Fill location JEEP GRAND CHEROKEE 2003 WJ / 2.G User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 2003, Model line: GRAND CHEROKEE, Model: JEEP GRAND CHEROKEE 2003 WJ / 2.GPages: 2199, PDF Size: 76.01 MB

Page 277 of 2199

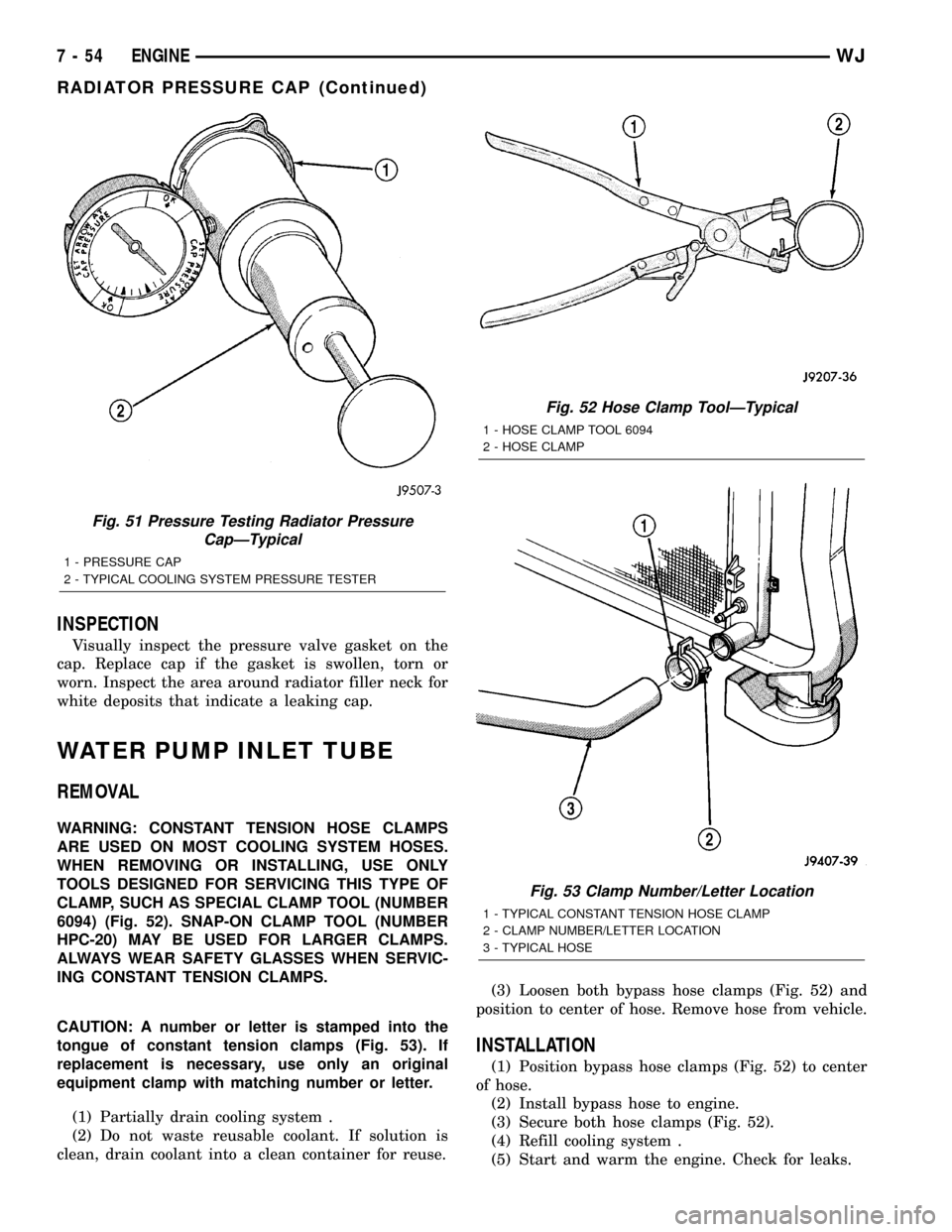

INSPECTION

Visually inspect the pressure valve gasket on the

cap. Replace cap if the gasket is swollen, torn or

worn. Inspect the area around radiator filler neck for

white deposits that indicate a leaking cap.

WATER PUMP INLET TUBE

REMOVAL

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAMP, SUCH AS SPECIAL CLAMP TOOL (NUMBER

6094) (Fig. 52). SNAP-ON CLAMP TOOL (NUMBER

HPC-20) MAY BE USED FOR LARGER CLAMPS.

ALWAYS WEAR SAFETY GLASSES WHEN SERVIC-

ING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps (Fig. 53). If

replacement is necessary, use only an original

equipment clamp with matching number or letter.

(1) Partially drain cooling system .

(2) Do not waste reusable coolant. If solution is

clean, drain coolant into a clean container for reuse.(3) Loosen both bypass hose clamps (Fig. 52) and

position to center of hose. Remove hose from vehicle.

INSTALLATION

(1) Position bypass hose clamps (Fig. 52) to center

of hose.

(2) Install bypass hose to engine.

(3) Secure both hose clamps (Fig. 52).

(4) Refill cooling system .

(5) Start and warm the engine. Check for leaks.

Fig. 51 Pressure Testing Radiator Pressure

CapÐTypical

1 - PRESSURE CAP

2 - TYPICAL COOLING SYSTEM PRESSURE TESTER

Fig. 52 Hose Clamp ToolÐTypical

1 - HOSE CLAMP TOOL 6094

2 - HOSE CLAMP

Fig. 53 Clamp Number/Letter Location

1 - TYPICAL CONSTANT TENSION HOSE CLAMP

2 - CLAMP NUMBER/LETTER LOCATION

3 - TYPICAL HOSE

7 - 54 ENGINEWJ

RADIATOR PRESSURE CAP (Continued)

Page 407 of 2199

OPERATION

Although cylinder firing order is the same as 4.0L

Jeep engines of previous years, spark plug firing is

not. The 3 coils dual-fire the spark plugs on cylinders

1-6, 2-5 and/or 3-4. When one cylinder is being fired

(on compression stroke), the spark to the opposite

cylinder is being wasted (on exhaust stroke).

Battery voltage is supplied to the three ignition

coils from the ASD relay. The Powertrain Control

Module (PCM) opens and closes the ignition coil

ground circuit for ignition coil operation.

Base ignition timing is not adjustable.By con-

trolling the coil ground circuit, the PCM is able to set

the base timing and adjust the ignition timing

advance. This is done to meet changing engine oper-

ating conditions.

The ignition coil is not oil filled. The windings are

embedded in an epoxy compound. This provides heat

and vibration resistance that allows the ignition coil

to be mounted on the engine.

Because of coil design, spark plug cables (second-

ary cables) are not used. The cables are integral

within the coil rail.

REMOVAL

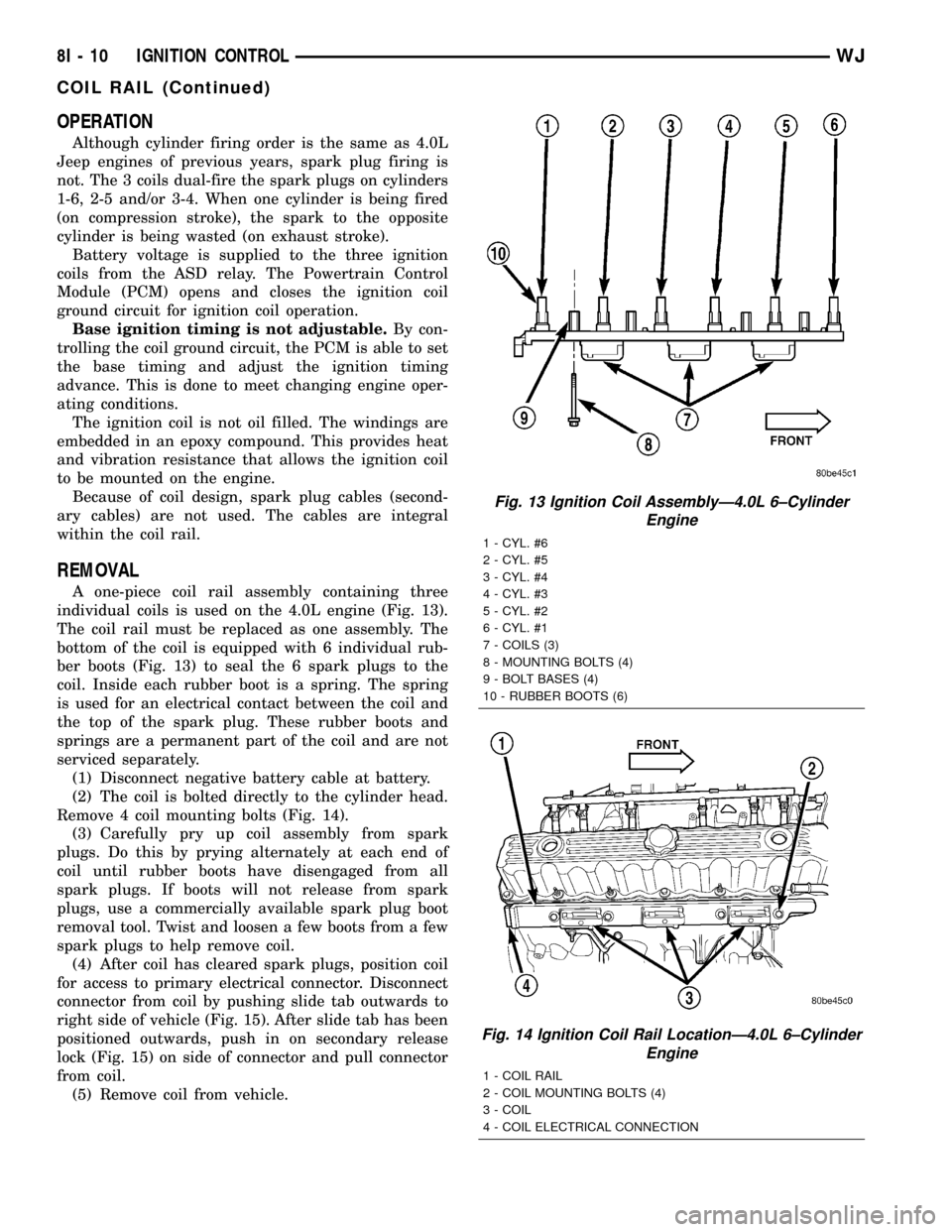

A one-piece coil rail assembly containing three

individual coils is used on the 4.0L engine (Fig. 13).

The coil rail must be replaced as one assembly. The

bottom of the coil is equipped with 6 individual rub-

ber boots (Fig. 13) to seal the 6 spark plugs to the

coil. Inside each rubber boot is a spring. The spring

is used for an electrical contact between the coil and

the top of the spark plug. These rubber boots and

springs are a permanent part of the coil and are not

serviced separately.

(1) Disconnect negative battery cable at battery.

(2) The coil is bolted directly to the cylinder head.

Remove 4 coil mounting bolts (Fig. 14).

(3) Carefully pry up coil assembly from spark

plugs. Do this by prying alternately at each end of

coil until rubber boots have disengaged from all

spark plugs. If boots will not release from spark

plugs, use a commercially available spark plug boot

removal tool. Twist and loosen a few boots from a few

spark plugs to help remove coil.

(4) After coil has cleared spark plugs, position coil

for access to primary electrical connector. Disconnect

connector from coil by pushing slide tab outwards to

right side of vehicle (Fig. 15). After slide tab has been

positioned outwards, push in on secondary release

lock (Fig. 15) on side of connector and pull connector

from coil.

(5) Remove coil from vehicle.

Fig. 13 Ignition Coil AssemblyÐ4.0L 6±Cylinder

Engine

1 - CYL. #6

2 - CYL. #5

3 - CYL. #4

4 - CYL. #3

5 - CYL. #2

6 - CYL. #1

7 - COILS (3)

8 - MOUNTING BOLTS (4)

9 - BOLT BASES (4)

10 - RUBBER BOOTS (6)

Fig. 14 Ignition Coil Rail LocationÐ4.0L 6±Cylinder

Engine

1 - COIL RAIL

2 - COIL MOUNTING BOLTS (4)

3 - COIL

4 - COIL ELECTRICAL CONNECTION

8I - 10 IGNITION CONTROLWJ

COIL RAIL (Continued)

Page 436 of 2199

FUEL GAUGE

DESCRIPTION

A fuel gauge is standard equipment on all instru-

ment clusters. The fuel gauge is located in the lower

left corner of the instrument cluster, to the left of the

tachometer. The fuel gauge consists of a movable

gauge needle or pointer controlled by the instrument

cluster circuitry and a fixed 90 degree scale on the

gauge dial face that reads left-to-right from E (or

Empty) to F (or Full). An International Control and

Display Symbol icon for ªFuelº is located on the

gauge dial face. An arrowhead pointed to the left side

of the vehicle is imprinted next to the ªFuelº icon on

the fuel gauge dial face to provide the driver with a

reminder as to the location of the fuel filler access.

The fuel gauge graphics are either white, gray and

orange against a black gauge dial face (base cluster)

or black and gray against a taupe gauge dial face

(premium cluster), making them clearly visible

within the instrument cluster in daylight. When illu-

minated from behind by the panel lamps dimmer

controlled cluster illumination lighting with the exte-

rior lamps turned On, the base cluster white gauge

graphics appear blue-green and the orange graphics

still appear orange, while the premium cluster taupe

gauge dial face appears blue-green with the black

graphics silhouetted against the illuminated back-

ground. The gray gauge graphics for both versions of

the cluster are not illuminated. The orange gauge

needle in the base cluster gauge is internally illumi-

nated, while the black gauge needle in the premium

cluster gauge is not.

Base cluster gauge illumination is provided by

replaceable incandescent bulb and bulb holder units

located on the instrument cluster electronic circuit

board. Premium cluster gauge illumination is pro-

vided by an integral electro-luminescent lamp that is

serviced as a unit with the instrument cluster. The

fuel gauge is serviced as a unit with the instrument

cluster.

OPERATION

The fuel gauge gives an indication to the vehicle

operator of the level of fuel in the fuel tank. This

gauge is controlled by the instrument cluster circuit

board based upon cluster programming and elec-

tronic messages received by the cluster from the

Powertrain Control Module (PCM) over the Program-

mable Communications Interface (PCI) data bus. The

fuel gauge is an air core magnetic unit that receives

battery current on the instrument cluster electronic

circuit board through the fused ignition switch out-

put (run-start) circuit whenever the ignition switch is

in the On or Start positions. The cluster is pro-

grammed to move the gauge needle back to the lowend of the scale after the ignition switch is turned to

the Off position. The instrument cluster circuitry

controls the gauge needle position and provides the

following features:

²Percent Tank Full Message- Each time the

cluster receives a message from the PCM indicating

the percent tank full, the cluster moves the gauge

needle to the relative fuel level position on the gauge

scale. The PCM applies an algorithm to the input

from the fuel tank sender to dampen gauge needle

movement against the negative effect that fuel slosh-

ing within the fuel tank can have on accurate inputs

to the PCM.

²Less Than 12.5 Percent Tank Full Message-

Each time the cluster receives messages from the

PCM indicating the percent tank full is less than

12.5 (one-eighth), the gauge needle is moved to the

proper position on the gauge scale and the low fuel

indicator is illuminated. The low fuel indicator

remains illuminated until the cluster receives mes-

sages from the PCM indicating that the percent tank

full is greater than 12.5 (one-eighth), or until the

ignition switch is turned to the Off position, which-

ever occurs first.

²Less Than Empty Percent Tank Full Mes-

sage- Each time the cluster receives a message from

the PCM indicating the percent tank full is less than

empty, the gauge needle is moved to the far left (low)

end of the gauge scale and the low fuel indicator is

illuminated immediately. This message would indi-

cate that the fuel tank sender input to the PCM is a

short circuit.

²More Than Full Percent Tank Full Message

- Each time the cluster receives a message from the

PCM indicating the percent tank full is more than

full, the gauge needle is moved to the far left (low)

end of the gauge scale and the low fuel indicator is

illuminated immediately. This message would indi-

cate that the fuel tank sender input to the PCM is an

open circuit.

²Communication Error- If the cluster fails to

receive a percent tank full message, it will hold the

gauge needle at the last indication for about twelve

seconds, until a new message is received, or until the

ignition switch is turned to the Off position, which-

ever occurs first. After twelve seconds, the cluster

will return the gauge needle to the low end of the

gauge scale.

²Actuator Test- Each time the cluster is put

through the actuator test, the gauge needle will be

swept across the entire gauge scale and back in order

to confirm the functionality of the gauge and the

cluster control circuitry.

The PCM continually monitors the fuel tank

sender to determine the fuel level. The PCM then

applies an algorithm to the input and sends the

WJINSTRUMENT CLUSTER 8J - 21

Page 610 of 2199

²Front Check Valve- The front washer system

check valve is integral to the wye fitting located in

the washer plumbing between the cowl plenum

washer hose and the front washer nozzles, and is

concealed beneath the cowl plenum cover/grille panel

at the base of the windshield.

²Front Washer Nozzle- Two fluidic front

washer nozzles are secured with integral snap fea-

tures to dedicated openings in the cowl plenum cover/

grille panel located near the base of the windshield.

²Front Washer Plumbing- The plumbing for

the front washer system consists of rubber hoses and

molded plastic fittings. The plumbing is routed along

the left side of the engine compartment from the

washer reservoir, and through the dash panel into

the cowl plenum to the front washer nozzle fittings

beneath the cowl plenum cover/grille panel.

²Front Washer Pump/Motor- The front washer

pump/motor unit is located in a dedicated hole on the

lower outboard side of the washer reservoir, behind

the inner fender liner ahead of the left front wheel.

The front washer pump is located ahead of and below

the rear washer pump.

²Front Wiper Arm- The two front wiper arms

are secured with nuts to the threaded studs on the

ends of the two wiper pivot shafts, which extend

through the cowl plenum cover/grille panel located

near the base of the windshield.

²Front Wiper Blade- The two front wiper

blades are secured to the two front wiper arms with

an integral latch, and are parked on the glass near

the bottom of the windshield when the front wiper

system is not in operation.

²Front Wiper Module- The front wiper pivot

shafts are the only visible components of the front

wiper module. The remainder of the module is con-

cealed within the cowl plenum beneath the cowl ple-

num cover/grille panel. The front wiper module

includes the module bracket, four rubber-isolated

wiper module mounts, the front wiper motor, the

wiper motor crank arm, the two wiper drive links,

and the two front wiper pivots.

²Rain Sensor Module- Models equipped with

the optional automatic wiper feature have a Rain

Sensor Module (RSM) located behind a trim cover on

a bracket bonded to the inside surface of the wind-

shield glass, just above the inside rear view mirror

mounting button.

²Right Multi-Function Switch- The right

(wiper) multi-function switch is secured to the right

side of the multi-function switch mounting housing

near the top of the steering column, just below the

steering wheel. Only the control stalk for the right

multi-function switch is visible, while the remainder

of the switch is concealed beneath the steering col-

umn shrouds. The right multi-function switch con-tains all of the switches and control circuitry for both

the front and rear wiper and washer systems.

²Washer Fluid Level Switch- The washer fluid

level switch is located in a dedicated hole near the

center of the forward surface of the washer reservoir,

behind the left front wheel house splash shield.

²Washer Reservoir- The washer reservoir is

concealed between the left inner fender shield and

the left outer fender panel, behind the inner fender

liner and ahead of the left front wheel. The washer

reservoir filler neck is the only visible portion of the

reservoir, and it is accessed from the left front corner

of the engine compartment.

²Wiper High-Low Relay- The wiper high-low

relay is an International Standards Organization

(ISO) micro relay located in the Power Distribution

Center (PDC) in the engine compartment near the

battery.

²Wiper On-Off Relay- The wiper on-off relay is

an International Standards Organization (ISO) micro

relay located in the Power Distribution Center (PDC)

in the engine compartment near the battery.

Hard wired circuitry connects the front wiper and

washer system components to the electrical system of

the vehicle. These hard wired circuits are integral to

several wire harnesses, which are routed throughout

the vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the front wiper and

washer system components through the use of a com-

bination of soldered splices, splice block connectors,

and many different types of wire harness terminal

connectors and insulators. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, further details on wire harness routing

and retention, as well as pin-out and location views

for the various wire harness connectors, splices and

grounds.

OPERATING MODES

The components of the front wiper and washer sys-

tem are designed to work in concert to provide the

following operating modes:

²Automatic Wiper- In models equipped with

the optional automatic wiper feature, the internal

circuitry of both the right (wiper) multi-function

switch, the rain sensor module, and the BCM work

in concert to provide an automatic wiper mode with

five sensitivity selections. The BCM tells the Rain

Sensor Module (RSM) when the automatic wiper

mode is selected and the manually selected sensitiv-

ity level, then the rain sensor module tells the BCM

each time enough water droplets have accumulated

within the wipe pattern on the windshield to require

front wiper operation. The BCM then automatically

WJFRONT WIPERS/WASHERS 8R - 3

FRONT WIPERS/WASHERS (Continued)

Page 634 of 2199

WASHER RESERVOIR

DESCRIPTION

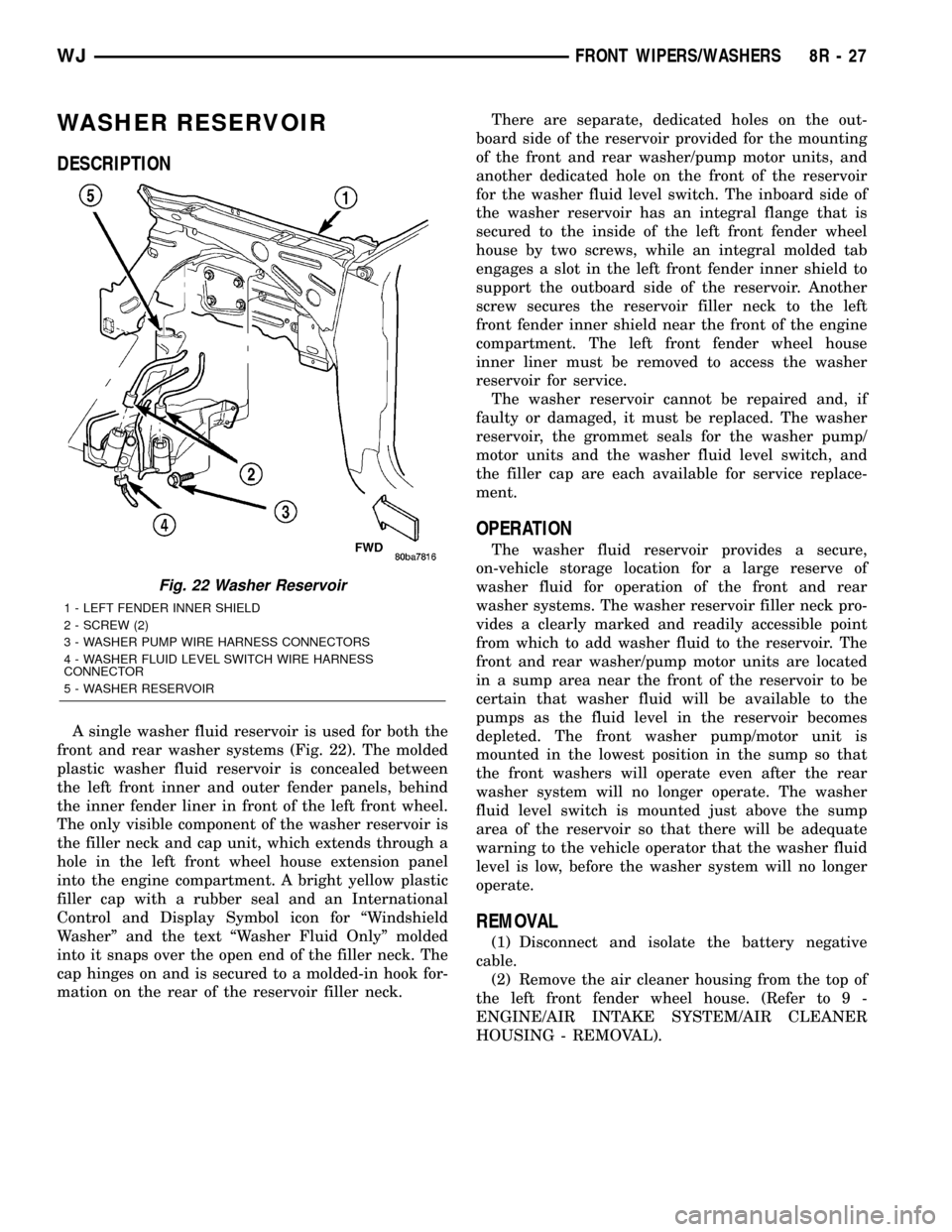

A single washer fluid reservoir is used for both the

front and rear washer systems (Fig. 22). The molded

plastic washer fluid reservoir is concealed between

the left front inner and outer fender panels, behind

the inner fender liner in front of the left front wheel.

The only visible component of the washer reservoir is

the filler neck and cap unit, which extends through a

hole in the left front wheel house extension panel

into the engine compartment. A bright yellow plastic

filler cap with a rubber seal and an International

Control and Display Symbol icon for ªWindshield

Washerº and the text ªWasher Fluid Onlyº molded

into it snaps over the open end of the filler neck. The

cap hinges on and is secured to a molded-in hook for-

mation on the rear of the reservoir filler neck.There are separate, dedicated holes on the out-

board side of the reservoir provided for the mounting

of the front and rear washer/pump motor units, and

another dedicated hole on the front of the reservoir

for the washer fluid level switch. The inboard side of

the washer reservoir has an integral flange that is

secured to the inside of the left front fender wheel

house by two screws, while an integral molded tab

engages a slot in the left front fender inner shield to

support the outboard side of the reservoir. Another

screw secures the reservoir filler neck to the left

front fender inner shield near the front of the engine

compartment. The left front fender wheel house

inner liner must be removed to access the washer

reservoir for service.

The washer reservoir cannot be repaired and, if

faulty or damaged, it must be replaced. The washer

reservoir, the grommet seals for the washer pump/

motor units and the washer fluid level switch, and

the filler cap are each available for service replace-

ment.

OPERATION

The washer fluid reservoir provides a secure,

on-vehicle storage location for a large reserve of

washer fluid for operation of the front and rear

washer systems. The washer reservoir filler neck pro-

vides a clearly marked and readily accessible point

from which to add washer fluid to the reservoir. The

front and rear washer/pump motor units are located

in a sump area near the front of the reservoir to be

certain that washer fluid will be available to the

pumps as the fluid level in the reservoir becomes

depleted. The front washer pump/motor unit is

mounted in the lowest position in the sump so that

the front washers will operate even after the rear

washer system will no longer operate. The washer

fluid level switch is mounted just above the sump

area of the reservoir so that there will be adequate

warning to the vehicle operator that the washer fluid

level is low, before the washer system will no longer

operate.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the air cleaner housing from the top of

the left front fender wheel house. (Refer to 9 -

ENGINE/AIR INTAKE SYSTEM/AIR CLEANER

HOUSING - REMOVAL).

Fig. 22 Washer Reservoir

1 - LEFT FENDER INNER SHIELD

2 - SCREW (2)

3 - WASHER PUMP WIRE HARNESS CONNECTORS

4 - WASHER FLUID LEVEL SWITCH WIRE HARNESS

CONNECTOR

5 - WASHER RESERVOIR

WJFRONT WIPERS/WASHERS 8R - 27

Page 641 of 2199

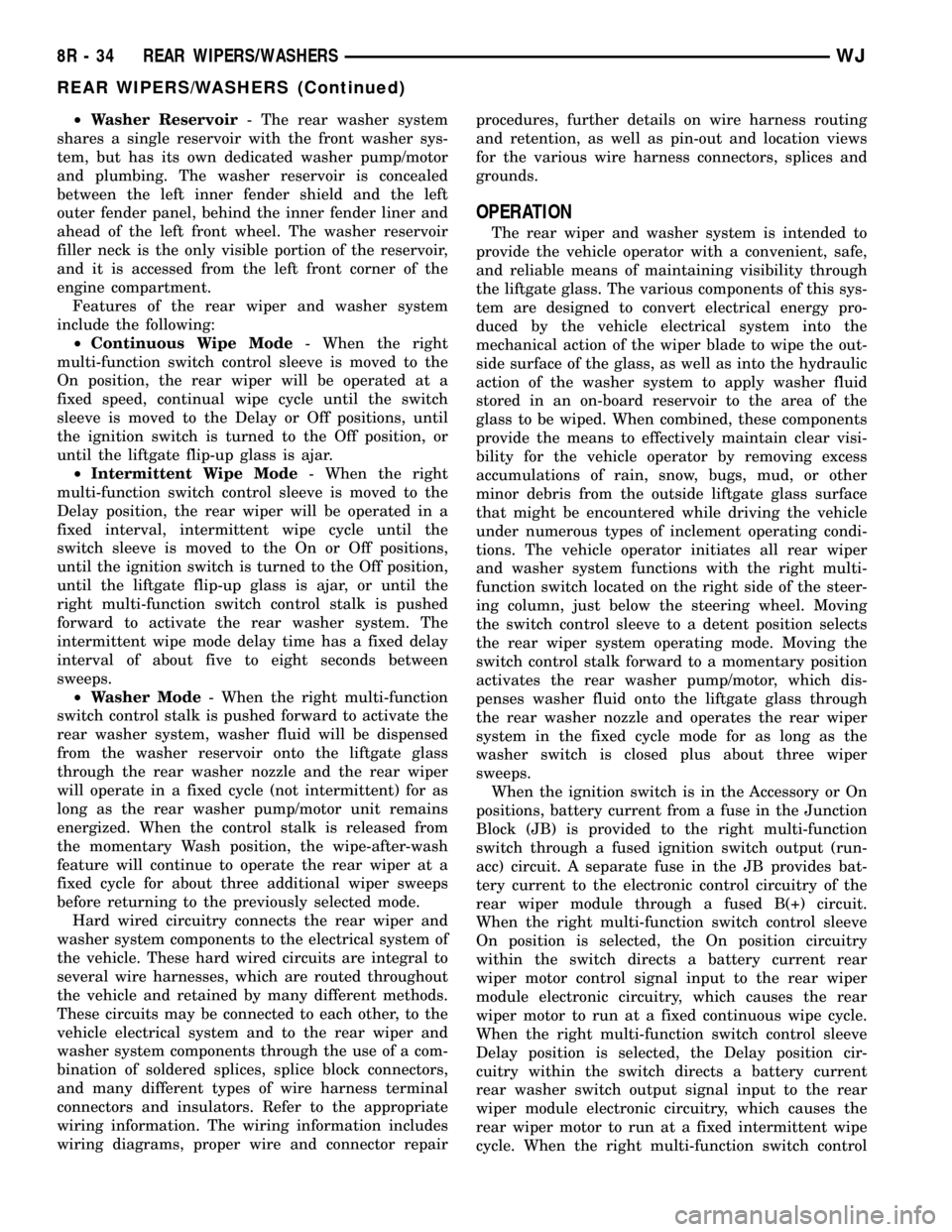

²Washer Reservoir- The rear washer system

shares a single reservoir with the front washer sys-

tem, but has its own dedicated washer pump/motor

and plumbing. The washer reservoir is concealed

between the left inner fender shield and the left

outer fender panel, behind the inner fender liner and

ahead of the left front wheel. The washer reservoir

filler neck is the only visible portion of the reservoir,

and it is accessed from the left front corner of the

engine compartment.

Features of the rear wiper and washer system

include the following:

²Continuous Wipe Mode- When the right

multi-function switch control sleeve is moved to the

On position, the rear wiper will be operated at a

fixed speed, continual wipe cycle until the switch

sleeve is moved to the Delay or Off positions, until

the ignition switch is turned to the Off position, or

until the liftgate flip-up glass is ajar.

²Intermittent Wipe Mode- When the right

multi-function switch control sleeve is moved to the

Delay position, the rear wiper will be operated in a

fixed interval, intermittent wipe cycle until the

switch sleeve is moved to the On or Off positions,

until the ignition switch is turned to the Off position,

until the liftgate flip-up glass is ajar, or until the

right multi-function switch control stalk is pushed

forward to activate the rear washer system. The

intermittent wipe mode delay time has a fixed delay

interval of about five to eight seconds between

sweeps.

²Washer Mode- When the right multi-function

switch control stalk is pushed forward to activate the

rear washer system, washer fluid will be dispensed

from the washer reservoir onto the liftgate glass

through the rear washer nozzle and the rear wiper

will operate in a fixed cycle (not intermittent) for as

long as the rear washer pump/motor unit remains

energized. When the control stalk is released from

the momentary Wash position, the wipe-after-wash

feature will continue to operate the rear wiper at a

fixed cycle for about three additional wiper sweeps

before returning to the previously selected mode.

Hard wired circuitry connects the rear wiper and

washer system components to the electrical system of

the vehicle. These hard wired circuits are integral to

several wire harnesses, which are routed throughout

the vehicle and retained by many different methods.

These circuits may be connected to each other, to the

vehicle electrical system and to the rear wiper and

washer system components through the use of a com-

bination of soldered splices, splice block connectors,

and many different types of wire harness terminal

connectors and insulators. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repairprocedures, further details on wire harness routing

and retention, as well as pin-out and location views

for the various wire harness connectors, splices and

grounds.

OPERATION

The rear wiper and washer system is intended to

provide the vehicle operator with a convenient, safe,

and reliable means of maintaining visibility through

the liftgate glass. The various components of this sys-

tem are designed to convert electrical energy pro-

duced by the vehicle electrical system into the

mechanical action of the wiper blade to wipe the out-

side surface of the glass, as well as into the hydraulic

action of the washer system to apply washer fluid

stored in an on-board reservoir to the area of the

glass to be wiped. When combined, these components

provide the means to effectively maintain clear visi-

bility for the vehicle operator by removing excess

accumulations of rain, snow, bugs, mud, or other

minor debris from the outside liftgate glass surface

that might be encountered while driving the vehicle

under numerous types of inclement operating condi-

tions. The vehicle operator initiates all rear wiper

and washer system functions with the right multi-

function switch located on the right side of the steer-

ing column, just below the steering wheel. Moving

the switch control sleeve to a detent position selects

the rear wiper system operating mode. Moving the

switch control stalk forward to a momentary position

activates the rear washer pump/motor, which dis-

penses washer fluid onto the liftgate glass through

the rear washer nozzle and operates the rear wiper

system in the fixed cycle mode for as long as the

washer switch is closed plus about three wiper

sweeps.

When the ignition switch is in the Accessory or On

positions, battery current from a fuse in the Junction

Block (JB) is provided to the right multi-function

switch through a fused ignition switch output (run-

acc) circuit. A separate fuse in the JB provides bat-

tery current to the electronic control circuitry of the

rear wiper module through a fused B(+) circuit.

When the right multi-function switch control sleeve

On position is selected, the On position circuitry

within the switch directs a battery current rear

wiper motor control signal input to the rear wiper

module electronic circuitry, which causes the rear

wiper motor to run at a fixed continuous wipe cycle.

When the right multi-function switch control sleeve

Delay position is selected, the Delay position cir-

cuitry within the switch directs a battery current

rear washer switch output signal input to the rear

wiper module electronic circuitry, which causes the

rear wiper motor to run at a fixed intermittent wipe

cycle. When the right multi-function switch control

8R - 34 REAR WIPERS/WASHERSWJ

REAR WIPERS/WASHERS (Continued)

Page 1253 of 2199

FORM-IN-PLACE GASKET AND SEALER

APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gaskets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - REPAIR DAMAGED

OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

STANDARD PROCEDUREÐHYDROSTATIC LOCK

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(Refer to 14 - FUEL SYSTEM/FUEL DELIVERY -

STANDARD PROCEDURE).(2) Disconnect the negative cable(s) from the bat-

tery.

(3) Inspect air cleaner, induction system, and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the spark plugs.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

(6) Identify the fluid in the cylinders (coolant, fuel,

oil, etc.).

(7) Be sure all fluid has been removed from the

cylinders.

(8) Repair engine or components as necessary to

prevent this problem from occurring again.

(9) Squirt a small amount of engine oil into the

cylinders to lubricate the walls. This will prevent

damage on restart.

(10) Install new spark plugs. Tighten the spark

plugs to 41 N´m (30 ft. lbs.) torque.

(11) Drain engine oil. Remove and discard the oil

filter.

(12) Install the drain plug. Tighten the plug to 34

N´m (25 ft. lbs.) torque.

(13) Install a new oil filter.

(14) Fill engine crankcase with the specified

amount and grade of oil. (Refer to LUBRICATION &

MAINTENANCE - SPECIFICATIONS).

(15) Connect the negative cable(s) to the battery.

(16) Start the engine and check for any leaks.

STANDARD PROCEDURE - CYLINDER BORE

HONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1)

Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light scuff-

ing, scoring and scratches. Usually, a few strokes will

clean up a bore and maintain the required limits.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

9 - 10 ENGINE - 4.0LWJ

ENGINE - 4.0L (Continued)

Page 1254 of 2199

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

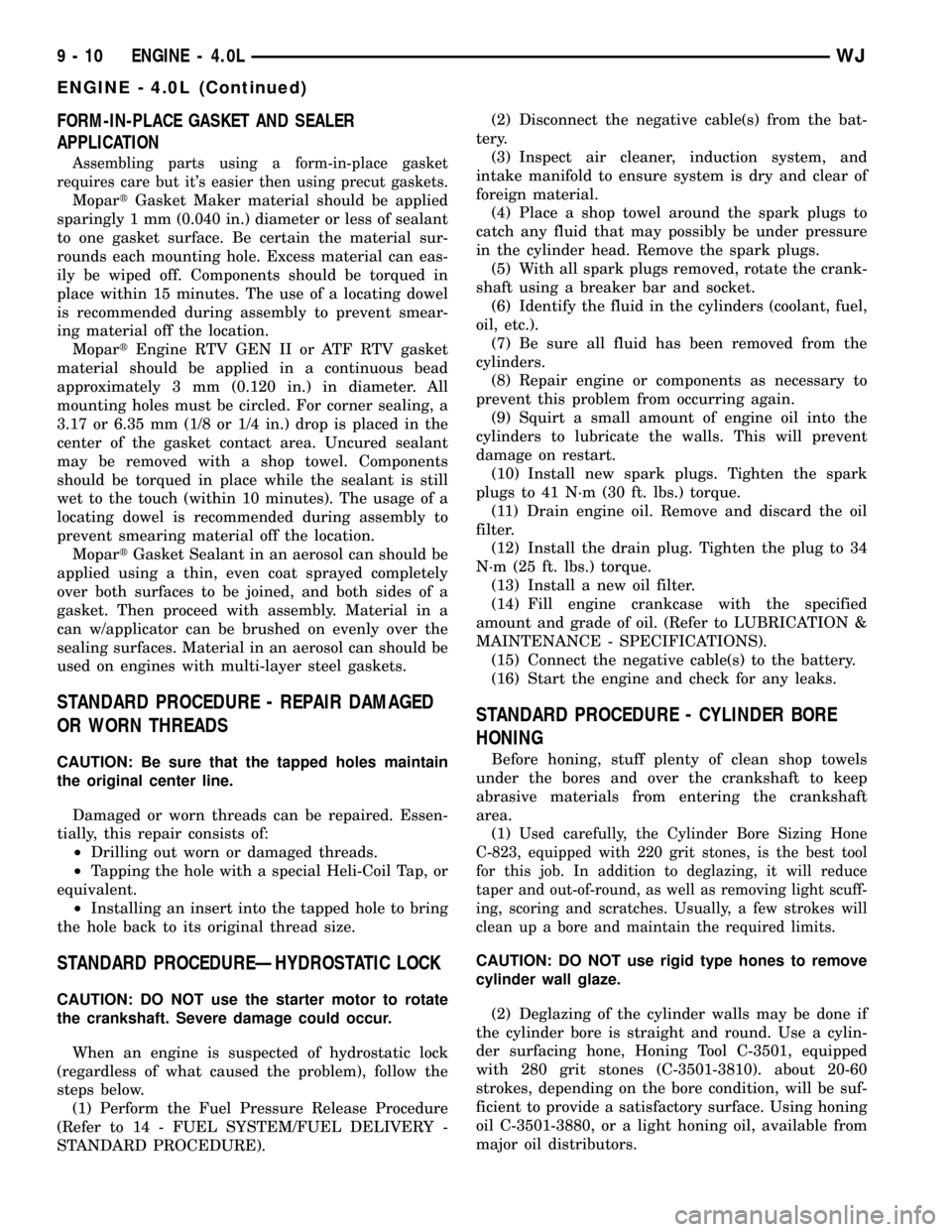

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.

The hone marks should INTERSECT at 40É to 60É

for proper seating of rings (Fig. 3).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 40É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

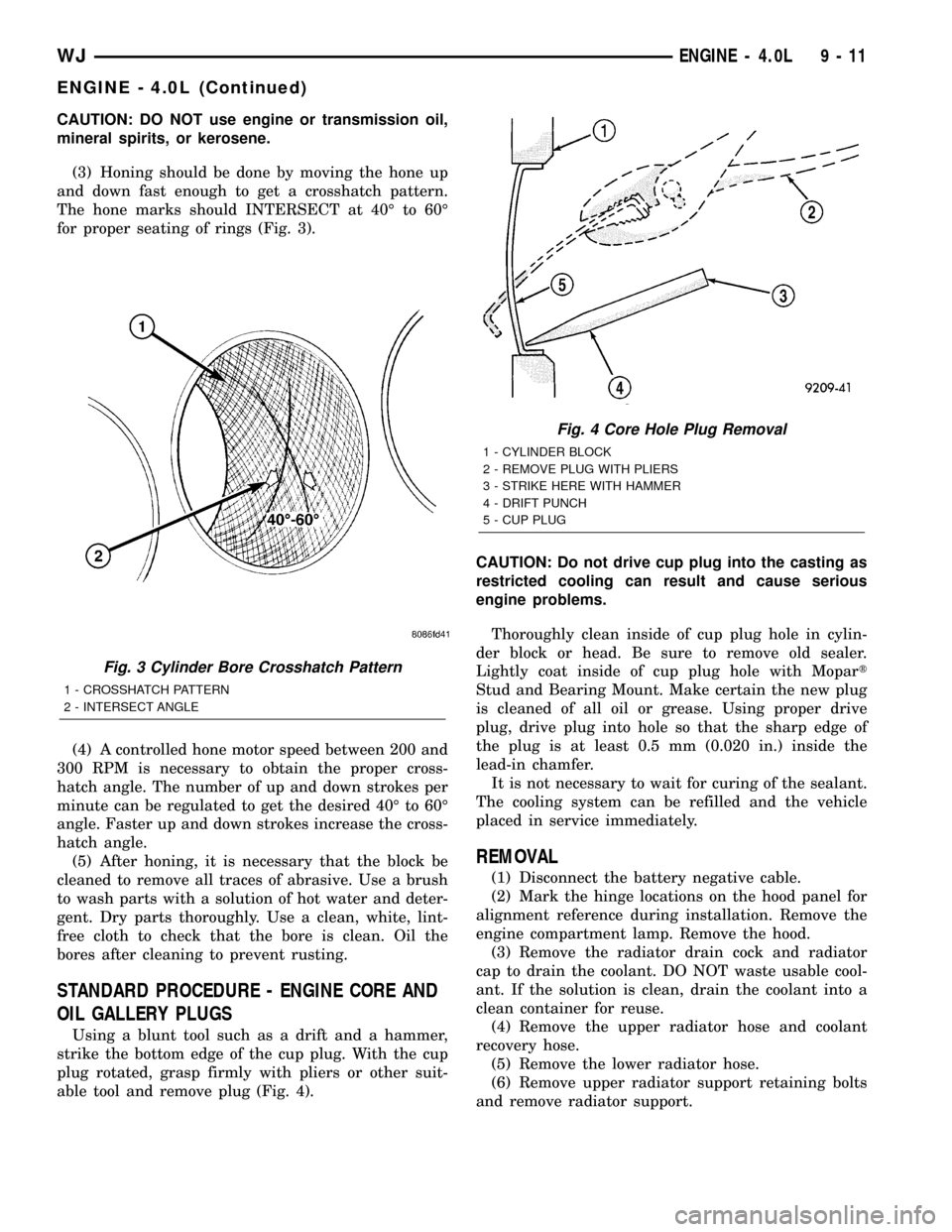

STANDARD PROCEDURE - ENGINE CORE AND

OIL GALLERY PLUGS

Using a blunt tool such as a drift and a hammer,

strike the bottom edge of the cup plug. With the cup

plug rotated, grasp firmly with pliers or other suit-

able tool and remove plug (Fig. 4).CAUTION: Do not drive cup plug into the casting as

restricted cooling can result and cause serious

engine problems.

Thoroughly clean inside of cup plug hole in cylin-

der block or head. Be sure to remove old sealer.

Lightly coat inside of cup plug hole with Mopart

Stud and Bearing Mount. Make certain the new plug

is cleaned of all oil or grease. Using proper drive

plug, drive plug into hole so that the sharp edge of

the plug is at least 0.5 mm (0.020 in.) inside the

lead-in chamfer.

It is not necessary to wait for curing of the sealant.

The cooling system can be refilled and the vehicle

placed in service immediately.

REMOVAL

(1) Disconnect the battery negative cable.

(2) Mark the hinge locations on the hood panel for

alignment reference during installation. Remove the

engine compartment lamp. Remove the hood.

(3) Remove the radiator drain cock and radiator

cap to drain the coolant. DO NOT waste usable cool-

ant. If the solution is clean, drain the coolant into a

clean container for reuse.

(4) Remove the upper radiator hose and coolant

recovery hose.

(5) Remove the lower radiator hose.

(6) Remove upper radiator support retaining bolts

and remove radiator support.

Fig. 3 Cylinder Bore Crosshatch Pattern

1 - CROSSHATCH PATTERN

2 - INTERSECT ANGLE

Fig. 4 Core Hole Plug Removal

1 - CYLINDER BLOCK

2 - REMOVE PLUG WITH PLIERS

3 - STRIKE HERE WITH HAMMER

4 - DRIFT PUNCH

5 - CUP PLUG

WJENGINE - 4.0L 9 - 11

ENGINE - 4.0L (Continued)

Page 1347 of 2199

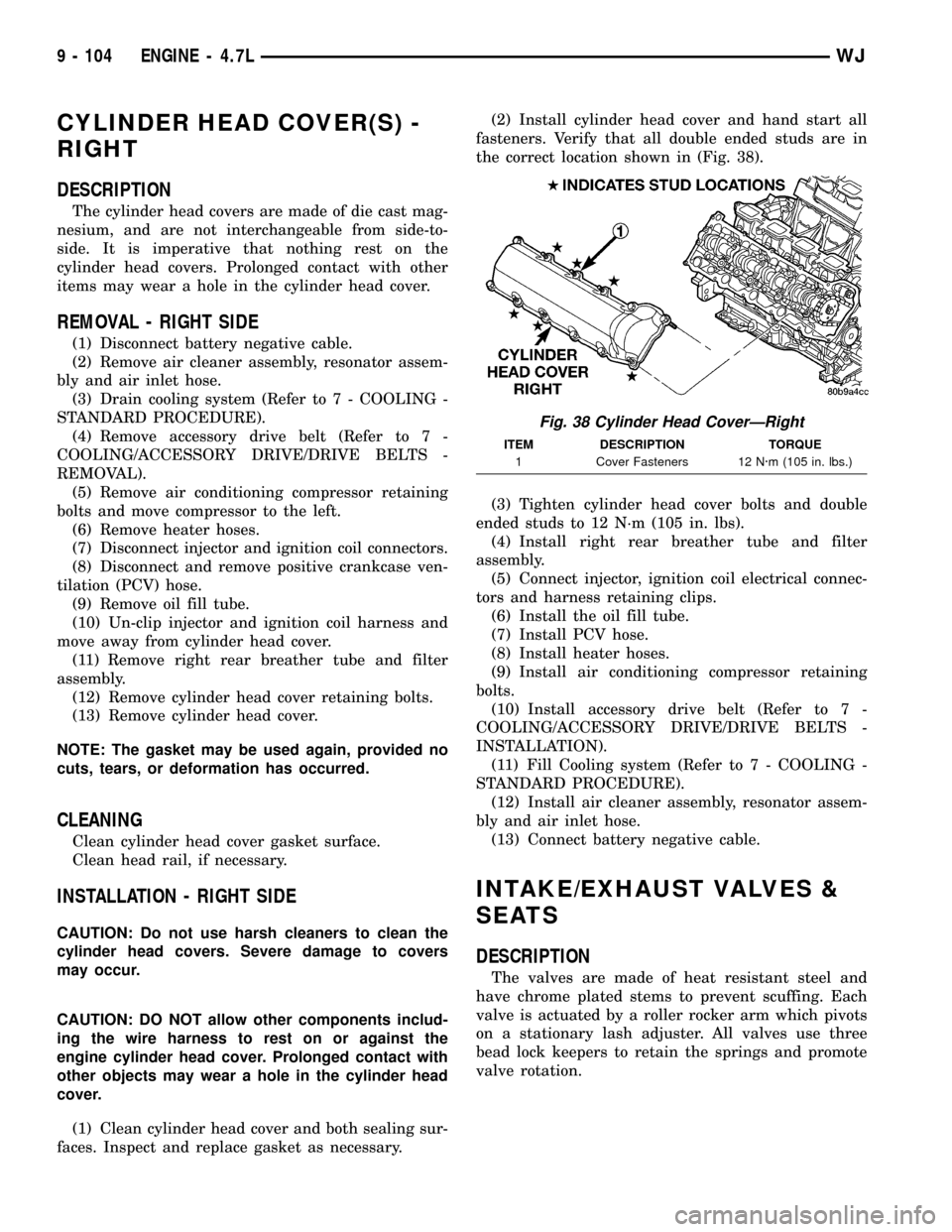

CYLINDER HEAD COVER(S) -

RIGHT

DESCRIPTION

The cylinder head covers are made of die cast mag-

nesium, and are not interchangeable from side-to-

side. It is imperative that nothing rest on the

cylinder head covers. Prolonged contact with other

items may wear a hole in the cylinder head cover.

REMOVAL - RIGHT SIDE

(1) Disconnect battery negative cable.

(2) Remove air cleaner assembly, resonator assem-

bly and air inlet hose.

(3) Drain cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(4) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(5) Remove air conditioning compressor retaining

bolts and move compressor to the left.

(6) Remove heater hoses.

(7) Disconnect injector and ignition coil connectors.

(8) Disconnect and remove positive crankcase ven-

tilation (PCV) hose.

(9) Remove oil fill tube.

(10) Un-clip injector and ignition coil harness and

move away from cylinder head cover.

(11) Remove right rear breather tube and filter

assembly.

(12) Remove cylinder head cover retaining bolts.

(13) Remove cylinder head cover.

NOTE: The gasket may be used again, provided no

cuts, tears, or deformation has occurred.

CLEANING

Clean cylinder head cover gasket surface.

Clean head rail, if necessary.

INSTALLATION - RIGHT SIDE

CAUTION: Do not use harsh cleaners to clean the

cylinder head covers. Severe damage to covers

may occur.

CAUTION: DO NOT allow other components includ-

ing the wire harness to rest on or against the

engine cylinder head cover. Prolonged contact with

other objects may wear a hole in the cylinder head

cover.

(1) Clean cylinder head cover and both sealing sur-

faces. Inspect and replace gasket as necessary.(2) Install cylinder head cover and hand start all

fasteners. Verify that all double ended studs are in

the correct location shown in (Fig. 38).

(3) Tighten cylinder head cover bolts and double

ended studs to 12 N´m (105 in. lbs).

(4) Install right rear breather tube and filter

assembly.

(5) Connect injector, ignition coil electrical connec-

tors and harness retaining clips.

(6) Install the oil fill tube.

(7) Install PCV hose.

(8) Install heater hoses.

(9) Install air conditioning compressor retaining

bolts.

(10) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(11) Fill Cooling system (Refer to 7 - COOLING -

STANDARD PROCEDURE).

(12) Install air cleaner assembly, resonator assem-

bly and air inlet hose.

(13) Connect battery negative cable.

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The valves are made of heat resistant steel and

have chrome plated stems to prevent scuffing. Each

valve is actuated by a roller rocker arm which pivots

on a stationary lash adjuster. All valves use three

bead lock keepers to retain the springs and promote

valve rotation.

Fig. 38 Cylinder Head CoverÐRight

ITEM DESCRIPTION TORQUE

1 Cover Fasteners 12 N´m (105 in. lbs.)

9 - 104 ENGINE - 4.7LWJ

Page 1423 of 2199

STANDARD PROCEDURE - FUEL SYSTEM

PRESSURE RELEASE

Use following procedure if the fuel injector

rail is, or is not equipped with a fuel pressure

test port.

(1) Remove fuel fill cap.

(2) Remove fuel pump relay from Power Distribu-

tion Center (PDC). For location of relay, refer to label

on underside of PDC cover.

(3) Start and run engine until it stalls.

(4) Attempt restarting engine until it will no

longer run.

(5) Turn ignition key to OFF position.

CAUTION: Steps 1, 2, 3 and 4 must be performed to

relieve high pressure fuel from within fuel rail. Do

not attempt to use following steps to relieve this

pressure as excessive fuel will be forced into a cyl-

inder chamber.

(6) Unplug connector from any fuel injector.

(7) Attach one end of a jumper wire with alligator

clips (18 gauge or smaller) to either injector terminal.(8) Connect other end of jumper wire to positive

side of battery.

(9) Connect one end of a second jumper wire to

remaining injector terminal.

CAUTION: Powering an injector for more than a few

seconds will permanently damage the injector.

(10) Momentarily touch other end of jumper wire

to negative terminal of battery for no more than a

few seconds.

(11) Place a rag or towel below fuel line quick-con-

nect fitting at fuel rail.

(12) Disconnect quick-connect fitting at fuel rail.

Refer to Quick-Connect Fittings.

(13) Return fuel pump relay to PDC.

(14) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in PCM memory due to fuel

pump relay removal. The DRBtscan tool must be

used to erase a DTC.

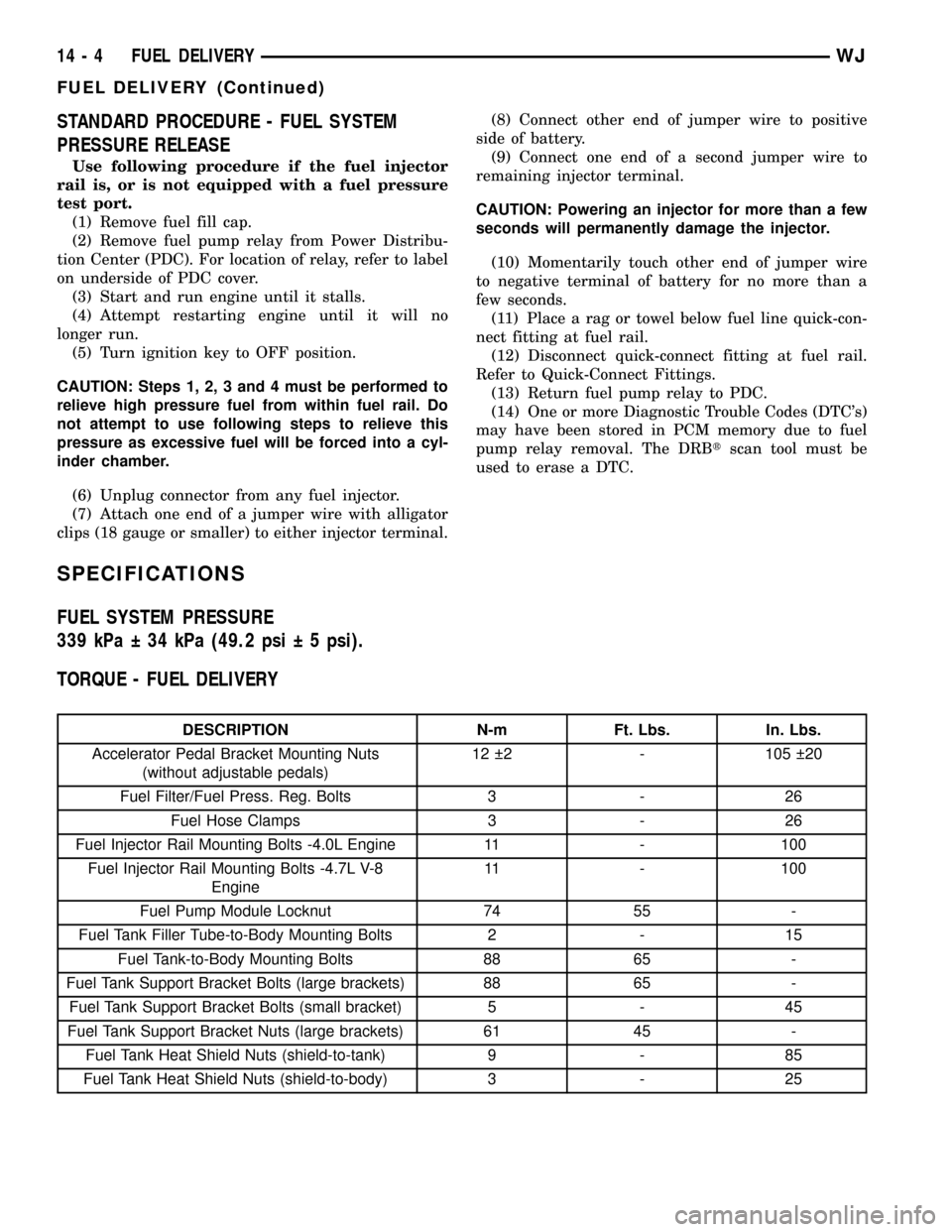

SPECIFICATIONS

FUEL SYSTEM PRESSURE

339 kPa 34 kPa (49.2 psi 5 psi).

TORQUE - FUEL DELIVERY

DESCRIPTION N-m Ft. Lbs. In. Lbs.

Accelerator Pedal Bracket Mounting Nuts

(without adjustable pedals)12 2 - 105 20

Fuel Filter/Fuel Press. Reg. Bolts 3 - 26

Fuel Hose Clamps 3 - 26

Fuel Injector Rail Mounting Bolts -4.0L Engine 11 - 100

Fuel Injector Rail Mounting Bolts -4.7L V-8

Engine11 - 100

Fuel Pump Module Locknut 74 55 -

Fuel Tank Filler Tube-to-Body Mounting Bolts 2 - 15

Fuel Tank-to-Body Mounting Bolts 88 65 -

Fuel Tank Support Bracket Bolts (large brackets) 88 65 -

Fuel Tank Support Bracket Bolts (small bracket) 5 - 45

Fuel Tank Support Bracket Nuts (large brackets) 61 45 -

Fuel Tank Heat Shield Nuts (shield-to-tank) 9 - 85

Fuel Tank Heat Shield Nuts (shield-to-body) 3 - 25

14 - 4 FUEL DELIVERYWJ

FUEL DELIVERY (Continued)