHT FRONT IMPACT SENSOR..... 8W-80-114

RIGHT FRONT PARK LAMP......... 8W-80-114

RIGHT FRONT PARK/TURN SIGNAL LAMP

(EXCEPT BUILT-UP-EXPORT)...... 8W-80-114

RIGHT FRONT SIDE MARKER LAMP

(EXCEPT BUILT-UP-EXPORT)...... 8W-80-115

RIGHT FRONT TURN SIGNAL LAMP

(BUILT-UP-EXPORT)............. 8W-80-115

8W - 80 - 4 8W-80 CONNECTOR PIN-OUTWJ

Page 1524 of 2199

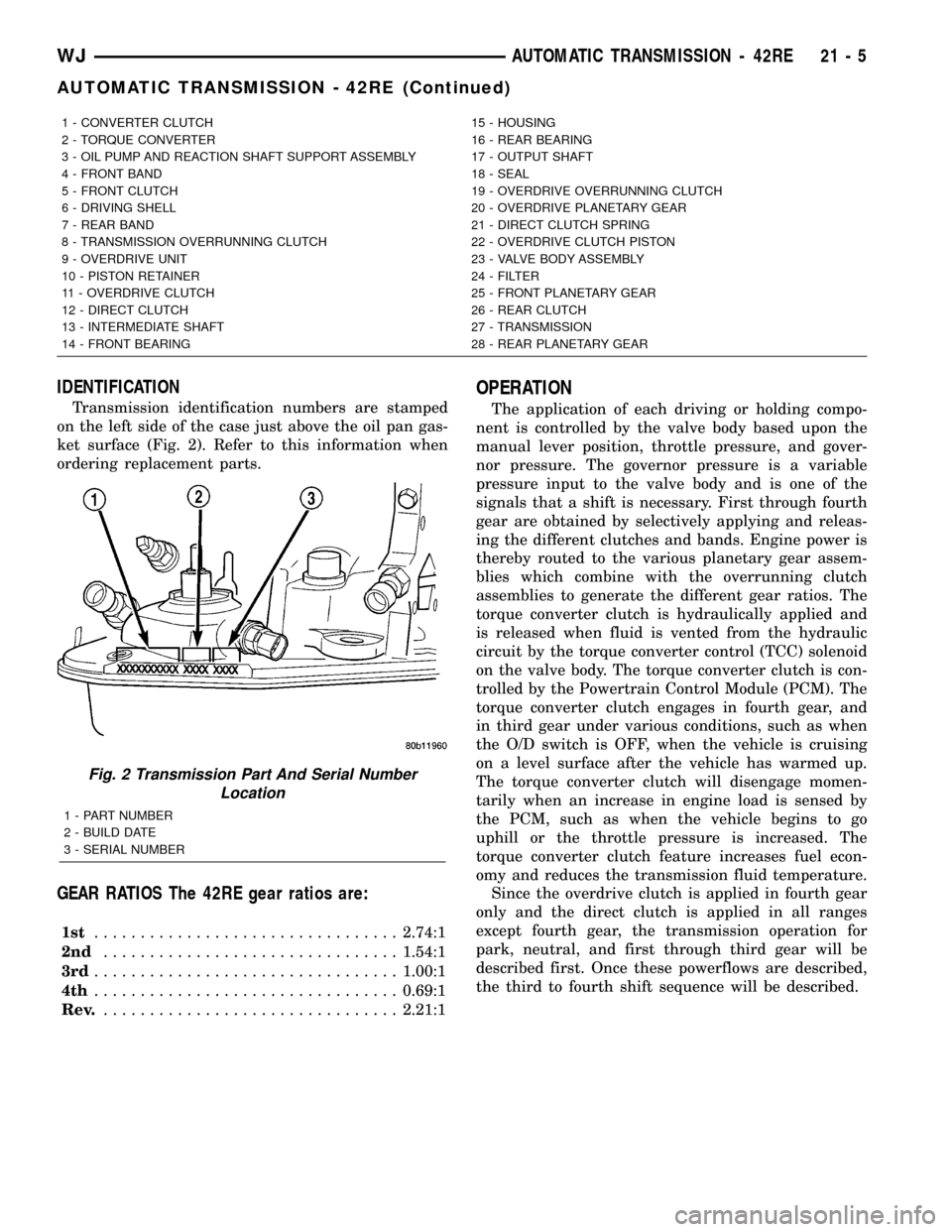

IDENTIFICATION

Transmission identification numbers are stamped

on the left side of the case just above the oil pan gas-

ket surface (Fig. 2). Refer to this information when

ordering replacement parts.

GEAR RATIOS The 42RE gear ratios are:

1st.................................2.74:1

2nd................................1.54:1

3rd.................................1.00:1

4th.................................0.69:1

Rev.................................2.21:1

OPERATION

The application of each driving or holding compo-

nent is controlled by the valve body based upon the

manual lever position, throttle pressure, and gover-

nor pressure. The governor pressure is a variable

pressure input to the valve body and is one of the

signals that a shift is necessary. First through fourth

gear are obtained by selectively applying and releas-

ing the different clutches and bands. Engine power is

thereby routed to the various planetary gear assem-

blies which combine with the overrunning clutch

assemblies to generate the different gear ratios. The

torque converter clutch is hydraulically applied and

is released when fluid is vented from the hydraulic

circuit by the torque converter control (TCC) solenoid

on the valve body. The torque converter clutch is con-

trolled by the Powertrain Control Module (PCM). The

torque converter clutch engages in fourth gear, and

in third gear under various conditions, such as when

the O/D switch is OFF, when the vehicle is cruising

on a level surface after the vehicle has warmed up.

The torque converter clutch will disengage momen-

tarily when an increase in engine load is sensed by

the PCM, such as when the vehicle begins to go

uphill or the throttle pressure is increased. The

torque converter clutch feature increases fuel econ-

omy and reduces the transmission fluid temperature.

Since the overdrive clutch is applied in fourth gear

only and the direct clutch is applied in all ranges

except fourth gear, the transmission operation for

park, neutral, and first through third gear will be

described first. Once these powerflows are described,

the third to fourth shift sequence will be described.

1 - CONVERTER CLUTCH 15 - HOUSING

2 - TORQUE CONVERTER 16 - REAR BEARING

3 - OIL PUMP AND REACTION SHAFT SUPPORT ASSEMBLY 17 - OUTPUT SHAFT

4 - FRONT BAND 18 - SEAL

5 - FRONT CLUTCH 19 - OVERDRIVE OVERRUNNING CLUTCH

6 - DRIVING SHELL 20 - OVERDRIVE PLANETARY GEAR

7 - REAR BAND 21 - DIRECT CLUTCH SPRING

8 - TRANSMISSION OVERRUNNING CLUTCH 22 - OVERDRIVE CLUTCH PISTON

9 - OVERDRIVE UNIT 23 - VALVE BODY ASSEMBLY

10 - PISTON RETAINER 24 - FILTER

11 - OVERDRIVE CLUTCH 25 - FRONT PLANETARY GEAR

12 - DIRECT CLUTCH 26 - REAR CLUTCH

13 - INTERMEDIATE SHAFT 27 - TRANSMISSION

14 - FRONT BEARING 28 - REAR PLANETARY GEAR

Fig. 2 Transmission Part And Serial Number

Location

1 - PART NUMBER

2 - BUILD DATE

3 - SERIAL NUMBER

WJAUTOMATIC TRANSMISSION - 42RE 21 - 5

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1535 of 2199

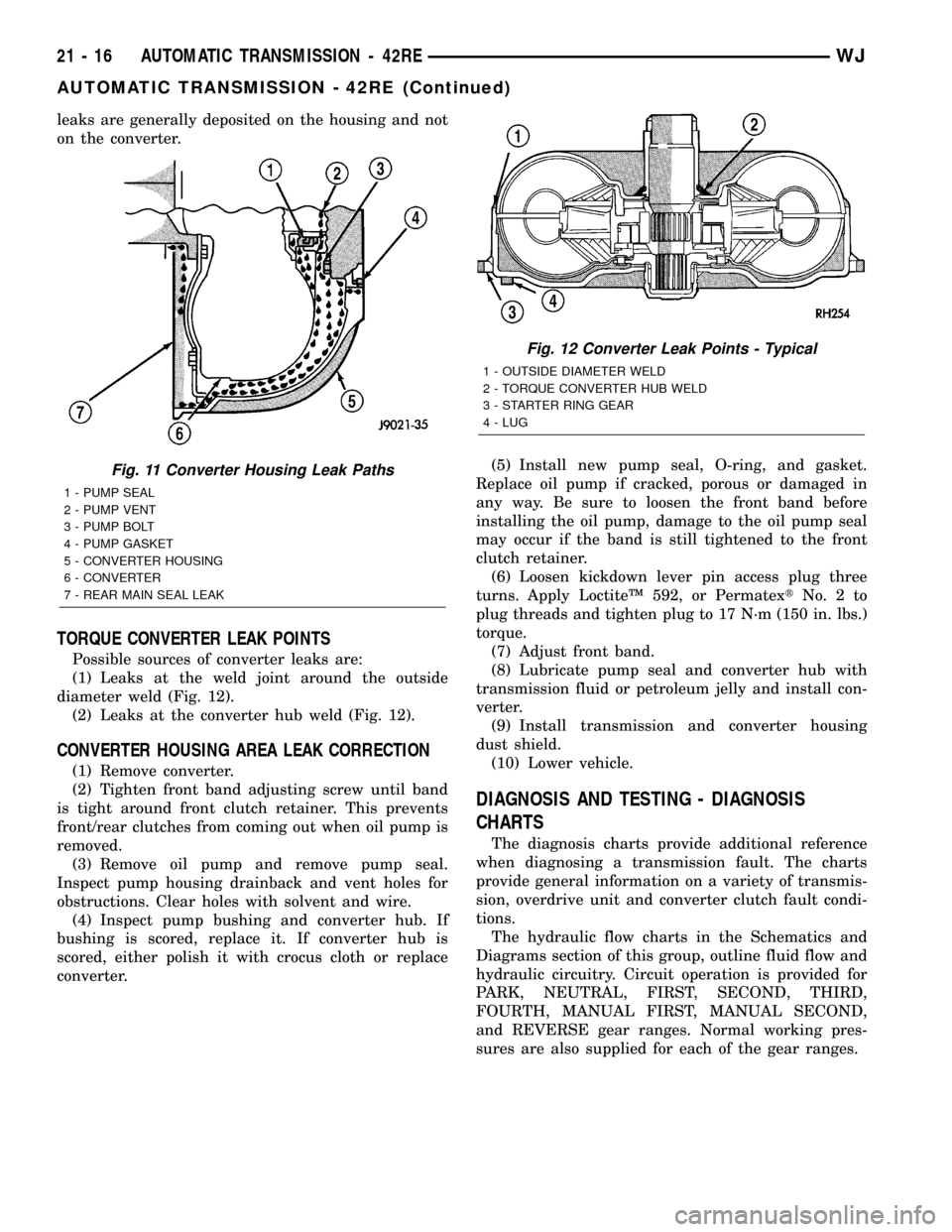

leaks are generally deposited on the housing and not

on the converter.

TORQUE CONVERTER LEAK POINTS

Possible sources of converter leaks are:

(1) Leaks at the weld joint around the outside

diameter weld (Fig. 12).

(2) Leaks at the converter hub weld (Fig. 12).

CONVERTER HOUSING AREA LEAK CORRECTION

(1) Remove converter.

(2) Tighten front band adjusting screw until band

is tight around front clutch retainer. This prevents

front/rear clutches from coming out when oil pump is

removed.

(3) Remove oil pump and remove pump seal.

Inspect pump housing drainback and vent holes for

obstructions. Clear holes with solvent and wire.

(4) Inspect pump bushing and converter hub. If

bushing is scored, replace it. If converter hub is

scored, either polish it with crocus cloth or replace

converter.(5) Install new pump seal, O-ring, and gasket.

Replace oil pump if cracked, porous or damaged in

any way. Be sure to loosen the front band before

installing the oil pump, damage to the oil pump seal

may occur if the band is still tightened to the front

clutch retainer.

(6) Loosen kickdown lever pin access plug three

turns. Apply LoctiteŸ 592, or PermatextNo.2to

plug threads and tighten plug to 17 N´m (150 in. lbs.)

torque.

(7) Adjust front band.

(8) Lubricate pump seal and converter hub with

transmission fluid or petroleum jelly and install con-

verter.

(9) Install transmission and converter housing

dust shield.

(10) Lower vehicle.

DIAGNOSIS AND TESTING - DIAGNOSIS

CHARTS

The diagnosis charts provide additional reference

when diagnosing a transmission fault. The charts

provide general information on a variety of transmis-

sion, overdrive unit and converter clutch fault condi-

tions.

The hydraulic flow charts in the Schematics and

Diagrams section of this group, outline fluid flow and

hydraulic circuitry. Circuit operation is provided for

PARK, NEUTRAL, FIRST, SECOND, THIRD,

FOURTH, MANUAL FIRST, MANUAL SECOND,

and REVERSE gear ranges. Normal working pres-

sures are also supplied for each of the gear ranges.

Fig. 11 Converter Housing Leak Paths

1 - PUMP SEAL

2 - PUMP VENT

3 - PUMP BOLT

4 - PUMP GASKET

5 - CONVERTER HOUSING

6 - CONVERTER

7 - REAR MAIN SEAL LEAK

Fig. 12 Converter Leak Points - Typical

1 - OUTSIDE DIAMETER WELD

2 - TORQUE CONVERTER HUB WELD

3 - STARTER RING GEAR

4 - LUG

21 - 16 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)