Fill location JEEP GRAND CHEROKEE 2003 WJ / 2.G Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 1435 of 2199

CAUTION: The left and right fuel rails are replaced

as an assembly. Do not attempt to separate rail

halves at connector tube (Fig. 22). Due to design of

tube, it does not use any clamps. Never attempt to

install a clamping device of any kind to tube. When

removing fuel rail assembly for any reason, be care-

ful not to bend or kink tube.

(1) Remove fuel tank filler tube cap.

(2) Perform Fuel System Pressure Release Proce-

dure.

(3) Remove negative battery cable at battery.

(4) Remove air duct at throttle body air box.

(5) Remove air box at throttle body.

(6) Remove wiring at rear of generator.

(7) Disconnect fuel line latch clip and fuel line at

fuel rail. A special tool will be necessary for fuel line

disconnection. Refer to Quick-Connect Fittings.

(8) Remove vacuum lines at throttle body.(9) Disconnect electrical connectors at all 8 fuel

injectors. To remove connector refer to (Fig. 23). Push

red colored slider away from injector (1). While push-

ing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring har-

ness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(10) Disconnect electrical connectors at throttle

body.

(11) Disconnect electrical connectors at MAP and

IAT sensors.

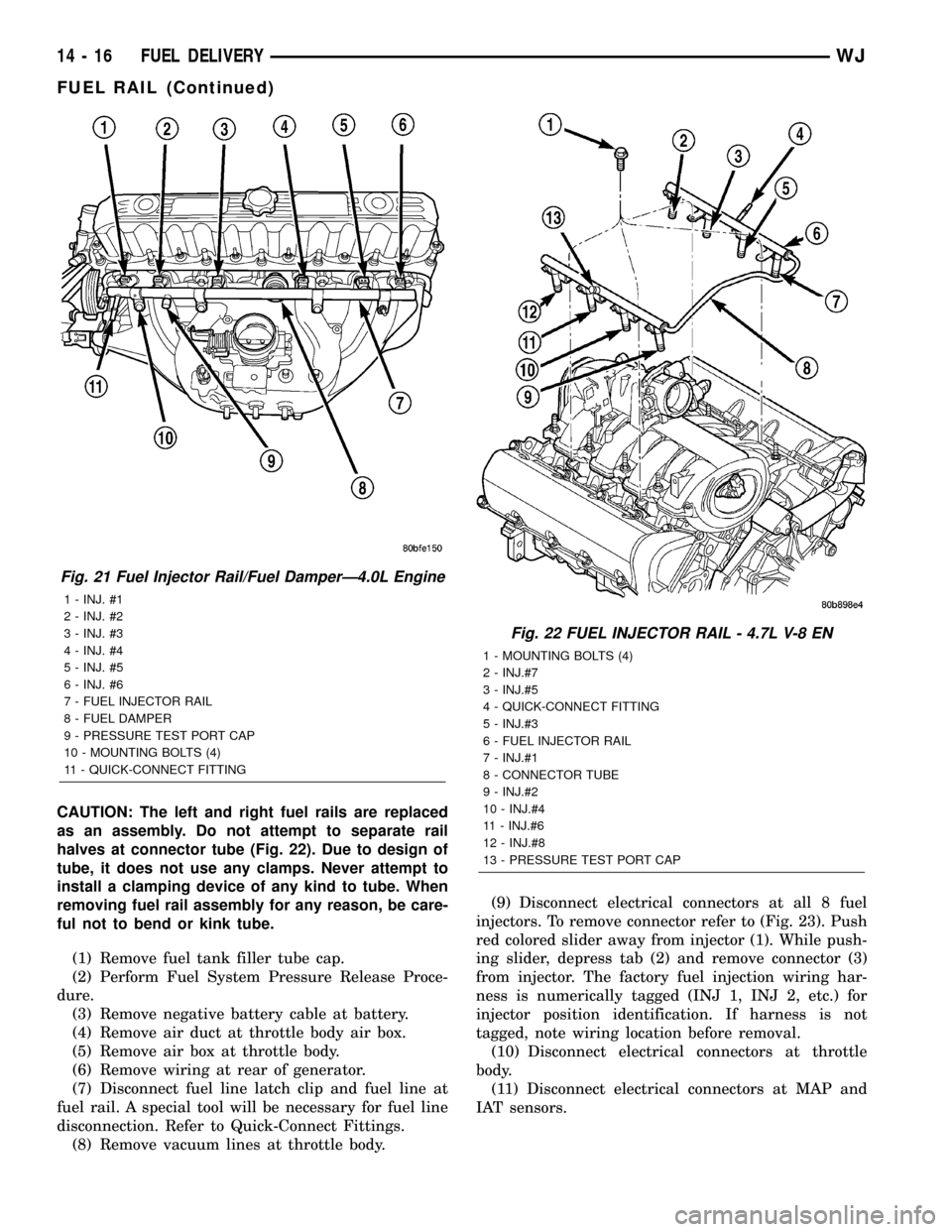

Fig. 21 Fuel Injector Rail/Fuel DamperÐ4.0L Engine

1 - INJ. #1

2 - INJ. #2

3 - INJ. #3

4 - INJ. #4

5 - INJ. #5

6 - INJ. #6

7 - FUEL INJECTOR RAIL

8 - FUEL DAMPER

9 - PRESSURE TEST PORT CAP

10 - MOUNTING BOLTS (4)

11 - QUICK-CONNECT FITTING

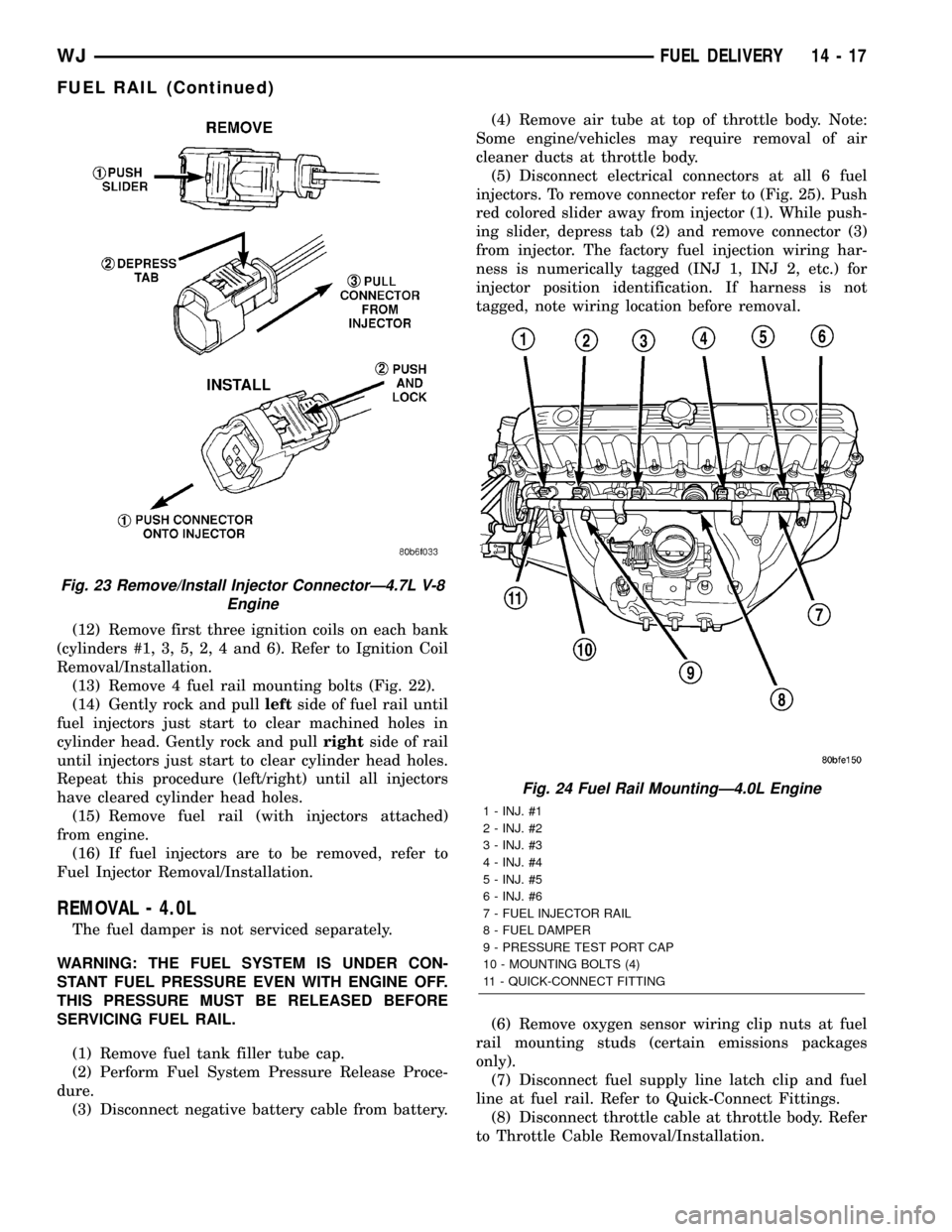

Fig. 22 FUEL INJECTOR RAIL - 4.7L V-8 EN

1 - MOUNTING BOLTS (4)

2 - INJ.#7

3 - INJ.#5

4 - QUICK-CONNECT FITTING

5 - INJ.#3

6 - FUEL INJECTOR RAIL

7 - INJ.#1

8 - CONNECTOR TUBE

9 - INJ.#2

10 - INJ.#4

11 - INJ.#6

12 - INJ.#8

13 - PRESSURE TEST PORT CAP

14 - 16 FUEL DELIVERYWJ

FUEL RAIL (Continued)

Page 1436 of 2199

(12) Remove first three ignition coils on each bank

(cylinders #1, 3, 5, 2, 4 and 6). Refer to Ignition Coil

Removal/Installation.

(13) Remove 4 fuel rail mounting bolts (Fig. 22).

(14) Gently rock and pullleftside of fuel rail until

fuel injectors just start to clear machined holes in

cylinder head. Gently rock and pullrightside of rail

until injectors just start to clear cylinder head holes.

Repeat this procedure (left/right) until all injectors

have cleared cylinder head holes.

(15) Remove fuel rail (with injectors attached)

from engine.

(16) If fuel injectors are to be removed, refer to

Fuel Injector Removal/Installation.

REMOVAL - 4.0L

The fuel damper is not serviced separately.

WARNING: THE FUEL SYSTEM IS UNDER CON-

STANT FUEL PRESSURE EVEN WITH ENGINE OFF.

THIS PRESSURE MUST BE RELEASED BEFORE

SERVICING FUEL RAIL.

(1) Remove fuel tank filler tube cap.

(2) Perform Fuel System Pressure Release Proce-

dure.

(3) Disconnect negative battery cable from battery.(4) Remove air tube at top of throttle body. Note:

Some engine/vehicles may require removal of air

cleaner ducts at throttle body.

(5) Disconnect electrical connectors at all 6 fuel

injectors. To remove connector refer to (Fig. 25). Push

red colored slider away from injector (1). While push-

ing slider, depress tab (2) and remove connector (3)

from injector. The factory fuel injection wiring har-

ness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, note wiring location before removal.

(6) Remove oxygen sensor wiring clip nuts at fuel

rail mounting studs (certain emissions packages

only).

(7) Disconnect fuel supply line latch clip and fuel

line at fuel rail. Refer to Quick-Connect Fittings.

(8) Disconnect throttle cable at throttle body. Refer

to Throttle Cable Removal/Installation.

Fig. 23 Remove/Install Injector ConnectorÐ4.7L V-8

Engine

Fig. 24 Fuel Rail MountingÐ4.0L Engine

1 - INJ. #1

2 - INJ. #2

3 - INJ. #3

4 - INJ. #4

5 - INJ. #5

6 - INJ. #6

7 - FUEL INJECTOR RAIL

8 - FUEL DAMPER

9 - PRESSURE TEST PORT CAP

10 - MOUNTING BOLTS (4)

11 - QUICK-CONNECT FITTING

WJFUEL DELIVERY 14 - 17

FUEL RAIL (Continued)

Page 1531 of 2199

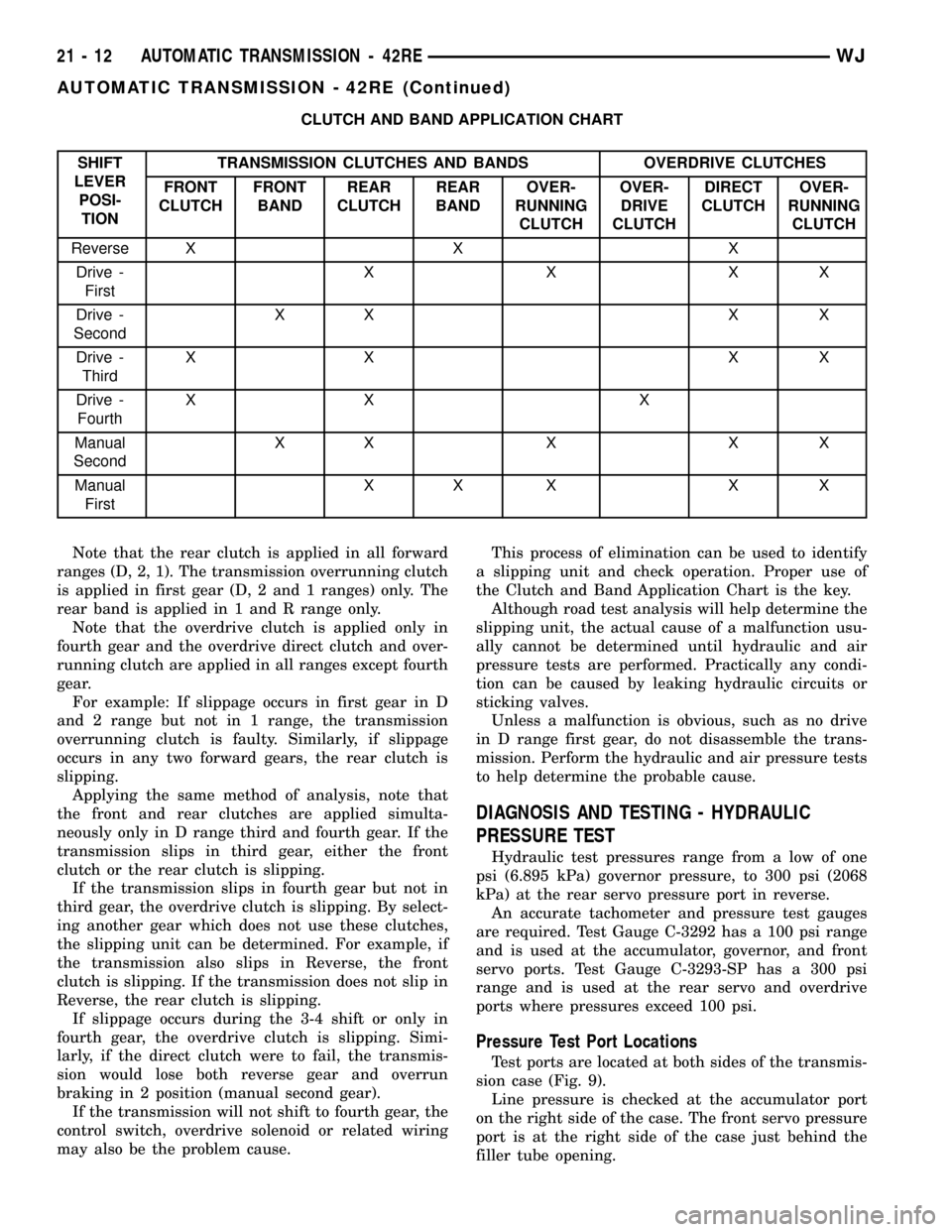

CLUTCH AND BAND APPLICATION CHART

SHIFT

LEVER

POSI-

TIONTRANSMISSION CLUTCHES AND BANDS OVERDRIVE CLUTCHES

FRONT

CLUTCHFRONT

BANDREAR

CLUTCHREAR

BANDOVER-

RUNNING

CLUTCHOVER-

DRIVE

CLUTCHDIRECT

CLUTCHOVER-

RUNNING

CLUTCH

Reverse X X X

Drive -

FirstXXXX

Drive -

SecondXX X X

Drive -

ThirdXX XX

Drive -

FourthXX X

Manual

SecondXXXXX

Manual

FirstXX X X X

Note that the rear clutch is applied in all forward

ranges (D, 2, 1). The transmission overrunning clutch

is applied in first gear (D, 2 and 1 ranges) only. The

rear band is applied in 1 and R range only.

Note that the overdrive clutch is applied only in

fourth gear and the overdrive direct clutch and over-

running clutch are applied in all ranges except fourth

gear.

For example: If slippage occurs in first gear in D

and 2 range but not in 1 range, the transmission

overrunning clutch is faulty. Similarly, if slippage

occurs in any two forward gears, the rear clutch is

slipping.

Applying the same method of analysis, note that

the front and rear clutches are applied simulta-

neously only in D range third and fourth gear. If the

transmission slips in third gear, either the front

clutch or the rear clutch is slipping.

If the transmission slips in fourth gear but not in

third gear, the overdrive clutch is slipping. By select-

ing another gear which does not use these clutches,

the slipping unit can be determined. For example, if

the transmission also slips in Reverse, the front

clutch is slipping. If the transmission does not slip in

Reverse, the rear clutch is slipping.

If slippage occurs during the 3-4 shift or only in

fourth gear, the overdrive clutch is slipping. Simi-

larly, if the direct clutch were to fail, the transmis-

sion would lose both reverse gear and overrun

braking in 2 position (manual second gear).

If the transmission will not shift to fourth gear, the

control switch, overdrive solenoid or related wiring

may also be the problem cause.This process of elimination can be used to identify

a slipping unit and check operation. Proper use of

the Clutch and Band Application Chart is the key.

Although road test analysis will help determine the

slipping unit, the actual cause of a malfunction usu-

ally cannot be determined until hydraulic and air

pressure tests are performed. Practically any condi-

tion can be caused by leaking hydraulic circuits or

sticking valves.

Unless a malfunction is obvious, such as no drive

in D range first gear, do not disassemble the trans-

mission. Perform the hydraulic and air pressure tests

to help determine the probable cause.

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TEST

Hydraulic test pressures range from a low of one

psi (6.895 kPa) governor pressure, to 300 psi (2068

kPa) at the rear servo pressure port in reverse.

An accurate tachometer and pressure test gauges

are required. Test Gauge C-3292 has a 100 psi range

and is used at the accumulator, governor, and front

servo ports. Test Gauge C-3293-SP has a 300 psi

range and is used at the rear servo and overdrive

ports where pressures exceed 100 psi.

Pressure Test Port Locations

Test ports are located at both sides of the transmis-

sion case (Fig. 9).

Line pressure is checked at the accumulator port

on the right side of the case. The front servo pressure

port is at the right side of the case just behind the

filler tube opening.

21 - 12 AUTOMATIC TRANSMISSION - 42REWJ

AUTOMATIC TRANSMISSION - 42RE (Continued)

Page 1581 of 2199

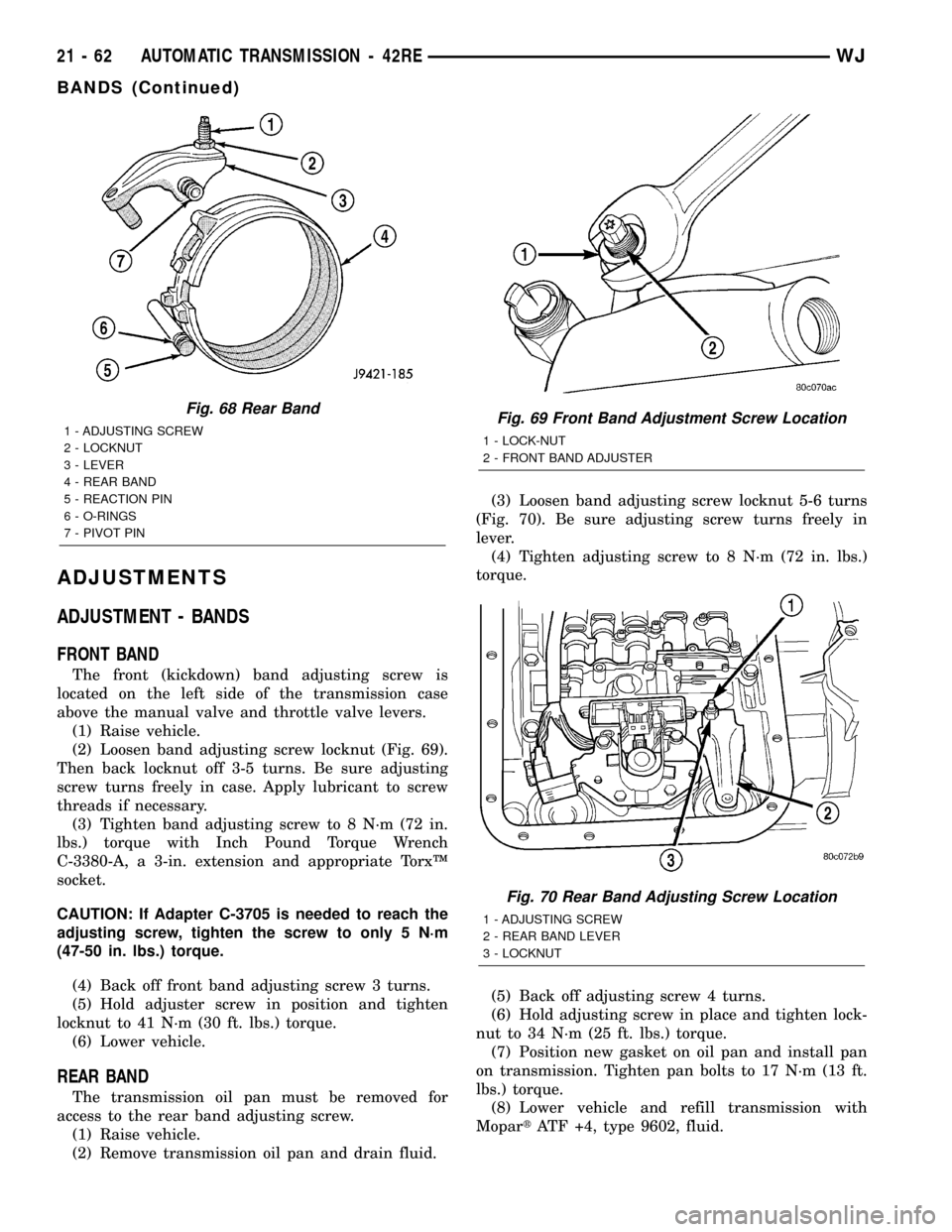

ADJUSTMENTS

ADJUSTMENT - BANDS

FRONT BAND

The front (kickdown) band adjusting screw is

located on the left side of the transmission case

above the manual valve and throttle valve levers.

(1) Raise vehicle.

(2) Loosen band adjusting screw locknut (Fig. 69).

Then back locknut off 3-5 turns. Be sure adjusting

screw turns freely in case. Apply lubricant to screw

threads if necessary.

(3) Tighten band adjusting screw to 8 N´m (72 in.

lbs.) torque with Inch Pound Torque Wrench

C-3380-A, a 3-in. extension and appropriate TorxŸ

socket.

CAUTION: If Adapter C-3705 is needed to reach the

adjusting screw, tighten the screw to only 5 N´m

(47-50 in. lbs.) torque.

(4) Back off front band adjusting screw 3 turns.

(5) Hold adjuster screw in position and tighten

locknut to 41 N´m (30 ft. lbs.) torque.

(6) Lower vehicle.

REAR BAND

The transmission oil pan must be removed for

access to the rear band adjusting screw.

(1) Raise vehicle.

(2) Remove transmission oil pan and drain fluid.(3) Loosen band adjusting screw locknut 5-6 turns

(Fig. 70). Be sure adjusting screw turns freely in

lever.

(4) Tighten adjusting screw to 8 N´m (72 in. lbs.)

torque.

(5) Back off adjusting screw 4 turns.

(6) Hold adjusting screw in place and tighten lock-

nut to 34 N´m (25 ft. lbs.) torque.

(7) Position new gasket on oil pan and install pan

on transmission. Tighten pan bolts to 17 N´m (13 ft.

lbs.) torque.

(8) Lower vehicle and refill transmission with

MopartATF +4, type 9602, fluid.

Fig. 68 Rear Band

1 - ADJUSTING SCREW

2 - LOCKNUT

3 - LEVER

4 - REAR BAND

5 - REACTION PIN

6 - O-RINGS

7 - PIVOT PINFig. 69 Front Band Adjustment Screw Location

1 - LOCK-NUT

2 - FRONT BAND ADJUSTER

Fig. 70 Rear Band Adjusting Screw Location

1 - ADJUSTING SCREW

2 - REAR BAND LEVER

3 - LOCKNUT

21 - 62 AUTOMATIC TRANSMISSION - 42REWJ

BANDS (Continued)

Page 1654 of 2199

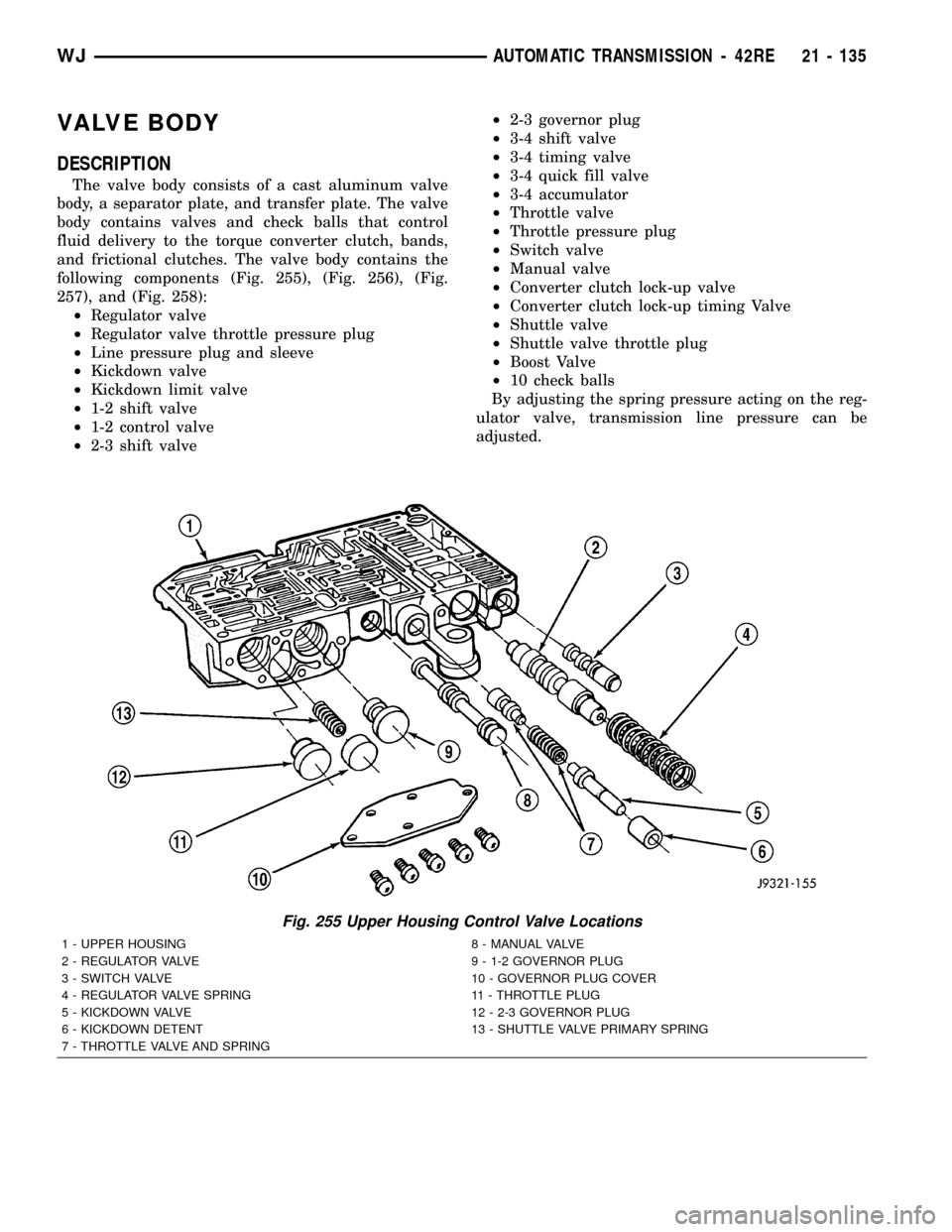

VALVE BODY

DESCRIPTION

The valve body consists of a cast aluminum valve

body, a separator plate, and transfer plate. The valve

body contains valves and check balls that control

fluid delivery to the torque converter clutch, bands,

and frictional clutches. The valve body contains the

following components (Fig. 255), (Fig. 256), (Fig.

257), and (Fig. 258):

²Regulator valve

²Regulator valve throttle pressure plug

²Line pressure plug and sleeve

²Kickdown valve

²Kickdown limit valve

²1-2 shift valve

²1-2 control valve

²2-3 shift valve²2-3 governor plug

²3-4 shift valve

²3-4 timing valve

²3-4 quick fill valve

²3-4 accumulator

²Throttle valve

²Throttle pressure plug

²Switch valve

²Manual valve

²Converter clutch lock-up valve

²Converter clutch lock-up timing Valve

²Shuttle valve

²Shuttle valve throttle plug

²Boost Valve

²10 check balls

By adjusting the spring pressure acting on the reg-

ulator valve, transmission line pressure can be

adjusted.

Fig. 255 Upper Housing Control Valve Locations

1 - UPPER HOUSING 8 - MANUAL VALVE

2 - REGULATOR VALVE 9 - 1-2 GOVERNOR PLUG

3 - SWITCH VALVE 10 - GOVERNOR PLUG COVER

4 - REGULATOR VALVE SPRING 11 - THROTTLE PLUG

5 - KICKDOWN VALVE 12 - 2-3 GOVERNOR PLUG

6 - KICKDOWN DETENT 13 - SHUTTLE VALVE PRIMARY SPRING

7 - THROTTLE VALVE AND SPRING

WJAUTOMATIC TRANSMISSION - 42RE 21 - 135

Page 1686 of 2199

²pressure adjusting screw and bracket assembly

²throttle lever

²manual lever and shaft seal

²throttle lever shaft seal, washer, and E-clip

²fluid filter and screws

²detent ball and spring

²valve body screws

²governor pressure solenoid

²governor pressure sensor and retaining clip

²park lock rod and E-clip

ASSEMBLY

CAUTION: Do not force valves or plugs into place

during reassembly. If the valve body bores, valves

and plugs are free of distortion or burrs, the valve

body components should all slide into place easily.

In addition, do not overtighten the transfer plate

and valve body screws during reassembly. Over-

tightening can distort the housings resulting in

valve sticking, cross leakage and unsatisfactory

operation. Tighten valve body screws to recom-

mended torque only.

LOWER HOUSING

(1) Lubricate valves, springs, and the housing

valve and plug bores with clean transmission fluid

(Fig. 309).

(2) Install 3-4 timing valve spring and valve in

lower housing.

(3) Install 3-4 quick fill valve in lower housing.

(4) Install 3-4 quick fill valve spring and plug in

housing.

(5) Install timing valve end plate. Tighten end

plate screws to 4 N´m (35 in. lbs.) torque.

3-4 ACCUMULATOR

(1) Lubricate accumulator piston, seals and hous-

ing piston bore with clean transmission fluid (Fig.

310).

(2) Install new seal rings on accumulator piston.

(3) Install piston and spring in housing.

(4) Install end plate on housing.

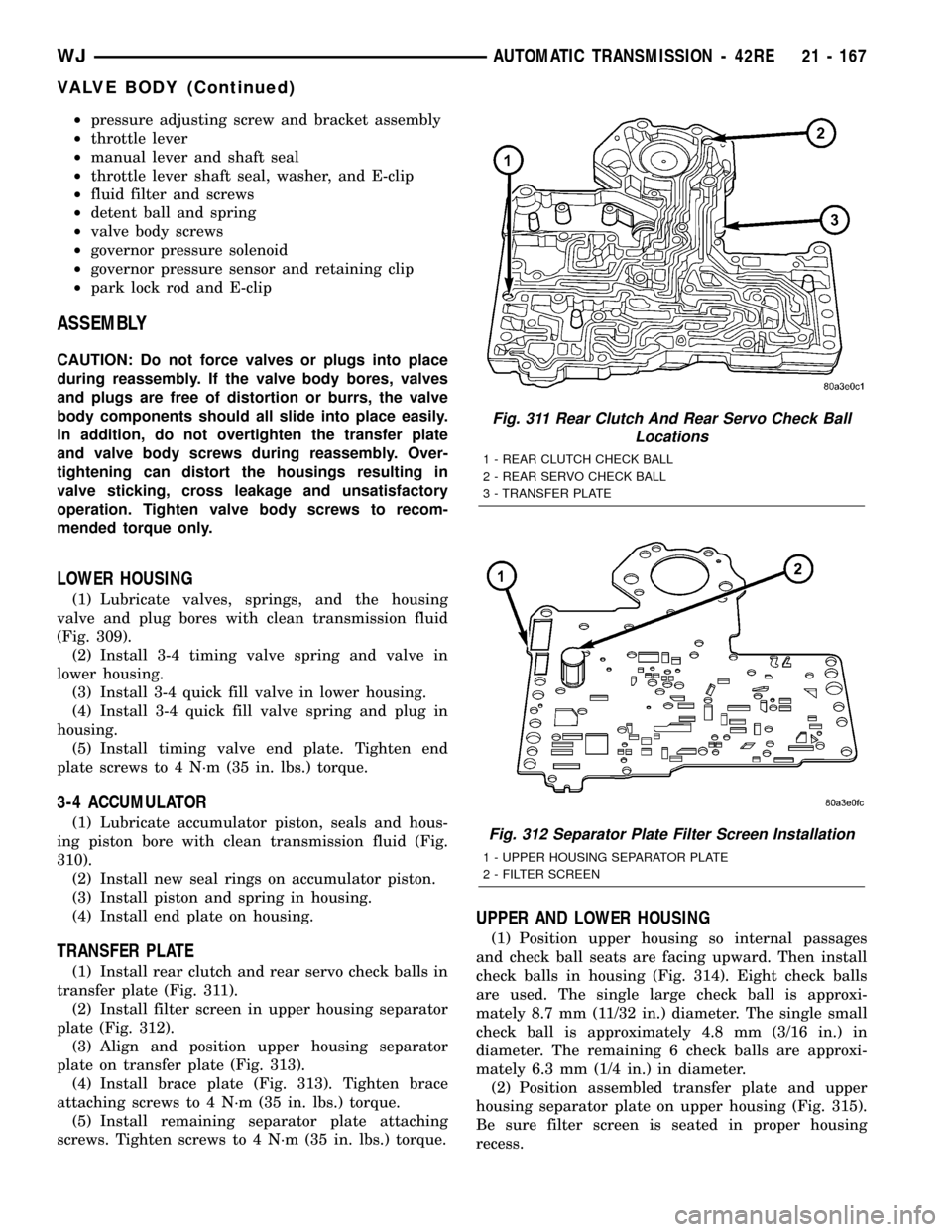

TRANSFER PLATE

(1) Install rear clutch and rear servo check balls in

transfer plate (Fig. 311).

(2) Install filter screen in upper housing separator

plate (Fig. 312).

(3) Align and position upper housing separator

plate on transfer plate (Fig. 313).

(4) Install brace plate (Fig. 313). Tighten brace

attaching screws to 4 N´m (35 in. lbs.) torque.

(5) Install remaining separator plate attaching

screws. Tighten screws to 4 N´m (35 in. lbs.) torque.

UPPER AND LOWER HOUSING

(1) Position upper housing so internal passages

and check ball seats are facing upward. Then install

check balls in housing (Fig. 314). Eight check balls

are used. The single large check ball is approxi-

mately 8.7 mm (11/32 in.) diameter. The single small

check ball is approximately 4.8 mm (3/16 in.) in

diameter. The remaining 6 check balls are approxi-

mately 6.3 mm (1/4 in.) in diameter.

(2) Position assembled transfer plate and upper

housing separator plate on upper housing (Fig. 315).

Be sure filter screen is seated in proper housing

recess.

Fig. 311 Rear Clutch And Rear Servo Check Ball

Locations

1 - REAR CLUTCH CHECK BALL

2 - REAR SERVO CHECK BALL

3 - TRANSFER PLATE

Fig. 312 Separator Plate Filter Screen Installation

1 - UPPER HOUSING SEPARATOR PLATE

2 - FILTER SCREEN

WJAUTOMATIC TRANSMISSION - 42RE 21 - 167

VALVE BODY (Continued)

Page 1800 of 2199

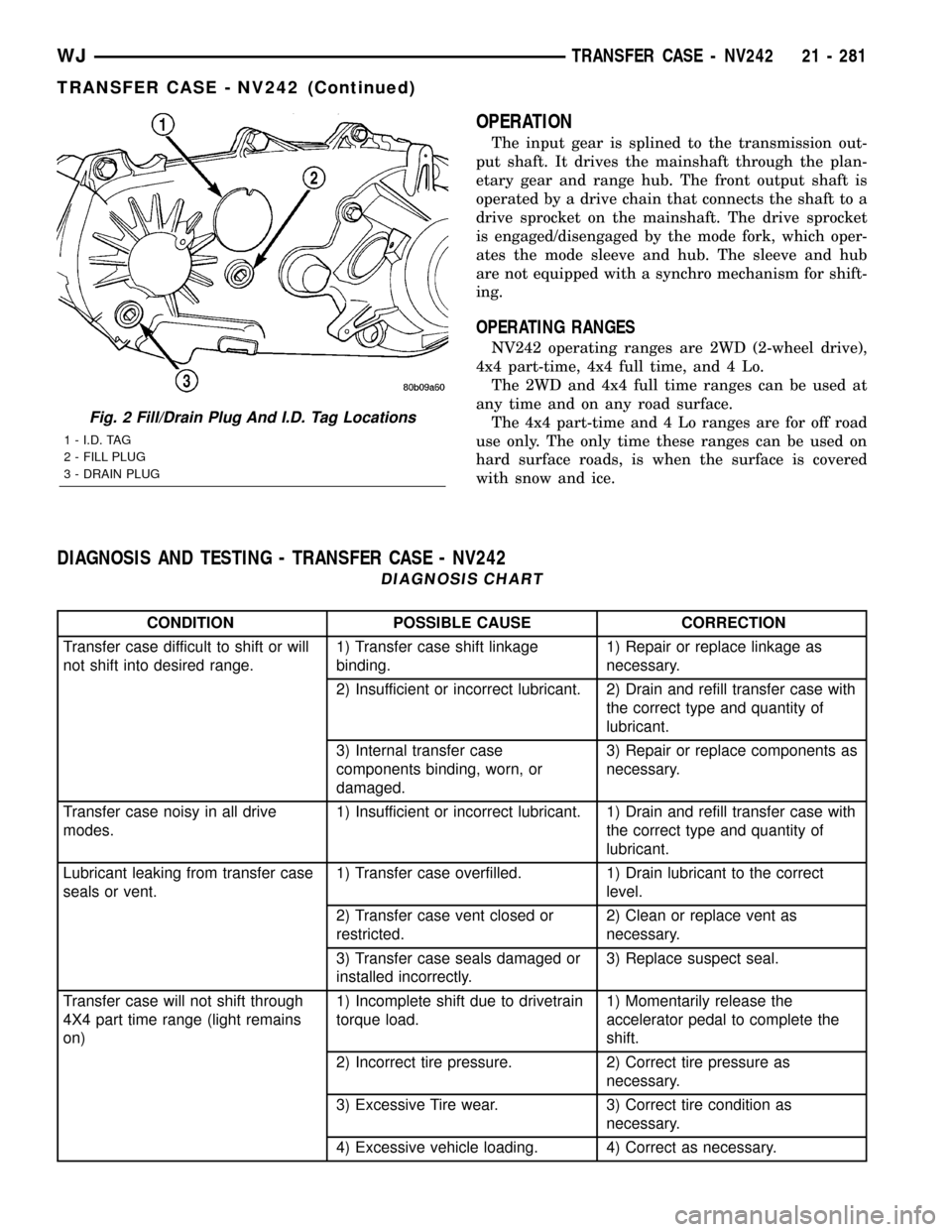

OPERATION

The input gear is splined to the transmission out-

put shaft. It drives the mainshaft through the plan-

etary gear and range hub. The front output shaft is

operated by a drive chain that connects the shaft to a

drive sprocket on the mainshaft. The drive sprocket

is engaged/disengaged by the mode fork, which oper-

ates the mode sleeve and hub. The sleeve and hub

are not equipped with a synchro mechanism for shift-

ing.

OPERATING RANGES

NV242 operating ranges are 2WD (2-wheel drive),

4x4 part-time, 4x4 full time, and 4 Lo.

The 2WD and 4x4 full time ranges can be used at

any time and on any road surface.

The 4x4 part-time and 4 Lo ranges are for off road

use only. The only time these ranges can be used on

hard surface roads, is when the surface is covered

with snow and ice.

DIAGNOSIS AND TESTING - TRANSFER CASE - NV242

DIAGNOSIS CHART

CONDITION POSSIBLE CAUSE CORRECTION

Transfer case difficult to shift or will

not shift into desired range.1) Transfer case shift linkage

binding.1) Repair or replace linkage as

necessary.

2) Insufficient or incorrect lubricant. 2) Drain and refill transfer case with

the correct type and quantity of

lubricant.

3) Internal transfer case

components binding, worn, or

damaged.3) Repair or replace components as

necessary.

Transfer case noisy in all drive

modes.1) Insufficient or incorrect lubricant. 1) Drain and refill transfer case with

the correct type and quantity of

lubricant.

Lubricant leaking from transfer case

seals or vent.1) Transfer case overfilled. 1) Drain lubricant to the correct

level.

2) Transfer case vent closed or

restricted.2) Clean or replace vent as

necessary.

3) Transfer case seals damaged or

installed incorrectly.3) Replace suspect seal.

Transfer case will not shift through

4X4 part time range (light remains

on)1) Incomplete shift due to drivetrain

torque load.1) Momentarily release the

accelerator pedal to complete the

shift.

2) Incorrect tire pressure. 2) Correct tire pressure as

necessary.

3) Excessive Tire wear. 3) Correct tire condition as

necessary.

4) Excessive vehicle loading. 4) Correct as necessary.

Fig. 2 Fill/Drain Plug And I.D. Tag Locations

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

WJTRANSFER CASE - NV242 21 - 281

TRANSFER CASE - NV242 (Continued)

Page 1829 of 2199

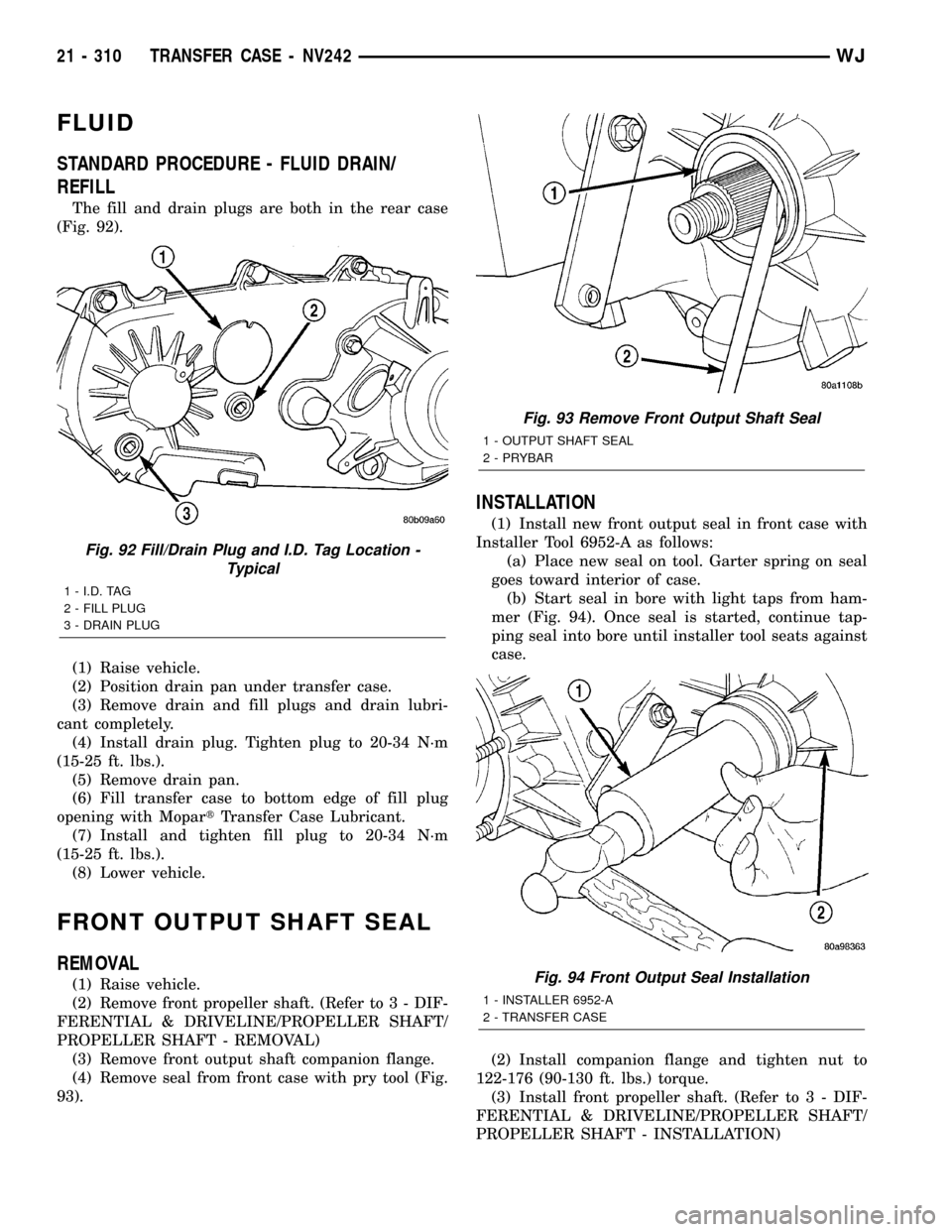

FLUID

STANDARD PROCEDURE - FLUID DRAIN/

REFILL

The fill and drain plugs are both in the rear case

(Fig. 92).

(1) Raise vehicle.

(2) Position drain pan under transfer case.

(3) Remove drain and fill plugs and drain lubri-

cant completely.

(4) Install drain plug. Tighten plug to 20-34 N´m

(15-25 ft. lbs.).

(5) Remove drain pan.

(6) Fill transfer case to bottom edge of fill plug

opening with MopartTransfer Case Lubricant.

(7) Install and tighten fill plug to 20-34 N´m

(15-25 ft. lbs.).

(8) Lower vehicle.

FRONT OUTPUT SHAFT SEAL

REMOVAL

(1) Raise vehicle.

(2) Remove front propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

(3) Remove front output shaft companion flange.

(4) Remove seal from front case with pry tool (Fig.

93).

INSTALLATION

(1) Install new front output seal in front case with

Installer Tool 6952-A as follows:

(a) Place new seal on tool. Garter spring on seal

goes toward interior of case.

(b) Start seal in bore with light taps from ham-

mer (Fig. 94). Once seal is started, continue tap-

ping seal into bore until installer tool seats against

case.

(2) Install companion flange and tighten nut to

122-176 (90-130 ft. lbs.) torque.

(3) Install front propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - INSTALLATION)

Fig. 92 Fill/Drain Plug and I.D. Tag Location -

Typical

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

Fig. 93 Remove Front Output Shaft Seal

1 - OUTPUT SHAFT SEAL

2 - PRYBAR

Fig. 94 Front Output Seal Installation

1 - INSTALLER 6952-A

2 - TRANSFER CASE

21 - 310 TRANSFER CASE - NV242WJ

Page 1834 of 2199

TRANSFER CASE - NV247

TABLE OF CONTENTS

page page

TRANSFER CASE - NV247

DESCRIPTION........................315

OPERATION..........................316

DIAGNOSIS AND TESTING - TRANSFER

CASE - NV247.......................316

REMOVAL............................317

DISASSEMBLY........................317

CLEANING...........................324

INSPECTION.........................324

ASSEMBLY...........................326

INSTALLATION........................335

SPECIFICATIONS

TRANSFER CASE - NV247.............336

SPECIAL TOOLS

TRANSFER CASE - NV247.............337FLUID

STANDARD PROCEDURE - FLUID DRAIN/

REFILL............................338

FRONT OUTPUT SHAFT SEAL

REMOVAL............................338

INSTALLATION........................338

REAR RETAINER BUSHING AND SEAL

REMOVAL............................339

INSTALLATION........................339

SHIFT CABLE

REMOVAL............................340

INSTALLATION........................340

TRANSFER CASE - NV247

DESCRIPTION

The NV247 (Fig. 1) is an on-demand 4-wheel drive

transfer case with two operating ranges and a neu-

tral position. Operating ranges are 4-high and 4-low.

The 4-low range is used for extra pulling power in

off-road situations.

TRANSFER CASE IDENTIFICATION

A circular I.D. tag is attached to the rear case of

each NV247 transfer case (Fig. 2). The tag indicates

the following information:

²Model number

²Serial number

²Assembly number

²Gear ratio

²Location of manufacture

The transfer case serial number also represents

the date of build.

Fig. 1 NV247 Transfer Case

Fig. 2 Transfer Case I.D. Tag

1 - FILL PLUG

2 - I.D. TAG

3 - DRAIN PLUG

WJTRANSFER CASE - NV247 21 - 315

Page 1857 of 2199

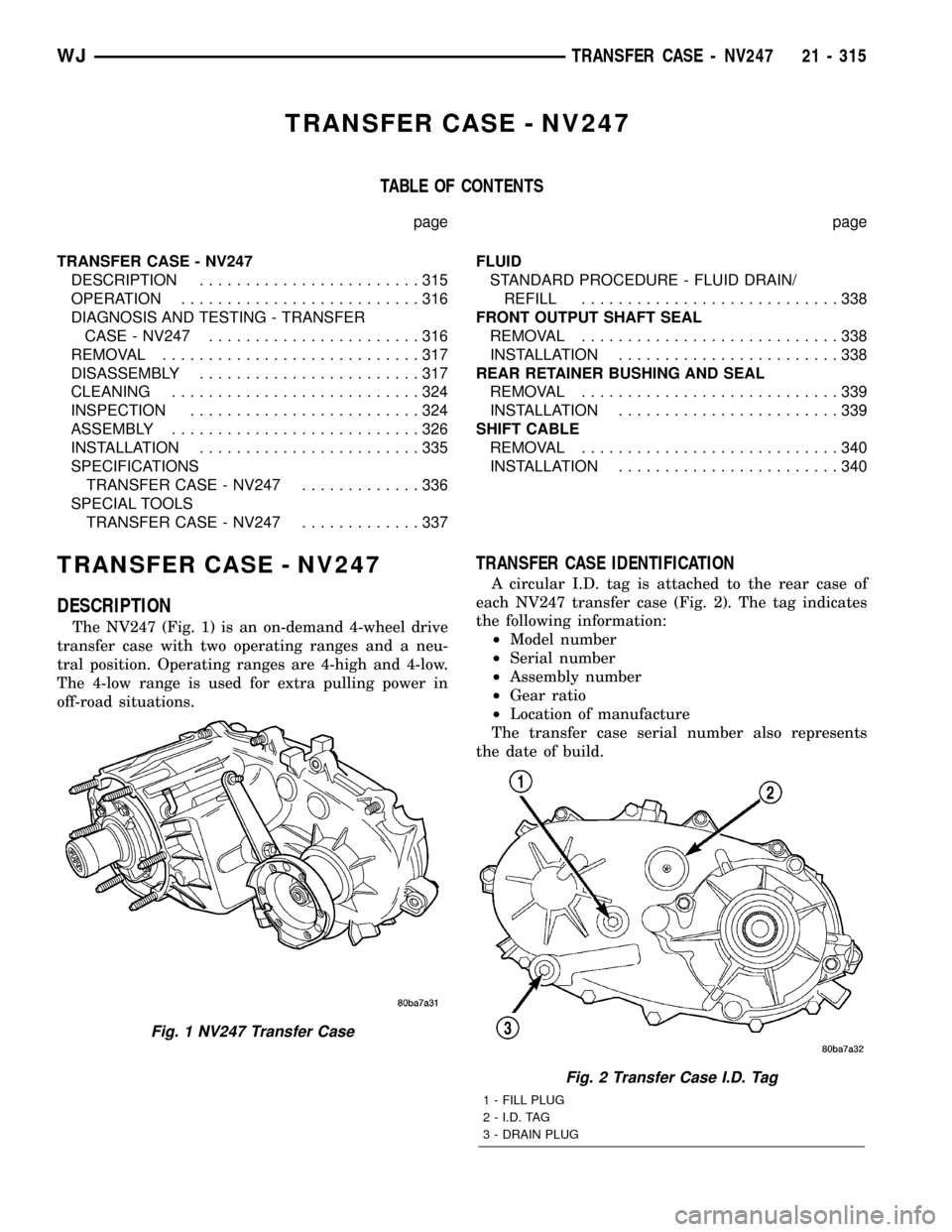

FLUID

STANDARD PROCEDURE - FLUID DRAIN/

REFILL

The fill and drain plugs are both in the rear case

(Fig. 72).

(1) Raise vehicle.

(2) Position drain pan under transfer case.

(3) Remove drain and fill plugs and drain lubri-

cant completely.

(4) Install drain plug. Tighten plug to 20-34 N´m

(15-25 ft. lbs.).

(5) Remove drain pan.(6) Fill transfer case to bottom edge of fill plug

opening with MopartTransfer Case Lubricant.

(7) Install and tighten fill plug to 20-34 N´m

(15-25 ft. lbs.).

(8) Lower vehicle.

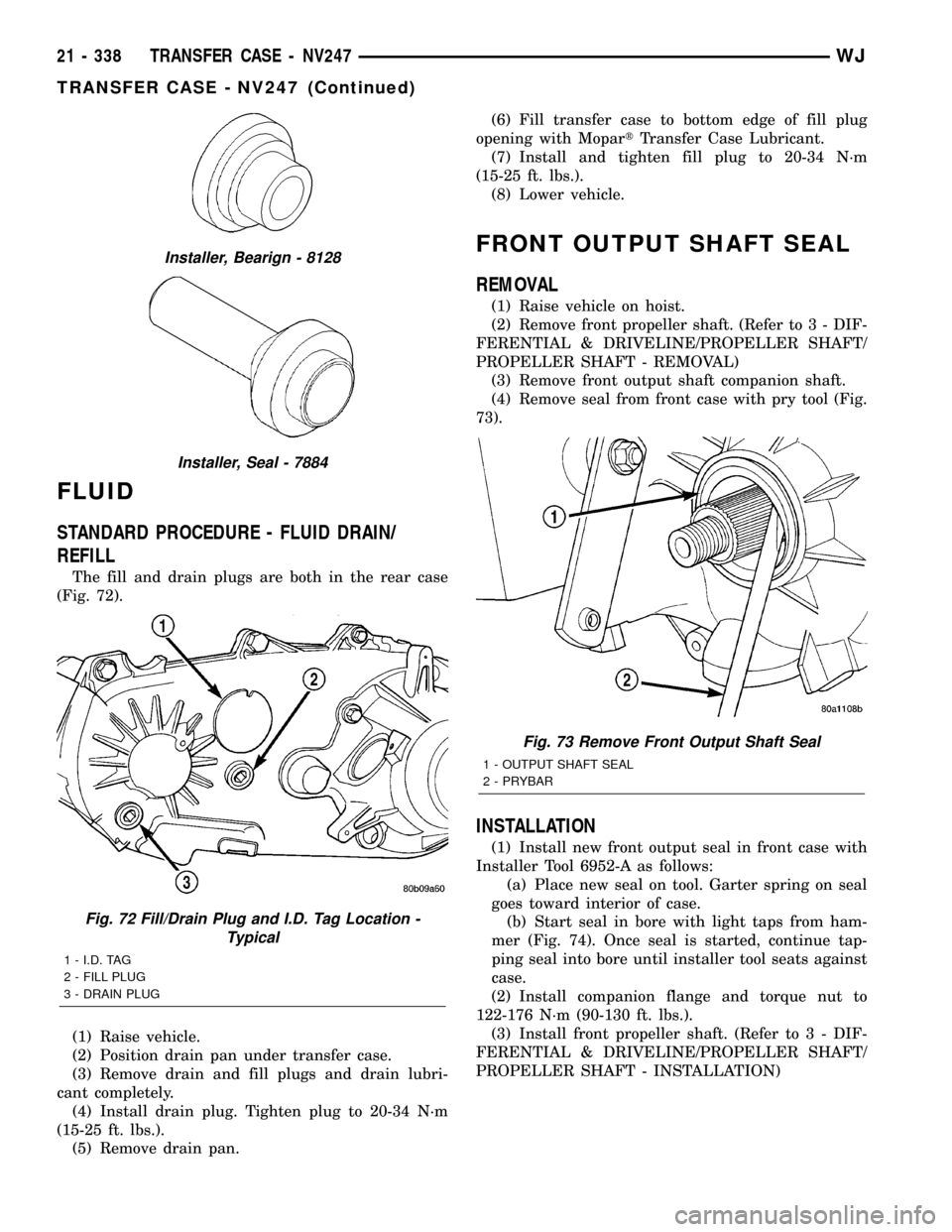

FRONT OUTPUT SHAFT SEAL

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove front propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - REMOVAL)

(3) Remove front output shaft companion shaft.

(4) Remove seal from front case with pry tool (Fig.

73).

INSTALLATION

(1) Install new front output seal in front case with

Installer Tool 6952-A as follows:

(a) Place new seal on tool. Garter spring on seal

goes toward interior of case.

(b) Start seal in bore with light taps from ham-

mer (Fig. 74). Once seal is started, continue tap-

ping seal into bore until installer tool seats against

case.

(2) Install companion flange and torque nut to

122-176 N´m (90-130 ft. lbs.).

(3) Install front propeller shaft. (Refer to 3 - DIF-

FERENTIAL & DRIVELINE/PROPELLER SHAFT/

PROPELLER SHAFT - INSTALLATION)

Installer, Bearign - 8128

Installer, Seal - 7884

Fig. 72 Fill/Drain Plug and I.D. Tag Location -

Typical

1 - I.D. TAG

2 - FILL PLUG

3 - DRAIN PLUG

Fig. 73 Remove Front Output Shaft Seal

1 - OUTPUT SHAFT SEAL

2 - PRYBAR

21 - 338 TRANSFER CASE - NV247WJ

TRANSFER CASE - NV247 (Continued)