Brake pedal JEEP GRAND CHEROKEE 2003 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 209 of 2199

INSTALLATION

INSTALLATION - FRONT DISC BRAKE ROTOR

NOTE: If a new rotor is installed it must be match

mounted to the hub/bearing.

(1) Install rotor on hub studs in its original loca-

tion.

(2) Install the caliper anchor assembly on the

knuckle. Install anchor bolts and tighten to 90-115

N´m (66-85 ft. lbs.).

(3) Install wheel and tire assembly.

(4) Remove support and lower the vehicle.

(5) Pump brake pedal to seat caliper pistons and

brake shoes. Do not move vehicle until firm brake

pedal is obtained.

INSTALLATION - REAR DISC BRAKE ROTOR

(1) Install rotor on axle studs.

(2) Install the caliper anchor assembly.

(3) Install anchor bolts and tighten to 90-115 N´m

(66-85 ft. lbs.).

(4) Install wheel and tire assembly.

(5) Remove support and lower the vehicle.

(6) Pump brake pedal until caliper pistons and

brake shoes are seated.

PARKING BRAKE

OPERATION

The parking brakes operated by a automatic ten-

sioner mechanism built into the hand lever and cable

system. The front cable is connected to the hand

lever and the equalizer. The rear cables attached to

the equalizer and the parking brake shoe actuator.

A set of drum type brake shoes are used for park-

ing brakes. The shoes are mounted to the rear disc

brake adaptor. The parking brake drum is integrated

into the rear disc brake rotor.

Parking brake cable adjustment is controlled by an

automatic tensioner mechanism. The only adjust-

ment if necessary is to the park brake shoes if the

linings are worn.

DIAGNOSIS AND TESTING - PARKING BRAKE

NOTE: Parking brake adjustment is controlled by an

automatic cable tensioner and does not require

adjustment. The only adjustment that may be nec-

essary would be to the park brake shoes if they are

worn.

The parking brake switch is in circuit with the red

warning lamp in the dash. The switch will cause the

lamp to illuminate only when the parking brakes are

applied. If the lamp remains on after parking brake

release, the switch or wires are faulty.

If the red lamp comes on a fault has occurred in

the front or rear brake hydraulic system.

If the red warning lamp and yellow warning lamp

come on, the electronic brake distribution may be at

fault.

In most cases, the actual cause of an improperly

functioning parking brake (too loose/too tight/won't

hold), can be traced to a parking brake component.

NOTE: The leading cause of improper parking brake

operation, is excessive clearance between the park-

ing brake shoes and the shoe braking surface.

Excessive clearance is a result of lining and/or

drum wear, drum surface machined oversize.

Excessive parking brake lever travel (sometimes

described as a loose lever or too loose condition), is

the result of worn brake shoes, improper brake shoe

adjustment, or improperly assembled brake parts.

A too loose condition can also be caused by inoper-

ative or improperly assembled parking brake shoe

parts.

A condition where the parking brakes do not hold,

will most probably be due to a wheel brake compo-

nent.

Items to look for when diagnosing a parking brake

problem, are:

²Brake shoe wear

²Drum surface (in rear rotor) machined oversize

²Front cable not secured to lever

²Rear cable not attached to actuator

²Rear cable seized

²Parking brake lever not seated

²Parking brake lever bind

5 - 34 BRAKES - BASEWJ

ROTORS (Continued)

Page 216 of 2199

BRAKES - ABS

TABLE OF CONTENTS

page page

BRAKES - ABS

DESCRIPTION.........................41

OPERATION...........................41

DIAGNOSIS AND TESTING - ANTILOCK

BRAKES............................42

STANDARD PROCEDURE - BLEEDING ABS

BRAKE SYSTEM......................42

SPECIFICATIONS

TORQUE CHART......................42

ELECTRIC BRAKE

DESCRIPTION.........................43

OPERATION...........................43

FRONT WHEEL SPEED SENSOR

DESCRIPTION.........................43

OPERATION...........................43

REMOVAL.............................43INSTALLATION.........................43

G-SWITCH

DESCRIPTION.........................44

OPERATION...........................44

REMOVAL.............................44

INSTALLATION.........................44

REAR WHEEL SPEED SENSOR

DESCRIPTION.........................45

OPERATION...........................45

REMOVAL.............................45

INSTALLATION.........................46

HCU (HYDRAULIC CONTROL UNIT)

DESCRIPTION.........................46

OPERATION...........................46

REMOVAL.............................47

INSTALLATION.........................47

BRAKES - ABS

DESCRIPTION

The purpose of the antilock system is to prevent

wheel lockup during periods of high wheel slip. Pre-

venting lockup helps maintain vehicle braking action

and steering control.

The hydraulic system is a three channel design.

The front brakes are controlled individually and the

rear brakes in tandem.

The ABS electrical system is separate from other

vehicle electrical circuits. A separate controller oper-

ates the system.

OPERATION

The antilock CAB activates the system whenever

sensor signals indicate periods of high wheel slip.

High wheel slip can be described as the point where

wheel rotation begins approaching 20 to 30 percent of

actual vehicle speed during braking. Periods of high

wheel slip occur when brake stops involve high pedal

pressure and rate of vehicle deceleration.

Battery voltage is supplied to the CAB ignition ter-

minal when the ignition switch is turned to Run posi-

tion. The CAB performs a system initialization

procedure at this point. Initialization consists of a

static and dynamic self check of system electrical

components.

The static check occurs after the ignition switch is

turned to Run position. The dynamic check occurs

when vehicle road speed reaches approximately 30kph (18 mph). During the dynamic check, the CAB

briefly cycles the pump and solenoids to verify oper-

ation.

If an ABS component exhibits a fault during ini-

tialization, the CAB illuminates the amber warning

light and registers a fault code in the microprocessor

memory.

ANTILOCK BRAKING

The antilock system prevents lockup during high

slip conditions by modulating fluid apply pressure to

the wheel brake units.

Brake fluid apply pressure is modulated according

to wheel speed, degree of slip and rate of decelera-

tion. A sensor at each wheel converts wheel speed

into electrical signals. These signals are transmitted

to the CAB for processing and determination of

wheel slip and deceleration rate.

The ABS system has three fluid pressure control

channels. The front brakes are controlled separately

and the rear brakes in tandem. A speed sensor input

signal indicating a high slip condition activates the

CAB antilock program.

Two solenoid valves are used in each antilock con-

trol channel. The valves are all located within the

HCU valve body and work in pairs to either increase,

hold, or decrease apply pressure as needed in the

individual control channels.

The solenoid valves are not static during antilock

braking. They are cycled continuously to modulate

pressure. Solenoid cycle time in antilock mode can be

measured in milliseconds.

WJBRAKES - ABS 5 - 41

Page 310 of 2199

ELECTRONIC CONTROL MODULES

TABLE OF CONTENTS

page page

ELECTRONIC CONTROL MODULES

STANDARD PROCEDURE - PCM/SKIM

PROGRAMMING.......................1

ADJUSTABLE PEDALS MODULE

REMOVAL.............................2

INSTALLATION..........................3

BODY CONTROL MODULE

DESCRIPTION..........................3

OPERATION............................3

DIAGNOSIS AND TESTING - BODY CONTROL

MODULE.............................4

REMOVAL.............................5

INSTALLATION..........................5

COMMUNICATION

DESCRIPTION..........................6

OPERATION............................6

CONTROLLER ANTILOCK BRAKE

DESCRIPTION..........................6

OPERATION............................6

REMOVAL.............................7

INSTALLATION..........................7

DATA LINK CONNECTOR

DESCRIPTION - DATA LINK CONNECTOR.....7

OPERATION - DATA LINK CONNECTOR......7

DOOR MODULE

DESCRIPTION..........................7

OPERATION............................9

DIAGNOSIS AND TESTING - DOOR MODULE . 10

REMOVAL.............................10

INSTALLATION.........................10

MEMORY HEATED SEAT/MIRROR MODULE

DESCRIPTION.........................10OPERATION...........................11

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - HEATED SEAT

MODULE............................11

REMOVAL.............................11

INSTALLATION.........................12

POWERTRAIN CONTROL MODULE

DESCRIPTION

DESCRIPTION - PCM..................12

MODES OF OPERATION................12

DESCRIPTION - 5 VOLT SUPPLIES.......14

DESCRIPTION - IGNITION CIRCUIT SENSE . 14

DESCRIPTION - POWER GROUNDS......15

DESCRIPTION - SENSOR RETURN.......15

OPERATION

OPERATION - PCM....................15

OPERATION - 5 VOLT SUPPLIES.........16

OPERATION - IGNITION CIRCUIT SENSE . . . 16

REMOVAL.............................16

INSTALLATION.........................17

SENTRY KEY IMMOBILIZER MODULE

DESCRIPTION.........................17

OPERATION...........................17

REMOVAL.............................18

INSTALLATION.........................19

TRANSMISSION CONTROL MODULE

DESCRIPTION.........................19

OPERATION...........................19

STANDARD PROCEDURE

STANDARD PROCEDURE - TCM QUICK

LEARN..............................22

ELECTRONIC CONTROL

MODULES

STANDARD PROCEDURE - PCM/SKIM

PROGRAMMING

NOTE: Before replacing the PCM, be sure to check

the related component/circuit integrity for failures

not detected due to a double fault in the circuit.

Most PCM failures are caused by internal compo-

nent failures (i.e. relays and solenoids) and shorted

circuits (i.e. pull-ups, drivers, and switched cir-

cuits). These failures are difficult to detect when a

double fault has occurred and only one DTC has

been set.When a PCM (JTEC) and the SKIM are replaced

at the same time, perform the following steps in

order:

(1) Program the new PCM (JTEC).

(2) Program the new SKIM.

(3) Replace all ignition keys and program them to

the new SKIM.

PROGRAMMING THE PCM (JTEC)

The SKIS Secret Key is an ID code that is unique

to each SKIM. This code is programmed and stored

in the SKIM, the PCM, and the ignition key tran-

sponder chip(s). When replacing the PCM, it is nec-

essary to program the secret key into the new PCM

using the DRBIIItscan tool. Perform the following

steps to program the secret key into the PCM.

WJELECTRONIC CONTROL MODULES 8E - 1

Page 311 of 2199

(1) Turn the ignition switch to the On position

(transmission in Park/Neutral).

(2) Use the DRBIIItand select THEFT ALARM,

SKIM, then MISCELLANEOUS.

(3) Select PCM REPLACED (GAS ENGINE).

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

(5) Select ENTER to update PCM VIN.

NOTE: If three attempts are made to enter secure

access mode using an incorrect PIN, secured

access mode will be locked out for one hour. To

exit this lockout mode, turn the ignition switch to

the ON position for one hour, then enter the correct

PIN. (Ensure all accessories are turned off. Also

monitor the battery state and connect a battery

charger if necessary).

(6) Press ENTER to transfer the secret key (the

SKIM will send the secret key to the PCM).

(7) Press Page Back to get to the Select System

menu and select ENGINE, MISCELLANEOUS, and

SRI MEMORY CHECK.

(8) The DRBIIItwill ask, ªIs odometer reading

between XX and XX?º Select the YES or NO button

on the DRBIIIt. If NO is selected, the DRBIIItwill

read, ªEnter Odometer Reading (From I.P. odome-

ter)º. Enter the odometer reading from the instru-

ment cluster and press ENTER.

PROGRAMMING THE SKIM

(1) Turn the ignition switch to the On position

(transmission in Park/Neutral).

(2) Use the DRBIIItand select THEFT ALARM,

SKIM, then MISCELLANEOUS.

(3) Select PCM REPLACED (GAS ENGINE).

(4) Program the vehicle four-digit PIN into SKIM.

(5) Select COUNTRY CODE and enter the correct

country.

NOTE: Be sure to enter the correct country code. If

the incorrect country code is programmed into

SKIM, it cannot be changed and the SKIM must be

replaced.

(6) Select YES to update VIN (the SKIM will learn

the VIN from the PCM).

(7) Press ENTER to transfer the secret key (the

PCM will send the secret key to the SKIM).

(8) Program ignition keys to the SKIM.

NOTE: If the PCM and the SKIM are replaced at the

same time, all vehicle ignition keys will need to be

replaced and programmed to the new SKIM.

PROGRAMMING IGNITION KEYS TO THE SKIM

(1) Turn the ignition switch to the On position

(transmission in Park/Neutral).

(2) Use the DRBIIItand select THEFT ALARM,

SKIM, then MISCELLANEOUS.

(3) Select PROGRAM IGNITION KEY'S.

(4) Enter secured access mode by entering the

vehicle four-digit PIN.

NOTE: A maximum of eight keys can be learned to

each SKIM. Once a key is learned to a SKIM it (the

key) cannot be transferred to another vehicle.

(5) Obtain ignition keys to be programmed from

the customer (8 keys maximum).

(6) Using the DRBIIIt, erase all ignition keys by

selecting MISCELLANEOUS, and ERASE ALL CUR-

RENT IGN. KEYS.

(7) Program all of the ignition keys.

If ignition key programming is unsuccessful, the

DRBIIItwill display one of the following messages:

²Programming Not Attempted- The DRBIIIt

attempts to read the programmed key status and

there are no keys programmed into SKIM memory.

²Programming Key Failed (Possible Used

Key From Wrong Vehicle)- SKIM is unable to pro-

gram an ignition key transponder due to one of the

following:

²The ignition key transponder is faulty.

²The ignition key transponder is or has been

already programmed to another vehicle.

²8 Keys Already Learned, Programming Not

Done- The SKIM transponder ID memory is full.

²Learned Key In Ignition- The ID for the igni-

tion key transponder currently in the ignition lock

cylinder is already programmed in SKIM memory.

ADJUSTABLE PEDALS

MODULE

REMOVAL

(1) Disconnect the negative battery cable.

(2) Remove the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL - REMOV-

AL).

(3) Remove the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - REMOVAL).

(4) Remove the adjustable pedal motor for accessi-

bility. (Refer to 5 - BRAKES/HYDRAULIC/MECHAN-

ICAL/PEDAL - REMOVAL).

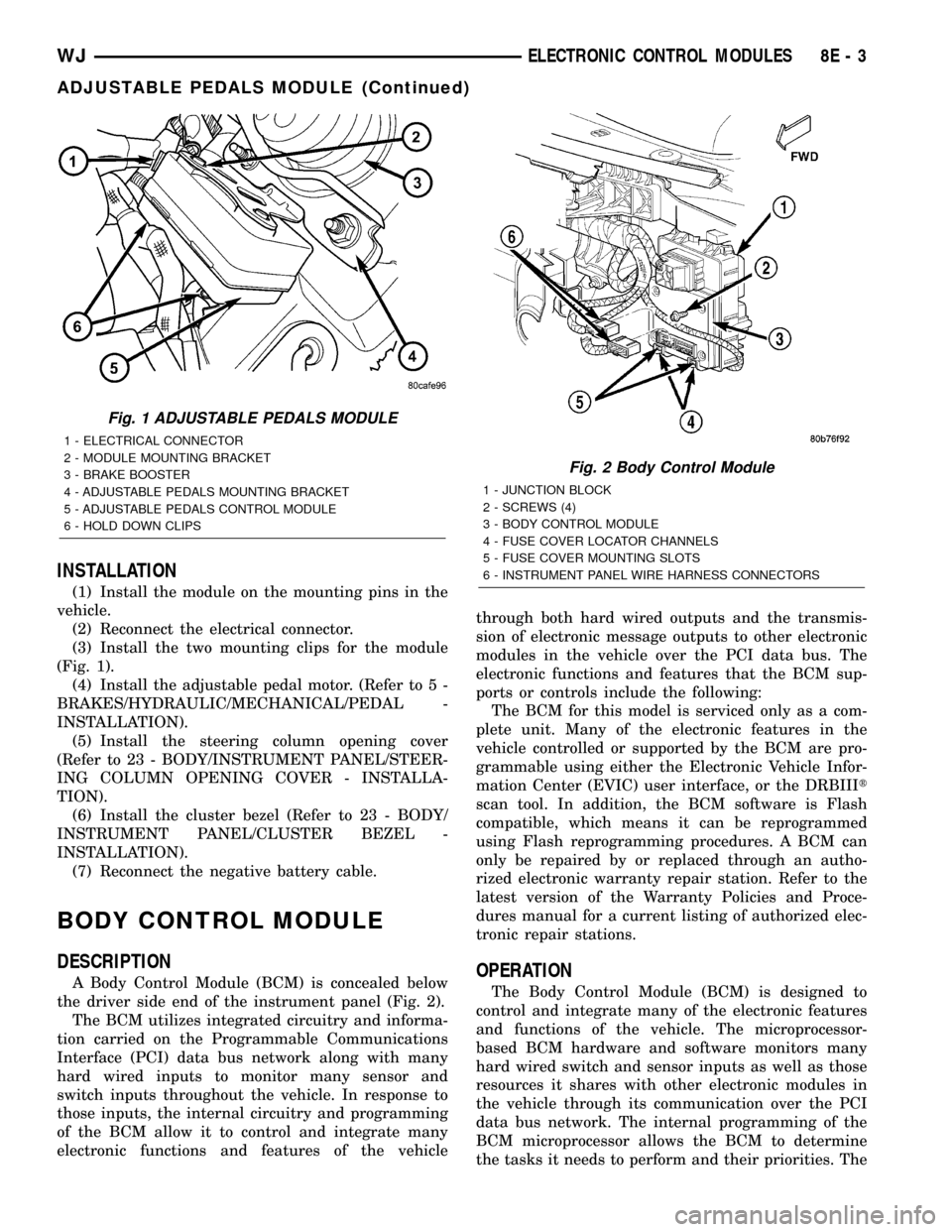

(5) Remove the two mounting clips from the mod-

ule (Fig. 1).

(6) Disconnect the electrical connector.

(7) Remove the adjustable pedal module.

8E - 2 ELECTRONIC CONTROL MODULESWJ

ELECTRONIC CONTROL MODULES (Continued)

Page 312 of 2199

INSTALLATION

(1) Install the module on the mounting pins in the

vehicle.

(2) Reconnect the electrical connector.

(3) Install the two mounting clips for the module

(Fig. 1).

(4) Install the adjustable pedal motor. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/PEDAL -

INSTALLATION).

(5) Install the steering column opening cover

(Refer to 23 - BODY/INSTRUMENT PANEL/STEER-

ING COLUMN OPENING COVER - INSTALLA-

TION).

(6) Install the cluster bezel (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(7) Reconnect the negative battery cable.

BODY CONTROL MODULE

DESCRIPTION

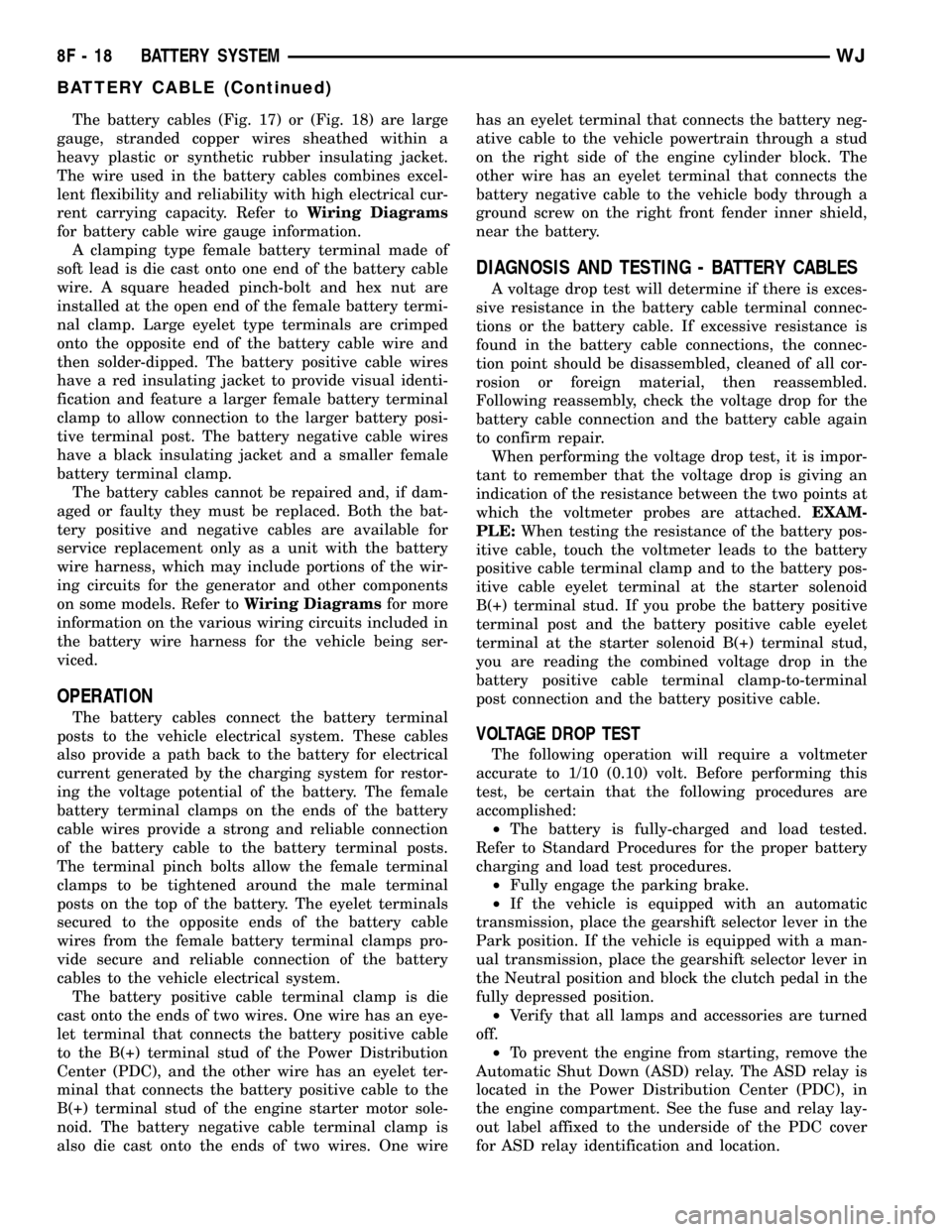

A Body Control Module (BCM) is concealed below

the driver side end of the instrument panel (Fig. 2).

The BCM utilizes integrated circuitry and informa-

tion carried on the Programmable Communications

Interface (PCI) data bus network along with many

hard wired inputs to monitor many sensor and

switch inputs throughout the vehicle. In response to

those inputs, the internal circuitry and programming

of the BCM allow it to control and integrate many

electronic functions and features of the vehiclethrough both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the PCI data bus. The

electronic functions and features that the BCM sup-

ports or controls include the following:

The BCM for this model is serviced only as a com-

plete unit. Many of the electronic features in the

vehicle controlled or supported by the BCM are pro-

grammable using either the Electronic Vehicle Infor-

mation Center (EVIC) user interface, or the DRBIIIt

scan tool. In addition, the BCM software is Flash

compatible, which means it can be reprogrammed

using Flash reprogramming procedures. A BCM can

only be repaired by or replaced through an autho-

rized electronic warranty repair station. Refer to the

latest version of the Warranty Policies and Proce-

dures manual for a current listing of authorized elec-

tronic repair stations.OPERATION

The Body Control Module (BCM) is designed to

control and integrate many of the electronic features

and functions of the vehicle. The microprocessor-

based BCM hardware and software monitors many

hard wired switch and sensor inputs as well as those

resources it shares with other electronic modules in

the vehicle through its communication over the PCI

data bus network. The internal programming of the

BCM microprocessor allows the BCM to determine

the tasks it needs to perform and their priorities. The

Fig. 1 ADJUSTABLE PEDALS MODULE

1 - ELECTRICAL CONNECTOR

2 - MODULE MOUNTING BRACKET

3 - BRAKE BOOSTER

4 - ADJUSTABLE PEDALS MOUNTING BRACKET

5 - ADJUSTABLE PEDALS CONTROL MODULE

6 - HOLD DOWN CLIPS

Fig. 2 Body Control Module

1 - JUNCTION BLOCK

2 - SCREWS (4)

3 - BODY CONTROL MODULE

4 - FUSE COVER LOCATOR CHANNELS

5 - FUSE COVER MOUNTING SLOTS

6 - INSTRUMENT PANEL WIRE HARNESS CONNECTORS

WJELECTRONIC CONTROL MODULES 8E - 3

ADJUSTABLE PEDALS MODULE (Continued)

Page 349 of 2199

The battery cables (Fig. 17) or (Fig. 18) are large

gauge, stranded copper wires sheathed within a

heavy plastic or synthetic rubber insulating jacket.

The wire used in the battery cables combines excel-

lent flexibility and reliability with high electrical cur-

rent carrying capacity. Refer toWiring Diagrams

for battery cable wire gauge information.

A clamping type female battery terminal made of

soft lead is die cast onto one end of the battery cable

wire. A square headed pinch-bolt and hex nut are

installed at the open end of the female battery termi-

nal clamp. Large eyelet type terminals are crimped

onto the opposite end of the battery cable wire and

then solder-dipped. The battery positive cable wires

have a red insulating jacket to provide visual identi-

fication and feature a larger female battery terminal

clamp to allow connection to the larger battery posi-

tive terminal post. The battery negative cable wires

have a black insulating jacket and a smaller female

battery terminal clamp.

The battery cables cannot be repaired and, if dam-

aged or faulty they must be replaced. Both the bat-

tery positive and negative cables are available for

service replacement only as a unit with the battery

wire harness, which may include portions of the wir-

ing circuits for the generator and other components

on some models. Refer toWiring Diagramsfor more

information on the various wiring circuits included in

the battery wire harness for the vehicle being ser-

viced.

OPERATION

The battery cables connect the battery terminal

posts to the vehicle electrical system. These cables

also provide a path back to the battery for electrical

current generated by the charging system for restor-

ing the voltage potential of the battery. The female

battery terminal clamps on the ends of the battery

cable wires provide a strong and reliable connection

of the battery cable to the battery terminal posts.

The terminal pinch bolts allow the female terminal

clamps to be tightened around the male terminal

posts on the top of the battery. The eyelet terminals

secured to the opposite ends of the battery cable

wires from the female battery terminal clamps pro-

vide secure and reliable connection of the battery

cables to the vehicle electrical system.

The battery positive cable terminal clamp is die

cast onto the ends of two wires. One wire has an eye-

let terminal that connects the battery positive cable

to the B(+) terminal stud of the Power Distribution

Center (PDC), and the other wire has an eyelet ter-

minal that connects the battery positive cable to the

B(+) terminal stud of the engine starter motor sole-

noid. The battery negative cable terminal clamp is

also die cast onto the ends of two wires. One wirehas an eyelet terminal that connects the battery neg-

ative cable to the vehicle powertrain through a stud

on the right side of the engine cylinder block. The

other wire has an eyelet terminal that connects the

battery negative cable to the vehicle body through a

ground screw on the right front fender inner shield,

near the battery.

DIAGNOSIS AND TESTING - BATTERY CABLES

A voltage drop test will determine if there is exces-

sive resistance in the battery cable terminal connec-

tions or the battery cable. If excessive resistance is

found in the battery cable connections, the connec-

tion point should be disassembled, cleaned of all cor-

rosion or foreign material, then reassembled.

Following reassembly, check the voltage drop for the

battery cable connection and the battery cable again

to confirm repair.

When performing the voltage drop test, it is impor-

tant to remember that the voltage drop is giving an

indication of the resistance between the two points at

which the voltmeter probes are attached.EXAM-

PLE:When testing the resistance of the battery pos-

itive cable, touch the voltmeter leads to the battery

positive cable terminal clamp and to the battery pos-

itive cable eyelet terminal at the starter solenoid

B(+) terminal stud. If you probe the battery positive

terminal post and the battery positive cable eyelet

terminal at the starter solenoid B(+) terminal stud,

you are reading the combined voltage drop in the

battery positive cable terminal clamp-to-terminal

post connection and the battery positive cable.

VOLTAGE DROP TEST

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing this

test, be certain that the following procedures are

accomplished:

²The battery is fully-charged and load tested.

Refer to Standard Procedures for the proper battery

charging and load test procedures.

²Fully engage the parking brake.

²If the vehicle is equipped with an automatic

transmission, place the gearshift selector lever in the

Park position. If the vehicle is equipped with a man-

ual transmission, place the gearshift selector lever in

the Neutral position and block the clutch pedal in the

fully depressed position.

²Verify that all lamps and accessories are turned

off.

²To prevent the engine from starting, remove the

Automatic Shut Down (ASD) relay. The ASD relay is

located in the Power Distribution Center (PDC), in

the engine compartment. See the fuse and relay lay-

out label affixed to the underside of the PDC cover

for ASD relay identification and location.

8F - 18 BATTERY SYSTEMWJ

BATTERY CABLE (Continued)

Page 430 of 2199

Diagnostic Trouble Code (DTC) for any malfunction it

detects. Each time the airbag indicator fails to illu-

minate due to an open or short in the cluster airbag

indicator circuit, the cluster sends a message notify-

ing the ACM of the condition, then the instrument

cluster and the ACM will each store a DTC. For

proper diagnosis of the airbag system, the ACM, the

PCI data bus, or the electronic message inputs to the

instrument cluster that control the airbag indicator,

a DRBIIItscan tool is required. Refer to the appro-

priate diagnostic information.

BRAKE/PARK BRAKE

INDICATOR

DESCRIPTION

A brake indicator is standard equipment on all

instrument clusters. The brake indicator is located

near the left edge of the instrument cluster, to the

left of the tachometer. There are two versions of the

brake indicator. The version used depends upon the

market for which the vehicle is manufactured. The

version of the brake indicator used for vehicles man-

ufactured for the United States consists of the word

ªBRAKEº imprinted on a red lens. The Rest-Of-World

(ROW) market version of this indicator has two

International Control and Display Symbol icons

imprinted on the red lens; one is the icon for ªBrake

Failureº, and the other is the icon for ªParking

Brakeº. In either case, the lens is located behind a

cutout in the opaque layer of the instrument cluster

overlay. The dark outer layer of the overlay prevents

the indicator from being clearly visible when it is not

illuminated. The ªBRAKEº text or the two icons

appear silhouetted against a red field through the

translucent outer layer of the overlay when the indi-

cator is illuminated from behind by a Light Emitting

Diode (LED), which is soldered onto the instrument

cluster electronic circuit board. The brake indicator

lens is serviced as a unit with the instrument cluster

lens, hood and mask unit.

OPERATION

The brake indicator gives an indication to the vehi-

cle operator when the parking brake is applied, when

the fluid level of the brake hydraulic system is low,

or if there are certain malfunctions of the Anti-lock

Brake System (ABS). This indicator is controlled by a

transistor on the instrument cluster electronic circuit

board based upon cluster programming, electronic

messages received by the cluster from the Controller

Anti-lock Brake (CAB) over the Programmable Com-

munications Interface (PCI) data bus, and a hard

wired input to the cluster from the park brake

switch. The brake indicator Light Emitting Diode(LED) is completely controlled by the instrument

cluster logic circuit, and that logic will only allow

this indicator to operate when the instrument cluster

receives a battery current input on the fused ignition

switch output (run-start) circuit. Therefore, the indi-

cator will always be off when the ignition switch is in

any position except On or Start. The LED only illu-

minates when it is provided a path to ground by the

instrument cluster transistor. The instrument cluster

will turn on the brake indicator for the following rea-

sons:

²Bulb Test- Each time the ignition switch is

turned to the On position the brake indicator is illu-

minated by the instrument cluster for about three

seconds as a bulb test.

²Brake Indicator Lamp-On Message- Each

time the cluster receives a brake indicator lamp-on

message from the CAB, the brake indicator will be

illuminated. The indicator remains illuminated until

the cluster receives a brake indicator lamp-off mes-

sage from the CAB.

²Park Brake Switch Input- Each time the

cluster logic circuit detects ground on the park brake

switch sense circuit (park brake switch closed = park

brake applied or not fully released) the brake indica-

tor is illuminated. The indicator remains illuminated

until the park brake switch sense input to the cluster

is an open circuit (park brake switch open = park

brake fully released), or until the ignition switch is

turned to the Off position, whichever occurs first.

²Communication Error- If the cluster receives

no brake indicator lamp-on or lamp-off messages

from the CAB for six consecutive seconds, the brake

indicator is illuminated. The indicator remains illu-

minated until the cluster receives a single valid

brake indicator lamp-off message from the CAB.

²Actuator Test- Each time the cluster is put

through the actuator test, the brake indicator will be

turned on for the duration of the test to confirm the

functionality of the LED and the cluster control cir-

cuitry.

The park brake switch on the park brake pedal

mechanism provides a hard wired ground input to

the instrument cluster circuitry through the red

brake warning indicator driver circuit whenever the

park brake is applied or not fully released. The CAB

continually monitors the input from the brake fluid

level switch and the circuits of the anti-lock brake

system, then sends the proper brake indicator

lamp-on or lamp-off messages to the instrument clus-

ter. If the CAB sends a brake indicator lamp-on mes-

sage after the bulb test, it indicates that the CAB

has detected a brake hydraulic system malfunction

and/or that the ABS system has become inoperative.

The CAB will store a Diagnostic Trouble Code (DTC)

for any malfunction it detects.

WJINSTRUMENT CLUSTER 8J - 15

AIRBAG INDICATOR (Continued)

Page 456 of 2199

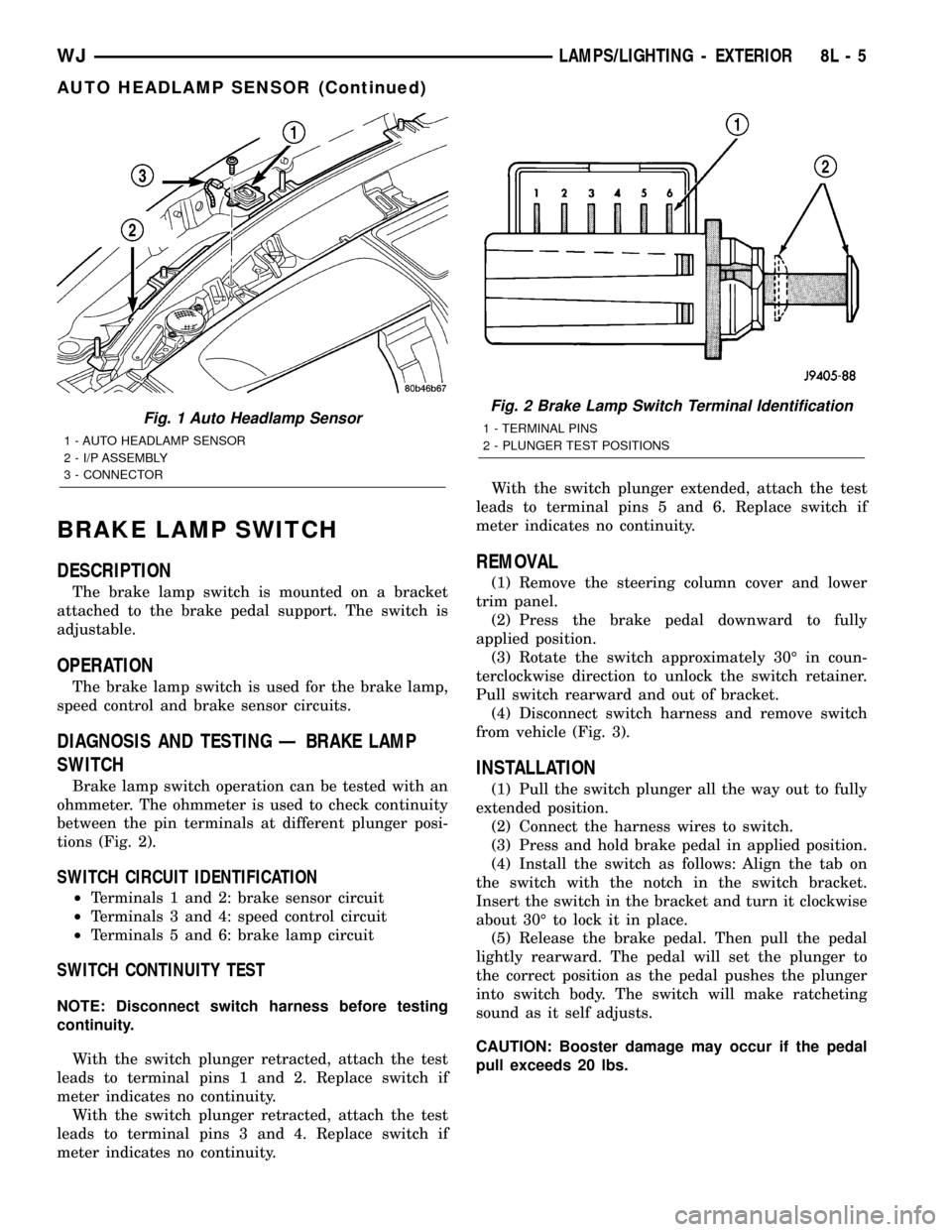

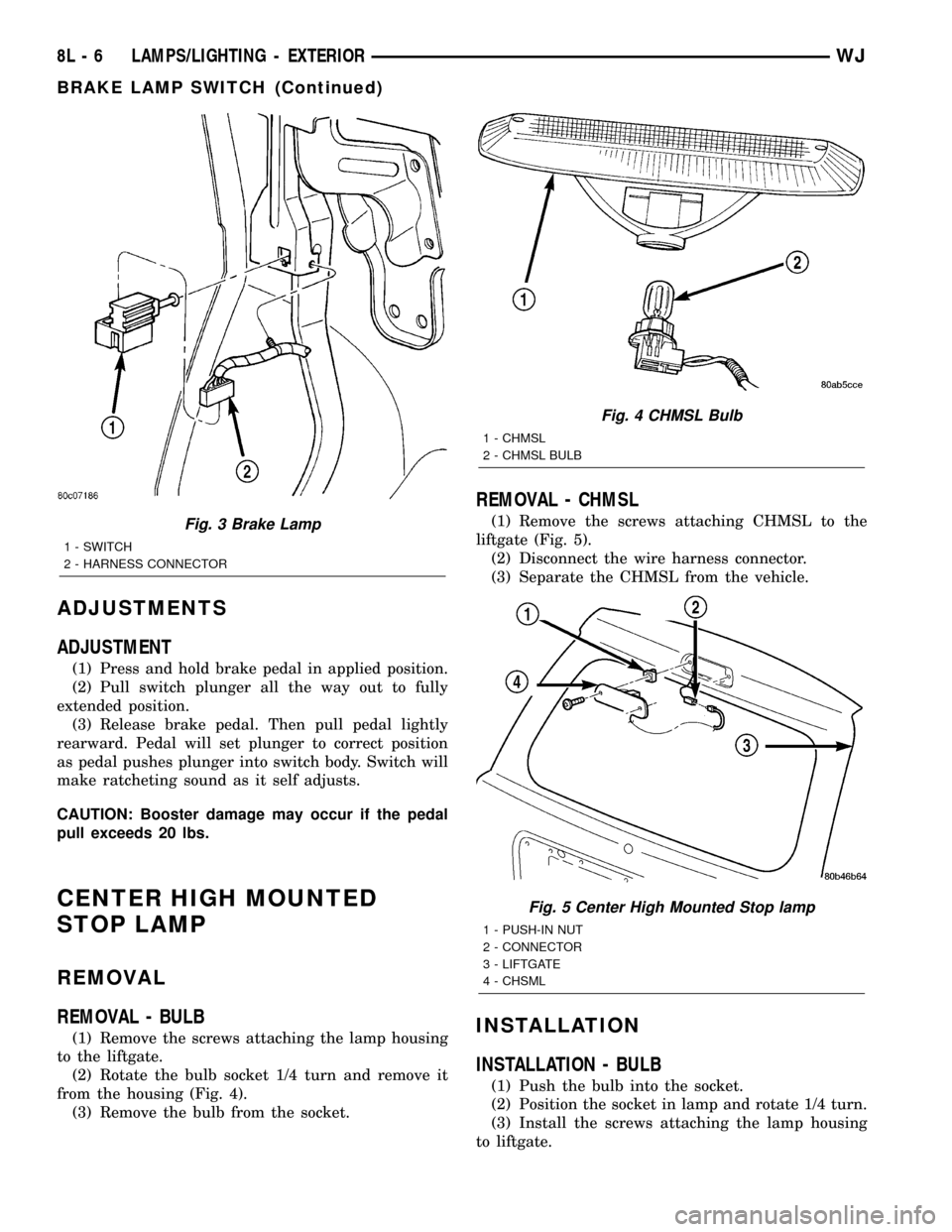

BRAKE LAMP SWITCH

DESCRIPTION

The brake lamp switch is mounted on a bracket

attached to the brake pedal support. The switch is

adjustable.

OPERATION

The brake lamp switch is used for the brake lamp,

speed control and brake sensor circuits.

DIAGNOSIS AND TESTING Ð BRAKE LAMP

SWITCH

Brake lamp switch operation can be tested with an

ohmmeter. The ohmmeter is used to check continuity

between the pin terminals at different plunger posi-

tions (Fig. 2).

SWITCH CIRCUIT IDENTIFICATION

²Terminals 1 and 2: brake sensor circuit

²Terminals 3 and 4: speed control circuit

²Terminals 5 and 6: brake lamp circuit

SWITCH CONTINUITY TEST

NOTE: Disconnect switch harness before testing

continuity.

With the switch plunger retracted, attach the test

leads to terminal pins 1 and 2. Replace switch if

meter indicates no continuity.

With the switch plunger retracted, attach the test

leads to terminal pins 3 and 4. Replace switch if

meter indicates no continuity.With the switch plunger extended, attach the test

leads to terminal pins 5 and 6. Replace switch if

meter indicates no continuity.

REMOVAL

(1) Remove the steering column cover and lower

trim panel.

(2) Press the brake pedal downward to fully

applied position.

(3) Rotate the switch approximately 30É in coun-

terclockwise direction to unlock the switch retainer.

Pull switch rearward and out of bracket.

(4) Disconnect switch harness and remove switch

from vehicle (Fig. 3).

INSTALLATION

(1) Pull the switch plunger all the way out to fully

extended position.

(2) Connect the harness wires to switch.

(3) Press and hold brake pedal in applied position.

(4) Install the switch as follows: Align the tab on

the switch with the notch in the switch bracket.

Insert the switch in the bracket and turn it clockwise

about 30É to lock it in place.

(5) Release the brake pedal. Then pull the pedal

lightly rearward. The pedal will set the plunger to

the correct position as the pedal pushes the plunger

into switch body. The switch will make ratcheting

sound as it self adjusts.

CAUTION: Booster damage may occur if the pedal

pull exceeds 20 lbs.

Fig. 1 Auto Headlamp Sensor

1 - AUTO HEADLAMP SENSOR

2 - I/P ASSEMBLY

3 - CONNECTOR

Fig. 2 Brake Lamp Switch Terminal Identification

1 - TERMINAL PINS

2 - PLUNGER TEST POSITIONS

WJLAMPS/LIGHTING - EXTERIOR 8L - 5

AUTO HEADLAMP SENSOR (Continued)

Page 457 of 2199

ADJUSTMENTS

ADJUSTMENT

(1) Press and hold brake pedal in applied position.

(2) Pull switch plunger all the way out to fully

extended position.

(3) Release brake pedal. Then pull pedal lightly

rearward. Pedal will set plunger to correct position

as pedal pushes plunger into switch body. Switch will

make ratcheting sound as it self adjusts.

CAUTION: Booster damage may occur if the pedal

pull exceeds 20 lbs.

CENTER HIGH MOUNTED

STOP LAMP

REMOVAL

REMOVAL - BULB

(1) Remove the screws attaching the lamp housing

to the liftgate.

(2) Rotate the bulb socket 1/4 turn and remove it

from the housing (Fig. 4).

(3) Remove the bulb from the socket.

REMOVAL - CHMSL

(1) Remove the screws attaching CHMSL to the

liftgate (Fig. 5).

(2) Disconnect the wire harness connector.

(3) Separate the CHMSL from the vehicle.

INSTALLATION

INSTALLATION - BULB

(1) Push the bulb into the socket.

(2) Position the socket in lamp and rotate 1/4 turn.

(3) Install the screws attaching the lamp housing

to liftgate.

Fig. 3 Brake Lamp

1 - SWITCH

2 - HARNESS CONNECTOR

Fig. 4 CHMSL Bulb

1 - CHMSL

2 - CHMSL BULB

Fig. 5 Center High Mounted Stop lamp

1 - PUSH-IN NUT

2 - CONNECTOR

3 - LIFTGATE

4 - CHSML

8L - 6 LAMPS/LIGHTING - EXTERIORWJ

BRAKE LAMP SWITCH (Continued)

Page 582 of 2199

SPEED CONTROL

TABLE OF CONTENTS

page page

SPEED CONTROL

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING - ROAD TEST.....2

SPECIFICATIONS

TORQUE - SPEED CONTROL.............3

CABLE

DESCRIPTION..........................3

OPERATION............................3

REMOVAL

REMOVAL - 4.0L.......................3

REMOVAL - 4.7L.......................3

INSTALLATION

INSTALLATION - 4.0L...................4

INSTALLATION - 4.7L...................4

SERVO

DESCRIPTION..........................5OPERATION............................5

REMOVAL.............................5

INSTALLATION..........................6

SWITCH

DESCRIPTION..........................7

OPERATION............................7

REMOVAL.............................7

INSTALLATION..........................7

VACUUM RESERVOIR

DESCRIPTION..........................8

OPERATION............................8

DIAGNOSIS AND TESTING - VACUUM

RESERVOIR..........................8

REMOVAL.............................8

INSTALLATION..........................9

SPEED CONTROL

DESCRIPTION

The speed control system is electronically con-

trolled and vacuum operated. Electronic control of

the speed control system is integrated into the Pow-

ertrain Control Module (PCM). The controls consist

of two steering wheel mounted switches. The

switches are labeled: ON/OFF, RES/ACCEL, SET,

COAST, and CANCEL.

The system is designed to operate at speeds above

30 mph (50 km/h).

WARNING: THE USE OF SPEED CONTROL IS NOT

RECOMMENDED WHEN DRIVING CONDITIONS DO

NOT PERMIT MAINTAINING A CONSTANT SPEED,

SUCH AS IN HEAVY TRAFFIC OR ON ROADS THAT

ARE WINDING, ICY, SNOW COVERED, OR SLIP-

PERY.

OPERATION

When speed control is selected by depressing the

ON switch, the PCM allows a set speed to be stored

in PCM RAM for speed control. To store a set speed,

depress the SET switch while the vehicle is moving

at a speed between 35 and 85 mph. In order for the

speed control to engage, the brakes cannot be

applied, nor can the gear selector be indicating the

transmission is in Park or Neutral.

The speed control can be disengaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

²Depressing the clutch pedal (if equipped).

NOTE: Depressing the OFF switch or turning off the

ignition switch will erase the set speed stored in

the PCM.

For added safety, the speed control system is pro-

grammed to disengage for any of the following condi-

tions:

²An indication of Park or Neutral

²A rapid increase rpm (indicates that the clutch

has been disengaged)

²Excessive engine rpm (indicates that the trans-

mission may be in a low gear)

²The speed signal increases at a rate of 10 mph

per second (indicates that the coefficient of friction

between the road surface and tires is extremely low)

WJSPEED CONTROL 8P - 1